Patents

Literature

45results about How to "Ensure uniformity of light" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Backlight module

InactiveCN102606960AImprove qualityGuaranteed mechanical strengthMechanical apparatusProtective devices for lightingElastomerLuminous intensity

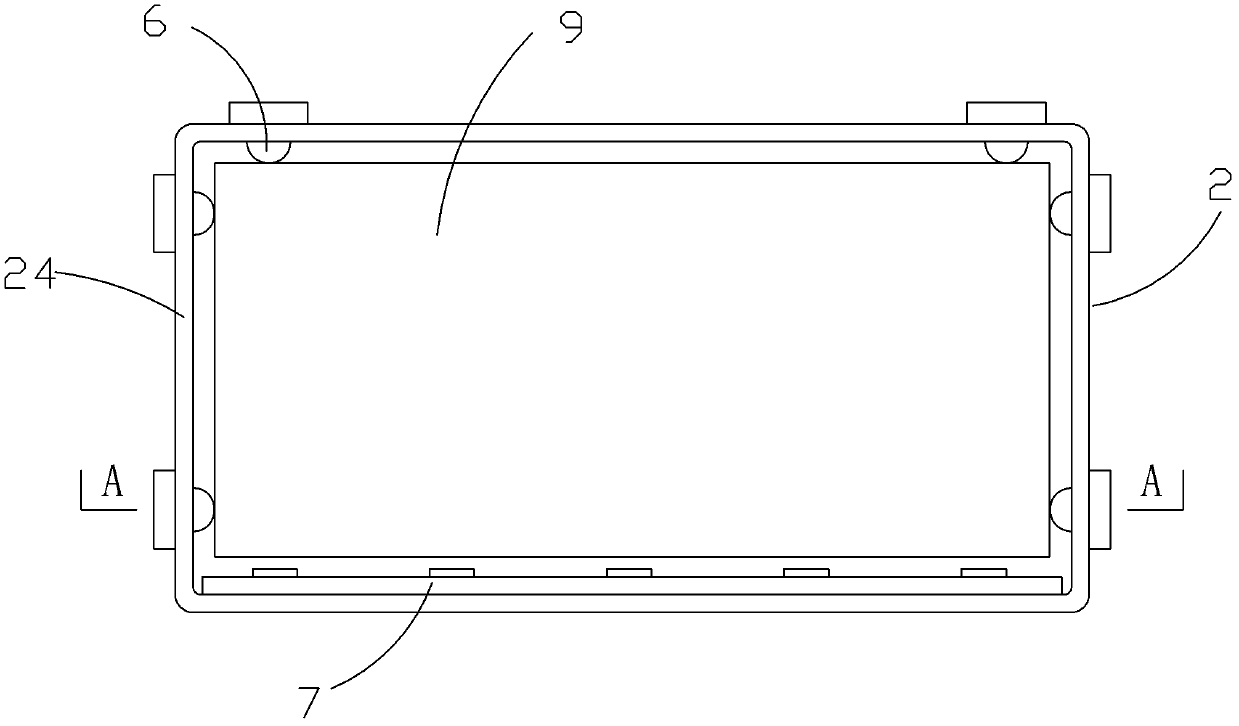

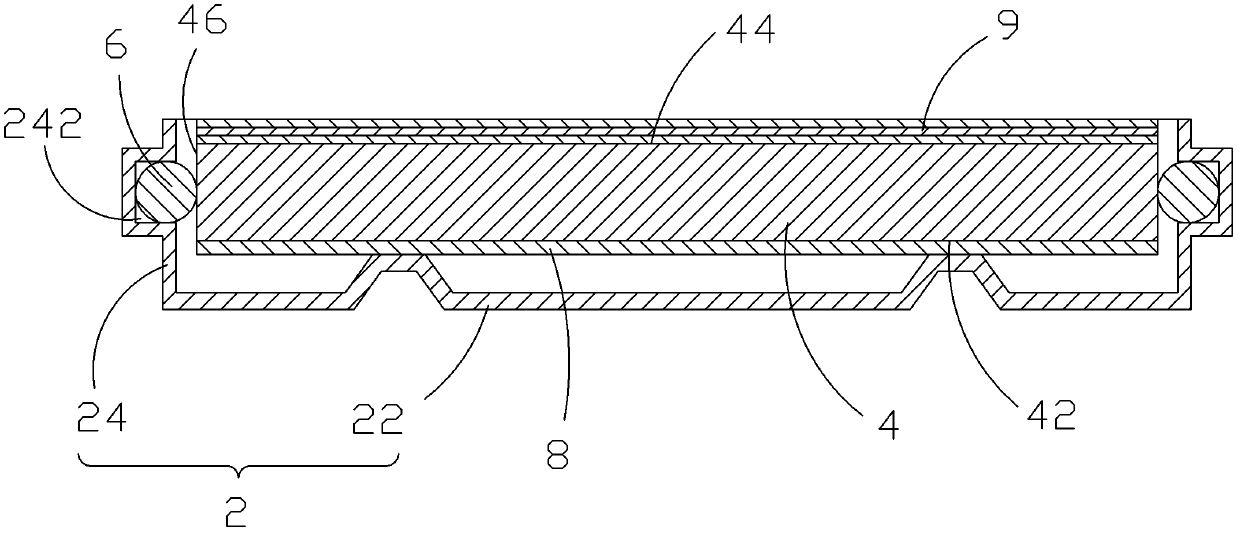

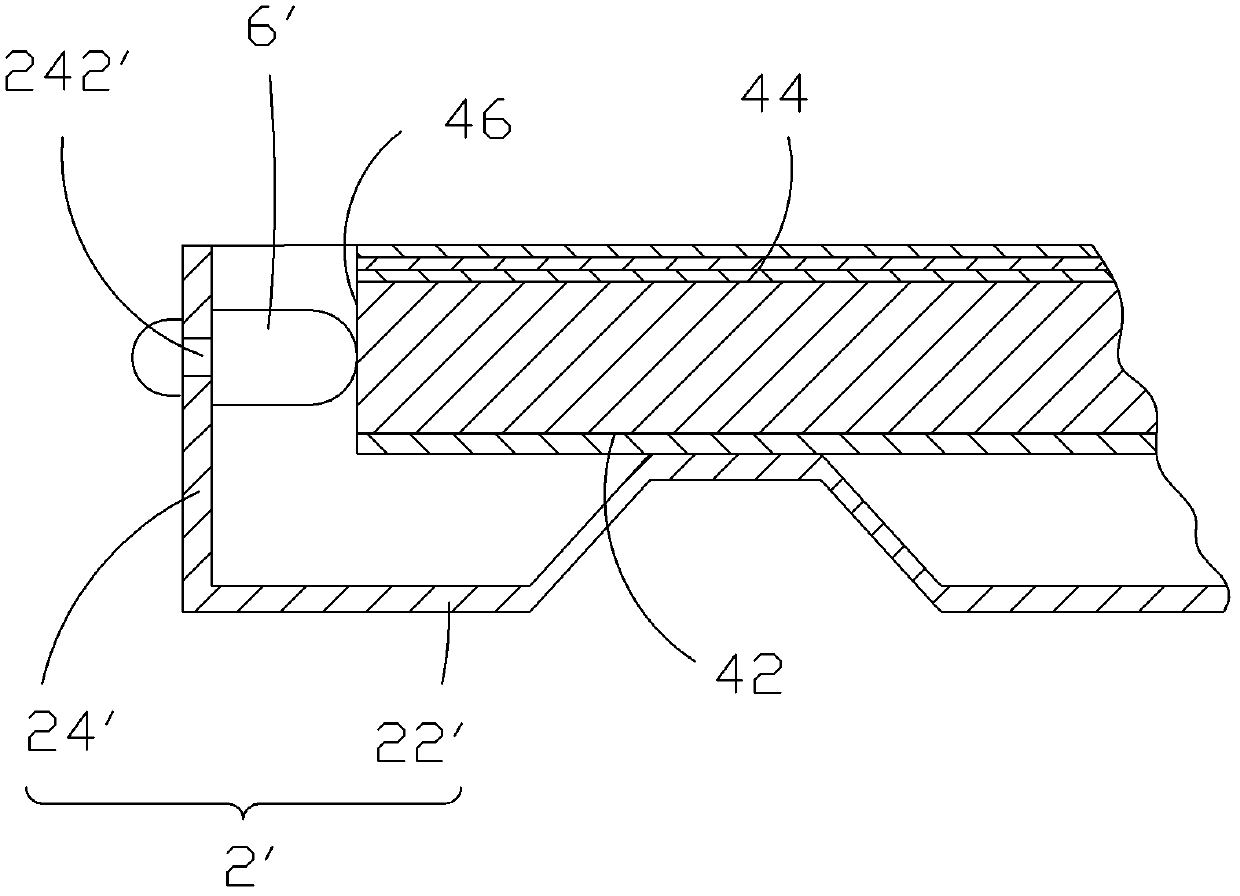

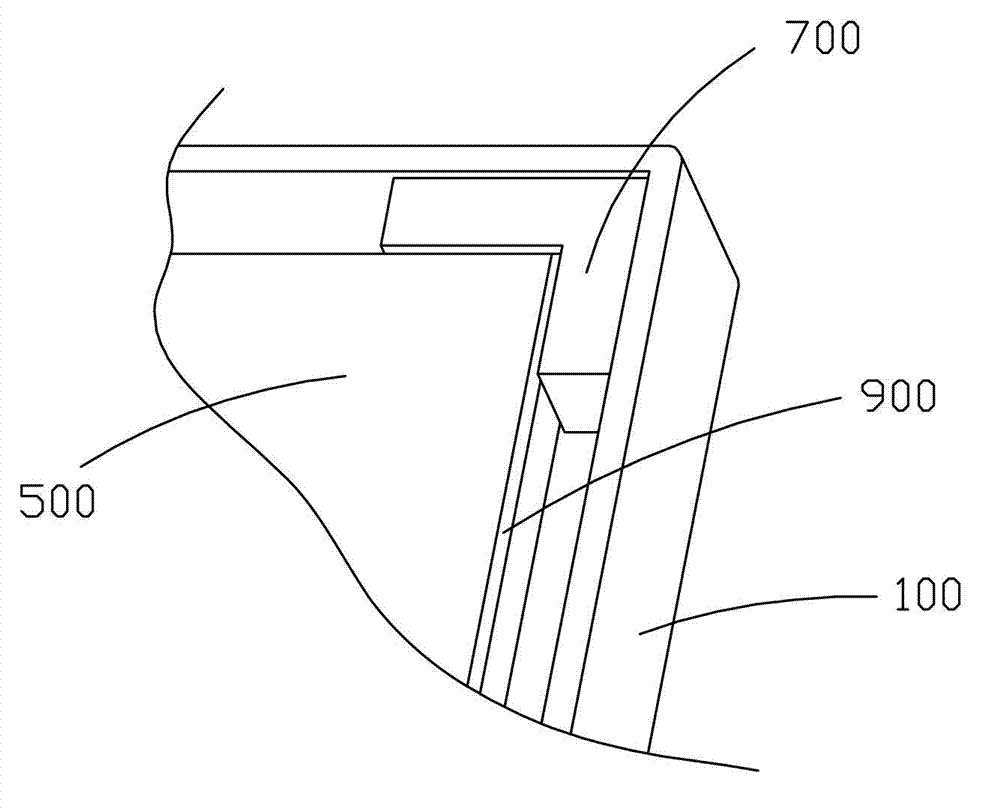

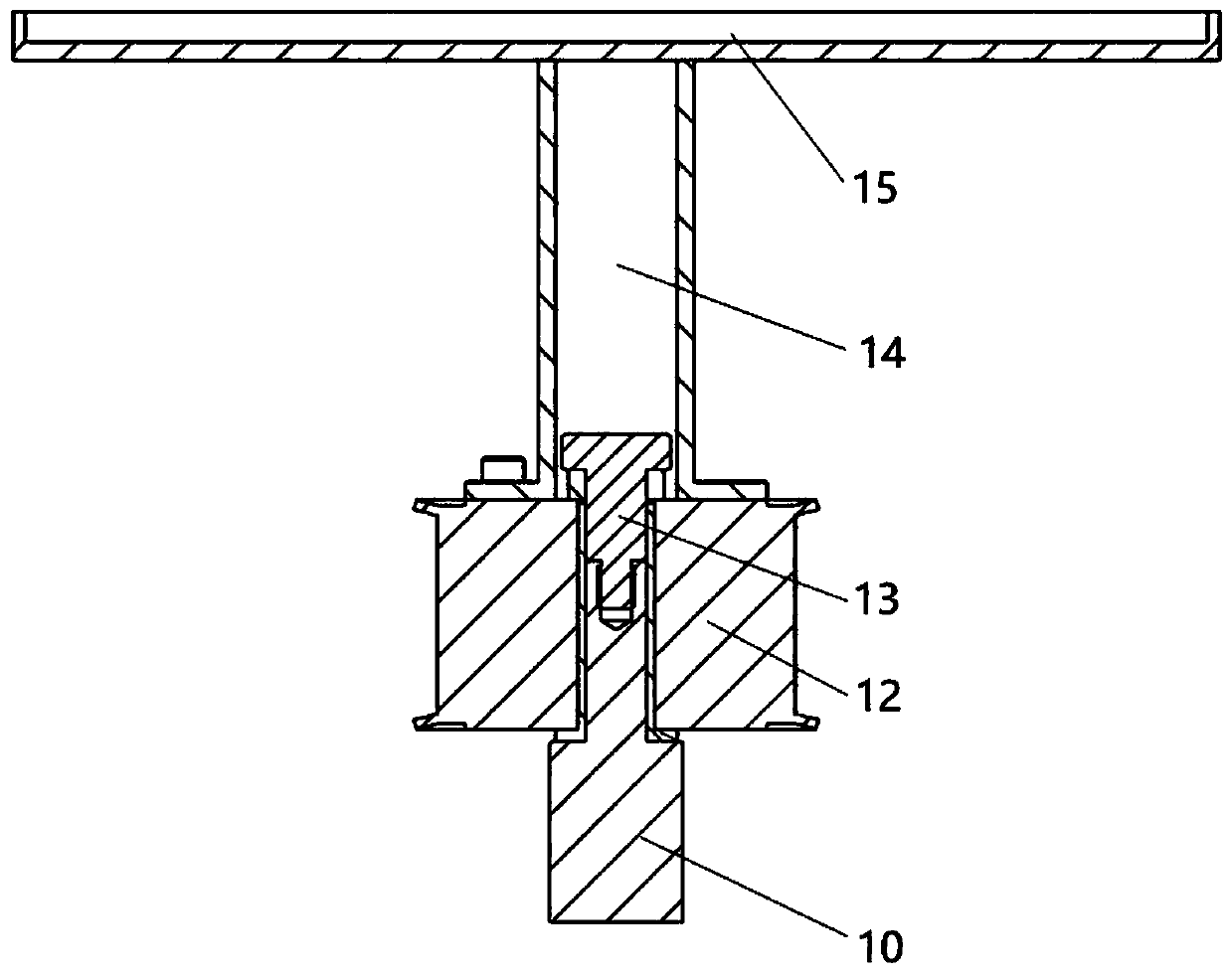

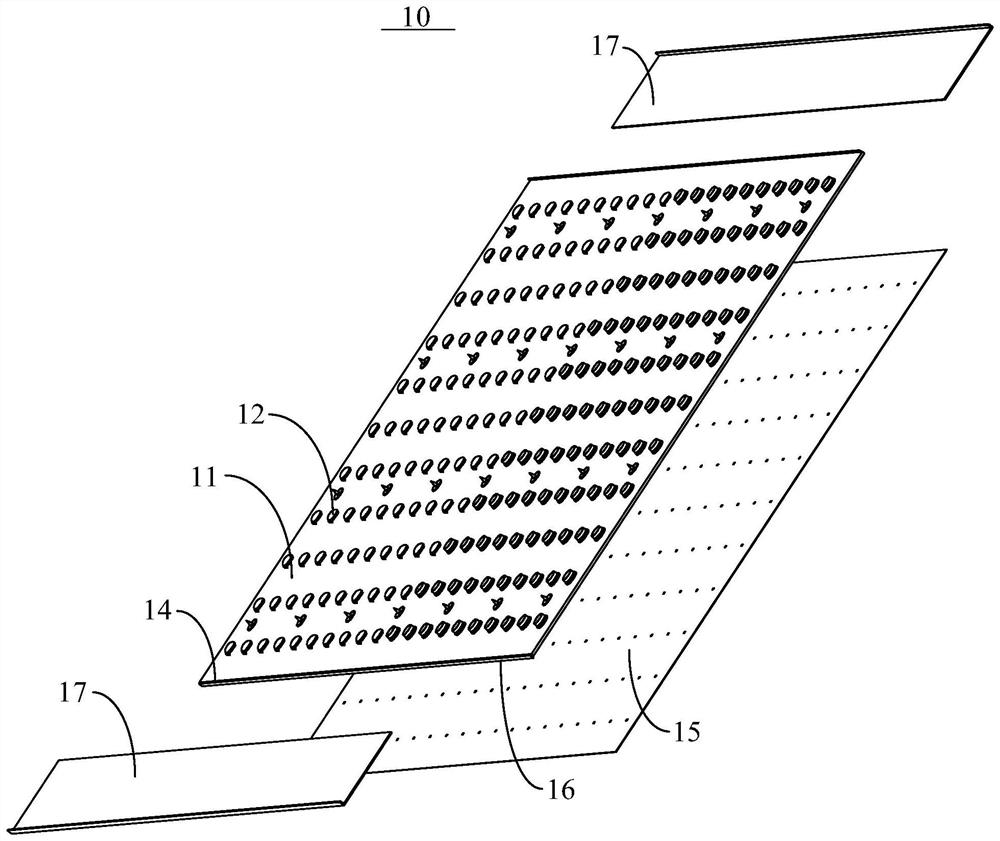

