Patents

Literature

298results about How to "Composite uniform" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphene/MoS2 compound nano material lithium ion battery electrode and preparation method thereof

InactiveCN102142537ALarge specific surface areaImprove mechanical propertiesNon-aqueous electrolyte accumulator electrodesLithium-ion batteryMaterials science

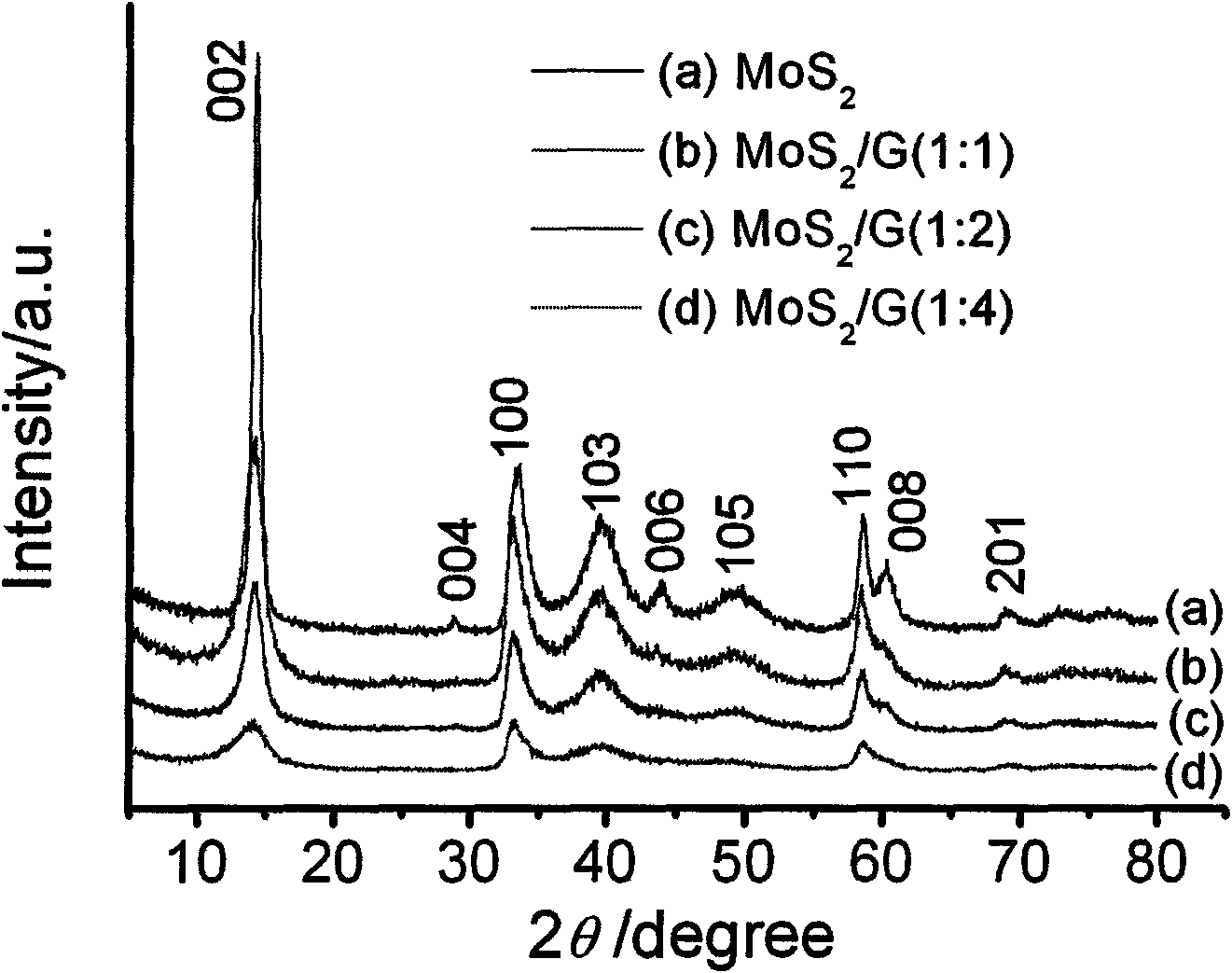

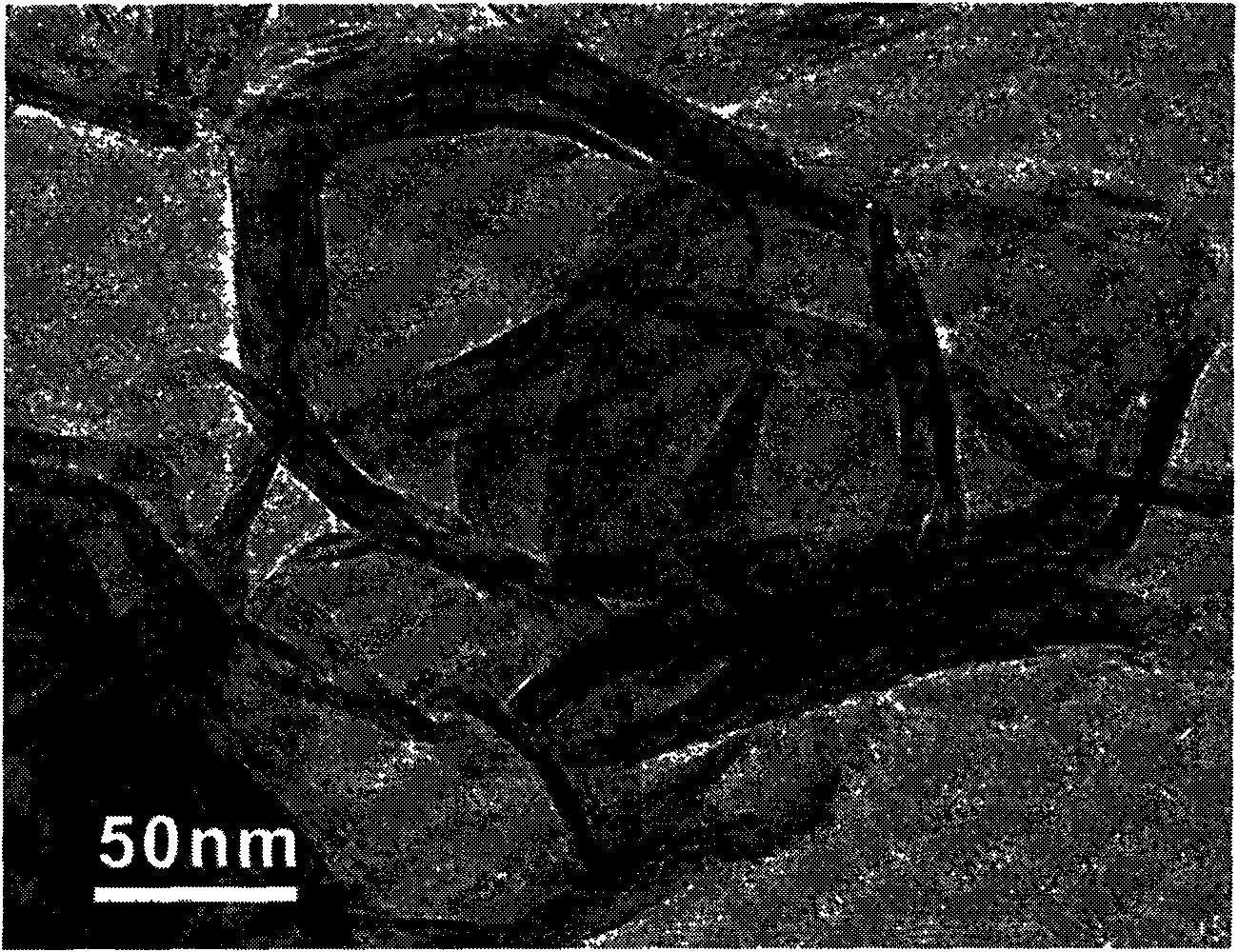

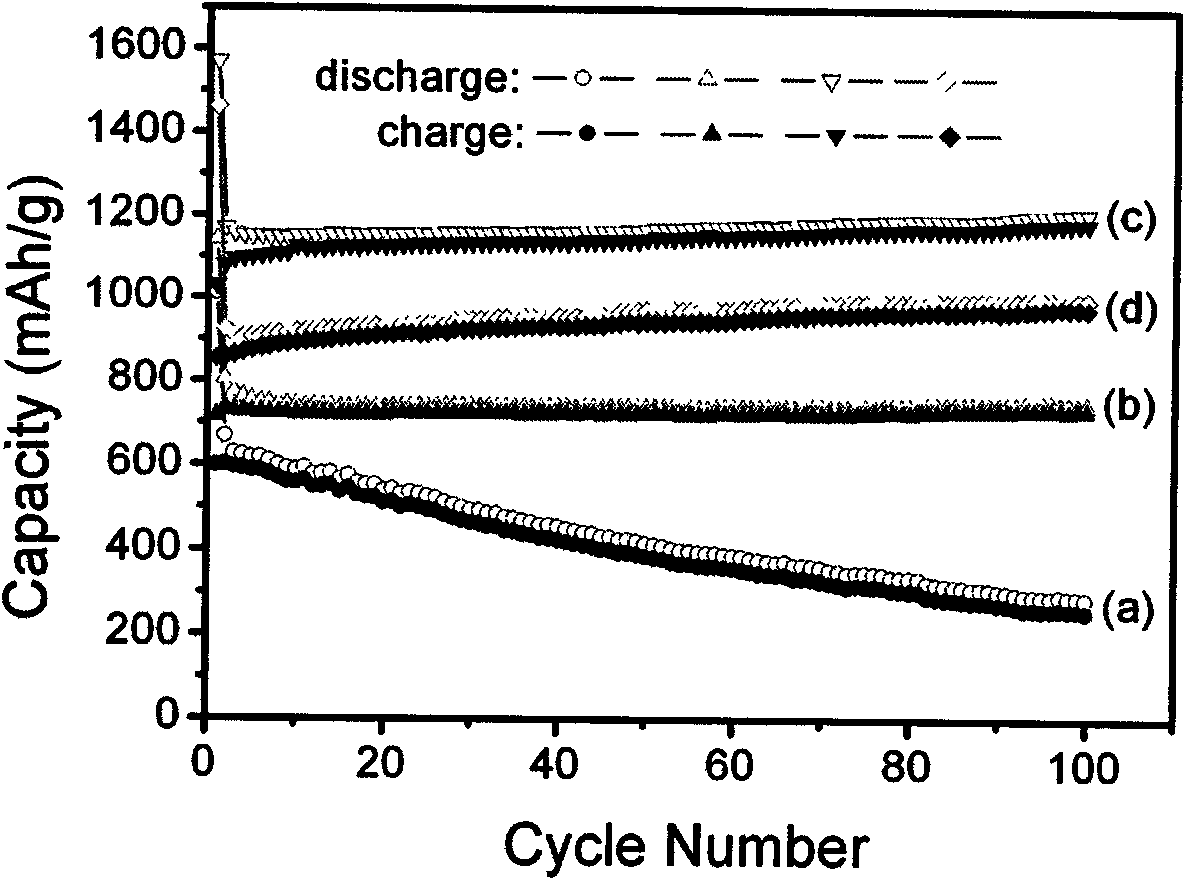

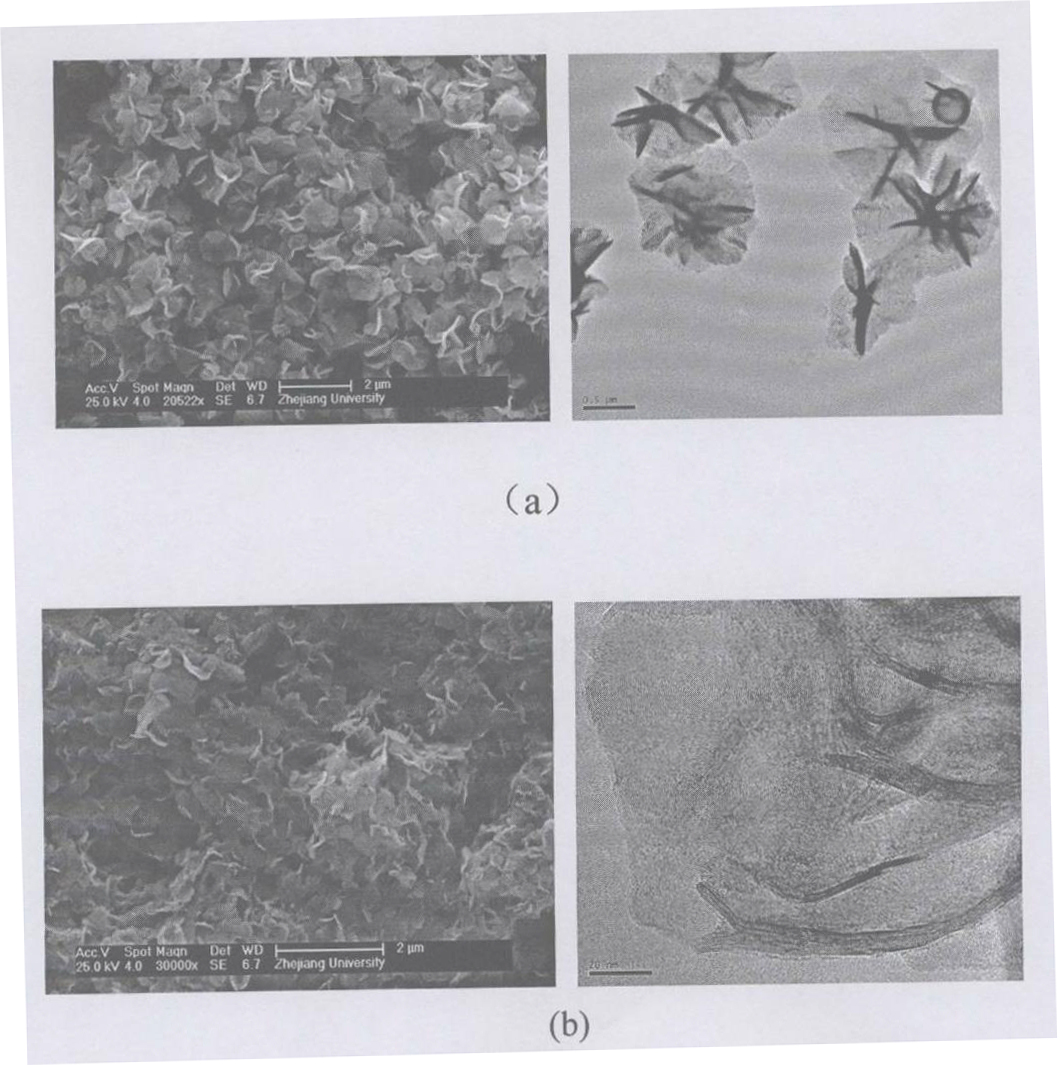

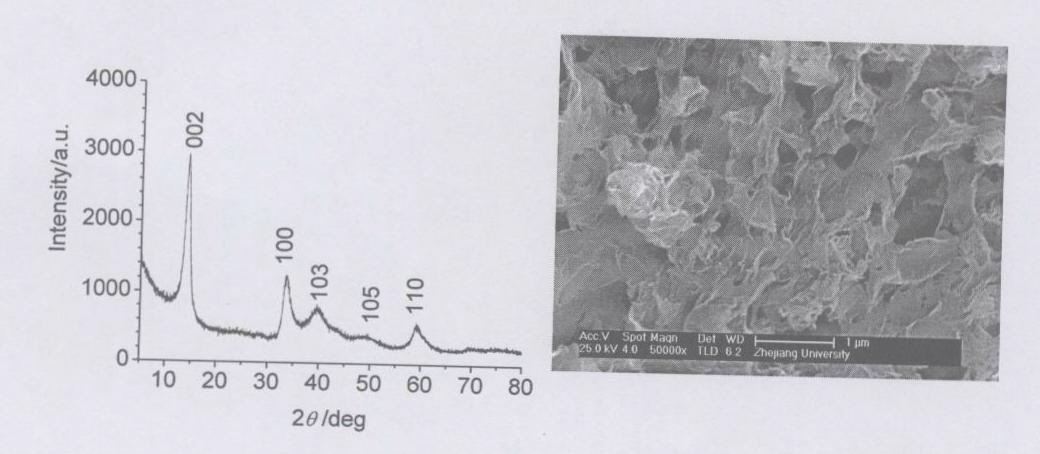

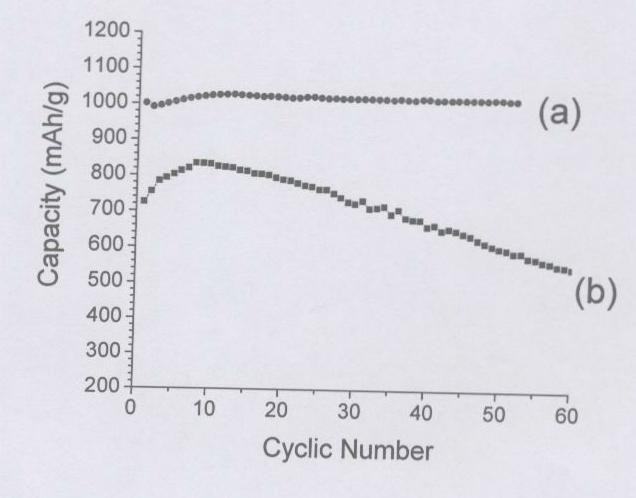

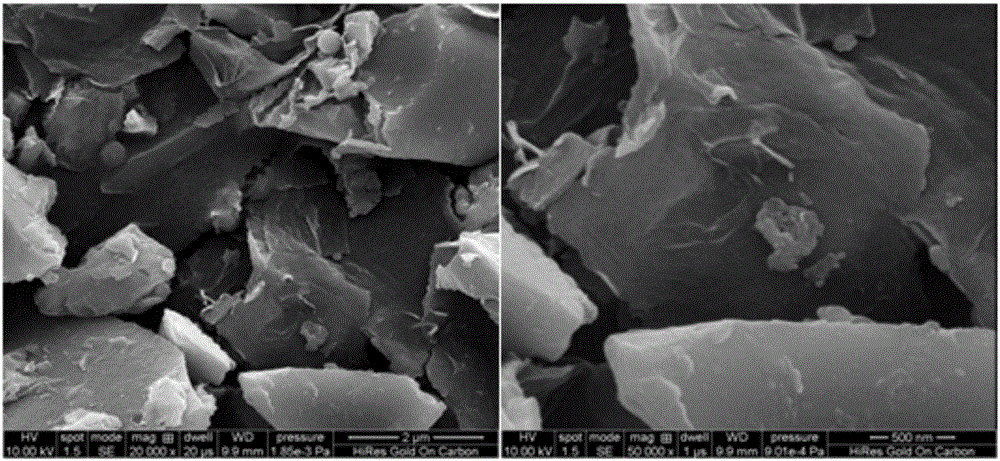

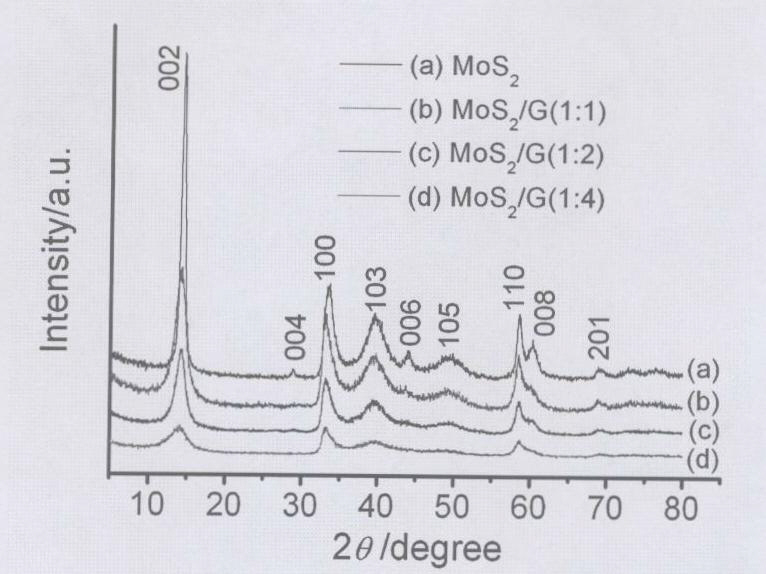

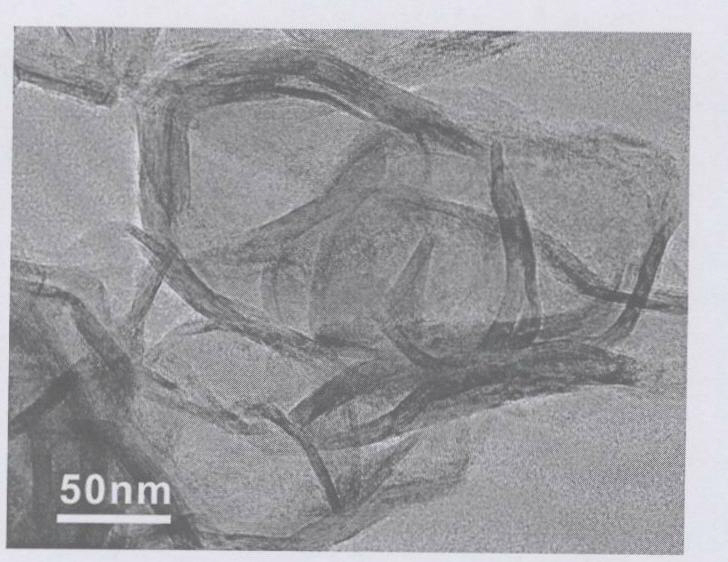

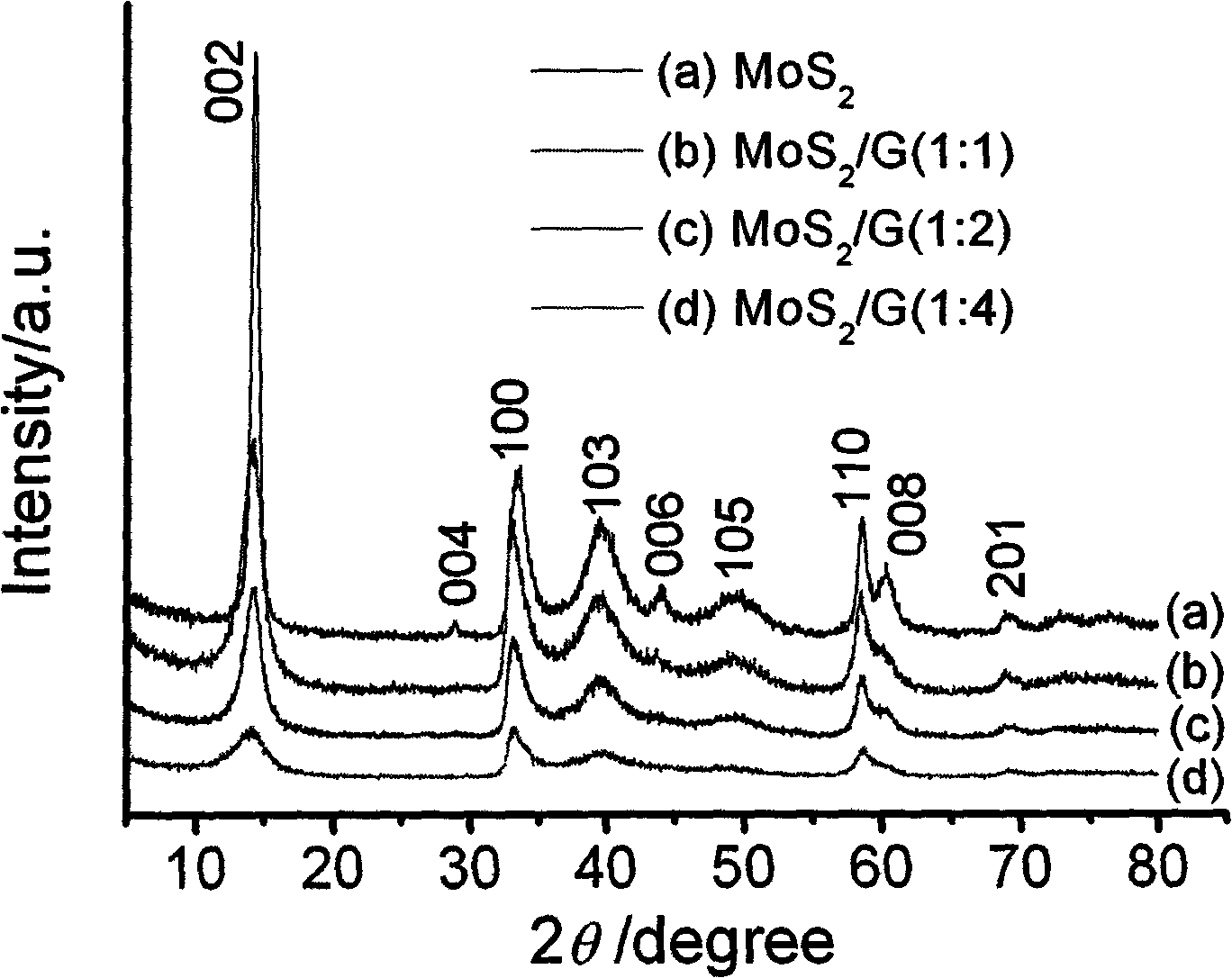

The invention discloses a graphene / molybdenum disulfide (MoS2) compound nano material lithium ion battery electrode and a preparation method thereof. The electrode comprises the following components in percentage by mass: 75 to 85 percent of compound nano material serving as an active substance, of a graphene nano slice and MoS2, and 5 to 10 percent of acetylene black and 10 percent of polyvinylidene fluoride; and the mass ratio of the graphene nano slice to the MoS2 nano material in the compound nano material active substance is (1 to 1)-(4 to 1). The preparation method of the electrode comprises the following steps of: preparing an oxidized graphite nano slice by using graphite as a raw material by a chemical oxidization method; synthesizing by a one-step hydrothermal in-situ reduction method in the presence of the oxidized graphite nano slice to obtain a graphene nano slice / MoS2 compound nano material; and finally, preparing the electrode by using the graphene nano slice / MoS2 compound nano material as the active substance. The electrode has high electrochemical lithium storage reversible capacity and cyclic stabilization performance, and can be widely applied to new generation lithium ion batteries.

