Gasification furnace for the gasification pilot plant test of underground coal and process thereof

A technology of gasification furnace and pilot test, applied in the direction of fixed bed gasification, furnace, furnace type, etc., which can solve the problems that the underground gasification process cannot be completely simulated, the pressure test cannot be carried out, and the test data cannot be obtained.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Referring to the accompanying drawings, several exemplary implementations of the underground coal gasification pressurized gasifier and its process method of the present invention will be described below.

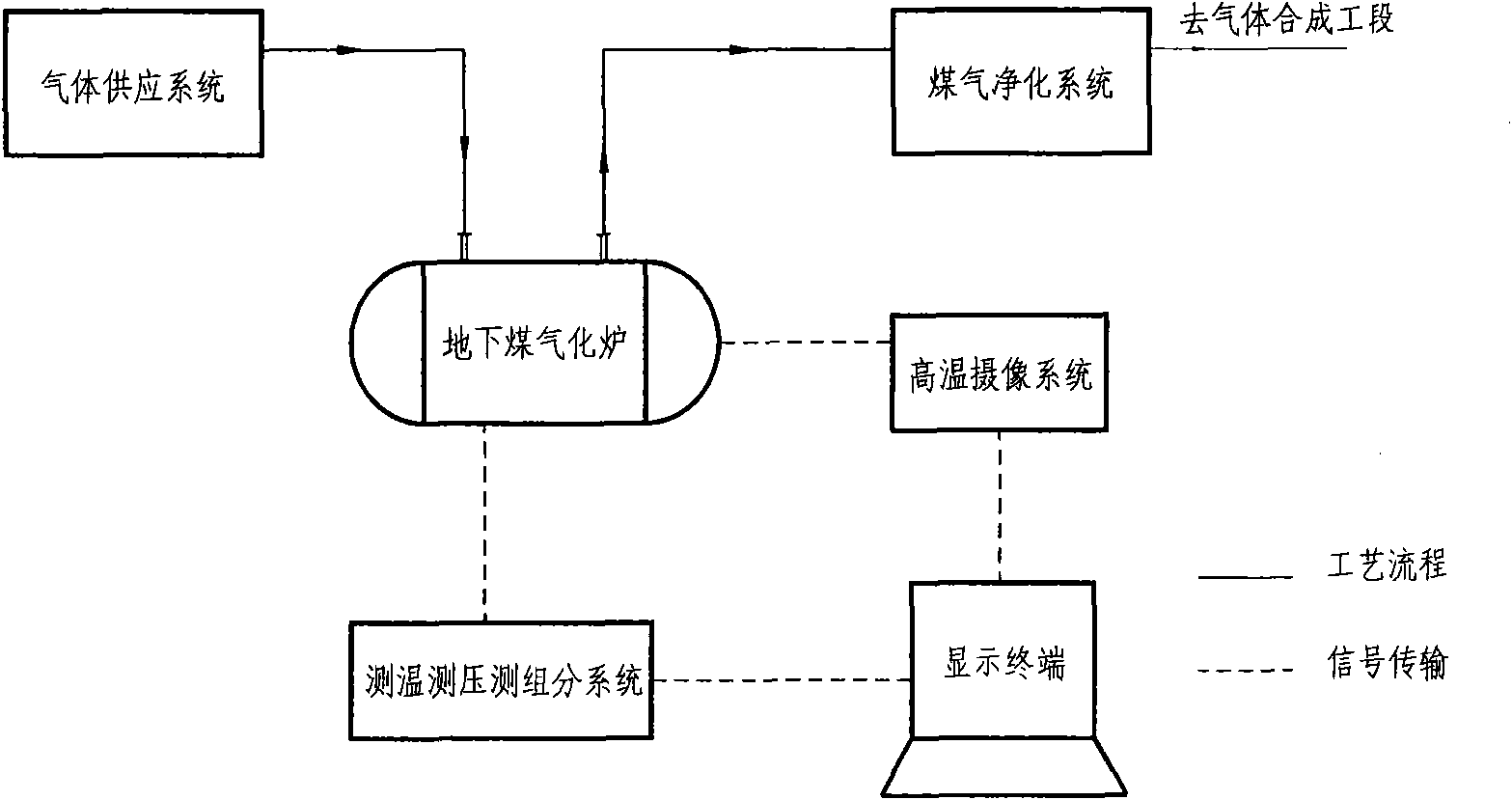

[0050] see figure 1 , the equipment involved in the underground coal gasification pilot test of the present invention includes a gas supply system, a gasifier, a gasifier temperature and pressure measurement system, a gasifier high-temperature camera system, a gas purification system, and a display terminal and central processing unit (not shown).

