Patents

Literature

393results about How to "Reduce direct impact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

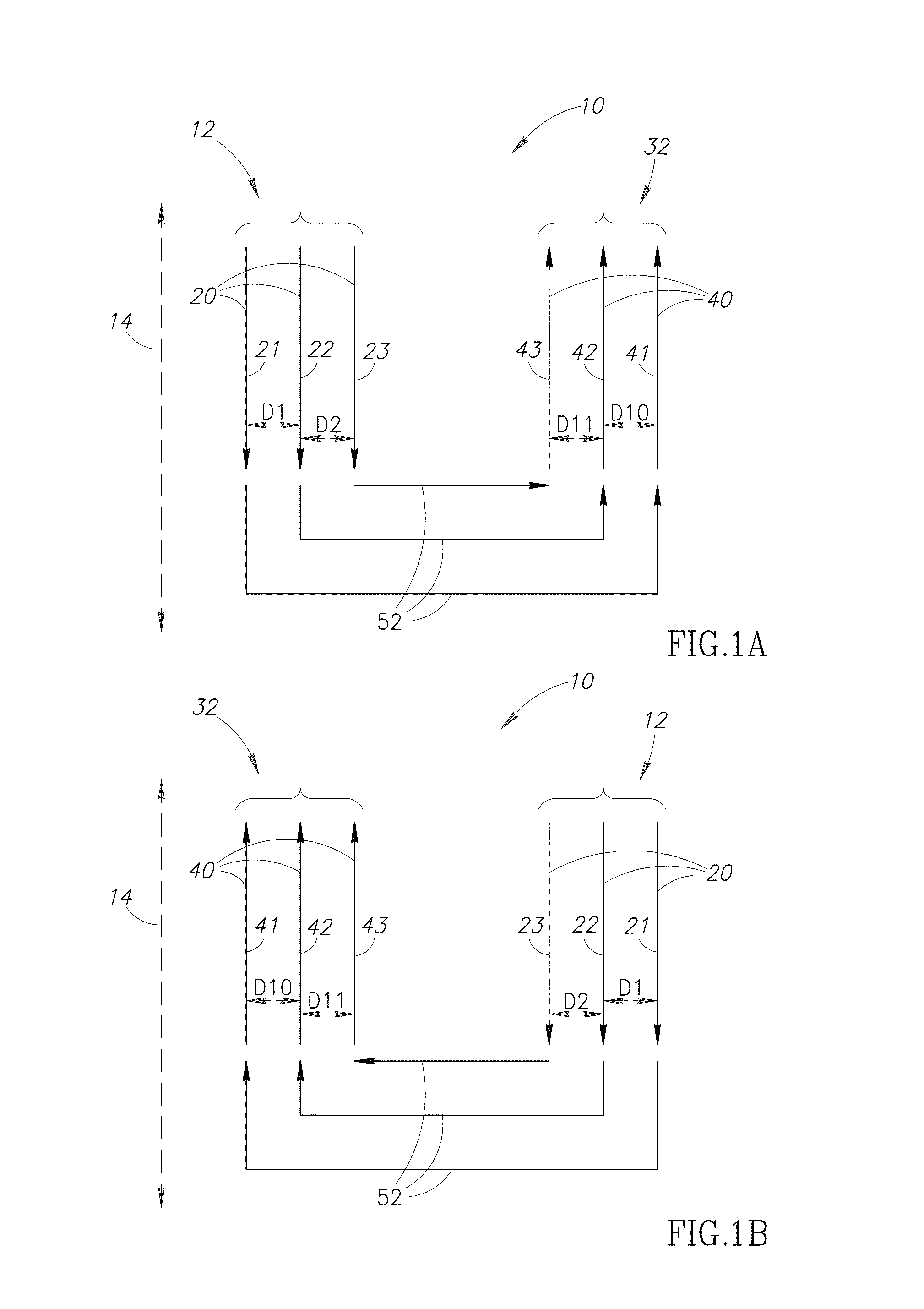

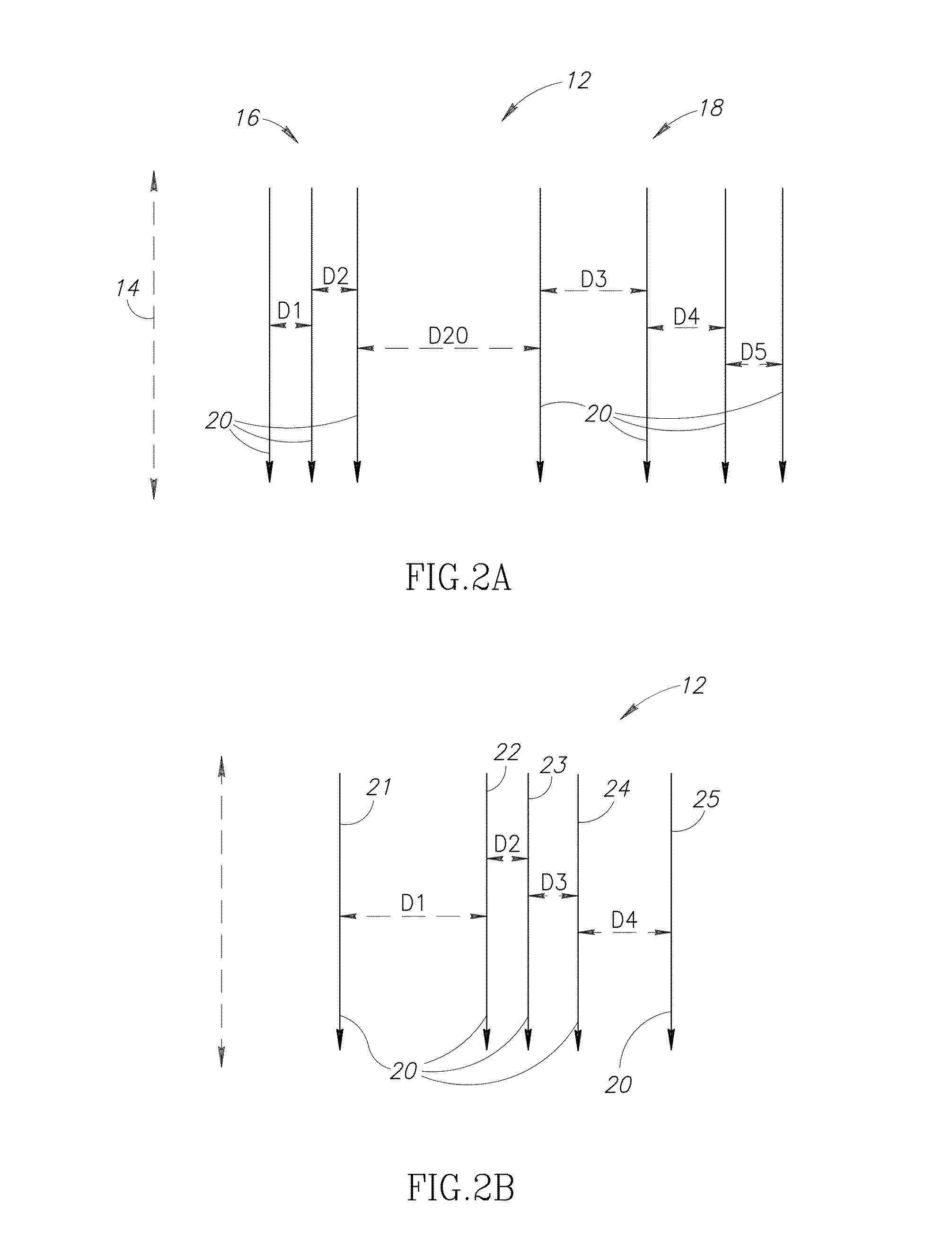

Biochip for High-Throughput Screening of Circulating Tumor Cells

ActiveUS20080318324A1Reduce direct impactShorten speedLiquid separation auxillary apparatusLaboratory glasswaresRe entryHigh-Throughput Screening Methods

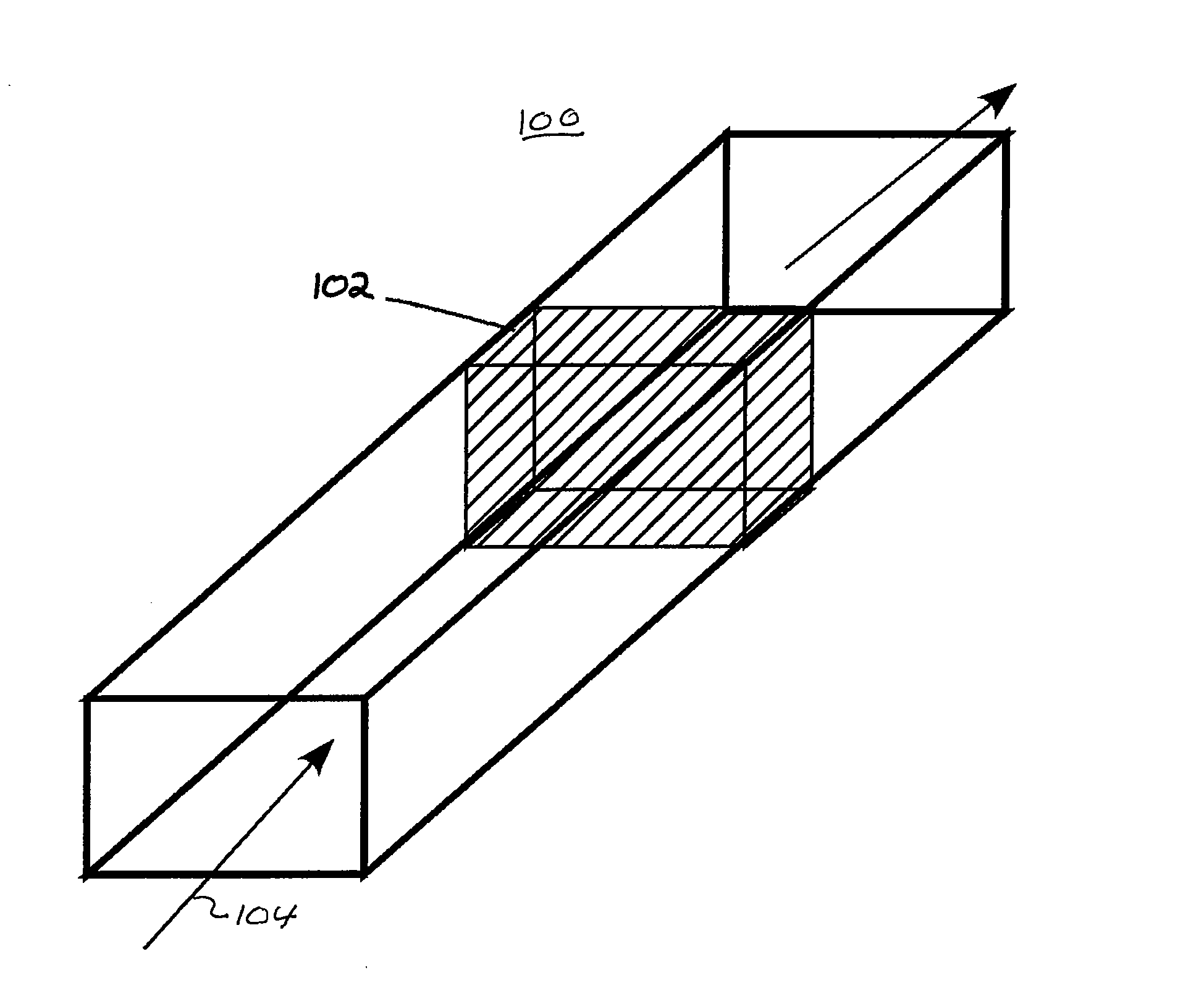

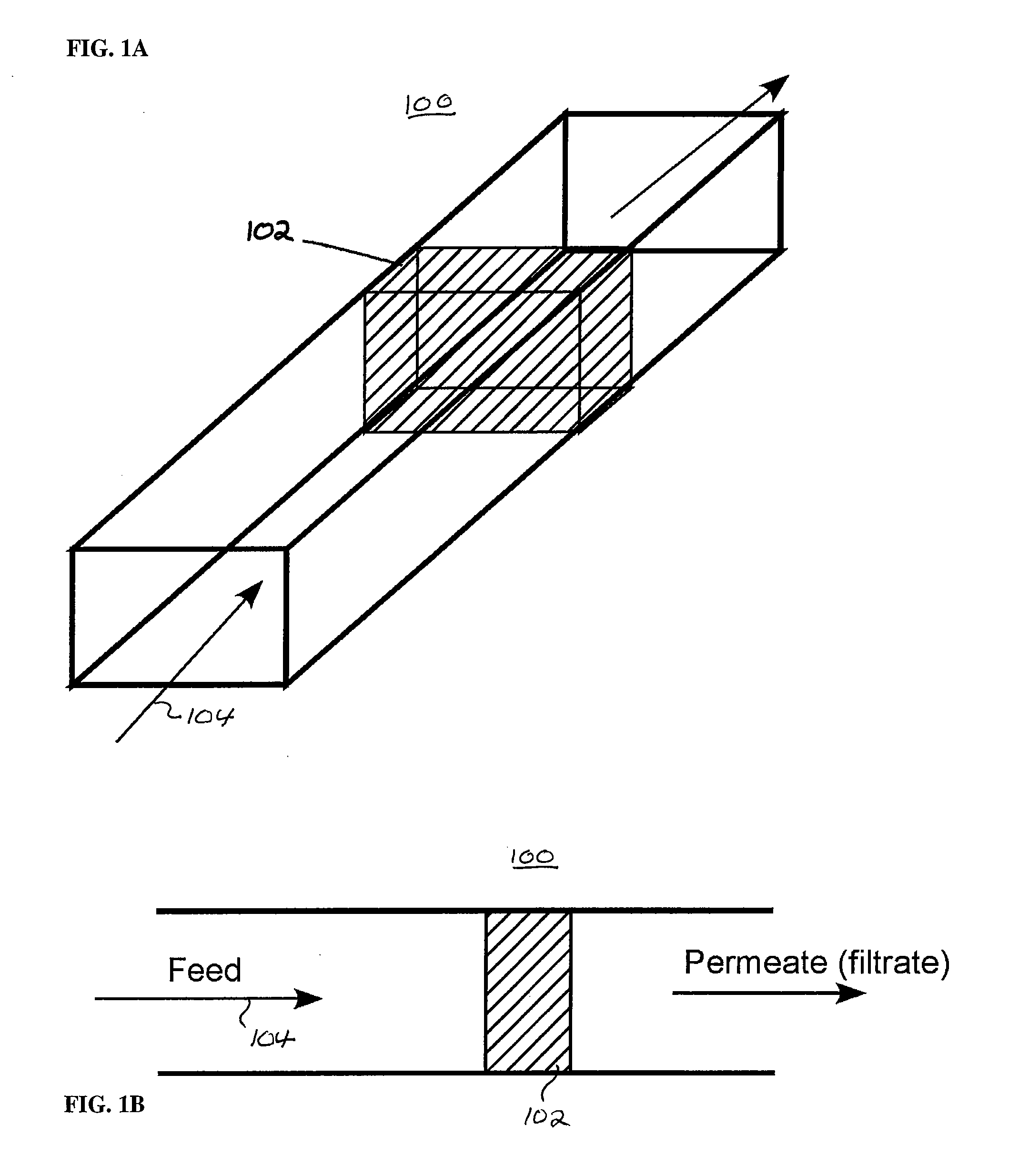

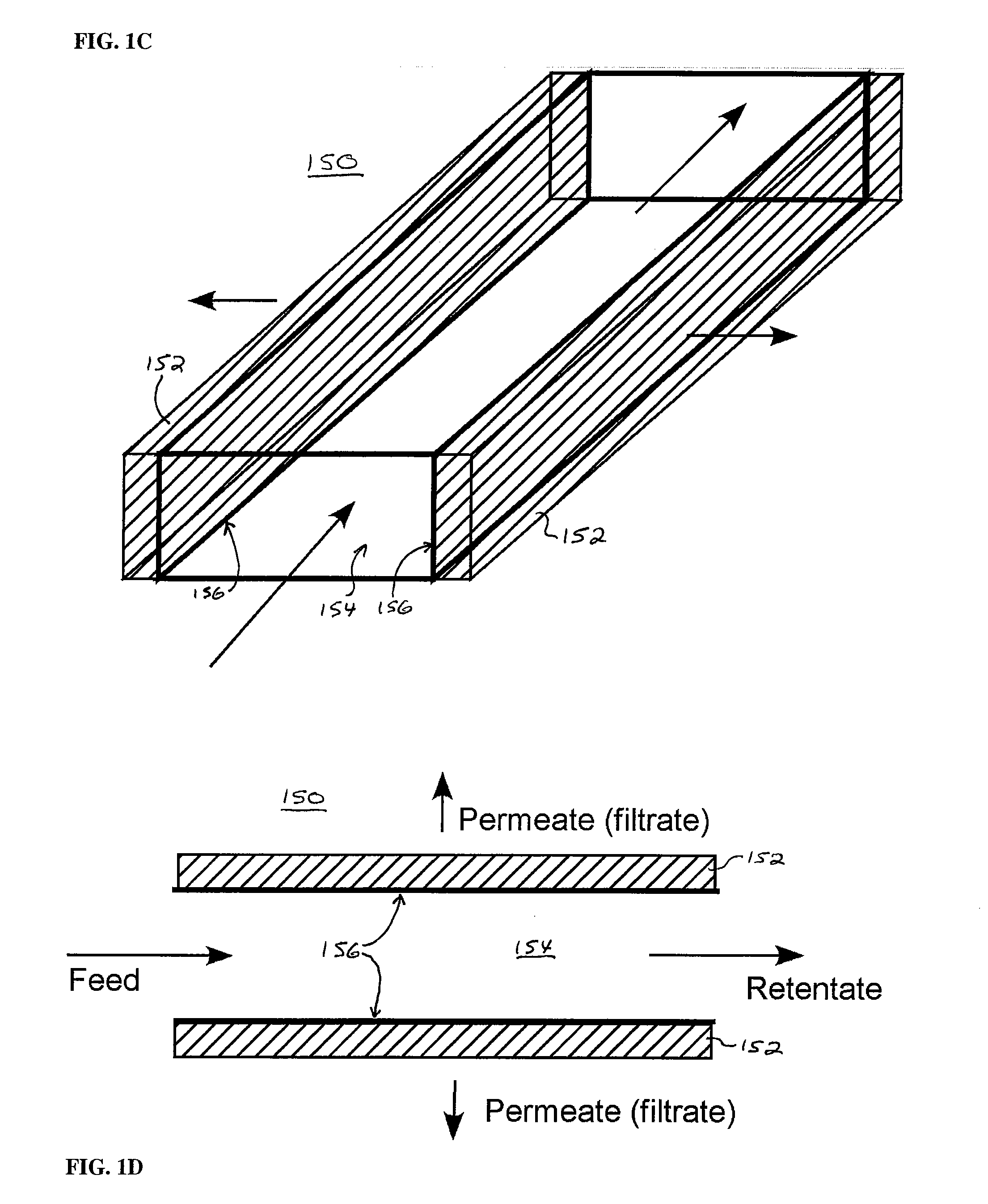

Embodiments in accordance with the present invention relate to the use of effusive filtration to segregate tumor cells from a sample of bodily fluid. In one embodiment, fluid containing a cell is flowed down a channel having a filtration medium present along at least one side wall. The tumor cell is captured when the fluid passes through the filtration medium. Accumulated pressure on the captured tumor cell is reduced by allowing the fluid that has passed through the filtration medium to re-enter the channel. In a particular embodiment, the filtration medium may comprise side wall apertures having a width smaller than that of the cell, with downstream apertures allowing re-entry of the fluid into the channel.