Owner:ZHEJIANG UNIV

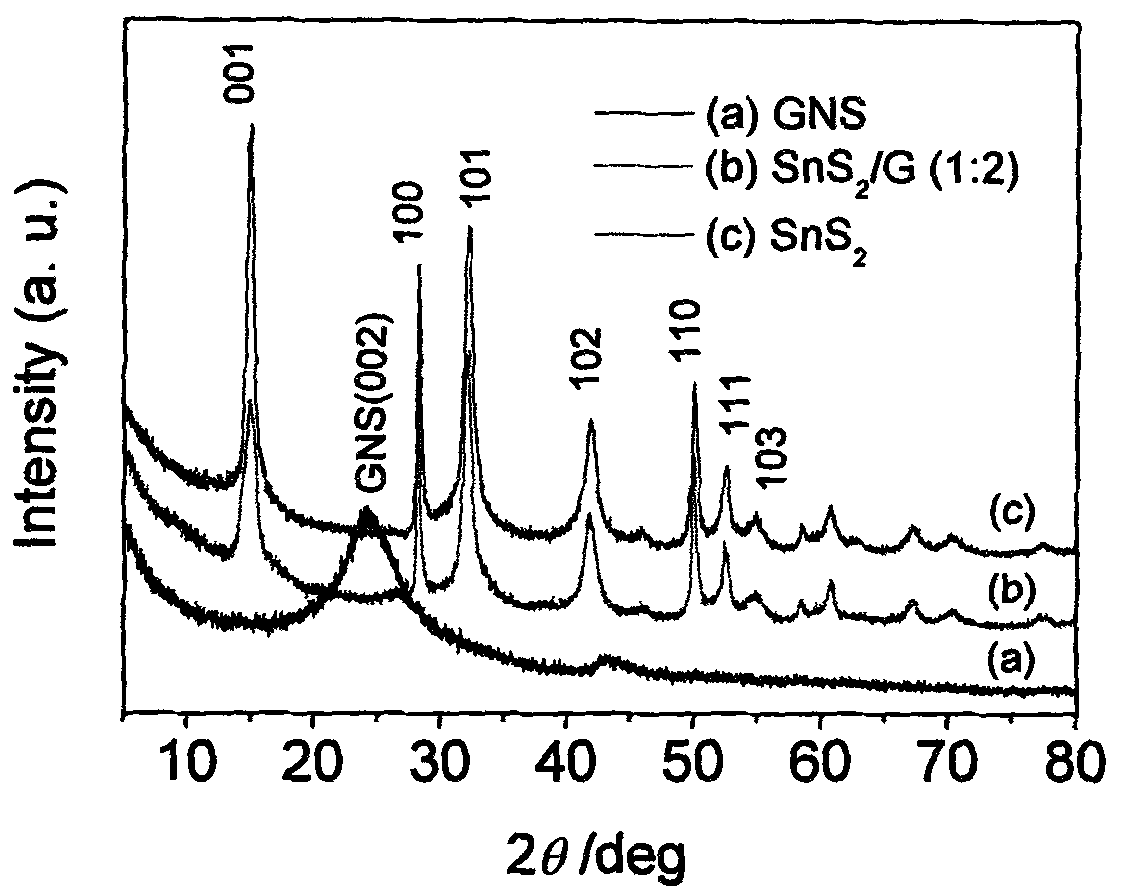

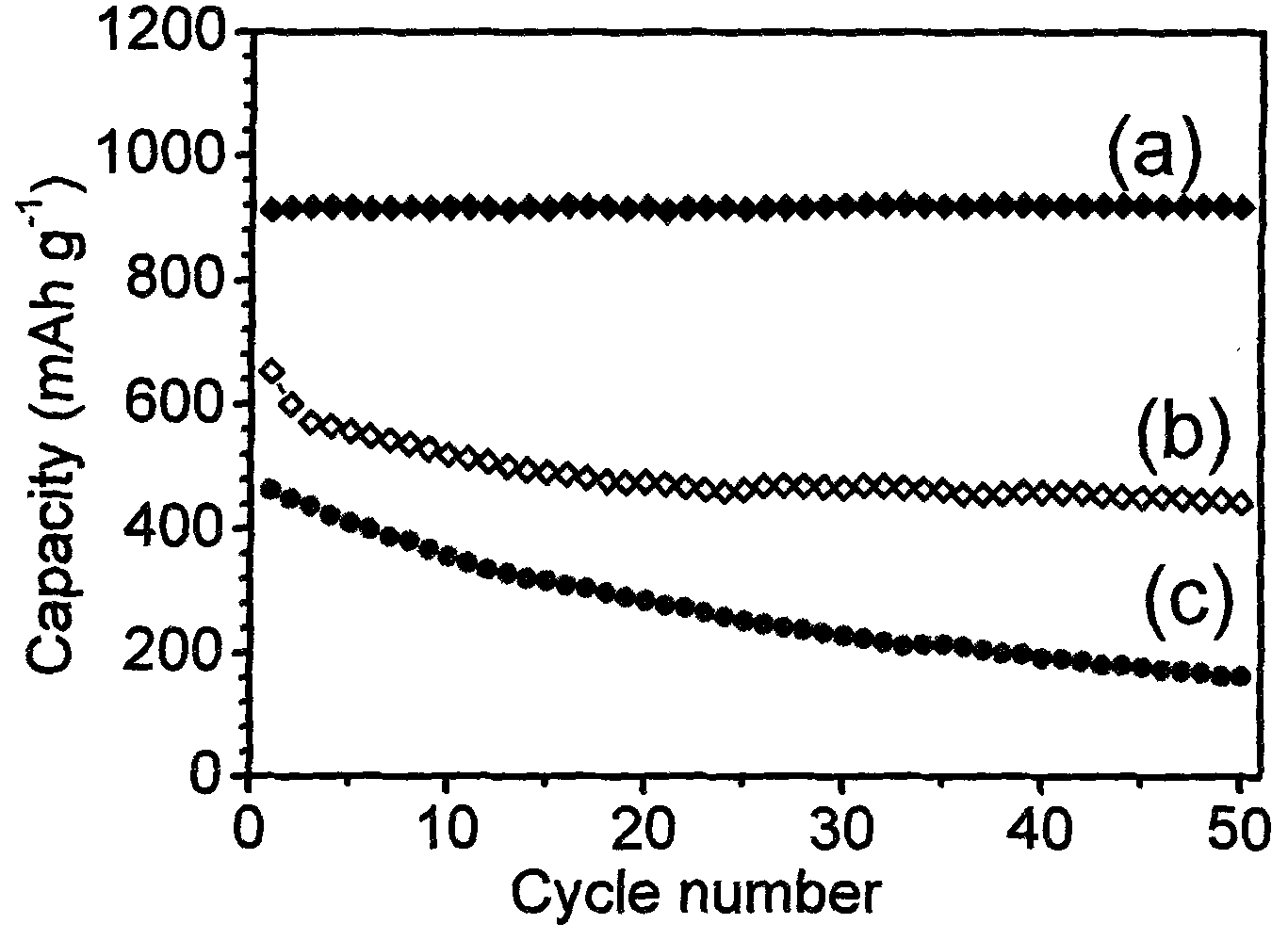

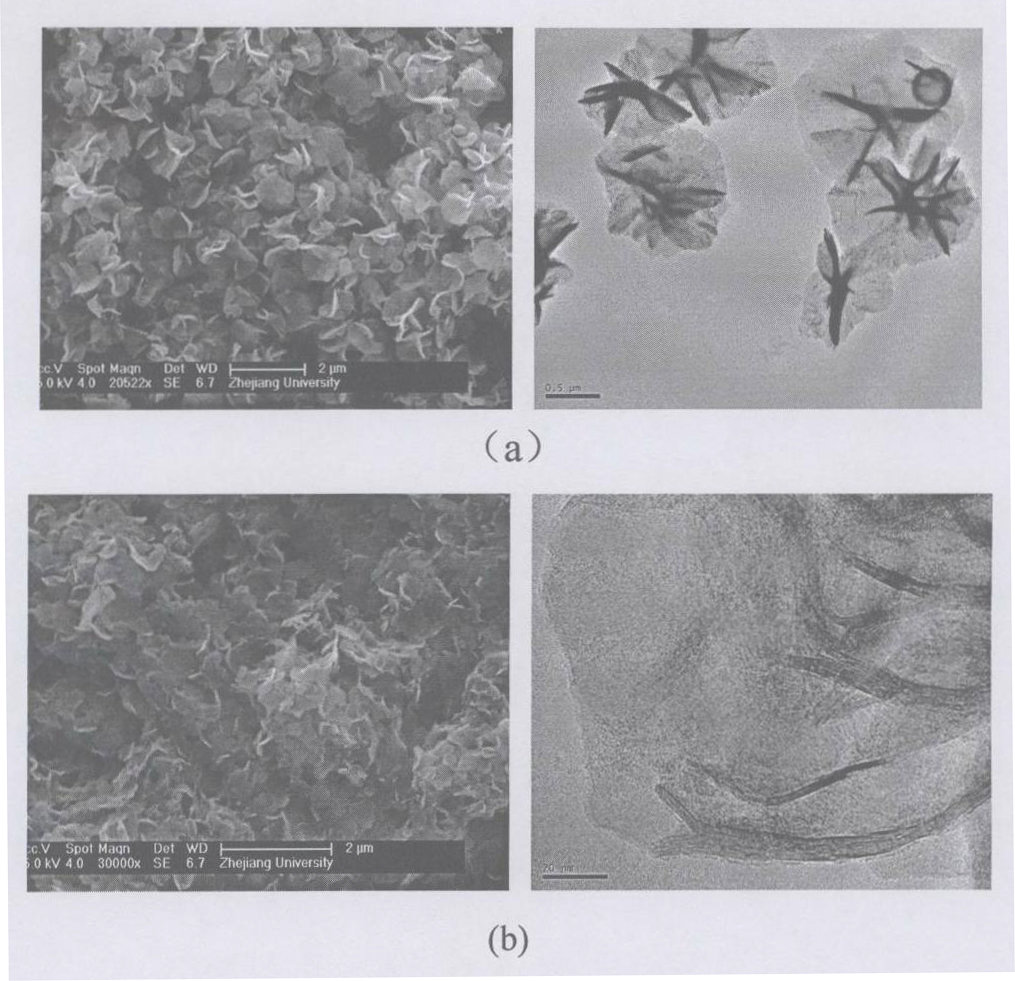

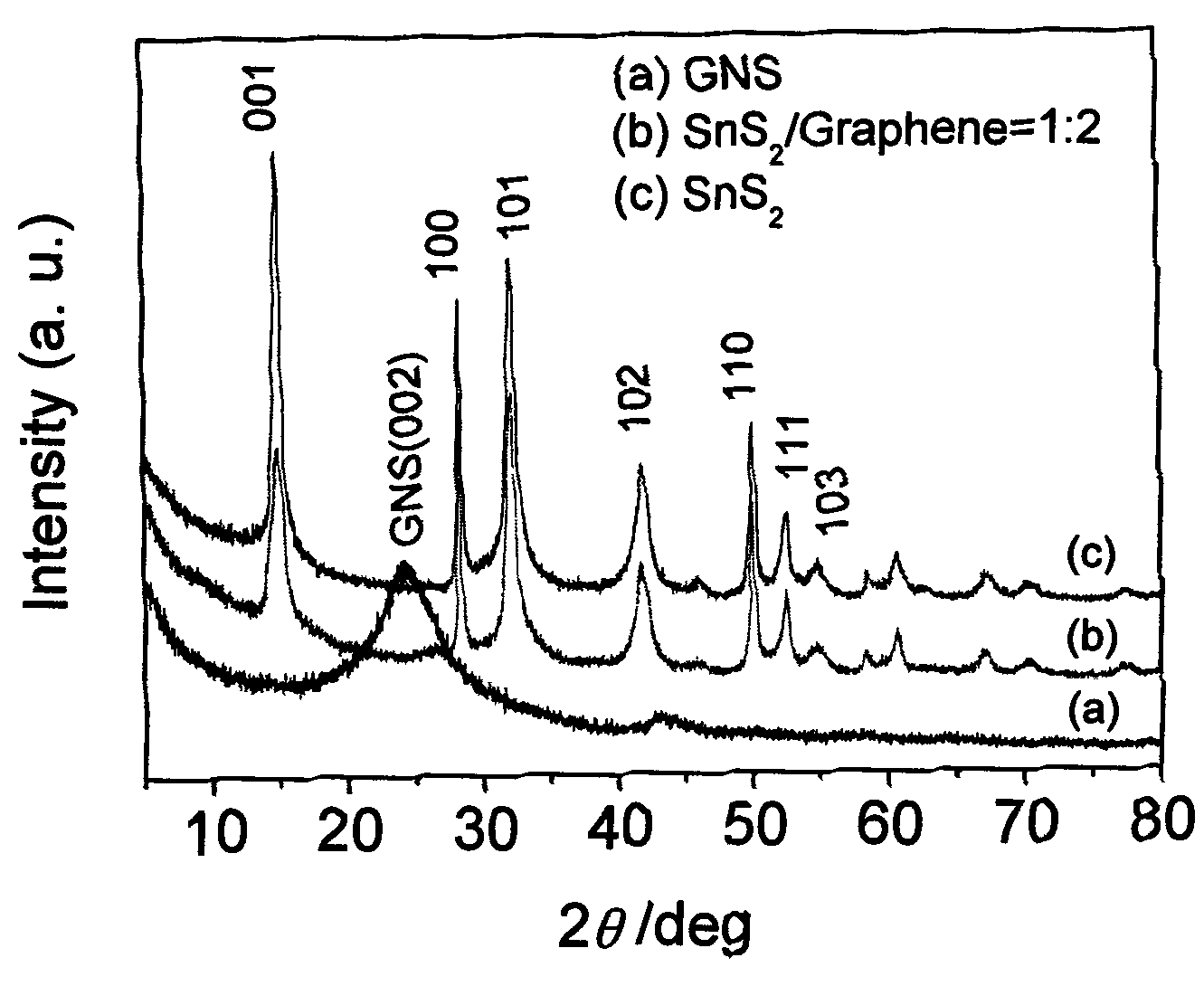

Lithium ion battery electrode made of graphene/SnS2 composite nanometer material and preparation method thereof

InactiveCN102142540AMild reaction conditionsSimple processCell electrodesMass ratioLithium-ion battery

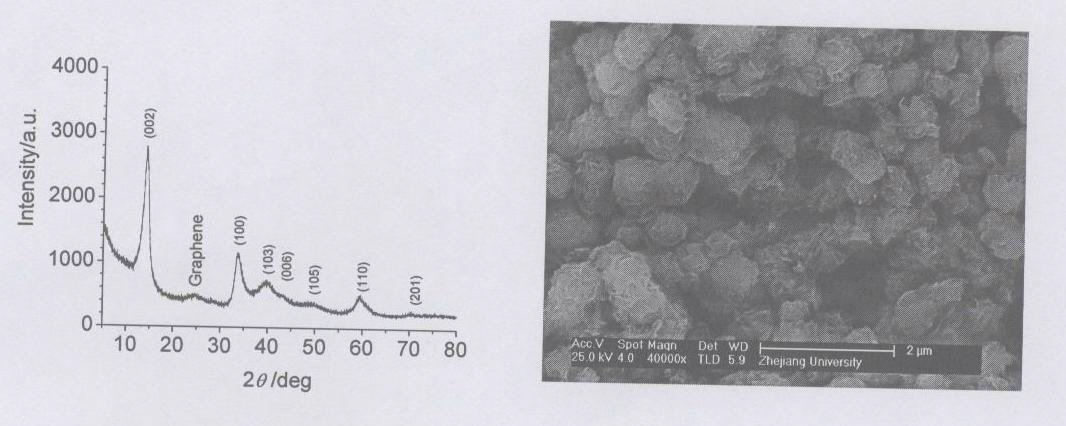

The invention discloses a lithium ion battery electrode made of a graphene / SnS2 composite nanometer material and a preparation method thereof. The lithium ion battery electrode is characterized in that the active substance of the electrode is the graphene / SnS2 composite nanometer material, and the other components of the electrode are acetylene black and polyvinylidene fluoride. The lithium ion battery electrode comprises the following components in percentage by weight: 75-85% of the composite nanometer material active substance, 5-10% of the acetylene black and 10% of the polyvinylidene fluoride; and the mass ratio of the graphene to SnS2 nanometer material in the composite nanometer material active substance is (1:1)-(4:1). The electrode preparation method disclosed by the invention comprises the following steps: preparing a graphite oxide nanometer sheet by taking graphite as a raw material by virtue of a chemical oxidation method; in the presence of the graphite oxide nanometer sheet, synthetizing to obtain the graphene / SnS2 composite nanometer material by virtue of a one-step hydrothermal in-situ reduction method; and finally, taking the graphene / SnS2 composite nanometer material as the active substance to prepare the electrode. The electrode disclosed by the invention has the advantages of higher electrochemical lithium storage capacity and excellent cyclical stability and can be widely used in the new generation of lithium ion batteries.

