Dual-rare earth-co-doped titanium dioxide gas sensitive sensing material preparation

A gas-sensing sensing material, titanium dioxide technology, applied in the fields of material analysis, material analysis by electromagnetic means, nanostructure manufacturing, etc., can solve the problems of inconspicuous photocatalytic activity, low proportion of rare earth atoms, and low doping utilization rate of rare earth elements. Advanced problems, to achieve the effect of simple process and process, wide adjustable range of parameters, and strong repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

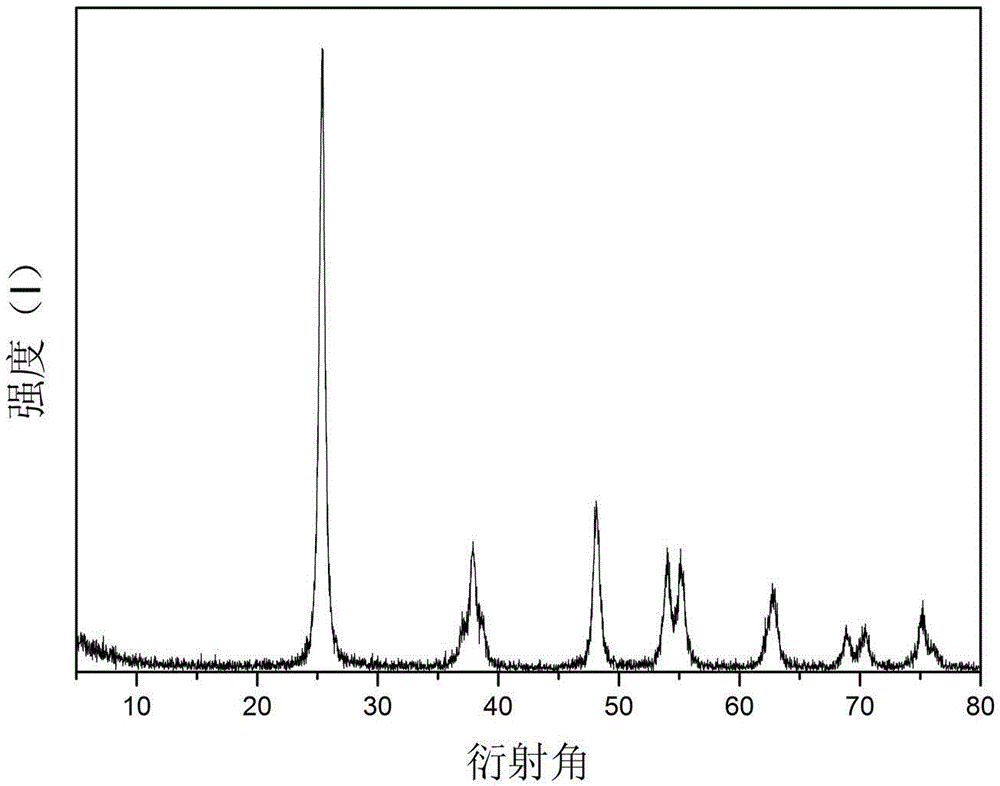

[0021] 1 g of urea, 0.1 g of lanthanum nitrate hexahydrate, and 0.3 g of cerium nitrate hexahydrate were sequentially added to 80 ml of absolute ethanol. After stirring to dissolve, add 12 ml of isopropyl titanate and stir evenly. Then, 7 ml of deionized water was added dropwise to the above system while stirring until a transparent gel was formed. The above gel was put into a Teflon-lined stainless steel autoclave for hydrothermal reaction at 170 °C for 48 hours. After the reaction, the precipitated product is washed with deionized water until the pH of the washing liquid is neutral, and then dried to obtain the target rare earth element doped titanium dioxide nanometer material.

