Preparation method of tough graphene/cellulose composite heat-conductive and electro-conductive film

A technology of conductive film and cellulose, which is applied in the field of nanomaterials and functional materials, can solve the problems of complex process, harsh conditions, and the decline of graphene's thermal and electrical conductivity, and achieve the effect of low preparation cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] In a specific embodiment, in the preparation method of the tough graphene / cellulose composite thermally and electrically conductive film of the present invention, respectively obtain graphene uniformly dispersed in a solvent and a fiber bundle solution of nanometer diameter uniformly dispersed in an aqueous solution, by Graphene / cellulose composite films were prepared by vacuum filtration. The specific steps are as follows:

[0026] 1. Preparation of Graphene Dispersion

[0027] The graphene used is industrialized graphene nanosheets as an example. The thickness is ~5 nm, the number of layers is about 10 layers, and the average sheet diameter is 5 μm. The graphene nanosheets and dispersant are added to the solvent to configure the concentration 1 mg / ml graphene nanosheet solution, and the graphene solution was ultrasonically treated for 3 min to obtain a uniformly dispersed graphene suspension;

[0028] 2. Preparation of Single Bundle Cellulose Dispersion

[0029] Di...

Embodiment 1

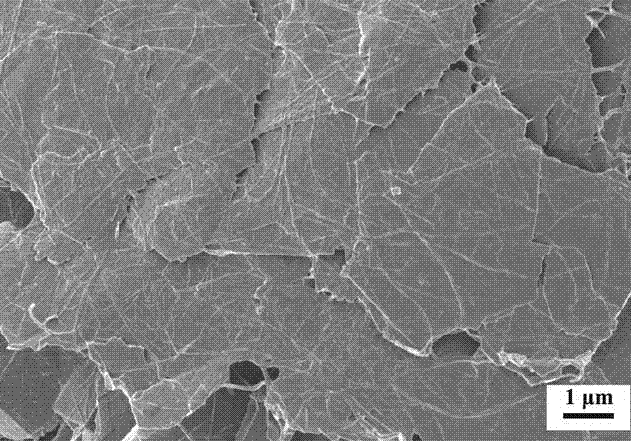

[0033] Embodiment 1: pure graphene nanosheet film

[0034] The 25 ml suspension of graphene nanosheets was vacuum-filtered using a microporous filter membrane. The graphene sheet reshaped the film-forming material by self-assembly. After filtering, it was rinsed with distilled water for several times, and the graphene film together with the filter paper was heated at room temperature. Then, the filter was peeled off from the microporous membrane, and then the sample was dried in a vacuum oven for 24 h. The dried graphene nanosheet film was placed on a hot press at a pressure of 65 MPa for 1 h to obtain a graphene nanosheet film with higher density.

[0035] The thickness of the graphene nanosheet / cellulose composite film prepared in this example is 0.095 mm, and its mechanical properties are poor, making it difficult to measure. Its in-plane thermal conductivity and electrical conductivity are 46 W / mK and 18 S / cm, respectively. It is worth noting that when the film was kept ...

Embodiment 2

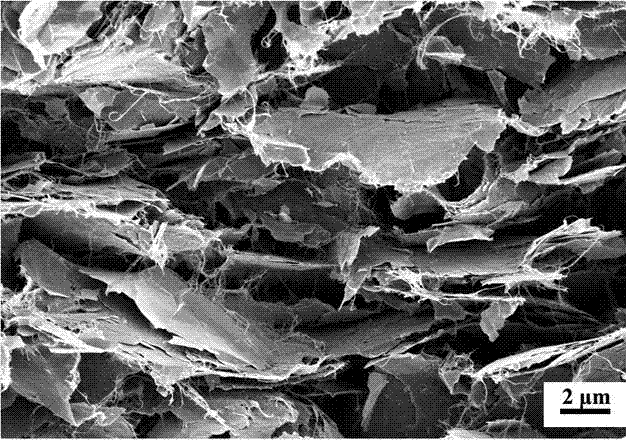

[0036] Example 2: Composite film with cellulose content of 10 wt%

[0037] Take 25 ml of a graphene nanosheet solution with a concentration of 1 mg / ml, then slowly add 2.8 ml of a cellulose aqueous solution with a concentration of 1 mg / ml under stirring, stir evenly, and then sonicate at a power of 120 W 5 min, followed by vacuum filtration, washing, drying and other steps to obtain a composite film with a cellulose content of 10 wt%.

[0038] The thickness of the graphene nanosheet / cellulose composite film prepared by this method is 0.09 mm, the tensile strength, modulus and elongation at break are 1.5 MPa, 0.19 MPa and 2.5% respectively; the thermal conductivity and electrical conductivity in the plane direction They are 58W / mK and 14 S / cm respectively. When the film was kept under 65 MPa pressure for 1 h, the tensile strength, modulus and elongation at break of the compacted graphene nanosheet / cellulose composite film were measured to be 11.4 MPa, 3.4 GPa and 1.9%, respectiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com