Patents

Literature

39results about How to "Wide adjustable range of parameters" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for rare earth element-doped titanium dioxide nano material

InactiveCN102992397AIn situ dopingSimple processMaterial nanotechnologyTitanium dioxideRare-earth elementNitrate

The invention relates to a preparation method for a rare earth element-doped titanium dioxide nano material. The method comprises the steps of dissolving urea and rare earth element nitrate in absolute ethyl alcohol; adding liquid titanium source into the above solution to form a homogeneous solution; adding deionized water with stirring to form a transparent gel; performing hydro-thermal treatment on the above gel; washing, filtering and drying to obtain the rare earth element-doped titanium dioxide nano material. An object of doping titanium dioxide by using the rare earth element is realized through automatic regulation and control of pH value of a reaction system by slow decomposition of urea in the hydrothermal process. The preparation method is simple in process and flow, has wide parameter adjustable range, strong repeatability and low cost, and can be used for preparing different rare earth element-doped titanium dioxide nano materials or a plurality of the rare earth elements co-doped titanium dioxide nano material.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Nano-silver peroxide composite antibacterial solution and preparation method thereof

InactiveCN103563983AImprove the bactericidal effectImprove antibacterial propertiesBiocideDisinfectantsColor changesSilver particles

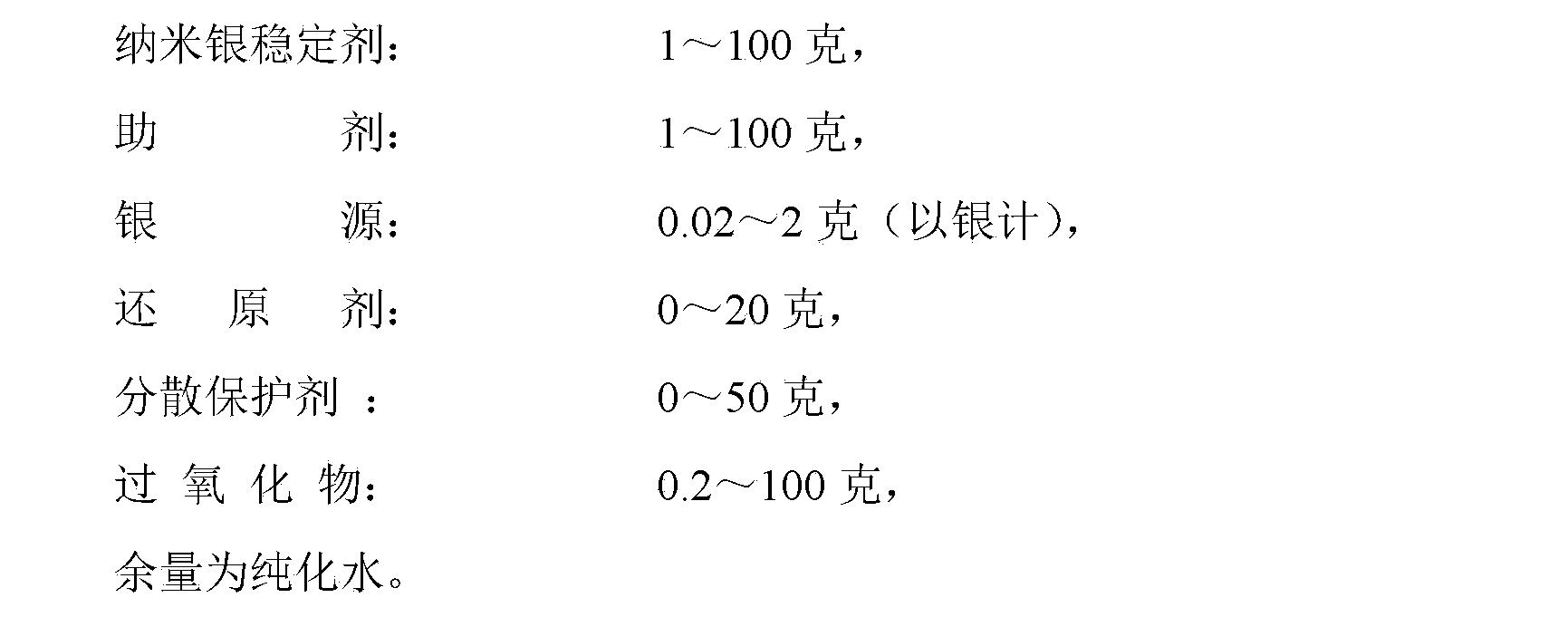

The invention discloses a nano-silver peroxide composite antibacterial solution and a preparation method thereof. The antibacterial solution is characterized in that the antibacterial solution comprises following raw materials based on 1000 mL of the nano-silver peroxide composite antibacterial solution: 1-100 g of a nano-silver stabilizing agent, 1-100 g of auxiliary agents, 0.02-2 g of a silver source (based on silver), 0-20 g of a reductant, 0-50 g of a dispersion protection agent and 0.2-100 g of a peroxide, with the balance being purified water. Nano-silver particles of the antibacterial solution have a size of 1-10 nm, and show monodispersity and no agglomeration. The antibacterial solution is colorless, transparent, color change resistant, strongly stable, wide in pH controllable range, and the like. In addition, under conditions that the concentrations of the nano-silver and the peroxide are both low, the antibacterial solution can reach a high sterilizing rate in short time, and has lasting bactericidal effects. The preparation method has characteristics of simple operation, wide parameter adjustable range, low energy consumption, short period, and the like, and is suitable for large-scale production.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