Owner:ZHEJIANG UNIV

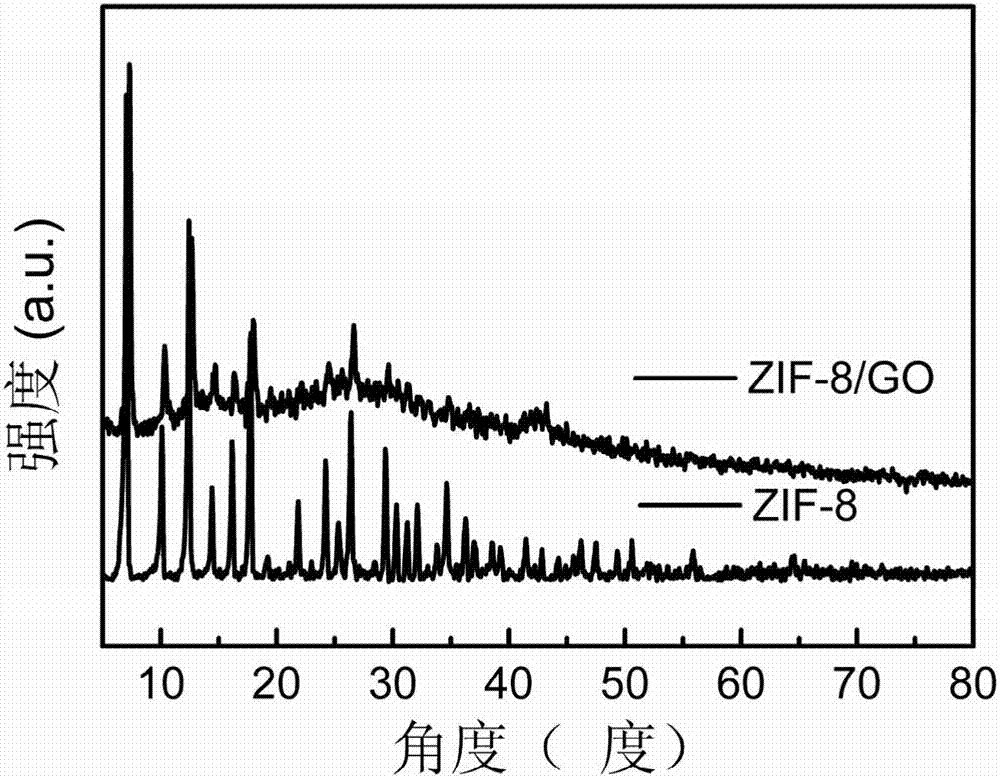

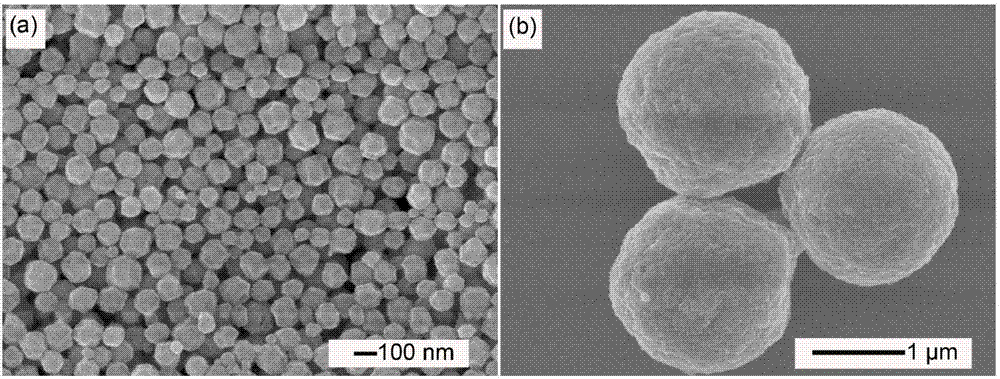

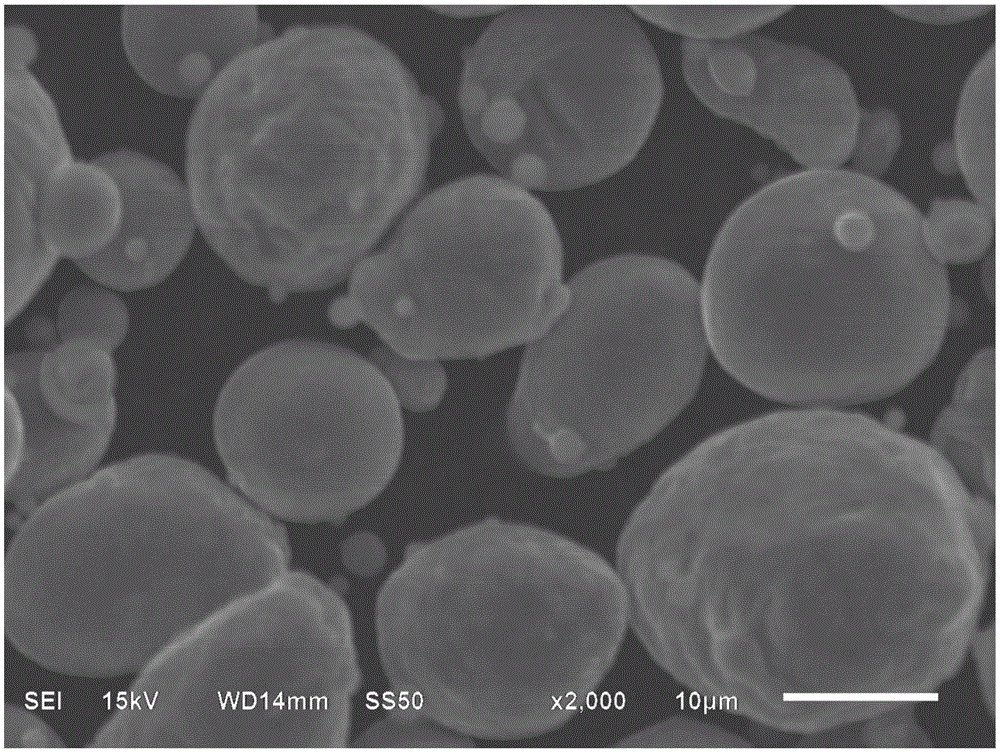

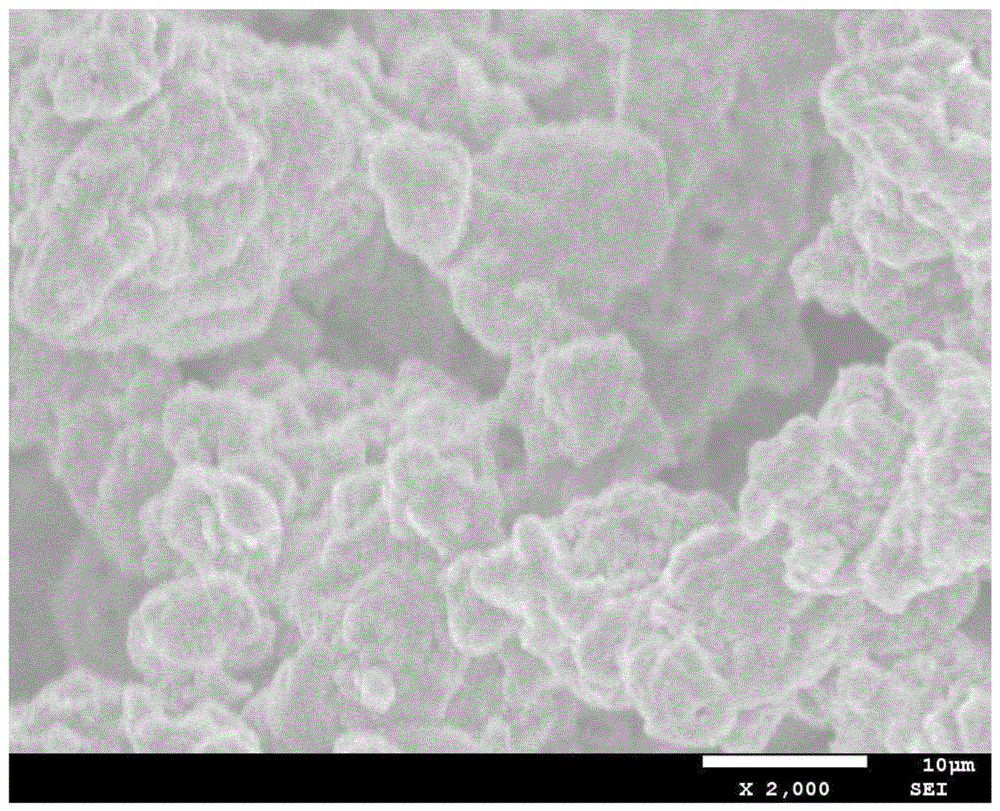

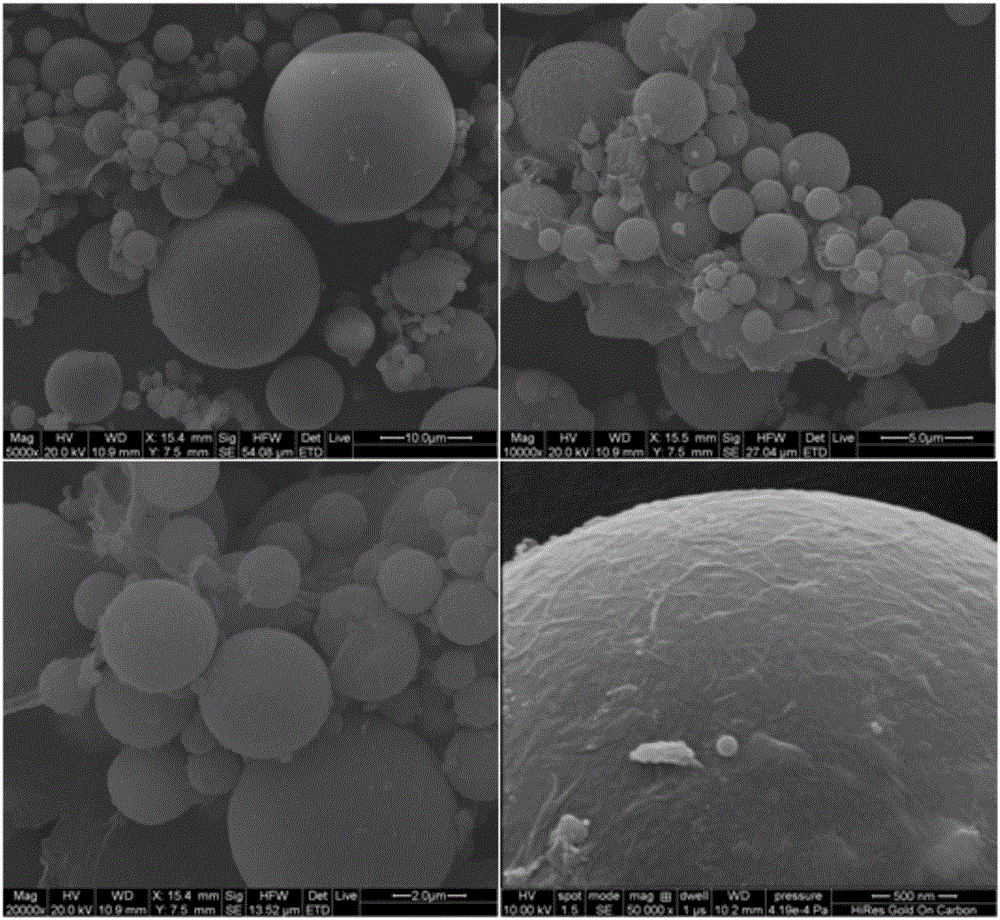

Preparation method of metal organic skeleton compound and oxidized graphene composite microspheres having uniform appearance

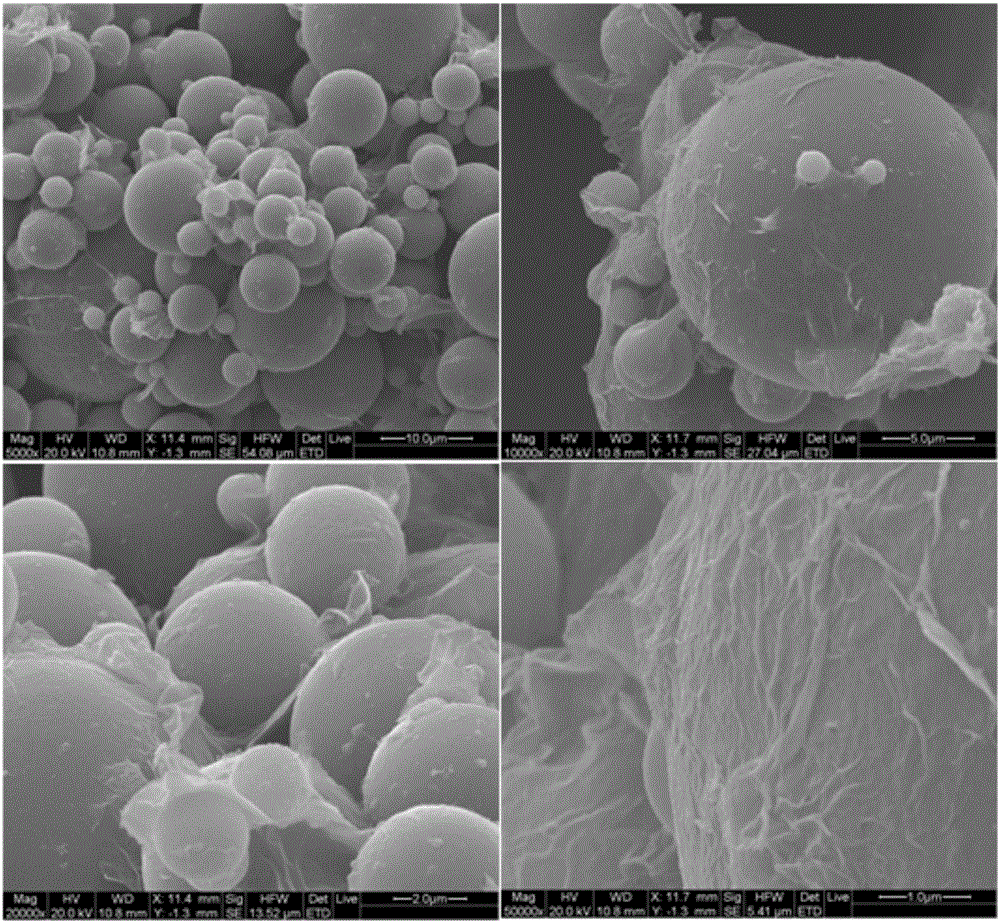

InactiveCN107497377AComposite uniformUniform sizeMicroballoon preparationMicrocapsule preparationMicrospherePorous carbon

The invention relates to a preparation method of metal organic skeleton compound and oxidized graphene composite microspheres having uniform appearance. The method comprises mixing a metal organic skeleton compound dispersion liquid with an oxidized graphene dispersion liquid, and performing spray drying to prepare composite microspheres. According to the spray drying method, the obtained microspheres are uniform in size and high in yield, and have the yield in a range of 70-85% and the average size at about 1.5 mum. To avoid agglomeration of oxidized graphene at a high temperature, ZIF-8 can be converted to nanometer porous carbon at a high temperature, and N-doped nanometer porous carbon and graphene composite microspheres having high specific surface area and nitrogen content. Through high-temperature carbonization treatment, the composite microspheres are improved in conductivity, and can be applied to aspects of CO2 adsorption, super capacitors, batteries, catalysis and separation.

Owner:SHANDONG UNIV

High capacity and stable cyclic performance lithium ion battery electrode and preparation method thereof

ActiveCN102142541AInhibition of agglomerationEasy to passCell electrodesMass ratioLithium-ion battery

The invention discloses a high capacity and stable cyclic performance lithium ion battery electrode and a preparation method thereof. The invention is characterized in that: the electrode comprises the following components in percentage by mass: 75 to 85 percent of graphene nano slice / molybdenum disulfide (MoS2) compound nano material serving as an active substance, and 5 to 10 percent of acetylene black and 5 to 15 percent of polyvinylidene fluoride; and the mass ratio of the graphene nano slice to the MoS2 compound nano material in the compound nano material active substance is (1 to 1)-(4 to 1). The preparation method for the electrode comprises the following steps of: preparing an oxidized graphite nano slice by using graphite as a raw material by a chemical oxidization method; synthesizing by a one-step hydrothermal in-situ reduction method in the presence of the oxidized graphite nano slice to obtain a graphene nano slice / MoS2 compound nano material; and finally, preparing the electrode by using the graphene nano slice / MoS2 compound nano material as the active substance. The electrode has high electrochemical lithium storage reversible capacity and cyclic stabilization performance, and can be widely applied to new generation lithium ion batteries.

Owner:ZHEJIANG UNIV

High temperature and wear resistant graphene coating and preparation method thereof

The invention relates to a high temperature and wear resistant graphene coating, and the graphene coating is characterized by comprising the following components by weight percent: 35.0-60.0wt% of silicate, 0.01-20.0wt% of graphene, 0.1-25.0wt% of additive, and the balance of water as a solvent. The invention further provides a method for preparing the coating. The high temperature and wear resistant graphene coating disclosed by the invention can be used for well protecting matrixes by coating on pipelines, chemical equipment, storage, kiln furnace, medicine, aerospace and sewage, the service life of the matrix is prolonged, and the performance of the coating is much greater than that of a common material.

Owner:ZHUHAI LETONG NEW MATERIAL TECH CO LTD

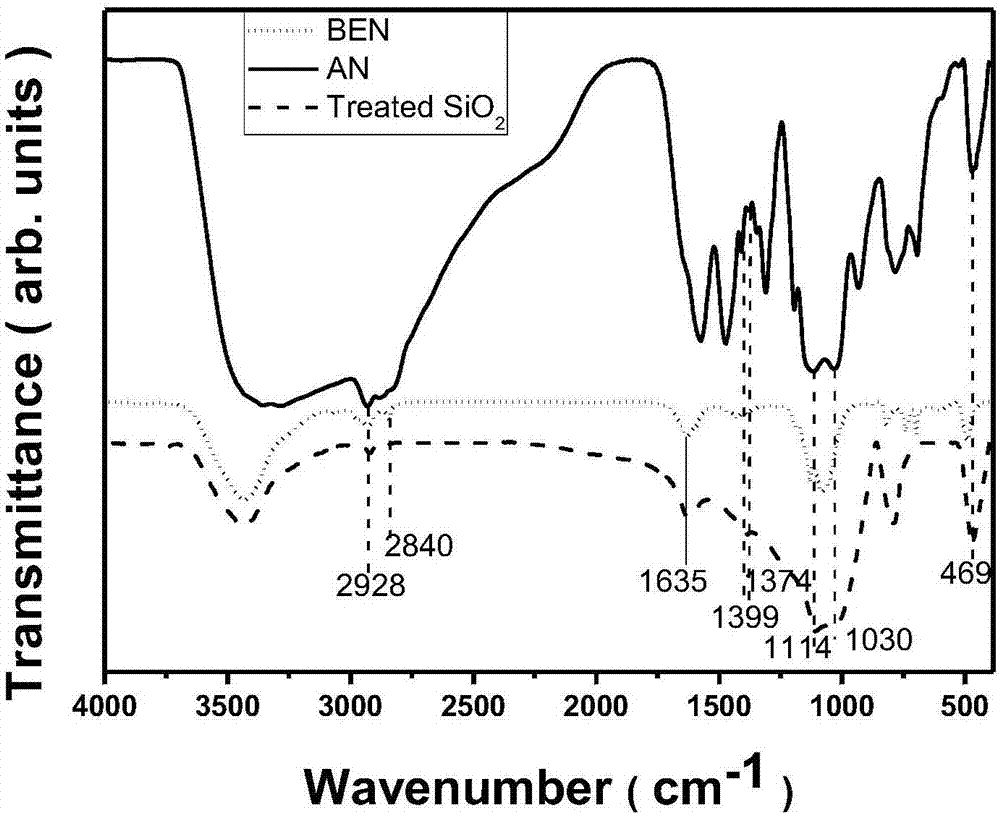

A preparing method of a ceramic-filled polytetrafluoroethylene microwave composite-medium substrate

A preparing method of a ceramic-filled polytetrafluoroethylene microwave composite-medium substrate is disclosed. The method includes 1) adding silicon dioxide ceramic powder into a liquid mixture of hydrogen peroxide and concentrated hydrochloric acid after the silicon dioxide ceramic powder is dried, and heating the mixture to 50-70 DEG C to obtain a suspension; 2) subjecting the suspension to suction filtration and drying a product in a vacuum environment; 3) adding the silicon dioxide ceramic powder obtained in the step 2) into a solution mixture of deionized water and absolute alcohol, adjusting the pH value to be 3-5, weighing a coupling agent the weight of which is 1.0-2.5% of the weight of the silicon dioxide ceramic powder, performing ball milling, and fully mixing the mixture to obtain a material mixture; 4) filtering and drying the material mixture to obtain modified silicon dioxide ceramic powder; 5) ball-milling and mixing the modified silicon dioxide powder, chopped glass fibers and polytetrafluoroethylene, and then performing demulsification to obtain dough; and 6) subjecting the dough to molding and hot-pressed sintering. The ceramic-filled material prepared by the method has a low dielectric constant (with epsilon being equal to 2.94), ultralow dielectric loss (with tg[delta] being less than 0.0008, 10 GHz), low water absorption (less than 0.02%) and a small thermal expansion coefficient (less than 20 ppm / DEG C).

Owner:汕头超声覆铜板科技有限公司

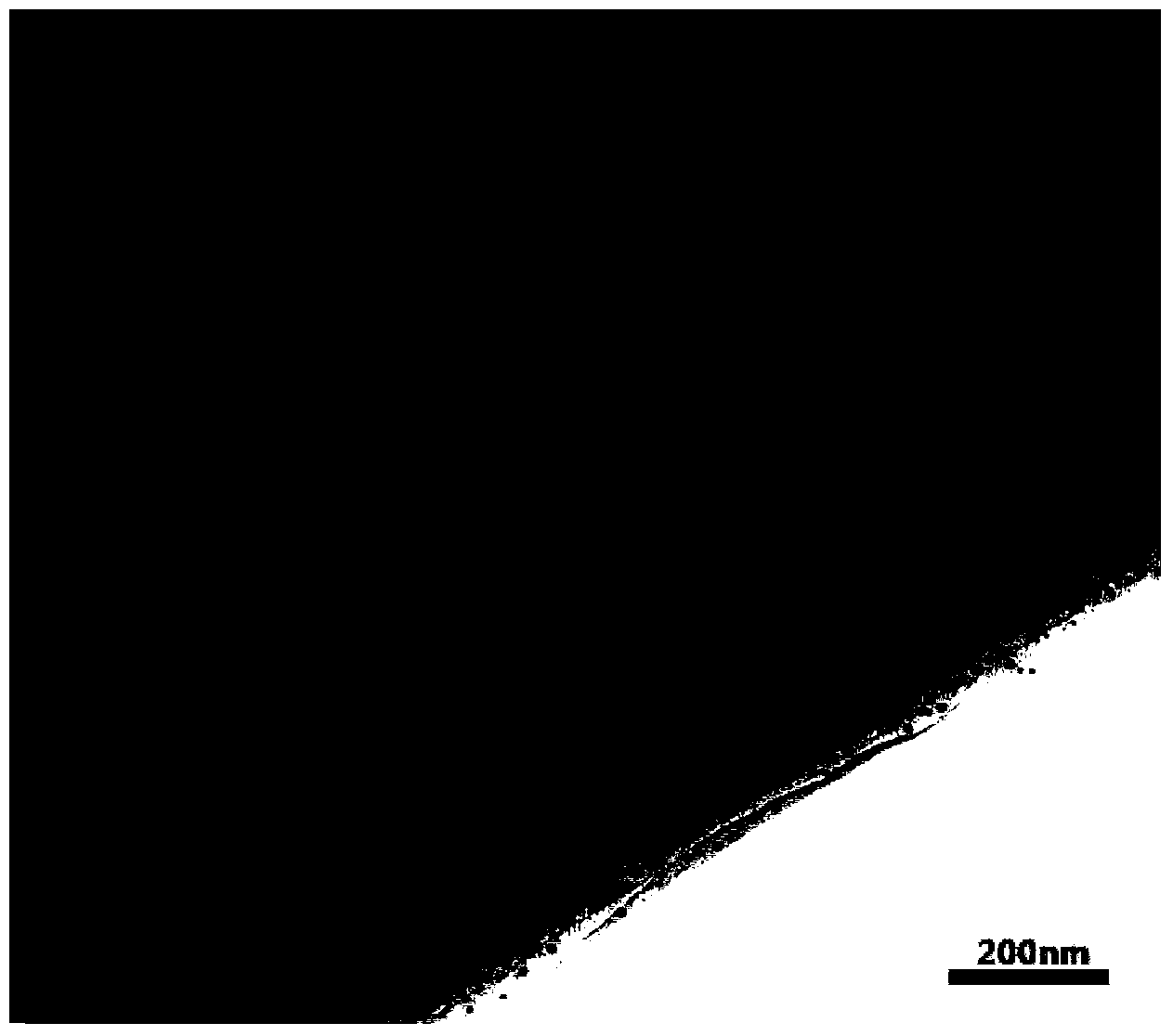

Nanocellulose/graphene composite flexible thin film as well as preparation method and application thereof

InactiveCN107915853AGood flexibilityImprove stabilityCatalyst carriersOrganic-compounds/hydrides/coordination-complexes catalystsElectrochemistryFlexible electronics

The invention discloses a nanocellulose / graphene composite flexible thin film as well as a preparation method and application thereof. According to the method disclosed by the invention, the surface of a graphene-shaped structure is uniformly coated with nanocellulose under the action of a hydrogen bond, Van der Waals force, a II-II bond and the like between a nanocellulose molecule and a graphenemolecule, so that a nanocellulose / graphene (CNC-G) composite flexible thin film with uniform distribution and a smooth surface is formed. The nanocellulose / graphene composite flexible thin film disclosed by the invention has good flexibility and transparency, can be uniformly dispersed in a solvent containing water and exists stably for a long time. The preparation method disclosed by the invention has the advantages of abundant raw material source, simple operation technology, low cost, greenness, environment friendliness, high efficiency and the like. The nanocellulose / graphene (CNC-G) composite flexible thin film disclosed by the invention has the advantages of high purity, uniformity in compounding and good composition structure and has a wide application prospect in the fields including flexible electronics, catalysis, electrochemistry and the like.

Owner:SOUTH CHINA UNIV OF TECH

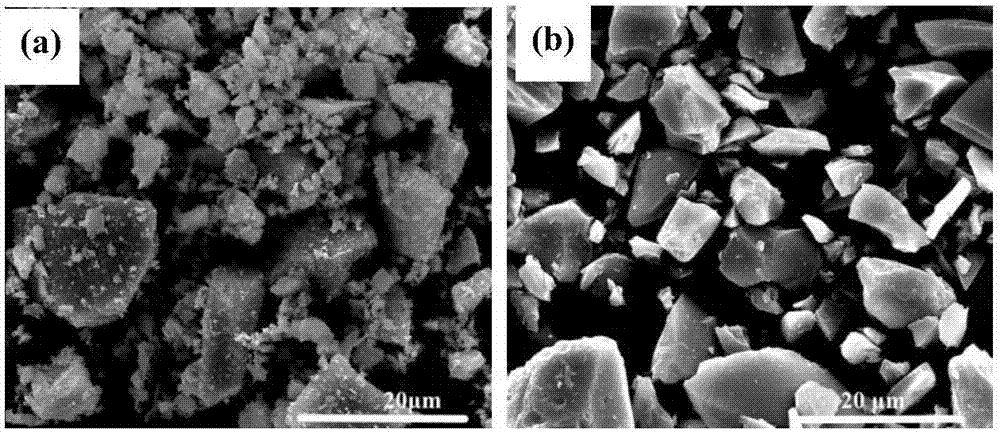

Graphene nano sheet and SnS2 composite nano material and synthesis method thereof

InactiveCN102142549ALarge specific surface areaStrong mechanical propertiesMaterial nanotechnologyCell electrodesSynthesis methodsTin

The invention discloses a graphene nano sheet and SnS2 composite nano material and a synthesis method thereof. The composite material is characterized by being formed by compounding a graphene nano sheet and a SnS2 nano material, wherein the substance amount ratio of the graphene nano sheet to the SnS2 nano material is 1:1-4:1. The preparation method comprises the following steps of: preparing a graphite oxide nano sheet from graphite by using a chemical oxidation method, then dissolving L-cysteine into deionized water, adding stannic chloride, and dissolving the stannic chloride with full stirring, wherein the molar ratio of the L-cysteine to the stannic chloride in the solution is 6:1-12:1; and adding the graphite oxide nano sheet into the solution, performing ultrasonic treatment so that the graphite oxide nano sheet is fully dispersed in the hydrothermal reaction solution, and synthesizing the graphene nano sheet and SnS2 composite nano material by a one-step hydrothermal method, wherein the mass ratio of the graphene nano sheet to the SnS2 nano material in the composite material is 1:1-4:1. The method has the characteristics of mild reaction condition and simple process. The synthesized graphene nano sheet and SnS2 composite nano material serving as an electrode material of a new energy battery or serving as other materials has wide application.