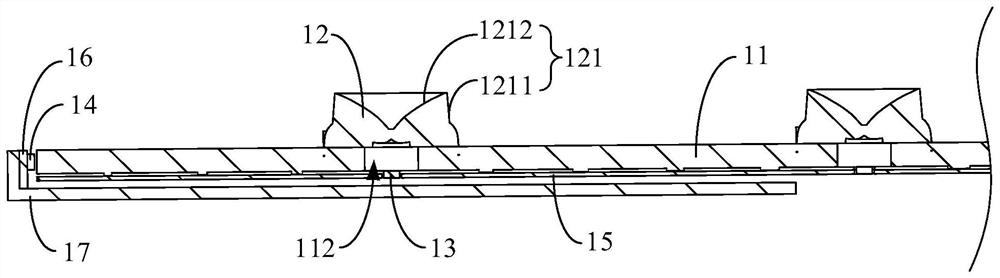

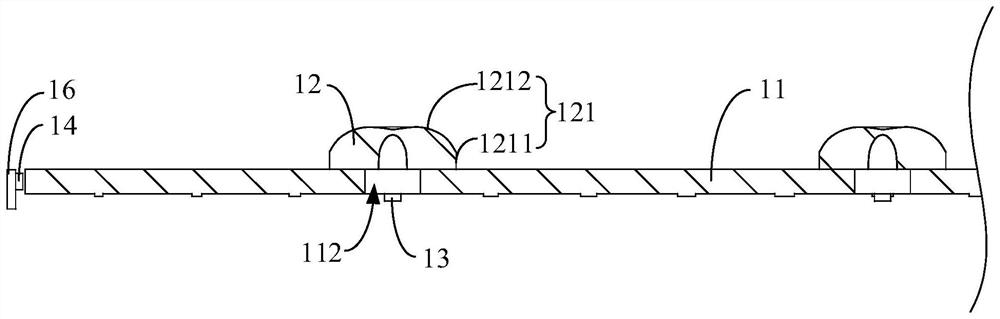

The invention provides a backlight module. The backlight module comprises a back plate, a light guide plate arranged in the back plate, and a plurality of elastic bodies mounted on the back plate, wherein the back plate includes a bottom plate, and a plurality of side plates vertically connected at the periphery of the bottom plate; the light guide plate includes a bottom surface facing the bottom plate, a top surface away from the bottom plate, and a plurality of side surfaces connected between the bottom surface and the top surface; the plurality of elastic bodies are respectively mounted on the three side plates of the back plate, and butt against the three side surfaces of the light guide plate; and the contact surface between the elastic bodies and the side surfaces of the light guide plate is an arc-shaped surface or a spherical surface. The backlight module provided by the invention can ensure the mechanical strength of the light guide plate by fixing the light guide plate in the back plate through the elastic bodies between the side plates of the back plate and the light guide plate without processing the periphery of the light guide plate by grooving, embossing and so on, and can supply a certain buffer space to prevent extrusion deformation of the light guide plate due to thermal expansion in the prior art, thereby ensuring the luminous intensity and uniformity and reducing the cost.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

