Explosive welding method for copper-aluminum composite material

An aluminum composite material and explosive welding technology, applied in welding equipment, welding/welding/cutting items, non-electric welding equipment, etc., can solve problems such as immature technology, drumming, and easy delamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

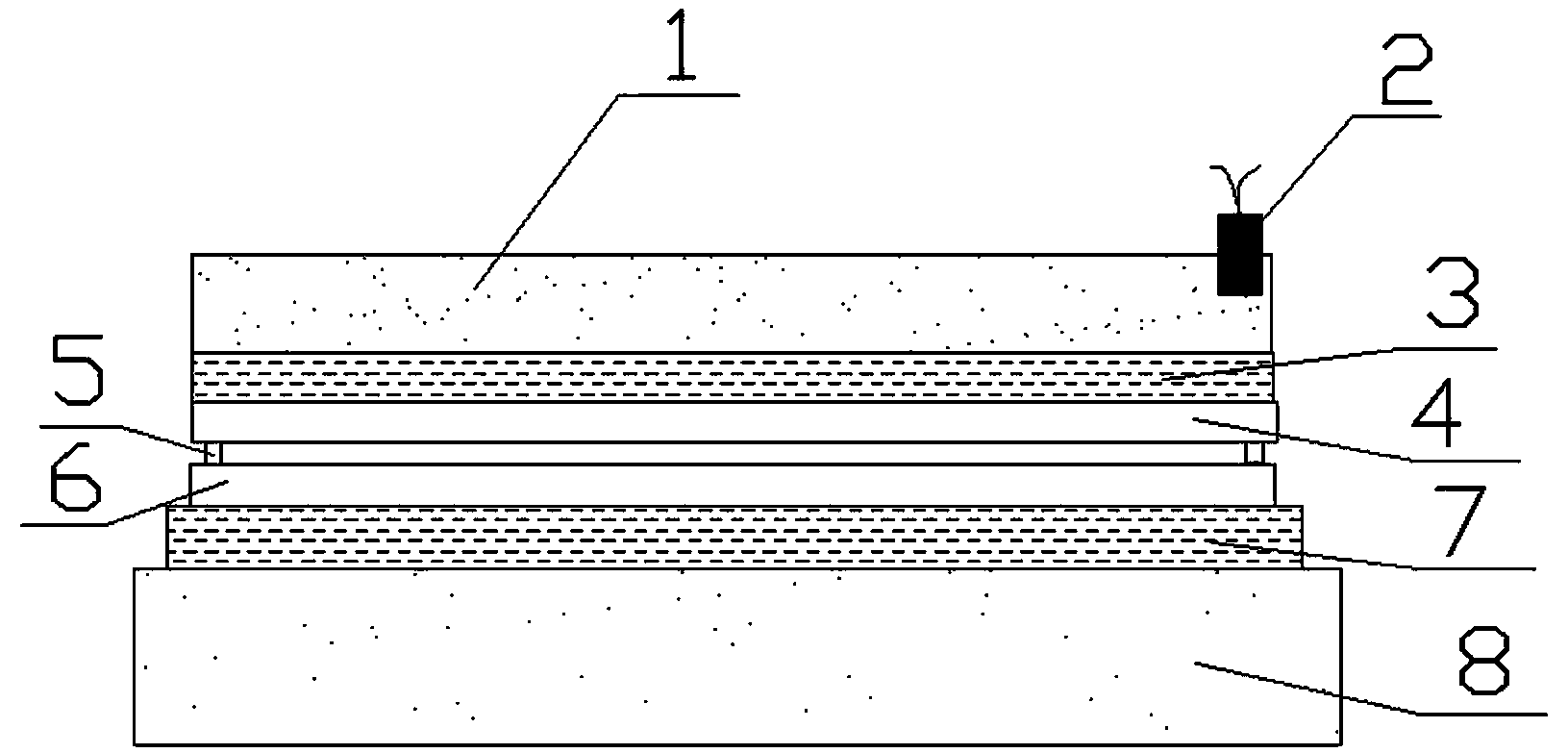

[0016] Polish the base copper (thickness 1mm, width 500mm, length 500mm) and doubler aluminum plate (grade 1060, thickness 1mm, width 500mm, length 500mm) with a wire wheel to remove the oxide layer and completely reveal the metallic luster. Press 1.7g / cm in the kit 2 The explosives are evenly arranged, and the detonator 2 is arranged in the center of one end, and the detonator is 2.2g / cm within a radius of 6cm around the detonator. 2 Arrange explosives, the explosives are No. 2 rock ammonium nitrate explosives; the drug box is placed flat on the 2mm thick rubber buffer layer 3; the buffer layer 3 is in direct contact with the doubler board 4; the doubler board 4 is arranged in parallel with the base plate 6, and an aluminum support is placed in the middle 5. The height of the support is 3.5mm; the substrate 6 is placed flat on the top of the 3mm thick rubber cushion 7; below the cushion 7 is a 20cm thick medium-fine sand foundation 8 (as attached figure 1 ). The industrial ...

Embodiment 2

[0018] Polish the base copper (thickness 0.8mm, width 500mm, length 500mm) and doubler aluminum plate (grade 1060, thickness 0.8mm, width 500mm, length 500mm) with a wire wheel to remove the oxide layer and completely expose the metallic luster. Press 1.6g / cm in the kit 2 Arrange the explosives evenly, and arrange the detonator at the center of one end, and use 2.5g / cm within a radius of 5cm around the detonator 2 Arrange explosives, the explosives are No. 2 rock ammonium nitrate explosives; the drug box is placed flat on the 2.5mm thick rubber buffer layer; the buffer layer is in direct contact with the doubler board; 3mm; the substrate is placed on top of a 4mm thick rubber cushion; under the cushion is a 30cm thick medium-fine sand foundation (as attached figure 1 ). The industrial detonator is detonated, and the formed copper-aluminum composite board can be produced. The copper-aluminum composite panel produced by this method has a welding composite rate of 100%, unifor...

Embodiment 3

[0020] Polish the base copper (thickness 0.5mm, width 500mm, length 500mm) and doubler aluminum plate (grade 1060, thickness 0.5mm, width 500mm, length 500mm) with a wire wheel to remove the oxide layer and completely expose the metallic luster. Press 1.5g / cm in the pill box 2 Arrange the explosives evenly, and arrange the detonator at the center of one end, and use 2.5g / cm within a radius of 5cm around the detonator 2 The explosives are arranged, and the explosives are No. 2 rock ammonium nitrate explosives; the drug box is placed flat on the 3mm thick rubber buffer layer; the buffer layer is in direct contact with the doubler plate; the doubler plate is arranged parallel to the base plate, and an aluminum support is placed in the middle, and the height of the support 2.5mm; the substrate is placed flat on top of a 5mm thick rubber cushion; below the cushion is a 20cm thick medium-fine sand foundation (if attached figure 1 ). The industrial detonator is detonated, and the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com