Owner:ZHEJIANG UNIV

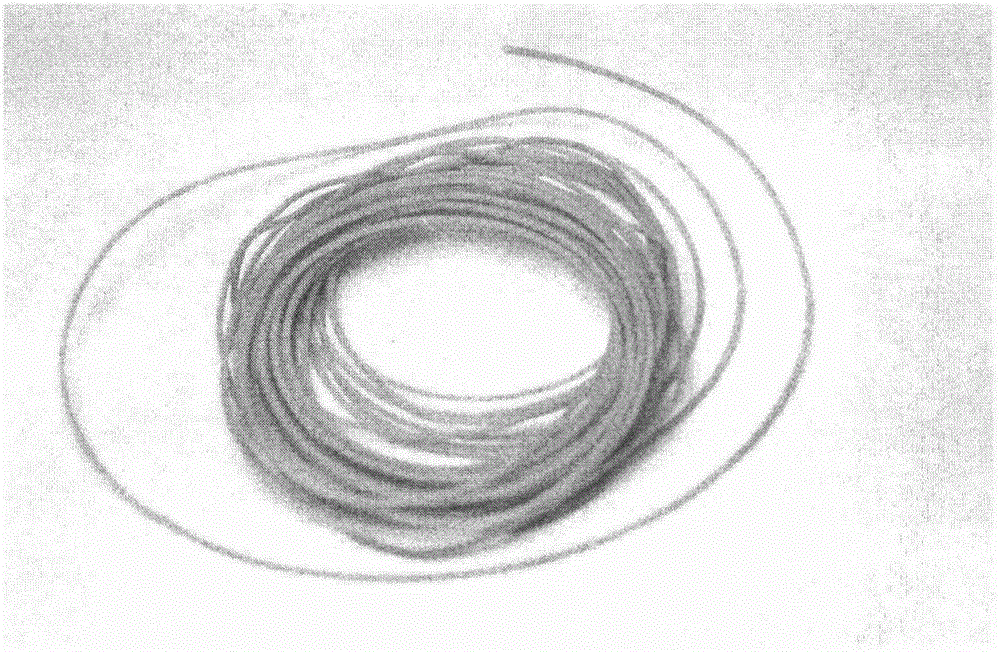

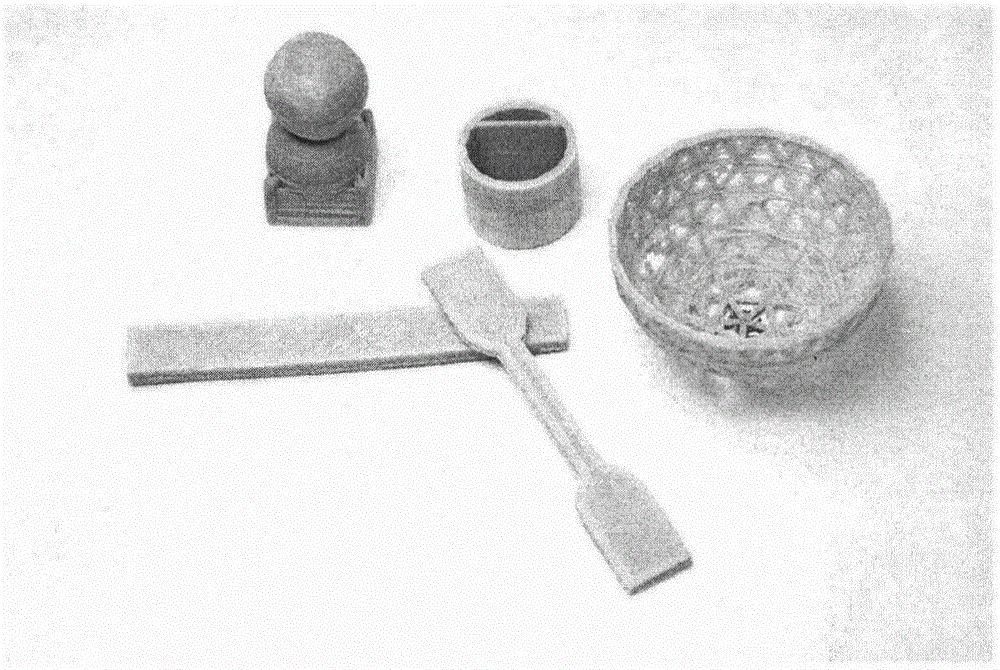

Preparation method of cellulose based 3D printing wire

The invention relates to a preparation method of a cellulose based 3D printing wire, and belongs to the field of biomass based 3D printing materials. The invention aims to provide a preparation method of a biomass based 3D printing material, which is low in production cost and can implement industrialization easily. The preparation method comprises the following steps: processing a cellulose raw material by virtue of polyethylene glycol (PEG:MW=400) in combination with a machine to prepare a cellulose polyethylene glycol dispersed solution smaller than 10 microns; flushing away polyethylene glycol by using dichloromethane to obtain a dichloromethane suspension of cellulose; adding a certain amount of silane coupling agent to perform surface silanization modification; adding modified cellulose, plasticizer polyethylene glycol and toughening agent solution into a dichloromethane solution of polylactic acid with certain concentration, mixing uniformly, and then recovering to remove a dichloromethane solvent by virtue of a condensing unit; and finally, performing extrusion molding at a certain temperature by virtue of a linear extrusion molding machine to prepare the cellulose based 3D printing wire.

Owner:NANJING FORESTRY UNIV

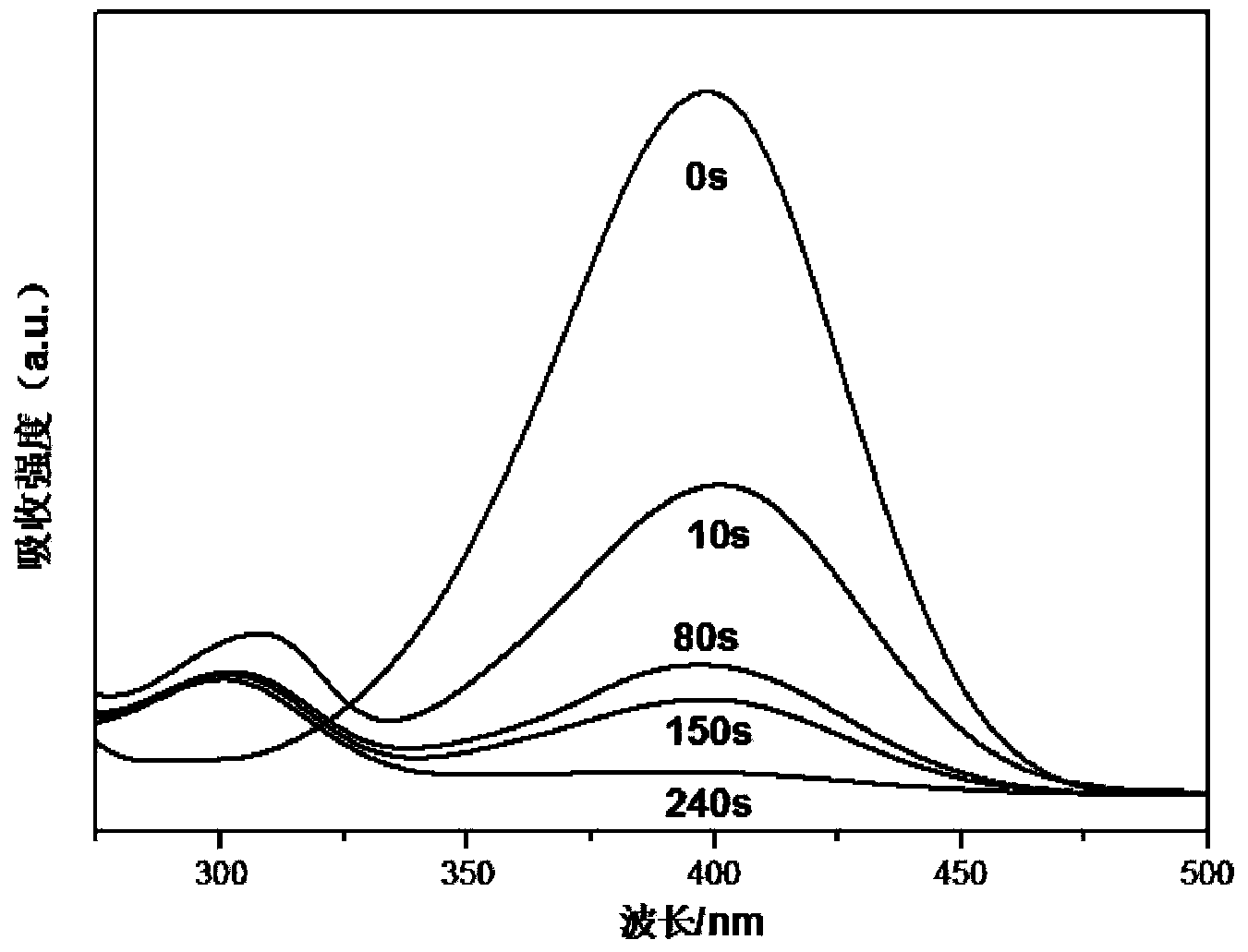

Method for preparing gold nano particle and graphene composite material through fast reduction

ActiveCN104227014AEvenly distributedSimple processMaterial nanotechnologyBiocompatibility TestingMaterials science

The invention discloses a method for preparing a gold nano particle and grapheme composite material through fast reduction. The method specifically comprises the steps of 1, preparing reduced grapheme oxide water solution by taking sodium borohydride as a reducer; 2, adding gold chloride acid in the reduced grapheme oxide water solution, and obtaining the gold nano particle and grapheme composite material in an in-situ reduction way by utilizing the reducibility of the grapheme through ultrasonic action under normal temperature; 3, centrifugally washing the obtained solution by using de-ionized water for multiple times so as to obtain the gold nano particle and grapheme composite material of which the dimension is uniform and the distribution is uniform. The method disclosed by the invention has the advantages that the technology is simple, the preparation period is short, the repeatability is strong, environment protection is realized, and a composite product is uniform and stable; the prepared gold nano particle and grapheme composite material has good stability in water solution and is not easy to reunite, and meanwhile, the method has the characteristics of multiple reaction active sites, large specific surface area, good biocompatibility, electric conduction and the like; the method has a wide application prospect in aspects of catalyzing, sensing, environment protection, SERS (Surface Enhanced Raman Scattering) and the like.

Owner:SOUTHEAST UNIV

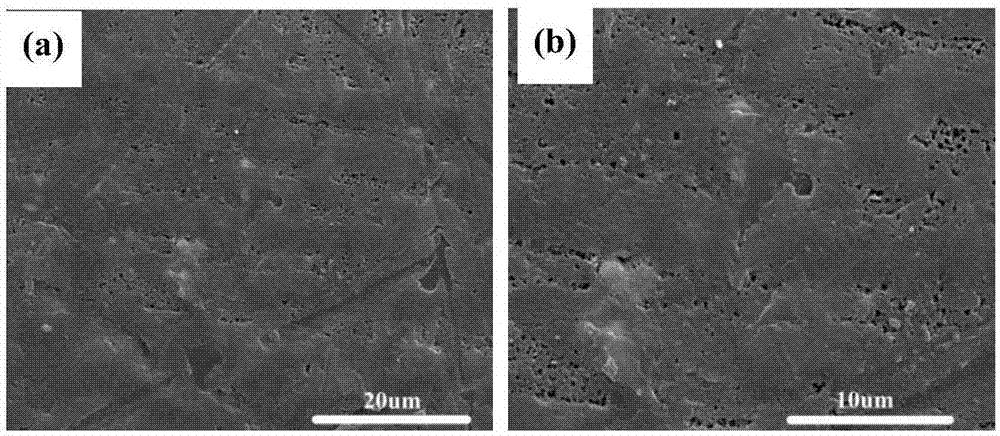

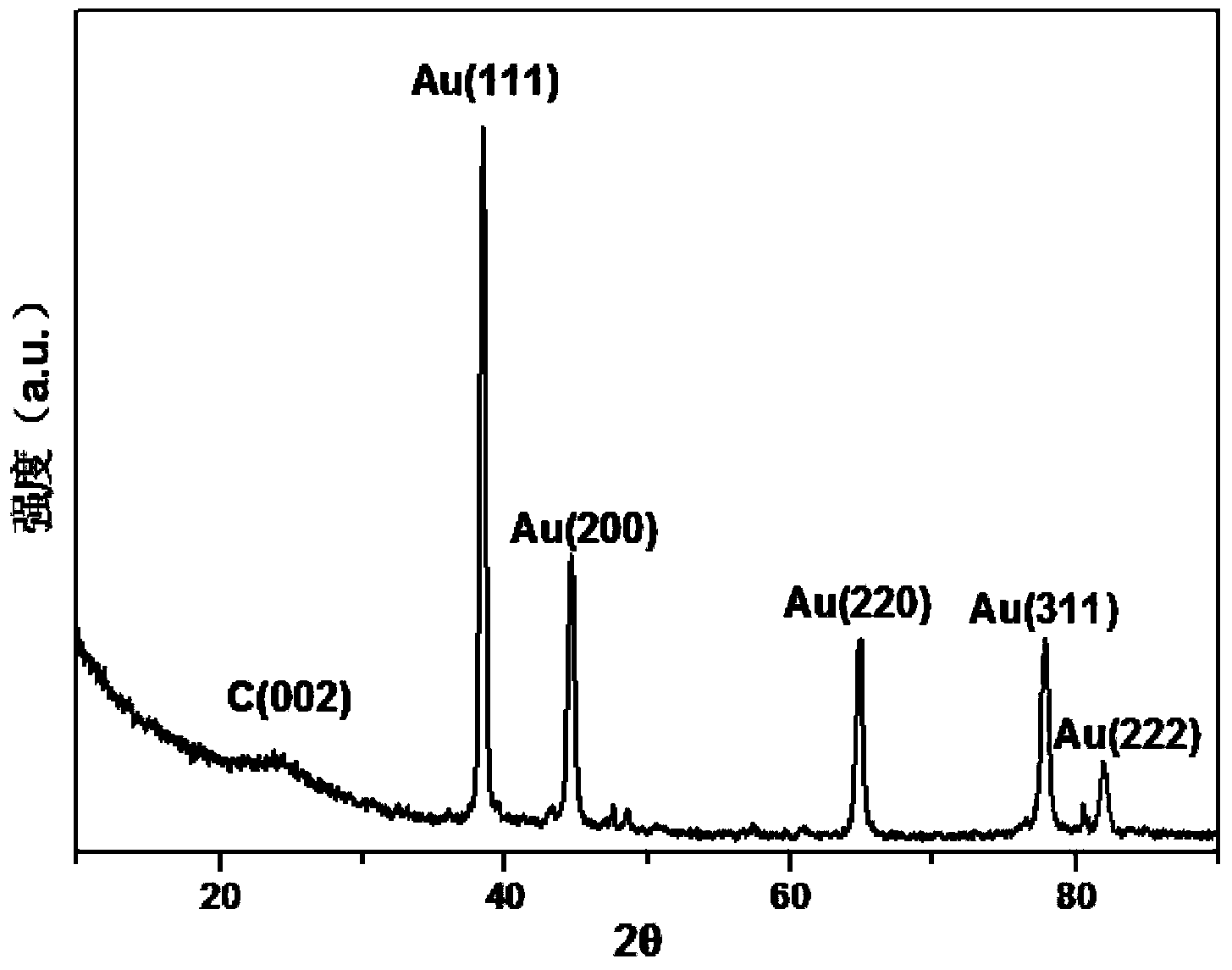

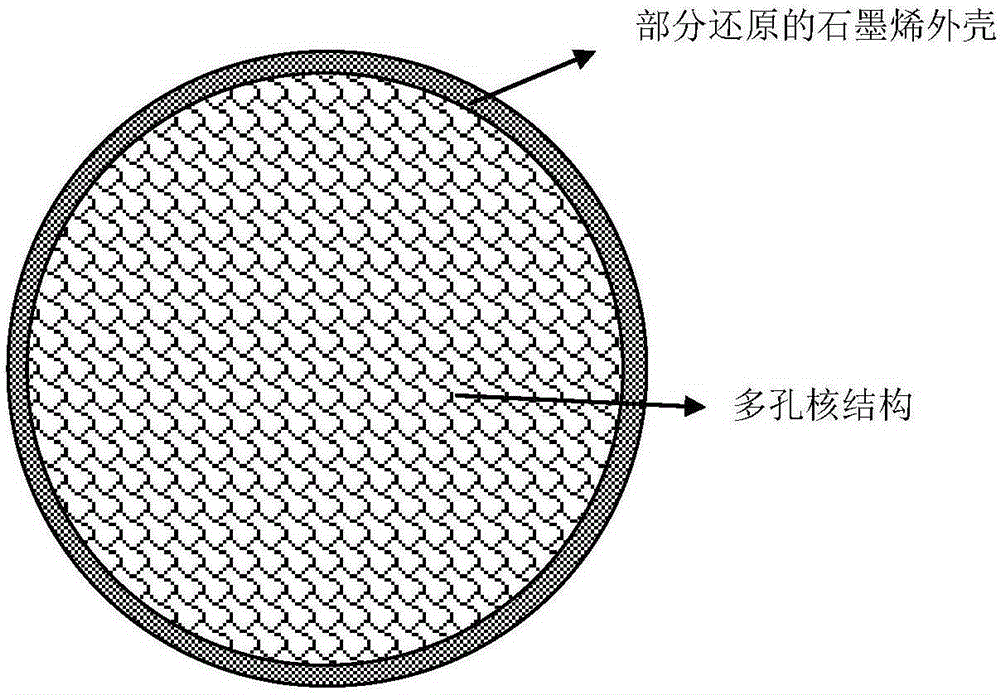

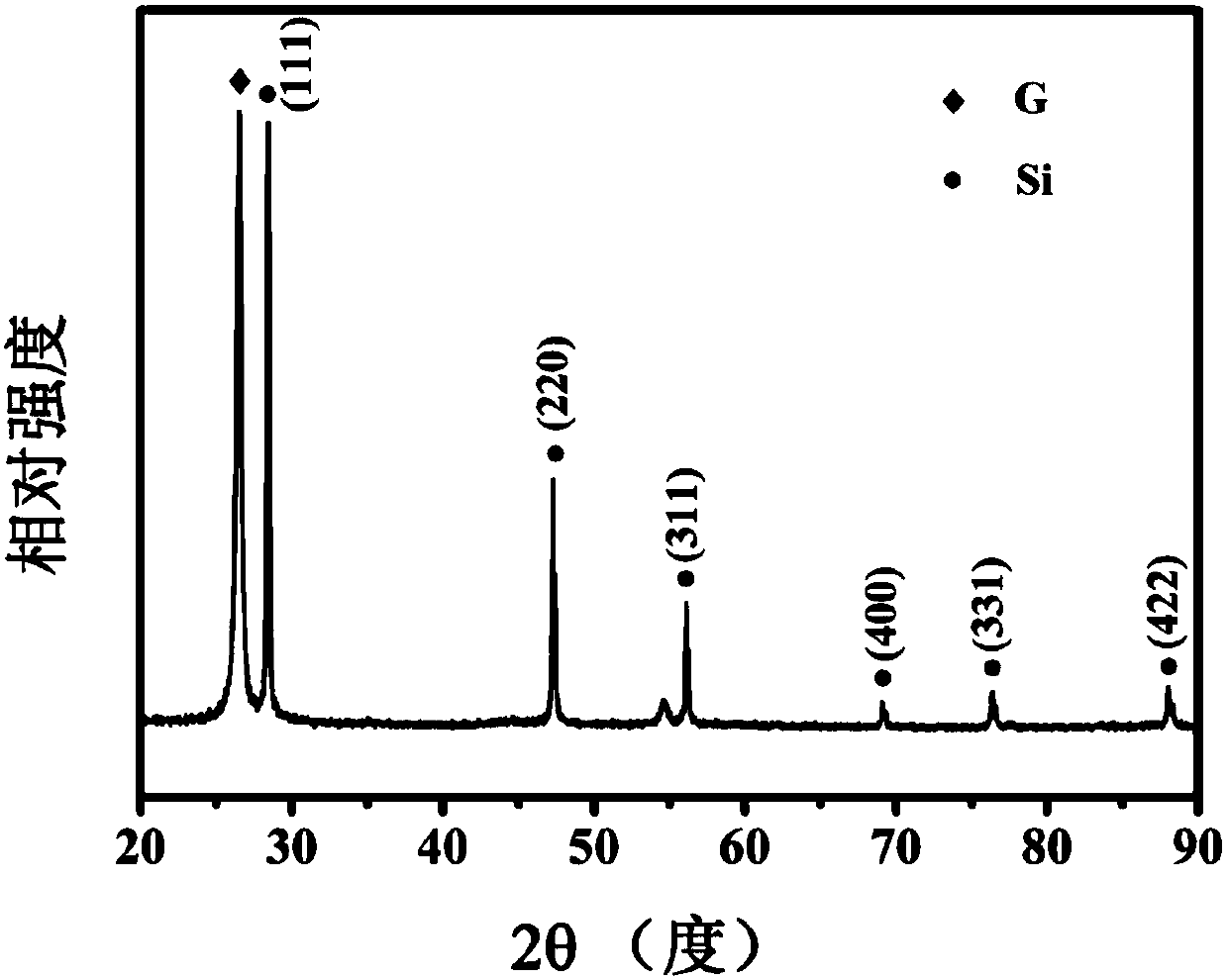

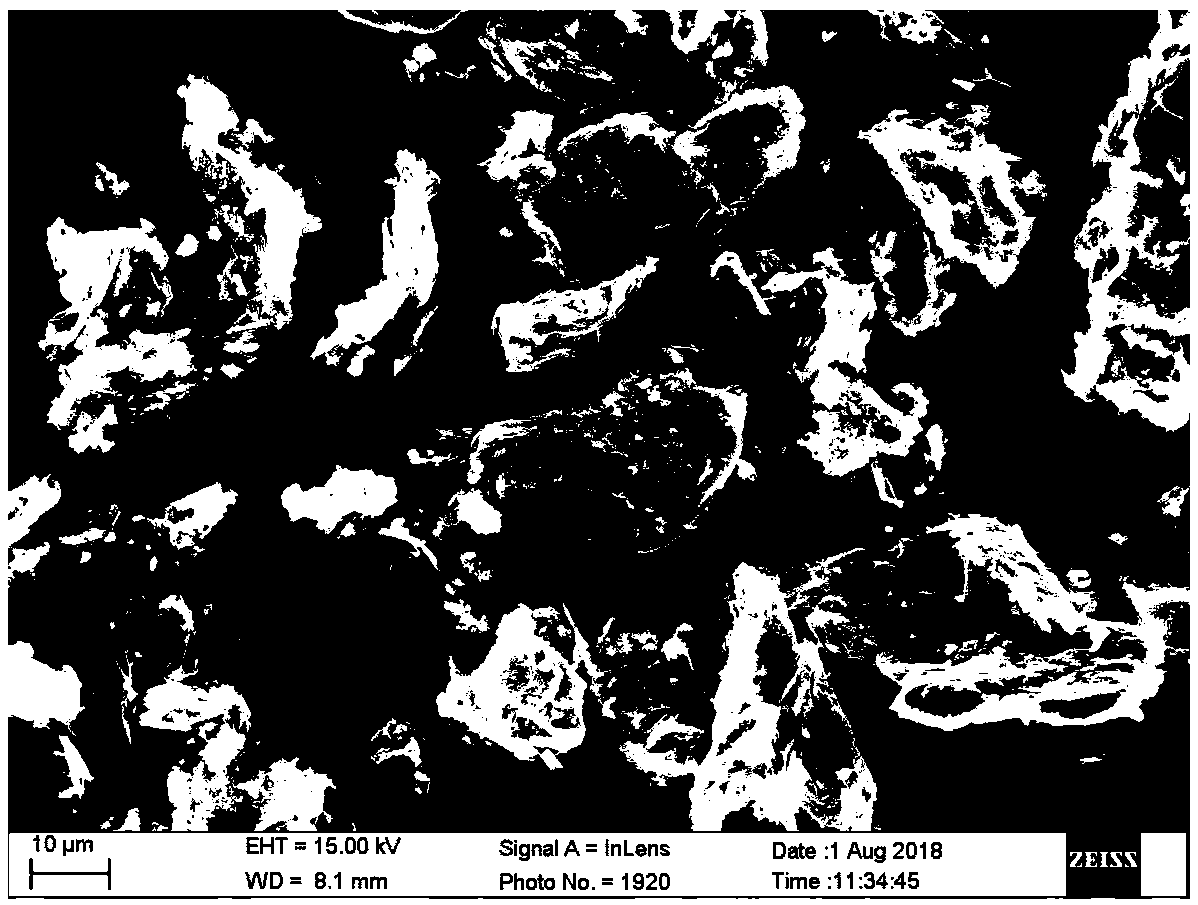

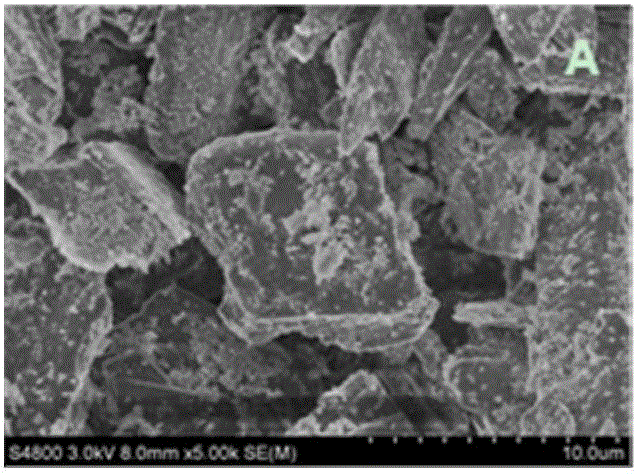

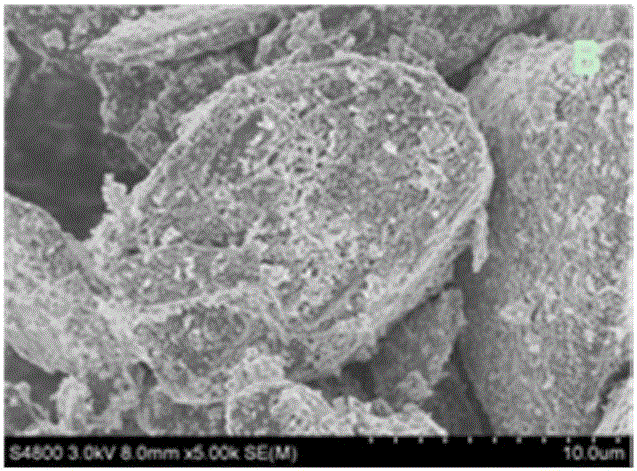

Graphene clad porous granular material and preparation method thereof

ActiveCN105226257AComposite uniformImprove conductivityCell electrodesSecondary cellsCvd grapheneEtching

The invention discloses a graphene clad porous granular material and a preparation method thereof. By utilizing the in-situ reduction action of active metal on graphene oxide, partial reduction of the graphene oxide is realized in graphene oxide aqueous solution as well as cladding on the granular material, and the clad material is alloy grains (such as silicon alloy of aluminum, magnesium, ferrum, nickel and the like), of metal and silicon; moreover, reduction can be performed on the graphene oxide by metal elements; selective etching is performed on metal phases in the alloy grains clad with graphene through dealloying to realize the porous granular material. According to the structure of graphene clad porous silicon obtained by the method disclosed by the invention, not only can direct contact between electrolyte and the silicon be avoided but also the electrical conductivity of the silicon material can be improved, therefore the formation of excessive solid electrolyte thin films is avoided, and the electrochemical performance is improved truly.

