Method for simulating steel board cooling control

A technology of cooling control and simulation method, which is applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., and can solve problems such as difficulty in realizing engineering research of general control technology, lack of sensors and controllers, and risk of production line debugging , to achieve the effect of automatically optimizing setting control, saving production debugging costs, and saving online debugging time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

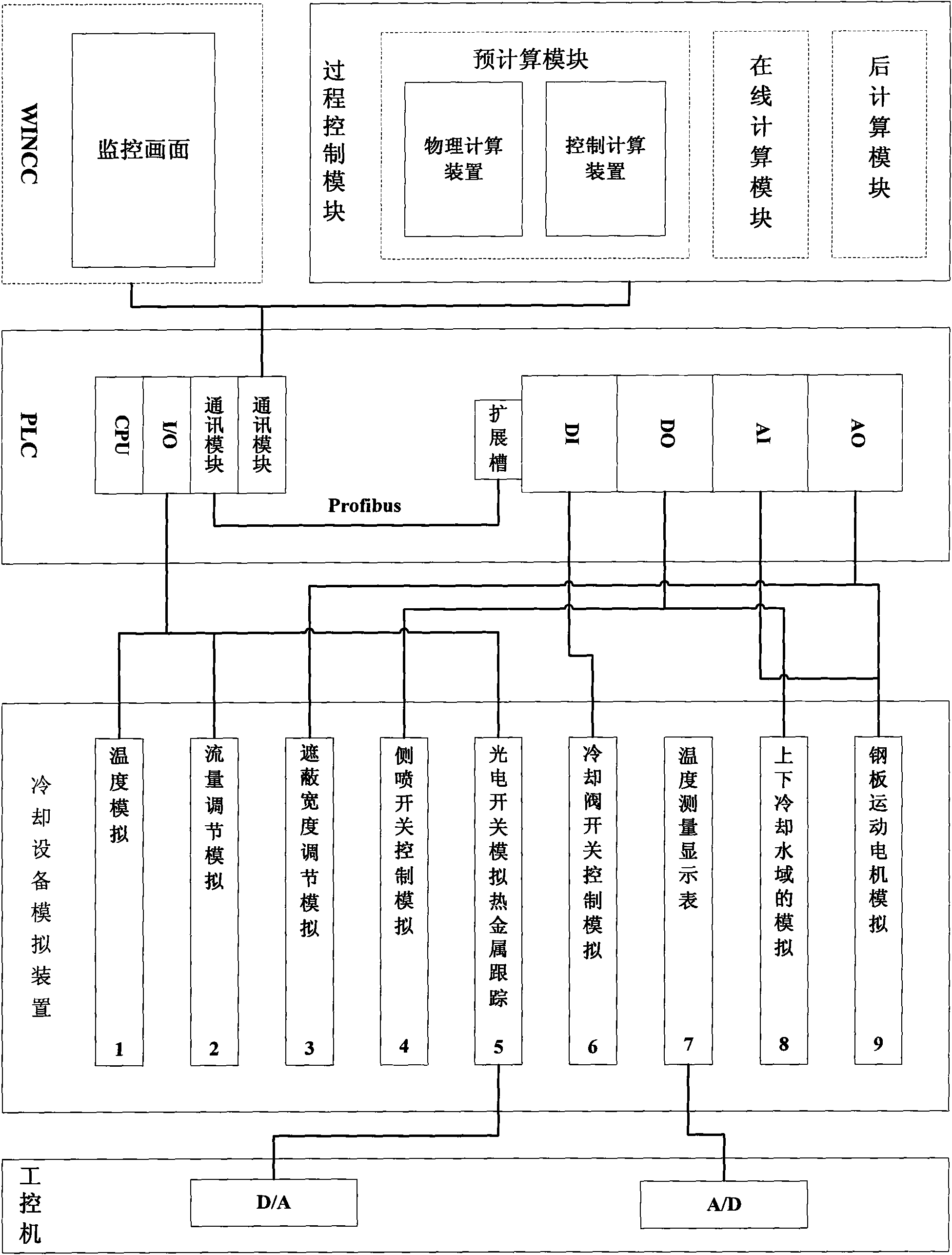

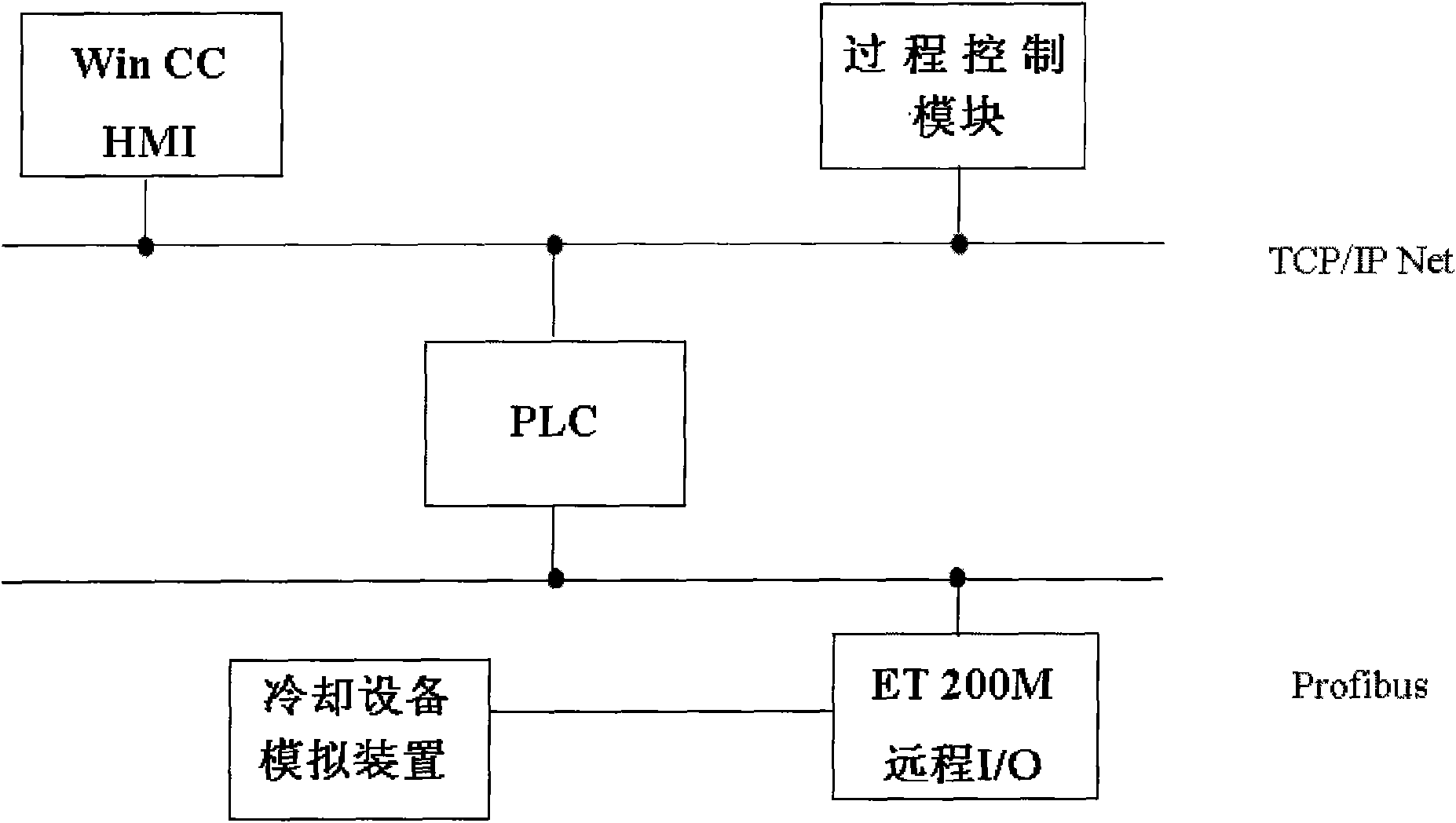

Method used

Image

Examples

example

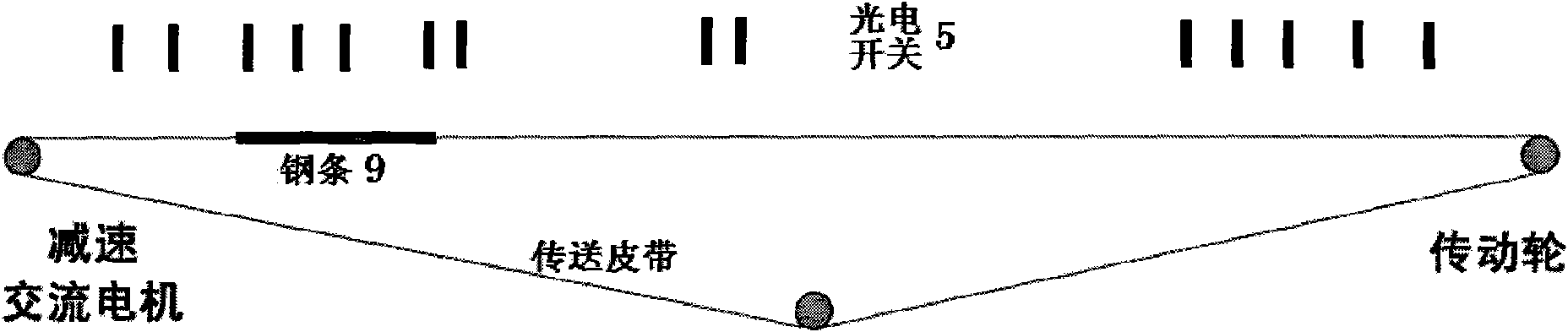

[0061] When the thickness of the steel plate is 25.35mm, the width is 3857mm, the length is 21559mm, the outlet temperature of the rolling mill is 793±5°C, the cooling target temperature is 530°C, the cooling rate is 20K / S, the steel type is given, the control amount and electromotive potential set by the process control device The actual flow rate fed back by the controller is as follows:

[0062]

[0063] After the PLC receives the set value of the process control device, press the start button, the motor refreshes the speed according to the 500ms cycle (set speed = 12mm / s), the motor drives the belt to rotate, and the steel bar mounted on the belt starts to move. When the head of the simulated steel plate moves to the first photoelectric switch position, the electric potentiometer for analog flow adjustment and electric potentiometer for analog shielding start to move, reaching the position required by the setting of flow rate and edge shielding. When the head of the sim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com