Owner:UNIV OF WASHINGTON

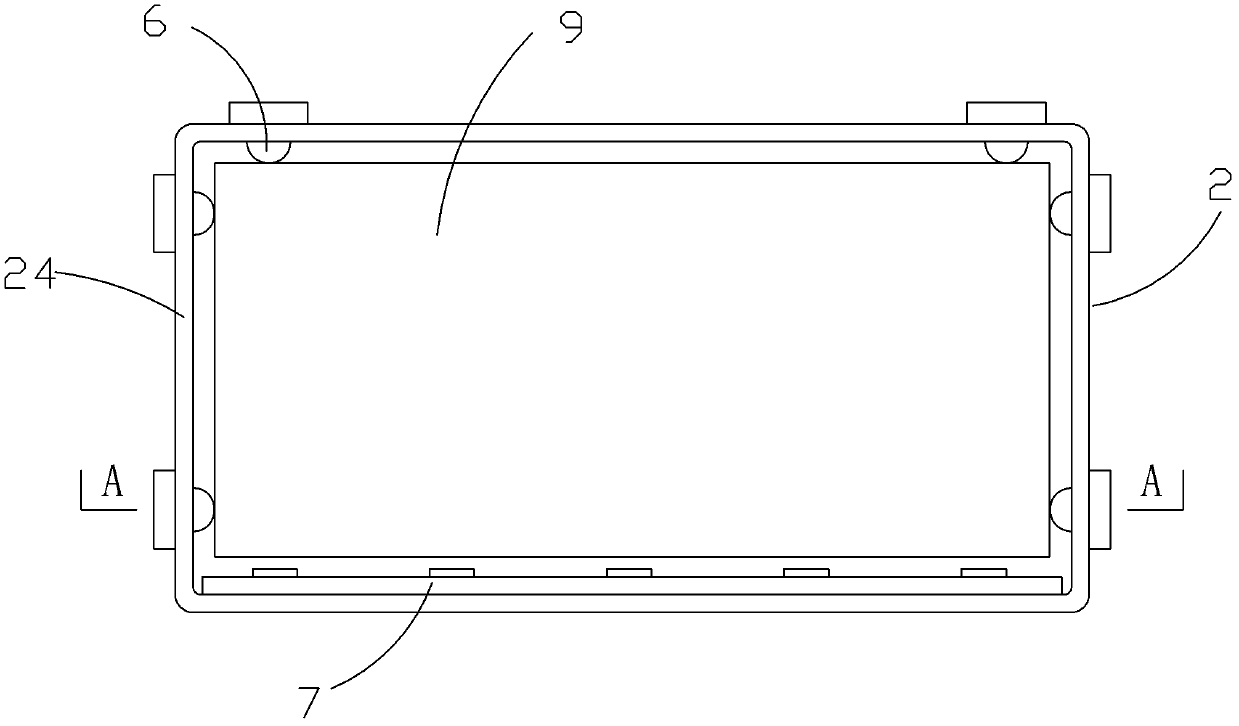

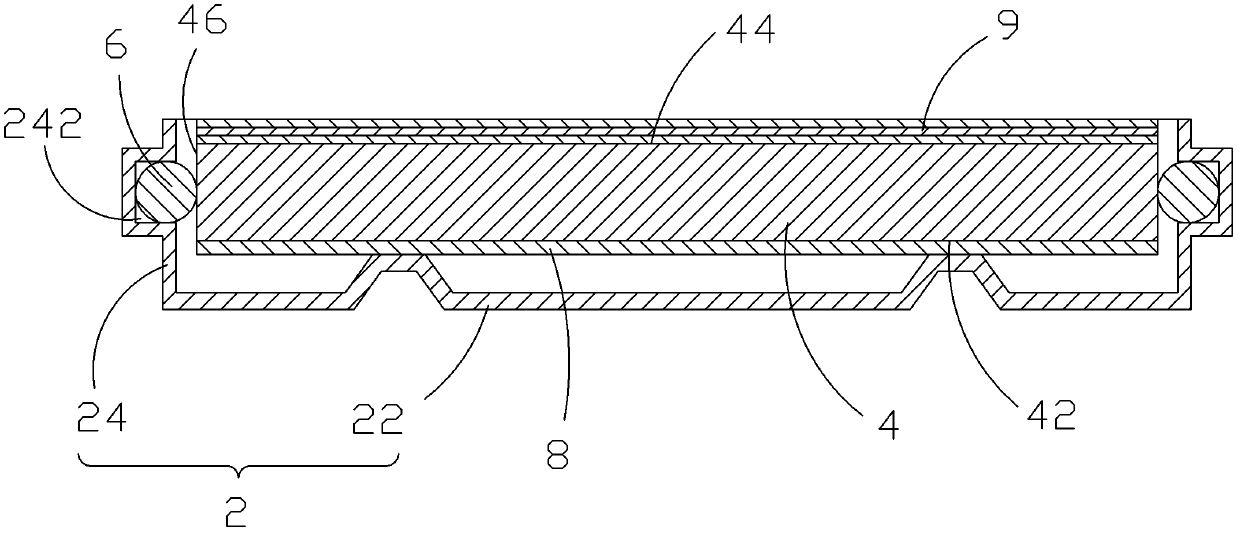

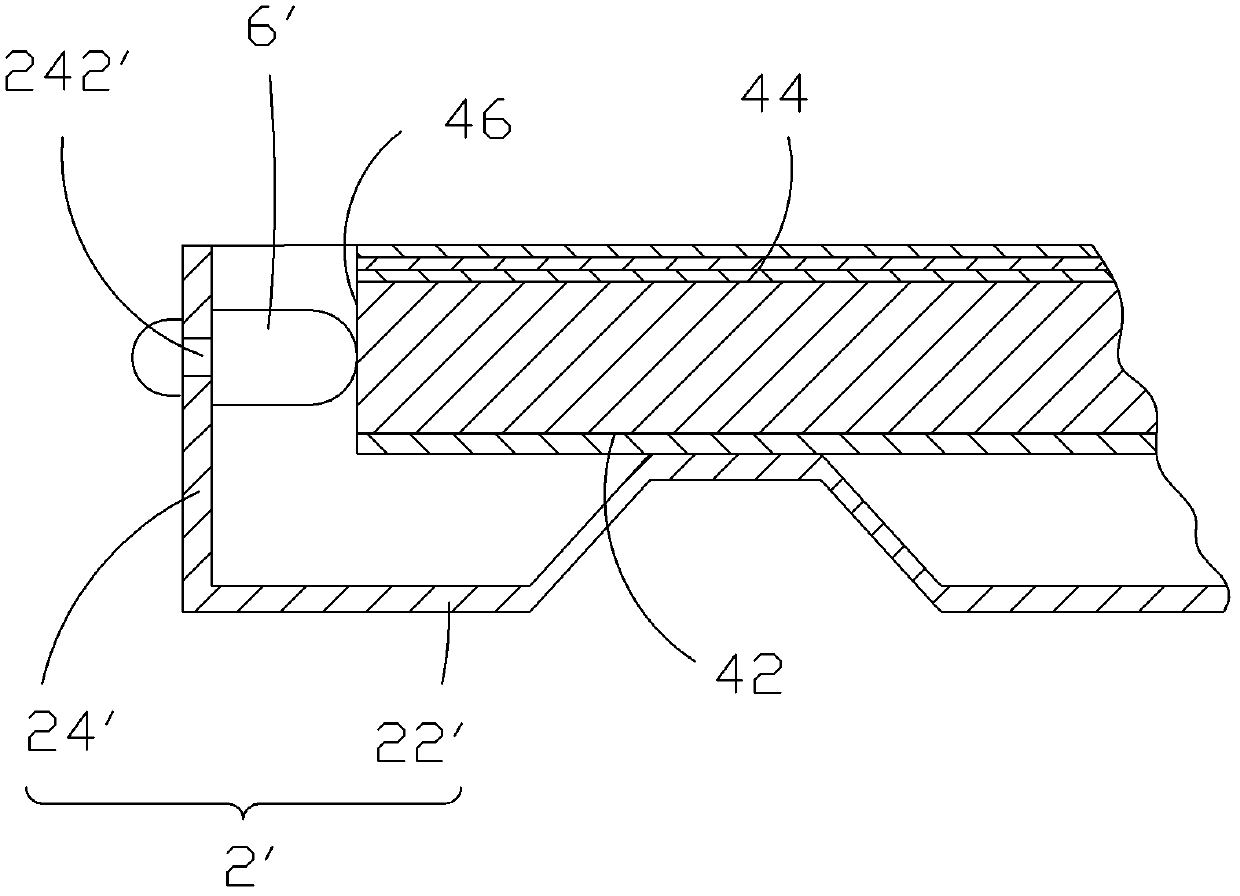

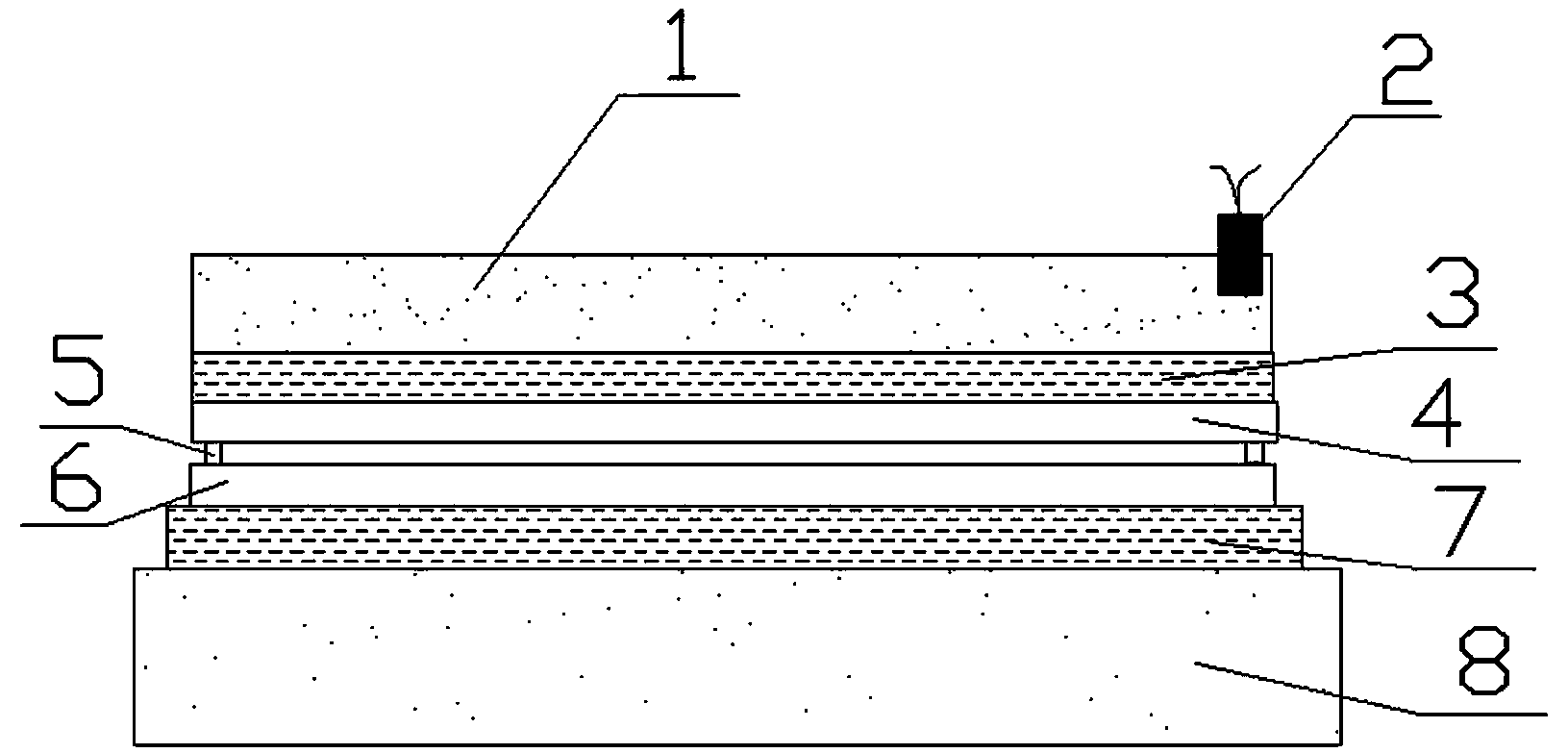

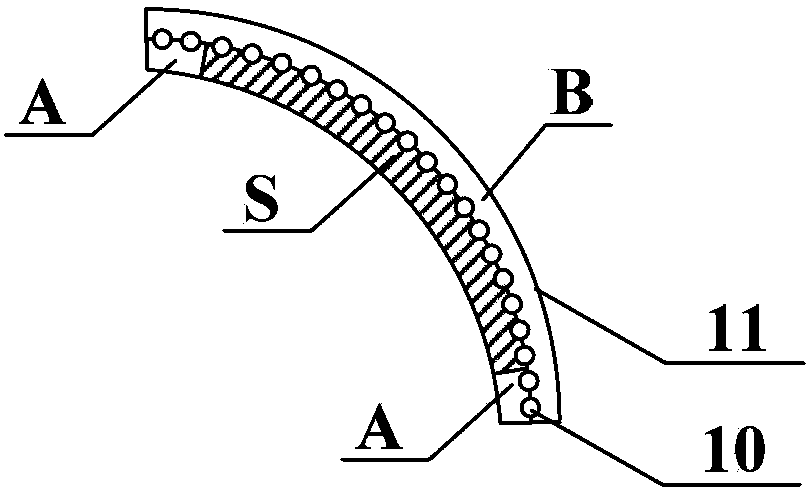

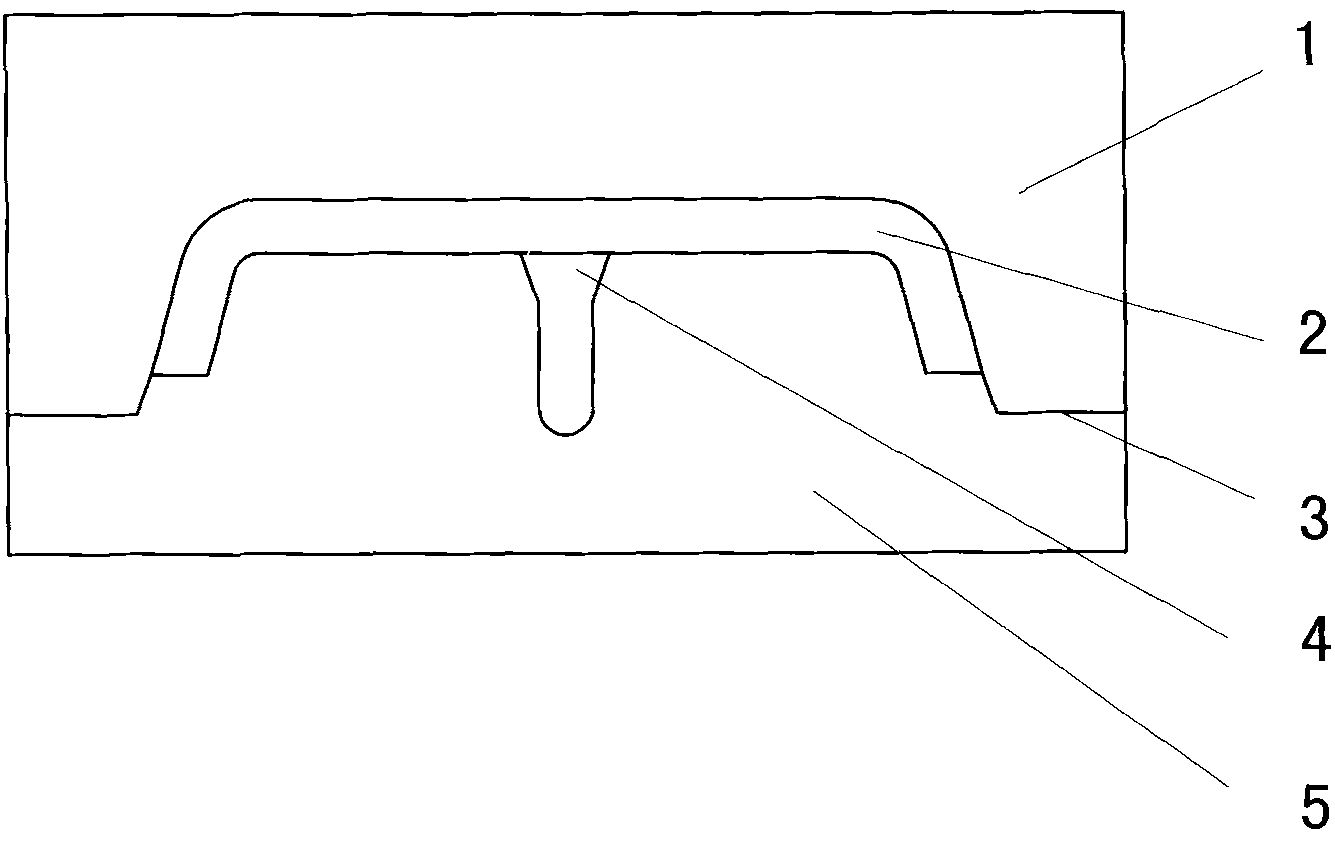

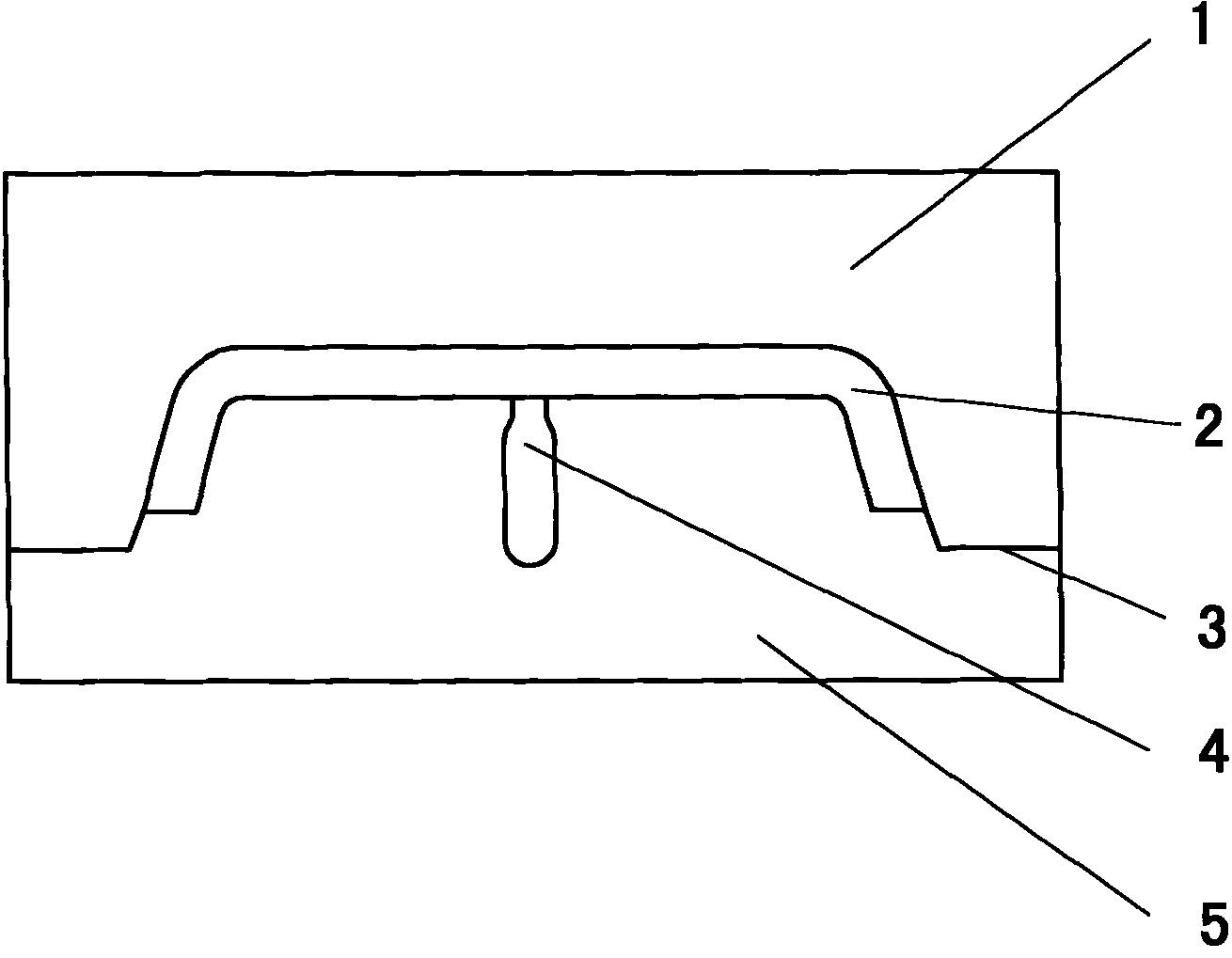

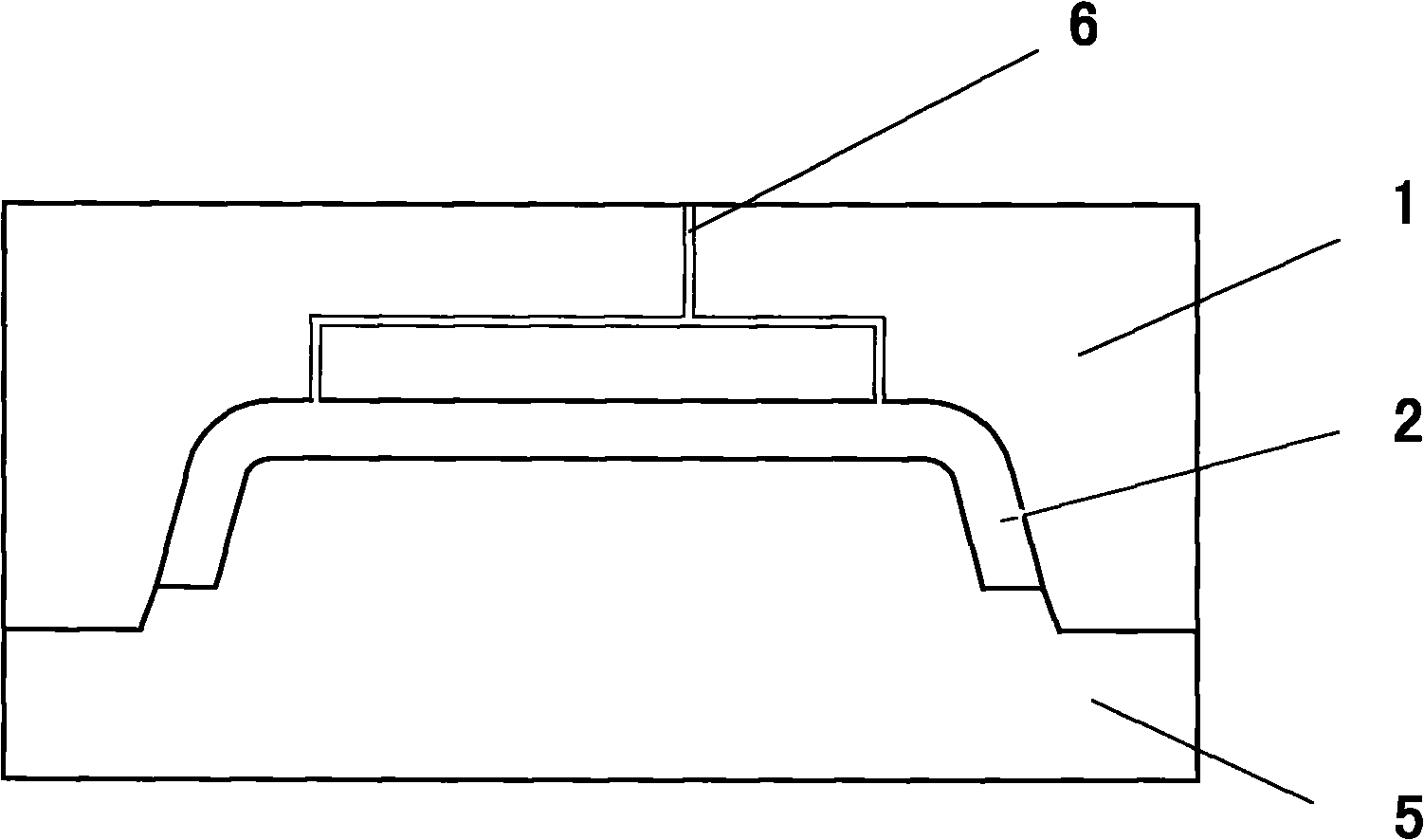

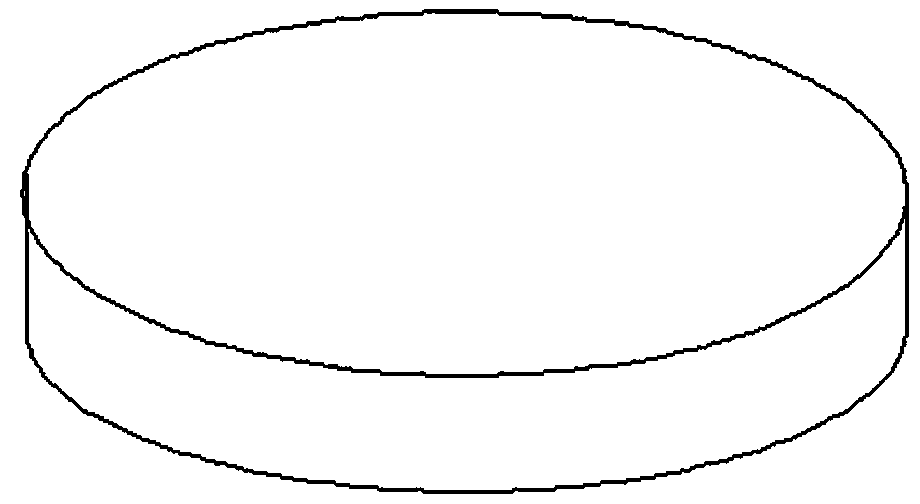

Backlight module

InactiveCN102606960AImprove qualityGuaranteed mechanical strengthMechanical apparatusProtective devices for lightingElastomerLuminous intensity

The invention provides a backlight module. The backlight module comprises a back plate, a light guide plate arranged in the back plate, and a plurality of elastic bodies mounted on the back plate, wherein the back plate includes a bottom plate, and a plurality of side plates vertically connected at the periphery of the bottom plate; the light guide plate includes a bottom surface facing the bottom plate, a top surface away from the bottom plate, and a plurality of side surfaces connected between the bottom surface and the top surface; the plurality of elastic bodies are respectively mounted on the three side plates of the back plate, and butt against the three side surfaces of the light guide plate; and the contact surface between the elastic bodies and the side surfaces of the light guide plate is an arc-shaped surface or a spherical surface. The backlight module provided by the invention can ensure the mechanical strength of the light guide plate by fixing the light guide plate in the back plate through the elastic bodies between the side plates of the back plate and the light guide plate without processing the periphery of the light guide plate by grooving, embossing and so on, and can supply a certain buffer space to prevent extrusion deformation of the light guide plate due to thermal expansion in the prior art, thereby ensuring the luminous intensity and uniformity and reducing the cost.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

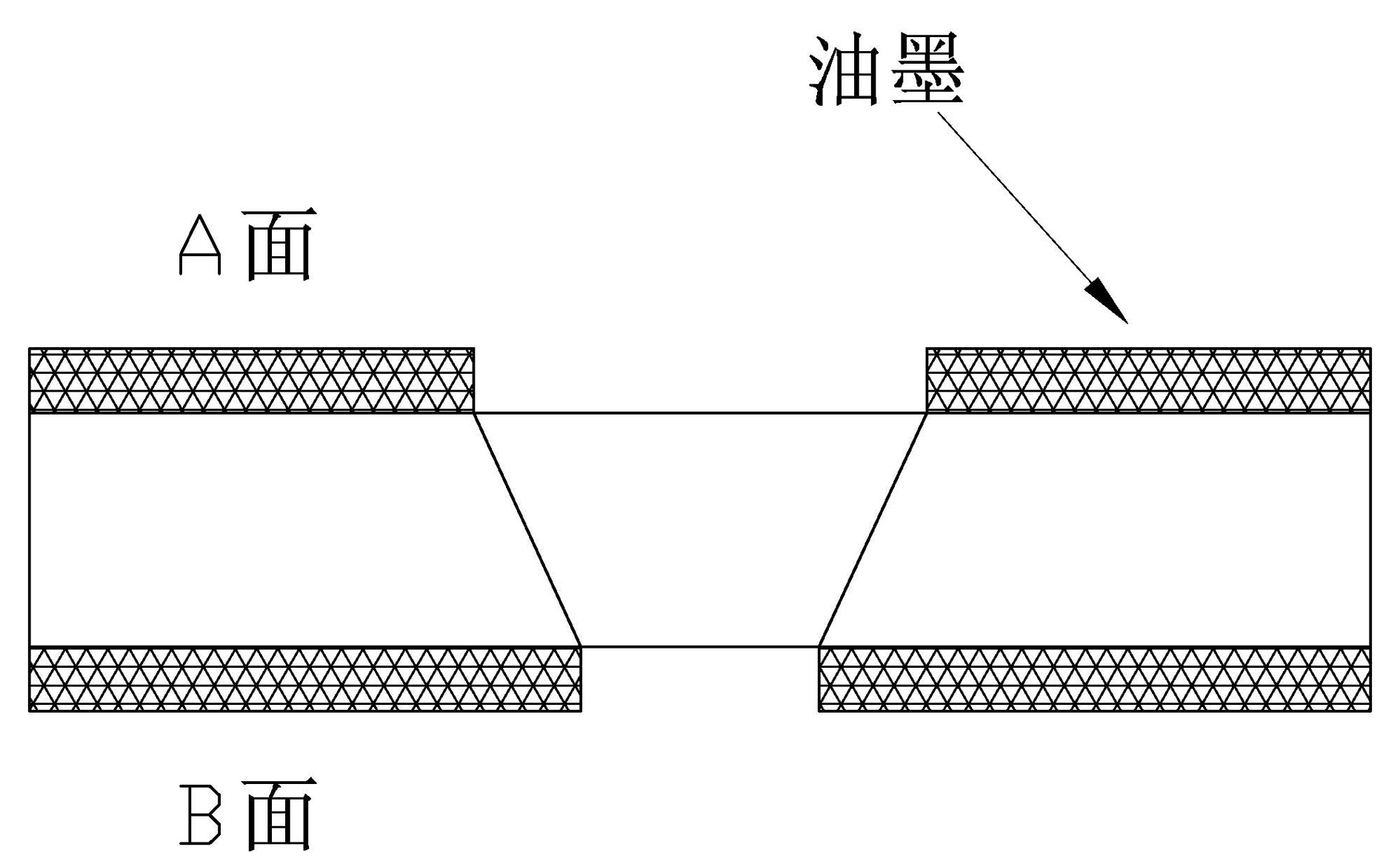

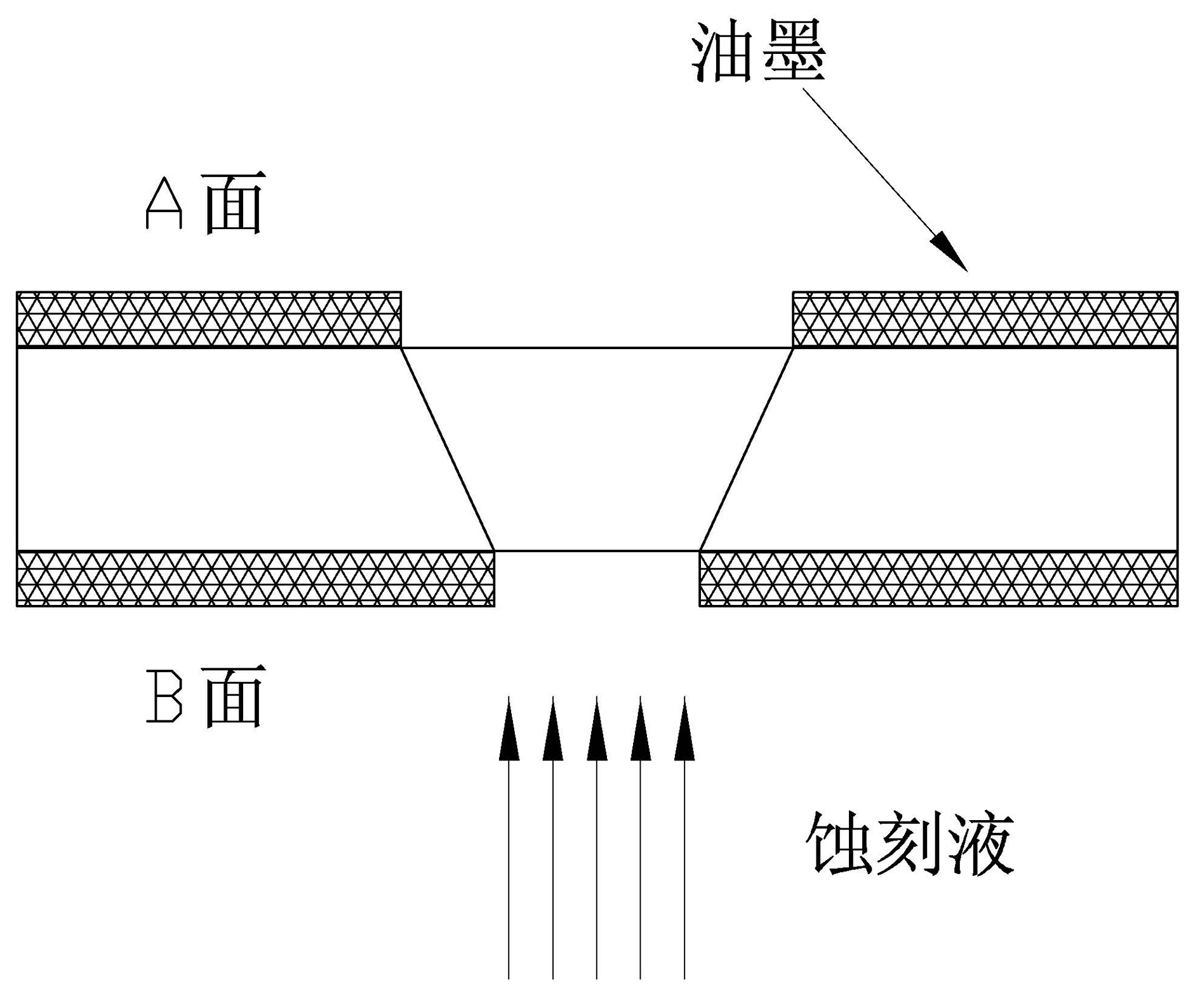

Etching method of metal micro-holes

InactiveCN101913065AEffective protectionImprove protectionLaser beam welding apparatusEtchingMachining process

The invention relates to an etching method of metal micro-holes, which comprises the following processing process steps: process step 1) spraying oil: uniformly spraying an ink layer on a metal workpiece, and leading the thickness of sprayed oil to meet the minimum requirement of avoiding the ink layer after laser perforation from shedding; process step 2) laser perforation: using laser to perforate on the metal workpiece, and leading the perforated hole diameter to be smaller than the finally formed hole diameter; and meeting the requirement of avoiding the laser energy from damaging an ink coating; and process step 3) chemical etching: using etching solution to respectively carry out etching by times from two sides of the workpiece, and leading the diameters at two ends of the hole to meet the finally formed hole diameter. The etching method of the metal micro-holes can process the micro-holes with the diameter of 0.2mm-0.5mm of 3D curved surfaces and stainless steel sheets with the thickness of 0.4mm-1.0mm which can not be processed by the traditional process, and eliminate burrs during the processing process.

Owner:叶淦波

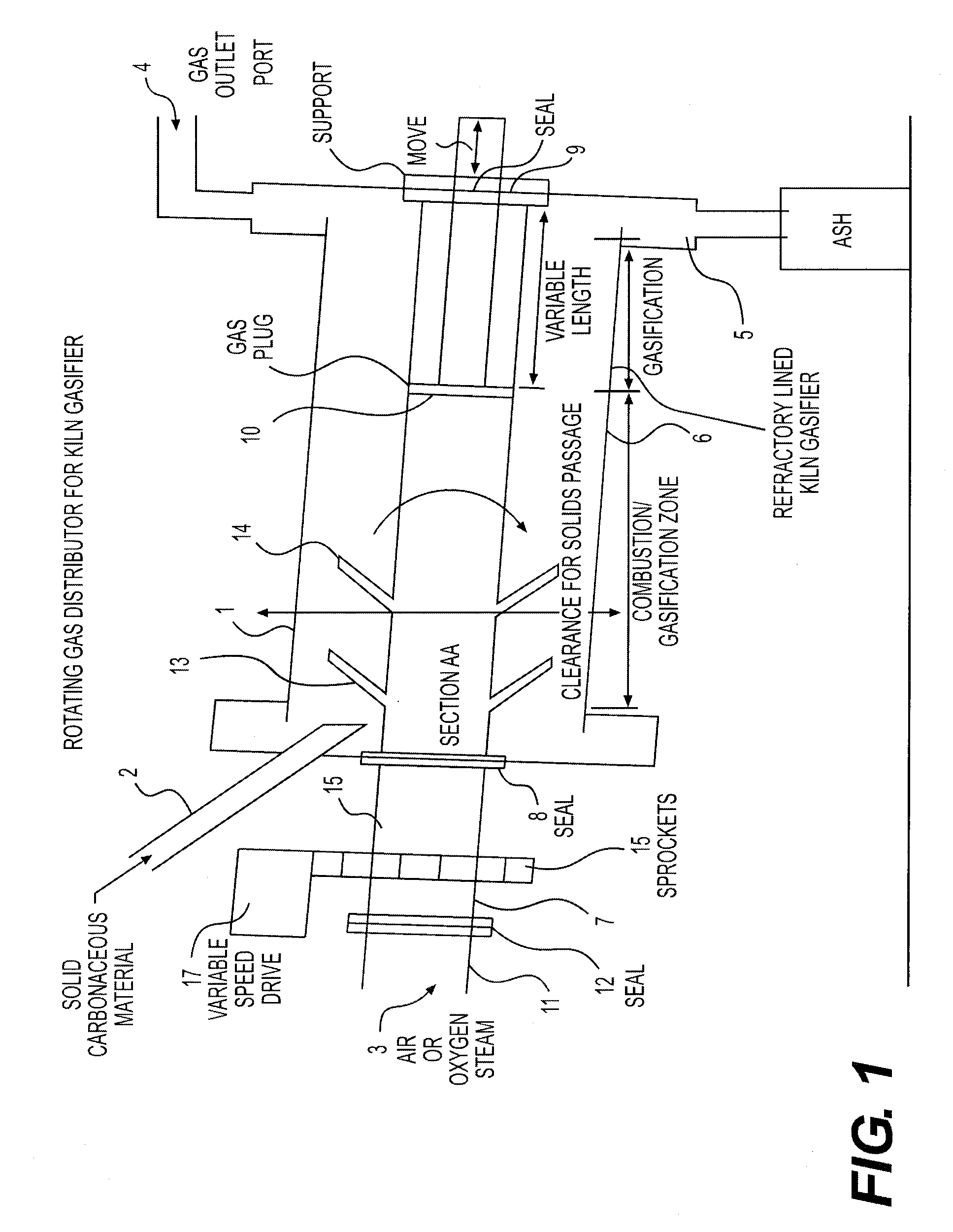

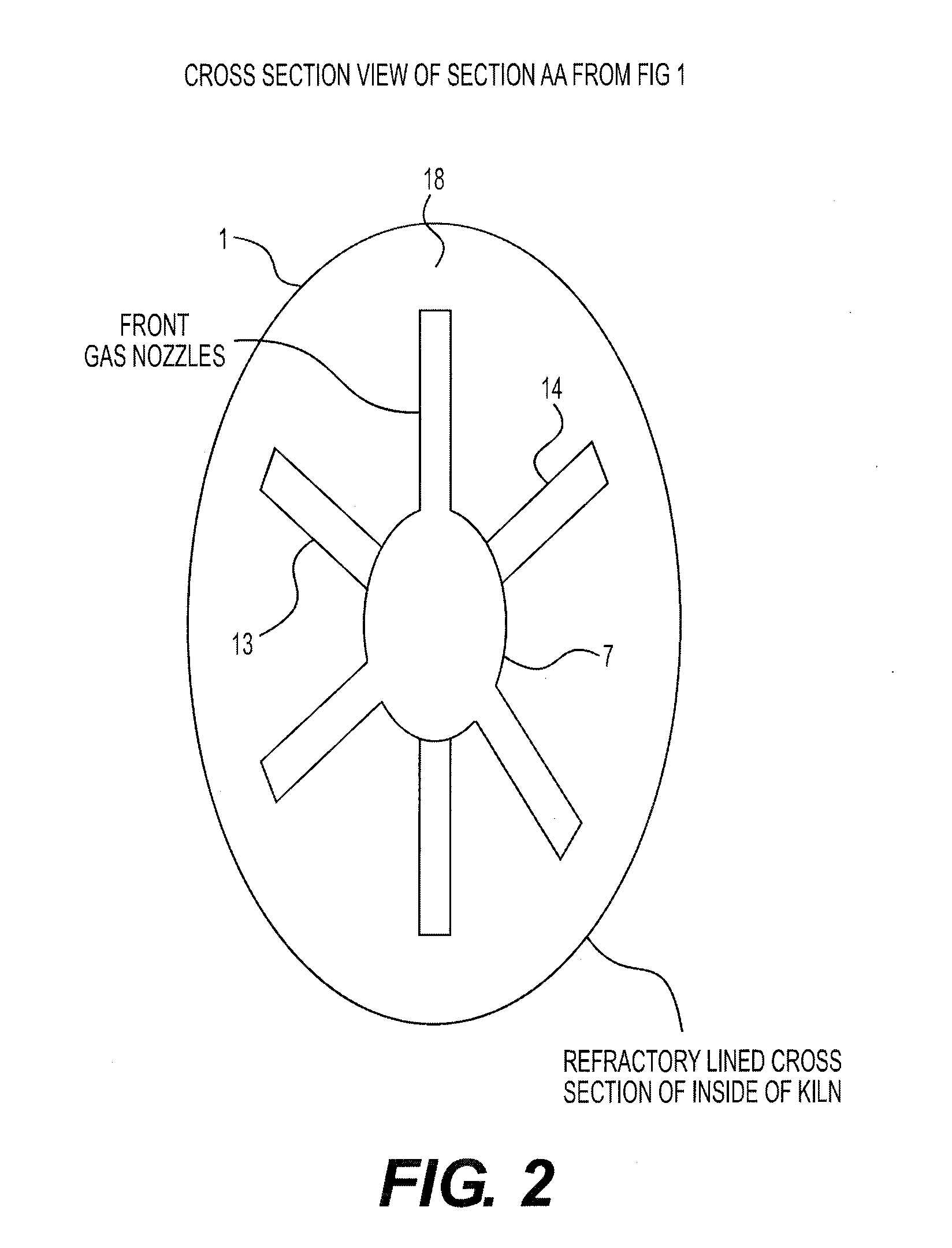

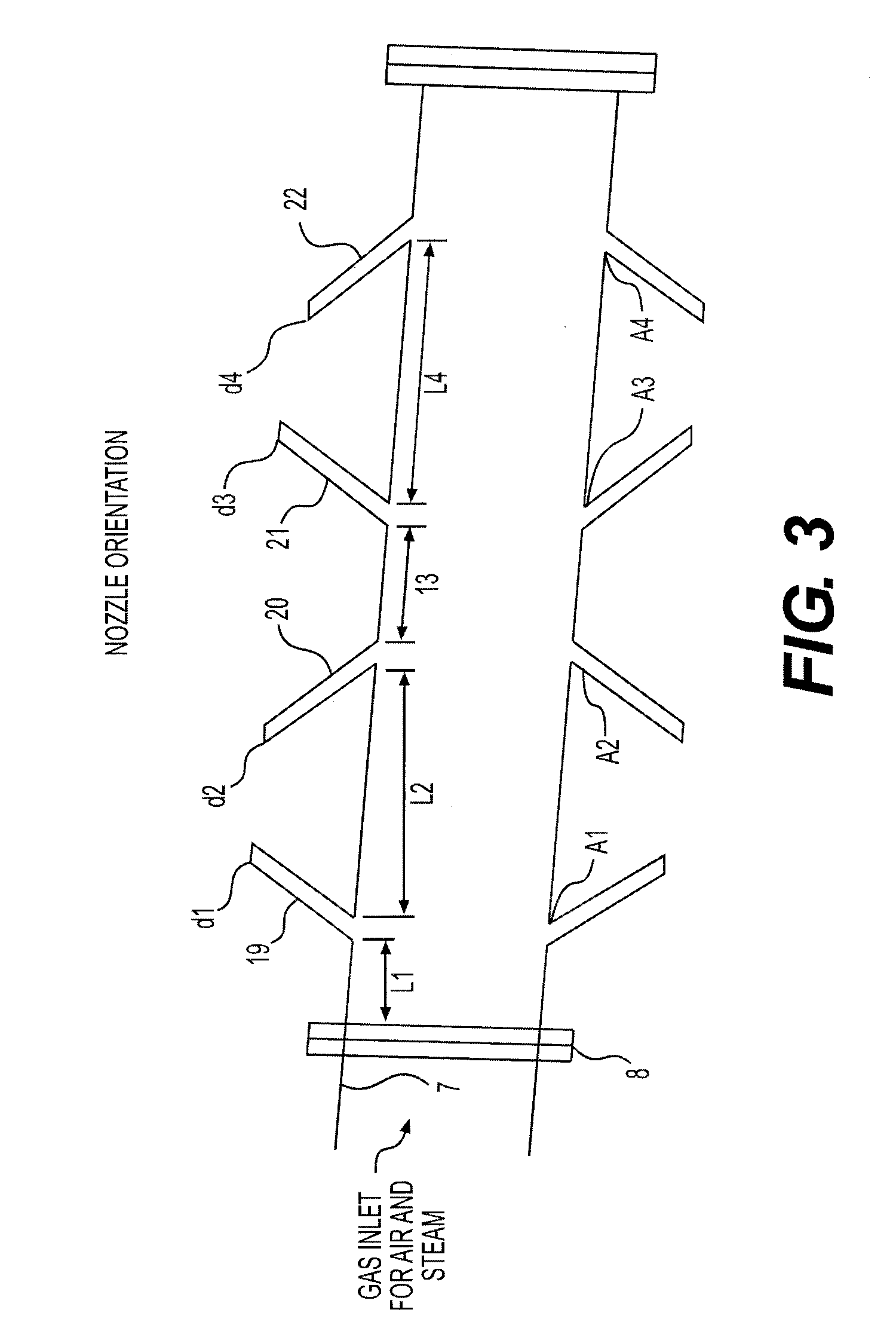

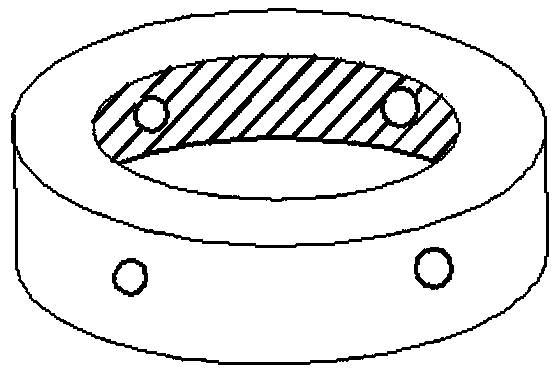

Gas distributor for a rotary kiln

InactiveUS20110116984A1Lower overall pressure dropReduce direct impactSolid waste disposalRotary drum furnacesProduct gasProcess engineering

