Electrocondution slurry and preparation method and application of electrocondution slurry

A technology of conductive paste and raw materials, applied in conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, circuits, etc., can solve the problem of reducing the effective light transmission area of thin-film solar cells and affecting the photoelectric conversion efficiency of battery devices , electrode electrical properties and stability damage, etc., to achieve the effect of improving photoelectric conversion efficiency, minimizing shadow shading, and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of the conductive paste of the embodiment of the present invention comprises the following steps:

[0038] (1) preparing the silver-graphene composite material, further comprising the following steps:

[0039] (1-1) Add graphite oxide and organic silver into a mixed system composed of organic solvent and deionized water at a mass ratio of 1:20-50 for ultrasonic dispersion for 20-40 minutes. Wherein, the organic silver is at least one of straight chain or branched saturated aliphatic monocarboxylic acid silver compounds with 5-22 carbon atoms. Organic solvents are methanol, ethanol, ethylene glycol, isopropanol, tert-butanol, acetone, methyl ethyl ketone, N,N-dimethylformamide, dimethyl sulfoxide, tetrahydrofuran, glacial acetic acid, acetonitrile and dioxane at least one of the The volume ratio of organic solvent to deionized water is 1:1-3.

[0040] (1-2) Keep the temperature of the mixed system at 0-10°C. While stirring the mixed system, add ...

Embodiment 1

[0045] Add 200 mg of graphite oxide and 10 g of silver behenate (mass ratio 1:50) into 200 mL of organic solvent (synthesized from tert-butanol and dioxane at a volume ratio of 1:1) and 200 mL of deionized water (organic solvent and deionized The volume ratio of ionized water is 1:1) in the mixed system composed of ultrasonic dispersion for 40min. Keep the temperature of the mixed system at 0-10°C. While stirring the mixed system, add hydrazine hydrate dropwise to the mixed system at a mass volume ratio of graphite oxide to hydrazine hydrate of 1:150 g / mL at a rate of 1.2 mL / min. After stirring at room temperature for 30 min, the temperature was raised to 70° C. for 2 h to obtain a black suspension, which was cooled to room temperature, filtered, washed with deionized water, and dried in vacuum to obtain a silver-graphene composite material.

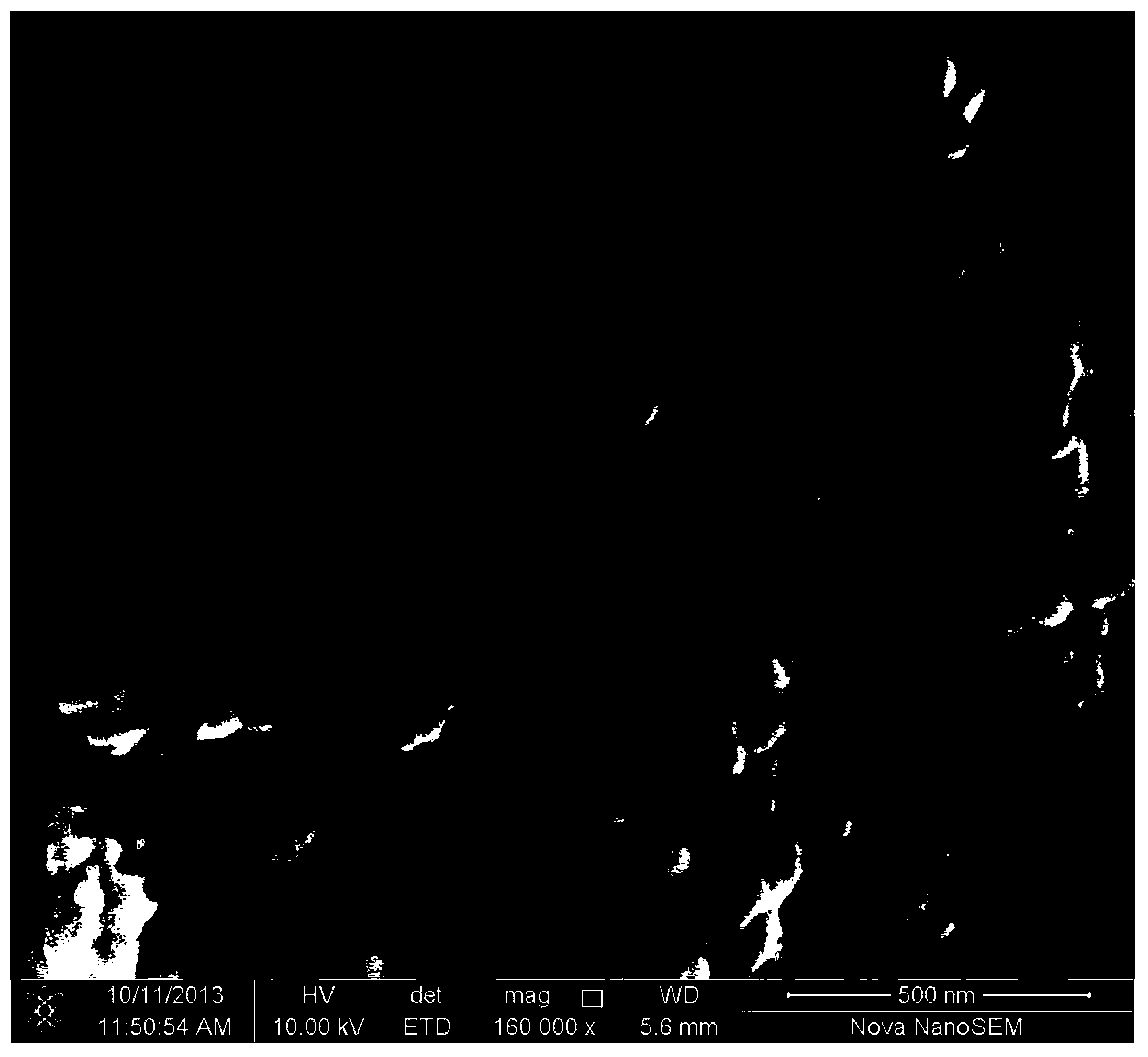

[0046] The SEM image of the silver-graphene composite figure 1 As shown, the silver nanoparticles are effectively dispersed to form a ...

Embodiment 2

[0049] Add 300mg of graphite oxide and 6g of silver hexanoate (mass ratio 1:20) into a mixed system consisting of 100mL organic solvent and 300mL deionized water (volume ratio of organic solvent to deionized water is 1:3) and ultrasonically disperse for 20min. Keep the temperature of the mixed system at 0-10°C. While stirring the mixed system, add hydrazine hydrate dropwise to the mixed system at a mass volume ratio of graphite oxide to hydrazine hydrate of 1:200 g / mL at a rate of 1.5 mL / min. After stirring at room temperature for 30 min, the temperature was raised to 60° C. for 2 h to obtain a black suspension, which was cooled to room temperature, filtered, washed with deionized water, and dried in vacuum to obtain a silver-graphene composite material.

[0050] The SEM image of the silver-graphene composite figure 2 As shown, the silver nanoparticles are effectively dispersed to form a dense and effective silver-graphene composite conductive network, which is beneficial to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com