Owner:SHANDONG UNIV

High-strength and high-conductivity graphene reinforced copper matrix composite material, preparation method and application thereof

ActiveCN108145169AIncrease mechanical stirringImprove drying efficiencyTransportation and packagingMetal-working apparatusHot isostatic pressingElectronics

The invention relates to the technical field of composite material preparation, in particular to a high-strength and high-conductivity graphene reinforced copper matrix composite material and a preparation method and application thereof. Spherical copper powder is used as a matrix material, graphene is used as a reinforcing phase, through the steps such as graphene liquid phase dispersion, ball milling predispersion, surface coating, hot isostatic pressing, hot extrusion and so on, and the high-strength and high-conductivity graphene reinforced copper matrix composite material with nearly fulldense, good conductivity, high tensile strength, high hardness, and high elongation is prepared. The preparation method has good process controllability and is easy to produce on a large scale. The prepared high-strength and high-conductivity grapheme reinforced copper matrix composite material is uniform in structure, the graphene is in good combination with the interface of a matrix, the performance is stable, and great application prospects in the fields of automobiles, aerospace and electronics are obtained.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

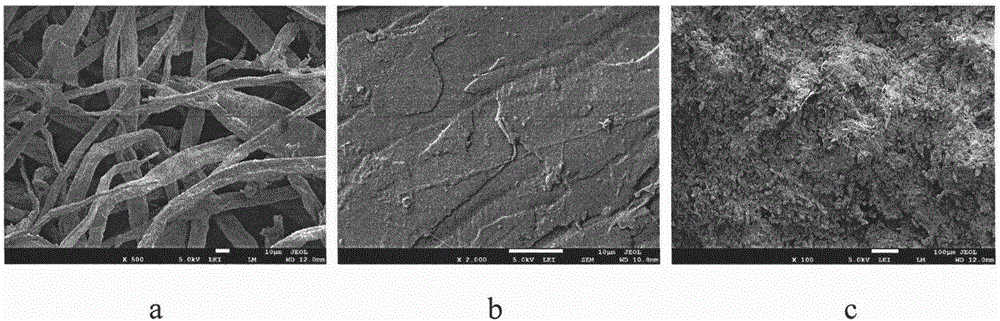

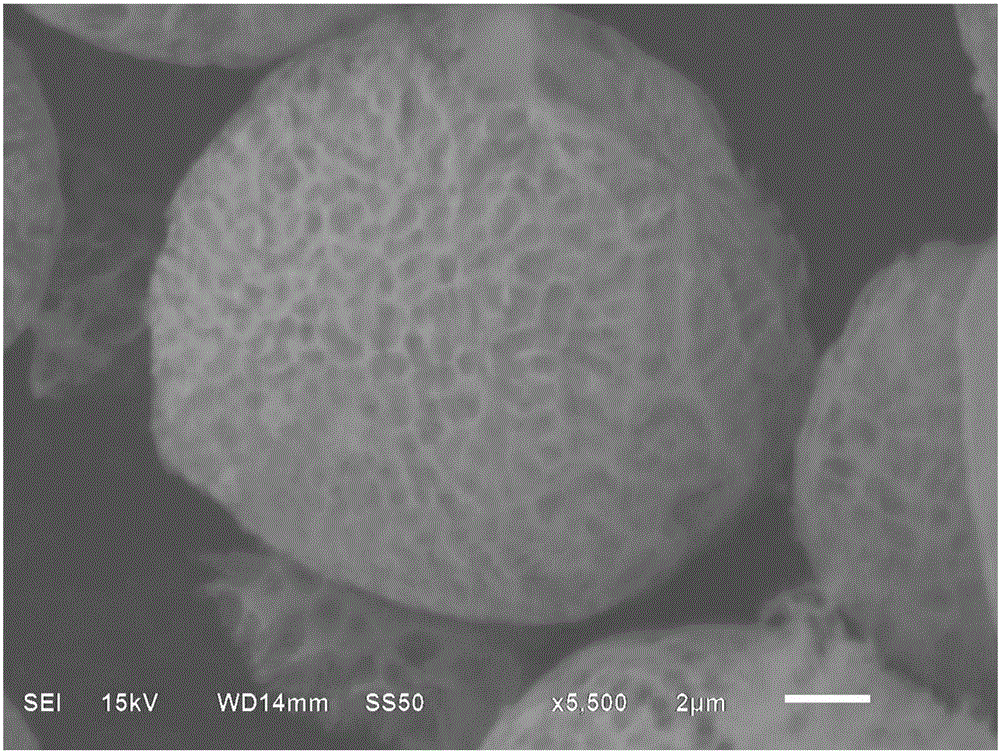

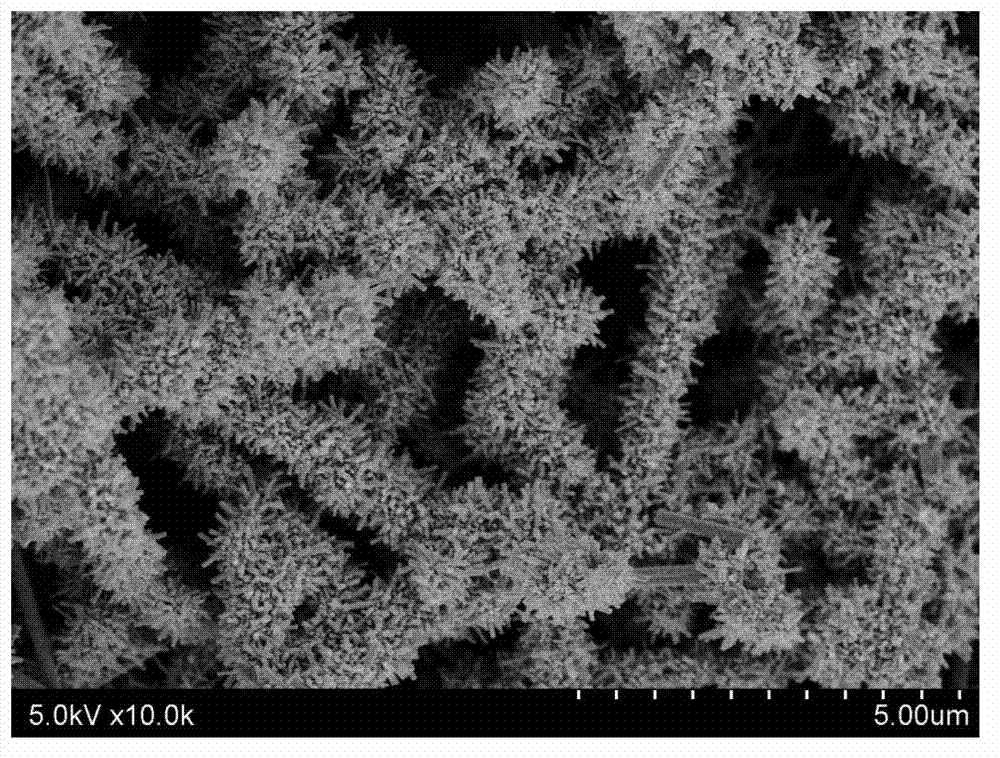

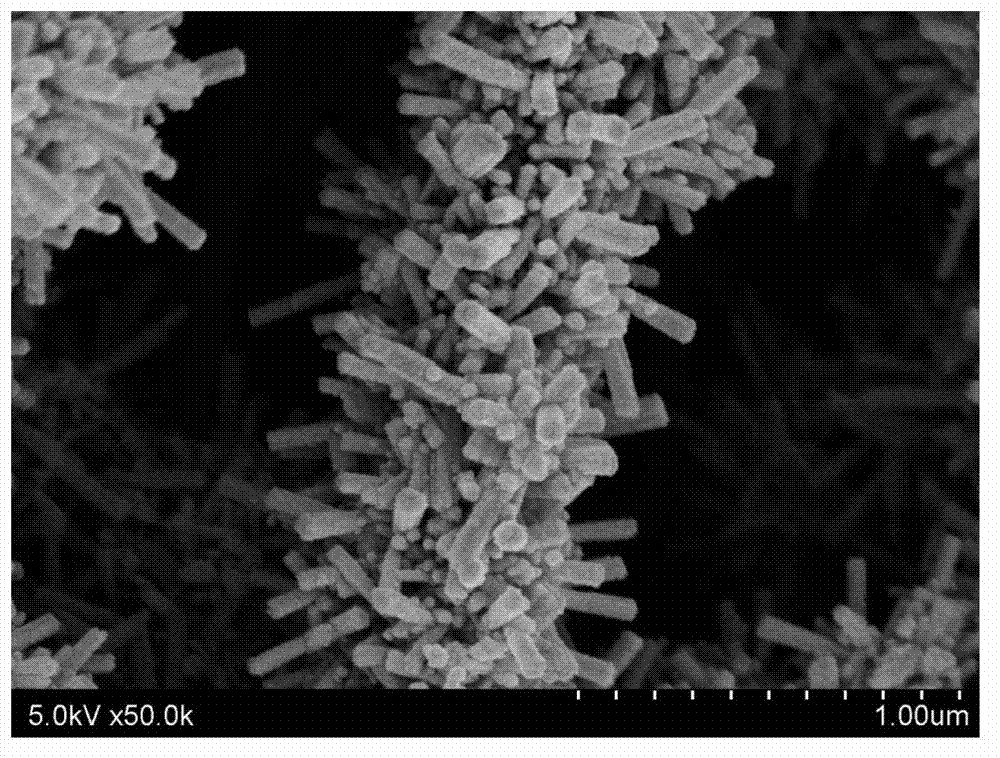

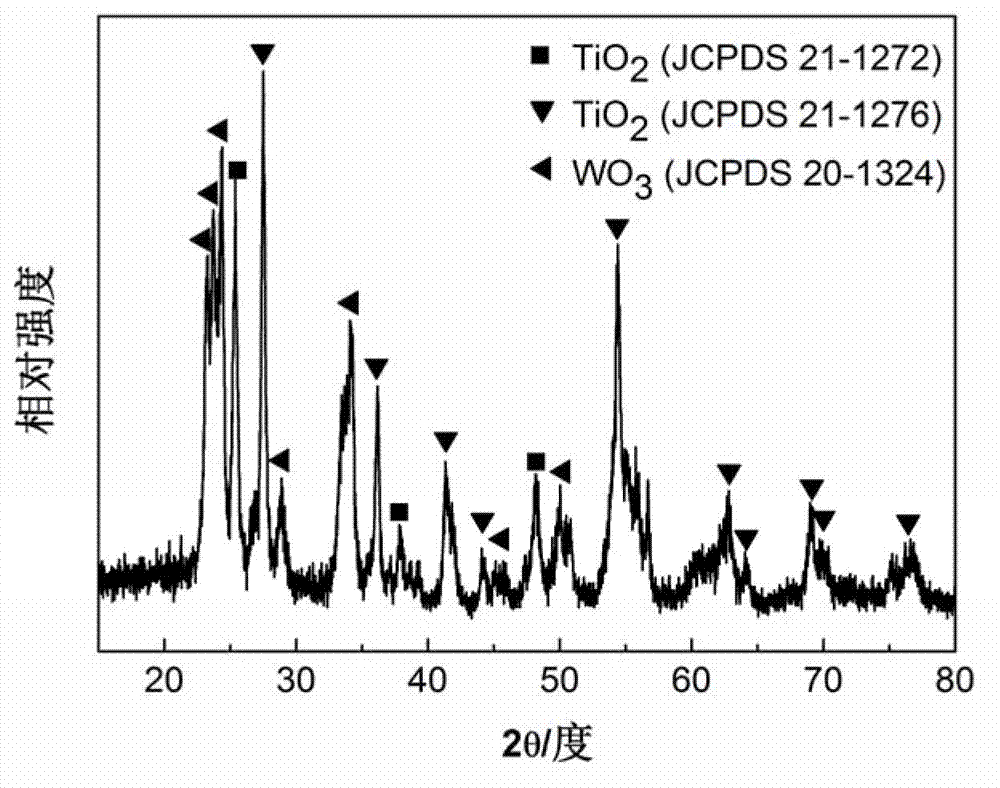

Preparation method of nano fiber containing TiO2/WO3 heterojunction

InactiveCN102926030ASimple methodComposite uniformInorganic material artificial filamentsFilament/thread formingSolventChemistry

The invention relates to a preparation method of a nano fiber containing TiO2 / WO3 heterojunction. The preparation method comprises the following steps of (1) adding soluble titanium salt into a mixed solvent of PVP (Poly Vinyl Pyrrolidone), absolute ethyl alcohol and acetic acid, and obtaining inorganic TiO2 nano fiber by adopting an electrostatic spinning and calcining method; and sequentially adding H2O2 and H2O in tungstic acid powder, and obtaining colorless and transparent WO3 sol; (2) preparing TiO2 nano fiber containing WO3 seed crystal by adding the TiO2 nano fiber into the WO3 sol; and (3) adding the WO3 sol, HMT (Hexamethylenetetramine) and water into the TiO2 nano fiber containing the WO3 seed crystal, and keeping warm for 6-12 hours under 120-180 DEG C; and drying a product which is obtained after hydrothermal in low temperature after centrifuging and water washing, and thus obtaining the nano fiber containing the TiO2 / WO3 heterojunction can be obtained. The preparation method disclosed by the invention is simple and practical, the composition of the TiO2 and the WO3 is more uniform and fuller, a large amount of contact interfaces can be formed, and the catalyzing ability can be increased.