A rotating air distributor for rotary reactors such as rotary kilns for the gasification of biomass and other carbonaceous materials for efficient mixing and maximum conversion of solid biomass and other carbonaceous materials into synthesis fuel gas is disclosed. The invention includes a gas distribution port comprises of one main supply from which several discharge nozzles emerge at different angles and at different locations along the length of the reactor to provide distribution of gas throughout the intended length of the reactor. The discharge of gas from the gas distribution port is adjusted by the variable position of a plug inside the port that can be adjusted during the operation of the kiln to achieve optimum gas-solid interaction along the length of the reactor. The rotating action of the gas distribution port also facilitates and eases the passage of reacted biomass solid and other carbonaceous material residue through the reactor.

Owner:REHMAT AMIRALI GULAMHUSSEIN +4

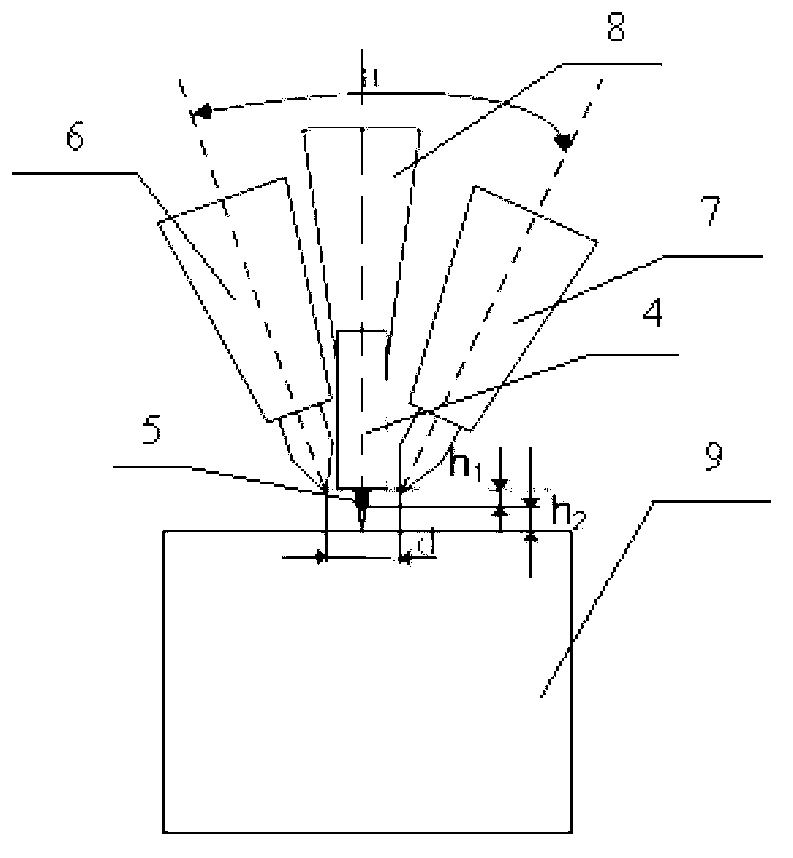

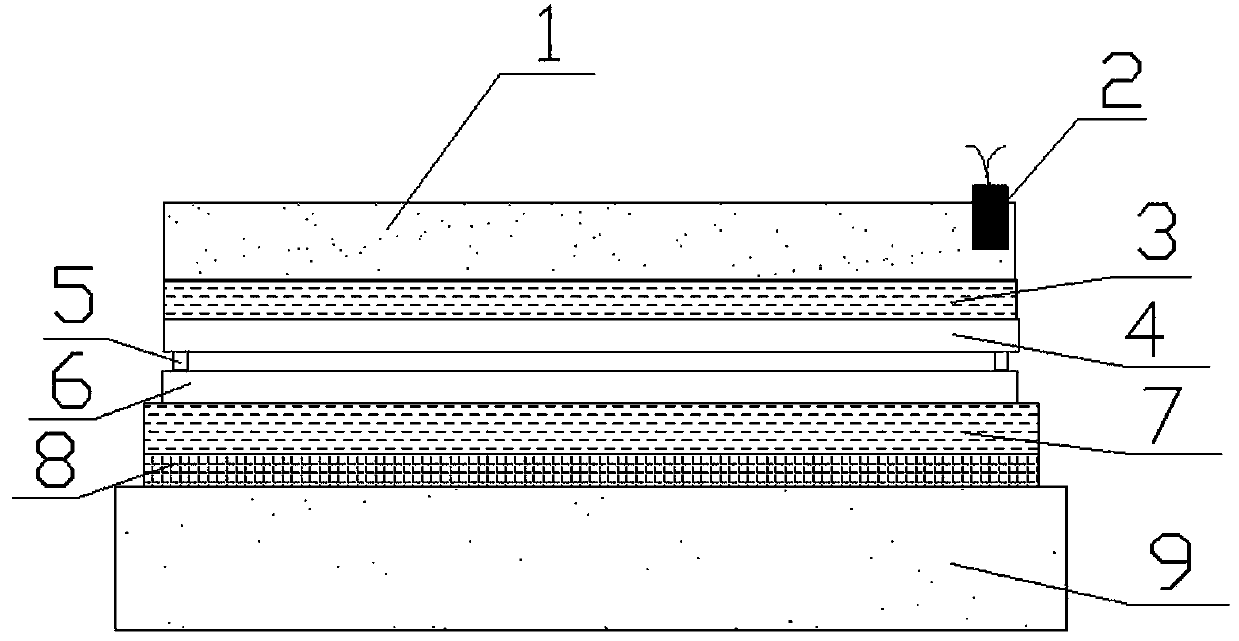

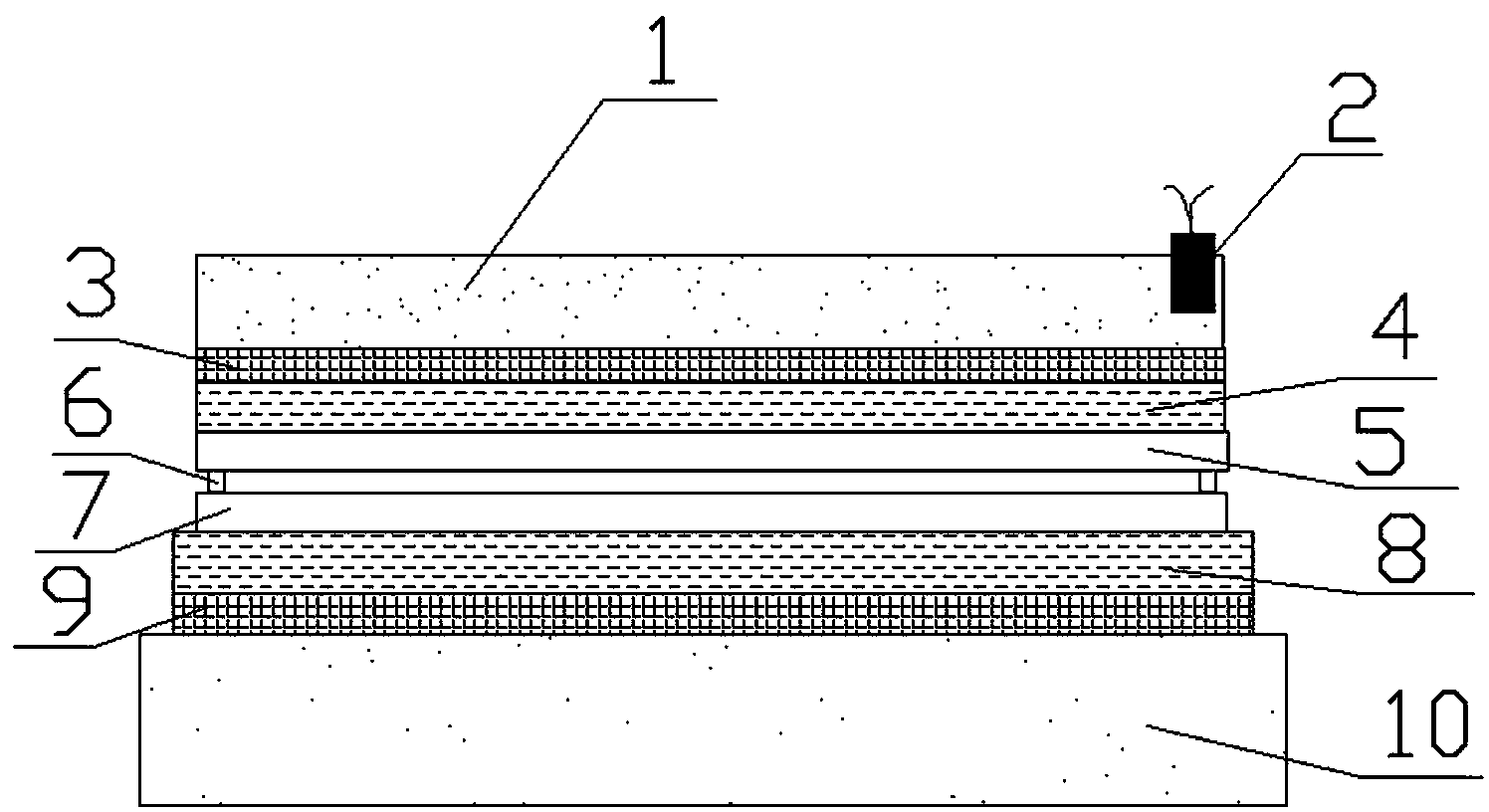

Explosive welding method for copper-aluminum composite material

ActiveCN103706940AReduce direct impactEvenly distributedWelding/soldering/cutting articlesMetal working apparatusEngineeringAluminum composites

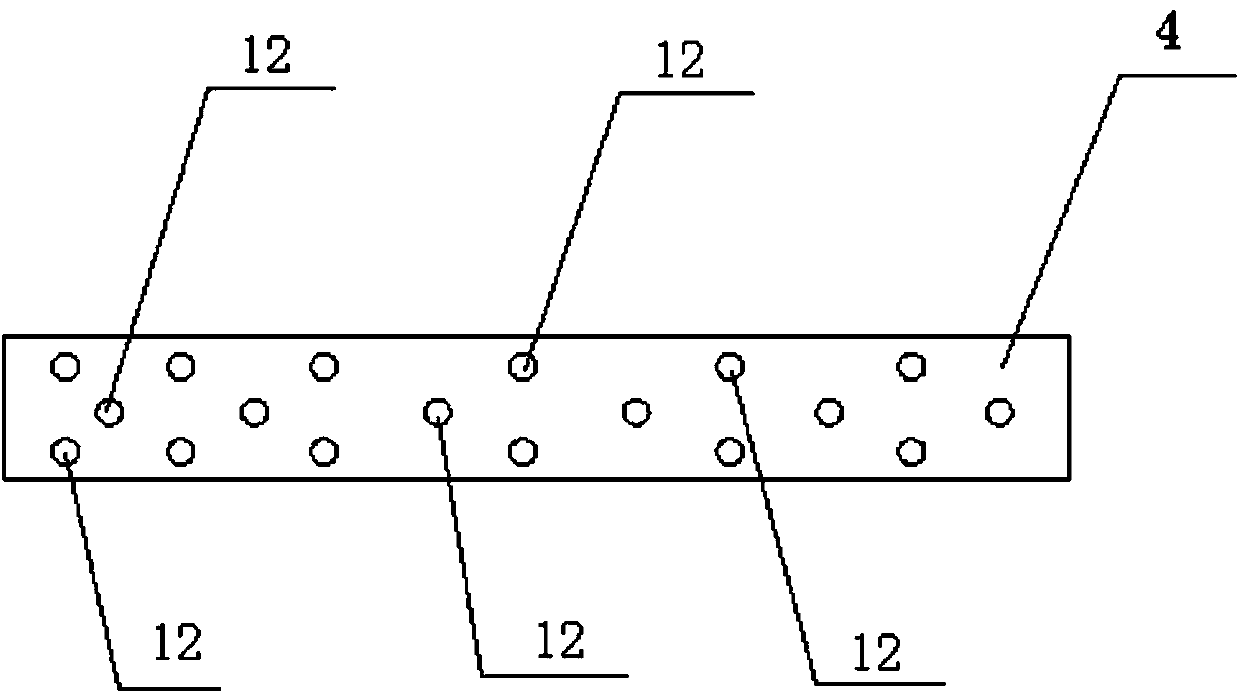

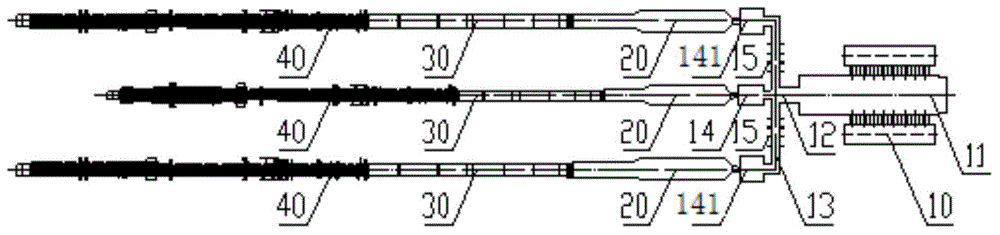

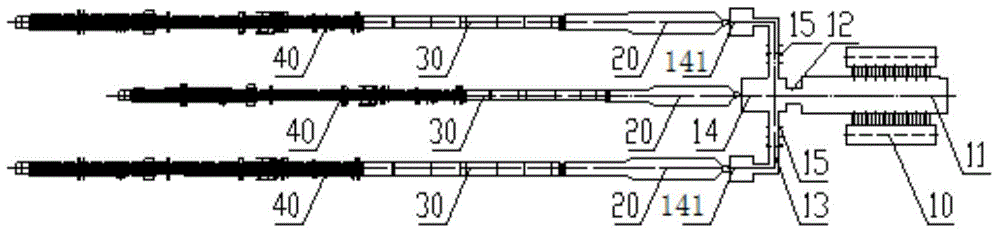

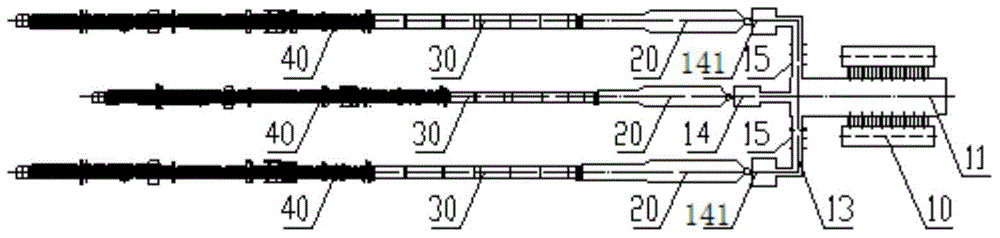

The invention relates to an explosive welding method for a copper-aluminum composite material. An aluminum composite plate (4) is arranged on a copper substrate (6) in a parallel mode through a supporting object (5), a rubber buffering layer (3) is laid on the aluminum composite plate (4), rock ammonium nitrate explosive cloth number two is arranged on a rubber buffering layer (3), the copper substrate (6) is arranged on a rubber cushion layer (7), a medium-fine sand foundation (8) is located below the rubber cushion layer (7), and the copper-aluminum composite material is obtained through explosive welding. A copper-aluminum composite plate produced through the explosive welding method can achieve 100% welding composite rate, is evenly formed in a composite mode without the phenomena of layering, swelling, vortex and the like.

Owner:HUNAN FORHOME COMPOSITE MATERIALS CO LTD

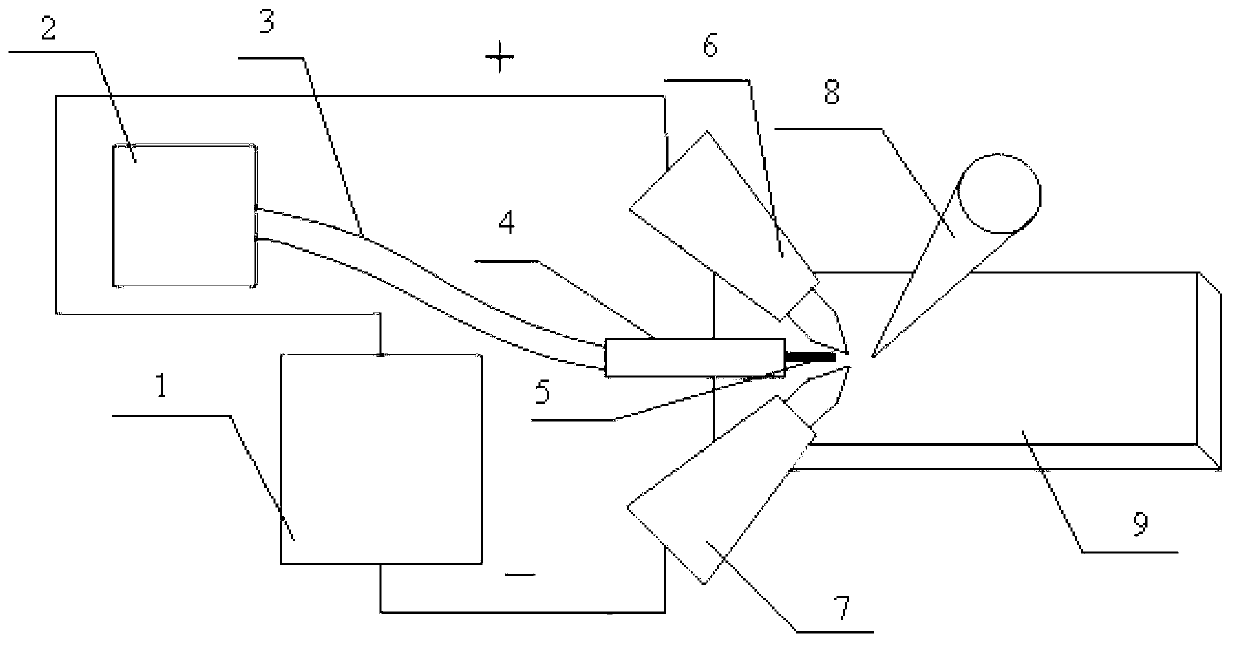

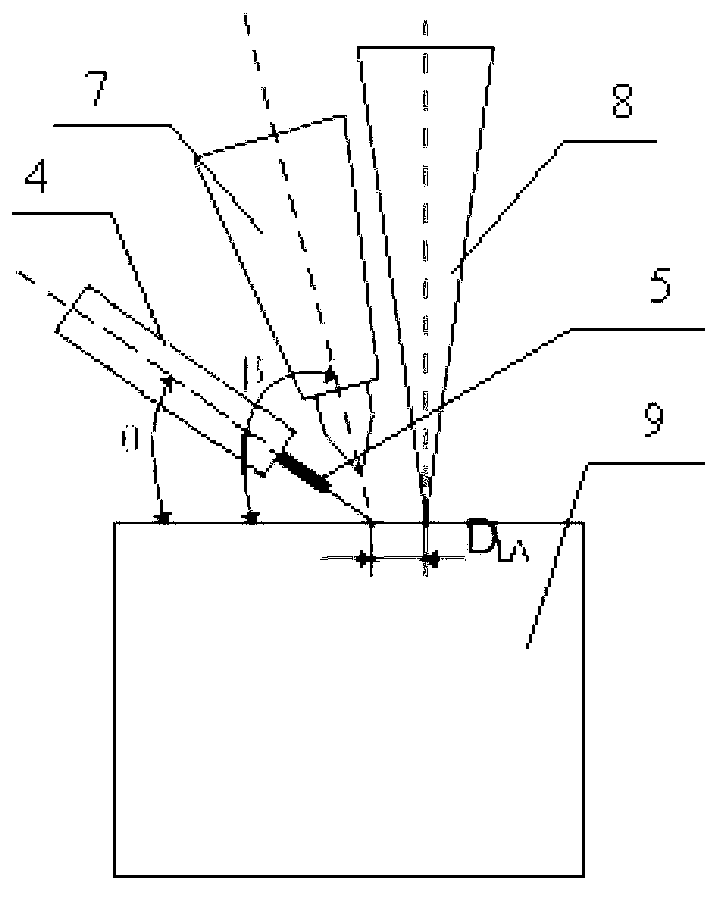

Fusing method of laser welding with filler wires using double TIG welding torches

ActiveCN102990235AReduce direct impactAvoid energy lossArc welding apparatusLaser beam welding apparatusElectric arcLarge deformation

The invention discloses a fusing method of laser welding with filler wires using double TIG welding torches, which relates to a fusing method of laser welding with filler wires, and mainly aims to solve the problems of high requirement on accuracy of alignment of a welding wire, large deformation of a welding joint and poor mechanical performance of a welding seam of a normal fusing method adopted by the conventional wire filling laser welding process. The fusing method comprises the following steps of: respectively connecting the two TIG welding torches with positive and negative poles of a TIG power supply; starting a laser device to form a welding pool on a workpiece to be welded by laser; and starting shielding gas which is sprayed out from a coaxial wire and gas feeding nozzle, connecting the TIG power supply to implement arc striking between the two welding torches, starting a wire feeding system to send out welding wires continuously, and adjusting the output current and the wire feeding speed of the TIG power supply to ensure that an electric arc fuses the welding wire stably, wherein the protection gas is not introduced into the two TIG welding torches independently. The fusing method can be applied to the field of metal laser filling welding connection engineering.

Owner:HARBIN INST OF TECH

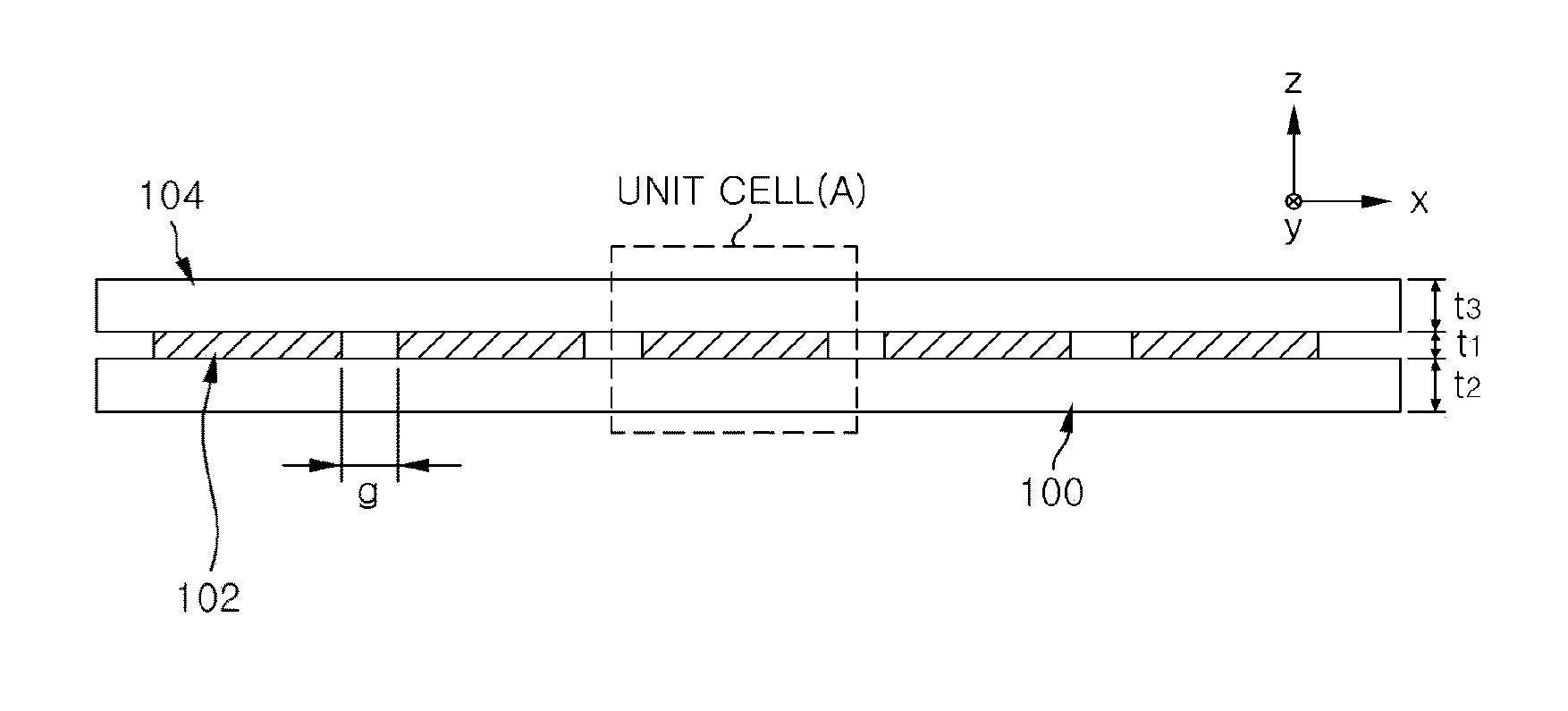

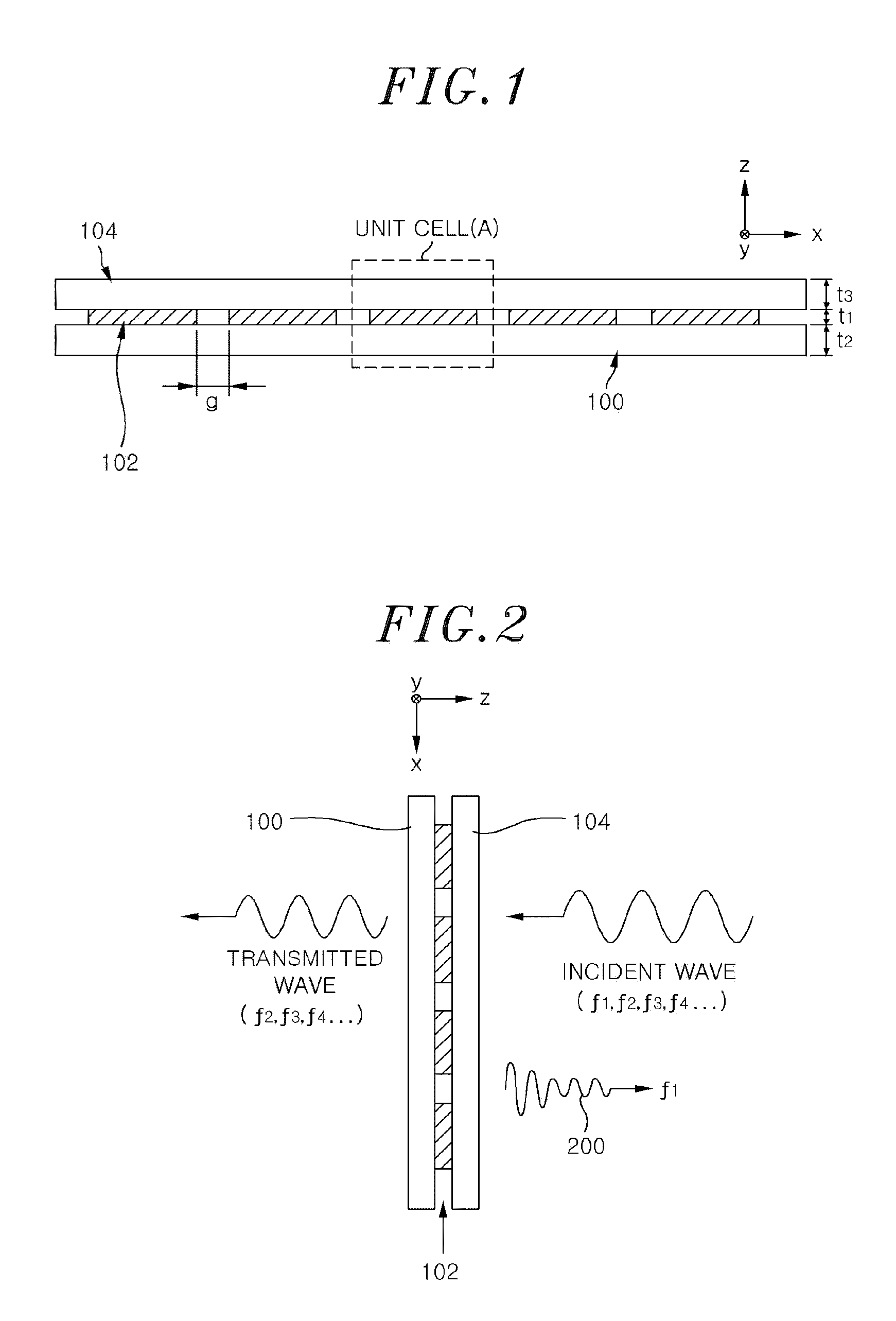

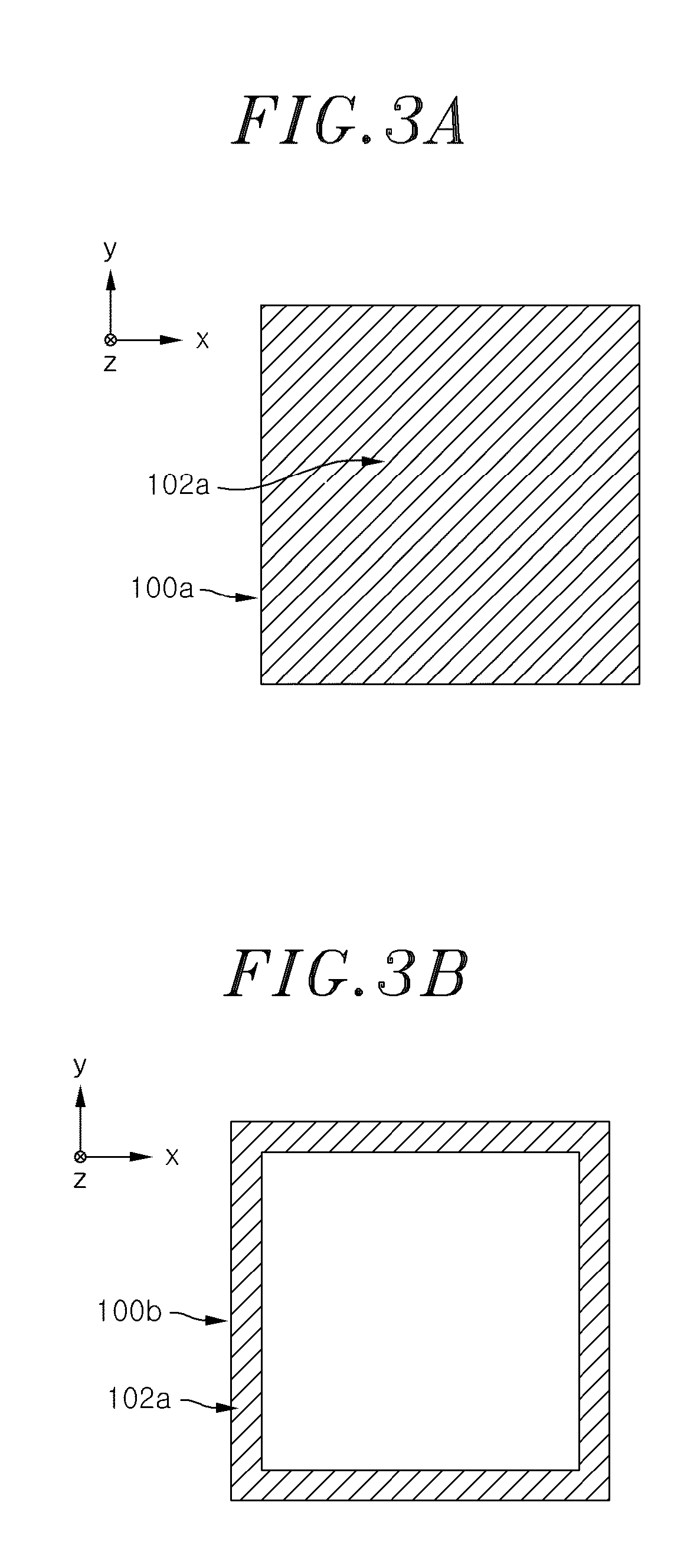

Transparent film for reducing electromagnetic waves and method of manufacturing the same