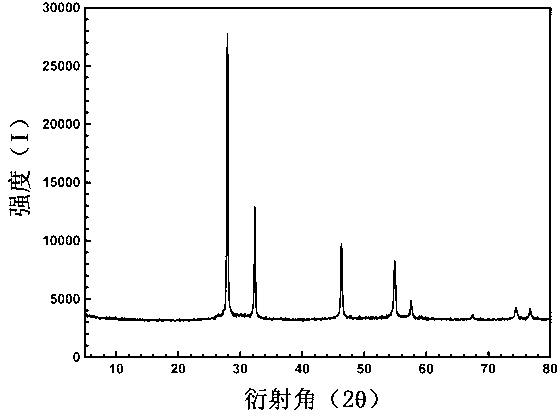

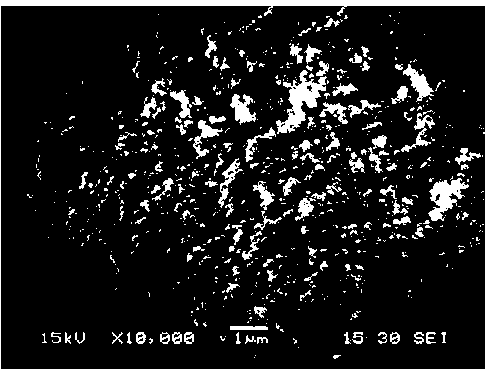

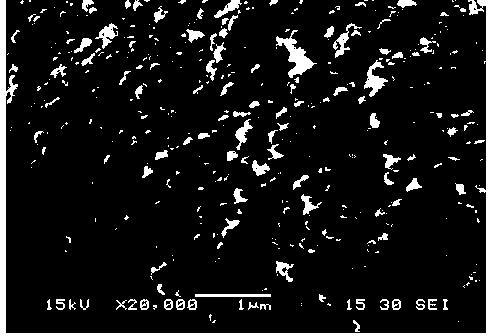

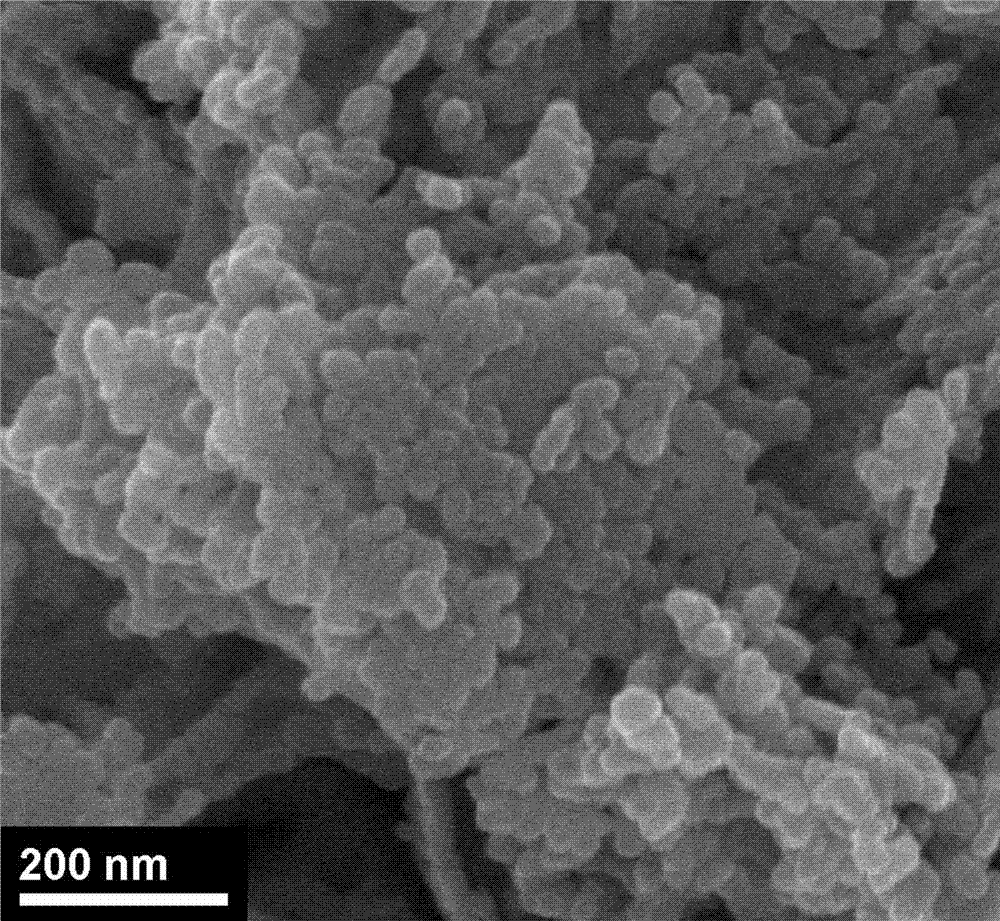

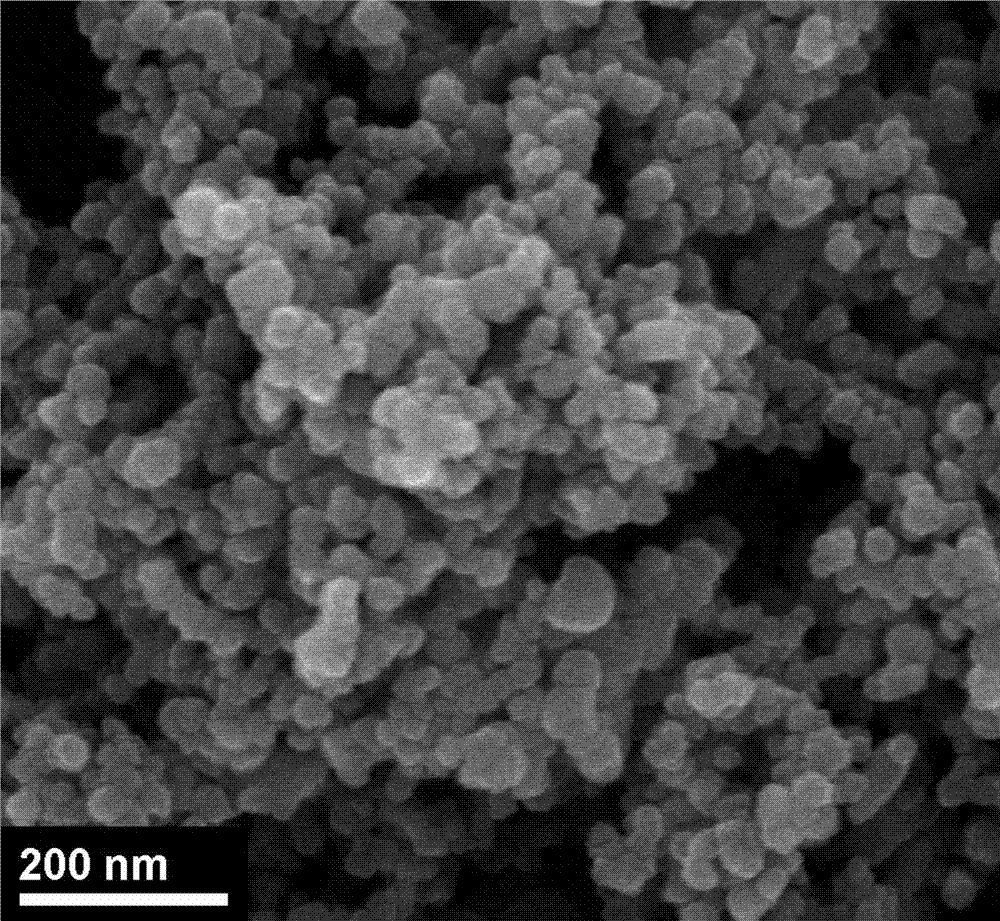

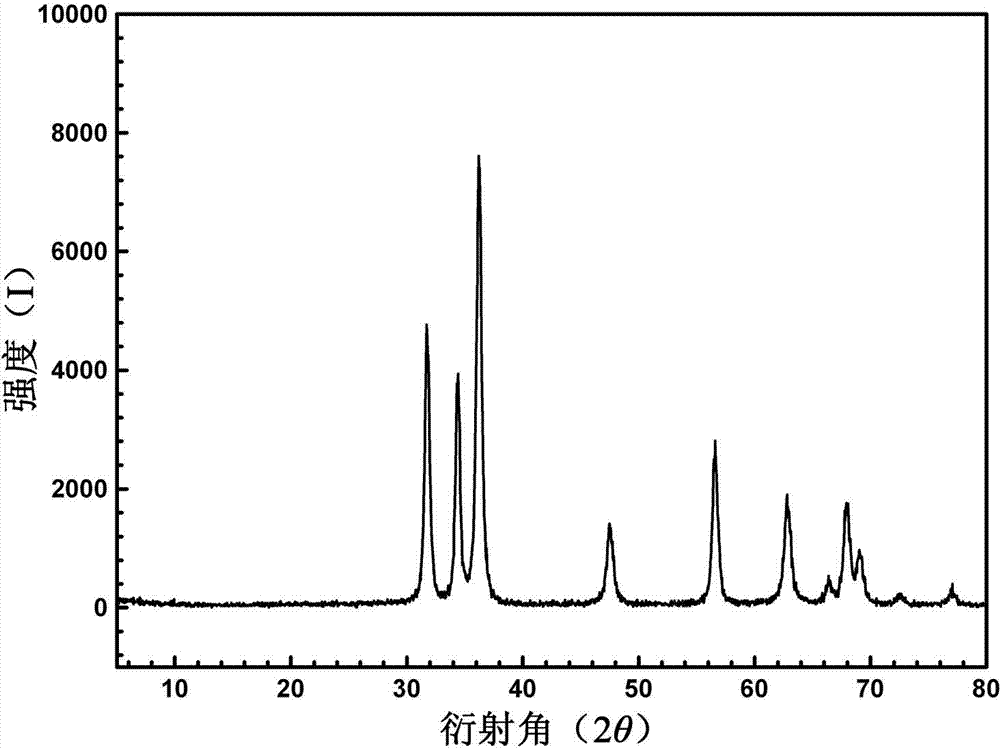

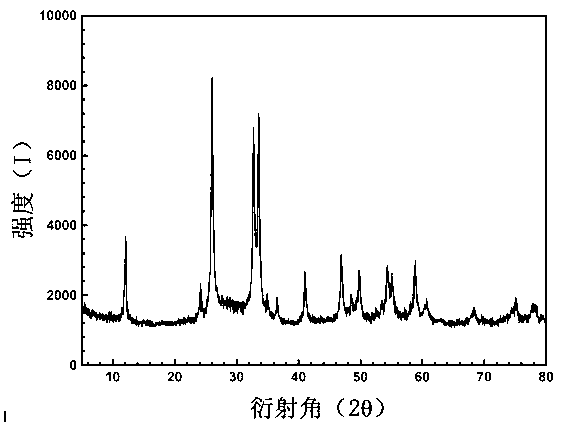

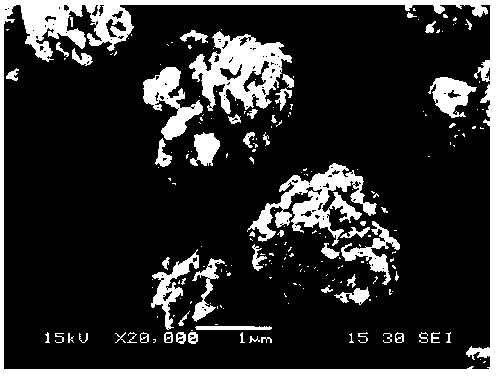

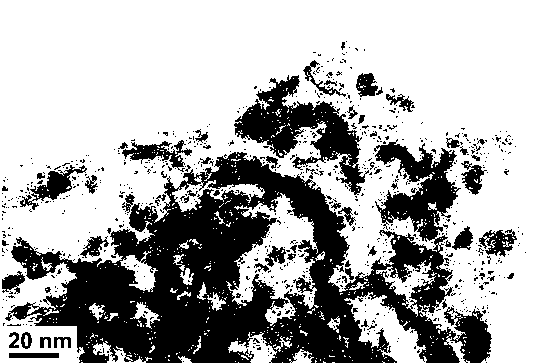

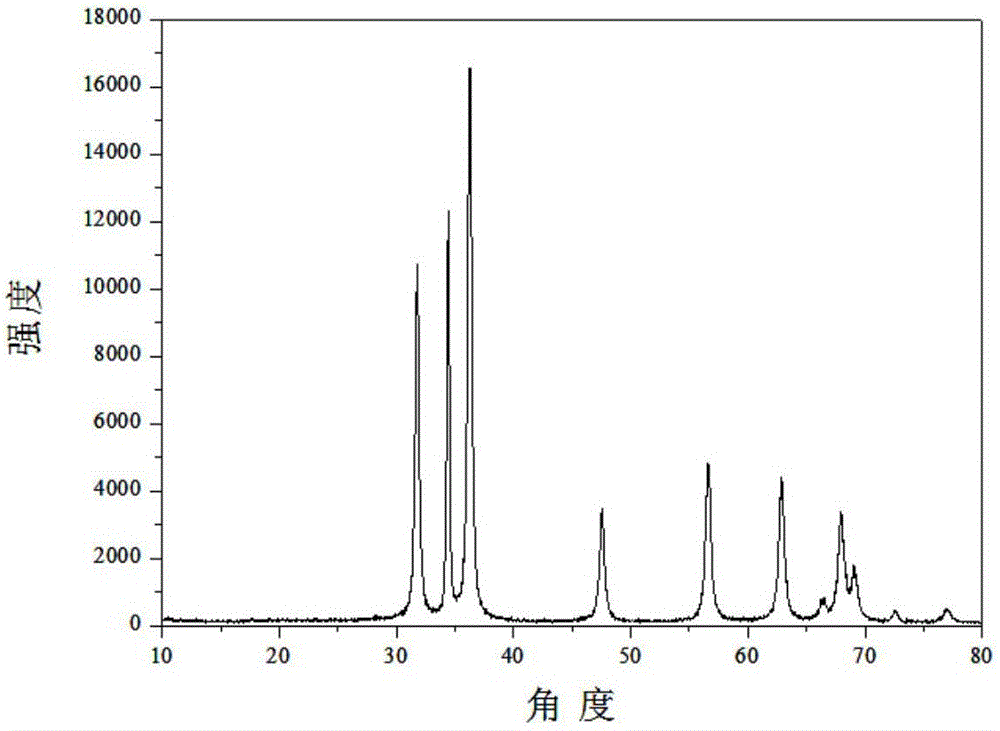

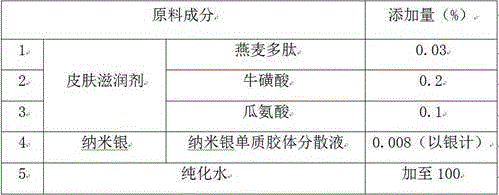

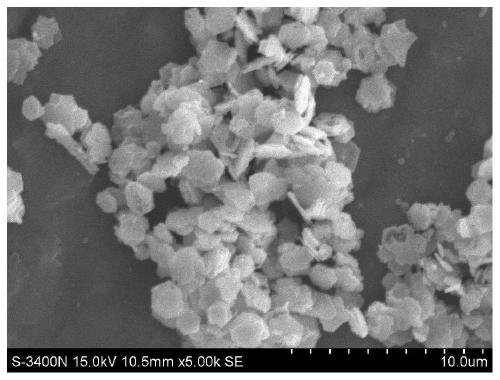

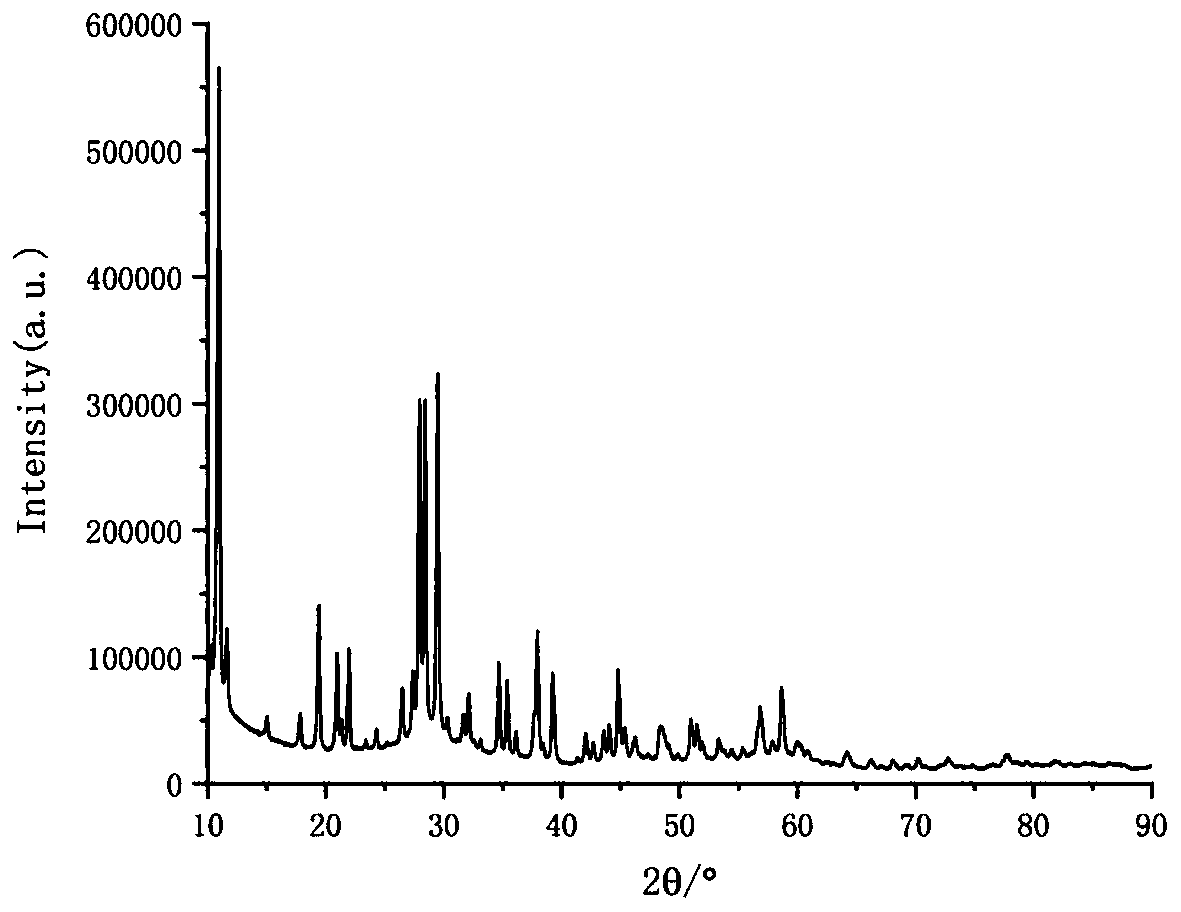

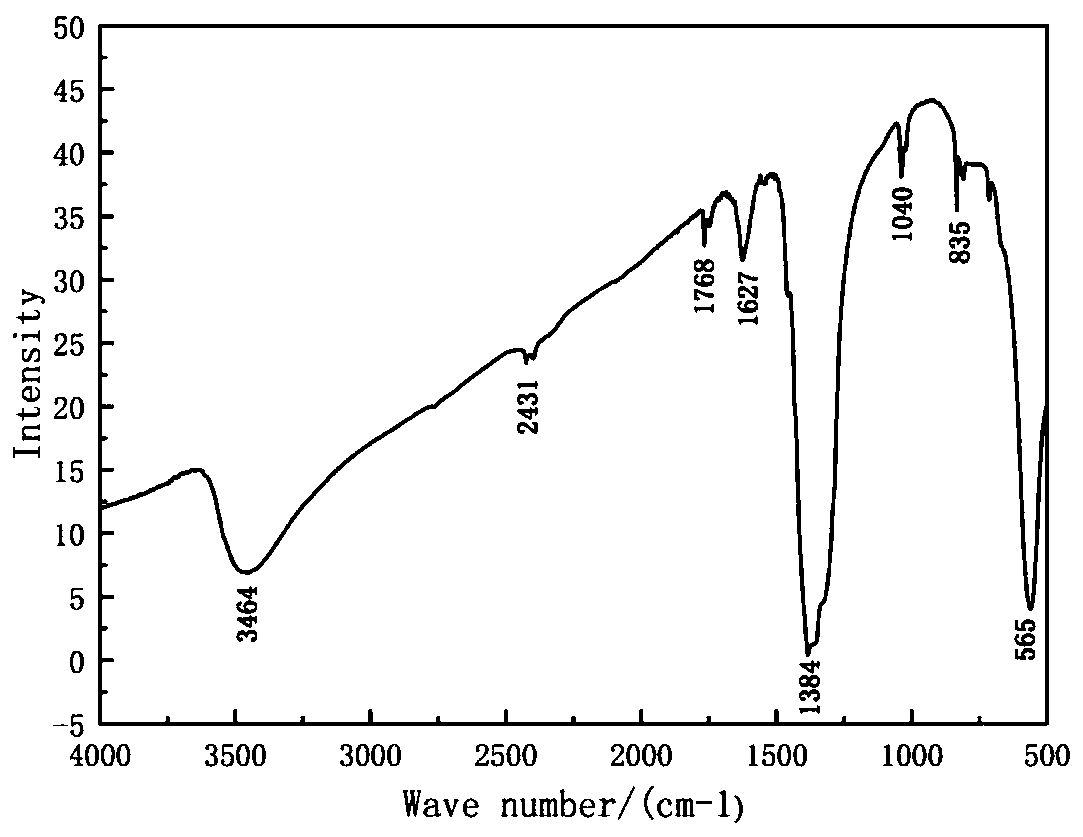

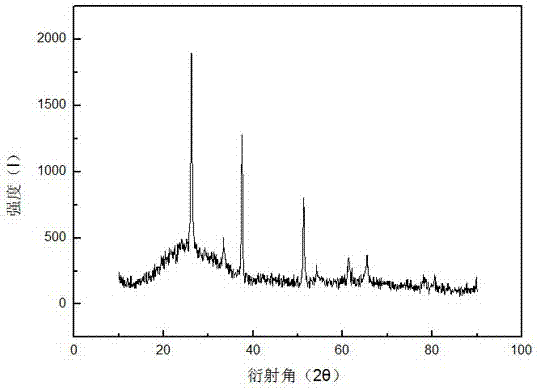

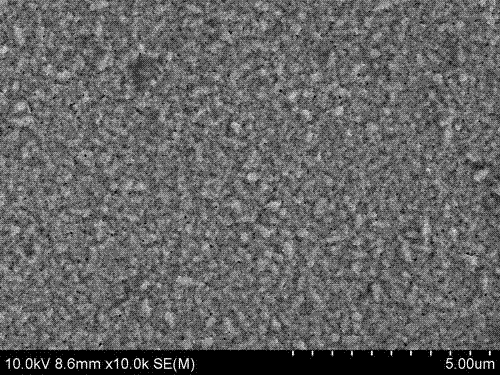

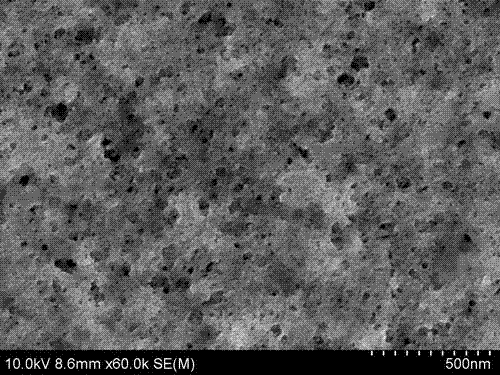

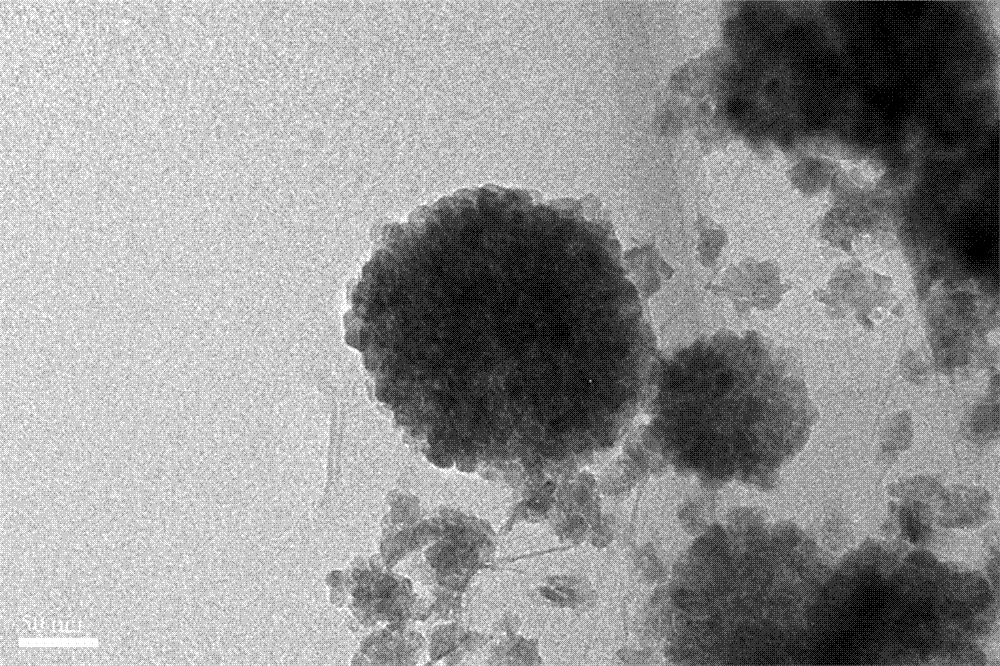

Bismuth tungstate nanocrystal and preparation method thereof

The invention relates to a bismuth tungstate nanocrystal and a preparation method thereof. The nanocrystal is a spherical bismuth tungstate nanocrystal with diameter of 100-200 nm, uniform size and high dispersion. The preparation method of the nanocrystal comprises steps of: adding a bismuth source to concentrated nitric acid, conducting preliminary stirring, adding deionized water and performing further stirring for dissolving dilution; adding tungstate to deionized water and conducting stirring to dissolve it; dropwisely adding the first solution into the second solution under stirring to form a homogeneous suspension; adjusting the pH value with an ammonia solution; then conducting ageing for 4-72h in a closed static state at a temperature of 323-373K; after the ageing, washing the precipitate product with deionized water; and drying to obtain the bismuth tungstate nanocrystal. The preparation method has simple process and flow, wide parameter adjustable range, strong repeatability and low cost, and shows commercial prospect. The prepared bismuth tungstate nanocrystal has high application value in the fields of photocatalysis, scintillation materials, gas sensitive materials, magnetic devices and light-guide fiber.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Preparation method of nanometer zinc oxide composite dispersion liquid

InactiveCN103693674AGood dispersionUniform and stable dispersionMaterial nanotechnologyZinc oxides/hydroxidesZno nanoparticlesOxide composite

The invention discloses a preparation method of a nanometer zinc oxide composite dispersion liquid. The method is characterized by comprising the following steps: mixing an oil phase component and an emulsifier according to certain proportion in an oil phase system; adding a dispersion stabilizing agent, a surfactant and a nano zinc oxide powder according to a certain ratio into water in a water dispersion system; and respectively uniformly mixing the two phases and heating to a certain temperature, rapidly stirring the two phases for homogeneous mixing, and cooling to room temperature to form a stable emulsion dispersion system. The nanometer zinc oxide composite dispersion liquid prepared by the above method, the particle size difference of zinc oxide particle and nano zinc oxide powder raw material is within 20%; in the dispersion liquid, nano zinc oxide particles are suspended in the liquid in a monodispersed form; and placing for more than 60 days, the nano zinc oxide composite dispersion liquid does not generate the phenomena of layering, demulsification or caking. Moreover, the preparation method has the advantages of simple operation, wide adjustable range of parameters, low energy consumption and short cycle, and is suitable for pilot plant test amplification and industrial large-scale production.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