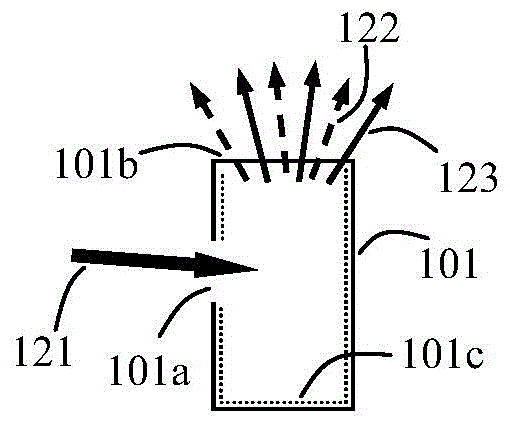

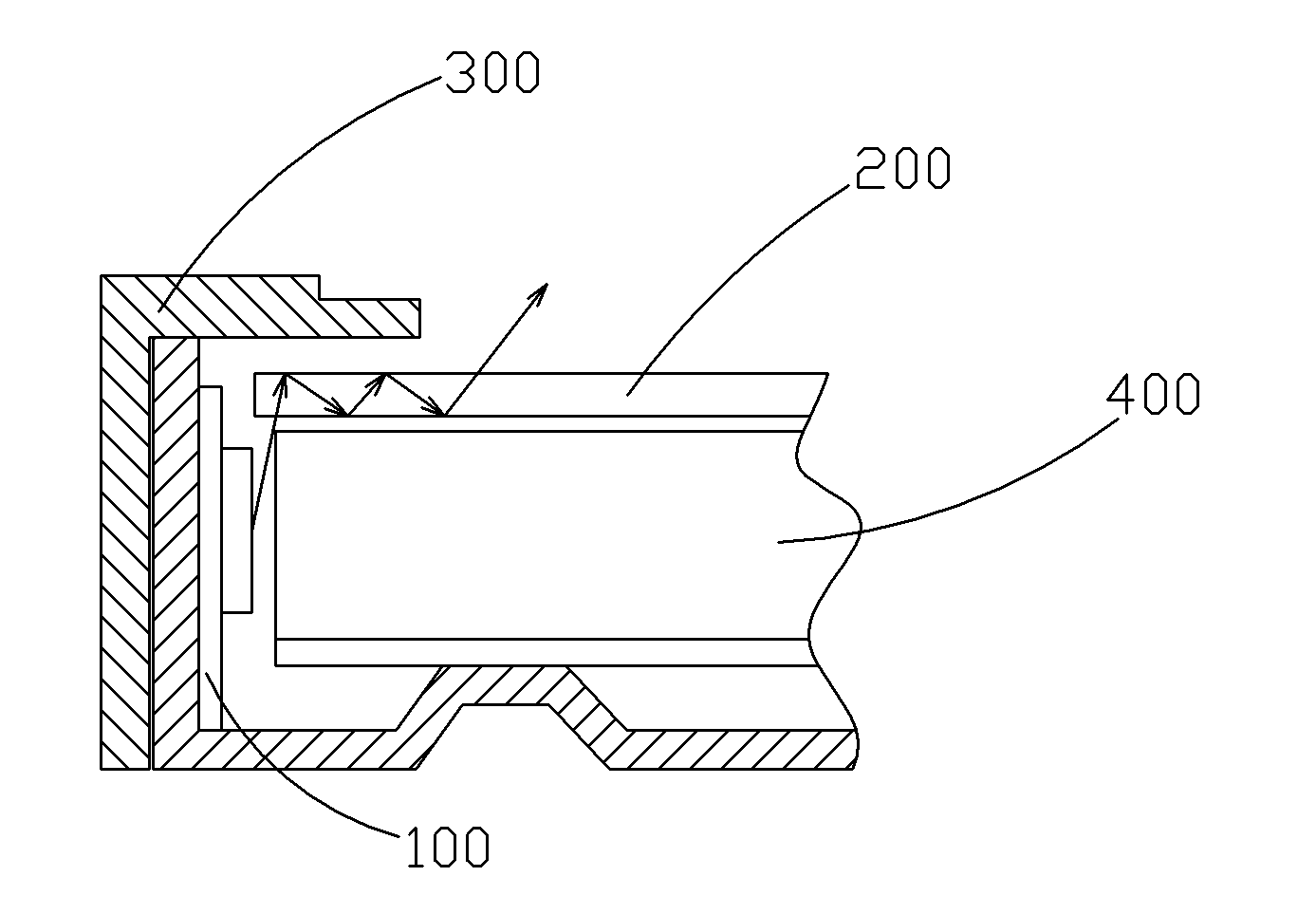

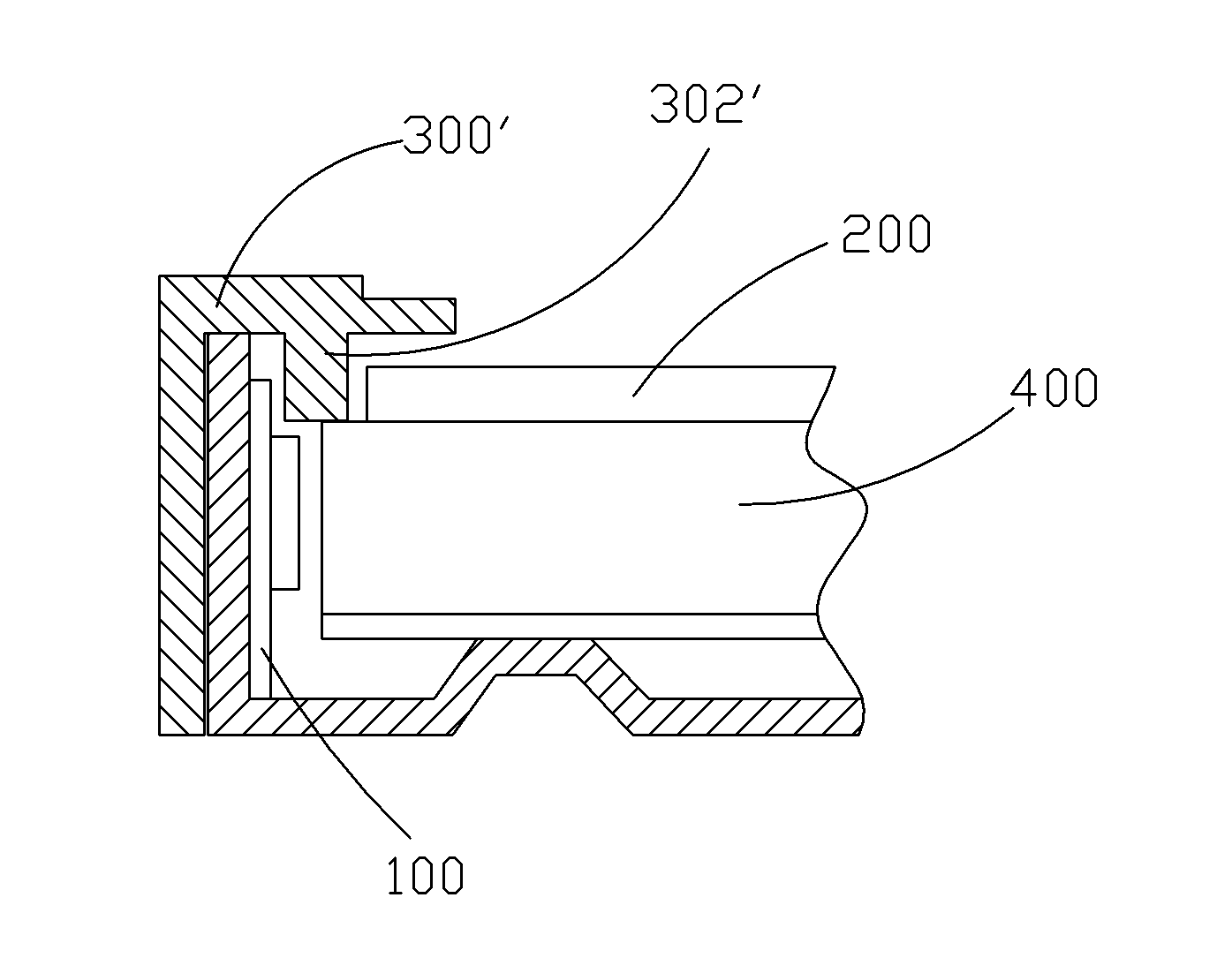

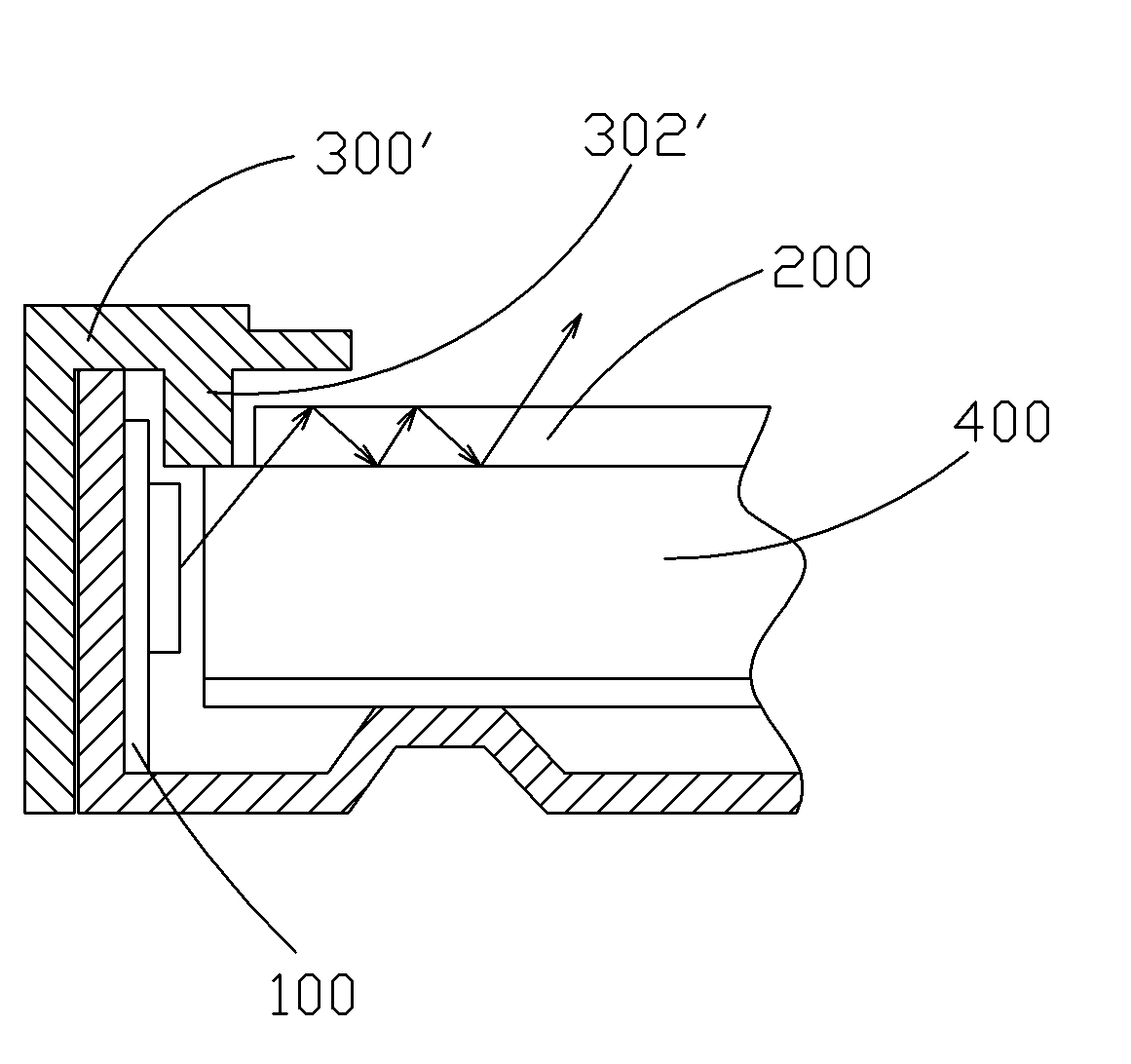

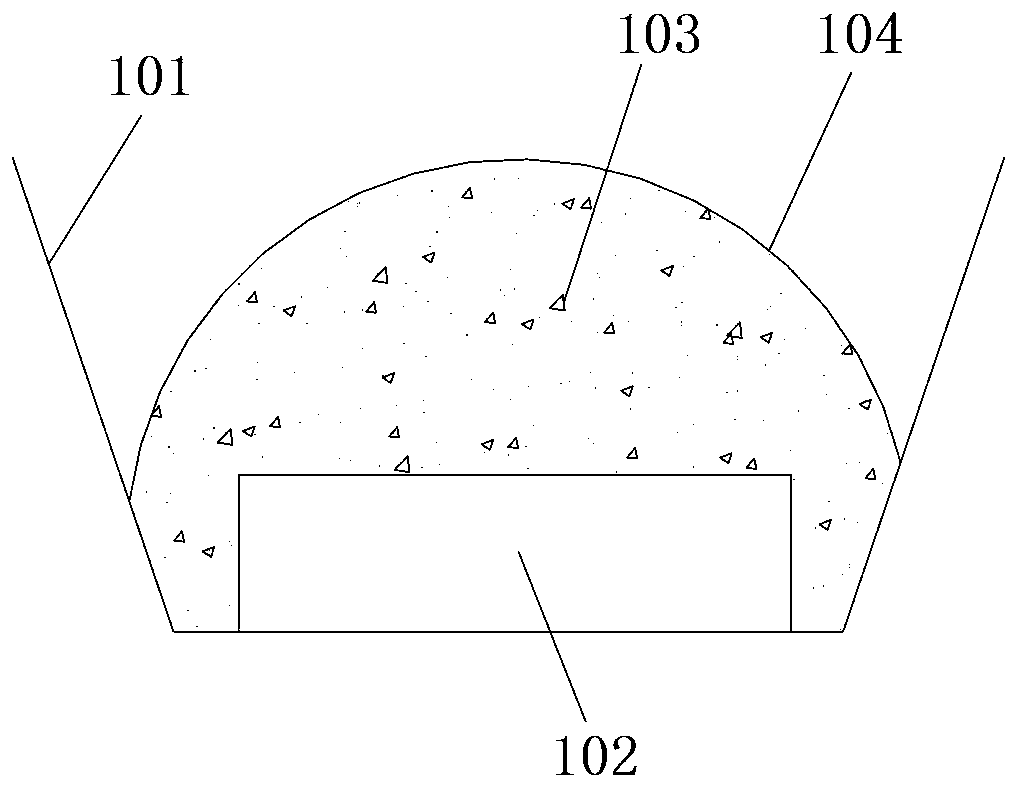

Wavelength conversion device and light-emitting device

InactiveCN104566231AEnsure uniformity of lightSpectral modifiersReflectorsWavelength conversionLight emitting device

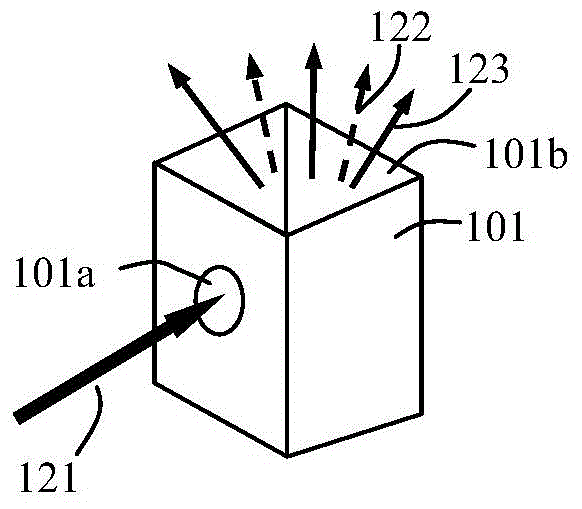

The invention discloses a wavelength conversion device and a light-emitting device. The wavelength conversion device comprises a cavity, wherein at least partial inner surface of the cavity is a reflection inner surface, and a wavelength conversion layer is arranged on the reflection inner surface; the cavity comprises a light inlet and a light outlet, wherein the light inlet is used for receiving incident exciting light, the exciting light is incident to the cavity to excite the wavelength conversion layer on the reflection inner surface and enables the wavelength conversion layer to emit excited light, and the exited light finally is emergent from the light