ActiveUS20130088408A1Reduce electromagnetic radiationImprove performanceMaterial nanotechnologyMagnetic/electric field screeningElectromagnetic electron waveOptoelectronics

A method of manufacturing a transparent film for reducing electromagnetic waves includes forming a first dielectric layer and forming a pattern layer on the first dielectric layer. The pattern layer is made of a transparent electrode material having surface resistance.

Owner:ELECTRONICS & TELECOMM RES INST

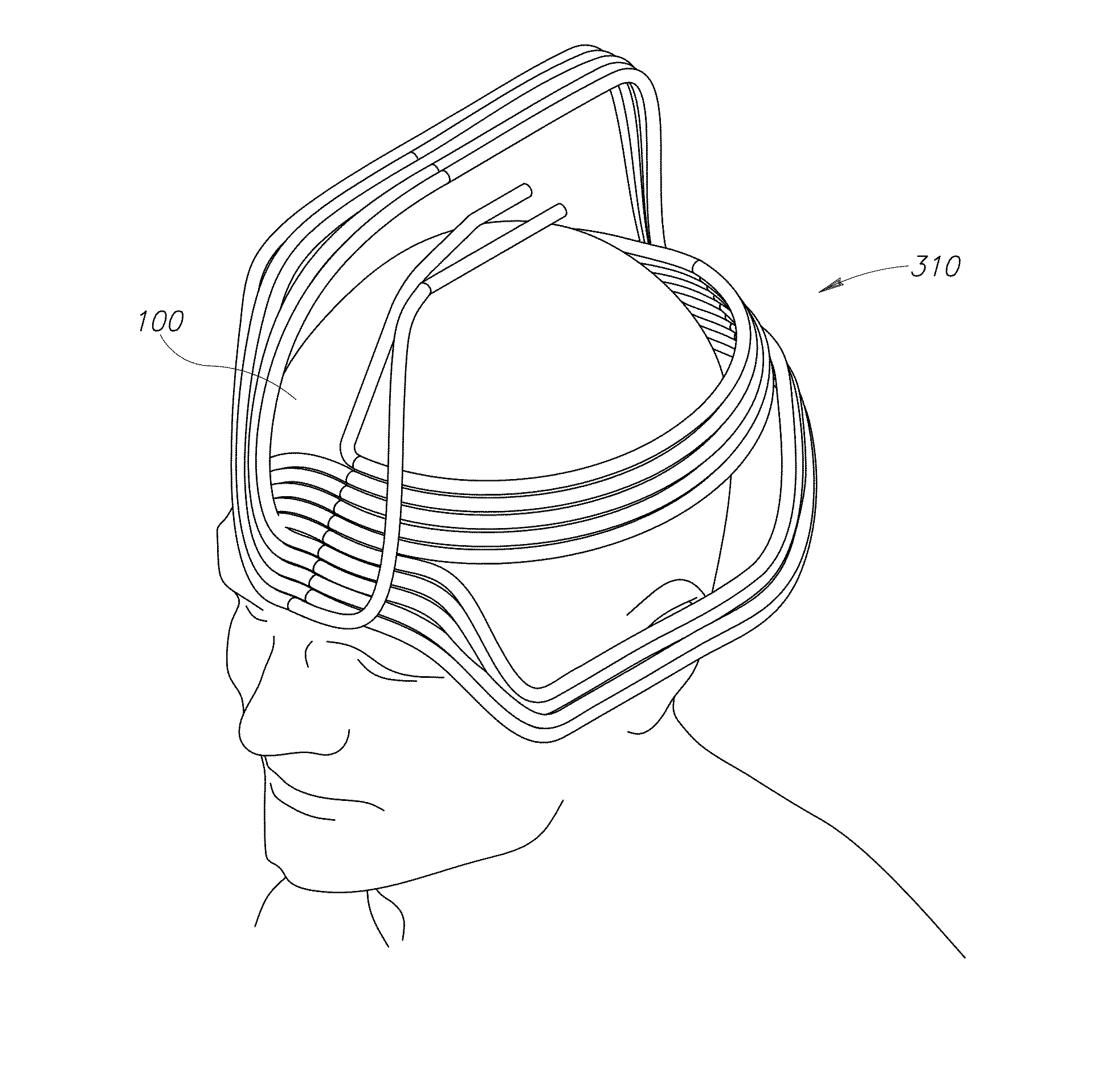

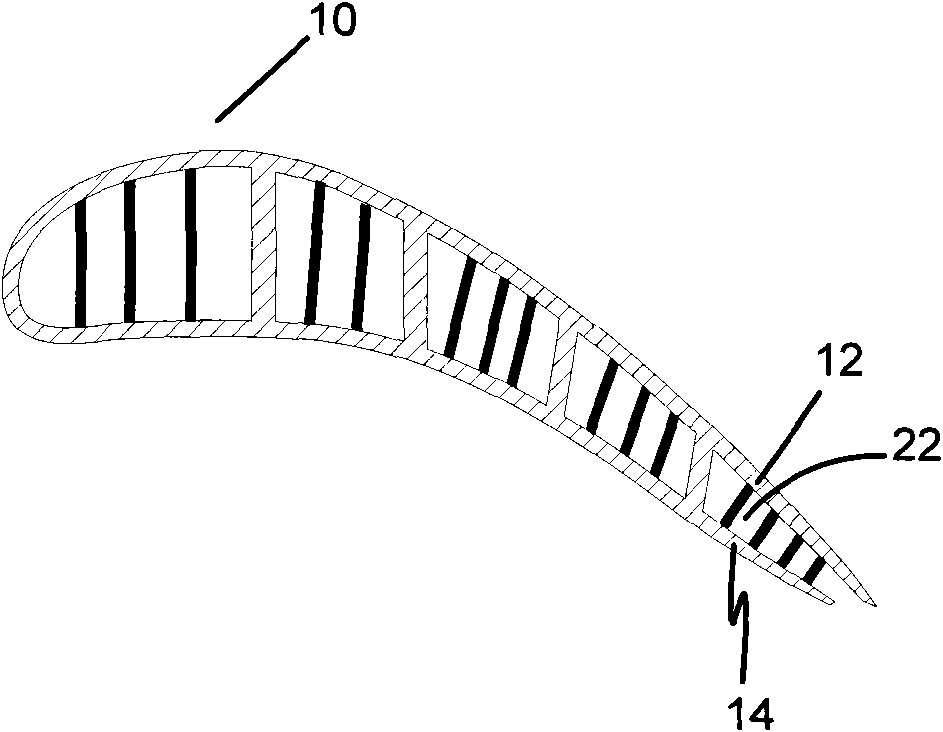

Unilateral coils for deep transcranial magnetic stimulation

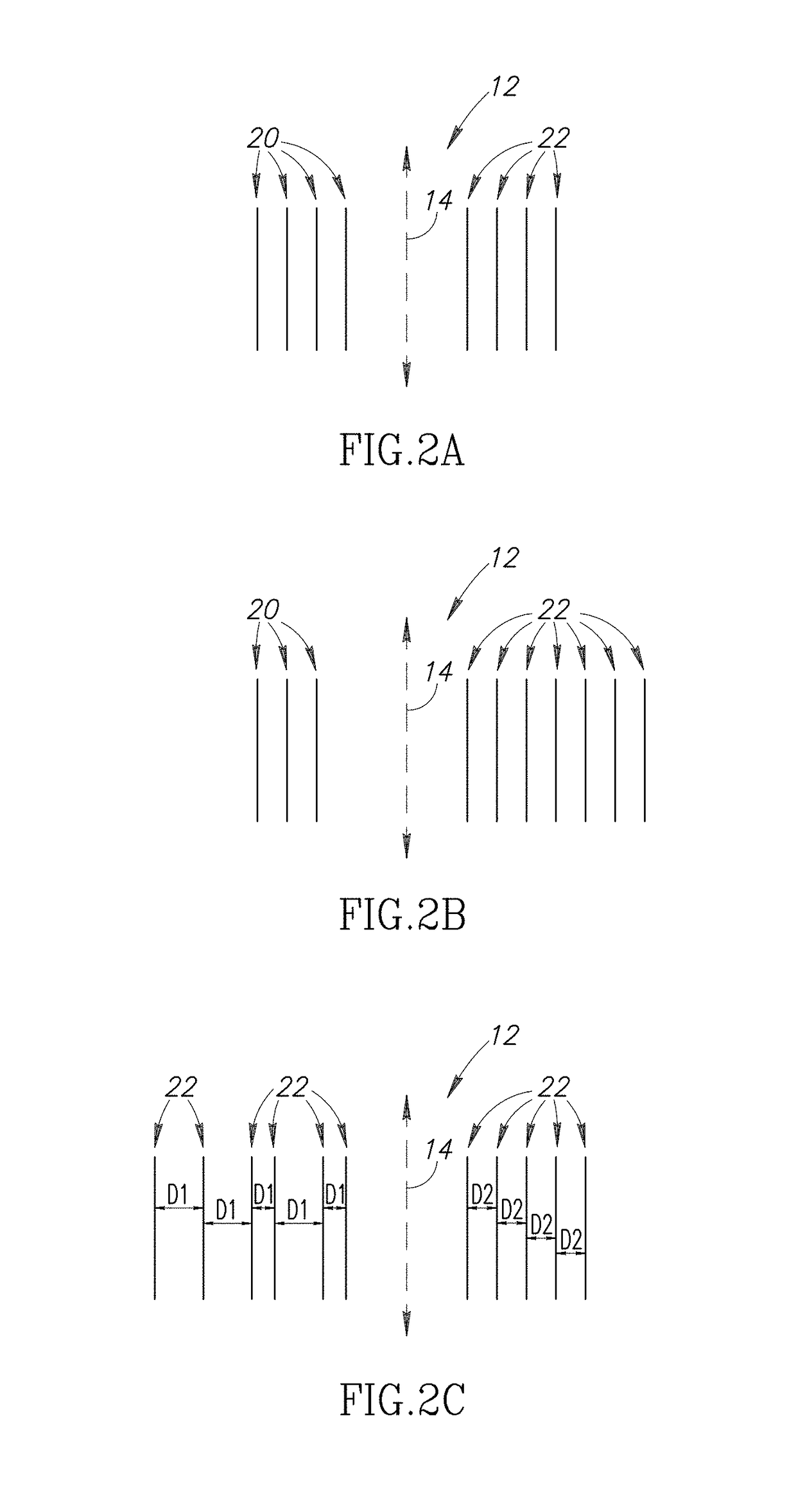

ActiveUS20140235927A1Better depth penetration profileImprove depth penetration profileElectrotherapyMagnetotherapy using coils/electromagnetsPower flowElectrical current

A coil for transcranial magnetic stimulation which is location-specific for unilateral brain regions is designed with multiple spaced apart stimulating elements having current flow in a first direction, and multiple return elements having current flow in a second direction which is opposite the first direction. The multiple stimulating elements and return elements are distributed on one side of a central axis of the coil.

Owner:BRAINSWAY

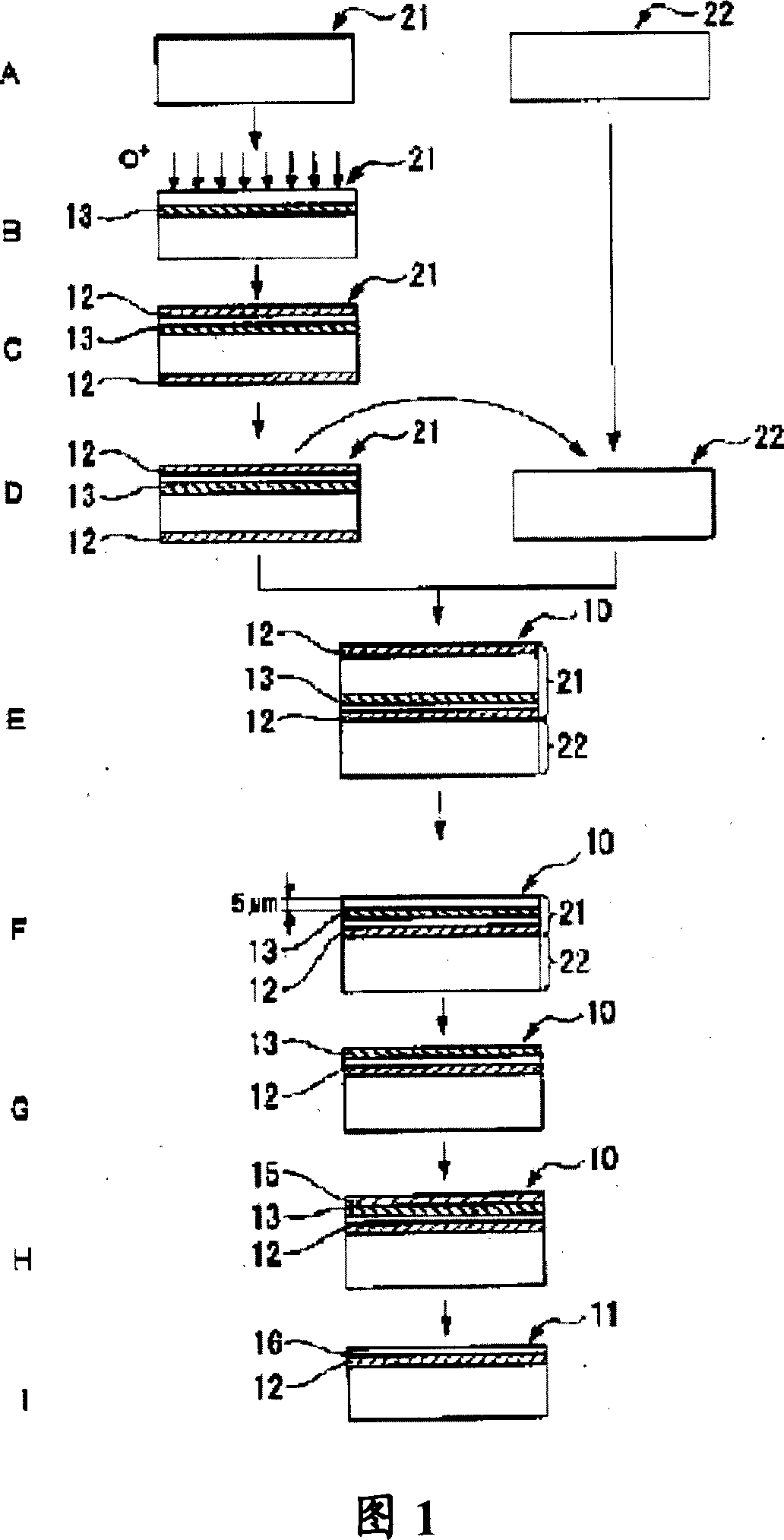

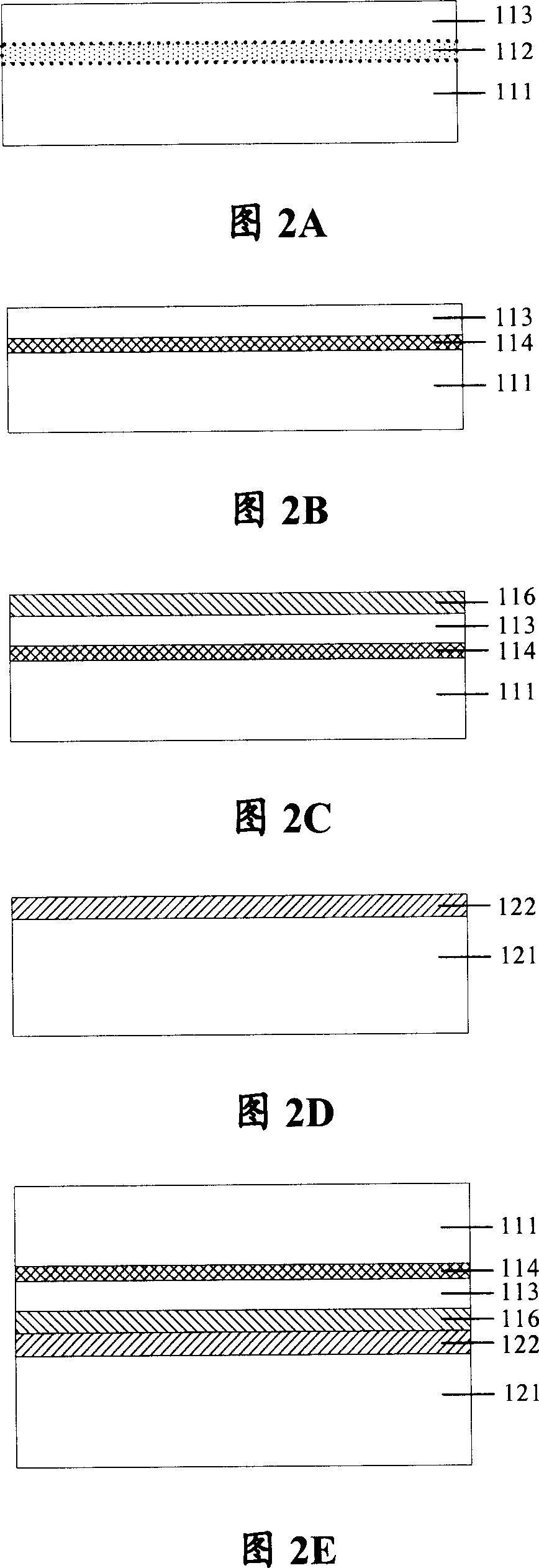

Silicon of insulator and its making technology

InactiveCN101101891AAdjustable thicknessImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingSurface layerSilicon chip

The invention is concerned with the silica isolator manufacturing method, it is: injects the silica sheet with the ion that effects with the silica to form the corrosion preventing material; annealing the silica and forms the structure with the isolating layer, on the outside of the sheet , places next to the silica surface layer, the corrosion preventing layer places next to the silica substrate layer, which is, too, on the outside of the silica sheet; next, forms the second isolating layer on the semiconductor wafer; attaches silica sheet with the wafer to join the isolating layer with the second isolating layer; reinforces the attachment; wipes off the silica substrate layer; and wipes off the corrosion preventing layer too. The invention produces the silica isolator with adjustable thickness, the better quality isolating layer, and the top layer silica is equally thick.

