Preparation method of nano fiber containing TiO2/WO3 heterojunction

A technology of nanofibers and heterojunctions, applied in fiber processing, fiber chemical characteristics, chemical instruments and methods, etc., can solve problems such as limiting sunlight utilization and affecting TiO2 photocatalytic efficiency, so as to improve catalytic ability and facilitate experimental conditions Controlled, topographical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Inorganic TiO 2 Preparation of nanofibers and WO 3 Sol preparation

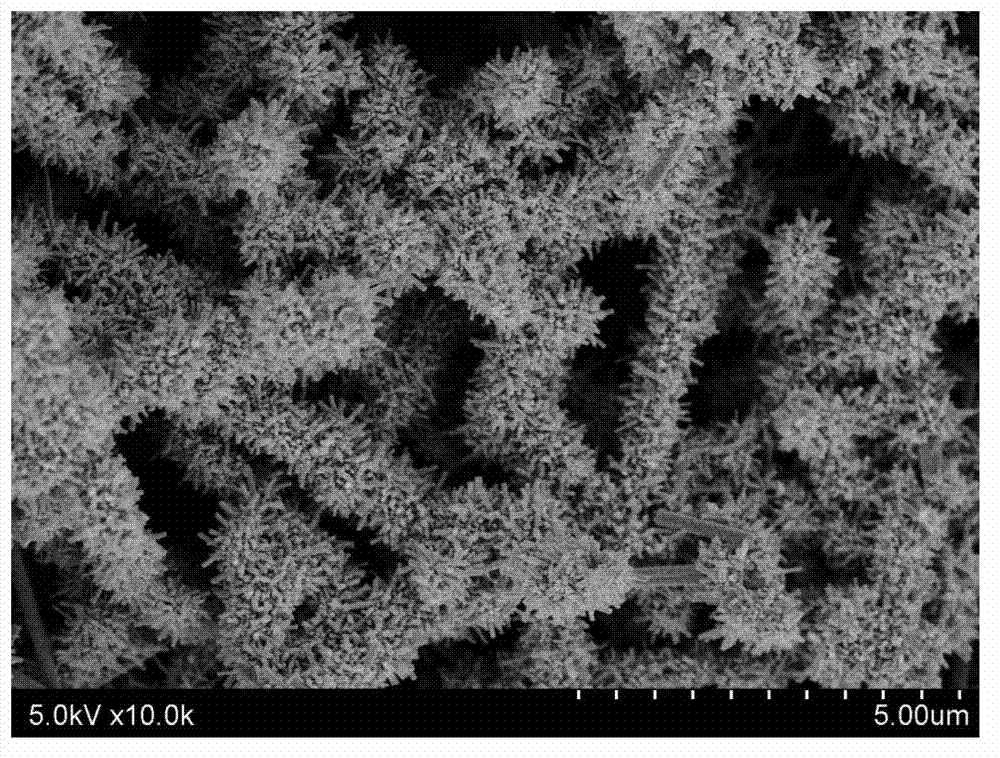

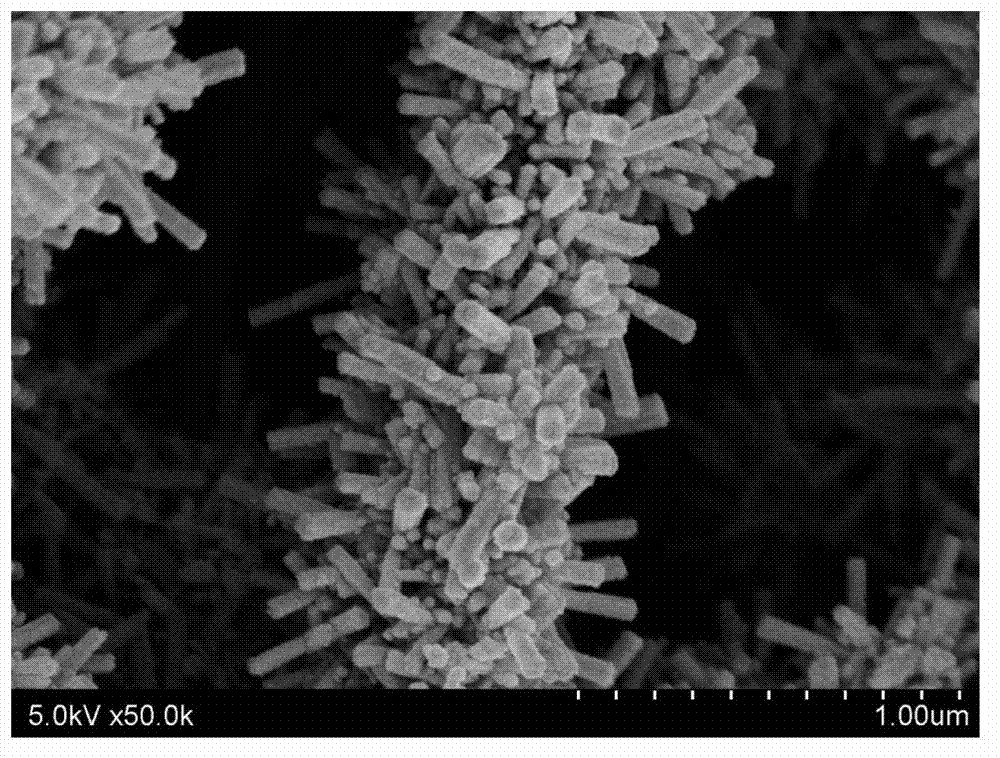

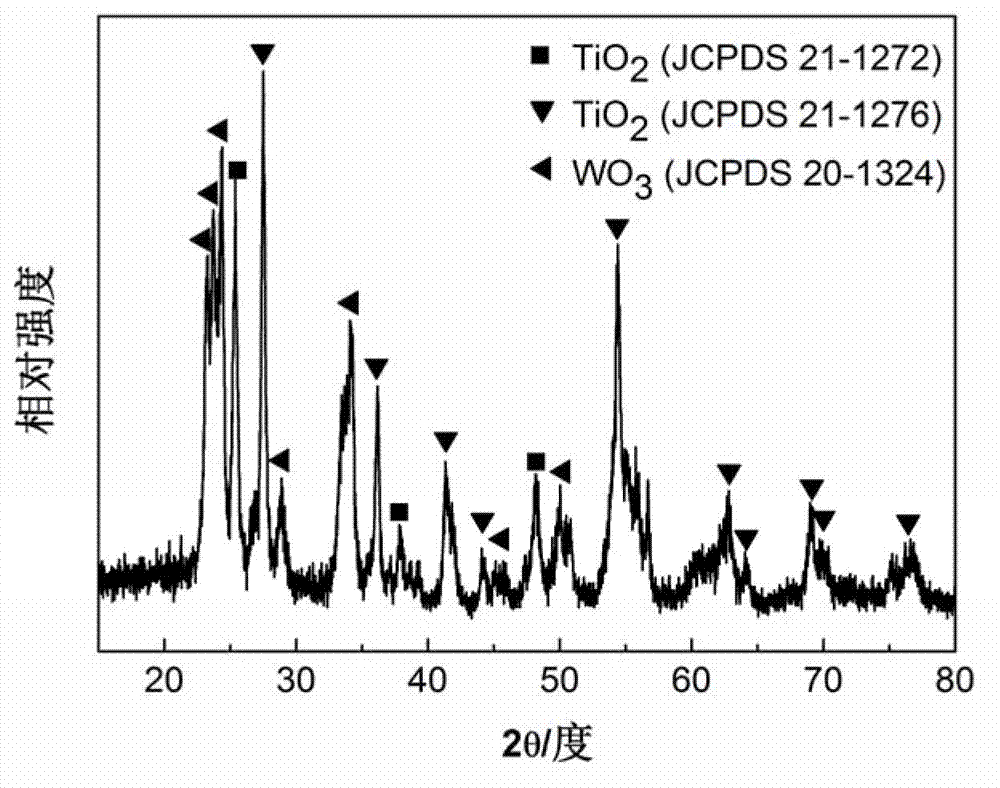

[0033] Weigh 1.50g of PVP into a beaker, add 14mL of absolute ethanol and 3mL of glacial acetic acid to it, and stir magnetically for 4 hours; slowly add 4ml of tetrabutyl titanate to the above solution dropwise under stirring, and continue magnetically stirring 4h, the spinning solution of titanium dioxide was obtained. Electrospinning the spinning liquid, setting the voltage at 13,000 volts, the propulsion rate of the spinning liquid in the needle tube is 30 μL / min, and the distance between the spinneret and the receiving device is 10 cm, and TiO 2 / PVP non-woven fabric. The obtained non-woven fabric is calcined at 500°C to obtain inorganic TiO 2 Nanofibers.

[0034] Add 25ml H to 2g tungstic acid powder 2 o 2 , heated at 90°C, and magnetically stirred for 4 hours, the tungstic acid powder was dissolved. Add 60ml H to it 2 O, stirred to obtain colorless and transparent WO 3 Sol.

[003...

Embodiment 2

[0041] (1) Inorganic TiO 2 Preparation of nanofibers and WO 3 Sol preparation