outlet; the sum of areas of the light inlet and the light outlet is smaller than area of the rest of the inner surface of the cavity; positions of the light inlet and the light outlet are not opposite. The wavelength conversion device is adopted, so that the exciting light and the excited light are emergent after being sufficiently reflected in the cavity; moreover, the exciting light cannot be directly project to the light outlet from the light inlet, so that the light-outlet uniformity of the light outlet is effectively guaranteed.

Owner:杨毅

Wide light evening light source module

InactiveCN101178514AEnsure uniformity of lightLow installation accuracy requirementsElongate light sourcesElectric lightingStraight tubeLight reflection

The invention relates to a backlight module with wide amplitude and even light, which can be used as light source by installing in lamp house by assembling one or a plurality of modules. The invention comprises a straight tube type light source, an even light reflection board with multi turning surfaces and an even light bowl. The reflection board with multi turning surfaces and even light respectively comprises a reflection area, a lens diffuse mixing reflection area and a diffuse reflection area from central line to two sides, and each reflection area is formed by one or more than one reflection surfaces, and positioned under the straight tube type light source. The even light bowl is positioned above the straight tube type light source, and provided with a rhomboidal beam orifice, and the edge is in randomly scattered tooth shape, and the face facing the light source is the lens reflecting surface, and the face facing the display surface is the diffuse reflection surface. The design of three areas solves the difficulty of reflected light distribution and control. Reflection ray can be reflected in a cross way in the distance by the even light bowl, and the light ray can be gentler. The effective use rate of the module reaches about 90 percent, wide amplitude reaches 500 to 600 mm, and lighting evenness reaches more than 90 percent. Moreover, the advertising light box thickness is controlled between 70 mm to 50 mm.