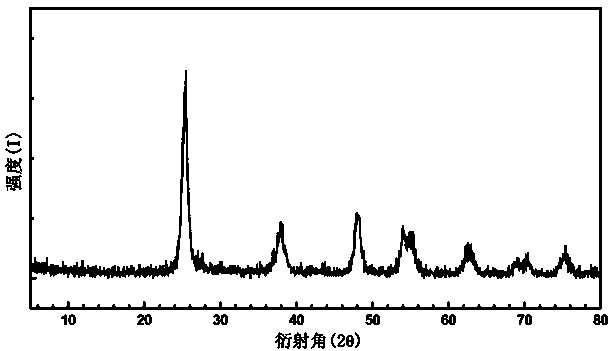

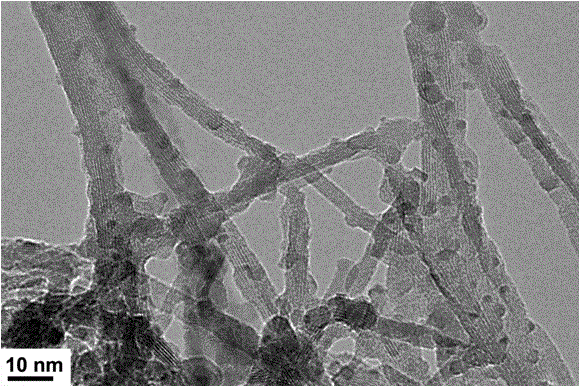

Potassium titanate nanowire and preparation method thereof

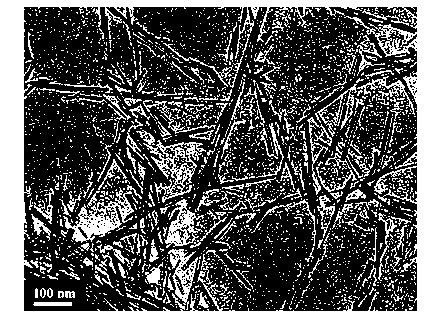

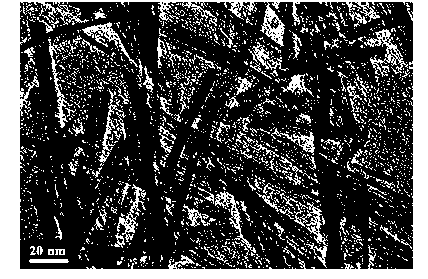

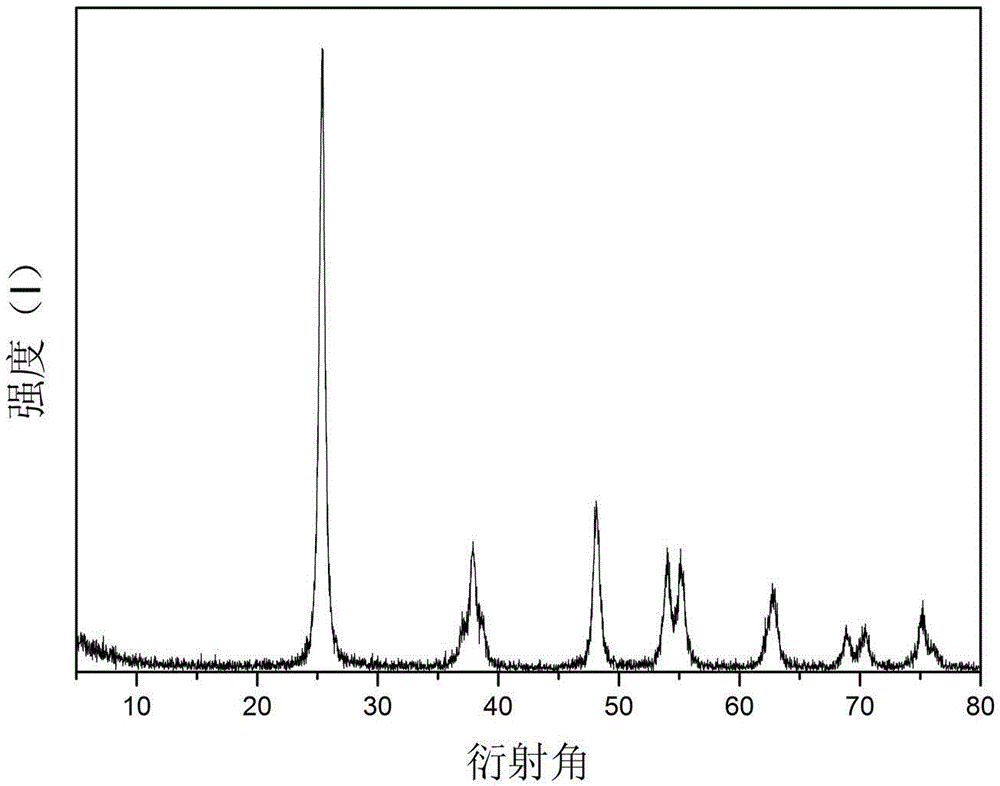

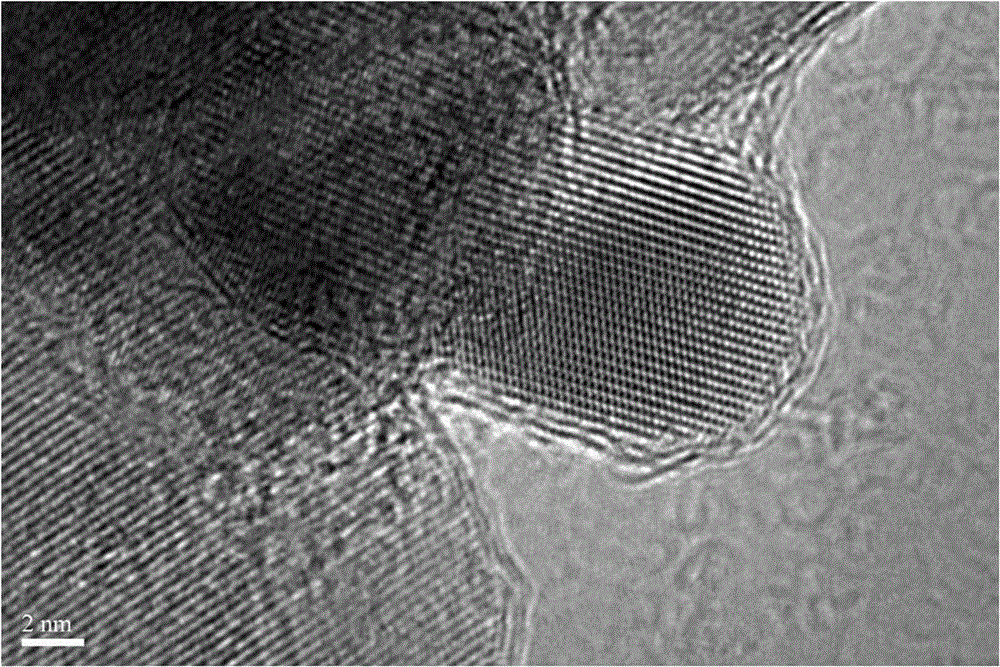

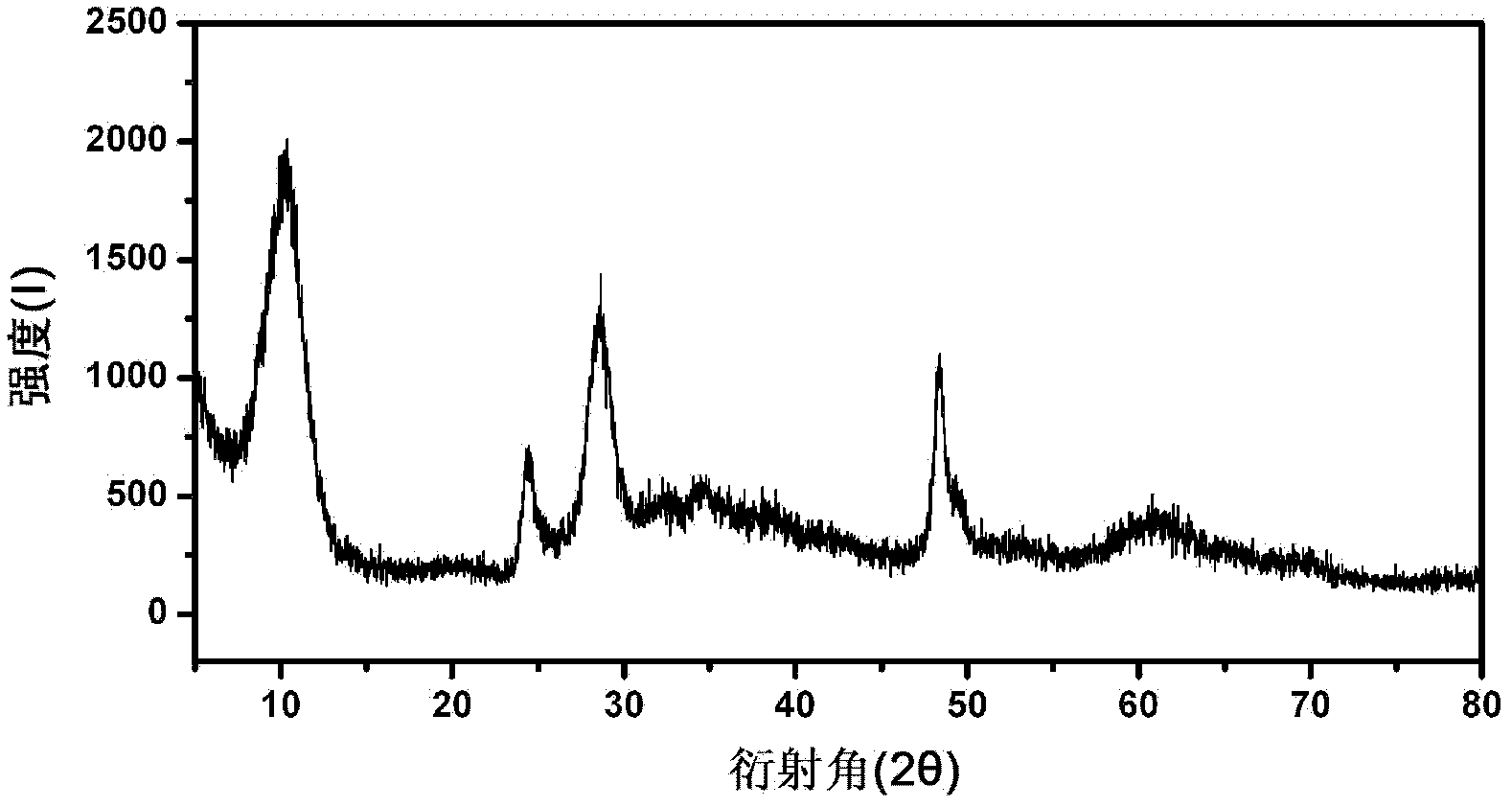

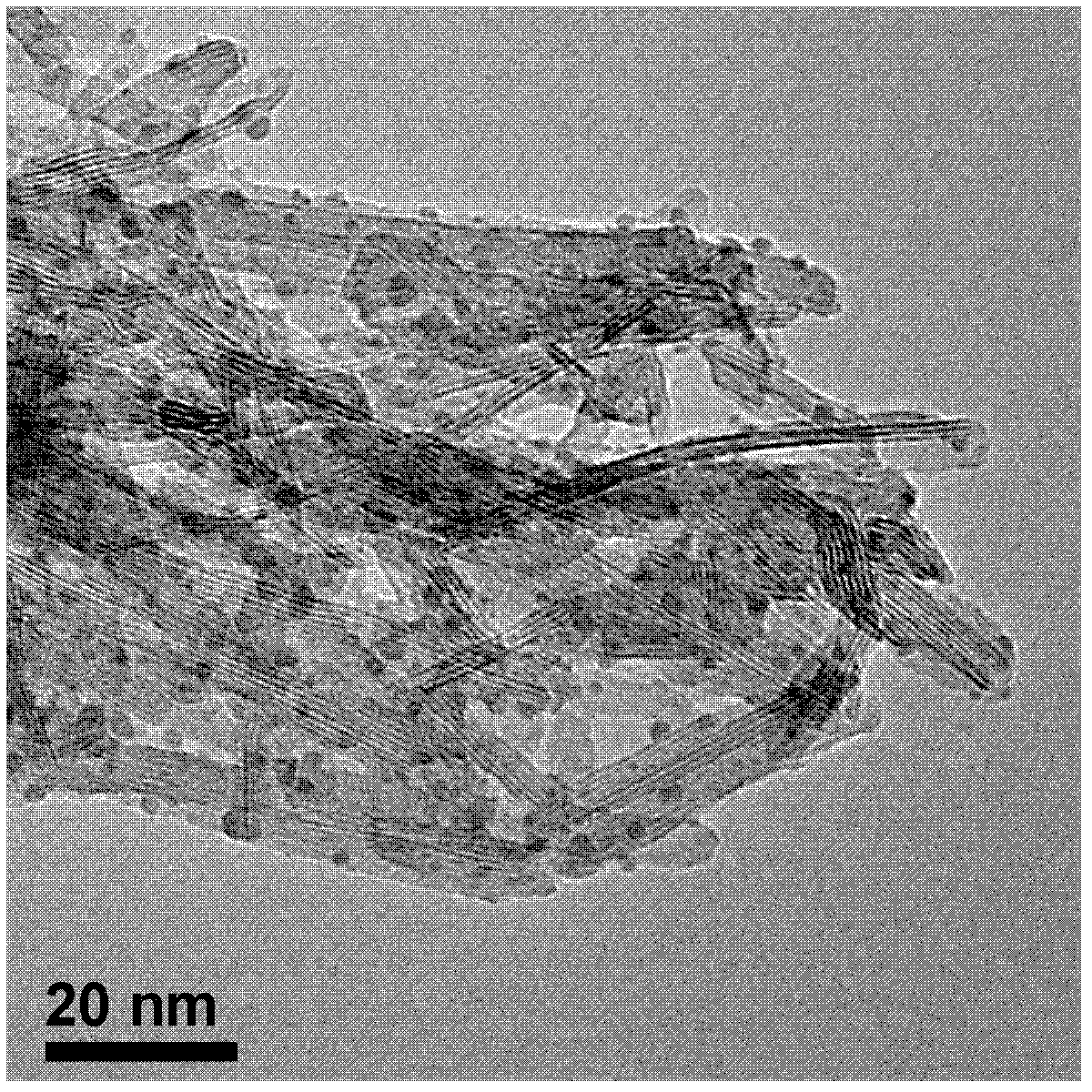

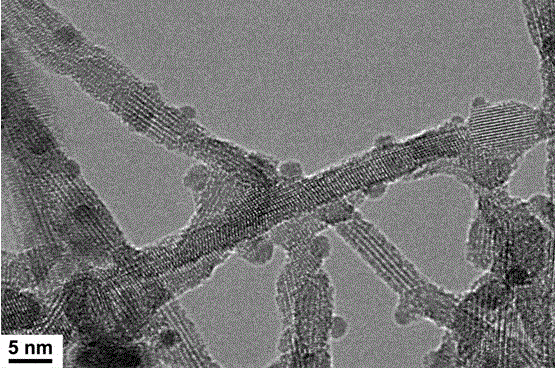

InactiveCN103101968AUniform shapeHigh purityNanotechnologyTitanium compoundsNanowirePotassium hydroxide

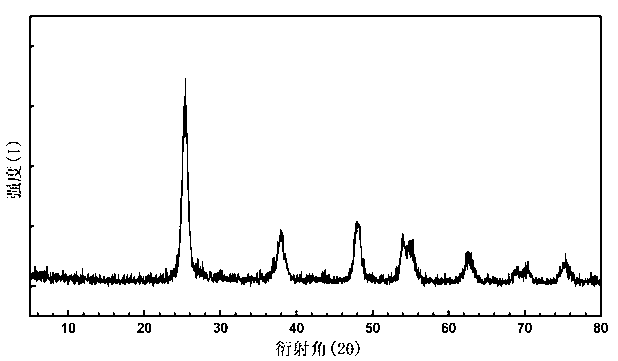

The invention relates to a potassium titanate nanowire and a preparation method thereof. The potassium titanate nanowire has a potassium octatitanate (K2Ti8O17) crystal form, diameter between 4 and 9 nm, length between 100 and 1000 nm, and uniform morphology. The preparation method of the potassium titanate nanowire is characterized by comprising the following steps: (1) adding a solid or liquid titanium source into an alcohol-water solution of potassium hydroxide, and rapidly stirring to form a homogeneous suspension; (2) placing the suspension obtained in the step (1) into stainless steel autoclave with a polytetrafluoroethylene lining, and subjecting the suspension to a hydrothermal treatment for 24-72 h at temperature of 373-473K; and (3) after the reaction, washing the precipitate product with deionized water and dilute hydrochloric acid until a washing fluid reaches a neutral state, and drying to obtain the potassium titanate nanowire. The preparation method has simple process and flow, wide parameter adjustable range, strong repeatability and low cost, and shows a commercial prospect.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

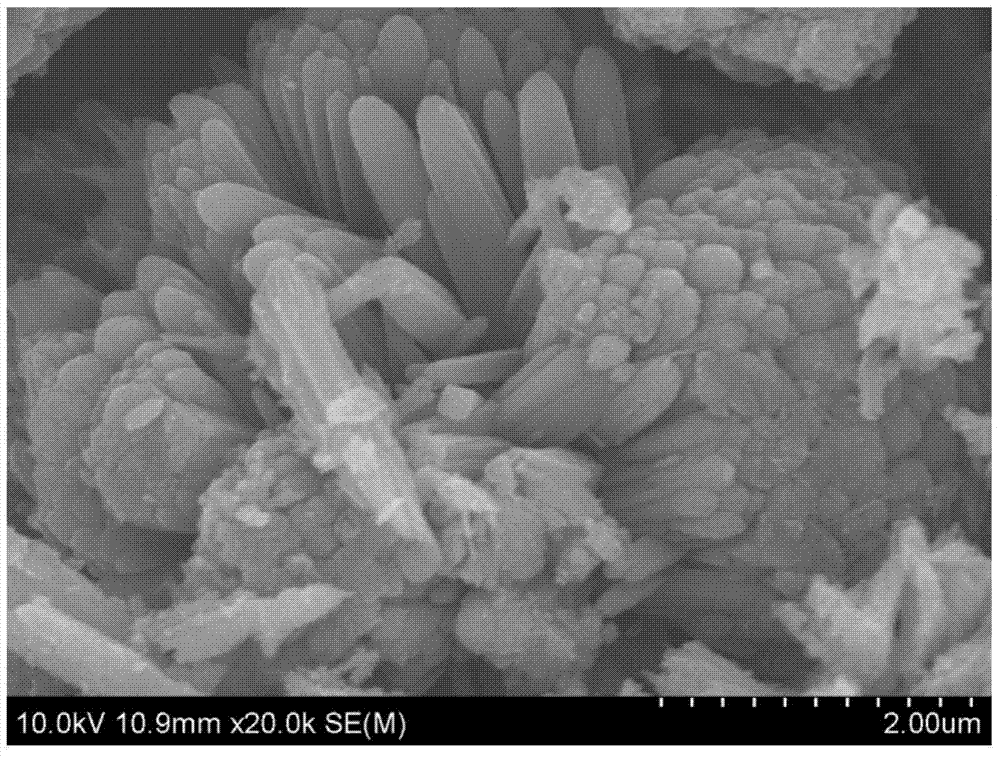

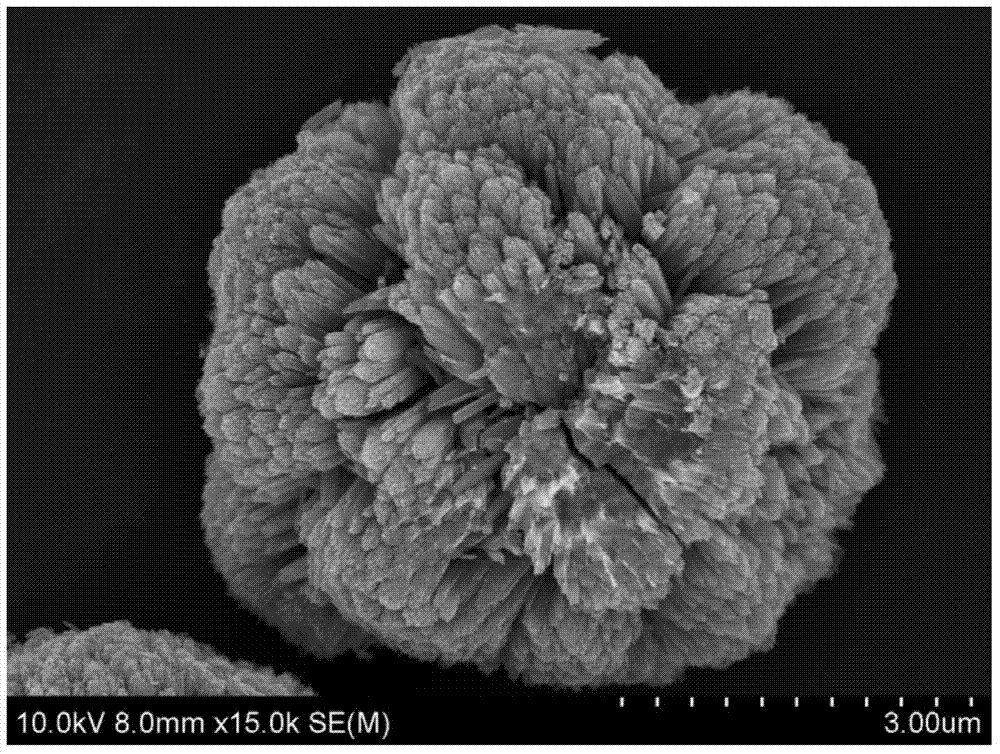

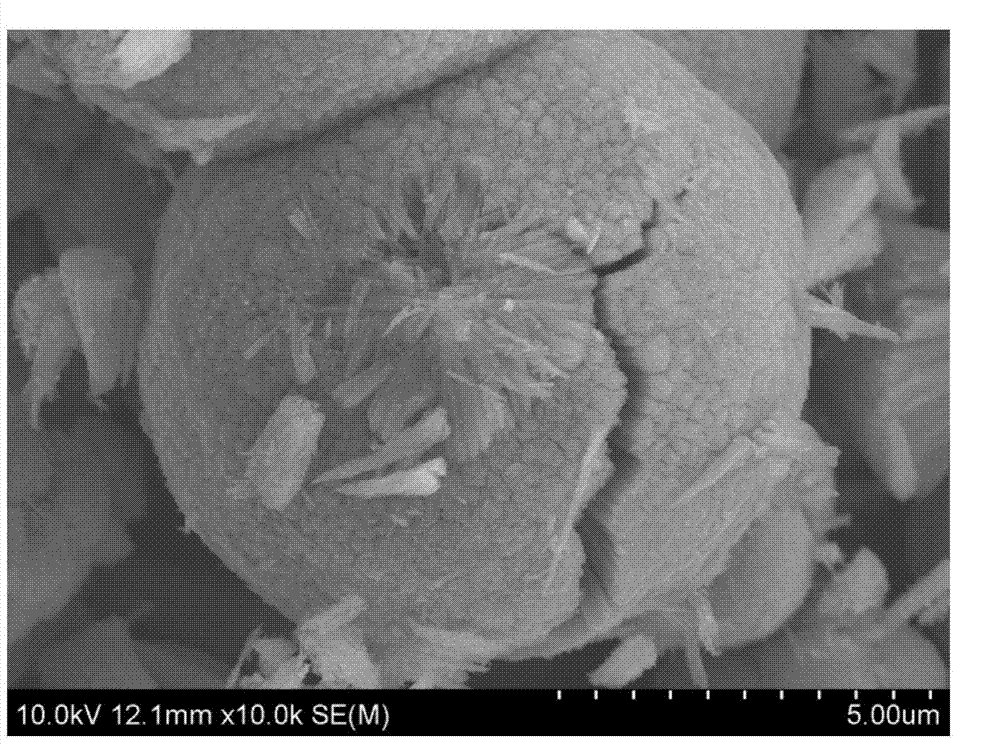

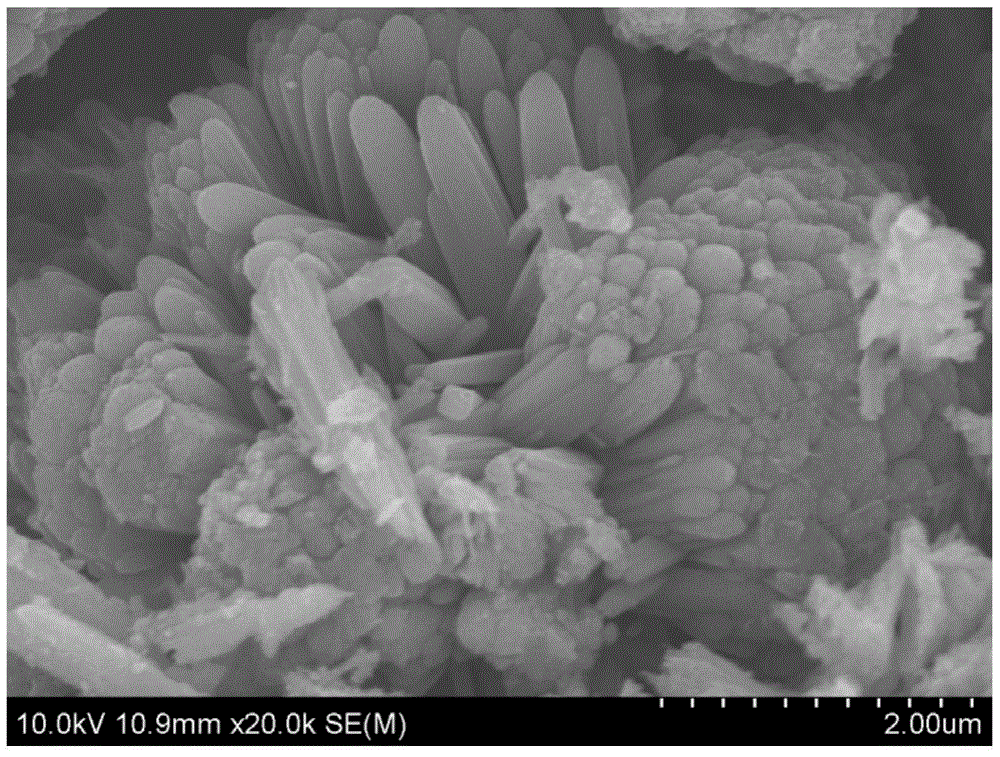

Controlled preparation method of ordered titanium dioxide nano-material

InactiveCN104118908AMaterials are readily availableEasy post-processingMaterial nanotechnologyTitanium dioxideNano structuringNanorod

The invention provides a controlled preparation method of an ordered titanium dioxide nano-material. The method comprises the following steps: preparing a mixed solution from acid and deionized water; dripping a titanium source into the mixed solution, intensively stirring to hydrolyze the titanium source quickly, and uniformly mixing the titanium source and the mixed solution; performing a hydrothermal reaction on the uniformly mixed suspension; washing precipitate with distilled water and absolute ethanol after the reaction is finished; and drying to obtain an ordered titanium dioxide nano-rod cluster, nano-flower or nano-ball. According to the preparation method, no surfactant is needed, and titanium dioxide nano-structures with different shapes and different crystal forms can be successfully prepared in an acid environment; in addition, the preparation method has the advantages of simple process and flow, wide parameter adjustable range, strong repeatability, low cost and the like.