[0042] Weigh 1.40g of PVP into a beaker, add 13mL of absolute ethanol and 4mL of glacial acetic acid to it, and stir magnetically for 2 hours; slowly add 3.5ml of isopropyl titanate into the above solution under stirring, and continue to magnetically Stir for 4 hours to obtain a spinning solution of titanium dioxide. Electrospinning the spinning liquid, setting the voltage at 15,000 volts, the propulsion rate of the spinning liquid in the needle tube is 20 μL / min, and the distance between the spinneret and the receiving device is 8 cm, and TiO 2 / PVP non-woven fabric. The obtained non-woven fabric is calcined at 450°C to obtain inorganic TiO 2 Nanofibers.

[0043] (2) Add 24ml H to 2g tungstic acid powder 2 o 2 , heated at 80°C, and magnetically stirred for 4 hours, the tungstic acid powder was dissolved. Add 50ml H to it 2 O, stirred to obtain colorless and transparent WO 3 Sol.

[0044...

Embodiment 3

[0050] (1) Inorganic TiO 2 Preparation of nanofibers and WO 3 Sol preparation

[0051] Weigh 1.30g of PVP into a beaker, add 14mL of absolute ethanol and 3mL of glacial acetic acid to it, and stir magnetically for 4 hours; slowly add 4ml of tetrabutyl titanate to the above solution under stirring, and continue magnetic stirring 4h, the spinning solution of titanium dioxide was obtained. Electrospinning the spinning liquid, setting the voltage at 13,000 volts, the propulsion rate of the spinning liquid in the needle tube is 20 μL / min, and the distance between the spinneret and the receiving device is 10 cm, and TiO 2 / PVP non-woven fabric. The obtained non-woven fabric is calcined at 550°C to obtain inorganic TiO 2 Nanofibers.

[0052] (2) Add 25ml H to 2g tungstic acid powder 2 o 2 , heated at 90°C, and magnetically stirred for 4 hours, the tungstic acid powder was dissolved. Add 60ml H to it 2 O, stirred to obtain colorless and transparent WO 3 Sol.

[0053] (3) Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com