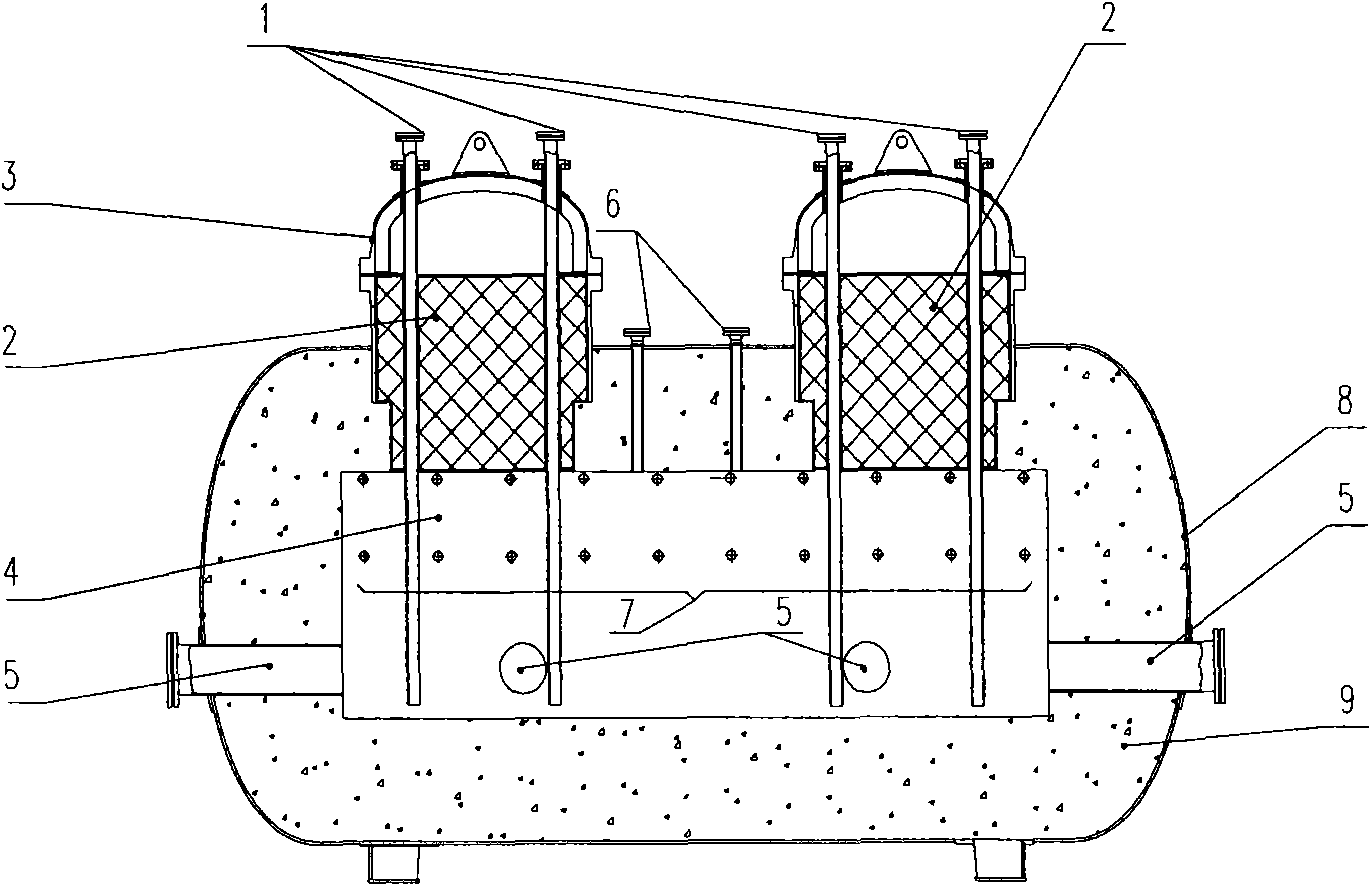

[0051] see figure 2 , the gasifier provided by the present invention is a gasifier used for the gasification pilot test of underground coal, and the pilot test is used to simulate the underground geological and hydrological conditions, and then carry out the normal pressure or Pressurized gasification simulation test, to obtain process parameters that can reflect the situation on site.

[0052] The gasification furnac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com