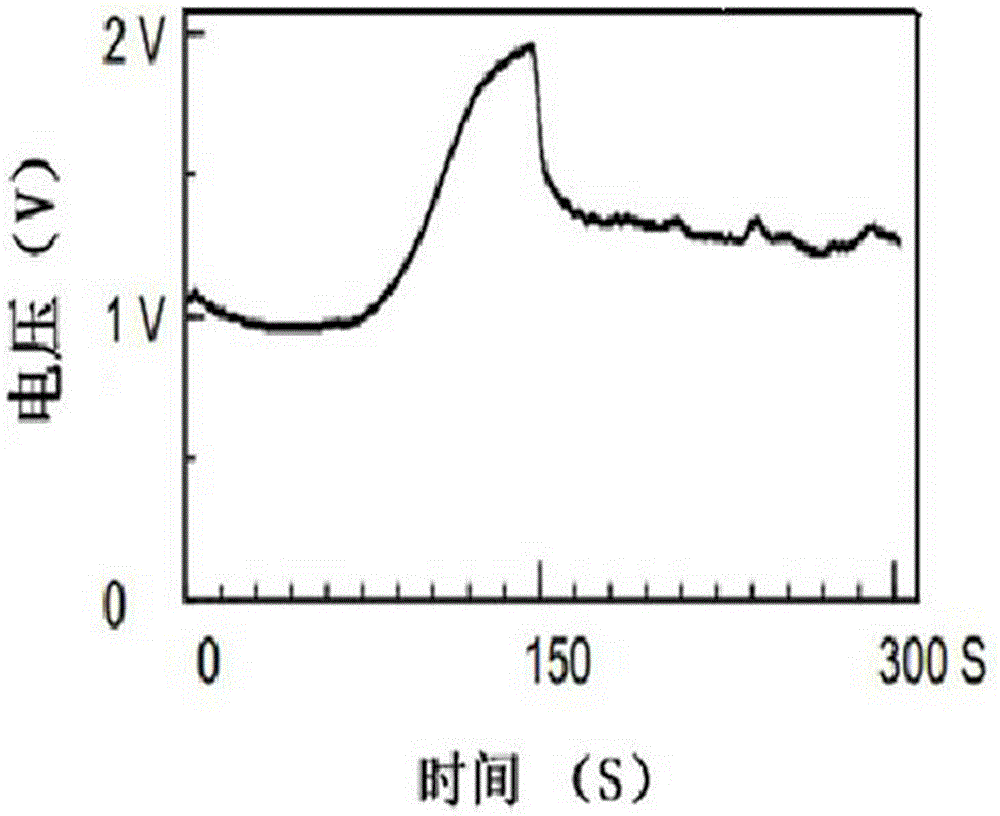

[0022] The obtained powder is dispersedly coated on the hexapod ceramic tube gas sensor test element, and the WS-30A gas sensor test system is used to test the response to NH3 gas at different concentrations. It has obvious response in 10ppm ammonia gas atmosphere at room temperature, and the sen...

Embodiment 2

[0024] Add 0.5 g of urea, 0.3 g of lanthanum nitrate hexahydrate, and 0.02 g of cerium nitrate hexahydrate in sequence in 50 ml of absolute ethanol. After stirring to dissolve, add 8 ml of n-tetrabutyl titanate and stir evenly. Then, 4 ml of deionized water was added dropwise to the above system while stirring until a transparent gel was formed. The above gel was put into a Teflon-lined stainless steel autoclave for hydrothermal reaction at 150 °C for 24 h. After the reaction, the precipitated product is washed with deionized water until the pH of the washing liquid is neutral, and then dried to obtain the target rare earth element-doped titanium dioxide nanomaterial.

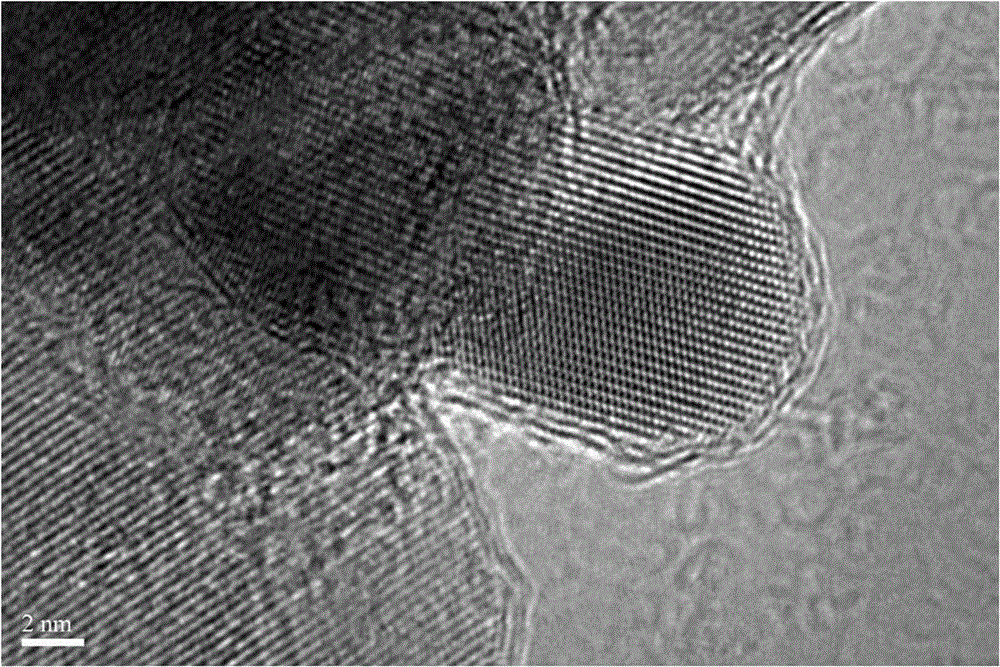

[0025] The obtained rare-earth-doped titanium dioxide nanometer material is a highly dispersed nanocrystal grain with a particle diameter of about 5-7 nanometers and uniform size. image 3 It shows that the obtained powder is dispersedly coated on the gas sensor test element of the hexapod ceramic tube, and t...

Embodiment 3

[0027] Add 1.2 g of urea, 0.1 g of gadolinium nitrate hexahydrate, and 0.05 g of neodymium nitrate hexahydrate in sequence in 100 ml of absolute ethanol. After stirring to dissolve, add 15 ml of tetraethyl titanate and stir well. Then, 8 ml of deionized water was added dropwise to the above system while stirring until a transparent gel was formed. The above gel was put into a Teflon-lined stainless steel autoclave for hydrothermal reaction at 200 °C for 16 h. After the reaction, the precipitated product is washed with deionized water until the pH of the washing liquid is neutral, and then dried to obtain the target rare earth element-doped titanium dioxide nanomaterial.

[0028] The obtained powder is dispersedly coated on the hexapod ceramic tube gas sensor test element, and the WS-30A gas sensor test system is used to test the response to NH3 gas at different concentrations. There is an obvious response in 10ppm ammonia gas atmosphere at room temperature, and the sensitivi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com