Owner:SHANGHAI JIAO TONG UNIV +1

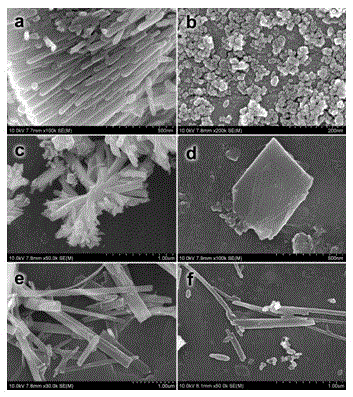

Low-temperature preparation method of morphology-controllable zinc oxide nano materials

InactiveCN104229864AThe size is easy to controlGood dispersionMaterial nanotechnologyZinc oxides/hydroxidesEmulsionAlcohol

The invention relates to a preparation method of morphology-controllable zinc oxide nano materials. The preparation method comprises the following steps: adding 0.01-0.2mol / L of a surfactant into an alcohol-aqueous solution with a volume ratio of 5 to 1, quickly stirring the solution at 20-100 DEG C to uniformly mix the solution; then, weighing and dispersing 0-0.2mol / L of a stabilizer and a zinc source into micro emulsion respectively; preparing 0.1-0.6mol / L of alkali liquor, adding the alkali liquor into zinc source micro emulsion at a speed of 2-3 days / second, continuously stirring for 20 minutes at 20-100DEG C; standing for 2-12 hours after the reaction is ended, washing precipitation products and drying the washed precipitation products to obtain zinc oxide nano material products with different morphologies. According to the preparation method disclosed by the invention, the process and the flow are simple and convenient, the adjustable range of the parameters is wide, the product size is controllable, the dispersion is good, the repeatability is good, the cost is low, the calcination is not needed, low carbon and environment-friendliness can be achieved, and various nano zinc oxide products with different morphologies can be prepared at the normal temperature or a low temperature.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

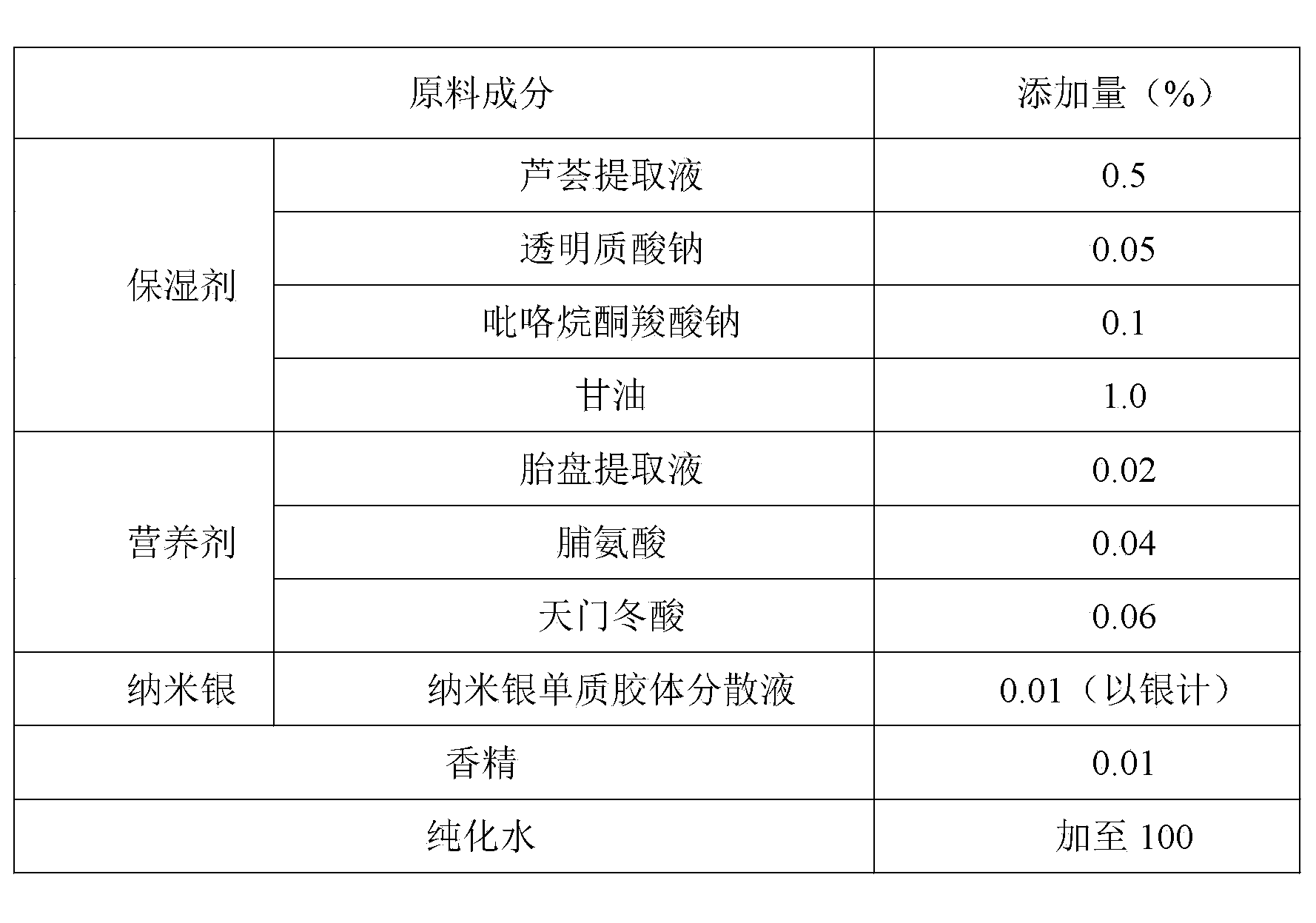

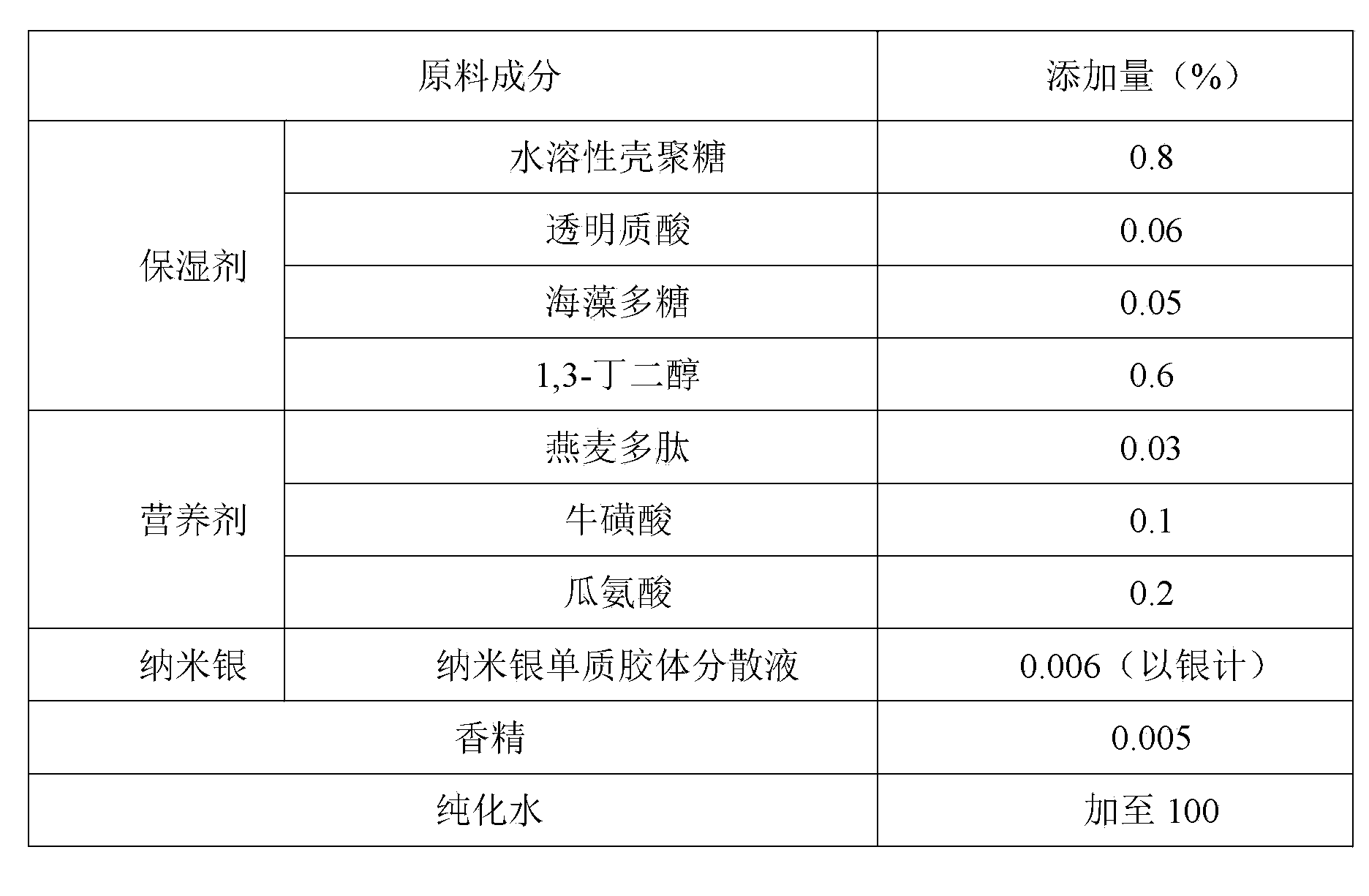

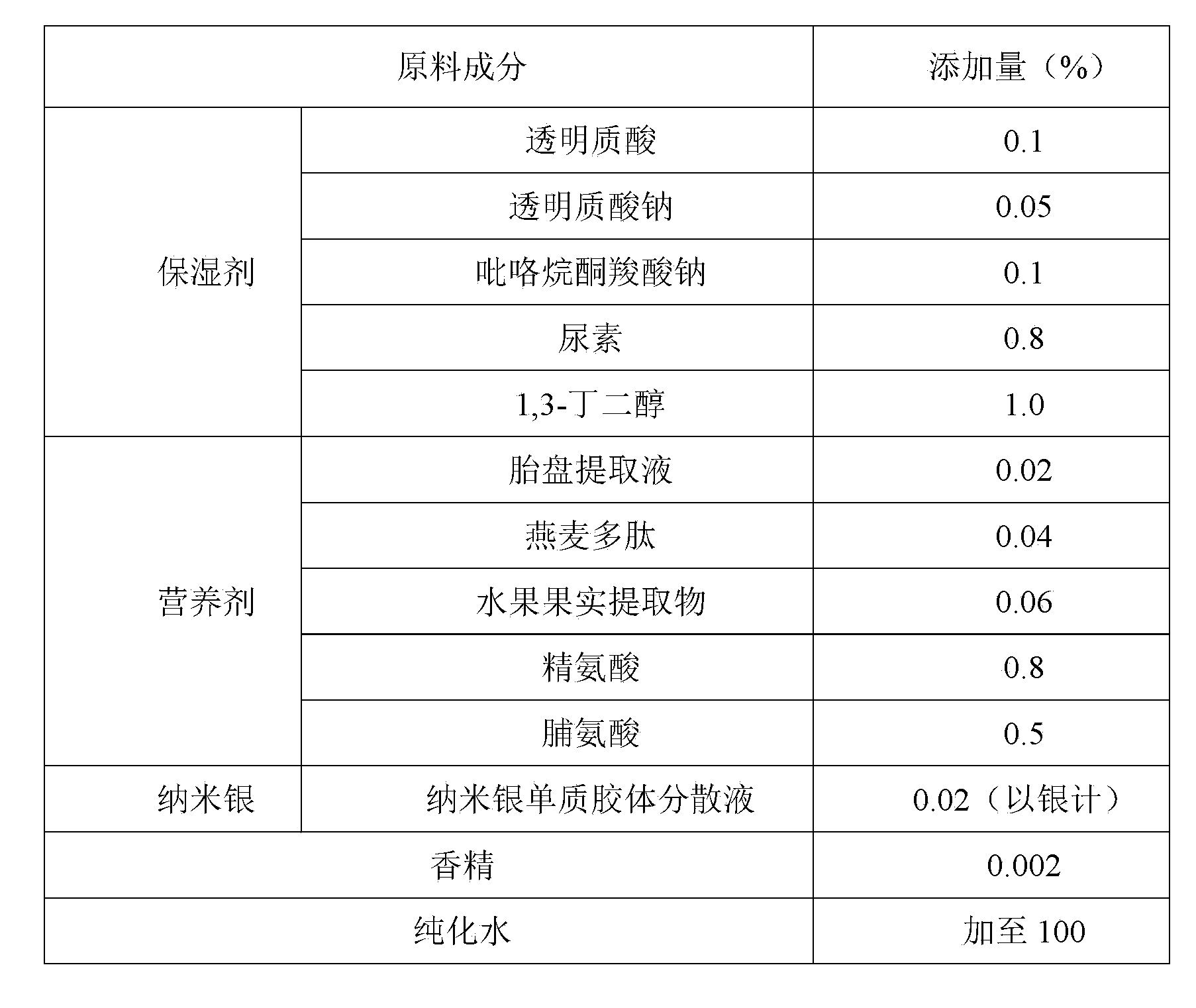

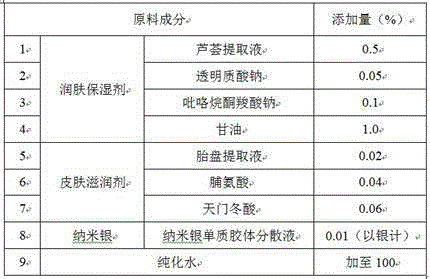

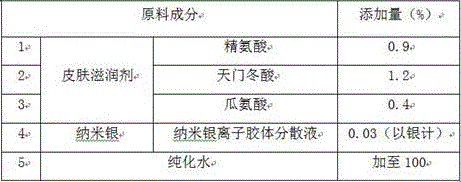

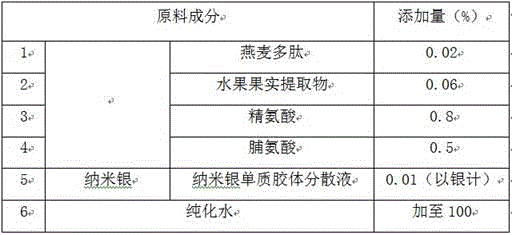

Nano-silver antibacterial moisture-preserving skin refreshing toner

InactiveCN103565709AGood antibacterial effectImprove the bactericidal effectCosmetic preparationsToilet preparationsWrinkly skinPreservative

The invention discloses a nano-silver antibacterial moisture-preserving skin refreshing toner. The skin refreshing toner is characterized in that the skin refreshing toner comprises following components by weight: 0.2-10% of a moisture-preserving agent, 0.1-3% of a nutritional agent, 0.0005-0.1% of nano-silver and 0.001-0.1% of an essence, the balance being water. The skin refreshing toner is free from organic preservatives and uses the nano-silver as an anticorrosion antibacterial agent. The nano-silver not only has an anticorrosion function to the product, but also has a function of antisepsis and anti-inflammation and a function of accelerating restoration of damaged skin. In addition, the skin refreshing toner is colorless and transparent, strongly stable, mild, fresh, and nonirritating. The skin refreshing toner has a perfect moisture preserving function, can replenishing skin with water rapidly, and also has functions of weakening skin winkles, enhancing skin elasticity, removing skin toxin, and activating skin. A preparation method has characteristics of simple operation, wide parameter adjustable range, low energy consumption, short period, and the like, and is particularly suitable for pilot plant test amplification and industrialized large-scale production.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

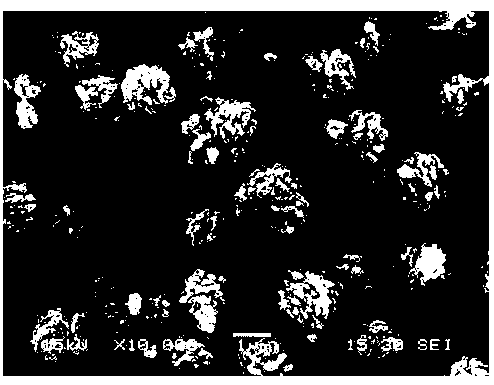

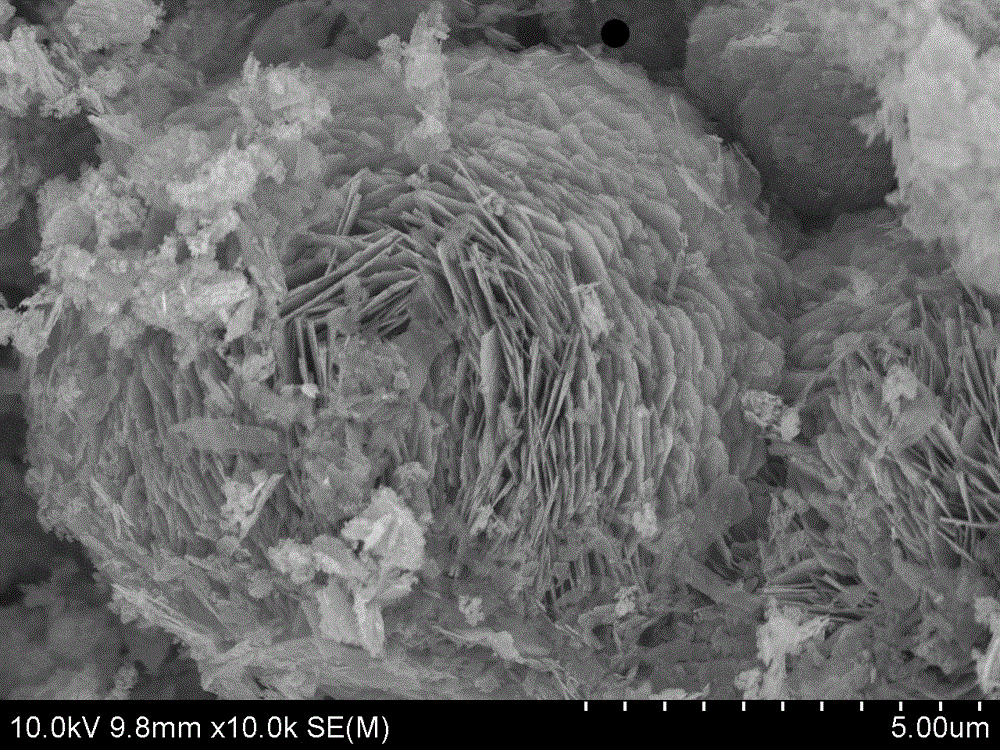

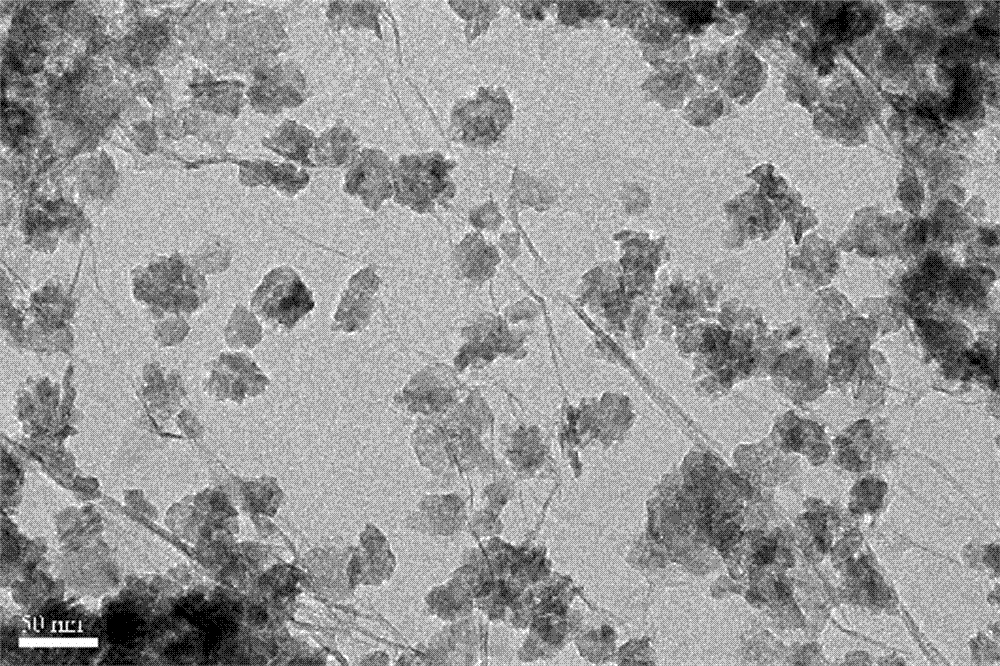

Bismuth oxychloride powder and preparation method thereof

InactiveCN103101974ASimple processWide adjustable range of parametersNanotechnologyBismuth compoundsMicrometerCompound (substance)