Owner:DONGHUA UNIV

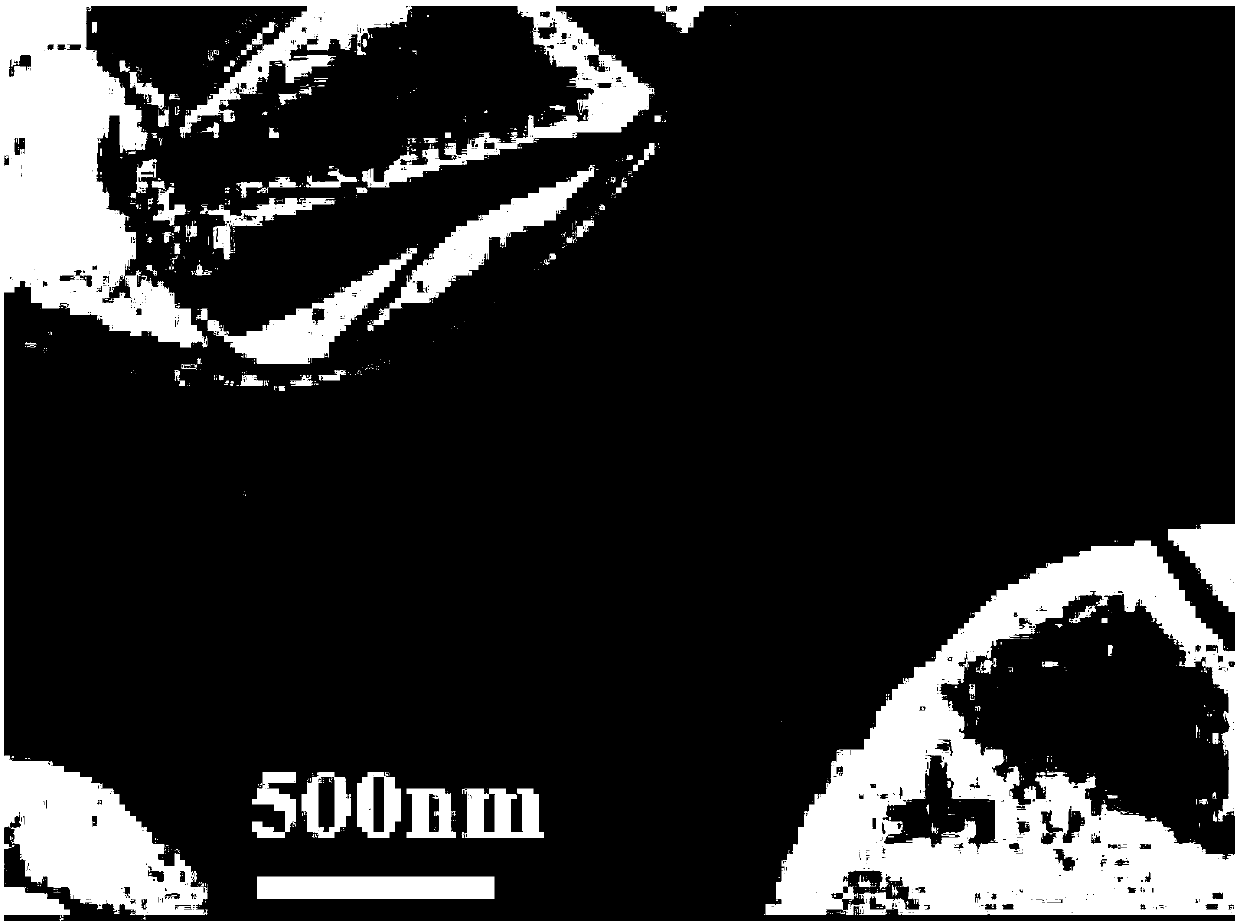

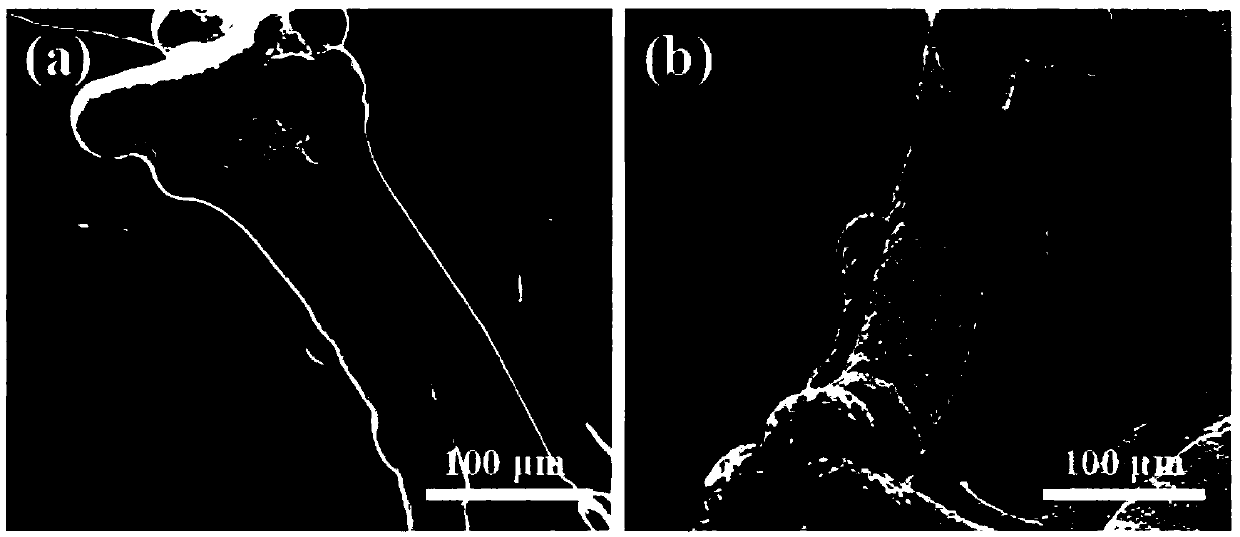

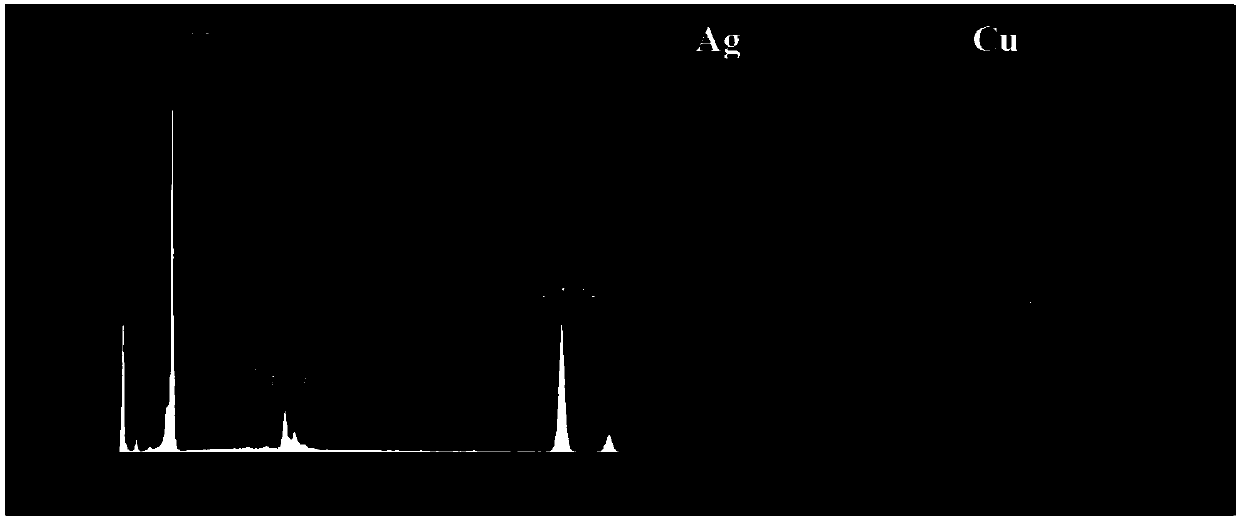

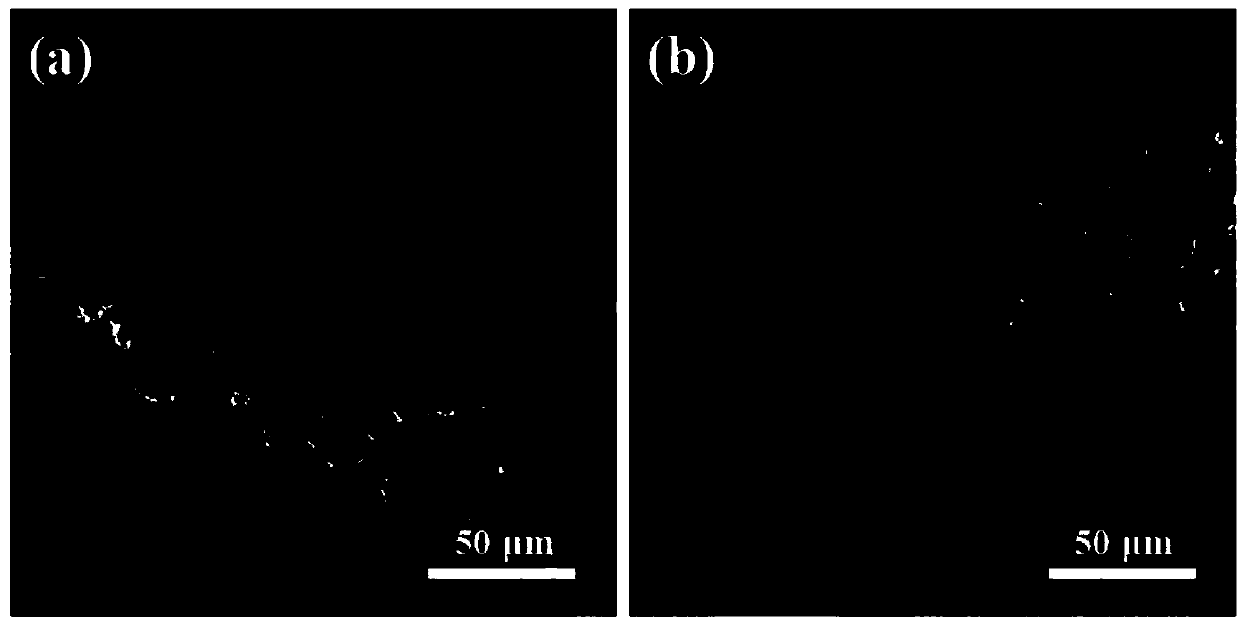

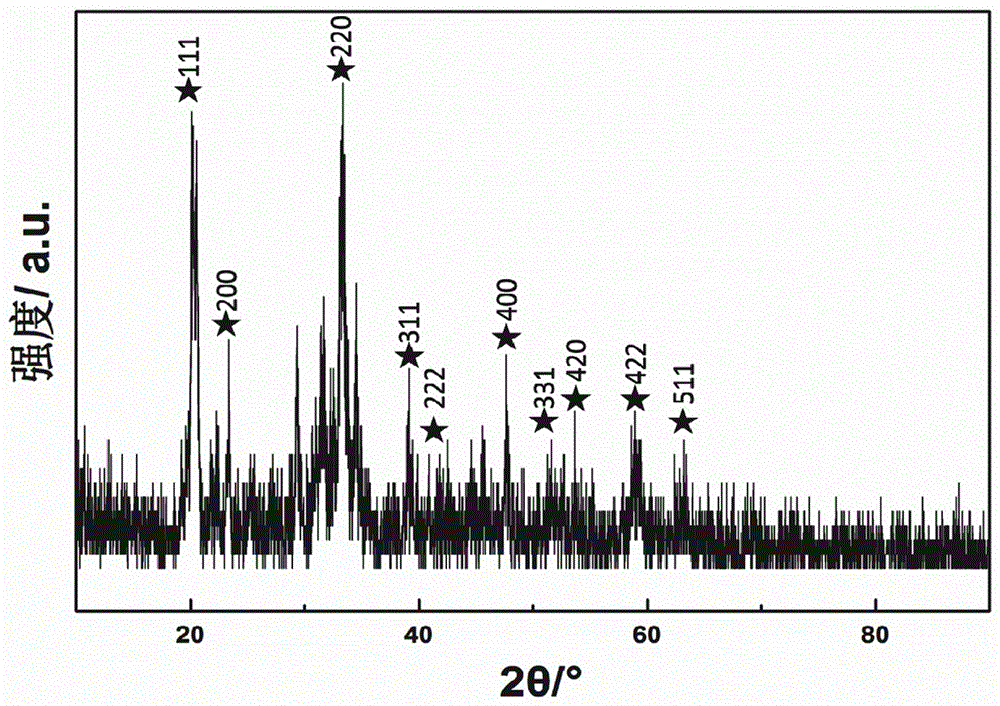

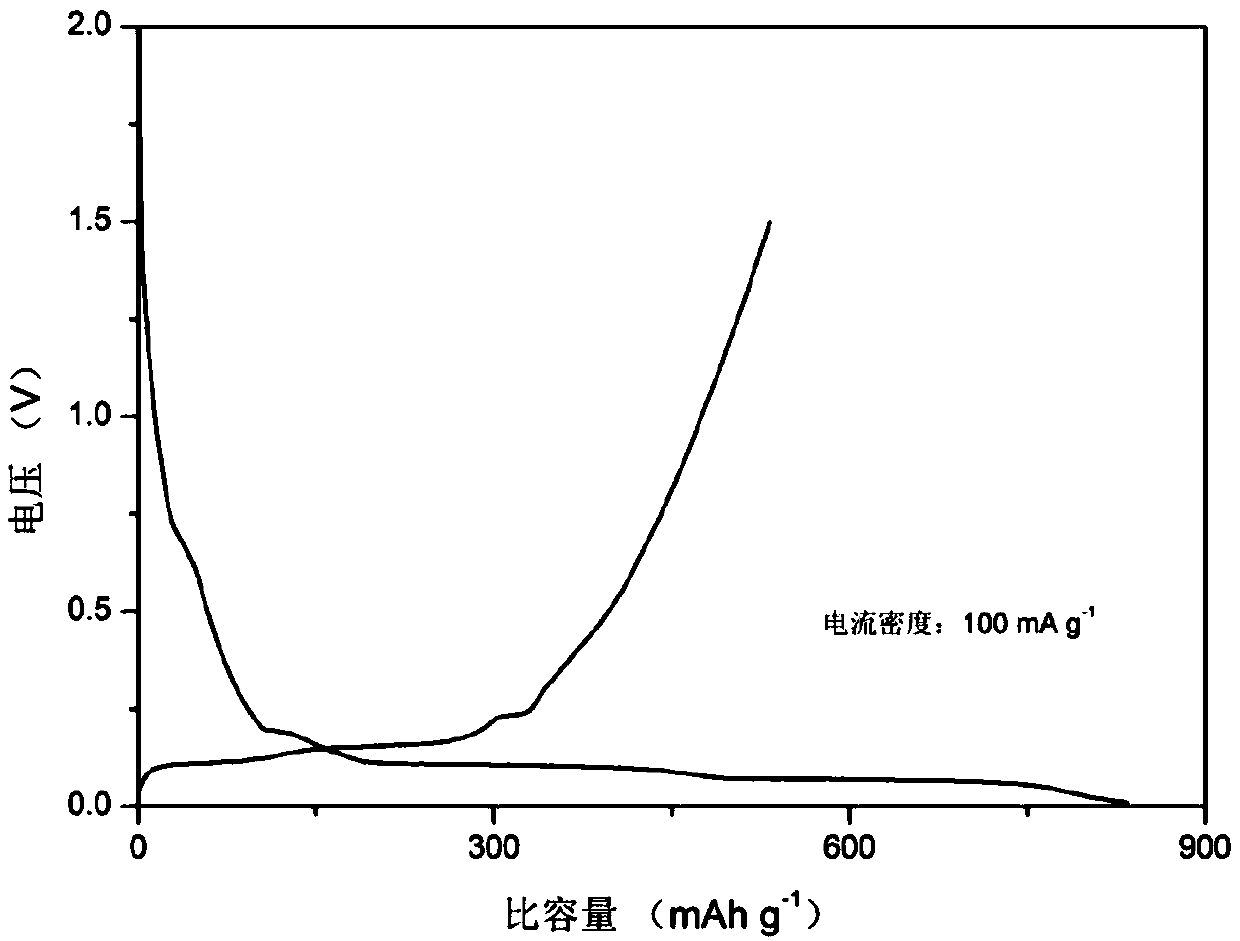

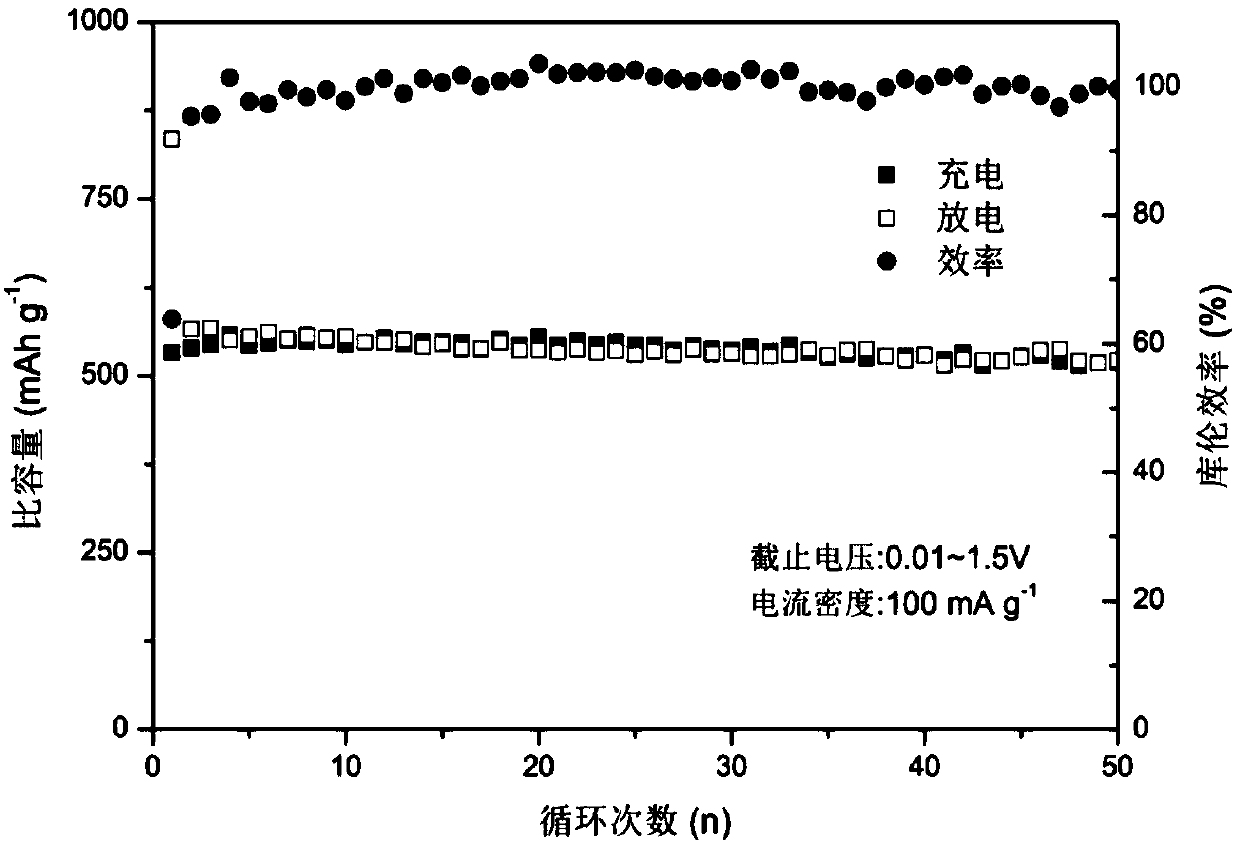

3D lithium-philic porous metal current collector, negative electrode, and preparation and application thereof

ActiveCN110828829AImprove cycle lifeTake advantage ofElectrode carriers/collectorsLi-accumulatorsLithium metalOverpotential

The invention belongs to the field of a lithium battery electrode material and particularly discloses a 3D lithium-philic porous metal current collector. The current collector comprises a 3D porous metal current collector and at least one of gold, silver and platinum compounded on a framework of the 3D porous metal current collector. The invention further discloses a preparation method and an application of the metal current collector. A 3D lithium-philic porous lithium ion negative electrode is particularly prepared. The current collector is advantaged in that at least one metal of gold, silver and platinum on the porous metal framework reduces the overpotential in the lithium metal nucleation and deposition process, uniform deposition and dissolution of lithium metal in the continuous cycle process are realized, growth of dendrites is effectively avoided, and the cycle life of a lithium metal battery is greatly prolonged.

Owner:CENT SOUTH UNIV

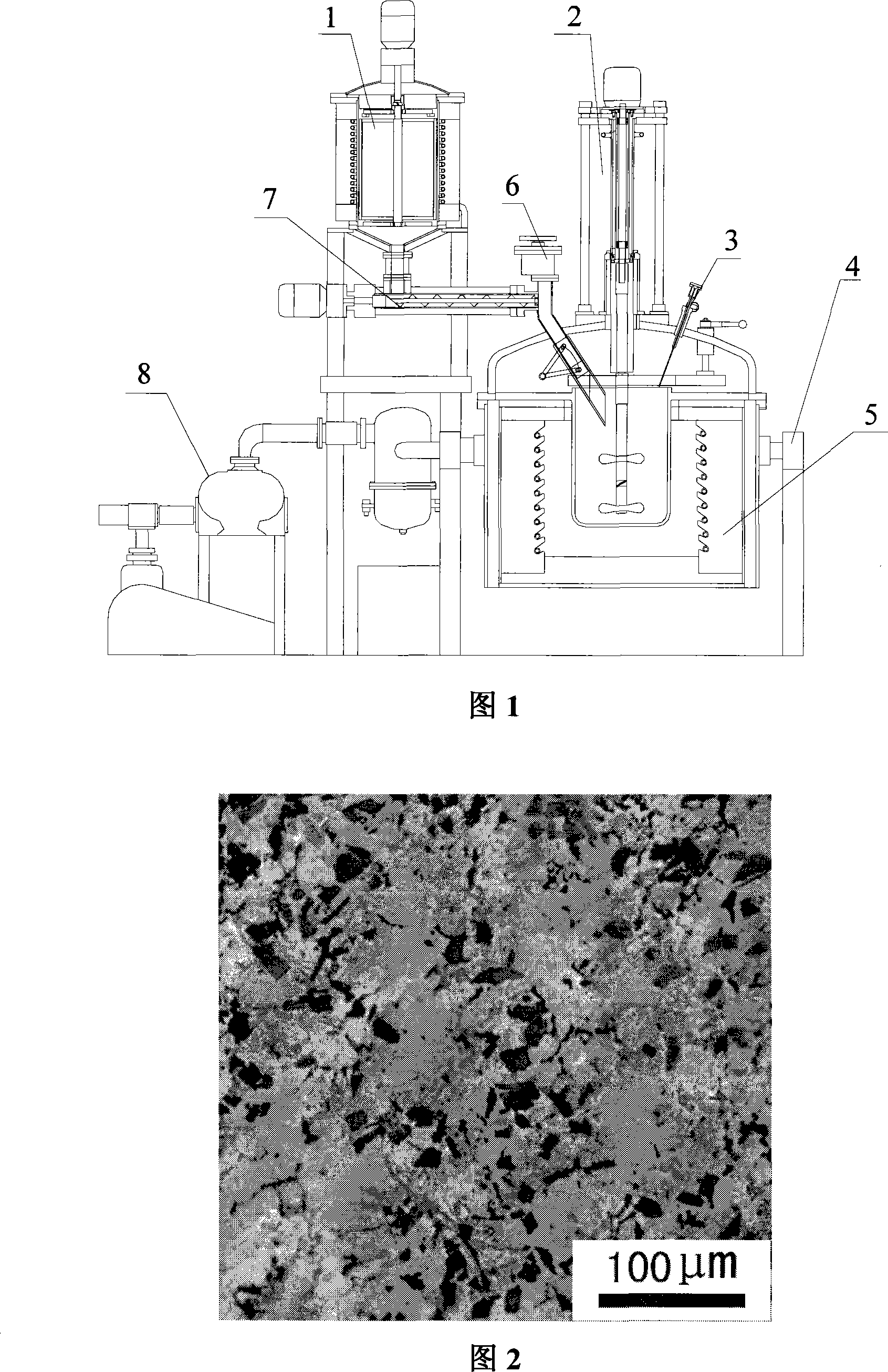

Vacuum stirring composite granule reinforcing aluminium-based composite material and preparation technique thereof

The invention relates to a composite material of vacuum churning composite granule enhanced aluminum matrix and a preparation technique, which comprises: Si 0-15Wt%, Mg 0-1.5Wt%, Cu 0-2.0Wt%, Mn 0-1.0Wt%, Cr 0-0.4Wt%, Ti 0-0.2Wt%, SiC 0.1-20% (volume proportion). Firstly base alloy is smelted, slag is removed, and refined, churned slowly in vacuum to complete degassing procedure for base melt, the pre-treated enhanced granule is continuously added into the aluminum base melt, mechanical churning to roll the granule into the melt, after the granule is completely rolled in the melt, strong churning and slow churning in reverse direction are conducted so as to disperse the granule evenly in the base; the temperature raises, modifier and refiner are added; the vacuum is dismounted, and placed in static, the floating slag is removed above the melt, and cast. The composition between the granule and the base is realized via vacuum mechanical churning, the joining interface is good, the enhanced granule is evenly dispersed in the base, the prepared composite material has low porosity rate, which is easy to realize industrial mass production.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND +1

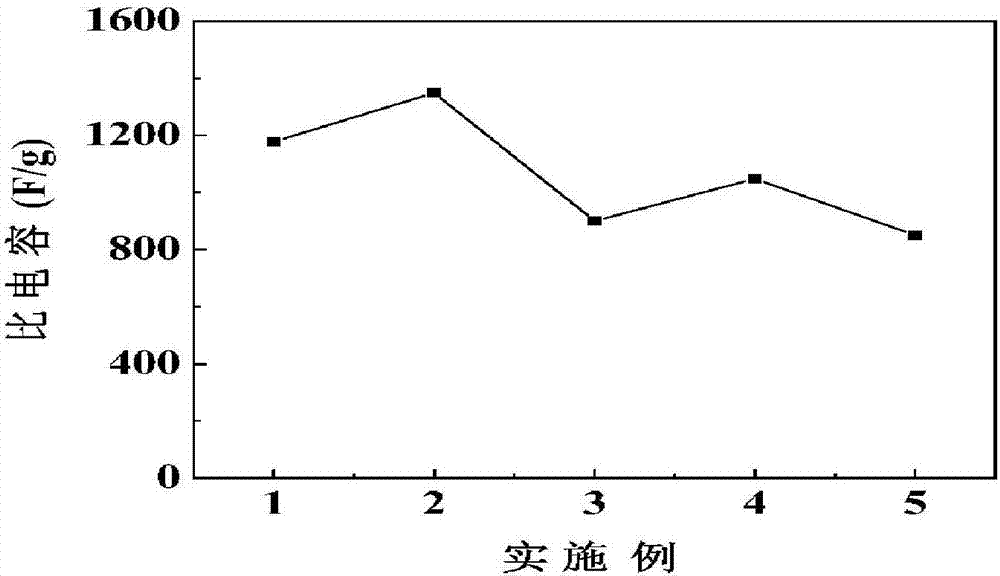

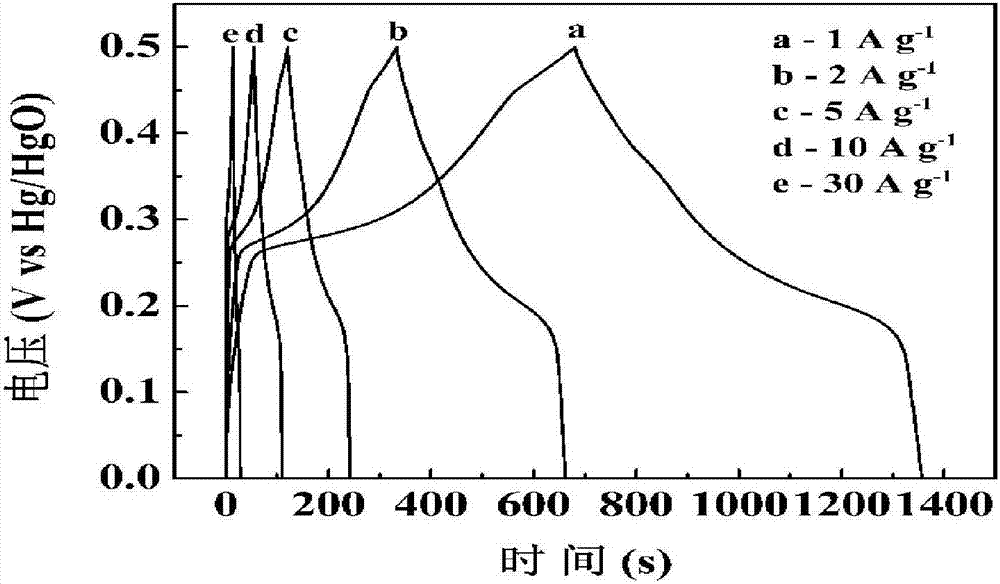

Method for preparing supercapacitor electrode material through cobalt-nickel bimetallic oxide and graphene

InactiveCN106935419ARealize the assemblyOptimal Control StructureHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceGraphene nanocomposites

The invention discloses a method for preparing supercapacitor electrode material through cobalt-nickel bimetallic oxide and graphene. According to the method, cobalt-nickel bimetallic hydroxide is stripped in deionized water, and graphene oxide having negative charges and the cobalt-nickel bimetallic hydroxide having positive charges are heterogeneously assembled so that compounding of the graphene oxide and the cobalt-nickel bimetallic hydroxide at the nanoscale can be realized. The reaction is controllable, and the prepared layered cobalt-nickel oxide and graphene nanocomposite material has great uniformity and has high specific capacitance, great rate performance and ultra-long cycle life when it is used for the supercapacitor electrode material so as to be wide in application prospect.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Fuel cell film electrode and preparation method thereof

ActiveCN101557001AImprove flatnessNo slurry penetration issuesCell electrodesCell component detailsPtru catalystMaterials science