Owner:SHANGHAI SIMGUI TECH +1

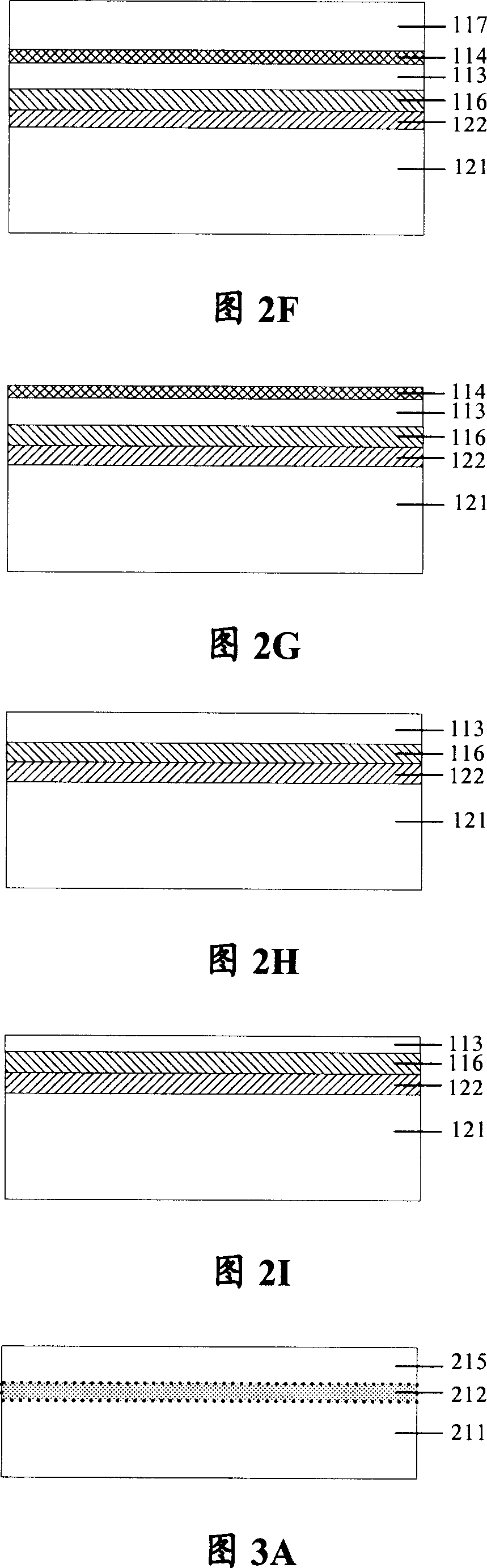

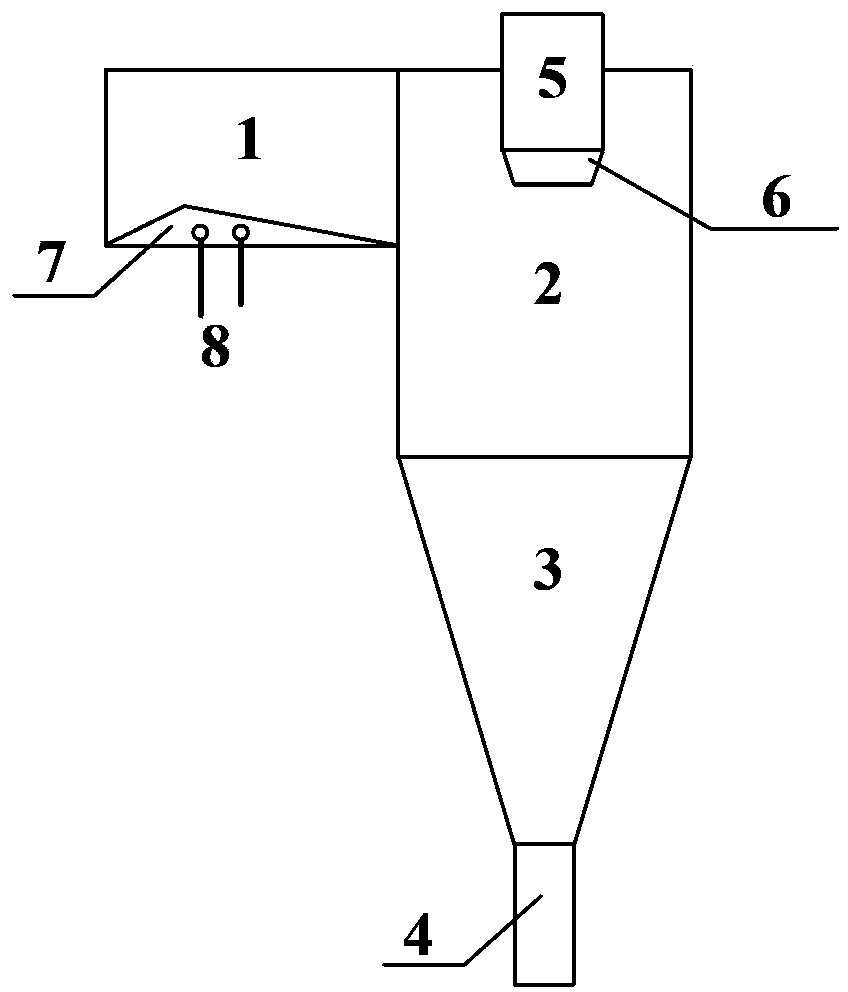

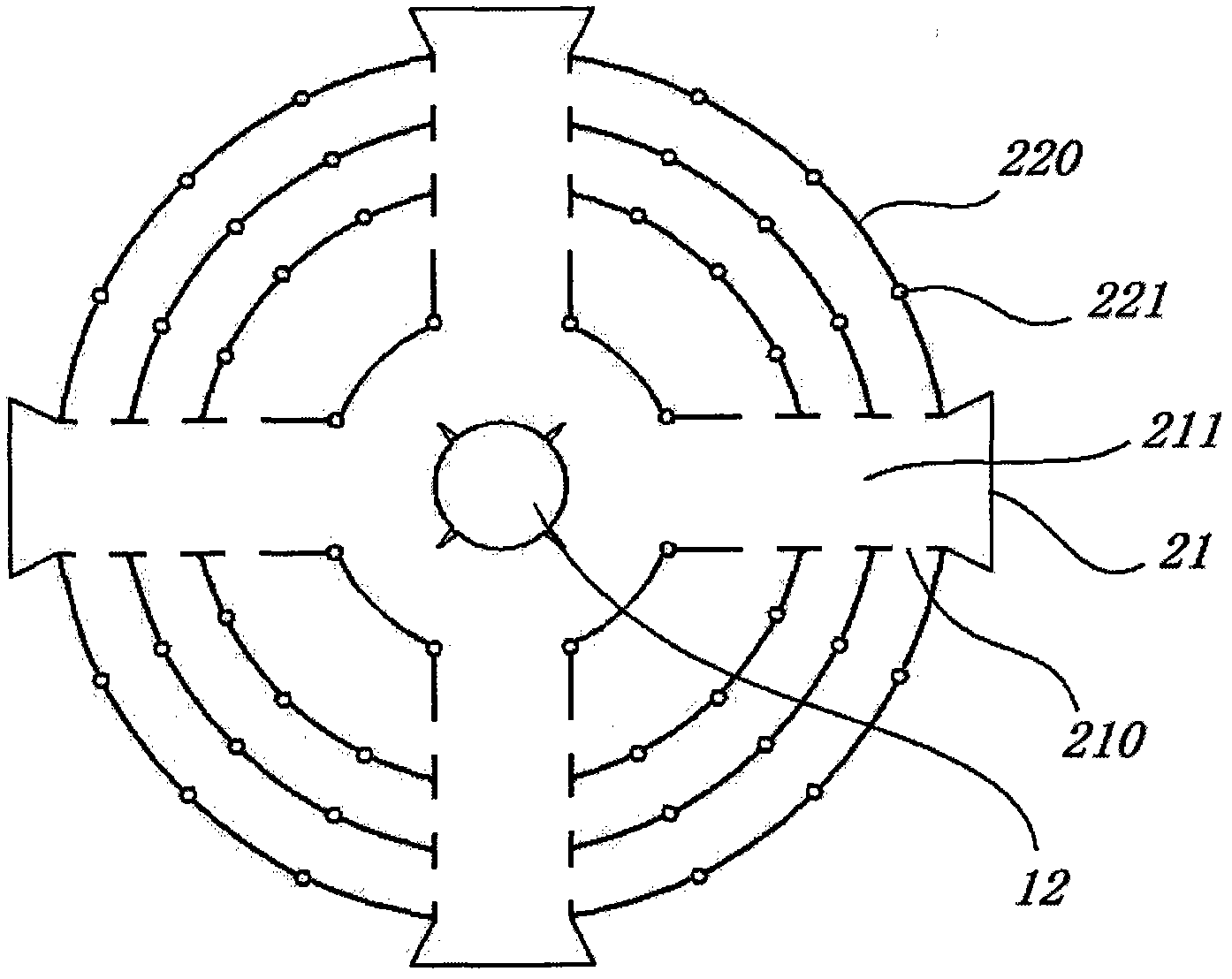

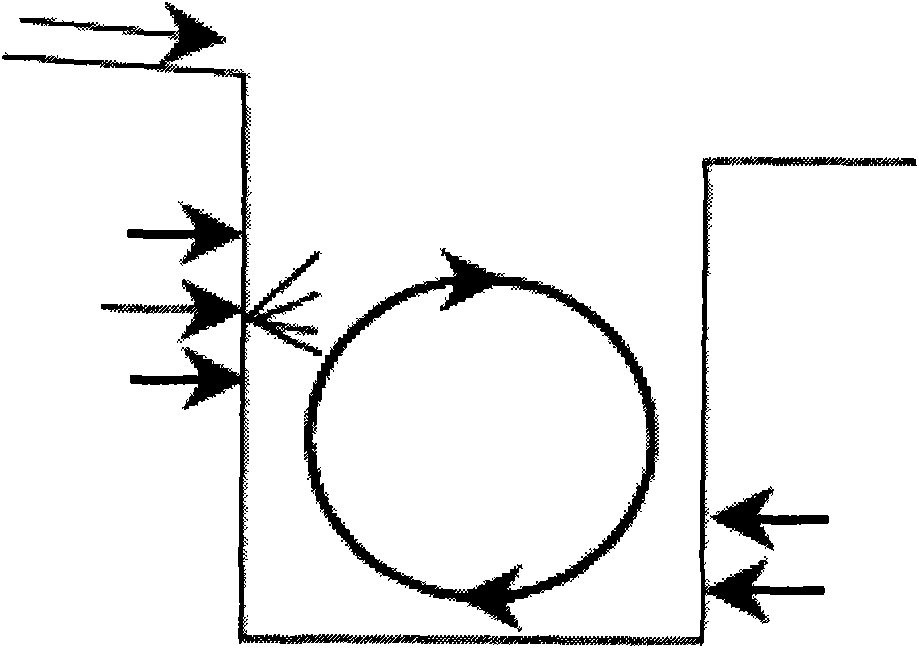

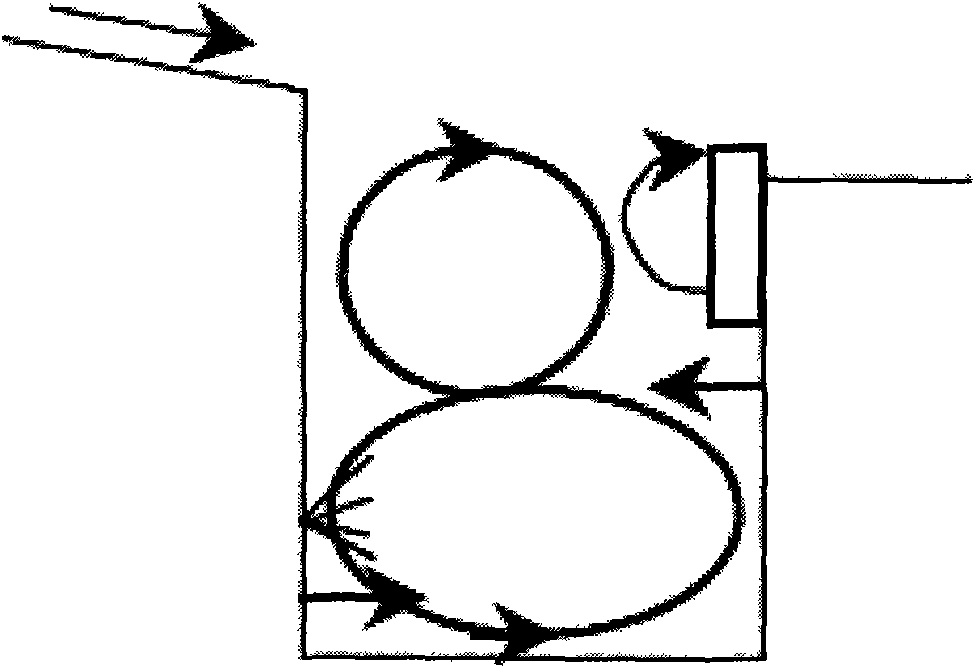

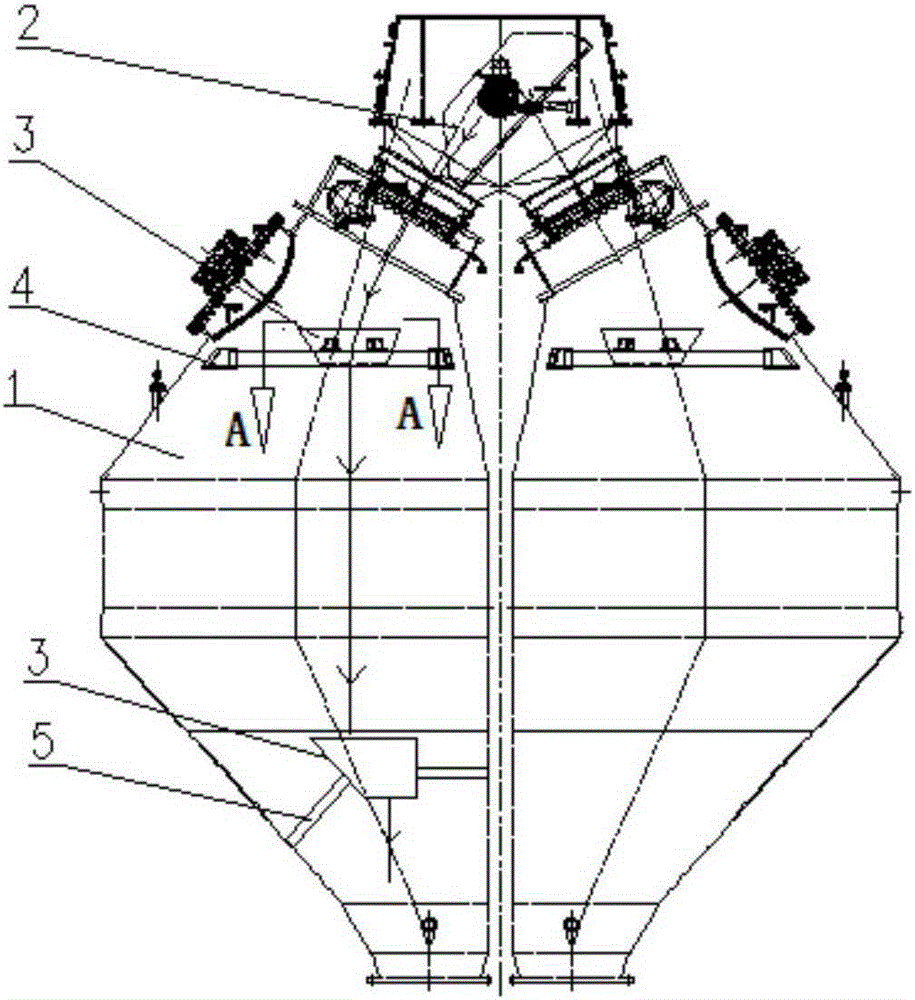

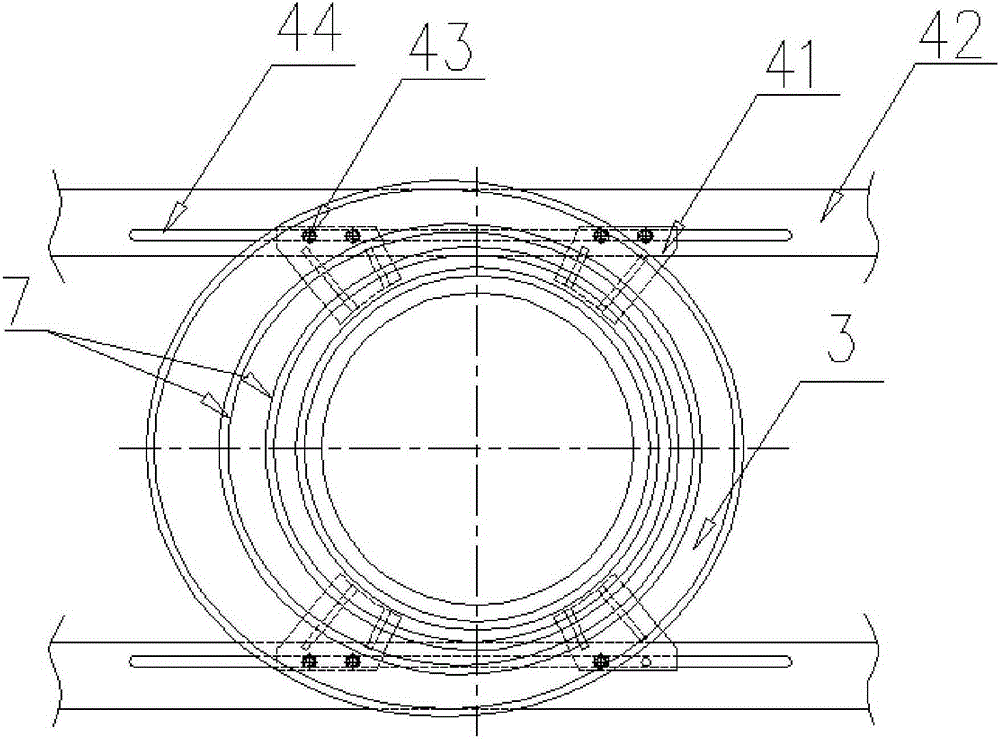

Cyclone separator with wear-resistant target section and guiding device for circulating fluidized bed boiler

ActiveCN103398375AIncreased flow velocityIncrease flow rateFluidized bed combustionApparatus for fluidised bed combustionRefractory wearCyclone

A cyclone separator with a wear-resisting target section and a guiding device for a circulating fluidized bed boiler. The cyclone separator comprises a separator inlet flue, a separator barrel body connected with an outlet of the separator inlet flue, a separator cone and a separator standpipe, which are successively connected below the separator cylinder body, and a separator central cylinder inserted into the upper part of the separator barrel body. The lower part of the separator central cylinder is provided with a central cylinder necking; the separator inlet flue is a tapered inlet flue, which is provided inside with a smoke guiding boss, and a smoke diversion part at the outlet; the smoke guiding boss and the smoke diversion part are covered with a high-strength refractory wear-resistant material layer; and one or a plurality of soot blowing mouths are arranged surrounding the smoke guiding boss. Optimization on the flow field in the cyclone separator reduces the direct impact of airflow and wear on the refractory wear-resistant material in the target section, and can improve the continuous operation cycle of the circulating fluidized bed boiler.

Owner:HUANENG CLEAN ENERGY RES INST

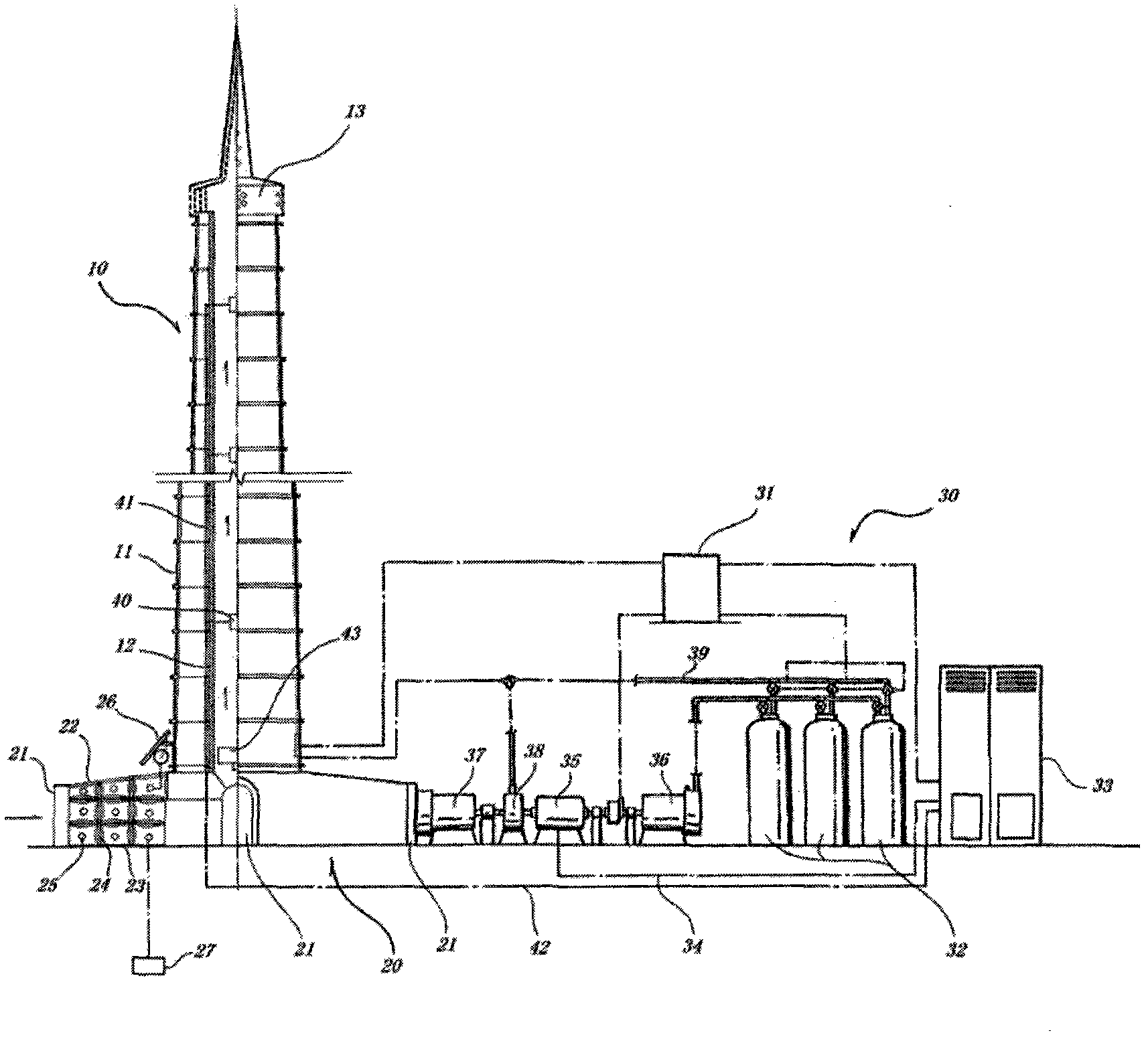

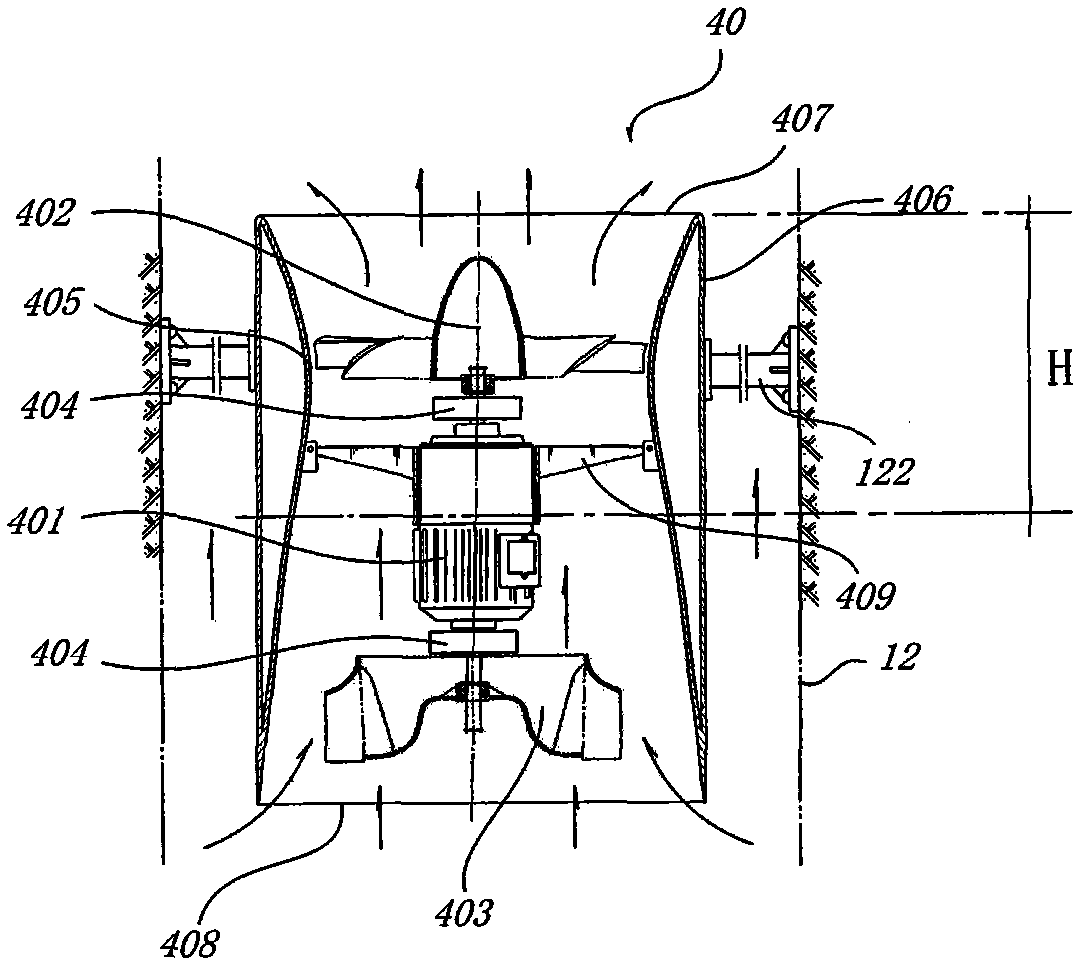

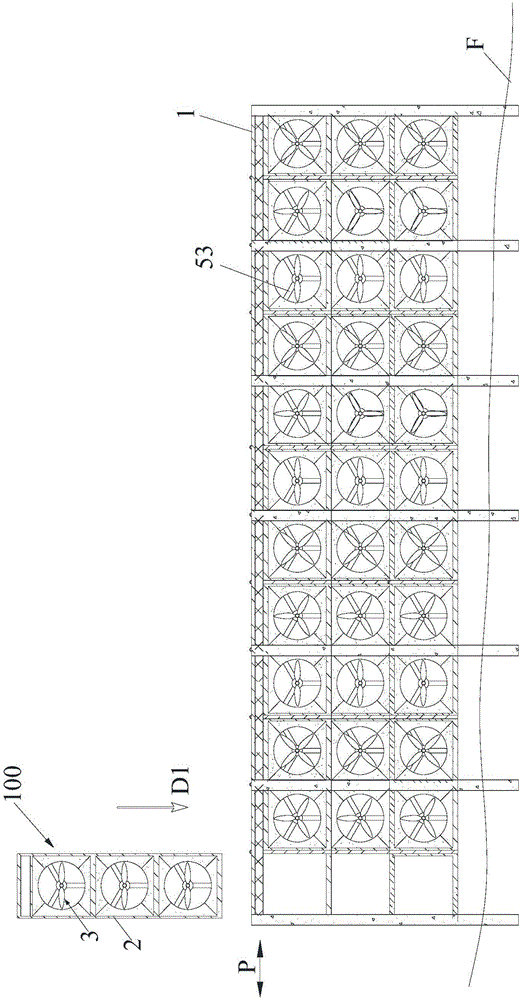

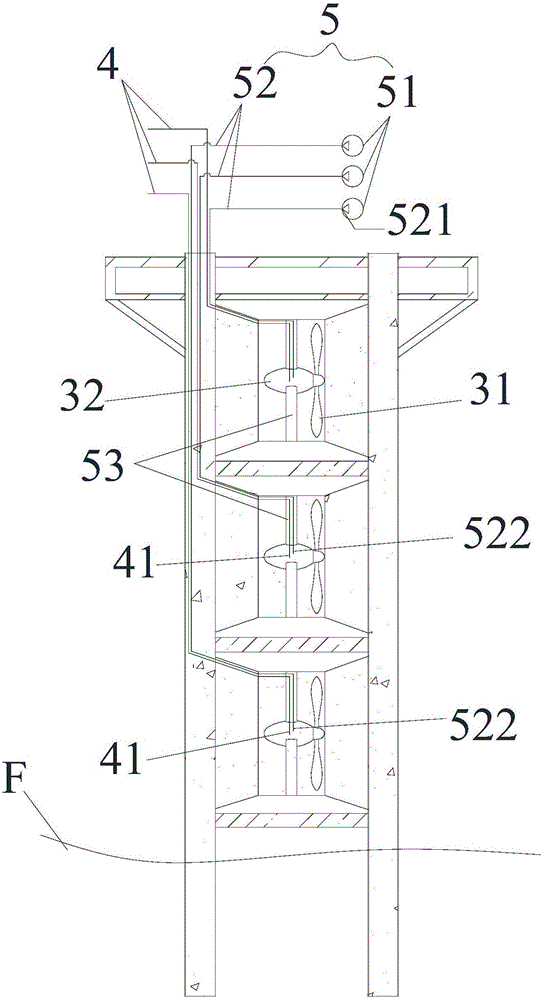

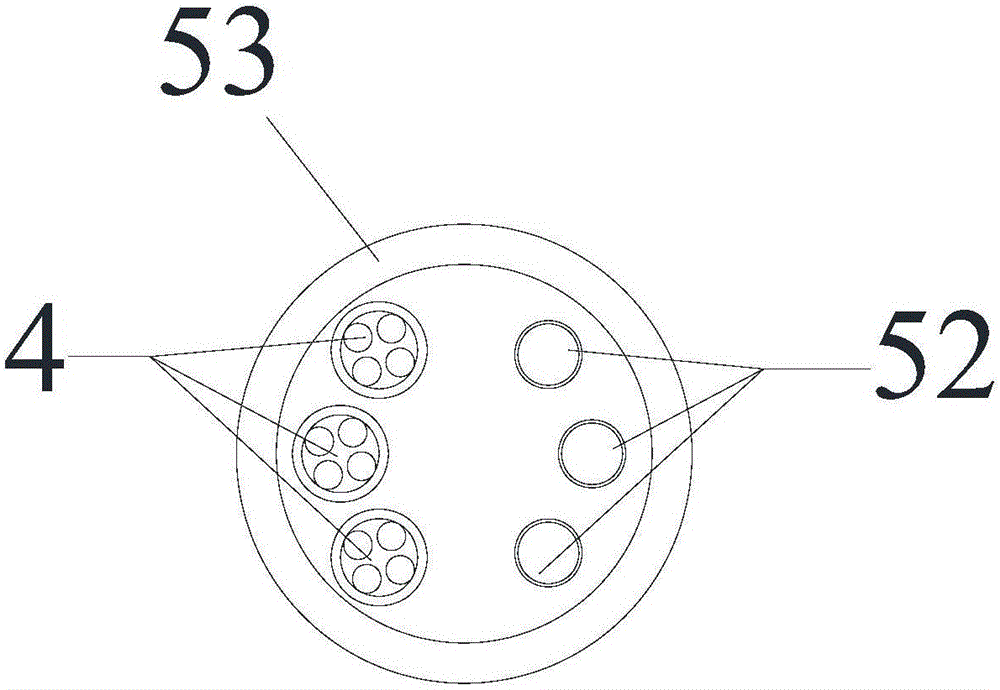

Natural energy storage power generation method and power generation system thereof

InactiveCN102996359AEfficient SupplementEnough temperatureGas turbine plantsEmission reduction for energy storageElectricityPower grid

Owner:周登荣 +1

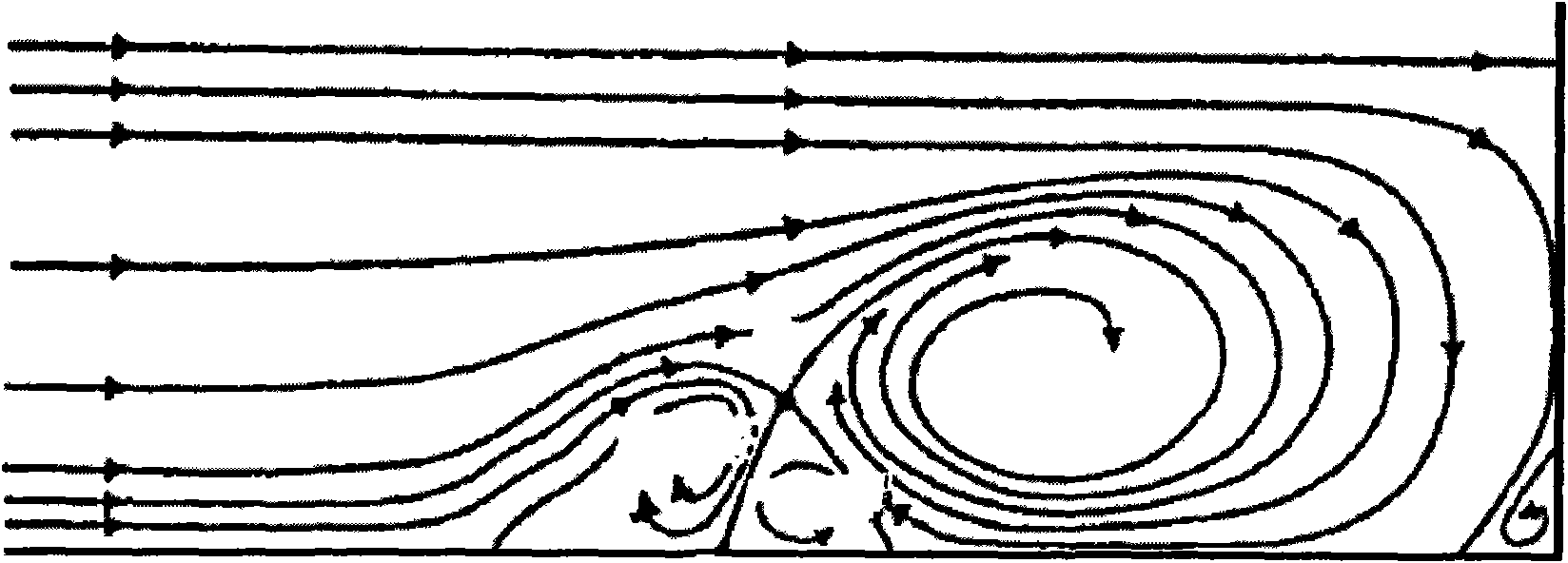

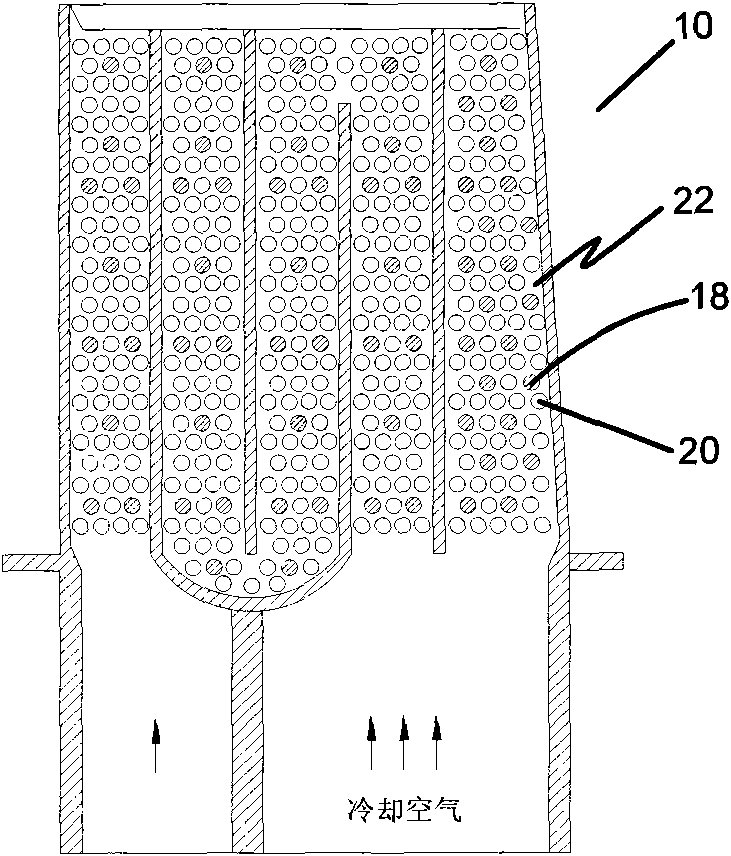

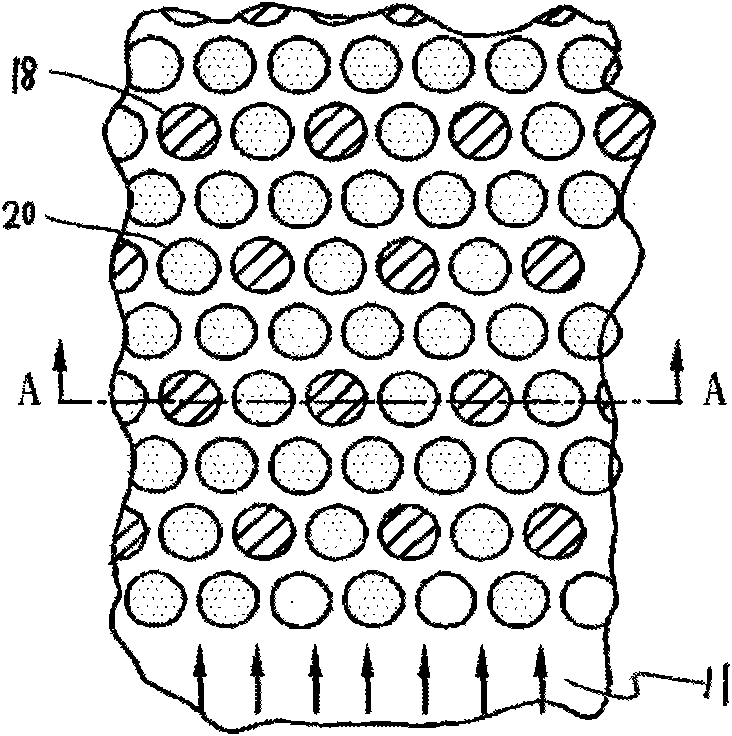

Turbine cooling cascade with vortex structure

InactiveCN101551120AReduce the spatial scaleReduce the impactContinuous combustion chamberCold airLeading edge

A turbine cooling cascade with a vortex structure relates to a turbine cooling cascade. The invention settles the problems of flowing loss, blending loss and easy burning of blade leading edge and end wall surface of blade leading edge caused by the existence of horse shoe vortex structure in the prior blade cascade. According to the blade (2) of the invention, a pressure surface (2-2) next to the blade leading edge (2-1), a suction surface (2-3) of blade (2) next to the blade leading edge (2-1) and the blade leading edge (1-1) of wall (1) are respectively provided with a plurality of elongated slots (3) which are distributed in row. One side wall of each elongated slot (3) is provided with a plurality of cold air injection openings (4). Furthermore the positions of cold air injection opening (4) are next to the base of elongated slot (3). The turbine cooling cascade with vortex structure according to the invention reduces the flowing loss at the inner part of flow passage, reduces the bigger blending loss of air currents with different flowing velocities, provides better thermal protection function for the end wall of blade and the blade surface, effectively protects the end wall adjacent with the blade leading edge and the high-temperature area on the surface of blade, and increases the usage factor of cold air.

Owner:HARBIN INST OF TECH

Turbine blade compound cooling structure with sunken internal pin

InactiveCN101581235AImprove heat transfer effectEnhanced blendingBlade accessoriesMachines/enginesTurbine bladeCooling fluid

The invention relates to a turbine blade compound cooling structure with sunken internal pins, comprising a blade passage and a pin; the cooling structure is characterized by further comprising a sunken part, pins are arranged in the blade passage, the blade passage has at least one internal wall surface provided with sunken parts; the sunken parts are arranged in the blade passage in a dislocation way; the sunken parts are of semisphere or part of the semisphere or cone with top part cut off. In the invention, the pins are respectively connected with two wall surfaces in the blade passage, thus on one hand increasing heat exchange area of cooling fluid and on the other hand consolidating the passage; the sunken parts cause the flowing through to generate vortex, thus improving convection and heat exchange effect between the air stream and wall surface of the blade passage and pin surface; meanwhile, when the air stream flows through the sunken parts, direct impact on the pins by the lower reaches of the fluid body is reduced, thus avoiding increase of flow losses while increasing heat exchange area.