The invention relates to a bismuth oxychloride powder and its preparation method. A single bismuth oxychloride nanocrystal grain is irregular in shape, and has a size of 50-150 nanometers; and a plurality of nanocrystal grains aggregate into clusters with a size of 0.8-2 micrometers. The preparation method specifically consists of: adding a bismuth salt solution acidified by nitric acid into an ammonium chloride solution of certain concentration, conducting rapid stirring to form a uniform suspension liquid, and using ammonia water to adjust the pH to neutrality, then subjecting the suspension liquid to a one-step hydrothermal treatment, thus obtaining the bismuth oxychloride powder. The preparation method has the advantages of simple process, wide parameter adjustable range, strong repeatability as well as low cost, thus being a preparation method with business prospects. The prepared bismuth oxychloride powder can be widely applied in daily use chemicals, environmental protection, plastics, paint, electronics and other industries and fields.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

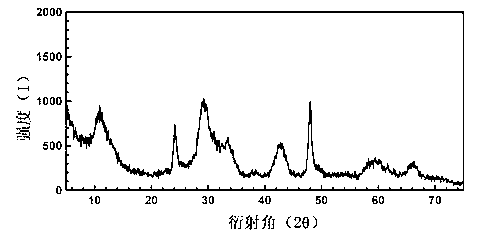

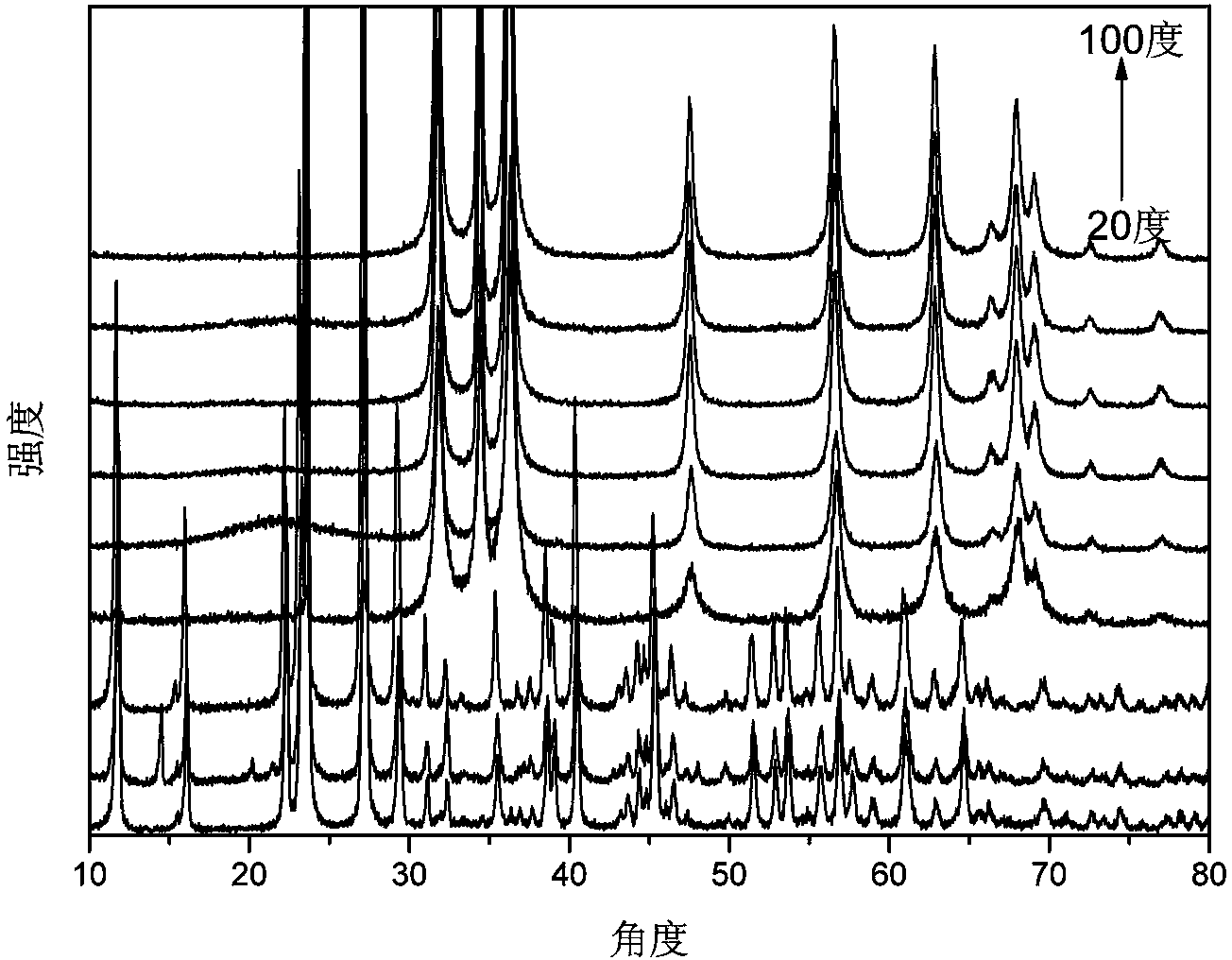

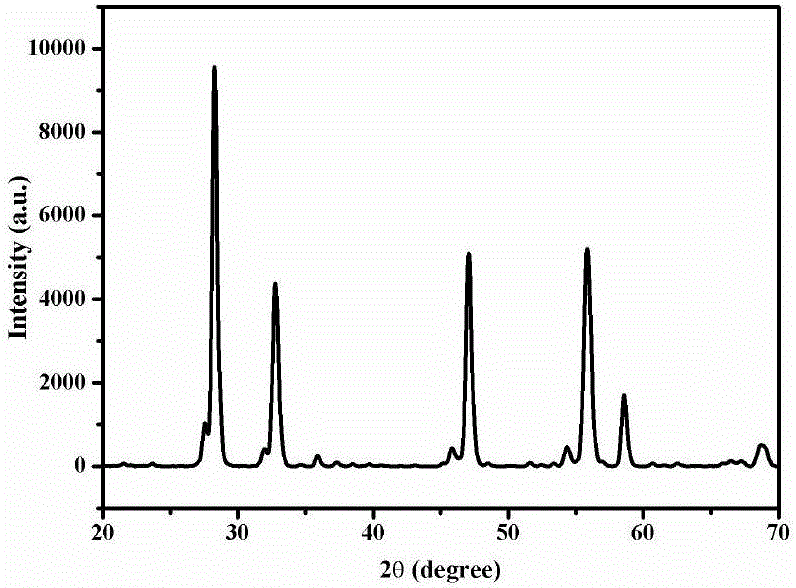

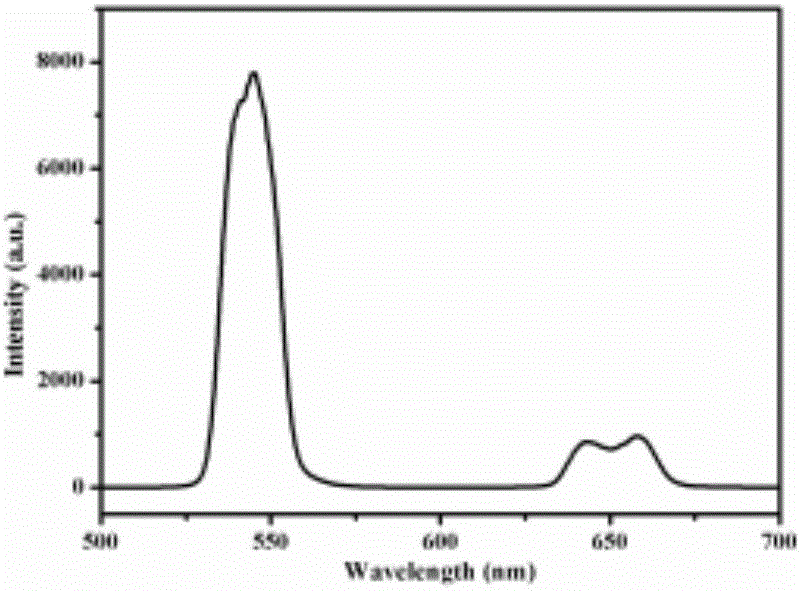

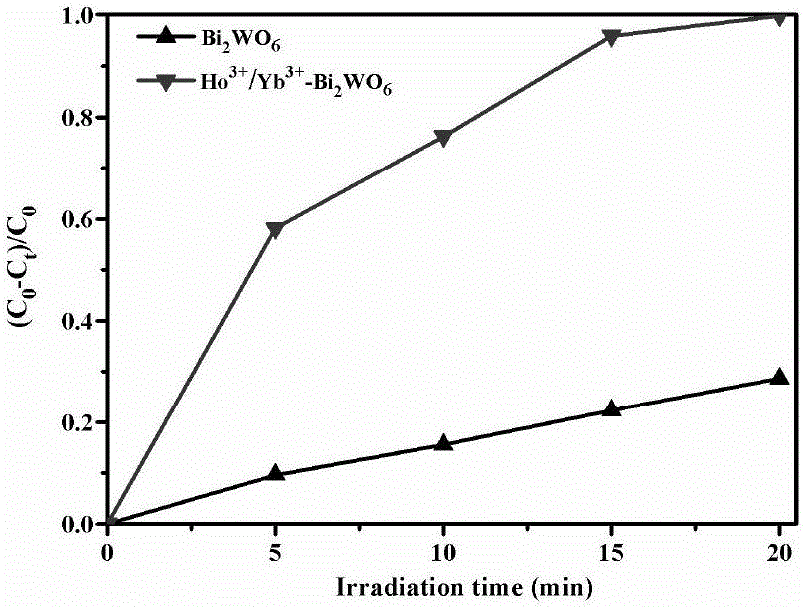

Holmium/ytterbium-codoped bisumth tungstate fluorescent powder and preparation method thereof

InactiveCN106753371ASimple ingredientsLow costHeterogenous catalyst chemical elementsLuminescent compositionsYTTERBIUM OXIDETungstate

The invention discloses a holmium / ytterbium-codoped bisumth tungstate fluorescent powder and a preparation method thereof. The preparation method comprises the following steps: by using bismuth nitrate pentahydrate, sodium tungstate, holmium oxide and ytterbium oxide as raw materials and ethanediol and dilute nitric acid as solvents, mixing the solution according to the stoichiometric proportion of Bi(2-x-y)HoxYbyWO6 (0<=x<2, and 0<=y<2) to form a uniform suspension, carrying out high-temperature reaction in a hydrothermal reaction kettle, centrifugating, washing, drying, and carrying out heat treatment to obtain the holmium / ytterbium-codoped bisumth tungstate fluorescent powder. The mixing ratio and the technological parameters for hydrothermal treatment, heat treatment and the like are controlled in the preparation process to obtain the powder with different fluorescence intensity levels. The preparation method has the advantages of simple technique and procedure, wide parameter adjustable range, high repeatability and low cost, and has commercial prospects. The fluorescent powder has important application values in the fields of ceramic raw powder, visible-light photocatalysis, solar cells and photoelectric sensors.

Owner:DALIAN POLYTECHNIC UNIVERSITY

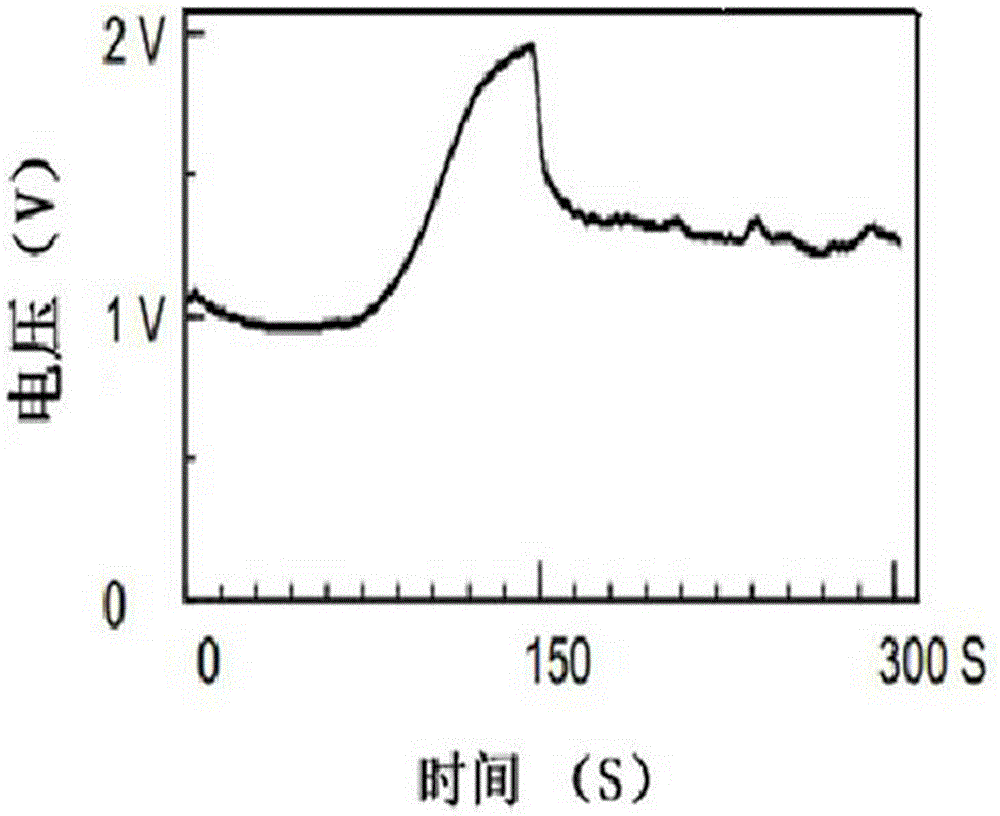

Dual-rare earth-co-doped titanium dioxide gas sensitive sensing material preparation

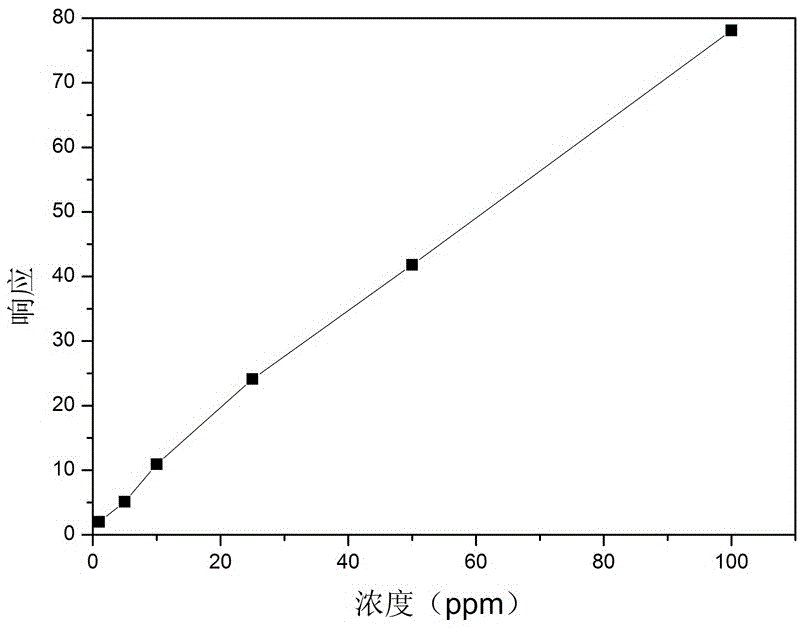

InactiveCN105399052AIn situ dopingGood dispersionNanostructure manufactureMaterial analysis by electric/magnetic meansRare-earth elementElectrochromism

The invention relates to a dual-rare earth-co-doped titanium dioxide gas sensitive sensing material preparation. The method includes the following steps of: adding urea and nitrate of rare earth elements into absolute ethyl alcohol and dissolving the urea and the nitrate of the rare earth elements to obtain solution; adding liquid phase titanium sources into the solution to form a homogeneous solution; stirring and adding deionized water into the homogeneous solution to form transparent gel; and performing hydro-thermal treatment on the transparent gel, and then performing washing, filtering and drying to obtain a dual-rare earth-co-doped titanium dioxide gas sensitive sensing nano-material. Through automatic regulation of pH to a reaction system by means of slow decomposition of the urea in a hydrothermal process, the rare earth elements can be doped into titanium dioxide; the raw materials are cheap, the dual-rare earth-co-doped titanium dioxide gas sensitive sensing nano-material with excellent crystallization can be prepared at the normal temperature, and the material is lower than 10 ppm in detection limit of ammonia gas. The dual-rare earth-co-doped titanium dioxide gas sensitive sensing material can be applied to the field of gas sensitive sensors, and also can be applied to the fields of microwave absorption materials, supercapacitors, electrochromism, and photocatalysts.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Method for preparing silver-loaded titanium oxide-zirconium phosphate composite nanometer material

InactiveCN103011276AImprove stabilityNot prone to discolorationBiocideFungicidesAlcoholPhosphoric acid

The invention discloses a method for preparing a silver-loaded titanium oxide-zirconium phosphate composite nanometer material. The method comprises the steps of: firstly, adding a liquid titanium source into absolute ethyl alcohol to be dispersed uniformly; adding phosphoric acid, and regulating pH using ammonia water; adding silver nitrate under a light-proof condition; adding an aqueous solution of zirconium salt after the silver nitrate is dissolved by stirring; stirring the resulting solution under the light-proof condition for 2-8 hours; washing and drying a sediment product after the stirring operation under the light-proof condition is ended; and roasting the sediment product at the temperature of 500-1200 DEG C to obtain the target product silver-loaded titanium oxide-zirconium phosphate composite nanometer material. The preparation method is simple and convenient in process and flow, wide in parameter adjustable range, strong in repeatability, low in cost, conductive to large-scale production, and has good business prospect.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