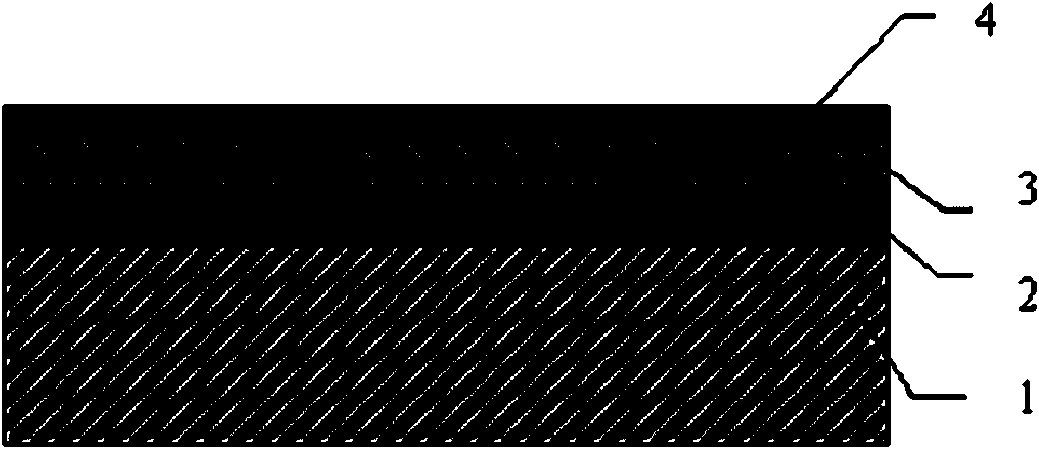

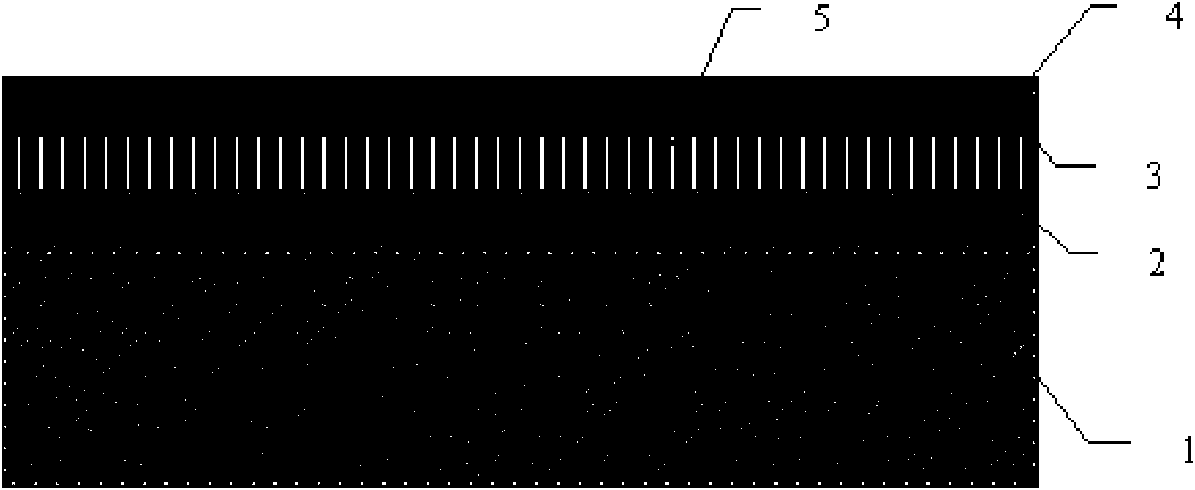

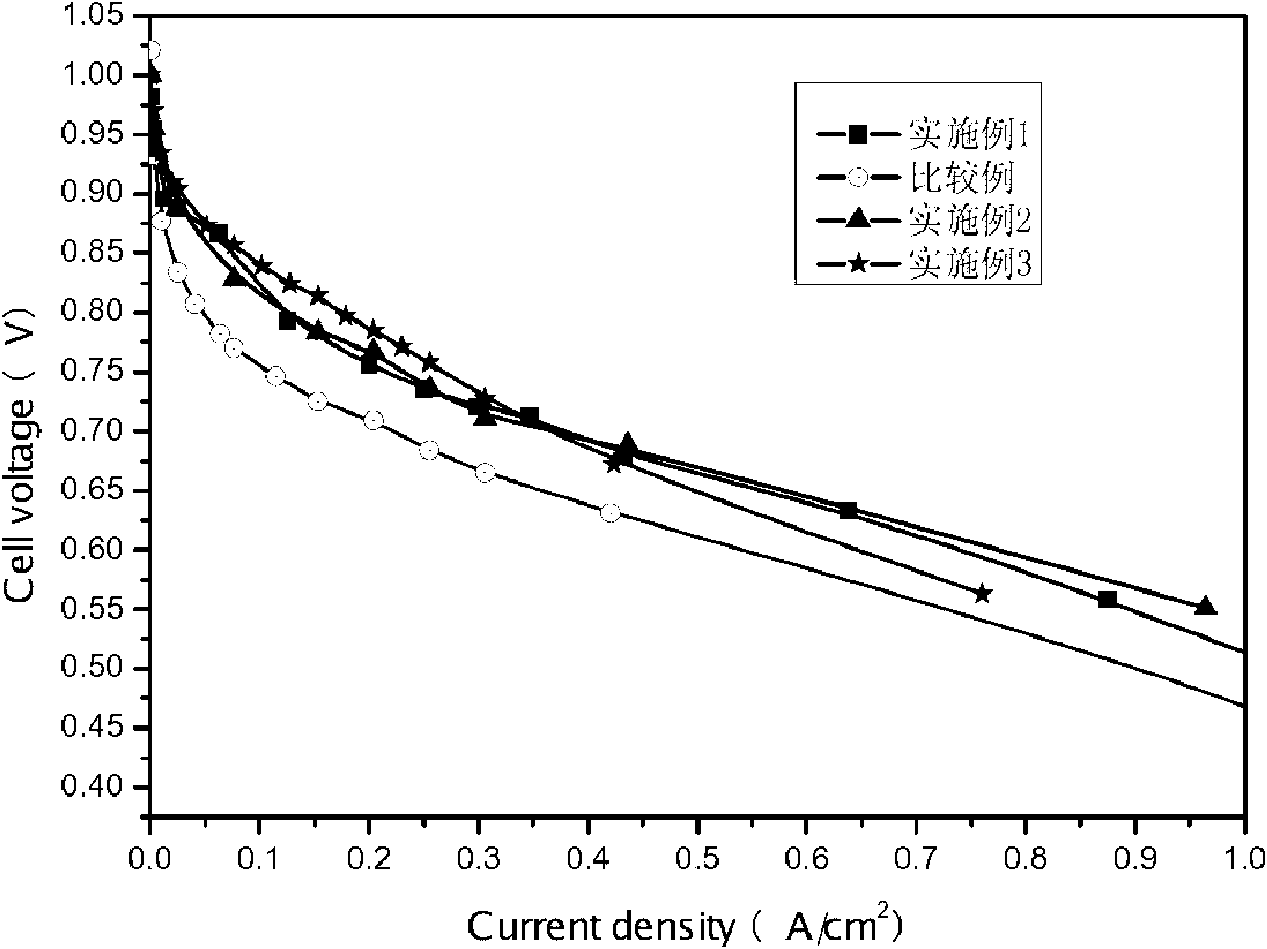

The invention discloses a fuel cell film electrode and a preparation method thereof. The film electrode comprises a gas diffusion layer and catalysis layers, wherein, the catalysis layer is of multilayer composite structure and is mainly composed of a catalytic active metal, a water repellent and a conductive ion polymer, wherein, the conductive ion polymer has different contents among the catalysis layers; the multilayer composite structure has at least two layers, wherein, the first layer is a partial hydrophobic catalysis layer while the second layer is a hydrophilic catalysis layer. The invention further discloses a preparation method of the fuel cell film electrode, wherein, the diffusion layer is prepared by the dry method, the inventive film electrode structure has better water-gasmanagement ability, more uniform and stabler mass transfer and excellent electron and proton conducting ability, thus increasing the utilization rate of catalysts and enhancing electric output performance of the fuel cell.

Owner:HANERGY TECH

Explosive welding method for copper-aluminum composite material

ActiveCN103706940AReduce direct impactEvenly distributedWelding/soldering/cutting articlesMetal working apparatusEngineeringAluminum composites

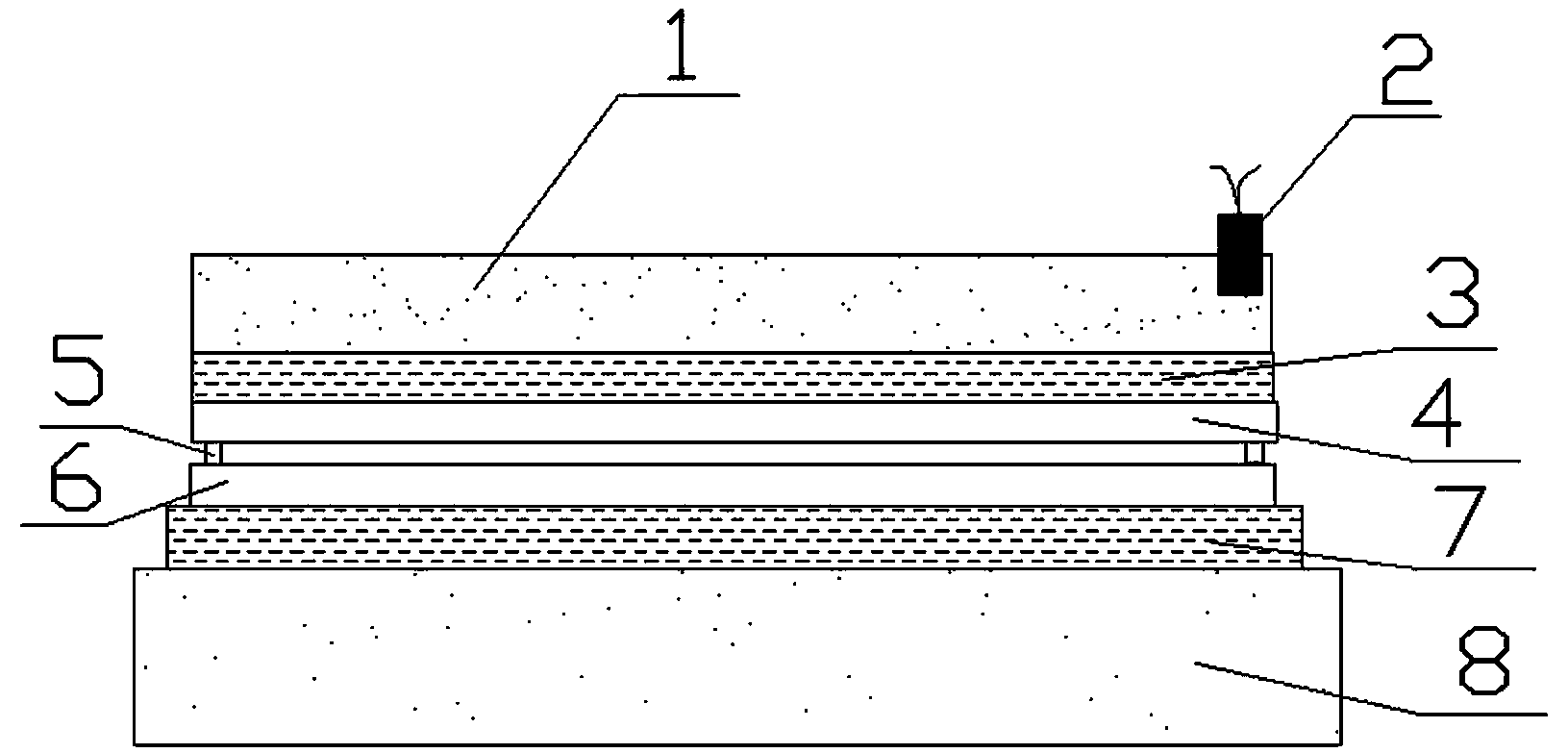

The invention relates to an explosive welding method for a copper-aluminum composite material. An aluminum composite plate (4) is arranged on a copper substrate (6) in a parallel mode through a supporting object (5), a rubber buffering layer (3) is laid on the aluminum composite plate (4), rock ammonium nitrate explosive cloth number two is arranged on a rubber buffering layer (3), the copper substrate (6) is arranged on a rubber cushion layer (7), a medium-fine sand foundation (8) is located below the rubber cushion layer (7), and the copper-aluminum composite material is obtained through explosive welding. A copper-aluminum composite plate produced through the explosive welding method can achieve 100% welding composite rate, is evenly formed in a composite mode without the phenomena of layering, swelling, vortex and the like.

Owner:HUNAN FORHOME COMPOSITE MATERIALS CO LTD

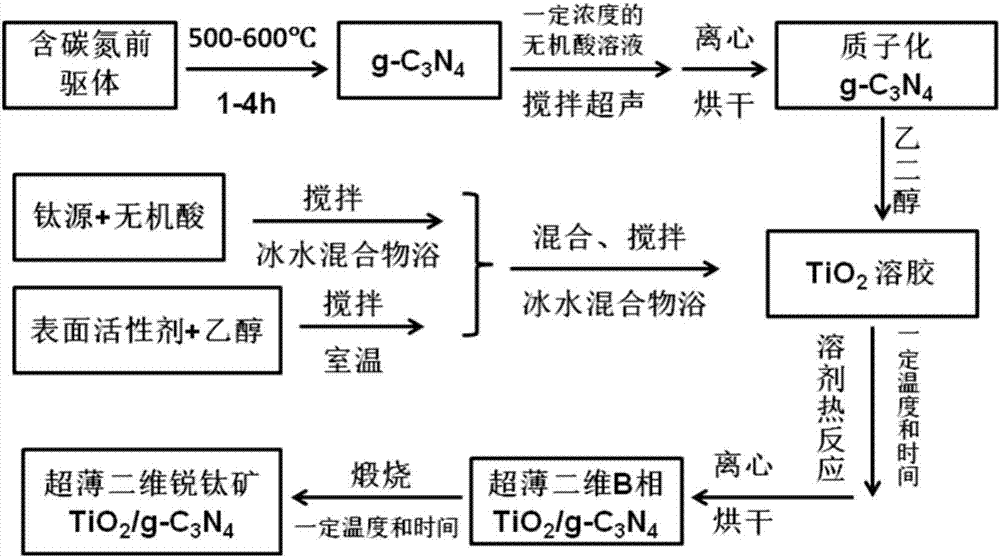

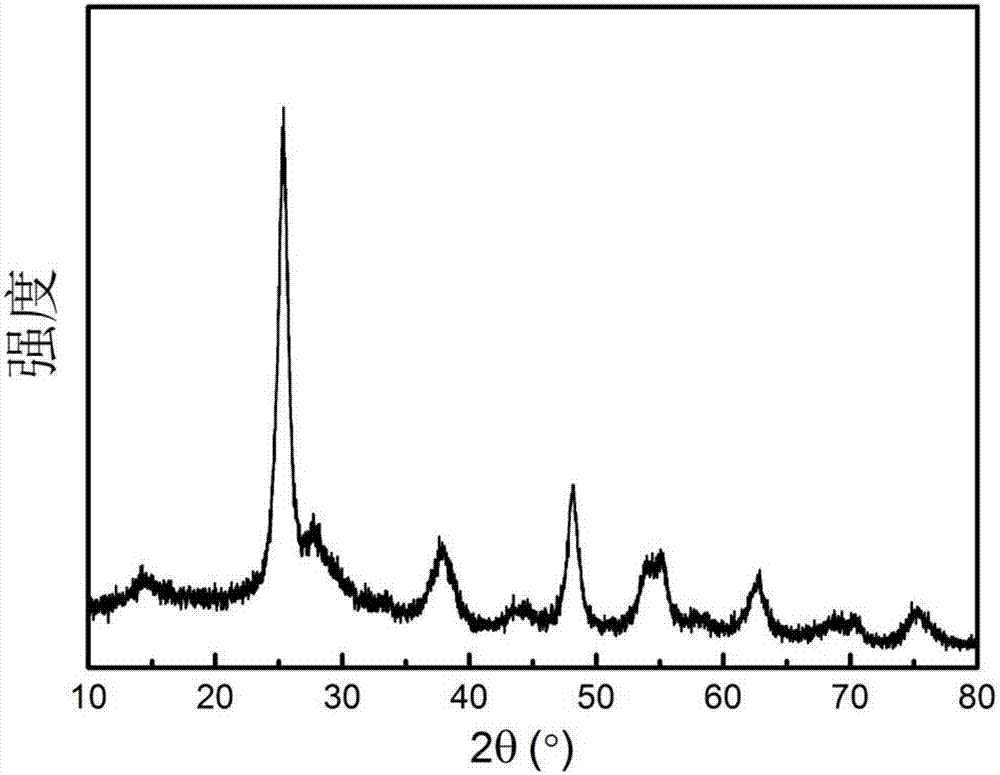

Two-dimensional anatase TiO2/g-C3N4 composite material, as well as preparation method and application thereof

ActiveCN107442150AReduce thicknessLarge horizontal sizeMaterial nanotechnologyPhysical/chemical process catalystsOxygen vacancyOrganic matter

The invention discloses a two-dimensional anatase TiO2 / g-C3N4 composite material. The material is a two-dimensional lamellar structure, and is obtained by compounding g-C3N4 and a TiO2 precursor through a surfactant. The composite material has a thickness of 2 to 20nm, a lateral dimension of 100nm to 2[mu]m and a specific surface area of 88 to 110m<2>*g<-1>. According to the composite material, an ethylene glycol modified Ti-O hydrate-surfactant-g-C3N4 sandwich structure is assembled under hydrophobic and hydrophilic actions, oxygen vacancies in TiO2(B) are supplied by air calcination, and the two-dimensional anatase TiO2 / g-C3N4 composite material is finally obtained to realize close and homogeneous compounding of two ultrathin nanosheets, so that a large-area heterogenous interface is formed, the electron transport rate is increased and light-generated electron home recombination is suppressed; the composite material has very high photocatalytic hydrogen production performance and photocatalytic organic matter degradation activity.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

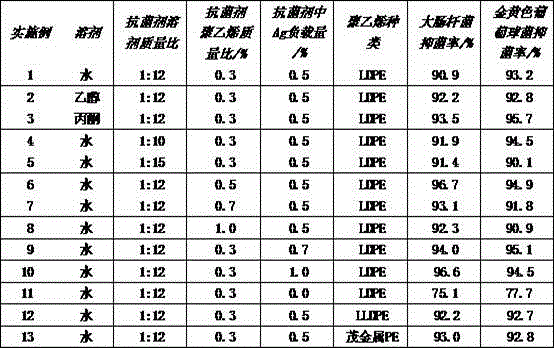

Preparation method of polyethylene antimicrobial packaging film

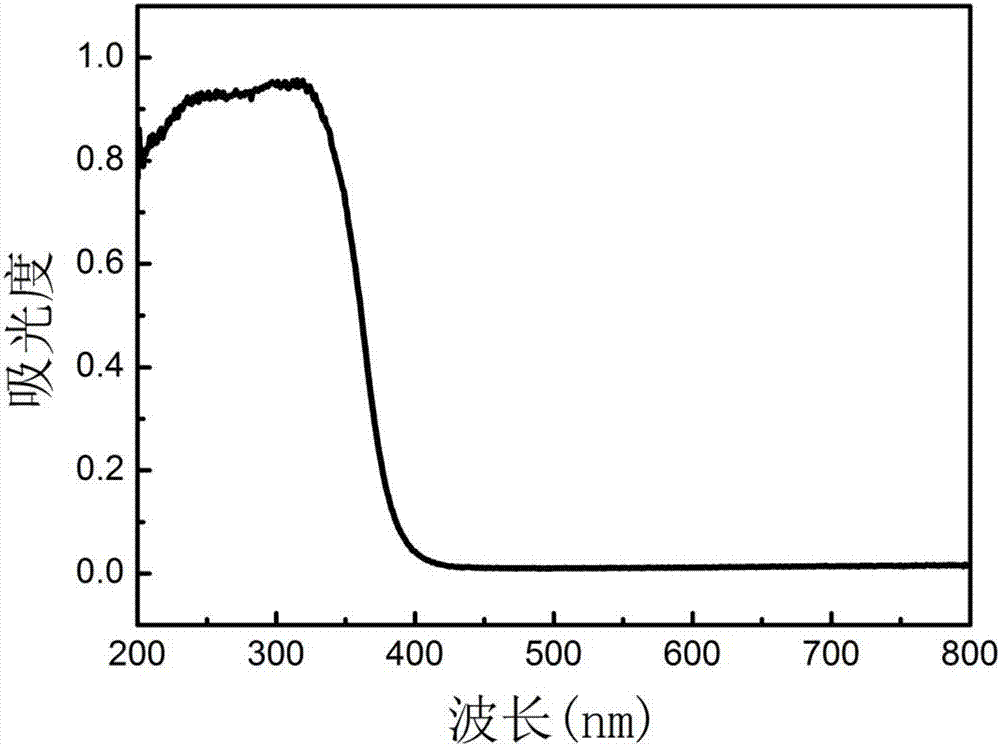

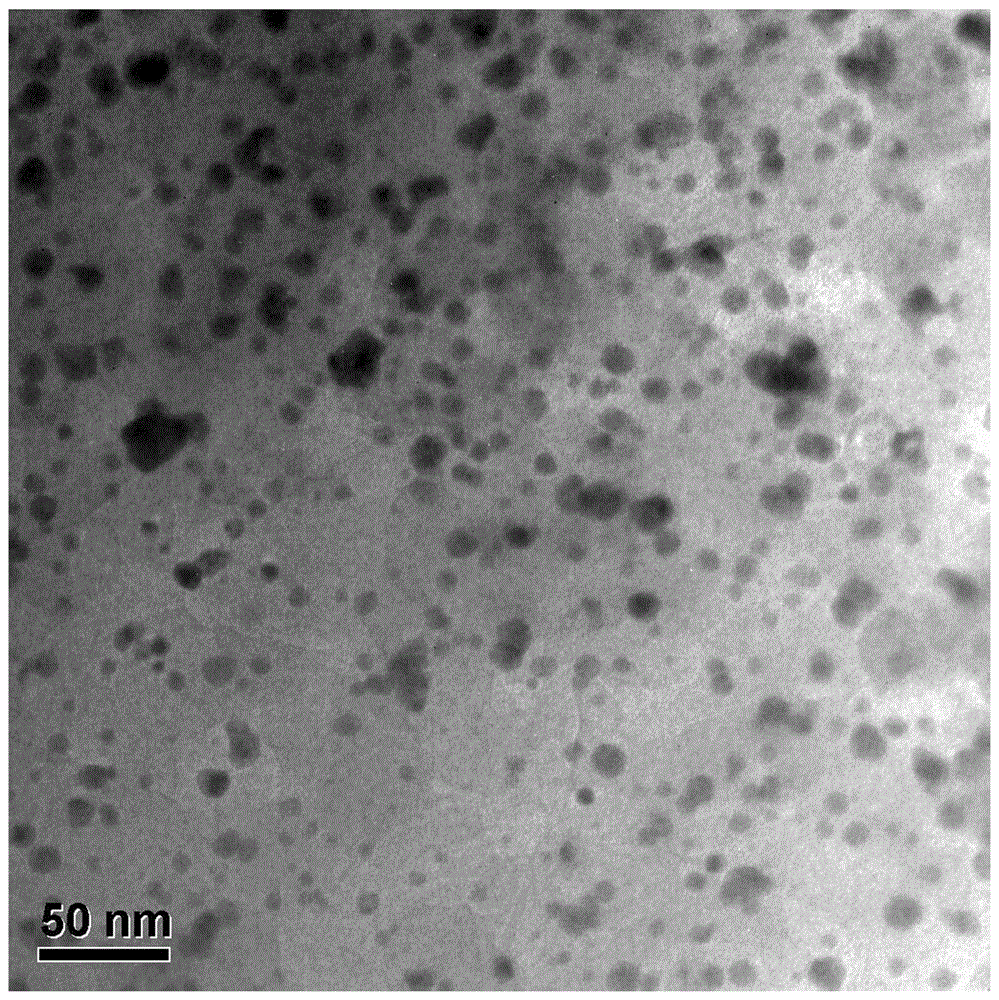

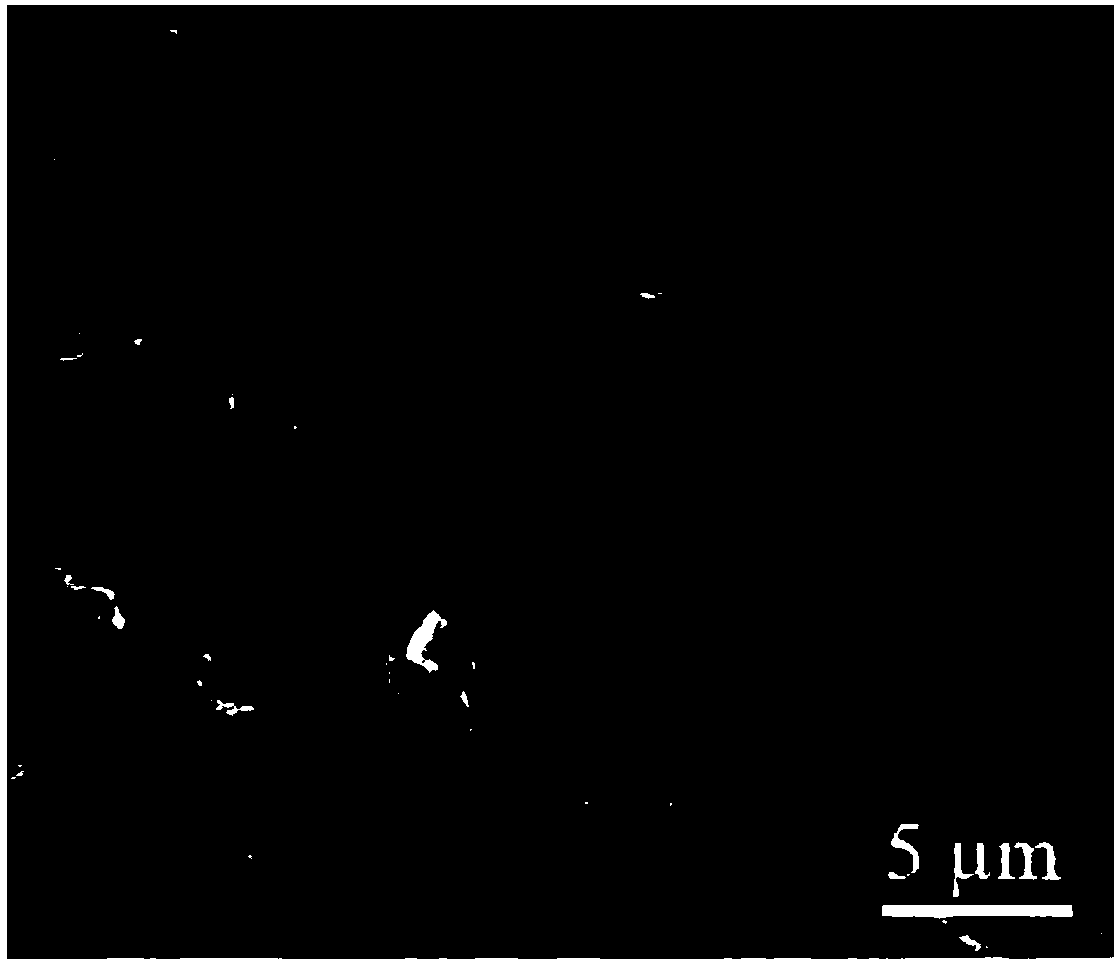

ActiveCN105968489AComposite uniformThe preparation process is simple and environmentally friendlyEscherichia coliEnvironmental resistance

The invention discloses a preparation method of a polyethylene antimicrobial packaging film. The preparation method is characterized by comprising the following steps of adding 0.3 to 1.0 part by weight of silver-loaded nano titania antimicrobial agent into 100 parts by weight of polyethylene resin; then adding 0.06 to 0.24 part of antioxidant 1076 and 0.04 to 0.16 part of auxiliary antioxidant 168; sufficiently mixing in a high-speed mixer, then granulating, drying and blowing film to prepare the polyethylene antimicrobial packaging film. Compared with the prior art, the preparation method disclosed by the invention has the beneficial effects that silver-ammonia ions are induced to form a strong interaction with the surface of titania by regulating a pH value; the silver-ammonia ions are reduced by using a water extract of a biomass loquat fruit, and further uniform compounding of silver and titania at the nanoscale is realized; no dispersing agent is needed, so that a preparation process is green and environmentally-friendly; the antibacterial rate of the prepared polyethylene antimicrobial packaging film to escherichia coli and staphylococcus aureus reaches 90 percent or above; the polyethylene antimicrobial packaging film is non-toxic, safe and sanitary.