Owner:SHANGHAI JIAO TONG UNIV

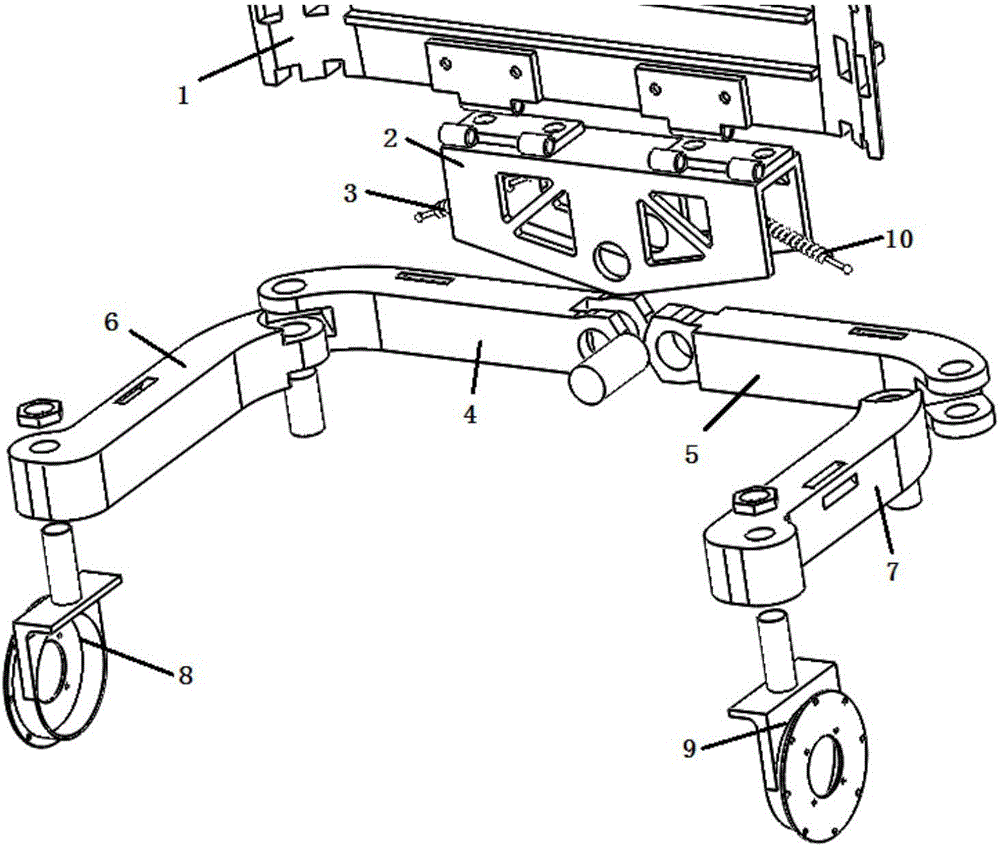

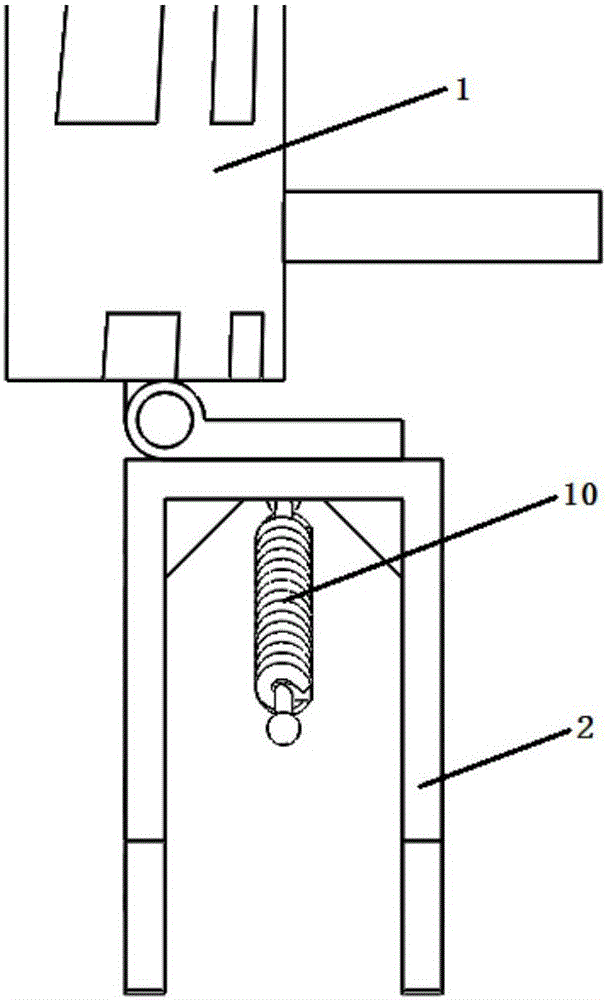

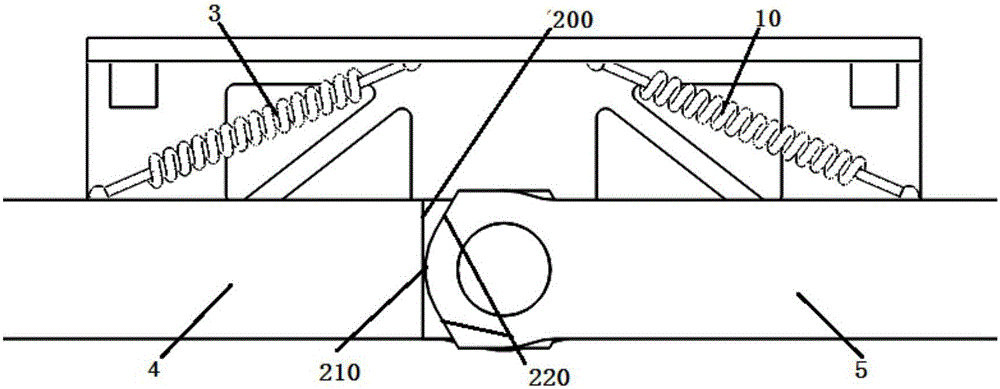

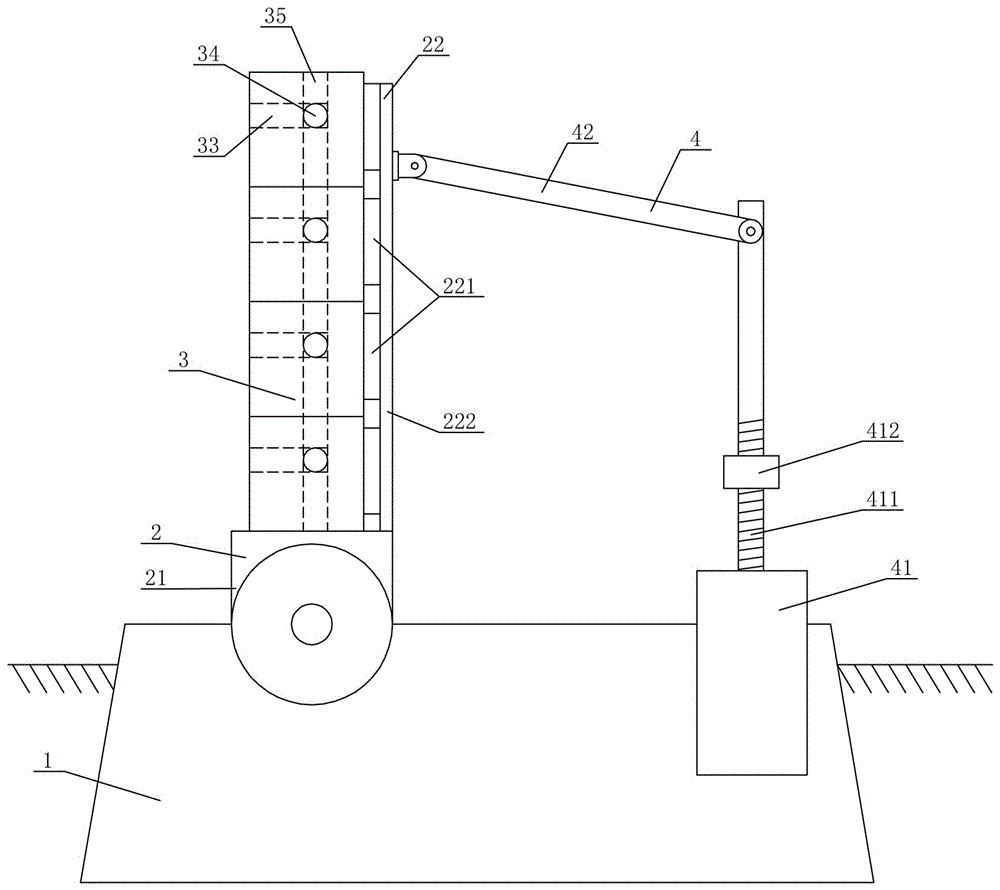

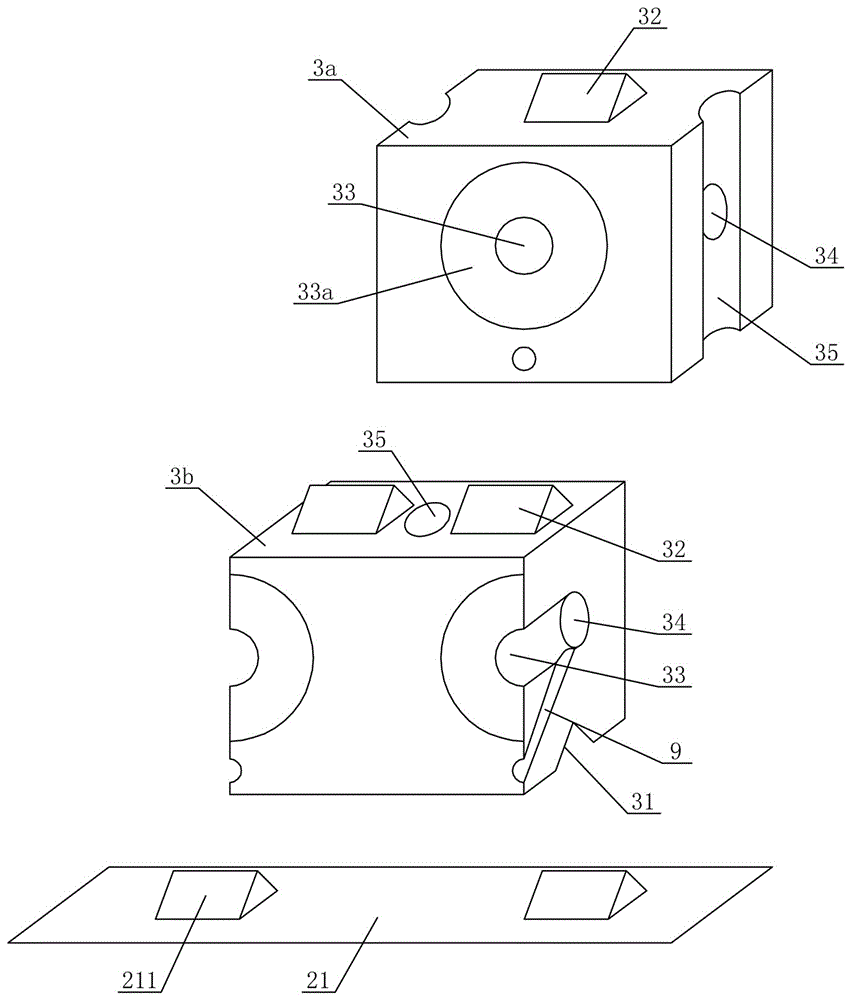

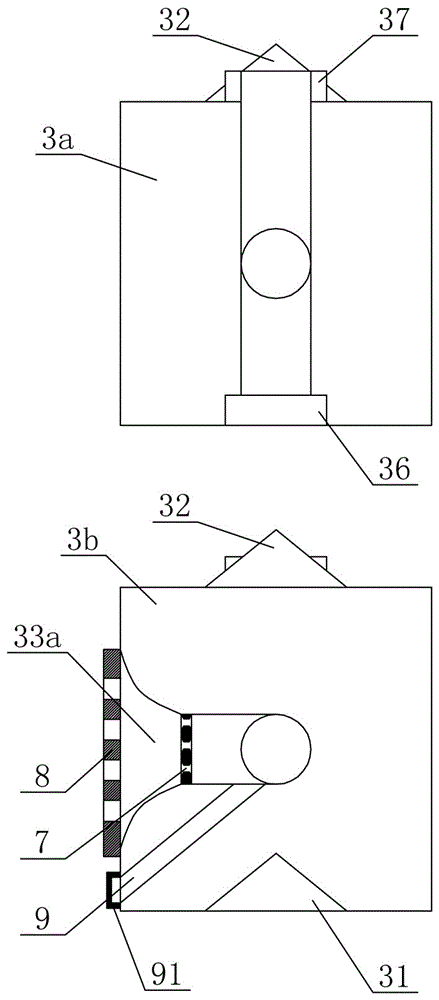

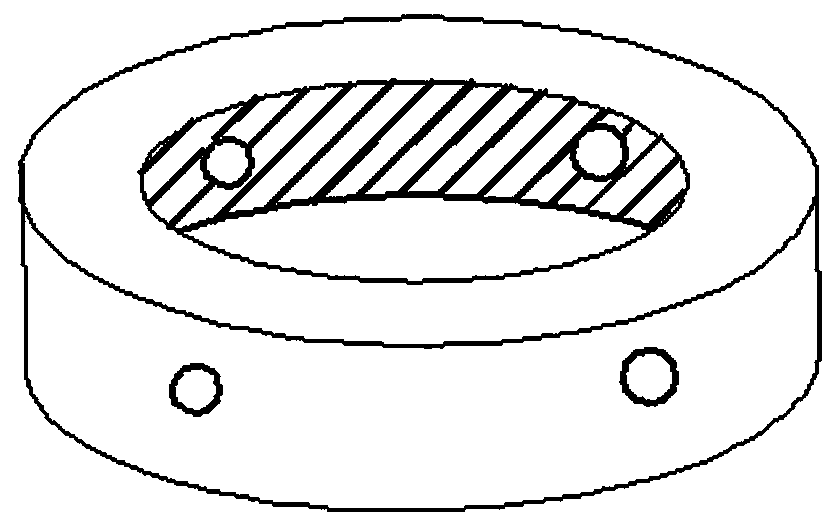

Bearing device for hip exoskeleton

InactiveCN105856194AReduce direct impactImprove coordinationProgramme-controlled manipulatorExoskeletonMechanical engineering

The invention discloses a bearing device for a hip exoskeleton. The bearing device comprises a frame carrier, a supporting table and a hip portion which are sequentially arranged from top to bottom, wherein the lower end of the frame carrier is hinged to the upper end of the supporting table; the hip portion is hinged to the lower end of the supporting table; and a first spring and a second spring are symmetrically arranged between the two sides of the hip portion and the supporting table. The bearing device for the hip exoskeleton can effectively improve the harmony of human-machine movement in a load bearing state, proper in overall freedom degree, high in structural reliability, large in practical value and worthy of popularization in the industry.

Owner:CHENGDU RUNHUI TECH CO LTD

Injection molding technology of composite panel

InactiveCN101879770AIncreased complexitySimplify production stepsFlat articlesEngineeringSurface plate

The invention relates to an injection molding technology of a composite panel, which comprises the following steps: selecting a film; printing patterns on the film; printing adhesion ink on the film; punching and heating to mold the film; punching the film until the size and the shape of the film are identical to those of the panel when the film is punched to be molded; arranging the film into an injection mould and positioning; and injecting to make resin base materials adhered with the film so as to process the composite panel. The lower die of a heating molding mould used for arranging the film is a silica gel mould. The silica gel mould can smooth the drawing process, and effectively protects the ink, and the molded film has small rebound and better shaping effect and is easier to operate.

Owner:ZHEJIANG DAAN MOLDING TECH

Ceramic shell preparation method for ameliorating physical sand burning of high-temperature alloy directional solidified casting

ActiveCN110465625AReduce direct impactReduce sticky sand tendencyFoundry mouldsFoundry coresWaxAlcohol

The invention discloses a ceramic shell preparation method for ameliorating physical sand burning of a high-temperature alloy directional solidified casting, and belongs to the technical field of ceramic shell preparation. The shell preparation method comprises the steps that a bottom pouring type pouring system is adopted for wax pattern combination at first, then surface layer slurry and reinforcement layer slurry are prepared, and afterwards, shell coating, shell dewaxing and shell roasting are sequentially conducted, wherein when the bottom pouring type pouring system is adopted for wax pattern combination, a filter screen is placed in a bottom transverse pouring gate of the bottom pouring type pouring system; when the surface layer slurry is prepared, the surface layer slurry is composed of corundum powder EC95, silica sol 830, a wetting agent JFC and a antifoaming agent of n-caprylic alcohol; and the corundum powder EC95 is formed by mixing EC95 with the particle size being W28 and EC95 with the particle size being W14 according to the weight ratio of 1:1. Through the method, the physical sand burning tendency of the casting can be reduced, the surface quality of the castingis improved, and the pass rate of the casting is increased.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

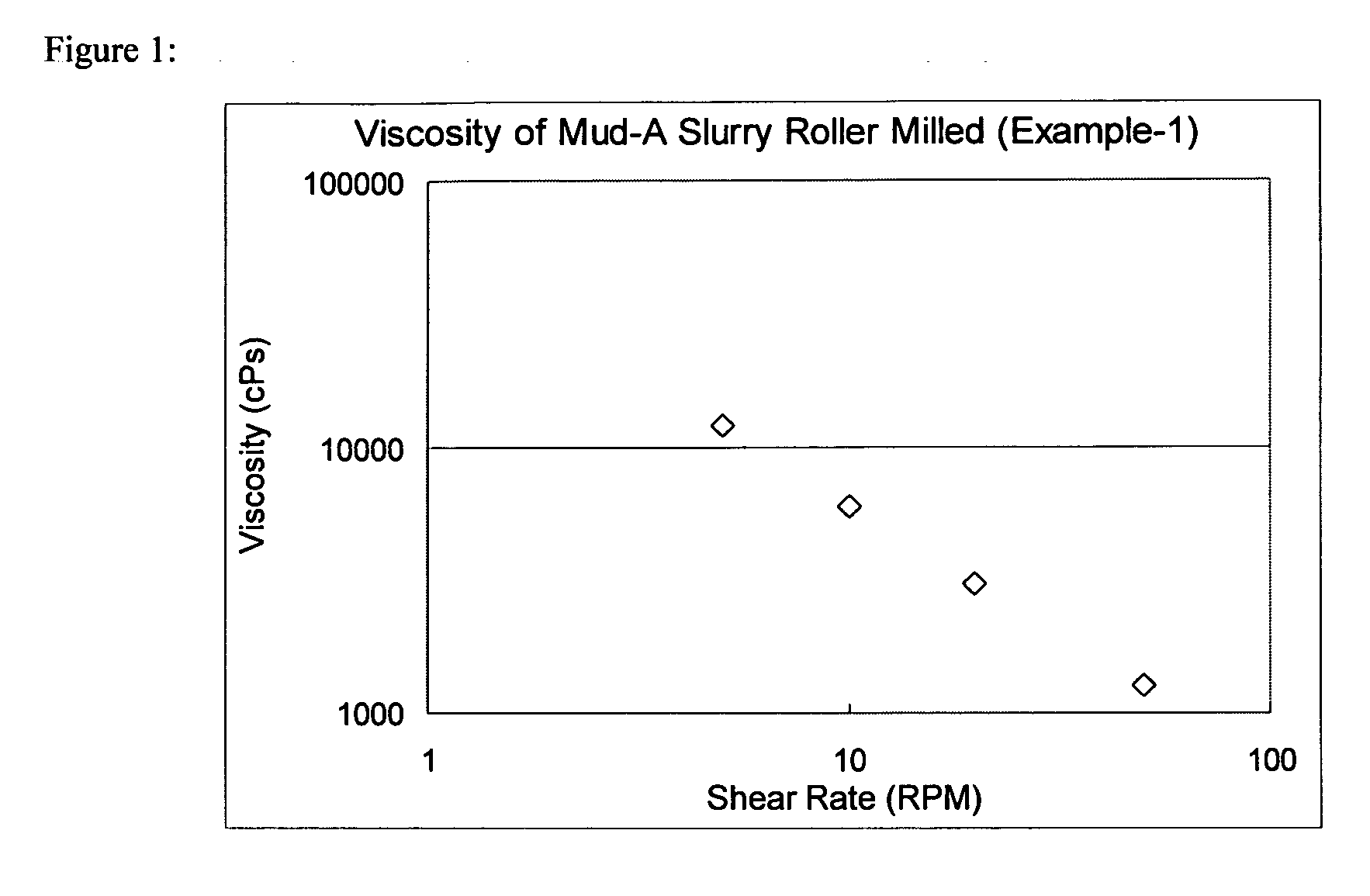

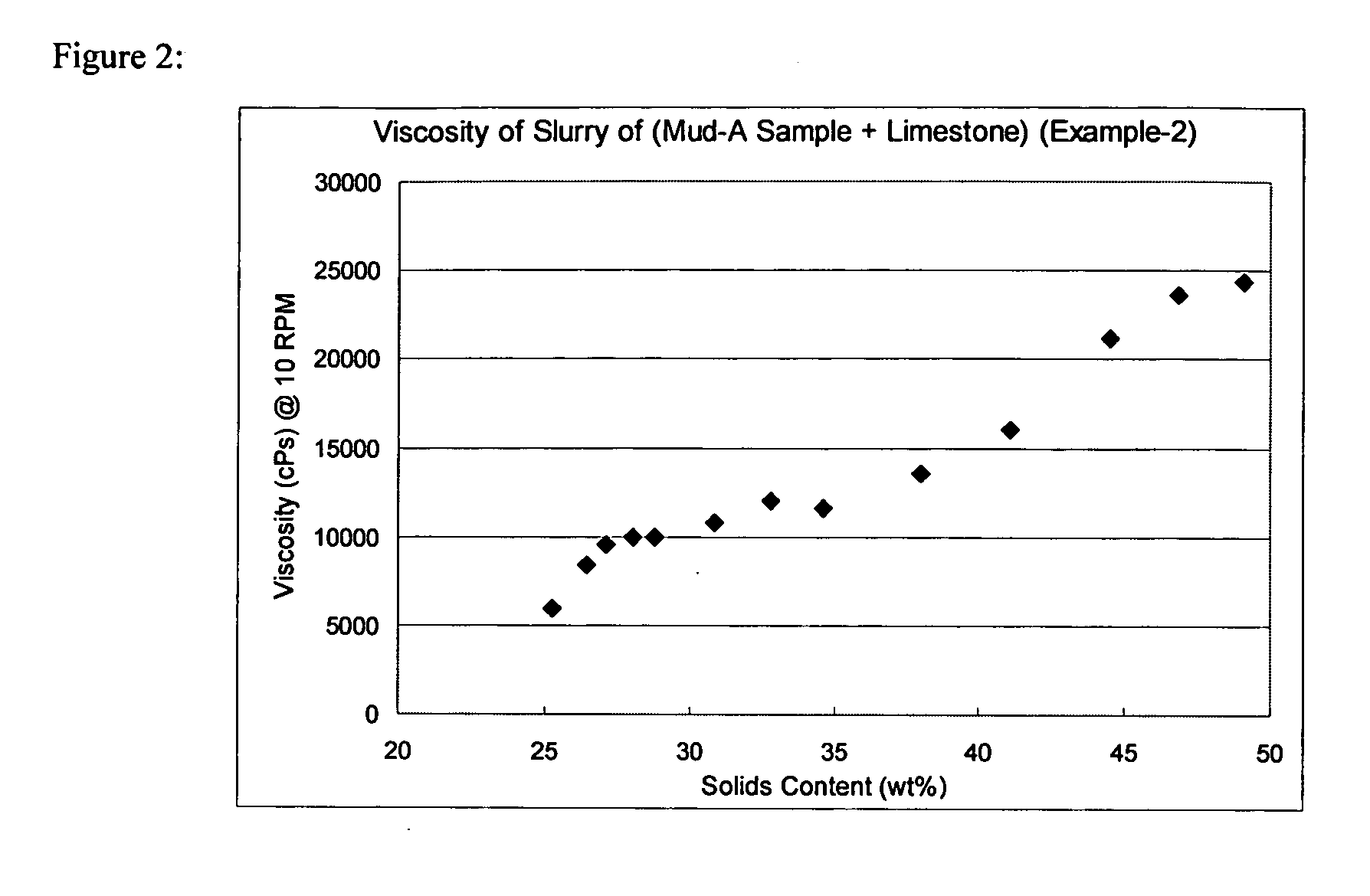

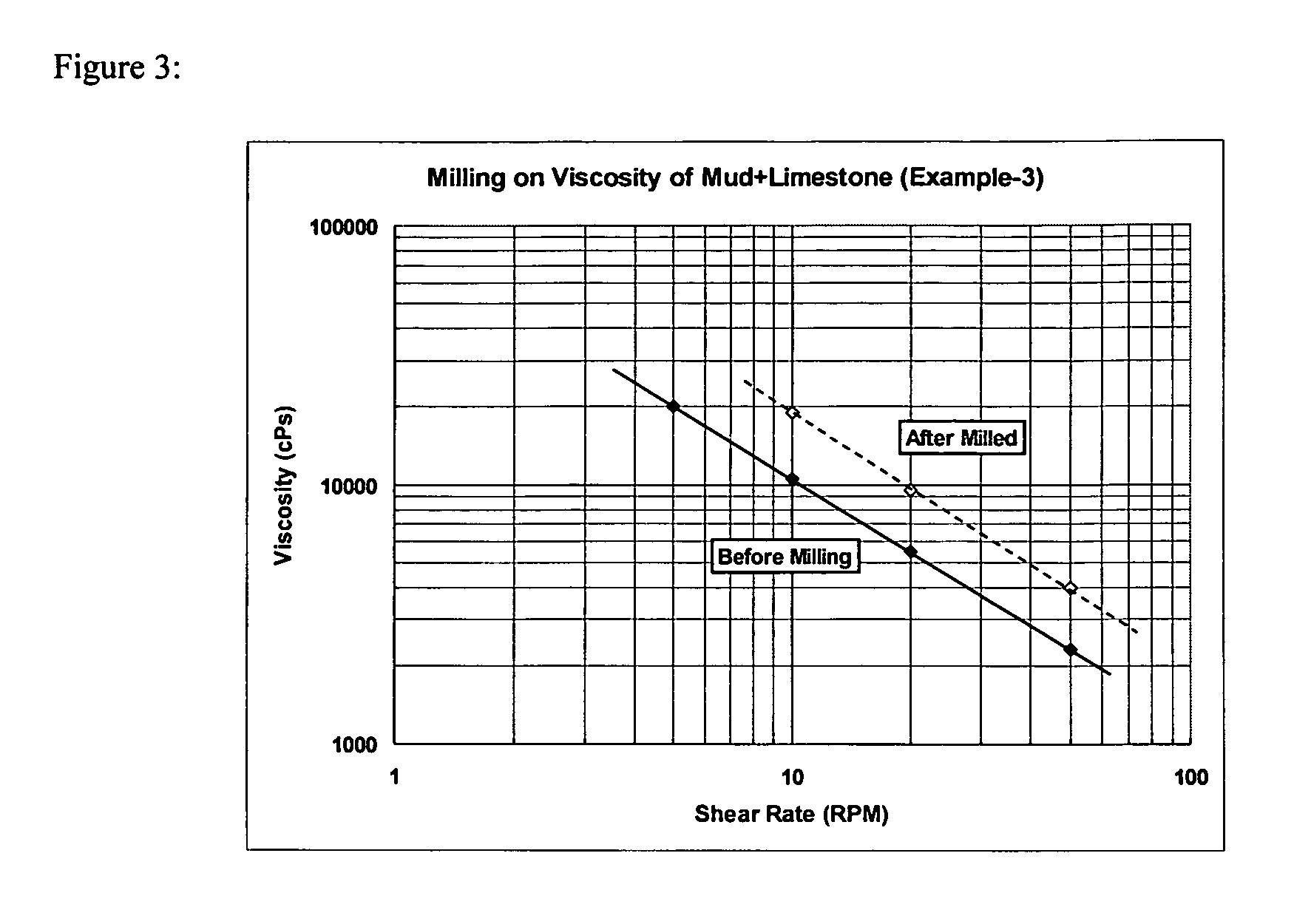

Decontamination of sediments through particle size reduction and stabilization treatment

InactiveUS20100303551A1Degree of reductionReduce direct impactBiocidePowder deliveryMedicinePARTICLE SIZE REDUCTION

A process of decontamination of sediment particles to reduce active pollutant components through particle size reduction and stabilization treatment.

