Loading segregation-prevention system

An anti-segregation and charging technology, applied in blast furnace parts, furnaces, blast furnace details, etc., can solve problems such as affecting the service life of equipment, accelerated wear of wear-resistant linings, uneven particle size of materials, etc., to prevent material segregation. , the effect of delaying service life and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

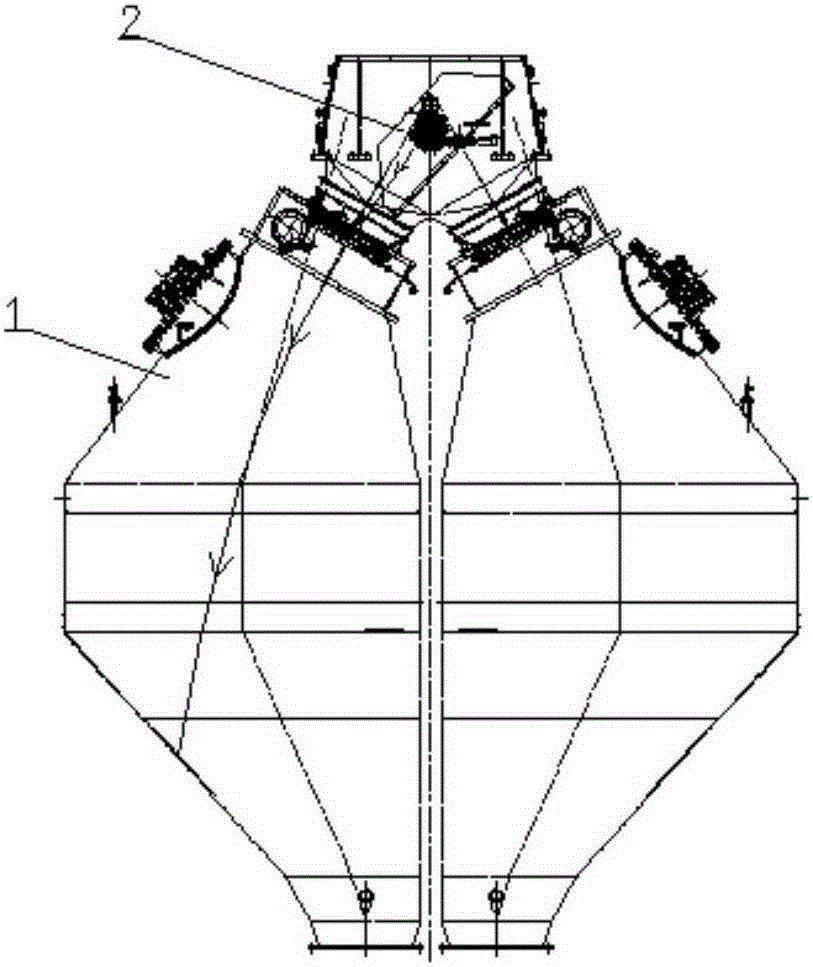

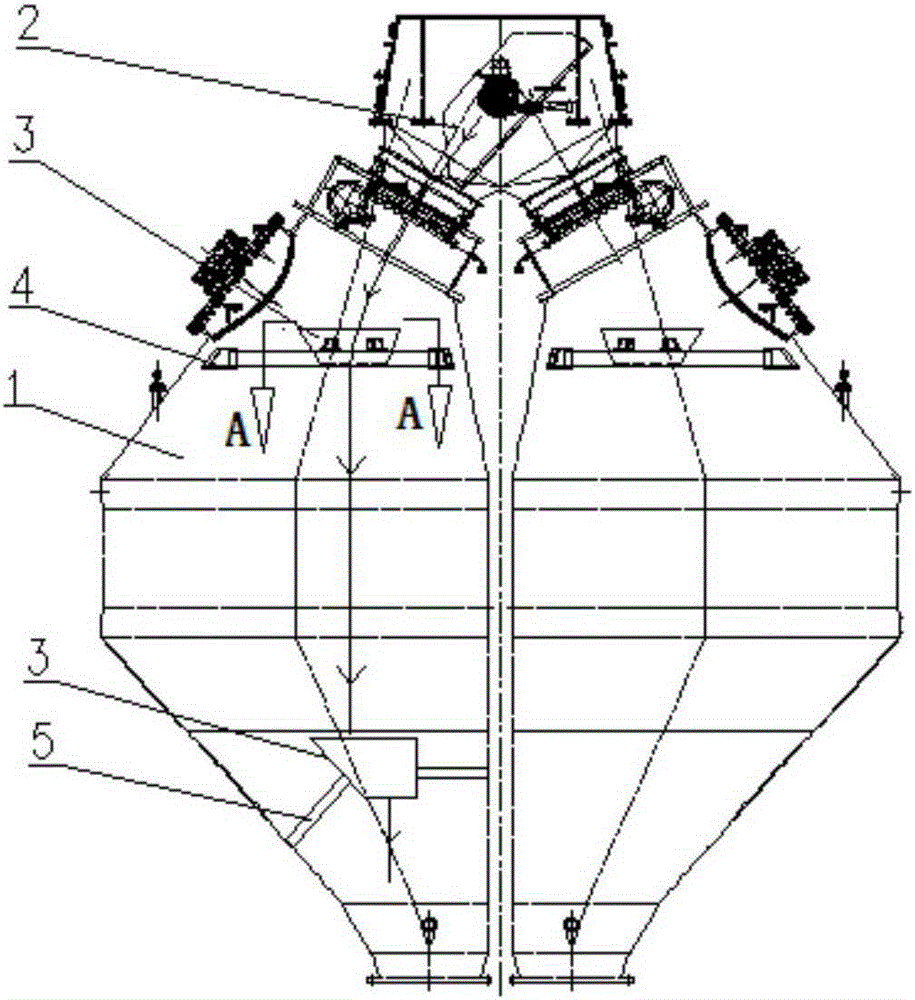

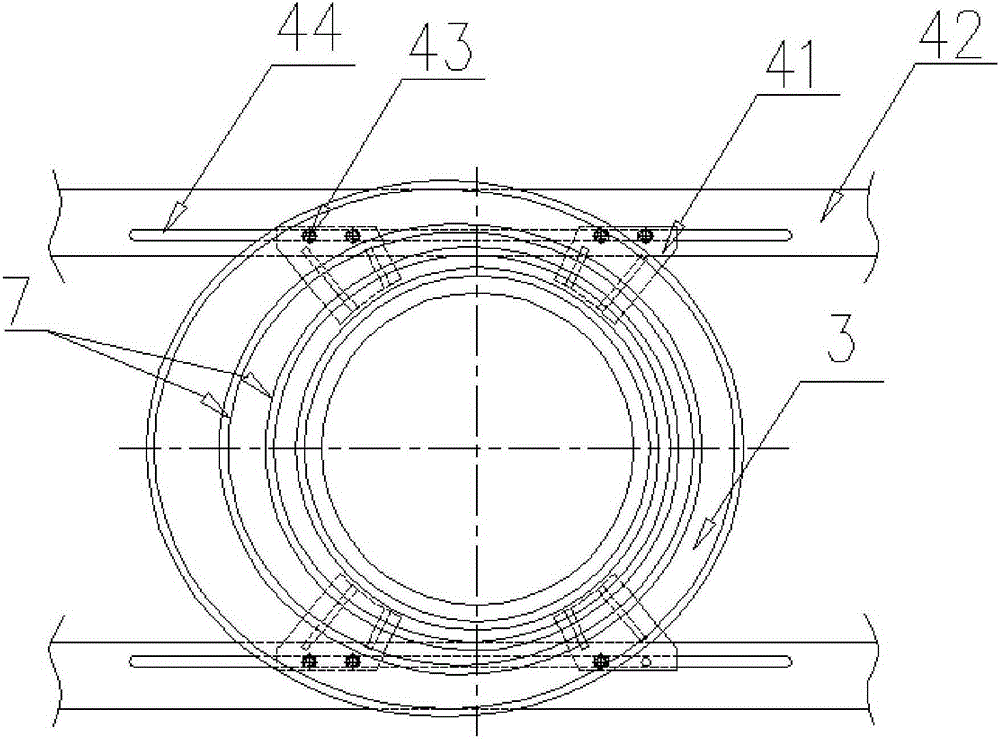

[0025] Such as Figure 2-4 As shown, the present invention provides a charging anti-segregation system, including at least two tanks 1 and an upper swing chute 2, the upper swing chute 2 is arranged above the tank 1, and also includes a separate tank 1 The anti-segregation device in the inner upper area or the anti-segregation device in the upper area and the lower area in the material tank 1 respectively, the anti-segregation device includes a concentration funnel 3 for charging and is used to fix the concentration funnel 3 in the material tank Positioning connection assembly 4 within 1.

[0026] Specifically, there are two material tanks in this embodiment, arranged in a tank type, and an upper swing chute 2 is arranged on it, and the upper swing chute 2 is used to put materials 6 into any material tank 2 according to production requirements. The upper area and the lower area in the tank 2 are each provided with an anti-segregation device to prevent material segregation dur...

Embodiment 2

[0032] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the inner wall of the concentration funnel 3 is provided with a detachable wear-resistant liner 9, when the wear-resistant liner 9 is damaged, it can be quickly replaced, and at the same time, It can also make the material 6 not be stored in the concentration funnel 3, which is beneficial to reduce the load of the concentration funnel. In addition, a layer of wear-resistant material 8 is coated on the surface of the wear-resistant lining 9 in direct contact with the material 6 by overlay welding, which can further protect the wear-resistant lining 9 to enhance the wear-resistant lining 9. abrasion resistance.

[0033] In the present invention, by rationally setting the anti-segregation device, the material can be discharged vertically during the charging process of the material tank, which effectively prevents the occurrence of material segregation, improves the uniformity of ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com