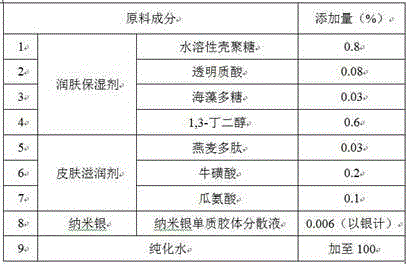

No-clean nano-silver antibacterial hand sanitizer

InactiveCN106798716AQuickly rehydrateImprove stabilityCosmetic preparationsToilet preparationsHand sanitizerAntibacterial agent

The invention discloses a no-clean nano-silver antibacterial hand sanitizer which is prepared by mixing the following raw material components in percentage by weight: 0.2 to 10 percent of a skin moisturizing humectant, 0.1 to 3 percent of a skin moisturizing agent, 0.0005 to 0.1 percent of nano silver and the balance of water, wherein the total weight percentage is equal to 100 percent. According to the no-clean nano-silver antibacterial hand sanitizer, no organic preservative is added, but only nano-silver is used as a preservative and antibacterial agent, so that the product has the preservative function, and also has the effects of resisting bacteria, diminishing inflammation and accelerating repairing of damaged skin; and besides, the no-clean nano-silver antibacterial hand sanitizer is quite strong in broad-spectrum bacteriostasis and sterilization effect, and can achieve a long-acting antibacterial effect. The nano-silver antibacterial hand sanitizer is mild, refreshing, non-irritating and low in damage to the skin, can effectively protect the tender skin of children, can be used by personnel outside under a condition of water shortage, and can protect the health of people.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH +1

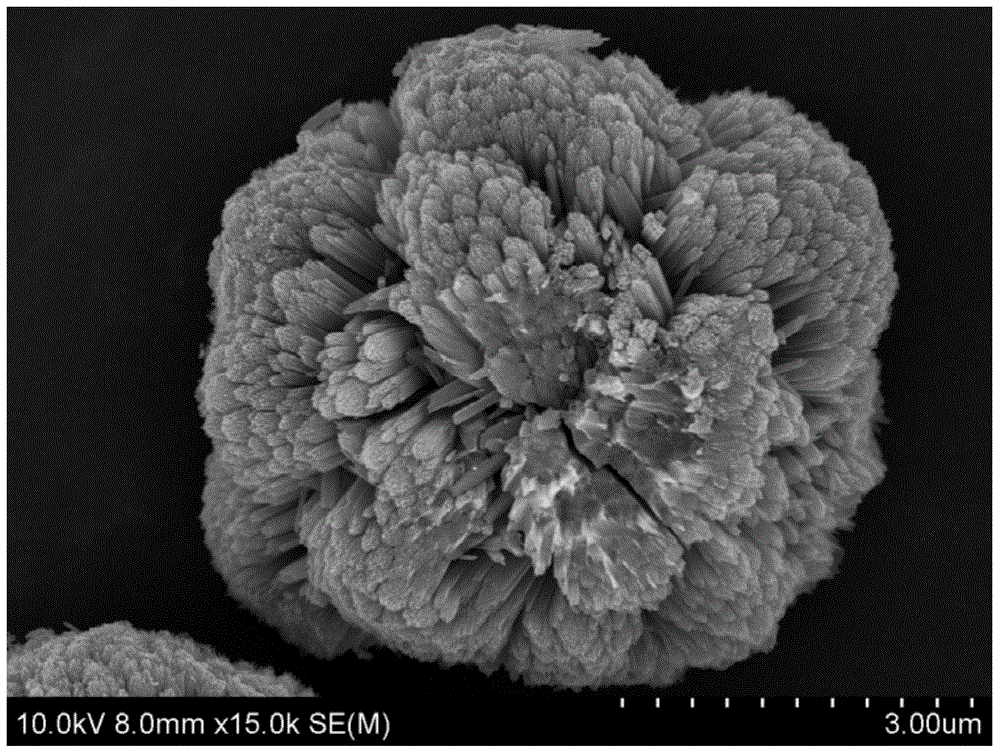

Ethanol-sensitive Co-doped graded porous structure ZnO microspheres, preparation and applications thereof

InactiveCN106248736AHigh sensitivityImprove response speedZinc oxides/hydroxidesMaterial analysis by electric/magnetic meansMicrosphereDecomposition

The invention relates to a Co-doped ZnO microsphere with hierarchical porous structure sensitive to ethanol and its preparation and application. The method is to configure a certain concentration of urea and ascorbic acid solution, and then add a zinc source to the solution to dissolve to form a homogeneous solution . Then the above solution is subjected to hydrothermal treatment, and then washed, filtered, dried, and roasted to obtain Co-doped hierarchical structure ZnO microspheres sensitive to ethanol. Through the slow decomposition of urea in the hydrothermal process, the pH value of the reaction system is self-regulated to realize the microsphere structure; through the roasting treatment, the formation of mesopores is realized. The preparation method does not require a template, the process and process are simple, the parameters can be adjusted in a wide range, the repeatability is strong, and the cost is low. The various pore structures of the material can increase the proportion of the volume of the depletion layer in the material and improve the sensitivity to gases. , a Co-doped hierarchically porous ZnO microsphere sensing material with excellent sensitivity to ethanol was obtained.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

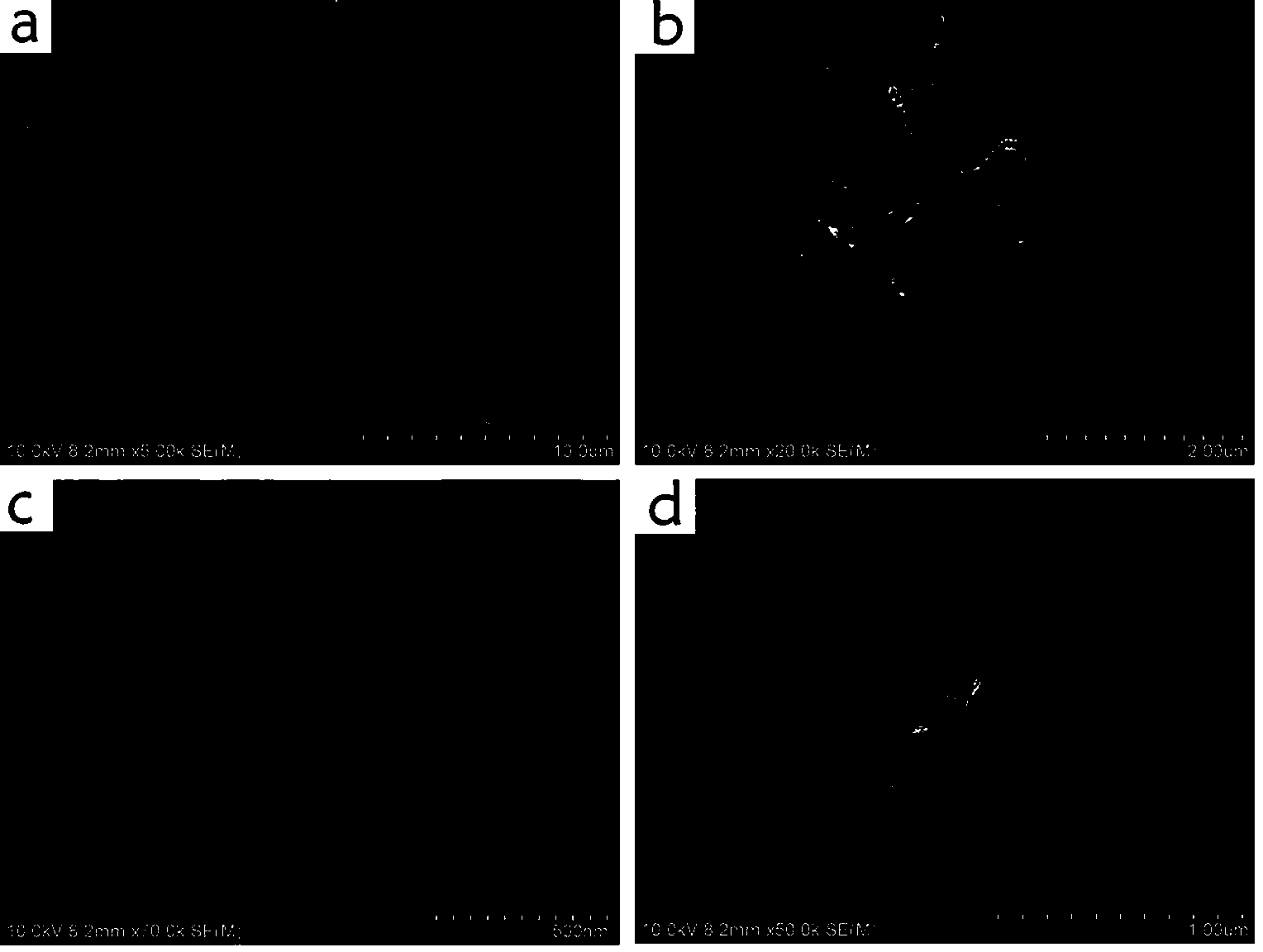

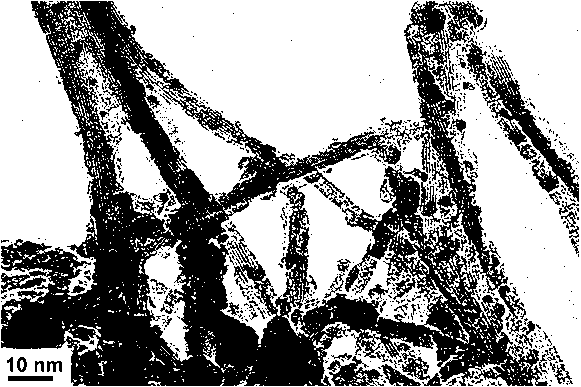

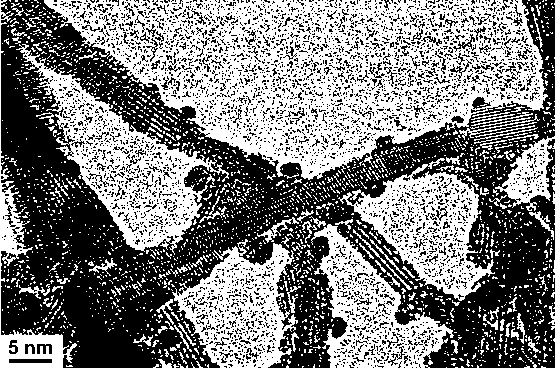

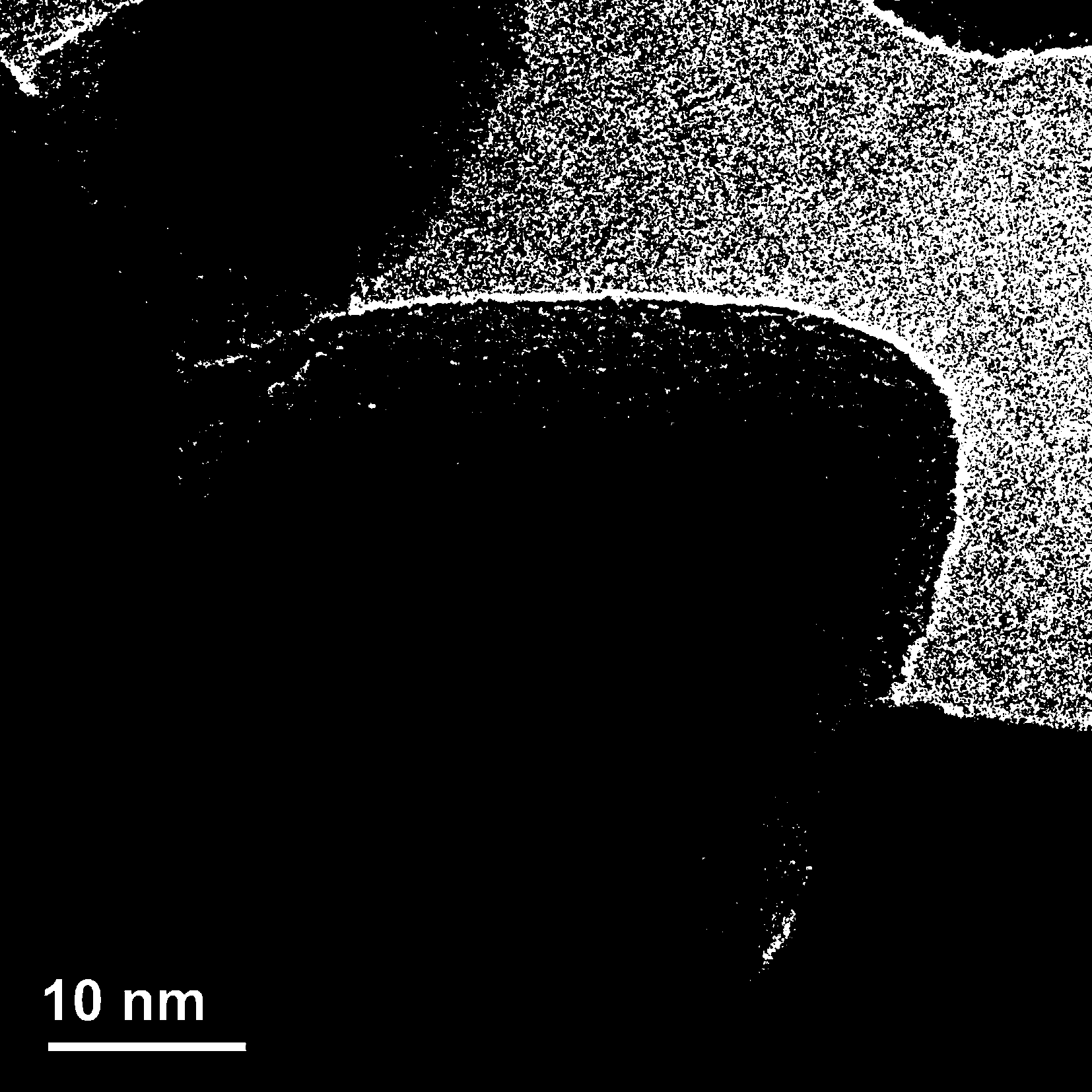

Preparation method of silver-carrying layered titanate composite nano-grade material

InactiveCN102986729AGood dispersionSmall particle sizeBiocideMaterial nanotechnologyIon exchangeDysprosium titanate

The invention relates to a preparation method of a silver-carrying layered titanate composite nano-grade material. The method is characterized in that: a certain amount of a solid-phase or liquid-phase titanium source is subjected to a high-pressure hydrothermal treatment or a normal-pressure reflux reaction in an alkali solution, such that a layered titanate nano-grade material is prepared; silver nitrate is dissolved in a dilute ammonia water solution; the prepared layered titanate powder is added; with an ion exchange reduction method, elemental silver nano-particle loading is carried out, such that the silver-carrying layered titanate composite nano-grade material is prepared. With the preparation method, silver nano-particles can be uniformly loaded on the inside and surface of the titanate layered structure. The particle size of the silver nano-particles is ultra-small, particle size distribution is narrow, and particle dispersion is high. The obtained composite product is pure white, and has the advantages such as stable performance and no discoloration. The preparation method and the process flow are simple, parameter adjustable range is wide, repeatability is high, and large-scale production can be carried out.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Perovskite solar cell electronic transmission layer and preparation method thereof

InactiveCN106025083AUniform shapeHigh puritySolid-state devicesSemiconductor/solid-state device manufacturingElectronic transmissionPerovskite solar cell

The invention provides a perovskite solar cell electronic transmission layer and a preparation method thereof. The preparing method includes the steps of cleaning electro-conductive glass, dissolving a zinc source in deionized water, stirring at a temperature of 60-70 DEG C to obtain solution A, adding aqueous alkali in the solution A drop by drop under constant temperature to obtain a solution B, placing clean electro-conductive glass in the solution B with the electro-conductive glass inclining on a container wall and the conducting surface facing downwards, placing at a 60-70 DEG C environment for two to four hours, cooling to the room temperature, cleaning the surface of the electro-conductive glass with deionized water to obtain a target perovskite cell zinc oxide nanorod ordered array electronic transmission layer. The diameter of the nanorod is 50-100nm, and the length thereof is 2-3 micrometers. The target perovskite cell zinc oxide nanorod ordered array electronic transmission layer is uniform in appearance, high in purity and stability, and can be formed in batch on electro-conductive glass substrate. The preparation method has the advantages of simple process and flow, wide parameter adjustable scope, high repeatability and low cost.

Owner:SHANGHAI JIAO TONG UNIV +1

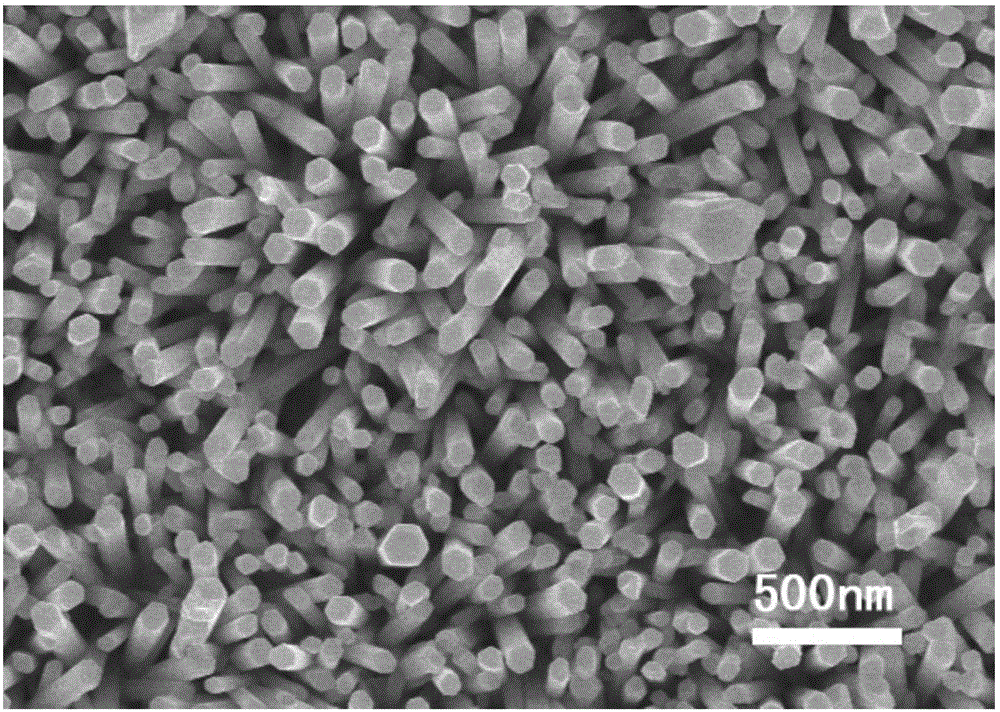

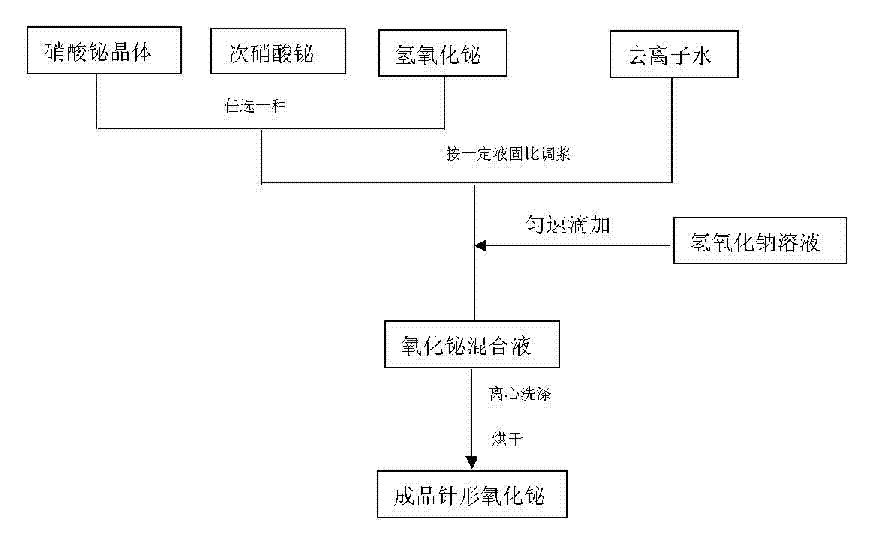

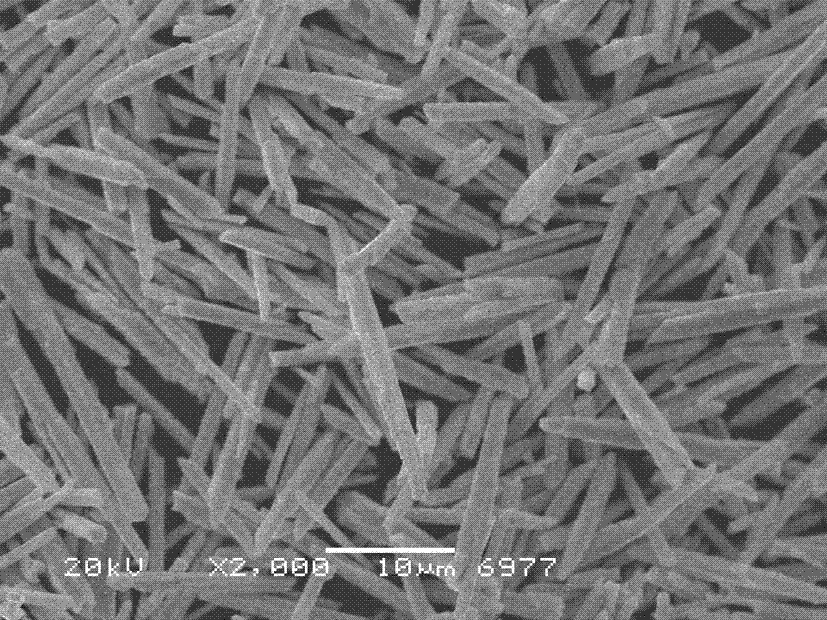

Process for preparing needle-like bismuth oxide powder

InactiveCN103922400ASimple process and processWide adjustable range of parametersBismuth compoundsDrawing ratioBismuth hydroxide