Owner:SHANTOU HONGQIAO PACKAGING IND

Silicon carbon composite material, and preparation method and application thereof

ActiveCN107611416AHigh tap densityIncrease compaction densityCell electrodesSandwich likeCarbon composites

The invention discloses a silicon carbon composite material, and a preparation method and an application thereof. The preparation method comprises the following steps of performing wet process ball milling on glass powder and a laminated layer carbon material to obtain a uniform mixed product of glass and the carbon material; next, performing uniform mixing and compacting on the product and magnesium powder and fused salt to form an ingot; and then performing a magnesium thermal reaction, and carrying out acid washing on the reaction product to obtain a sandwich layer-shaped porous silicon / graphene-like structured composite material. The preparation method are simple in steps and easy to implement, and the raw materials are wide in resource; more importantly, the mixture is made into the ingot through the compacting process, and then the magnesium thermal reaction is performed, so that the tap density of the silicon carbon negative electrode material is greatly improved, and the volumetric specific capacity of the negative electrode material is improved; meanwhile, by compounding with the graphite and other carbon material to form the sandwich-like structure, the electronic conductivity of the material is improved effectively, and the compatibility between the silicon base material and an electrolyte can be improved, thereby improving cycle performance and rate capability of the material; and therefore, the silicon carbon composite material can be applied to the negative electrode material with high power density and high energy density of the lithium ion battery.

Owner:WUHAN UNIV OF SCI & TECH

Method for preparing anode material of lithium-iron disulphide battery

The invention relates to a method for preparing anode material of lithium-iron disulphide battery by using conductive carbon material, natrium thiosulfuricum, ferrous sulfate and elemental sulfur as raw material through low temperature hydrothermal reaction. The formulation of the anode material comprises, conductive carbon material 0.5-10%, natrium thiosulfuricum 40-70%, ferrous sulphate 40-70%, and elemental sulfur 1-10%.

Owner:TSINGHUA UNIV

Carbon coated Na3VO4 composite anode material and preparation method and application thereof

InactiveCN105742591AEasy to operateGood repeatabilityNon-aqueous electrolyte accumulatorsCell electrodesSucroseHexamethylenetetramine

The invention provides a carbon coated Na3VO4 composite anode material and a preparation method thereof. The preparation method comprises the following steps of separately placing a sodium source, a vanadium source and hexamethylenetetramine in 10ml of distilled water, and stirring the distilled water for 40 minutes so that the sodium source, the vanadium source and the hexamethylenetetramine are fully dissolved; transferring the obtained mixed solution into a lining of a hydrothermal kettle, adding the distilled water into the linear in an amount of 80% of the volume, carrying out reaction in an air blower at 120 DEGC for 24 hours, carrying out reaction in the air blower at 180 DEG C for 24-72 hours, and naturally cooling the air blower to a room temperature to obtain a reaction liquid; and adding citric acid, sucrose or glucose into the above reaction liquid, stirring the reaction liquid to obtain an intermediate product, drying the intermediate product in a drying oven at 80 DEG C for 12 hours, and carrying out calcination in a nitrogen or argon protection atmosphere at 400-600 DEG C for 5-10 hours to obtain the carbon coated Na3VO4 composite material. The material is endowed with relatively high electrochemical performance when applied as an anode material of a sodium ion battery.

Owner:CHINA THREE GORGES UNIV

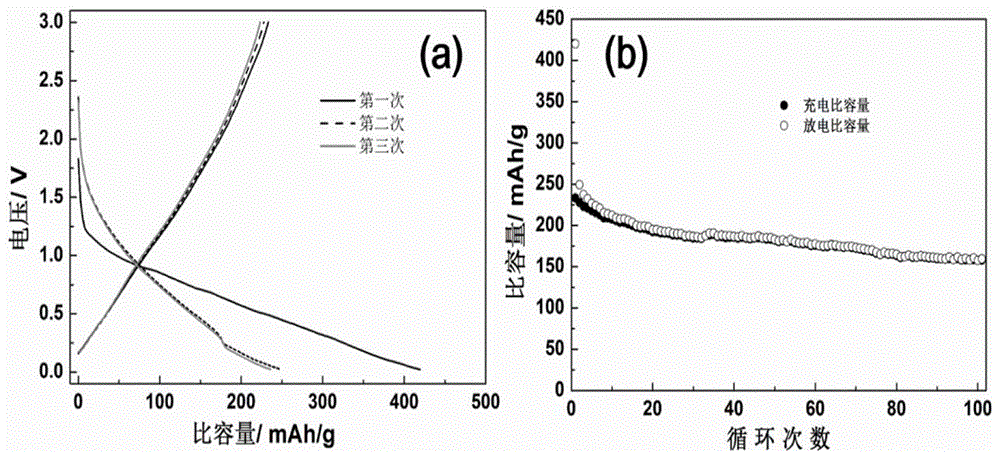

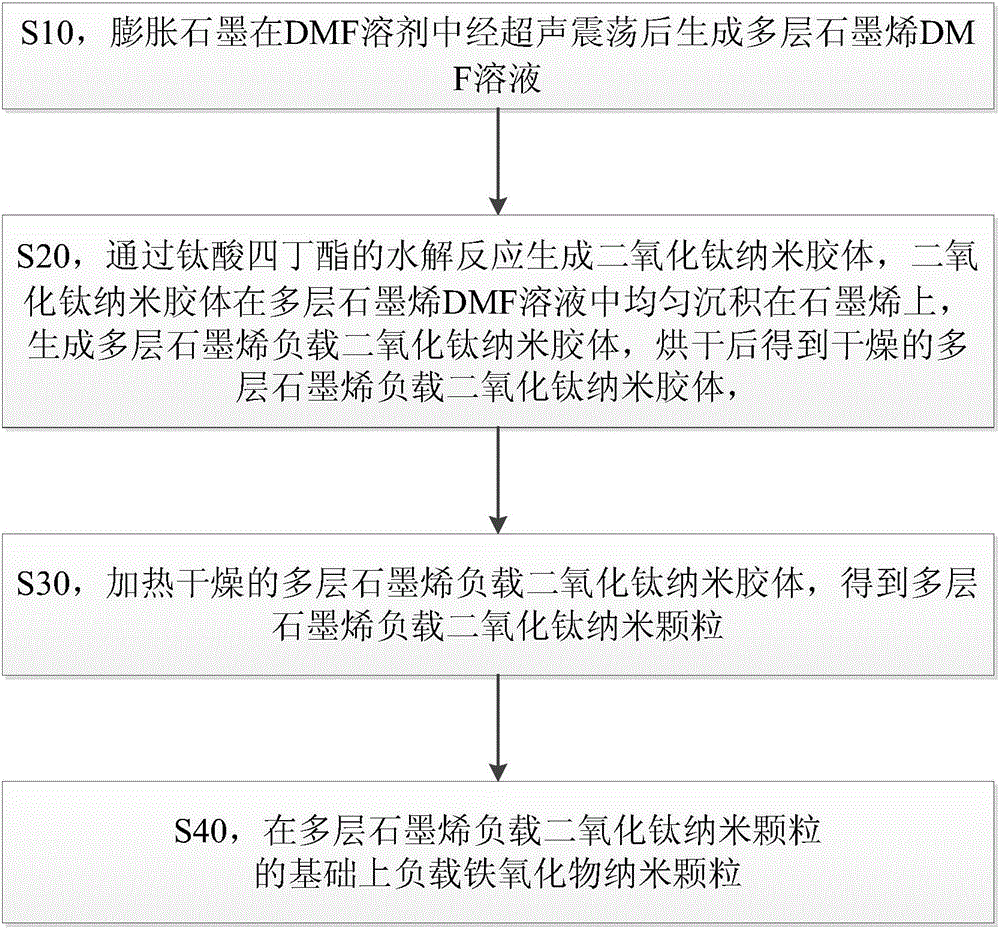

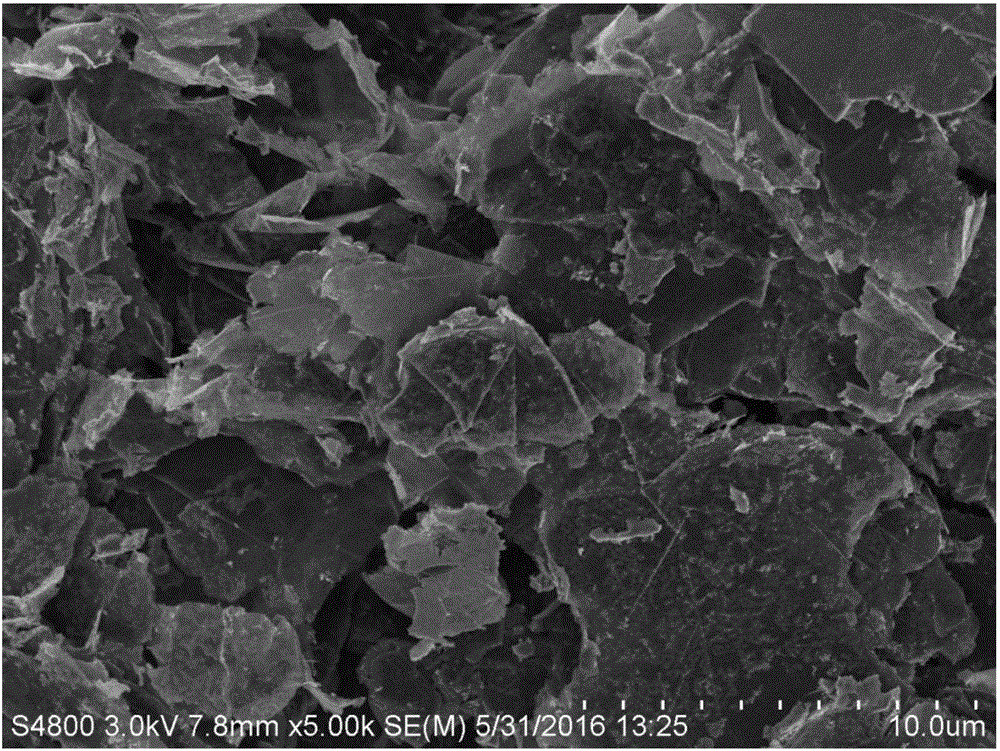

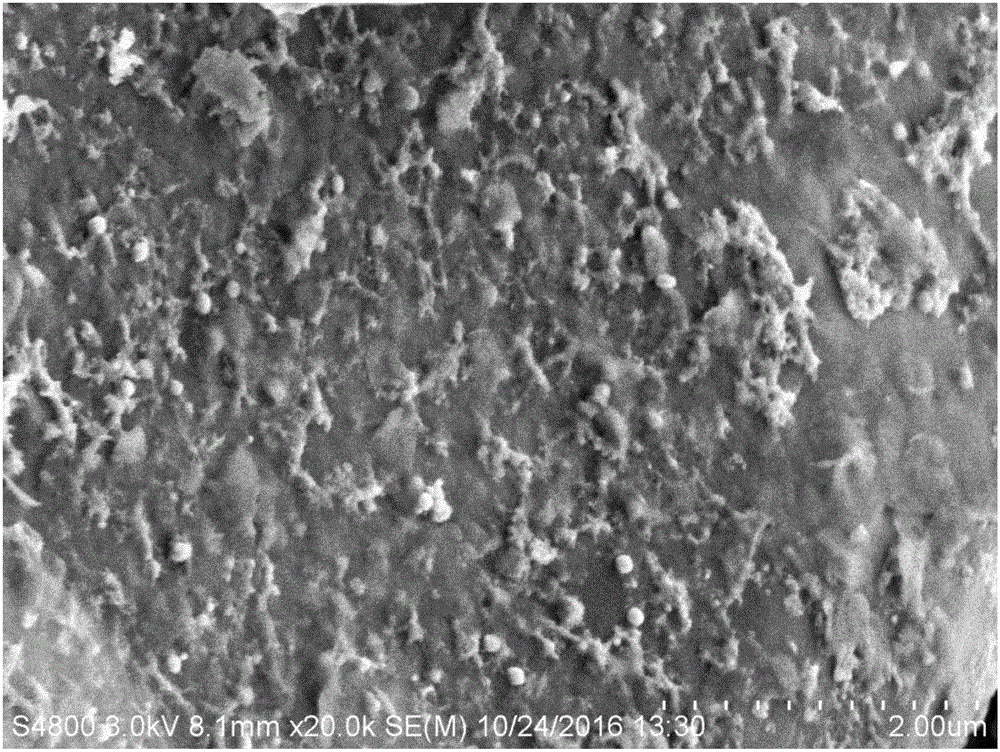

Multilayer-graphene-carried titanium dioxide-ferrotitanium bimetal nanoparticles and preparation method thereof

ActiveCN106512939AInhibit growthEvenly distributedMaterial nanotechnologyOther chemical processesN dimethylformamideSolvent

The invention belongs to the technical field of materials, and discloses multilayer-graphene-carried titanium dioxide-ferrotitanium bimetal nanoparticles and a preparation method thereof. The preparation method comprises the following steps: carrying out ultrasonic oscillation in a DMF (N,N-dimethylformamide) solvent to generate a multilayer graphene DMF solution, carrying out hydrolysis reaction on tetrabutyl titanate to generate a titanium dioxide nano colloid, drying to obtain a dried multilayer-graphene-carried titanium dioxide nano colloid, heating to obtain multilayer-graphene-carried titanium dioxide nanoparticles, and preparing the multilayer-graphene-carried ferrotitanium bimetal oxide nanoparticles on such basis. The size of the prepared nano titanium dioxide particles on the graphene surface is less than 20nm; and the particles are distributed uniformly and have gaps, thereby providing space for depositing other oxide nanoparticles on the graphene surface. The multilayer-graphene-carried ferrotitanium bimetal oxide nanoparticles have the advantages of favorable particle crystallinity, small particle size and larger specific area.

Owner:江阴普朗克科技有限公司

Preparation method of lithium ion battery negative electrode material silicon oxide-carbon/graphite

ActiveCN109560278AImprove electronic conductanceCoulombic efficiency is highCell electrodesSecondary cellsSucroseSilicon oxygen

The invention relates to a preparation method of a lithium ion battery negative electrode material silicon oxide-carbon / graphite. The preparation method comprises the steps of taking tetraethyl orthosilicate as a silicon source and sucrose as a carbon source, performing in-situ combination on a gel-state silicon oxide, the sucrose and the graphite by hydrolysis-condensation reaction of the tetraethyl orthosilicate, and performing ball-milling to disperse the graphite to obtain a uniform silicon-oxygen-sucrose-graphite precursor; and allowing the sucrose to split and reducing silicon oxide during the subsequent thermal treatment process so as to prepare the uniformly-combined silicon oxide-carbon / graphite material. The in-site process of the silicon oxide and the graphite is simple in process and low in cost, and the prepared silicon oxide-carbon / graphite material is uniform in combination; with the introduction of the graphite, the electron conductivity of the composite material can beimproved, the coulombic efficiency of the composite electrode material is effectively improved, so that the electrochemical performance of the electrode material is remarkably improved; and the silicon oxide-carbon / graphite material can be used as a potential high-performance lithium ion battery negative electrode material and is expected to be widely applied to the fields of various types portable electronic equipment, an electric automobile and aerospace.

Owner:UNIV OF SCI & TECH BEIJING

Method for preparing modified micro particles coated with graphene oxide

InactiveCN106587691AGood dispersionComposite uniformSolid waste managementMaterials scienceGraphene oxide paper

The invention relates to a method for preparing modified micro particles coated with graphene oxide, and the method comprises the following steps: (1) dispersing micro particles into absolute ethanol, adding a silane coupling agent, heating for reaction, cooling and separating to obtain coupling-agent-modified micro particles; (2) dispersing graphite oxide into water to obtain a graphene oxide solution; (3) adding dropwise the graphene oxide solution prepared by the step (2) into the coupling-agent-modified micro particles prepared by the step (1) until the solution is transparent and the coupling-agent-modified micro particles are all precipitated, separating and drying to obtain the modified micro particles coated with the graphene oxide. Compared with the prior art, the surface of the micro particles are coated evenly with the graphene oxide by the functional groups on the surface of the graphene oxide, the graphene oxide and the micro particles are uniformly compounded, performances of the micro particles can be effectively improved, and particle and graphene application and the like can be expanded.

Owner:TONGJI UNIV

Electrochemical insertion/deinsertion magnesium ion electrode with high capacity and stable circulation and preparation method

InactiveCN102142539AHigh electrochemical magnesium storage capacitySuper stable cycle performanceNon-aqueous electrolyte accumulator electrodesMaterials scienceMagnesium ion

The invention discloses an electrochemical insertion / deinsertion magnesium ion electrode with high capacity and stable circulation and a preparation method. The active material of the electrode is a composite nano-material of graphene nano-sheets and MoS2, and the balance is acetylene black and polyvinylidene fluoride. The mass percentage of each component is: 75-85% of active material of composite nano-material, 5-10%of acetylene black and 10% of polyvinylidene fluoride, wherein the mass ratio of the graphene nano-sheets and the MoS2 nano-material in the active material of composite nano-material is 1 to 1-4 to 1. The preparation method of the electrode comprises the following steps of: using graphite as a raw material to prepare graphite oxide nano-sheets with a method of chemical oxidation; in the presence of the graphite oxide nano-sheets, compounding to obtain the composite nano-material of the graphene nano-sheets / MoS2 with a one-step hydrothermal in-situ reduction method; and finally using the composite nano-material of the graphene nano-sheets / MoS2 as the active material to prepare the electrode. The electrode has not only high electrochemical magnesium intercalating reversible capacity but also good stable circulation property and is widely applied to the new generation of magnesium ion batteries.

Owner:ZHEJIANG UNIV

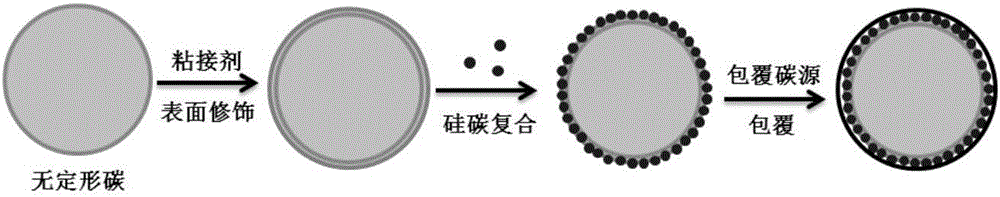

Carbon-silicon composite material and preparation method of carbon-silicon composite material as well as lithium-ion battery comprising composite material

ActiveCN106784741AEasy to operateSuitable for large-scale productionMaterial nanotechnologyCell electrodesNano siliconCharge rate

The invention discloses a carbon-silicon composite material and a preparation method of the carbon-silicon composite material as well as a lithium-ion battery comprising the composite material. The carbon-silicon composite material comprises an amorphous carbon inner core and a shell which is formed by dispersing nano silicon into a pyrolytic carbon layer. The method is simple and easy to operate, is environmental-friendly and is suitable for large-scale production; the prepared carbon-silicon composite material has a stable structure, the nano silicon has good dispersibility and the coated degree of the nano silicon is very high; the carbon-silicon composite material is used as a negative electrode material of the lithium-ion battery and has a very high lithium removing specific capacity, a good circulating performance and an excellent rapid charging property; the lithium removing specific capacity is 391.7mAh / g or more, the capacity retention rate is 95.3 percent or more after the lithium-ion battery is charged and discharged at constant current of 1.0C for 50 times, and the charging rate of 10min can reach 90.2 percent.

Owner:深圳市贝特瑞新能源技术研究院有限公司

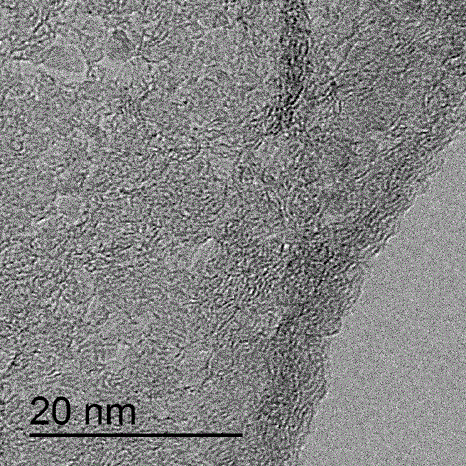

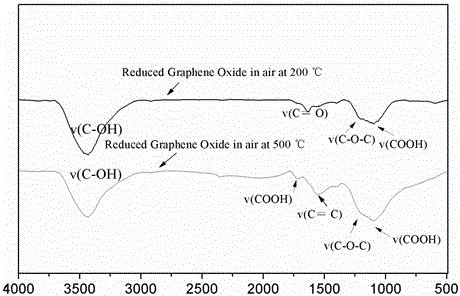

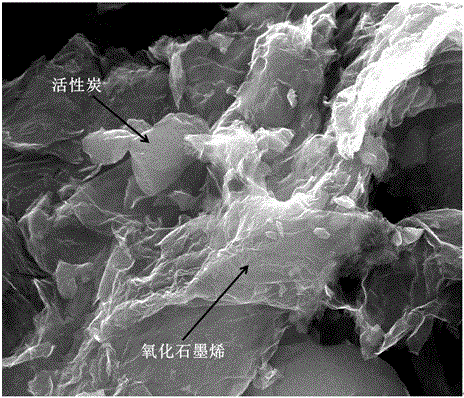

Preparation method for high-specific-capacitance graphene/high-surface-activated carbon composite material

InactiveCN106486295AImprove performanceSimple preparation processCarbon compoundsHybrid capacitor electrodesCapacitanceAir atmosphere

The invention discloses a preparation method for a high-specific-capacitance graphene / high-surface-activated carbon composite material, and aims to provide the preparation method for active carbon composite material with low cost, high specific capacitance and high specific surface area utilization ratio. The preparation method is realized by the technical scheme as follows: taking peeled graphite oxide slurry as a raw material, and drying the graphite oxide slurry at a temperature of minus 40 to minus 20 DEG C; then reducing the graphite oxide into graphene oxide at a temperature of 200-500 DEG C, and adding high-surface-activated carbon in the graphite oxide stage; meanwhile, adding a dispersing agent to be stirred and mixed, and performing ultrasonic dispersion to enable the graphite oxide and the high-surface-activated carbon to be uniformly mixed, coating the surface of the high-surface-activated carbon with the graphite oxide to realize in-situ compositing of the graphite oxide and active carbon; and after performing low-temperature freezing and drying, performing puffing and reducing in the air atmosphere at a lower temperature of lower than 500 DEG C to reduce the graphite oxide into graphene oxide to prepare the in-situ composited graphene oxide / high-surface-activated carbon composite material.

Owner:DAYING JUNENG TECH & DEV

Nano alumina-containing modified wood production method

InactiveCN104859011AHigh surface hardnessEfficient processingWood treatment detailsPretreatment apparatusPolyethylene glycolNano al2o3

The invention discloses a nano alumina-containing modified wood production method including five steps of wood pretreatment, preparation of a wood modification agent, preparation of a wood modification fluid, dipping treatment and post drying treatment, the wood modification agent comprises nano alumina, polyethylene glycol (peg), aluminum and titanium compound coupling agent OL-AT1618, distilled water, sodium octaborate, diammonium phosphate, boric acid, carbendazim, dodecyl dimethyl benzyl ammonium chloride, sodium dodecyl benzene sulfonate and silicon sol, and the particle size of the nano alumina is in the 1-100 nm range. The beneficial effect is that the nano alumina-containing modified wood has the advantages of simple process, high efficiency, environmental protection, strong permeability, stable performance, even composite and the like, and the surface hardness, smoothness, wear resistance, cold and hot fatigue, fracture toughness, good processing properties, dimension stability, anti-corrosion flame retardant properties and the like of the treated wood are improved obviously.

Owner:王玉燕

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com