Nano tourmaline dispersion liquid and preparation method thereof

A nano-tourmaline and dispersion technology, applied in the directions of botanical equipment and methods, mixing methods, chemical instruments and methods, etc., can solve the problems of weak market competitiveness, limited scope of use, high cost, and achieve a wide adjustable range of parameters. , The effect of a wide range of use and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

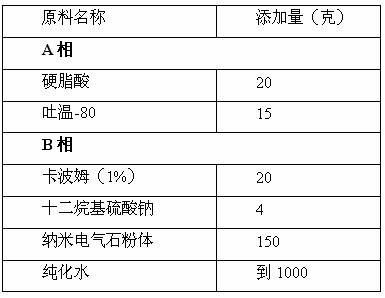

[0036] Based on 1 kg of the nano-tourmaline composite dispersion liquid, a dispersion liquid with a tourmaline content of 10% is prepared. The particle size of the nano-tourmaline powder used is about 30 nanometers. The raw materials and proportioning ratio are shown in the following table:

[0037]

[0038] Preparation method: Before preparation, prepare carbomer into a 1% solution for later use. During preparation, in container A, mix stearic acid and Tween-80 according to the addition amount in the table, heat to 80 degrees, stir while heating, make it fully melt, and form a uniform and transparent liquid state; at the same time, in In container B, add carbomer (1%) and sodium lauryl sulfate to water, stir to form a uniform solution, then add nano-tourmaline powder, heat to 70 degrees, and stir while heating to form a well-dispersed Slurry; then, under rapid stirring, add phase A at 80 degrees to phase B at 70 degrees, then use a high-speed homogenizer to homogenize for ...

Embodiment 2

[0041] Based on 1 kg of the nano-tourmaline composite dispersion, prepare a dispersion with a tourmaline content of 15%. The particle size of the nano-tourmaline powder used is about 30 nanometers. The raw materials and proportioning ratio are shown in the following table:

[0042]

[0043] Preparation method: Before preparation, prepare carbomer into a 1% solution for later use. During preparation, in container A, mix stearic acid and Tween-80 according to the addition amount in the table, heat to 80 degrees, stir while heating, make it fully melt, and form a uniform and transparent liquid state; at the same time, in In container B, add carbomer (1%) and sodium lauryl sulfate to water, stir to form a uniform solution, then add nano-tourmaline powder, heat to 80 degrees, and stir while heating to form a well-dispersed solution Slurry; then under rapid stirring, add phase A at 80 degrees to phase B at 80 degrees, then use a high-speed homogenizer to homogenize for 3 minutes,...

Embodiment 3

[0046] Based on 1 kg of the nano-tourmaline composite dispersion liquid, a dispersion liquid with a tourmaline content of 20% is prepared. The particle size of the nano-tourmaline powder used is about 30 nanometers. The raw materials and proportioning ratio are shown in the following table:

[0047]

[0048] Preparation method: Before preparation, prepare carbomer into a 1% solution for later use. During preparation, in container A, mix stearic acid and Tween-80 according to the addition amount in the table, heat to 90 degrees, stir while heating, make it fully melt, and form a uniform and transparent liquid; at the same time, in In container B, add carbomer (1%) and sodium lauryl sulfate to water, stir to form a uniform solution, then add nano tourmaline powder, heat to 80 degrees, stir while heating, A well-dispersed slurry is formed; then, under rapid stirring, add phase A at 90 degrees to phase B at 80 degrees, then use a high-speed homogenizer to homogenize for 4 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com