The invention discloses a process for preparing needle-like bismuth oxide powder, and belongs to the fields of micro-powder materials and synthesis technology. The process is characterized by taking bismuth nitrate crystal, bismuth subnitrate and bismuth hydroxide as raw materials, taking sodium hydroxide as a precipitator, adopting adding reaction and adjusting synthesis process parameters, so as to obtain the bismuth oxide powder which is good in dispersibility and obvious in needle shape. The bismuth oxide powder is a spindle needle stick in morphology, the particle size is scattered and even, the diameter is about 1-2mu m, the length is 10-20mu m, the draw ratio is greater than 10, and the purity is over 99.95%. The preparation method provided by the invention is free of environmental pollution, simple and convenient in technology and process, wide in adjustable parameter range, strong in repeatability, and low in production cost, and massive industrial production can be carried out.

Owner:HUNAN XIANGYUN FINE CHEM MFG

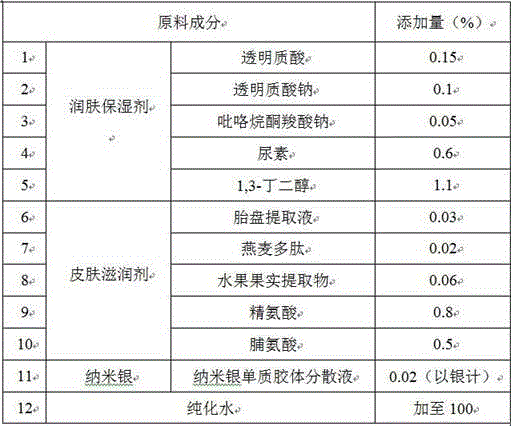

Nano-silver antibacterial spray for treating dermatophytosis, preparation method and application

InactiveCN106491534AEasy to sprayTo achieve the purpose of curing beriberiAntimycoticsInorganic active ingredientsMedicinePathogenic bacteria

The invention discloses a nano-silver antibacterial spray for treating dermatophytosis, a preparation method and application. The spray is prepared by mixing, by weight, 0.1%-3% of skin moisturizer, 0.005%-0.05% of nano-silver sol dispersion liquid and water added to reach 100%. The product spray is colorless, transparent, high in stability and good in antibacterial / bacteriostatic performance, and the pH is controlled to range from 6 to 8. According to the spray, no organic antibacterial agent is added, and nano-silver serves as an antibacterial / bacteriostatic agent instead; besides, the spray has the effects of resisting bacteria, diminishing inflammation and quickening repair of damaged skin; moreover, the spray has a quite strong broad-spectrum bacteriostatic and bactericidal effect and can resist fungi lastingly without generating drug tolerance. The spray for treating dermatophytosis can be conveniently sprayed after being shaken; besides, the spray can relieve itching and eliminate pathogenic bacteria causing dermatophytosis to achieve the purpose of curing dermatophytosis and save the trouble of foot itching, rotting and festering.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Flaky bismuth subnitrate and preparation method thereof

InactiveCN109911936AThe synthesis process is simpleShort cyclePhysical/chemical process catalystsBismuth compoundsAlcoholHexamethylenetetramine

The invention provides a preparation method of flaky bismuth subnitrate. The preparation method is characterized by comprising the following steps: 1, putting Bi(NO3)3*5H2O into a nitric acid solution, and carrying out ultrasonic dispersion so as to obtain a bismuth nitrate solution; 2, putting the bismuth nitrate solution obtained in the step 1 into deionized water, continuously stirring, heatingto 40-80 DEG C, adding a solution of hexamethylenetetramine 25-35 minutes later, continuously stirring for 2.0-3.0 hours at 40-80 DEG C, stopping heating, further stirring for 1.0-2.0 hours, and leaving to stand for 10-20 minutes, pouring off supernate so as to obtain precipitate; 3, putting deionized water into the obtained precipitate, leaving to stand for 10-20 minutes, and pouring off supernate; 4, repeating the step 3 for 1-3 times, respectively washing for 3-5 times with deionized water and absolute ethyl alcohol, centrifuging, collecting precipitate, dispersing with absolute ethyl alcohol into a crucible, and drying at 60-100 DEG C, thereby obtaining the flaky bismuth subnitrate. The flaky bismuth subnitrate prepared by using the method is good in catalyst morphology and high in catalysis activity, is capable of degrading RhB by 97% or greater within 180 minutes when being used as a photocatalyst, and has good application prospects.

Owner:SHANGHAI INST OF TECH

Preparation method, product and application of tungsten oxide electron transfer layer

InactiveCN107887475ASimple process and processWide adjustable range of parametersFinal product manufactureSolid-state devicesSolventAlcohol

The invention relates to a preparation method, a product and an application of a tungsten oxide electron transfer layer. The tungsten oxide electron transfer layer is prepared by WO<x> at a low temperature, and batch synthesis of the tungsten oxide electron transfer layer can be realized on a conductive glass substrate; the preparation method comprises the steps of weighing 5ml of alcohol solution, weighing a certain amount of tungsten hexachloride to be dissolved into a solvent alcohol, and performing stirring until the solution is fully dissolved to obtain a yellow solution; performing continuous stirring until the yellow solution is changed into a transparent shallow blue solution; performing spin coating on cleaned FTO conductive glass for 30s; performing heating on the spin-coated substrate in a drying oven at a temperature of 150 DEG C; and repeatedly executing the steps for 2-4 times to obtain the tungsten oxide electron transfer layer with high performance. The electron transfer layer prepared at the temperature of 150 DEG C obtains efficiency of 8.3%. The electron transfer layer prepared by the method does not need the complex processes of high-temperature sintering and the like, and simple and convenient preparation method and technological process, large parameter adjustable range, high repeatability and low energy consumption are achieved, so that the battery manufacturing cost is lowered effectively, and large-scale technology popularization can be promoted.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

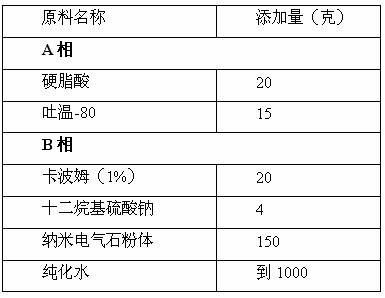

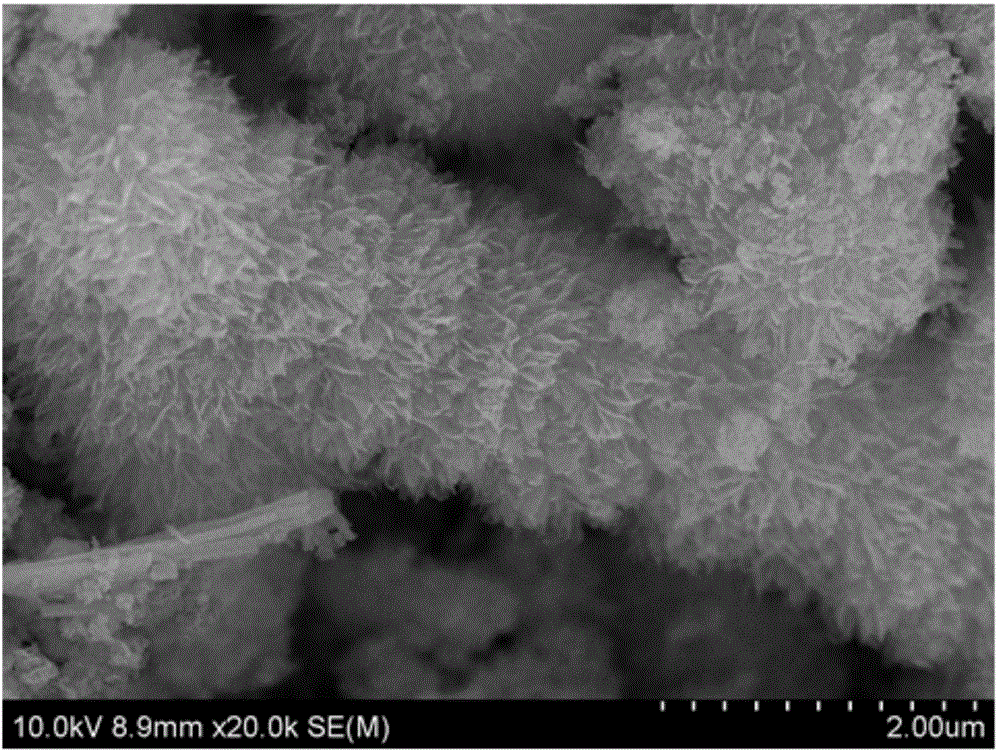

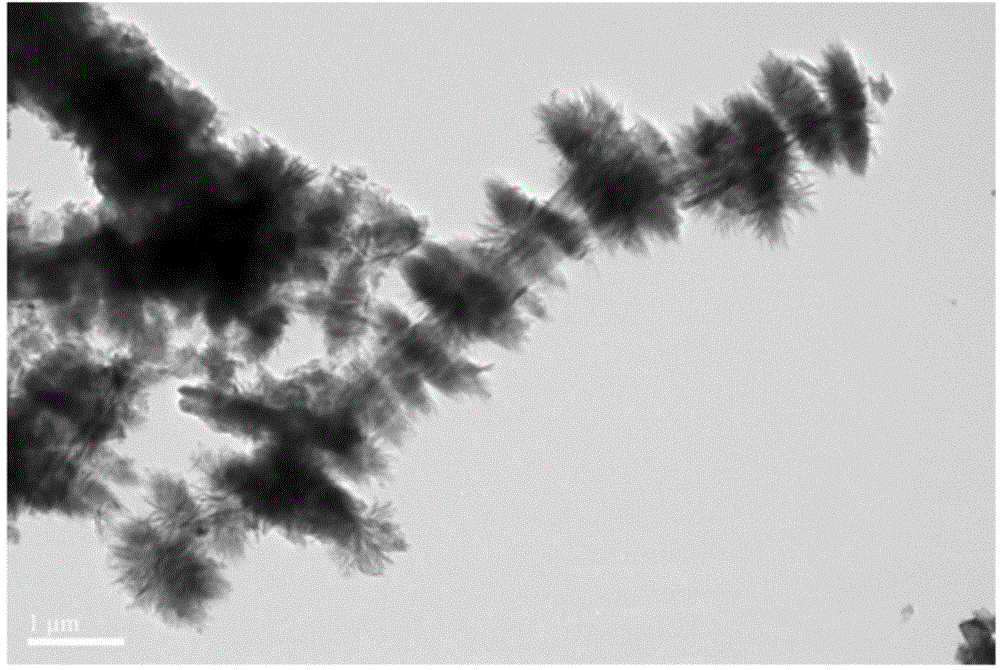

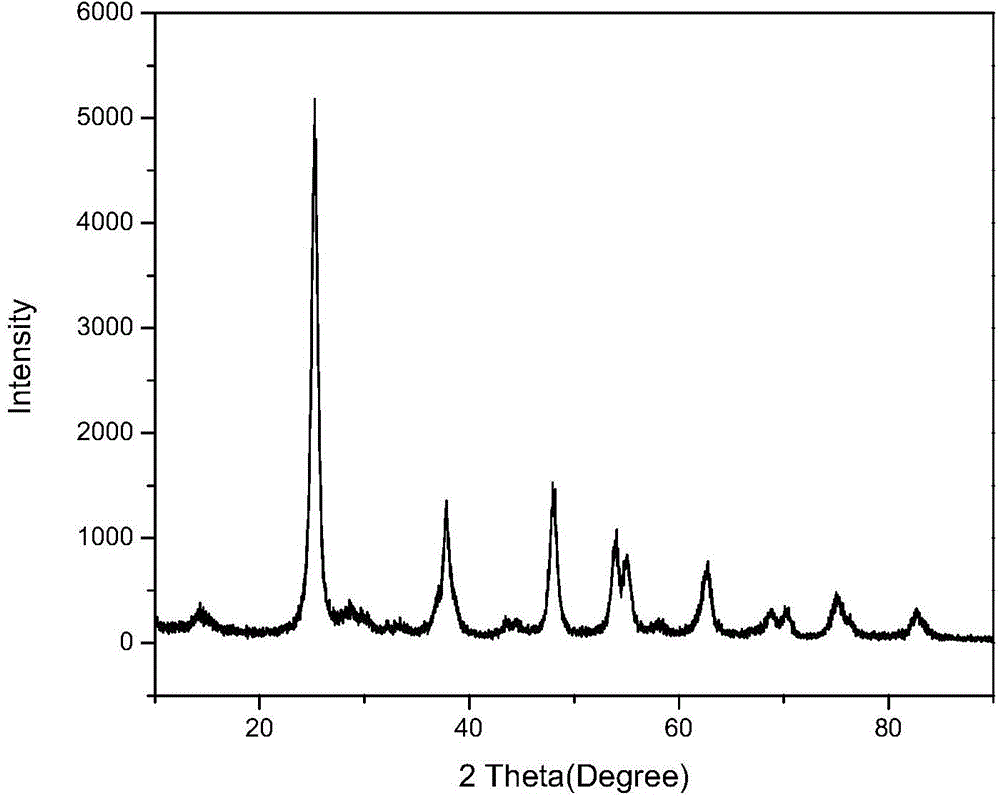

Nano tourmaline dispersion liquid and preparation method thereof

PendingCN112044295AUniform and stable dispersionStable composite systemBiocideCosmetic preparationsActive agentPhysical chemistry

The invention discloses nano tourmaline dispersion liquid and a preparation method thereof. The preparation method comprises the following steps: mixing an oil phase component and an emulsifier in anoil phase system according to a certain addition ratio; adding a dispersion stabilizer, a surfactant and nano tourmaline powder into water according to a certain addition ratio in the water dispersionsystem, and performing mixing; respectively uniformly mixing the two phases, performing heating to a certain temperature, carrying out homogeneous mixing on the two phases under rapid stirring, and performing cooling to room temperature to form a stable emulsion dispersion system; according to the nano tourmaline composite dispersion liquid prepared by the method, the difference between the tourmaline particle size and the particle size of a nano tourmaline powder raw material is within 20%; in the dispersion liquid, the nano tourmaline particles are suspended in the solution in a monodisperse form; and after the nano tourmaline composite dispersion liquid is placed for more than 60 days, the phenomena of layering, demulsification or caking of the nano tourmaline composite dispersion liquid are avoided. Moreover, the preparation method is simple and convenient to operate, wide in parameter adjustable range, low in energy consumption, short in period and suitable for pilot scale-up andindustrial large-scale production.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

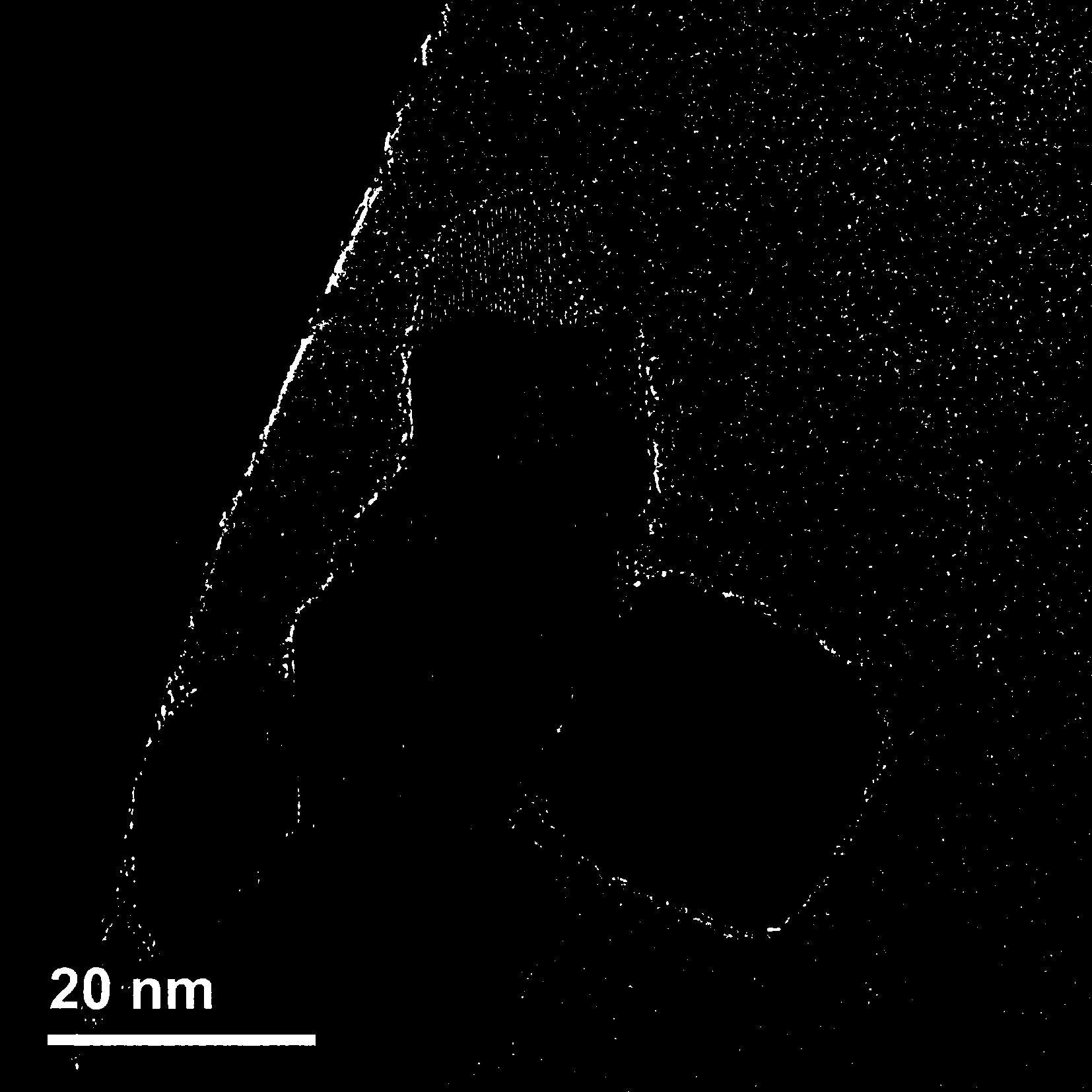

Preparation method of multilevel structural titanium dioxide nano flower string

InactiveCN104528820AEvenly distributedLarge specific surface areaMaterial nanotechnologyTitanium dioxideMuffle furnaceMaterials science

The invention discloses a preparation method of a multilevel structural titanium dioxide nano flower string. The method is characterized by comprising the steps: dispersing a titanium dioxide nanoribbon into a mixed solution of a titanium source, a silver source and an acid, severely stirring and uniformly mixing to obtain a suspension, placing the suspension into a stainless steel autoclave with a polytetrafluoroethylene liner, carrying out hydrothermal reaction to obtain a product, washing and drying the product, then grinding the product into powder, and calcining the obtained powder in a muffle furnace to obtain a multilevel structural titanium dioxide nano flower string growing on the nanoribbon. By adopting the preparation method, the flower-shaped titanium dioxide can be successfully enabled to grow along the direction of the nanoribbon to form a flower-string structure; the product is uniform in distribution, the specific surface area is large, and the photocatalytic activity is high; meanwhile, the method has the advantages of simple and convenient process and flow and the like.

