Diamond micro-channel Cu-based CVD diamond heat sink sheet and preparation method thereof

A diamond and micro-channel technology, which is applied in the direction of modification through conduction and heat transfer, cooling/ventilation/heating transformation, etc., can solve the problems of large thermal expansion coefficient and damage to electronic components, and achieve excellent heat dissipation performance, easy peeling, and improved shape. Effects of nucleus density and growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] A kind of preparation method of diamond microchannel Cu base CVD diamond heat sink of the present invention comprises the following steps:

[0066] S1. Wire cutting the oxygen-free copper substrate with a purity of 99.99% to 99.999% and a diameter of 10 to 20 mm into copper sheets of 0.5 to 1 mm as a Cu substrate, and cleaning the surface of the Cu substrate;

[0067] S2. Fabrication of the micro-via template, the micro-via template adopts oxygen-free copper with the same specifications as the Cu substrate;

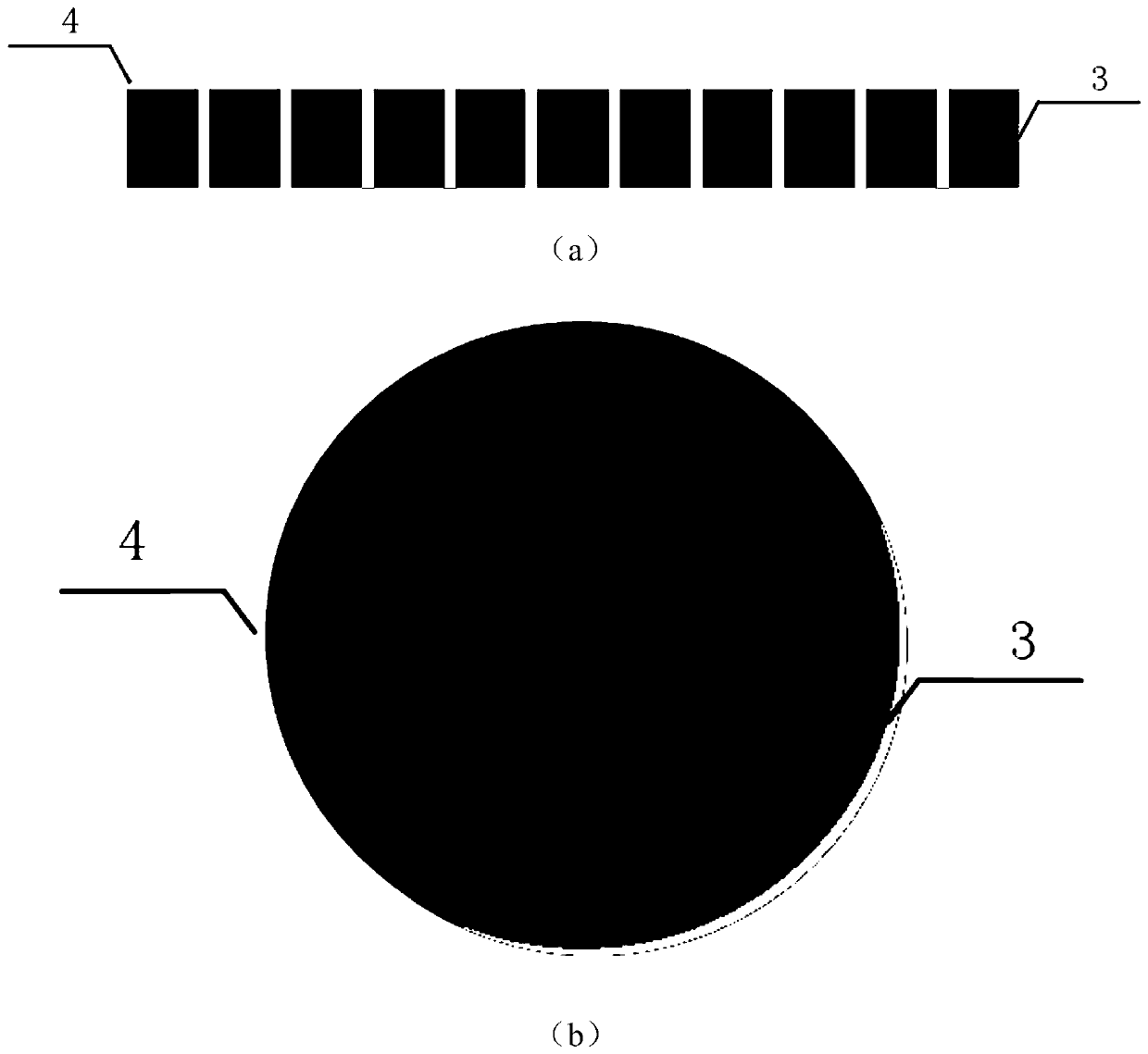

[0068] S201, Cu substrate stamping and drilling, the micro-via manufacturing process includes mechanical stamping and drilling, hydraulic drilling, laser drilling, drilling, etc.; the micro-via template is composed of a micro-via array, and the diameter of the micro-via is 0.3 ~0.5mm, channel spacing 2~3mm; micro-via shapes include circle, regular triangle, square, regular hexagon or regular octagon, etc., such as Figure 5 shown;

[0069] S202. Use a hydrochlori...

Embodiment 1

[0092] S1, cutting the oxygen-free copper substrate with a purity of 99.99% and a diameter of 10mm into 0.5mm copper sheets as the Cu substrate, and cleaning the surface of the Cu substrate;

[0093] S201, Cu substrate stamping and drilling, the micro-via manufacturing process includes mechanical stamping and drilling, hydraulic drilling, laser drilling, drilling, etc.; the micro-via template is composed of a micro-via array, and the diameter of the micro-via is 0.3 mm, the channel spacing is 2mm; the shape of micro-vias includes circle, regular triangle, square, regular hexagon or regular octagon;

[0094] S202, use a hydrochloric acid solution with a volume ratio of 0.5% to slightly corrode the Cu substrate and the micro-via template for 3 minutes, and remove the oxide film and processing burrs in the micro-via;

[0095] S203, using acetone, alcohol, and deionized water to ultrasonically clean the substrate and the micro-via template for 3 minutes, remove organic matter on t...

Embodiment 2

[0113] S1. Wire cutting the oxygen-free copper substrate with a purity of 99.99% and a diameter of 14mm into 0.7mm copper sheets as a Cu substrate, and cleaning the surface of the Cu substrate;

[0114] S201, Cu substrate stamping and drilling, the micro-via manufacturing process includes mechanical stamping and drilling, hydraulic drilling, laser drilling, drilling, etc.; the micro-via template is composed of a micro-via array, and the diameter of the micro-via is 0.4 mm, the channel spacing is 2mm; the shape of micro-vias includes circle, regular triangle, square, regular hexagon or regular octagon;

[0115] S202, use a hydrochloric acid solution with a volume ratio of 0.5% to slightly corrode the Cu substrate and the micro-via template for 4 minutes, and remove the oxide film and processing burrs in the micro-via;

[0116] S203, sequentially use acetone, alcohol, and deionized water to ultrasonically clean the substrate and the micro-via template for 4 minutes, remove organ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com