Preparation method of nanometer zinc oxide composite dispersion liquid

A technology of nano-zinc oxide and nano-zinc oxide powder, which is applied in the field of nanotechnology and fine chemical industry, and can solve problems such as inability to form a stable suspension, unsatisfactory dispersion effect, demulsification of dispersion liquid, delamination and even solid agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

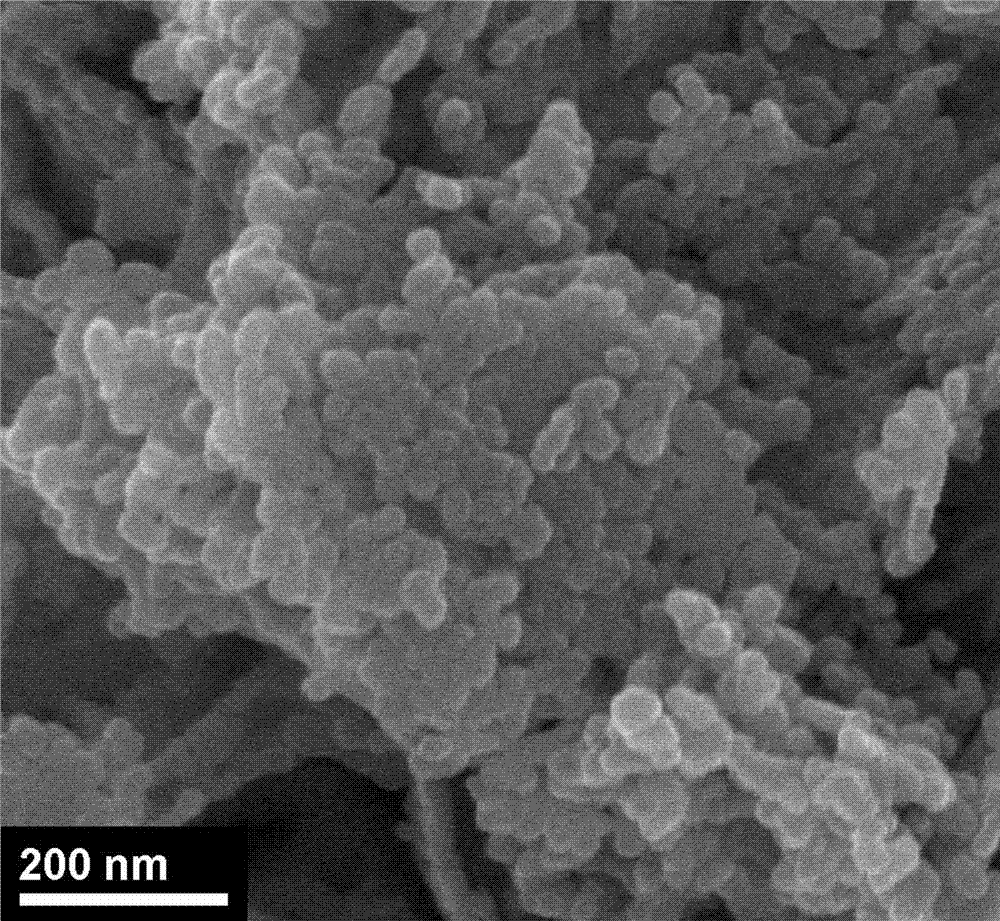

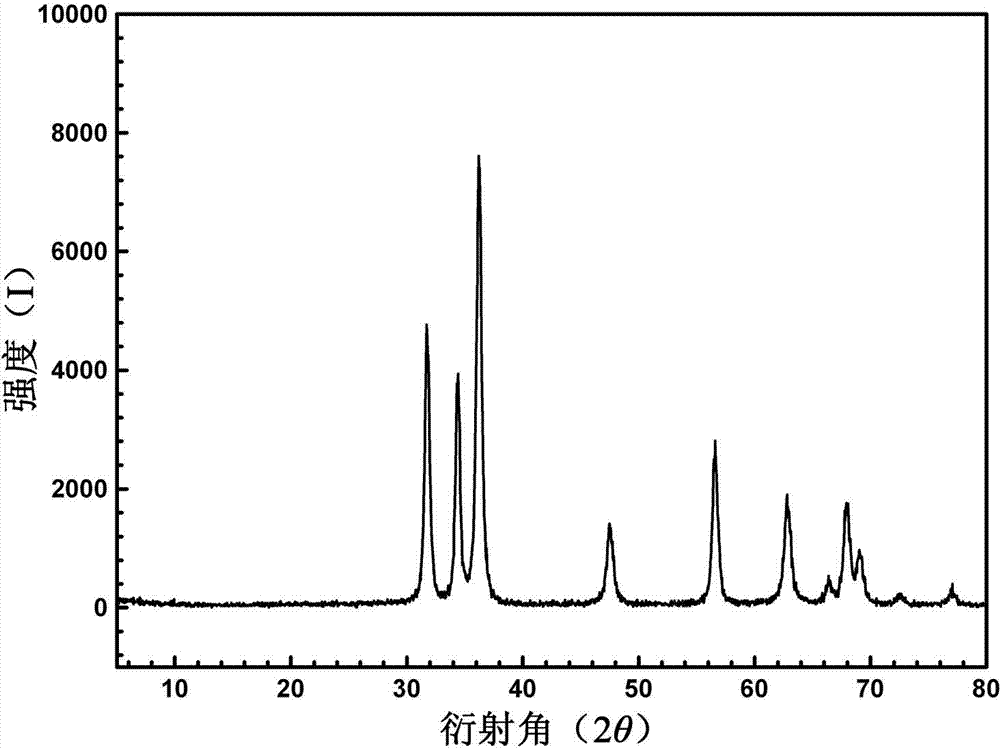

[0024] Based on 1 kg of the nano-zinc oxide composite dispersion liquid, a dispersion liquid with a zinc oxide content of 10% is prepared. The particle size of the nano-zinc oxide powder used is about 30 nanometers. The raw materials and proportioning ratio are shown in the following table:

[0025]

[0026] Preparation method: Before preparation, prepare carbomer into a 1% solution for later use. During preparation, in container A, mix stearic acid and Tween-80 according to the addition amount in the table, heat to 80 degrees, stir while heating, make it fully melt, and form a uniform and transparent liquid state; at the same time, in In container B, add carbomer (1%) and sodium lauryl sulfate to water, stir to form a uniform solution, then add nano-zinc oxide powder, heat to 70 degrees, and stir while heating to form a well-dispersed Slurry; then, under rapid stirring, add phase A at 80 degrees to phase B at 70 degrees, then use a high-speed homogenizer to homogenize for ...

Embodiment 2

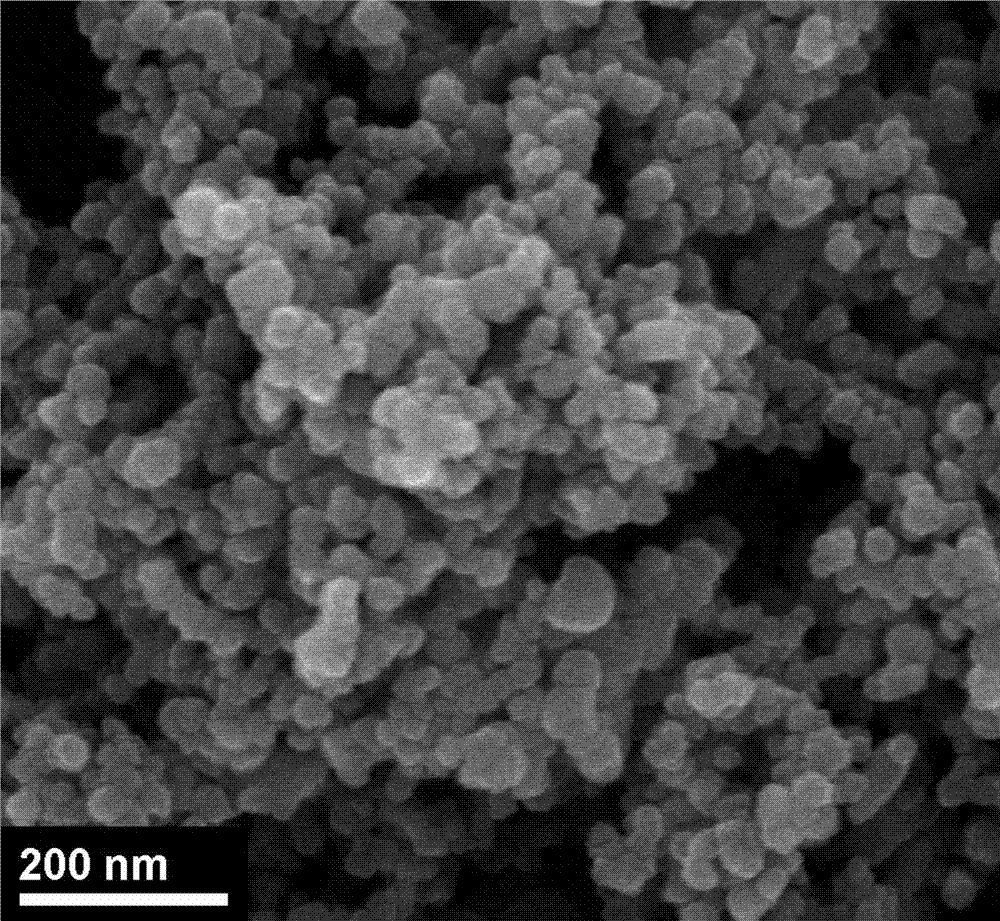

[0029] Based on 1 kg of the nano-zinc oxide composite dispersion liquid, a dispersion liquid with a zinc oxide content of 15% is prepared. The particle size of the nano-zinc oxide powder used is about 30 nanometers. The raw materials and the proportioning ratio are shown in the following table:

[0030]

[0031] Preparation method: Before preparation, prepare carbomer into a 1% solution for later use. During preparation, in container A, mix stearic acid and Tween-80 according to the addition amount in the table, heat to 80 degrees, stir while heating, make it fully melt, and form a uniform and transparent liquid state; at the same time, in In container B, add carbomer (1%) and sodium lauryl sulfate to water, stir to form a uniform solution, then add nano-zinc oxide powder, heat to 80 degrees, stir while heating, and form a well-dispersed Slurry; then under rapid stirring, add phase A at 80 degrees to phase B at 80 degrees, then use a high-speed homogenizer to homogenize for...

Embodiment 3

[0034] Based on 1 kg of the nano-zinc oxide composite dispersion liquid, a dispersion liquid with a zinc oxide content of 20% is prepared. The particle size of the nano-zinc oxide powder used is about 30 nanometers. The raw materials and proportioning ratio are shown in the following table:

[0035]

[0036]Preparation method: Before preparation, prepare carbomer into a 1% solution for later use. During preparation, in container A, mix stearic acid and Tween-80 according to the addition amount in the table, heat to 90 degrees, stir while heating, make it fully melt, and form a uniform and transparent liquid; at the same time, in In container B, add carbomer (1%) and sodium lauryl sulfate to water, stir to form a uniform solution, then add nano-zinc oxide powder, heat to 80 degrees, and stir while heating to form a well-dispersed Slurry; then, under rapid stirring, add phase A at 90 degrees to phase B at 80 degrees, then use a high-speed homogenizer to homogenize for 4 minut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com