Multifunctional automatic control column leaching experimental facility

A test device and automatic control system technology, applied in the field of multifunctional automatic control leaching test device, can solve the problems of lack of comprehensive test device for simulating the heap leaching process, research on the interaction process of multi-phase media, etc., and achieve high degree of automation and functional various effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below, but the protection scope of the present invention is not limited to the scope of the specific embodiments described below.

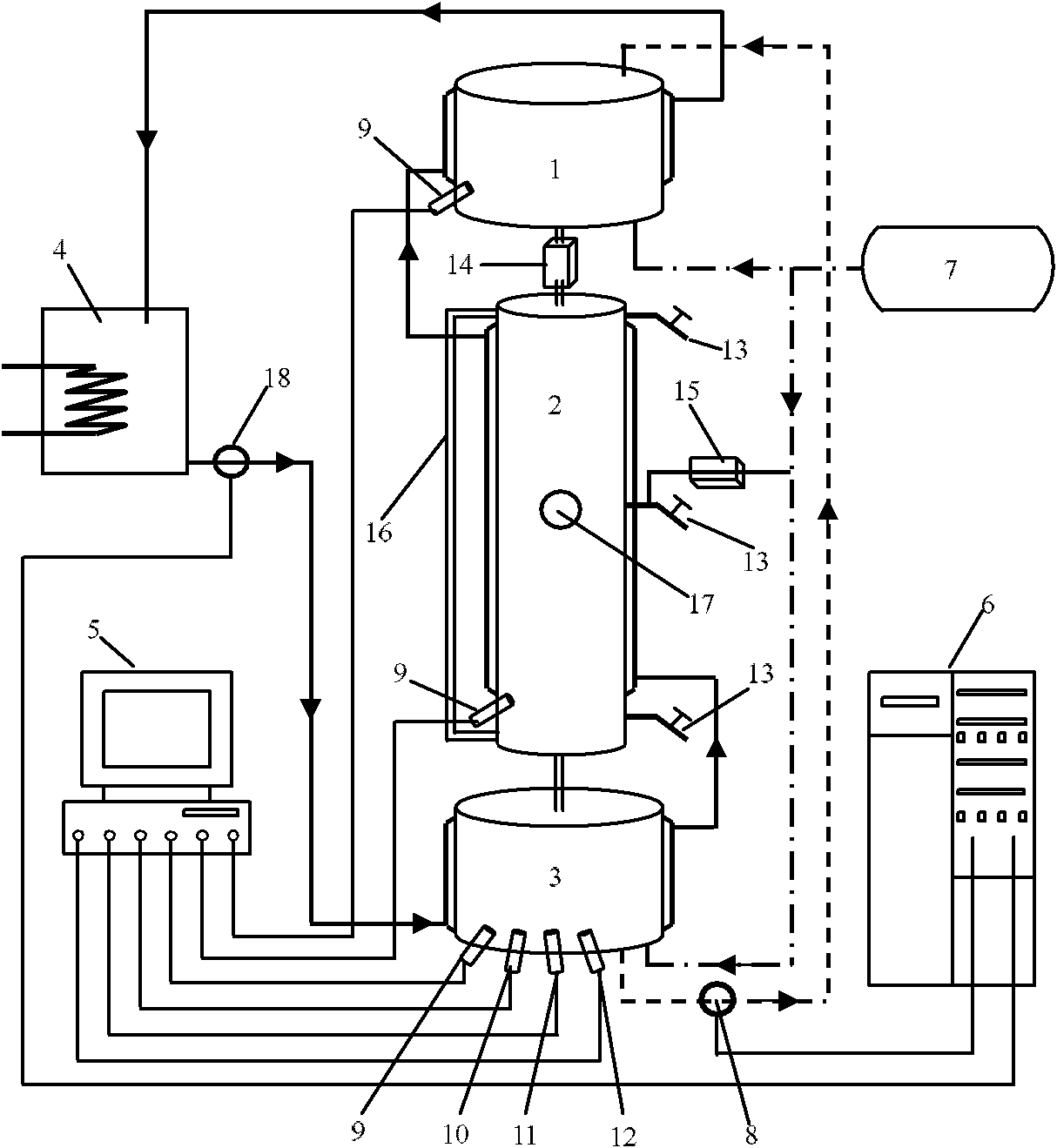

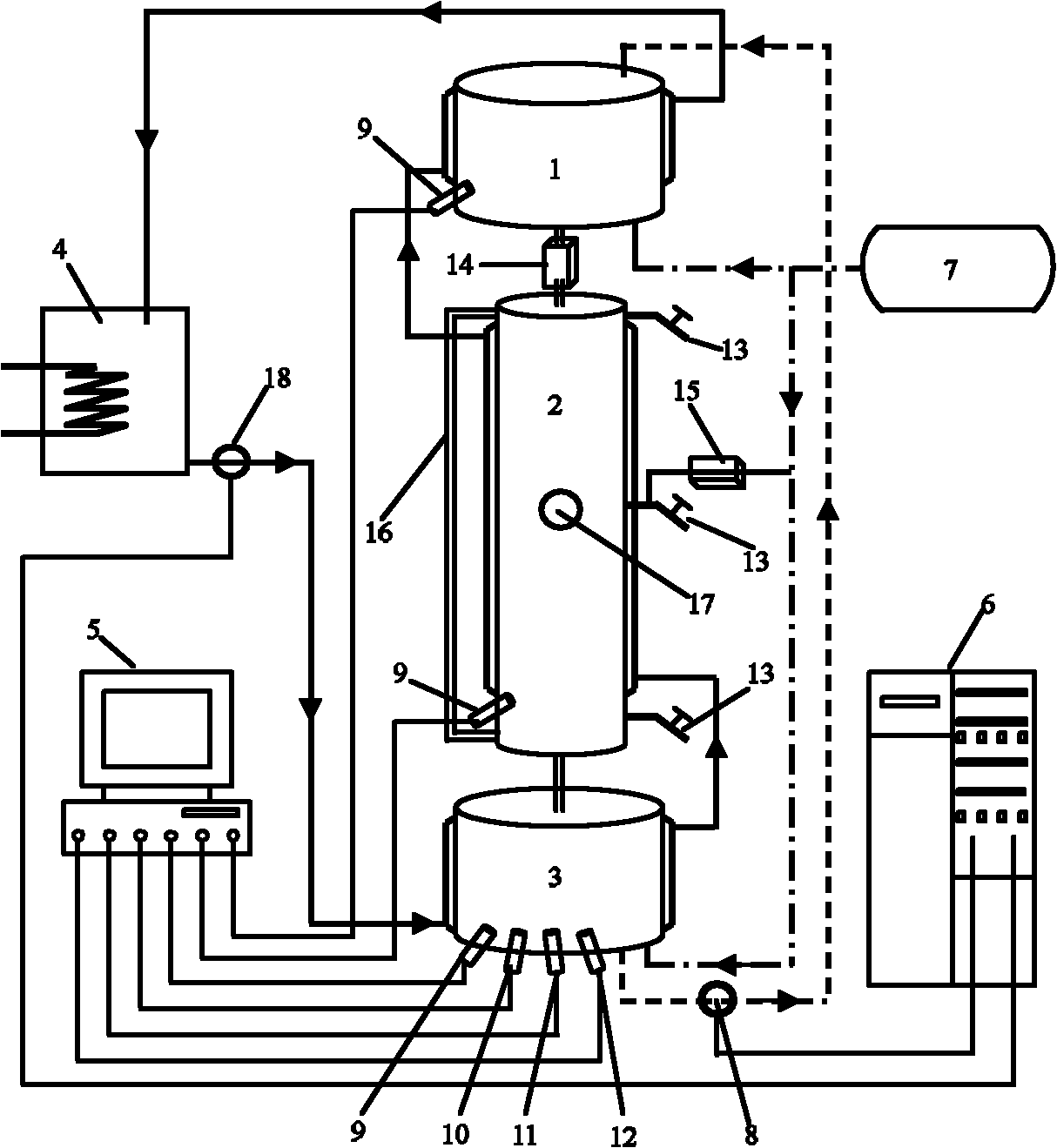

[0017] Such as figure 1 , The main body of the device includes a high level tank 1, a reaction column 2, a liquid receiving tank 3, a hot water tank 4, a display 5, a controller 6, and an air compressor 7. Introduce the specific implementation manner of the present invention below in conjunction with example.

[0018] A certain copper sulfide ore was taken as a test sample for microbial leaching test.

[0019] (1) Ore preparation: After the ore is crushed to a certain size, it is loaded into the reaction column through the sampling port 13 on the reaction column 2, and the sampling port 13 is closed.

[0020] (2) Temperature control: the controller 6 sets the water temperature of the hot water tank 4, the heater starts to work, and the circulating water starts to heat up. When the temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com