Owner:SHANGHAI JIAO TONG UNIV +1

Method for preparing silver-loaded titanate-zirconium phosphate composite nanometer material

InactiveCN103004877AImprove stabilityNot prone to discolorationBiocideFungicidesPhosphoric acidAqueous solution

The invention discloses a method for preparing a silver-loaded titanate-zirconium phosphate composite nanometer material. The method comprises the steps of: firstly, adding titanate into deionized water to be dispersed, adding phosphoric acid; regulating pH using ammonia water, adding silver nitrate after uniform dispersion; stirring the resulting solution under a light-proof condition for 6-24 hours; adding an aqueous solution of zirconium salt, and further stirring the resulting solution under the light-proof condition for 2-8 hours; washing and drying a sediment product after the stirring operation is ended; and roasting the sediment product at the temperature of 500-1200 DEG C to obtain the target product silver-loaded titanate-zirconium phosphate composite nanometer material. The preparation method is simple and convenient in process and flow, wide in parameter adjustable range, strong in repeatability, low in cost, conductive to large-scale production, and has good business prospect.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Preparation method for rare earth element-doped titanium dioxide nano material

InactiveCN102992397BIn situ dopingSimple processMaterial nanotechnologyTitanium dioxideRare-earth elementNitrate

The invention relates to a preparation method for a rare earth element-doped titanium dioxide nano material. The method comprises the steps of dissolving urea and rare earth element nitrate in absolute ethyl alcohol; adding liquid titanium source into the above solution to form a homogeneous solution; adding deionized water with stirring to form a transparent gel; performing hydro-thermal treatment on the above gel; washing, filtering and drying to obtain the rare earth element-doped titanium dioxide nano material. An object of doping titanium dioxide by using the rare earth element is realized through automatic regulation and control of pH value of a reaction system by slow decomposition of urea in the hydrothermal process. The preparation method is simple in process and flow, has wide parameter adjustable range, strong repeatability and low cost, and can be used for preparing different rare earth element-doped titanium dioxide nano materials or a plurality of the rare earth elements co-doped titanium dioxide nano material.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

A controlled preparation method of ordered titanium dioxide nanomaterials

InactiveCN104118908BMaterials are readily availableEasy post-processingMaterial nanotechnologyTitanium dioxideHydrolysisTitanium oxide

Owner:SHANGHAI JIAOTONG UNIV +1

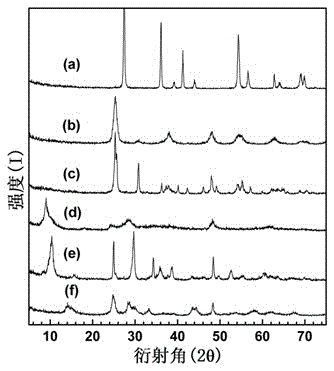

A preparation method for controlling the crystal form and morphology of titanium-based nanomaterial products

InactiveCN103803644BSimple processEasy to prepareMaterial nanotechnologyTitanium dioxideAcid washingHigh pressure

The invention relates to a preparation method for controlling product crystal form and morphology of a titanium-based nanometer material. The method comprises the following steps: adding a liquid phase titanium source into a solution of hydrochloric acid or sodium hydroxide with a certain concentration, and rapidly stirring, so that the materials are uniformly mixed; adding the suspension into a stainless steel high-pressure autoclave with a polytetrafluoroethylene lining for carrying out a hydrothermal reaction; washing and drying the precipitation product after the hydrothermal reaction is ended, thereby obtaining a titanium dioxide or titanate nanometer material product in the high-pressure autoclave. The aim of controlling the product crystal form and morphology can be achieved by controlling the concentration of the solution of hydrochloric acid or sodium hydroxide. If the product is titanate, the product crystal form and morphology can be further controlled by virtue of an acid washing and roasting treatment method. The preparation method is simple and convenient in process and flow, the parameter adjustable range is wide, the repeatability is high, the cost is low, and various titanium dioxide or titanate products of different crystal forms can be prepared.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

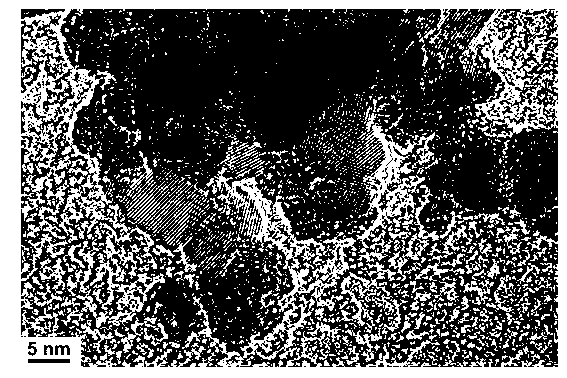

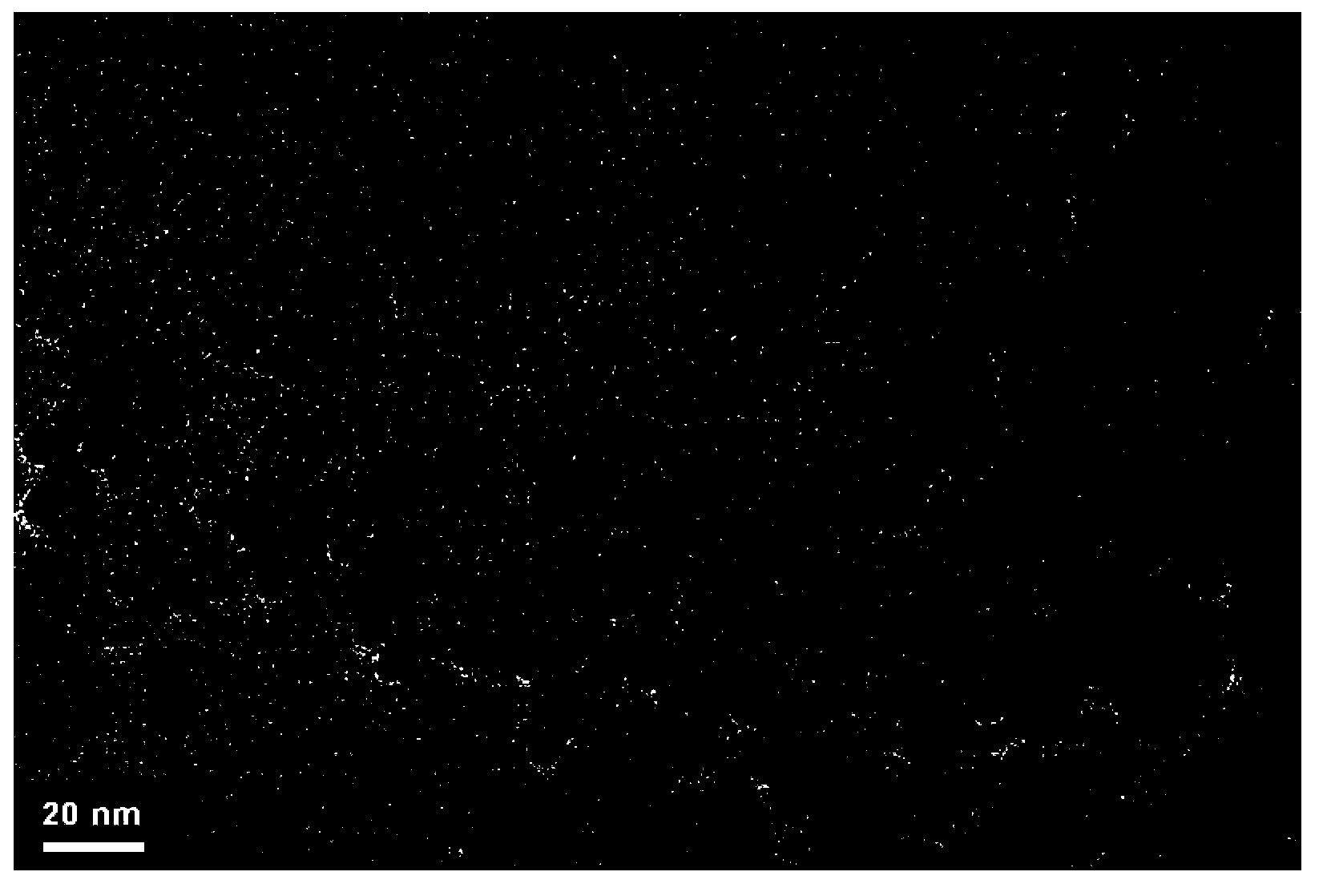

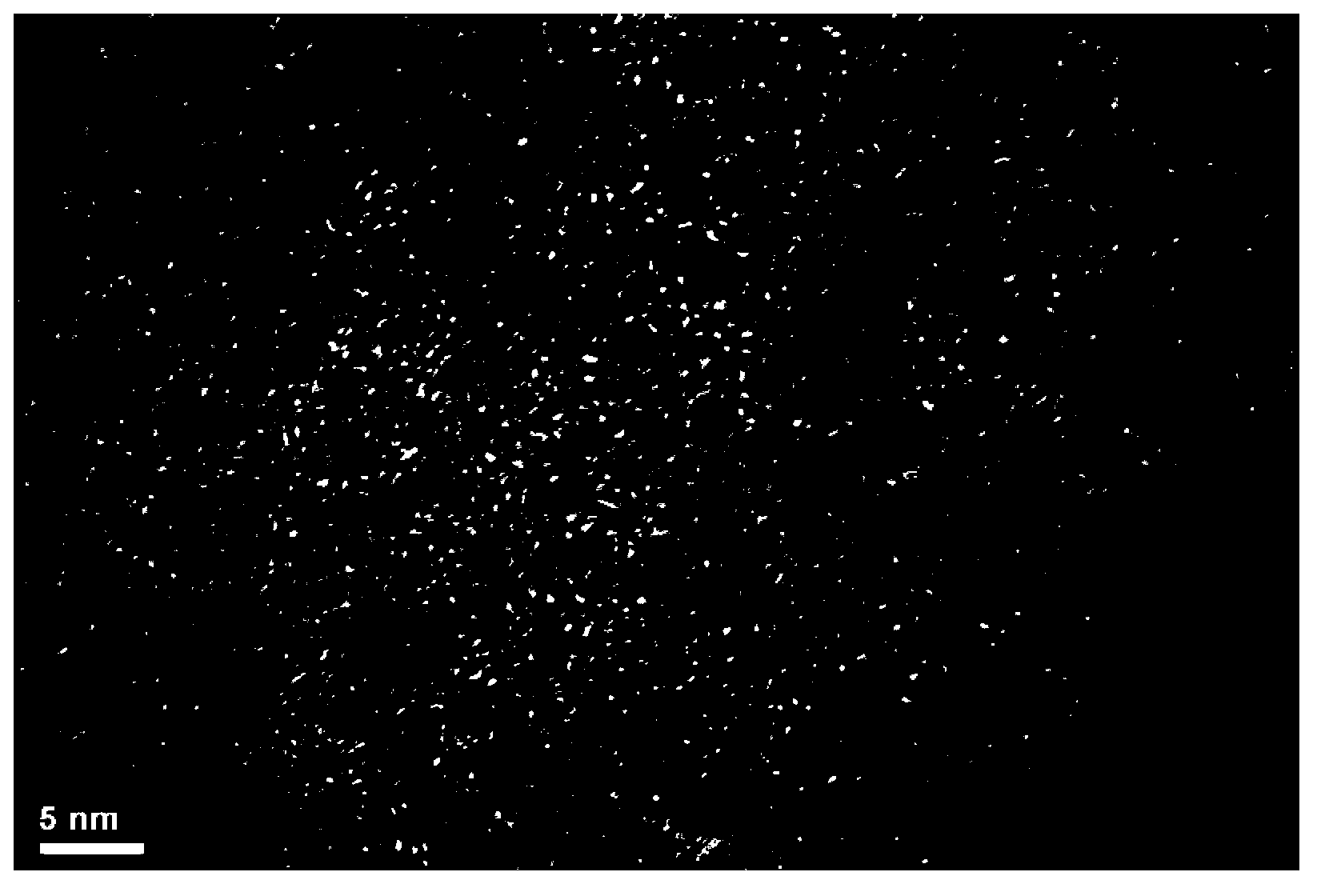

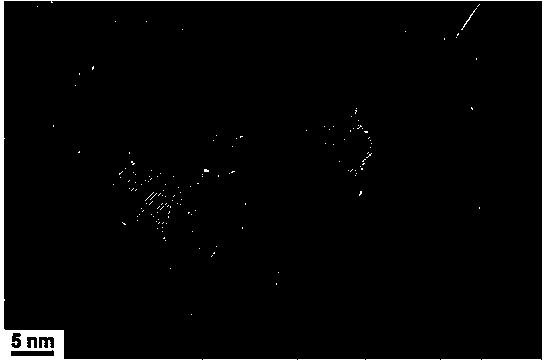

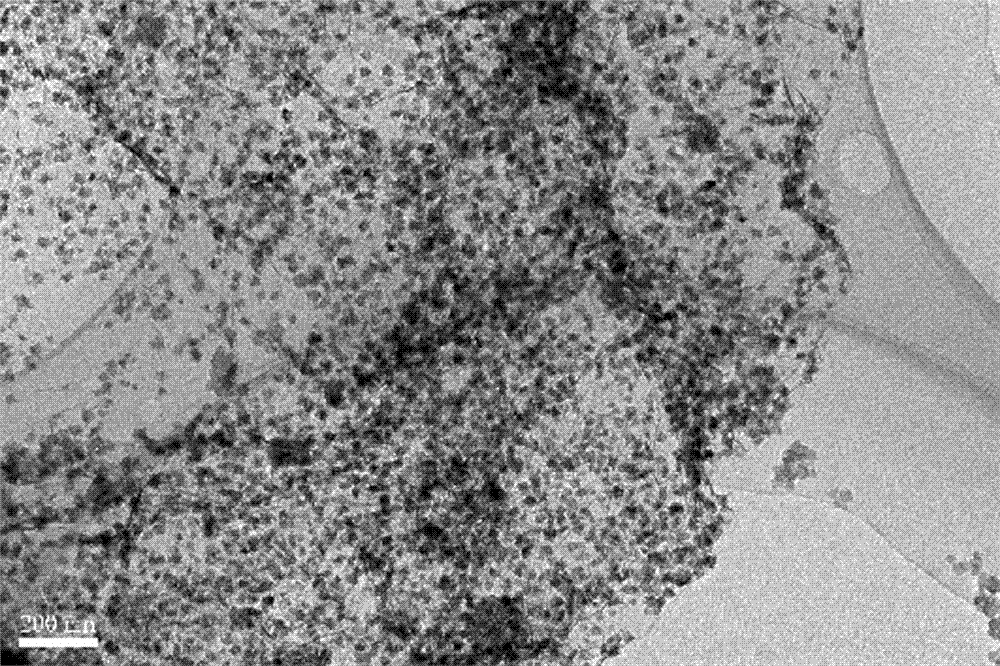

A kind of preparation method of sheet graphene single/multi-loaded noble metal nanoparticles

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Method for preparing silver-loaded titanate-zirconium phosphate composite nanometer material

InactiveCN103004877BImprove stabilityNot prone to discolorationBiocideFungicidesPhosphoric acidAqueous solution

The invention discloses a method for preparing a silver-loaded titanate-zirconium phosphate composite nanometer material. The method comprises the steps of: firstly, adding titanate into deionized water to be dispersed, adding phosphoric acid; regulating pH using ammonia water, adding silver nitrate after uniform dispersion; stirring the resulting solution under a light-proof condition for 6-24 hours; adding an aqueous solution of zirconium salt, and further stirring the resulting solution under the light-proof condition for 2-8 hours; washing and drying a sediment product after the stirring operation is ended; and roasting the sediment product at the temperature of 500-1200 DEG C to obtain the target product silver-loaded titanate-zirconium phosphate composite nanometer material. The preparation method is simple and convenient in process and flow, wide in parameter adjustable range, strong in repeatability, low in cost, conductive to large-scale production, and has good business prospect.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Preparation method for coating metal nanoparticles on surface of nano-titania

InactiveCN102886279BGood dispersionStable in natureCatalyst activation/preparationNanotechnologyNitrateHigh pressure

The invention provides a preparation method for coating metal nanoparticles on the surface of nano-titania. The preparation method comprises the following steps of 1, dissolving a nitrate of a transition metal in ammonia water to obtain a metal-ammonia complex ion-containing solution, 2, adding a titanate into the metal-ammonia complex ion-containing solution obtained by the step 1, and vigorously stirring during titanate fast-hydrolysis so that the mixture is mixed uniformly, 3, putting the suspension mixed uniformly by the step 2 into a stainless steel high-pressure kettle with a Teflon lining, and carrying out a hydrothermal reaction process at a temperature of 433 to 473K for 12 to 72 hours, and 4, washing precipitates by deionized water after the hydrothermal reaction, and drying at a temperature of 333 to 373K for 6 to 24 hours to obtain a nano-titania product of which surface is uniformly coated with metal nanoparticles. The preparation method has the advantages of simple process flow, wide parameter adjustment range, low cost, strong repeatability and large synthesis amount.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

A kind of porous monolith, its preparation method and application

ActiveCN111672485BSimple ingredientsLow costFatty/oily/floating substances removal devicesOther chemical processesSorbentMetal-organic framework

The present invention relates to a porous monolith and its preparation method and application. The preparation method comprises the following steps: (1) dissolving a polymer in a solvent to obtain a first slurry; (2) adding an aqueous solution of MOFs to step (1) Among the obtained first slurry, the second slurry is obtained after the reaction; (3) The second slurry obtained in step (2) is sequentially subjected to thermal phase separation, solvent replacement and drying to obtain the porous monolith. The porous monolith provided by the invention has simple raw materials and low cost, uses organic polymers as the main raw material, and uses metal-organic framework grains as modified bodies to solve the problem of low selectivity and low efficiency of adsorbents in the oil-water separation process in the prior art. Low and so on.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com