Owner:CHANG YUN FENG

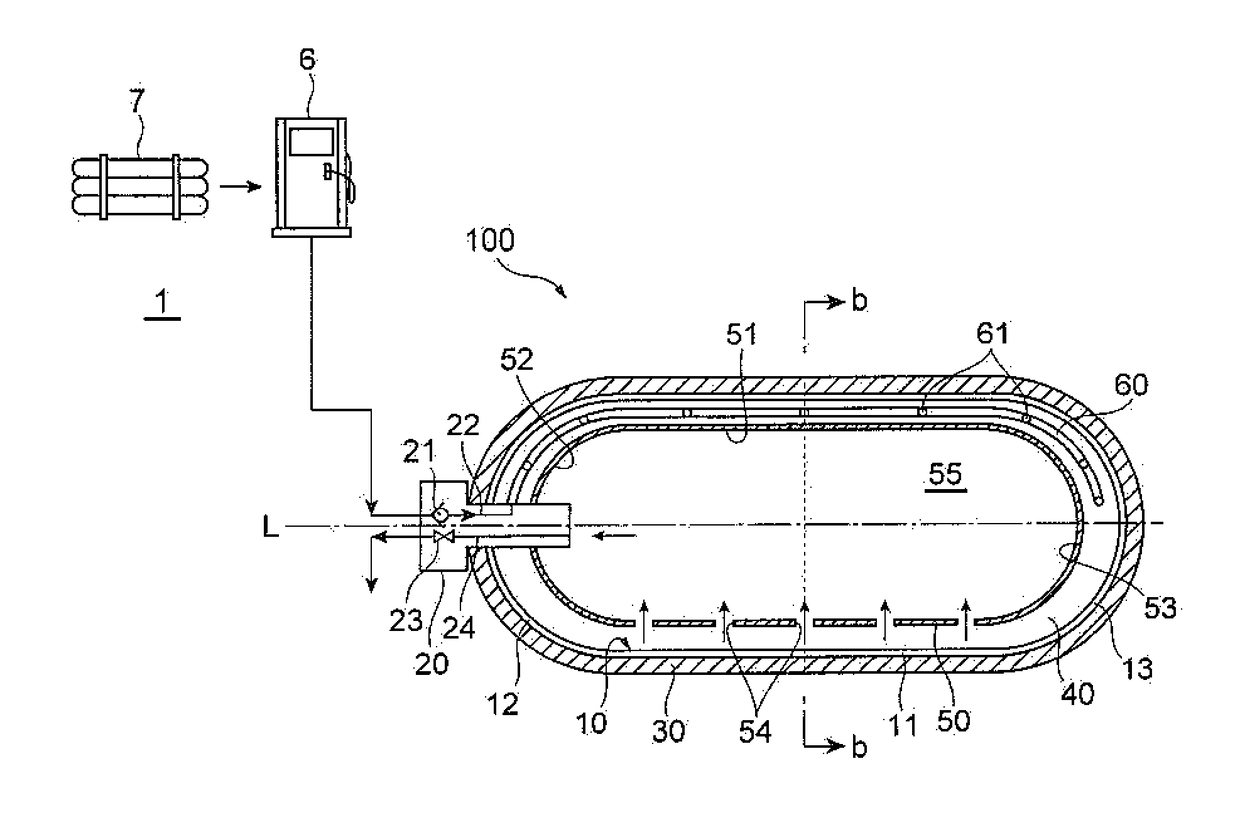

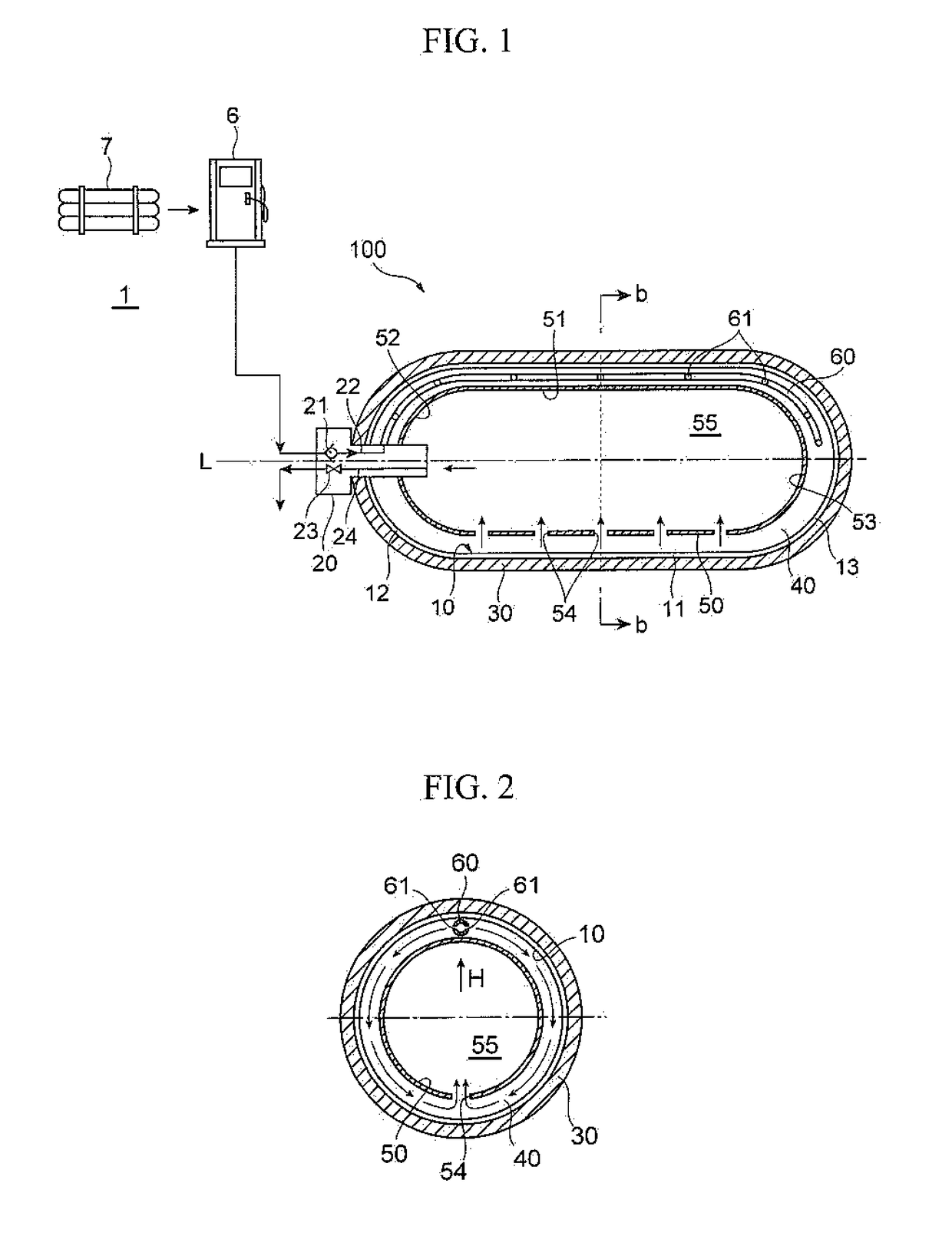

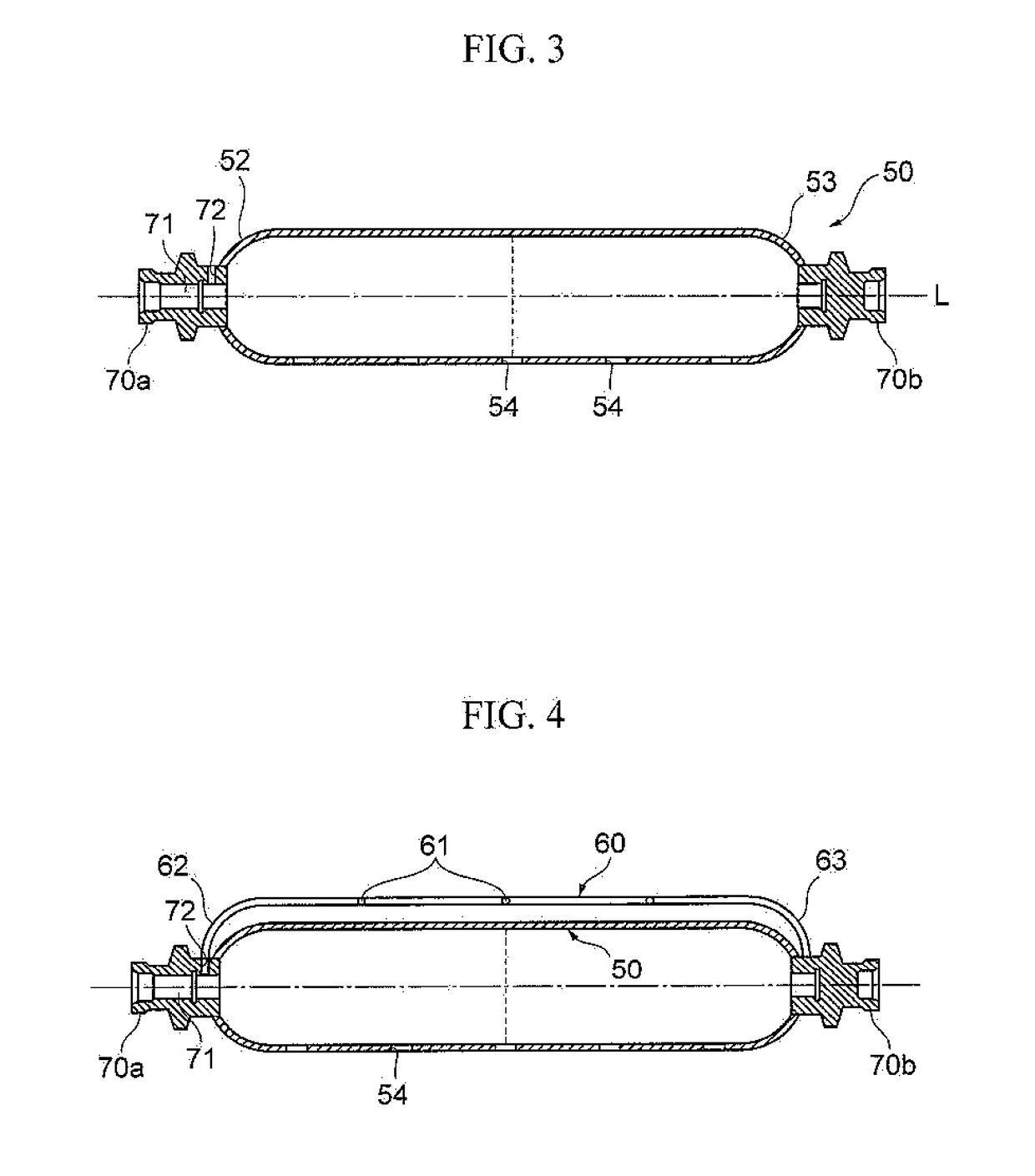

High-pressure tank

ActiveUS20180259124A1Decrease volumetric efficiencyReduce operating costVessel mounting detailsVessel geometry/arrangement/sizeHigh pressureGas supply

A high-pressure tank in which a liner can be formed using the conventionally used material, a decrease in the volumetric efficiency within the liner can be suppressed, and influence of a temperature rise due to adiabatic compression on the liner can be significantly alleviated. The tank includes a liner that suppresses permeation of gas; a valve device that allows the inside of the liner and the outside of the tank to communicate with each other and blocks communication therebetween; and an inner container with a through-hole disposed within the liner such that a gap is formed between the inner container and an inner periphery of the liner. The first communication channel of the valve device connects with a pipe extending in the gap and having holes therein. Gas supplied to the valve device is supplied into the gap from the holes in the pipe, and fills the inner container in a high-pressure state from the gap through the through-hole in the inner container.

Owner:TOYOTA JIDOSHA KK

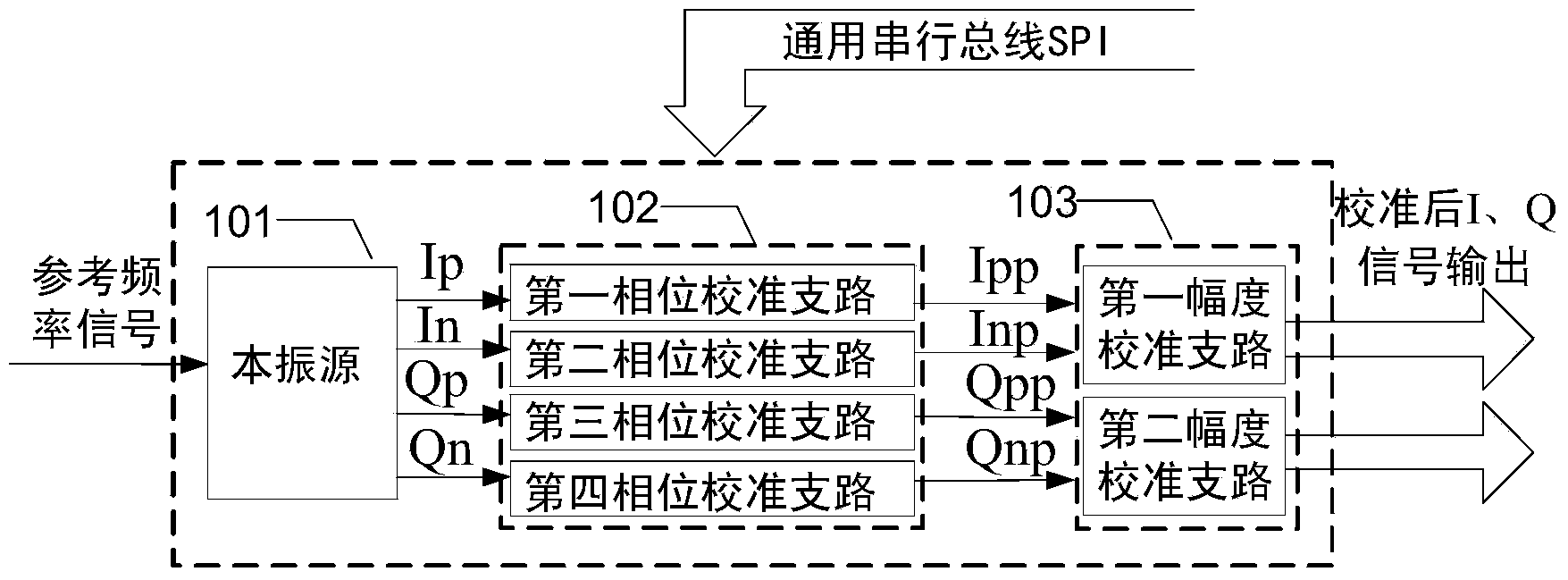

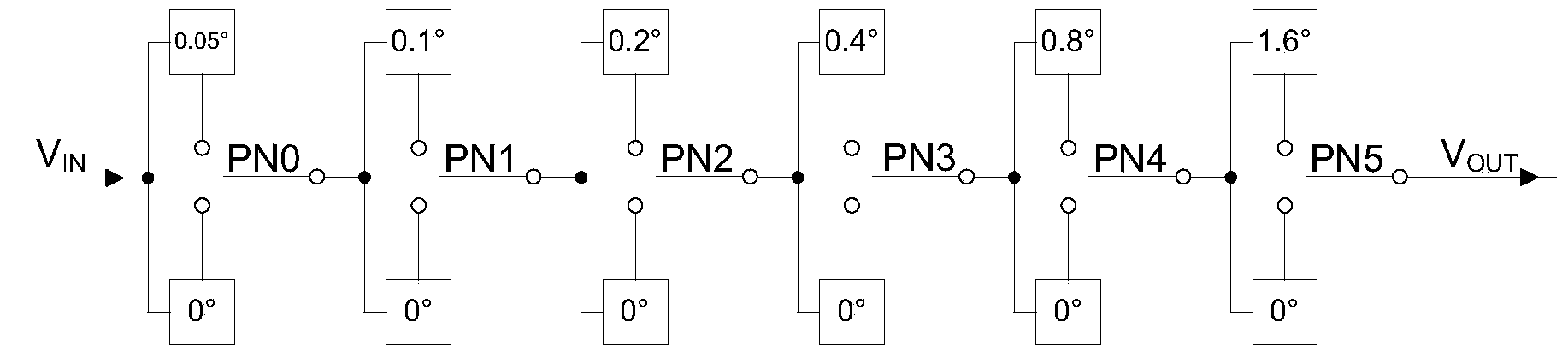

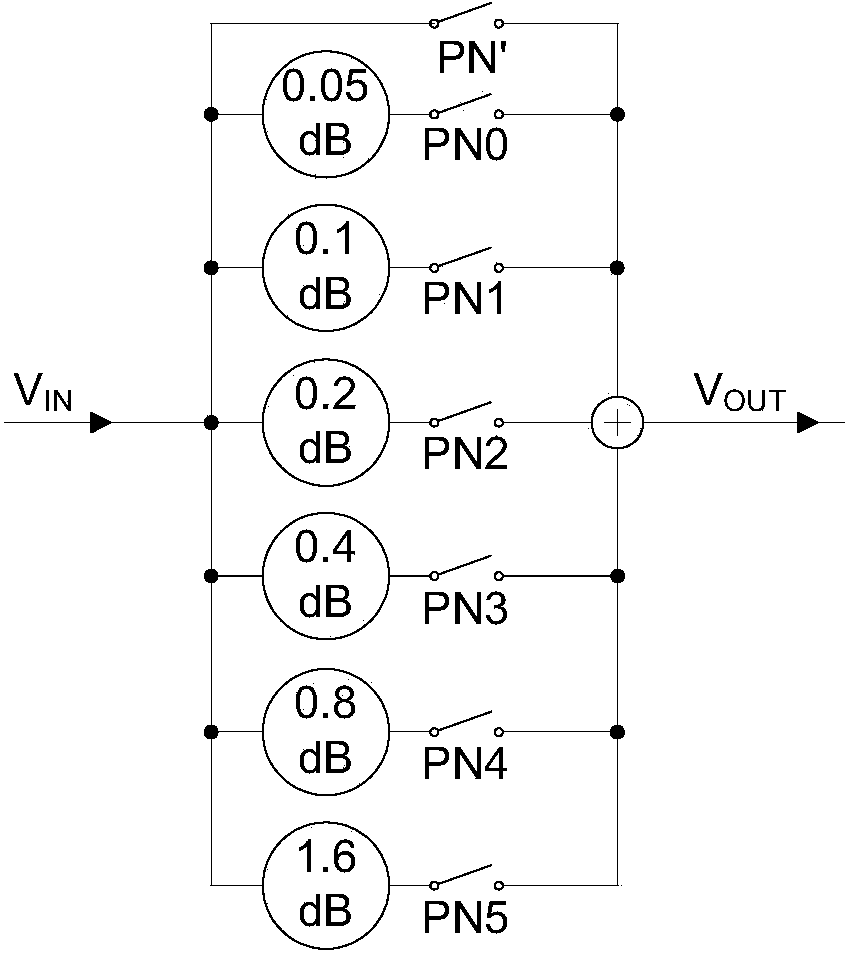

Local oscillator IQ signal phase and amplitude calibration device

ActiveCN104320204AReduce direct impactAvoid spurious problemsTransmitters monitoringReceivers monitoringLocal oscillator signalWireless transceiver

The invention discloses a local oscillator IQ signal phase and amplitude calibration device, and belongs to the technical field of radio frequency integrated circuits. Phase calibration and amplitude calibration of two paths of IQ signals by adding an amplitude calibration module and a phase calibration module to an output end port of a local oscillator. The method is suitable for various wireless transceivers, electronic interference machines, vector network analyzers in modern microwave measurement instruments, microwave sweep signal generators and other devices, is particularly suitable for phase calibration and amplitude calibration of local oscillator signals at a satellite navigation radio frequency front end, and can conveniently realize correction and calibration work in a digital-analog combined mode according to the parameters in a digital signal control simulation circuit. A calibration circuit is good in performance, wide in correction range, high in correction capacity, convenient to control, feasible, flexible and diverse in work mode and good in application prospect.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

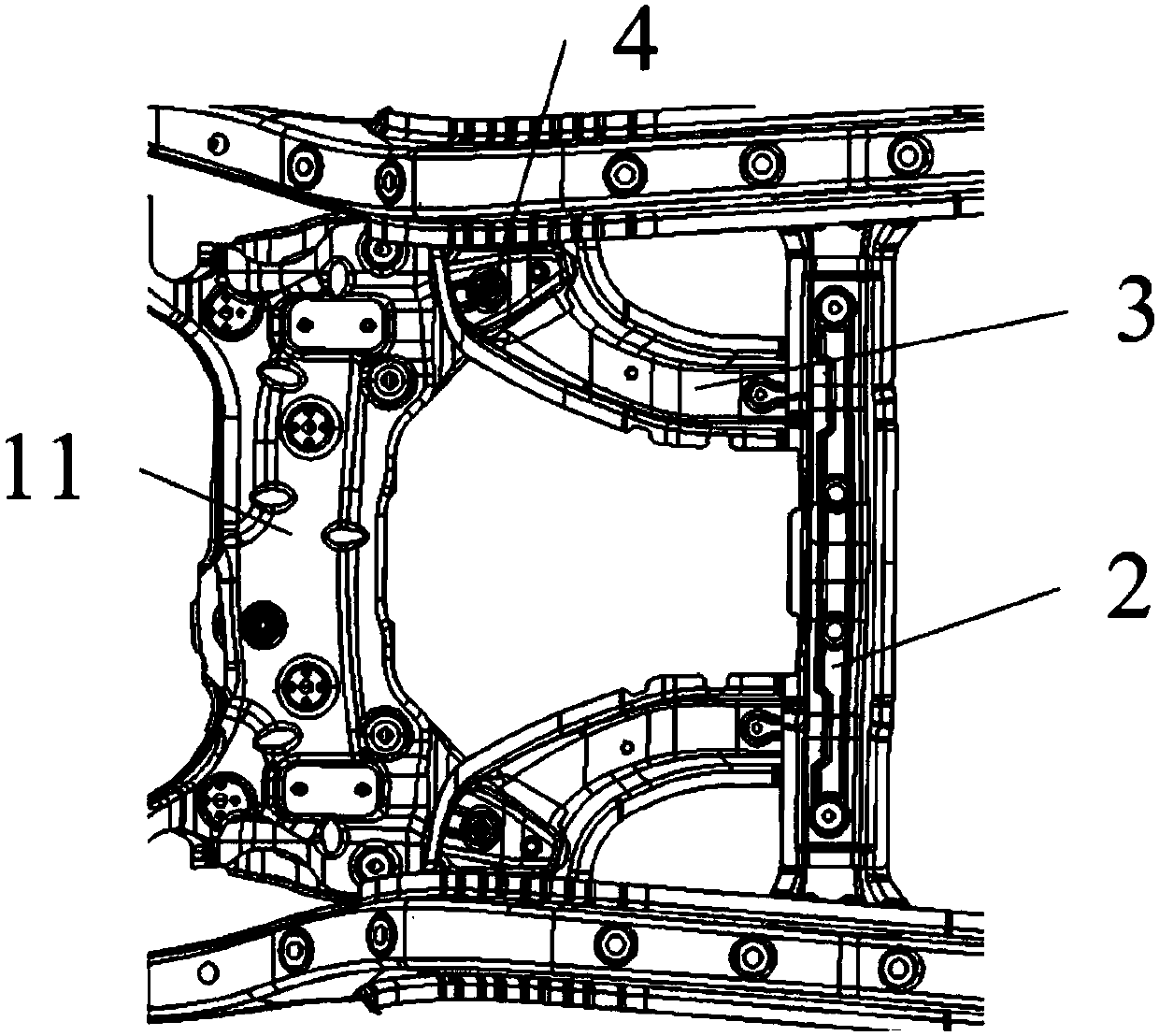

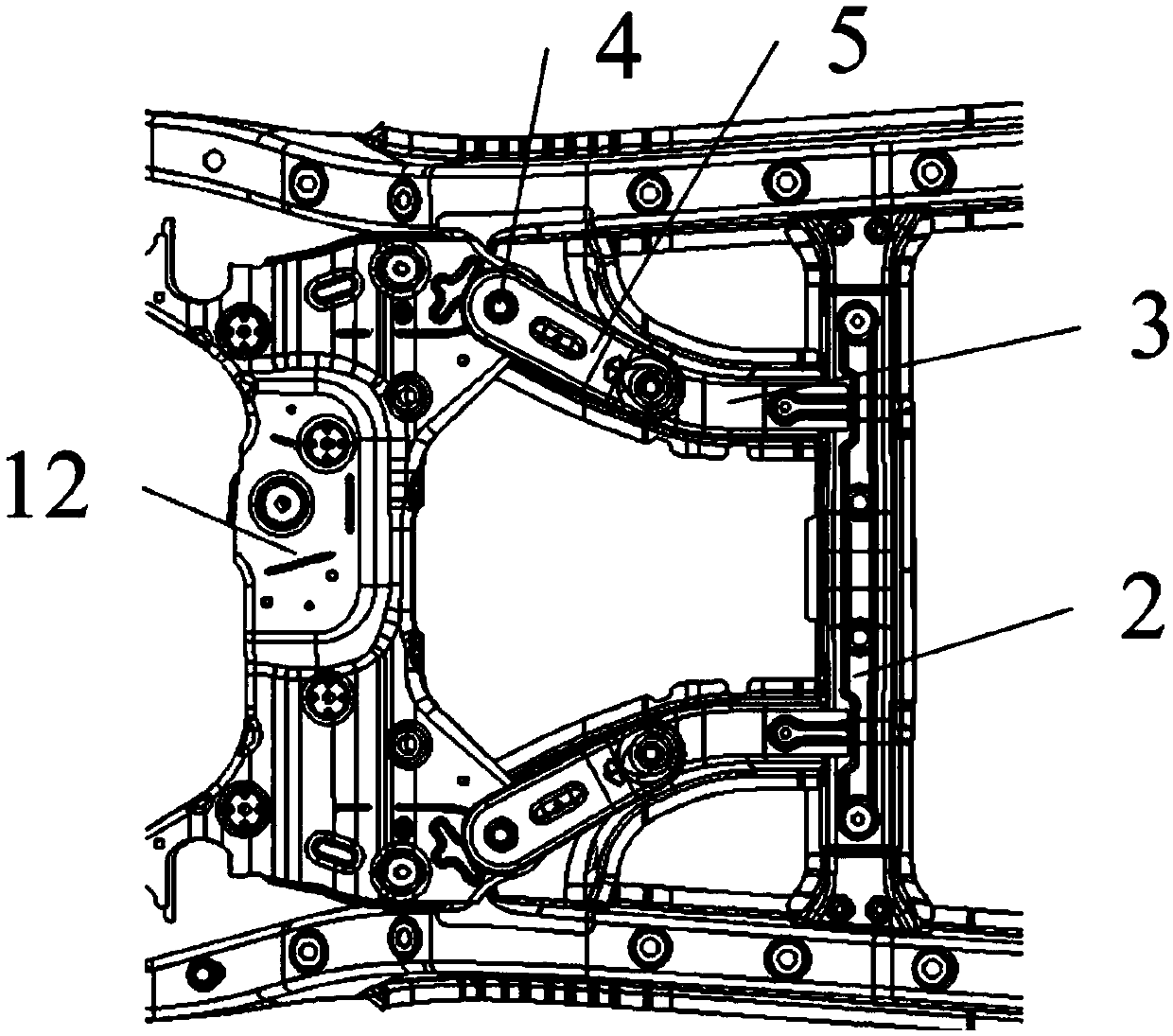

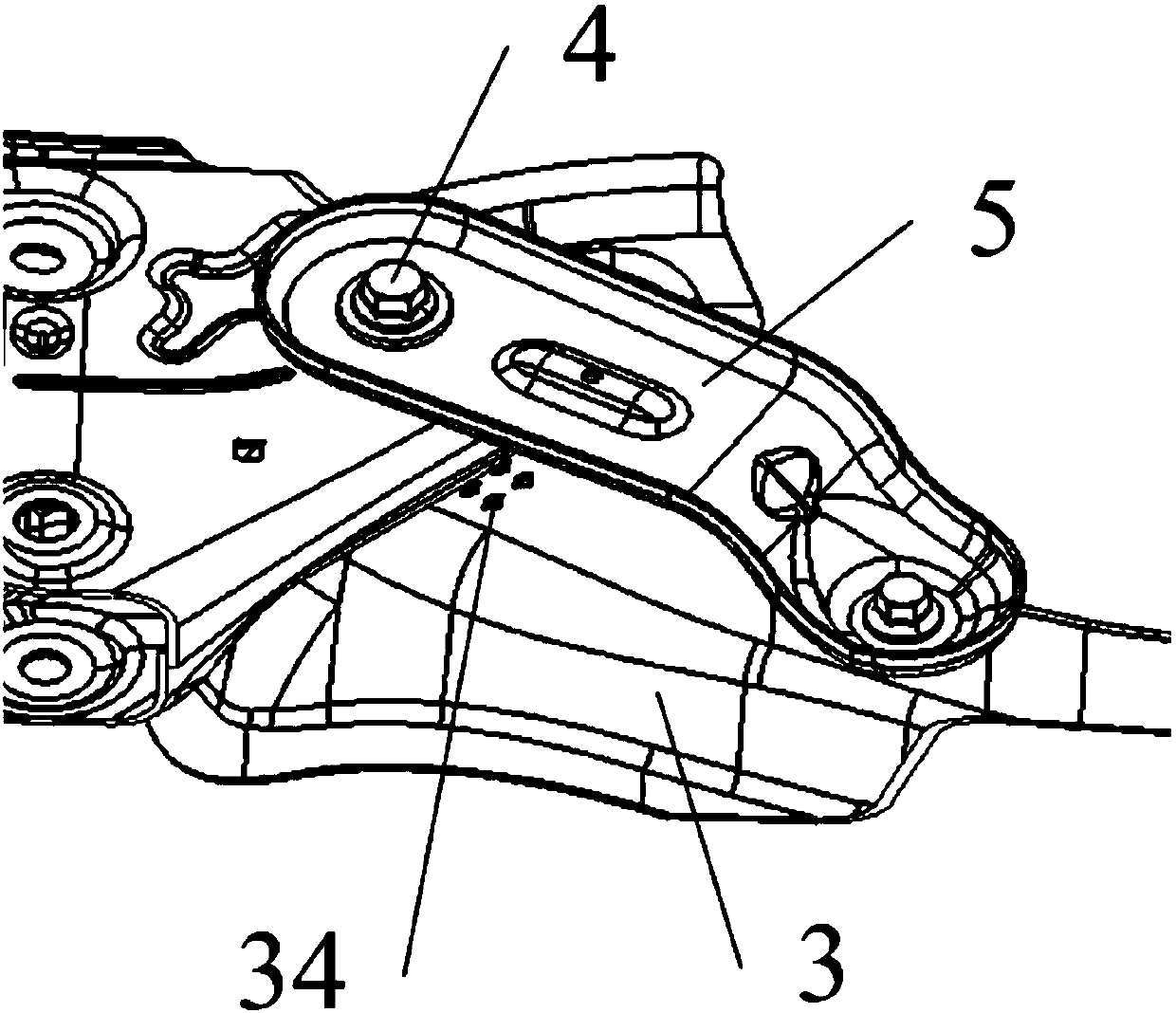

Vehicle, sub-frame mounting structure and design method of sub-frame mounting structure

ActiveCN109808771AHigh energy absorption efficiencyLess intrusiveUnderstructuresVehicle frameEnergy absorption

The invention relates to a vehicle, a sub-frame mounting structure and a design method of the sub-frame mounting structure, wherein the sub-frame mounting structure comprises vehicle body mounting brackets and connecting bolts; the vehicle body mounting brackets are connected between a sub-frame and a floor first cross beam; the connecting bolts are used for connecting the vehicle body mounting brackets with an upper connecting plate and a lower connecting plate of the sub-frame; a reinforcing support is further fixedly arranged on each vehicle body mounting bracket; a notch facing each reinforcing support is formed in each bolt mounting hole; during collision, the connecting bolts squeeze the notches to enable the notches to undergo tear deformation and extend toward the reinforcing supports; and the connecting bolts move with the tear deformation to the reinforcing supports until the connecting bolts break. According to the sub-frame mounting structure, the dynamic collision space ofa whole vehicle can be increased by controlling the deformation of the sub-frame and the vehicle body mounting brackets and the bolt failure under the condition of a certain front suspension size, sothat the carrying capacity of the dynamic collision space is improved, the overall energy absorption efficiency of the vehicle is enhanced, the intrusion of a vehicle powertrain into a front wall isreduced and the direct impact on a passenger compartment is reduced.

Owner:SAIC MOTOR

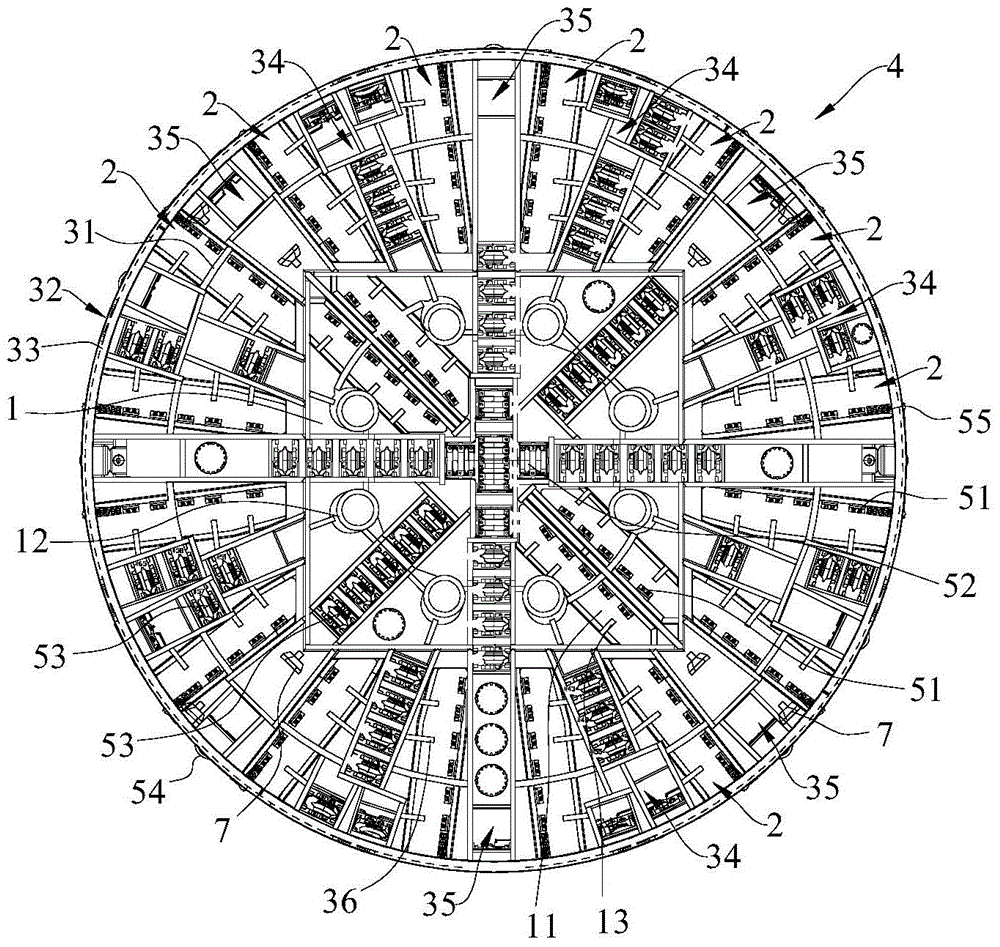

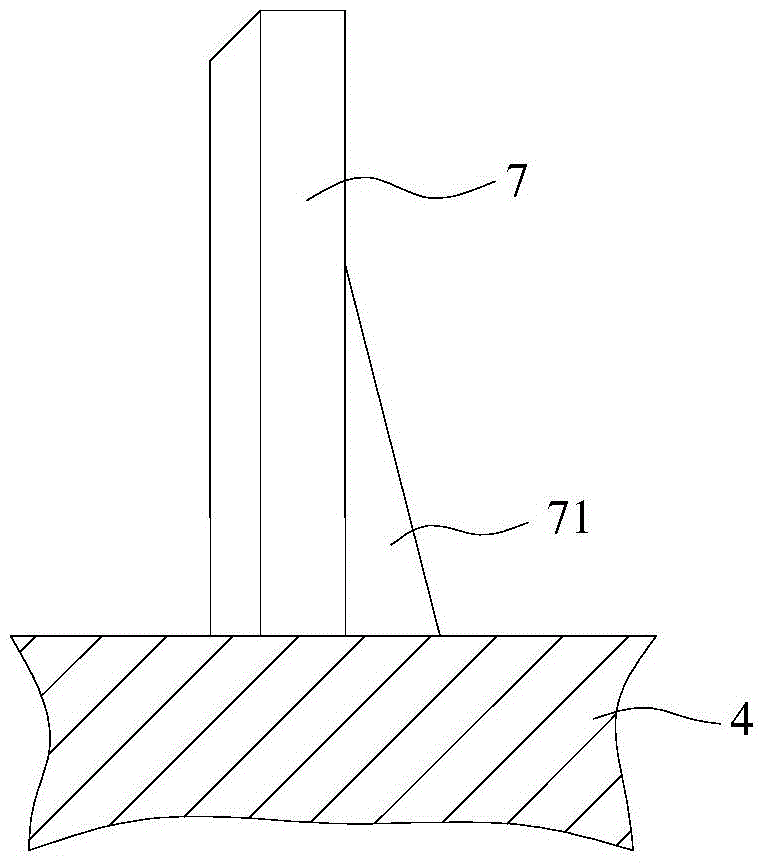

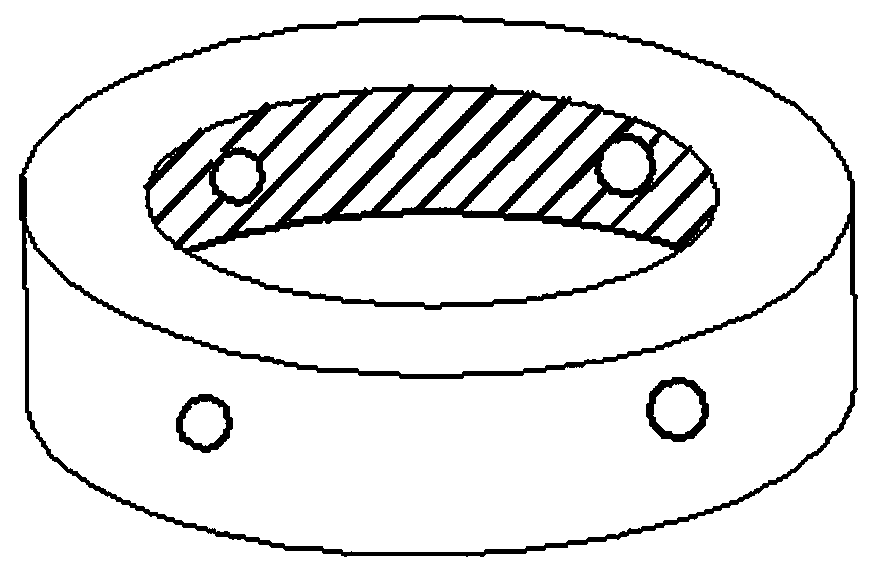

Spoke-type shield cutter disk

The invention discloses a spoke-type shield cutter disk. The spoke-type shield cutter disk comprises a cutter disk body and a plurality of cutter disk spoke plates which are arranged on the periphery of the cutter disk body and are separated from one another so as to form a plurality of first through grooves. The cutter disk body is fixedly connected with all the cutter disk spoke plates to form the disk-shaped cutter disk. Four cutter installation ribs which intersect mutually at the central position of the cutter disk body and form 45-degree included angles are arranged on the cutter disk body, the cutter installation ribs comprise three first installation ribs provided with a plurality of hobs and one second installation rib provided with a plurality of cutters, second through grooves are formed in the positions, located on the two sides of the second installation rib, of the cutter disk body, the cutter disk spoke plates comprise the first spoke plates provided with a plurality of hobs and the second spoke plates provided with a plurality of cutters, and the first spoke plates and the second spoke plates are arranged alternately all around the cutter disk body. According to the spoke-type shield cutter disk, through the cutters and the hobs reasonably arranged on the cutter disk body and the cutter disk spoke plates, the construction ground breaking capacity is improved and construction resistance during construction in a tunnel compound stratum is reduced on the basis that smooth flow of soil and sand is guaranteed.

Owner:CHINA RAILWAY 15TH CONSTR BUREAU GRP

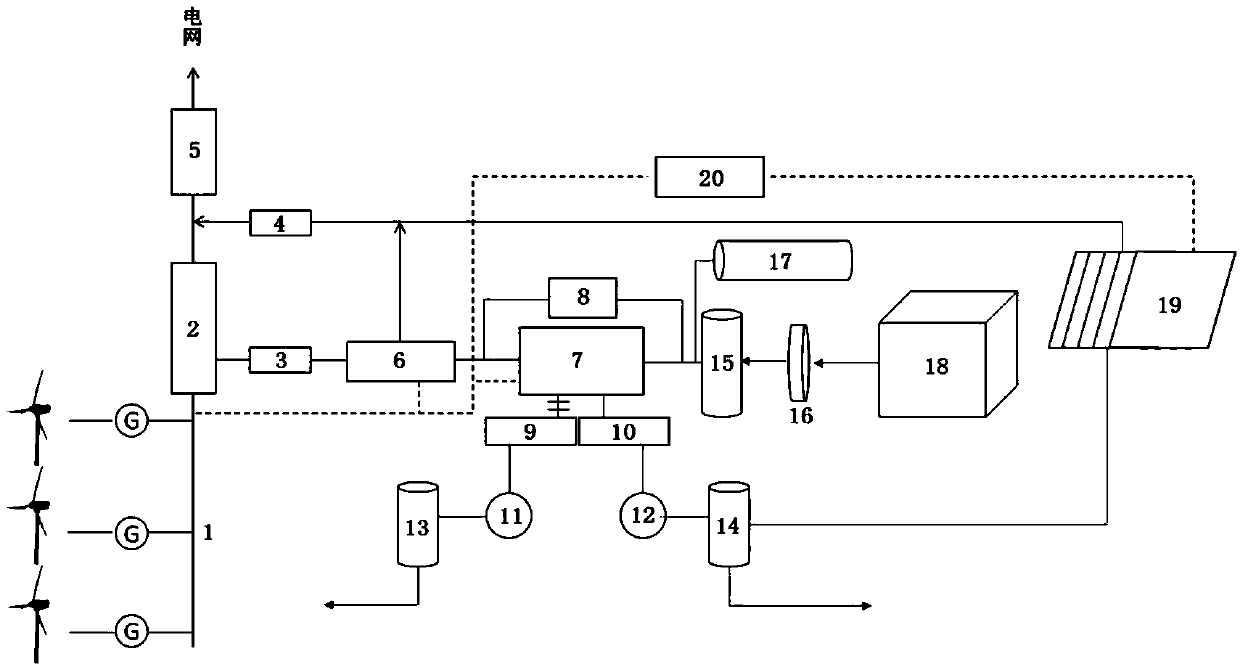

High-safety and high-efficiency peak shaving and frequency modulation system using urea wastewater for wind power hydrogen production

PendingCN109638893AImprove power generation efficiencyIncrease resourcesBatteries circuit arrangementsSingle network parallel feeding arrangementsTransformerEngineering

The invention discloses a high-safety and high-efficiency peak shaving and frequency modulation system using urea wastewater for wind power hydrogen production. An output end of a wind power generation system is connected with an input end of a power distributor; two output ends of a power divider are respectively connected with an input end of a transformer and a charging interface of a storage battery; a discharge interface of the storage battery is connected with a power interface of an electrolytic cell; a urea wastewater input pipe is communicated with a liquid inlet of the electrolytic cell sequentially through a filtering device and a wastewater storage tank; a cathode product outlet of the electrolytic cell is communicated with a hydrogen inlet of a fuel cell sequentially through ahydrogen buffer tank, a hydrogen compressor and a hydrogen storage tank; an output end of the fuel cell is connected with an input end of the transformer, and an anode product outlet of the electrolytic cell is communicated with an inlet of the oxygen storage tank sequentially through the oxygen buffer tank and an oxygen compressor; and an output end of the transformer is connected with a power grid. According to the invention, the system can achieve the electrolysis hydrogen production of urea in urea waste water through wind abandoning and electricity abandoning, and the hydrogen productionamount and the service life of the electrolytic cell are better.

Owner:HUANENG CLEAN ENERGY RES INST

Method for explosively welding copper-silver composite materials

ActiveCN103737171AReduce direct impactReduce transfer speedWelding/soldering/cutting articlesMetal working apparatusEngineeringComposite plate

The invention relates to a method for explosively welding copper-silver composite materials. The method includes parallelly arranging a silver composite plate (4) on a copper base plate (6) via supports (5); laying a corrugated paper buffer layer (3) on the composite plate (4); arranging second rock ammonium nitrate explosives on the corrugated paper buffer layer (3); placing the base plate (6) on a corrugated paper cushion (7); arranging a rubber cushion (8) under the corrugated paper cushion (7); positioning a clay foundation (9) under the rubber cushion (8); explosively welding the components to obtain a copper-silver composite material. The method has the advantages that the welding composite rate of copper-silver composite plates manufactured by the method is 100%, and the copper-silver composite plates are uniformly composited and are free of phenomena such as layering, bulging and vortexes.

Owner:HUNAN FORHOME COMPOSITE MATERIALS CO LTD

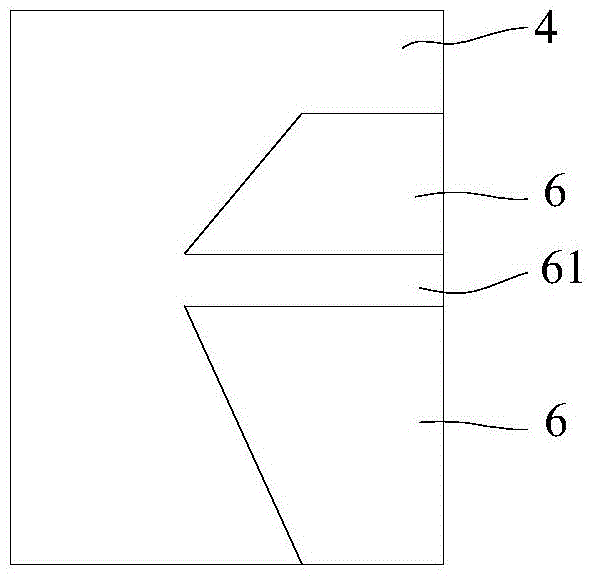

Wind resistant wall block provided with wind guiding structure

The invention discloses a wind resistant wall block provided with a wind guiding structure. Uniform wall blocks are adopted to be vertically and horizontally stacked, the height and the width of a whole wall can be controlled according to actual needs, and mounting and dismounting adjustment is facilitated. The wall is vertically assembled through clamping of triangular structures, good stacking and positioning can be achieved, the firmness is good, and all the wall blocks are mutually restricted; matched front wind guiding holes, horizontal wind guiding holes and vertical wind guiding holes are formed, wind blowing towards the front surfaces of the wall blocks is introduced into the front wind guiding holes and can be discharged towards the side faces of the wall blocks through the horizontal wind guiding holes and discharged upwards through the vertical wind guiding holes, accordingly, wind force borne by the wall blocks is decreased, and the wind resistant effect is improved. Mounting racks and adjustment brackets are arranged to achieve angle adjustment of the whole wall, the angle of the wall can be changed according to needs, direct impact of wind to the wall is reduced, and after the height of the wall is decreased, a space can be opened conveniently when the wind is small or blocking is not needed. A base is arranged to improve the firmness and the stability of the whole wall.

Owner:WENZHOU UNIV OUJIANG COLLEGE

Tidal current energy power generation device and underwater sealing protective device thereof

InactiveCN105781864AOvercome the problem of not being able to "go deep"Overcoming the impossibility of commercializationHydro energy generationMachines/enginesUnderwaterWater flow

The invention provides a tidal current energy power generation device and an underwater sealing protective device thereof. The underwater sealing protective device of a tidal current energy power generation unit is used for protecting the power generation unit located in water. The underwater sealing protective device of the tidal current energy power generation unit at least comprises an air pump and at least one pressurization pipe. One end of the pressurization pipe communicates with the air pump, and the other end of the pressurization pump communicates with the power generation unit. The air pump is used for pressurizing the power generation unit independently so that the pressure in the power generation unit can be controlled to be higher than or equal to the outside pressure, accordingly water flow in the outside can be prevented from entering the power generation unit, and the sealing performance of the power generation unit is guaranteed.

Owner:HANGZHOU LINDONG NEW ENERGY TECH INC

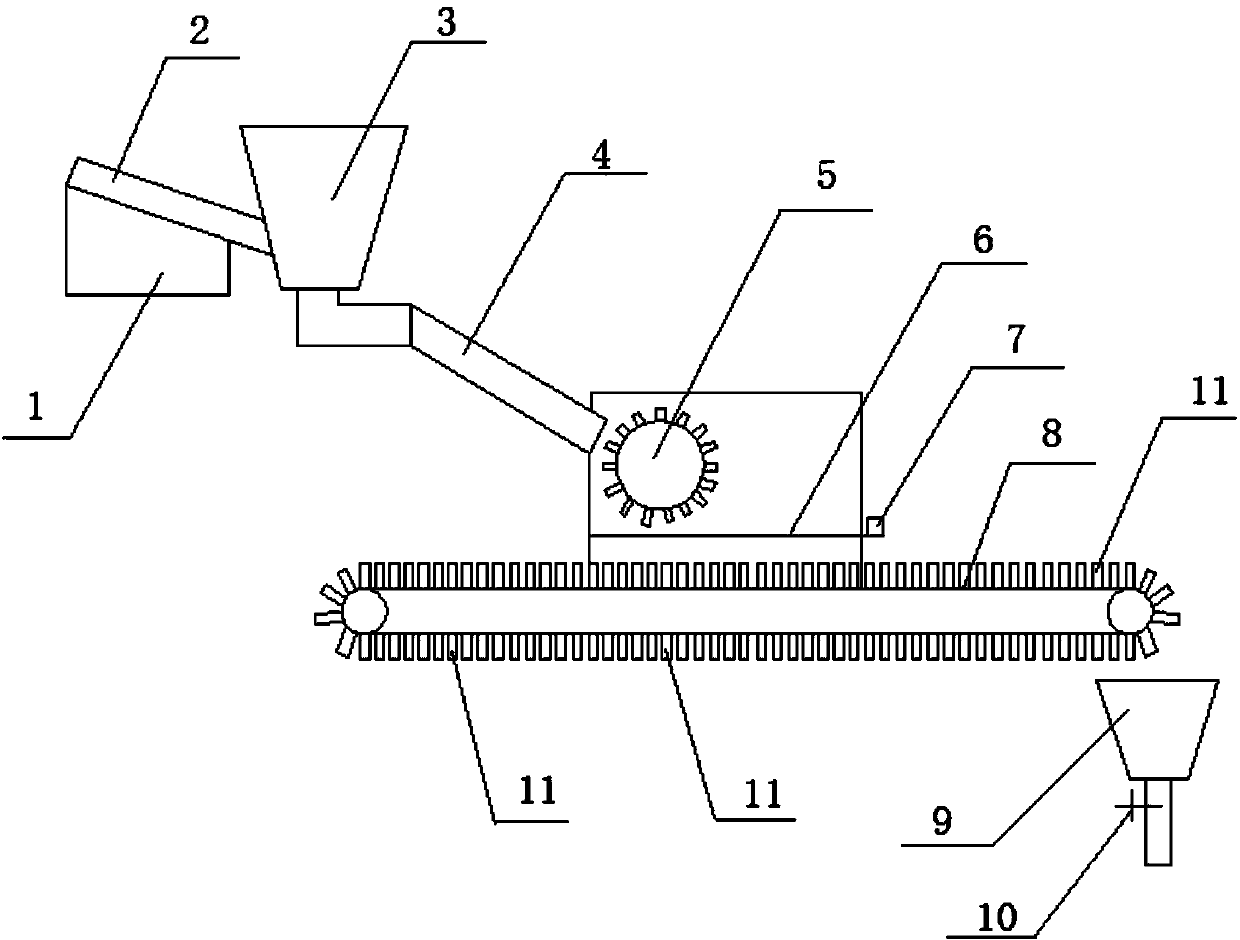

Ore processing device

The invention relates to an ore processing device, and particularly relates to a device used for ore feeding, smashing and sorting. The ore processing device comprises a feeding hopper, a feeding platform, a conveying pipeline, a smasher, a sorting screen, a conveyor belt and a storing box. The feeding platform is connected to the feeding hopper. One end of the conveying pipeline is connected to the feeding hopper and the other end of the conveying pipeline is connected to the smasher. The sorting screen is below the outlet of the smasher. The conveyor belt is below the sorting screen. The storing box is below the tail end of the conveyor belt. The beneficial effects of the device are that: the structure of the device is simple, operation is convenient, ore feeding, smashing and screening are performed synchronously, the processing efficiency is high, and the production cost is reduced.

Owner:GUANYANG CHENGONG ORE DRESSING MACHINERY MFG

One-kiln multi-line float glass production method and device

The invention discloses a one-kiln multi-line float glass production method and device. According to the method, part of molten glass produced in a large-tonnage melting furnace is guided to an ultra-thin glass production line through a main cooling part, and the rest is guided to a float glass production line through one or more large paths by means of a branch cooling part. The device comprises the large-tonnage melting furnace, wherein the large-tonnage melting furnace is connected with the ultra-thin glass production line through the main cooling part and further connected one or more large paths which are connected with the float glass production line through the branch cooling part, and temperature and pressure regulators are arranged on two sides of the large paths. The production lines can simultaneously and stably produce glass with different thicknesses and specifications, the production cost for the different specifications of glass is reduced, the energy consumption of each production line is reduced, and product quality is improved.

Owner:CHINA NEW BUILDING MATERIALS DESIGN & RES INST

Aluminum-aluminum composite material explosive welding method

ActiveCN103753012AEvenly distributedReduce direct impactWelding/soldering/cutting articlesMetal working apparatusEngineeringAluminum composites

The invention relates to an aluminum-aluminum composite material explosive welding method. The method includes: parallelly placing an lead compound plate (5) on an aluminum base plate (7) through a support (6), laying a rubber buffer layer (4) on the compound plate (5) , laying a corrugated paper layer (3) on the rubber buffer layer (4), distributing a second rock ammonium nitrate explosives on the corrugated paper layer (3), placing the base plate (7) on a flexible cushion layer (8), placing a rigid cushion layer (9) below the flexible cushion layer (8), placing a clay foundation (10) below the rigid cushion layer (9), and obtaining the aluminum-aluminum composite material through explosive welding. The welding composite rate of the aluminum-aluminum composite plate produced by the method can reach 100%, and the aluminum-aluminum composite plate is even in composition, and free of phenomena such as layering, bulking and vortex.

Owner:HUNAN FORHOME COMPOSITE MATERIALS CO LTD

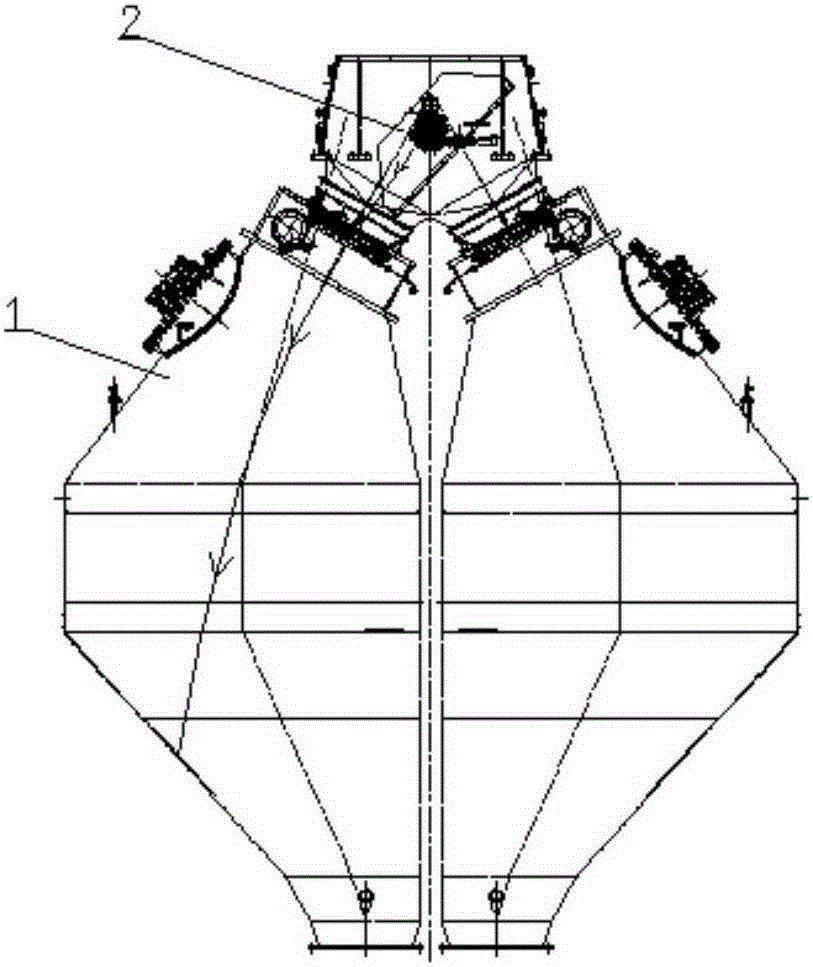

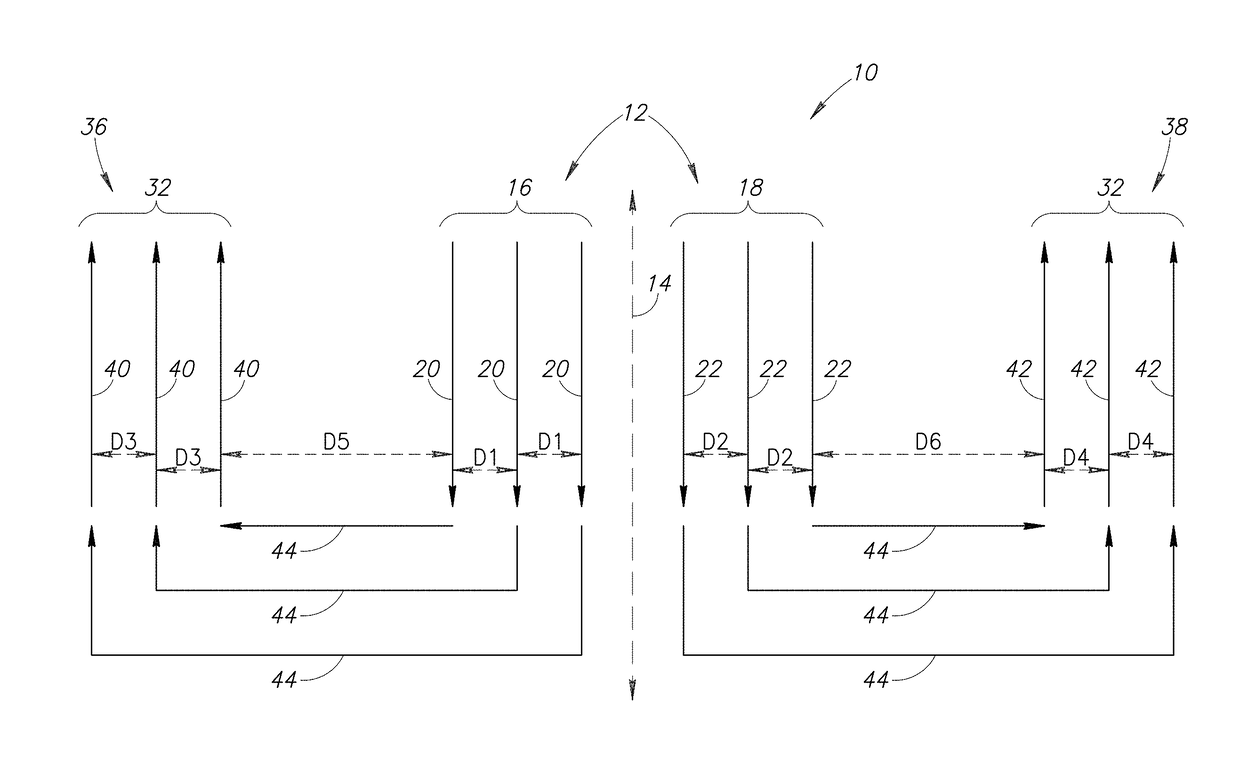

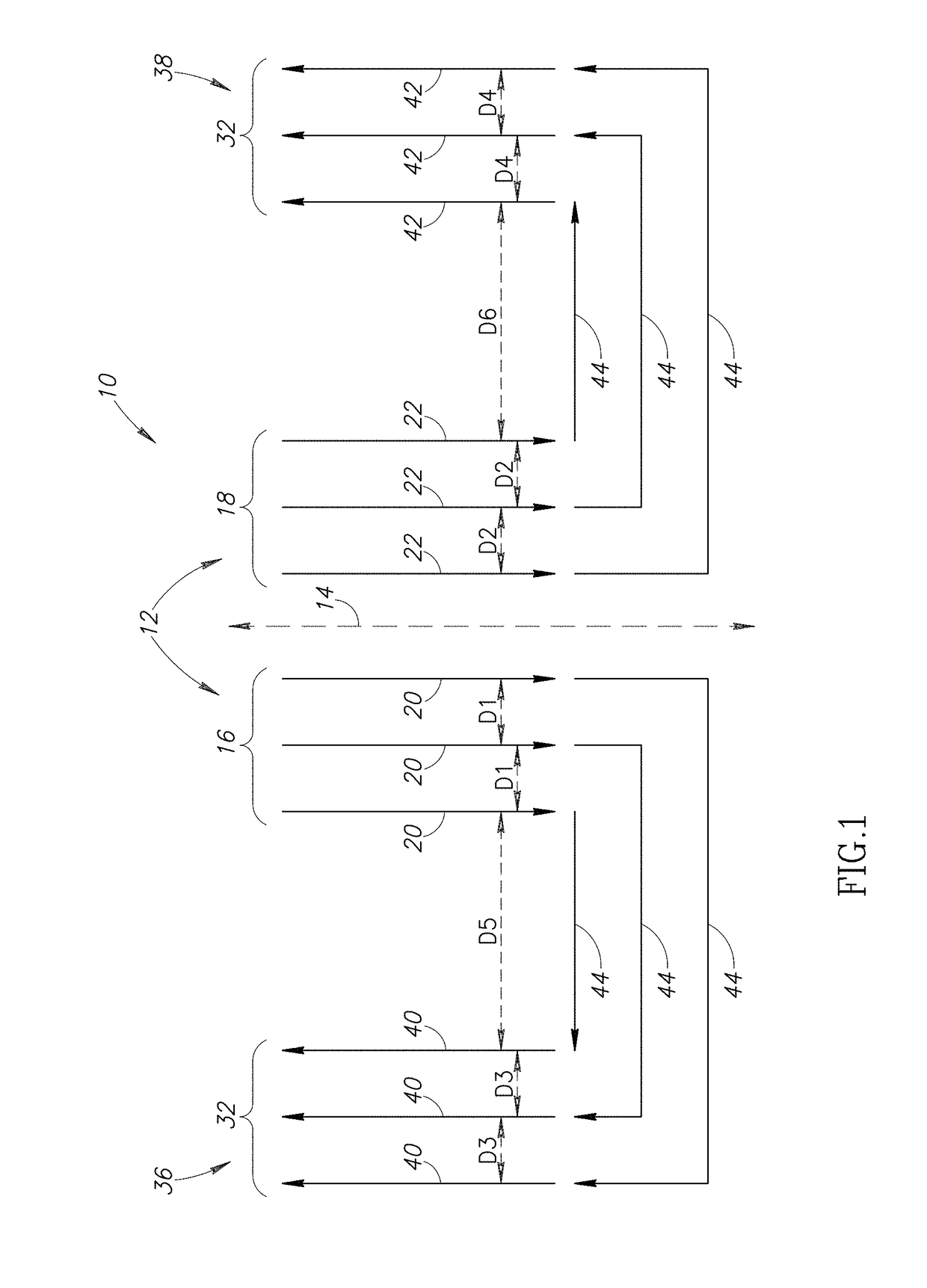

Loading segregation-prevention system

ActiveCN105296696AInhibition of segregationImprove uniformityBlast furnace componentsBlast furnace detailsEngineeringMechanical engineering

The invention discloses a loading segregation-prevention system, and belongs to the technical field of metallurgical smelting equipment. The system comprises at least two material tanks and an upper swing chute. The upper swing chute is arranged above the material tanks, and the system further comprises a segregation-prevention device independently arranged on the upper area inside the material tank or segregation-prevention devices which are arranged on the upper area and the lower area inside the material tank; each segregation-prevention device comprises a concentration hopper for loading materials and a positioning connecting assembly for fixing the concentration hopper into the material tank; and according to the loading segregation-prevention system, the materials are vertically discharged in the loading process, material segregation can be effectively prevented, distribution uniformity of the materials in the material tanks is improved, the direct impact of the materials on the inclined walls of the material tanks is reduced, the service life of wear-resisting lining plates inside the material tanks is prolonged, and the system can be widely used for a blast-furnace bell-less top loading system or other vertical shaft type loading systems.

Owner:CISDI ENG CO LTD

Central base coils for deep transcranial magnetic stimulation

ActiveUS9802058B2Undesired side-effectReduce direct impactElectrotherapyMagnetotherapy using coils/electromagnetsPower flowMagnetic brain stimulation

Owner:BRAINSWAY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com