Owner:刘俊波

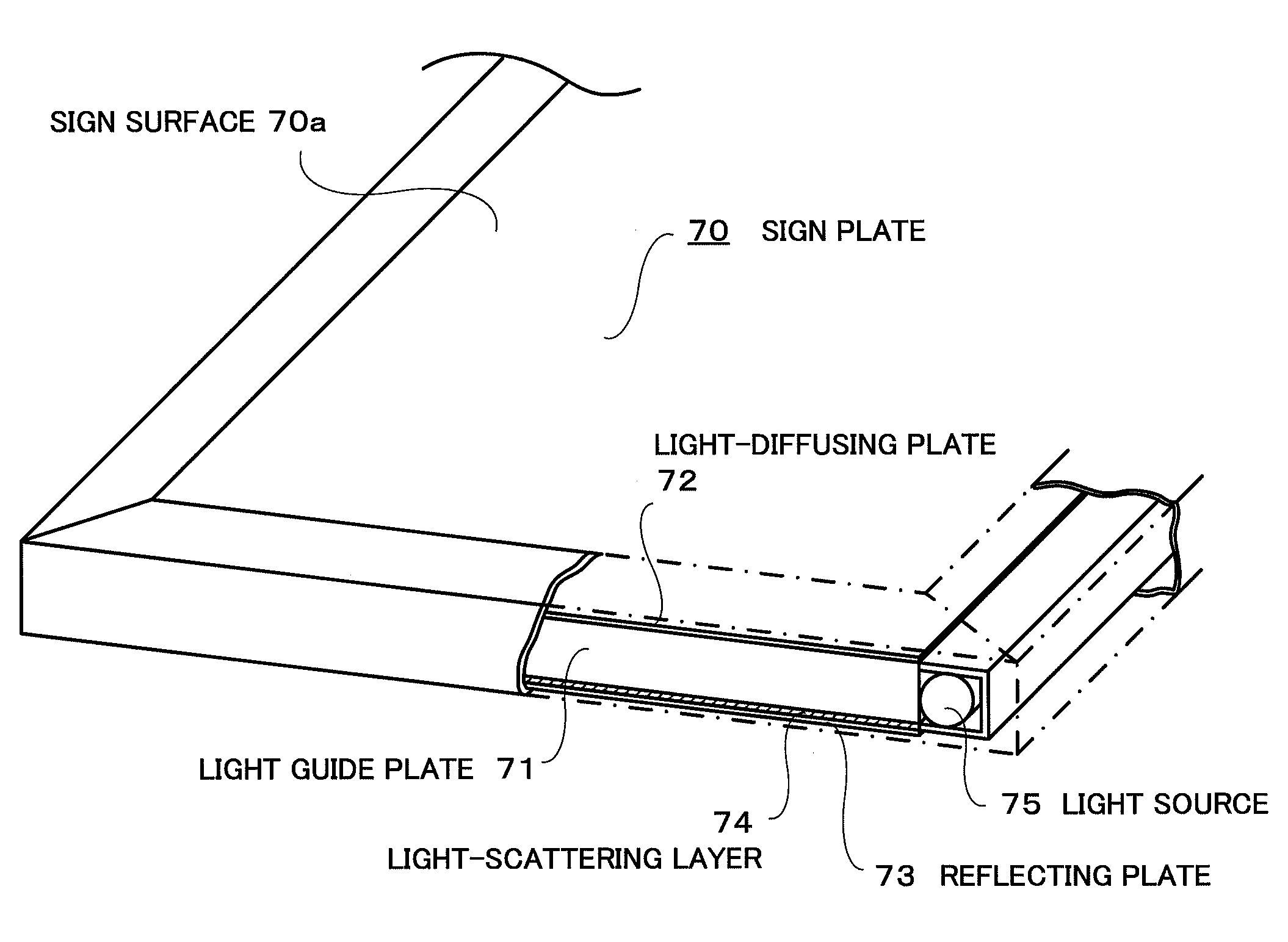

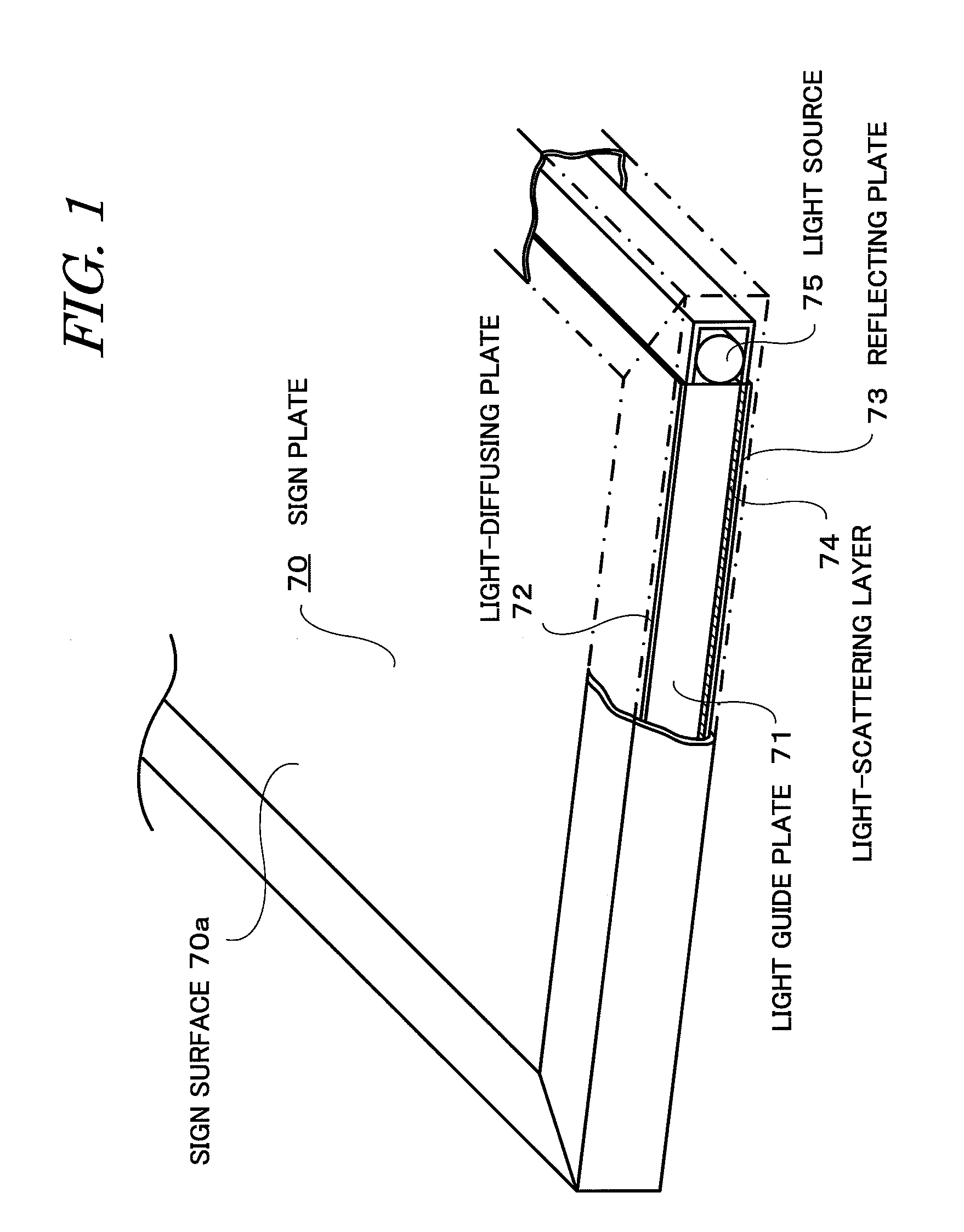

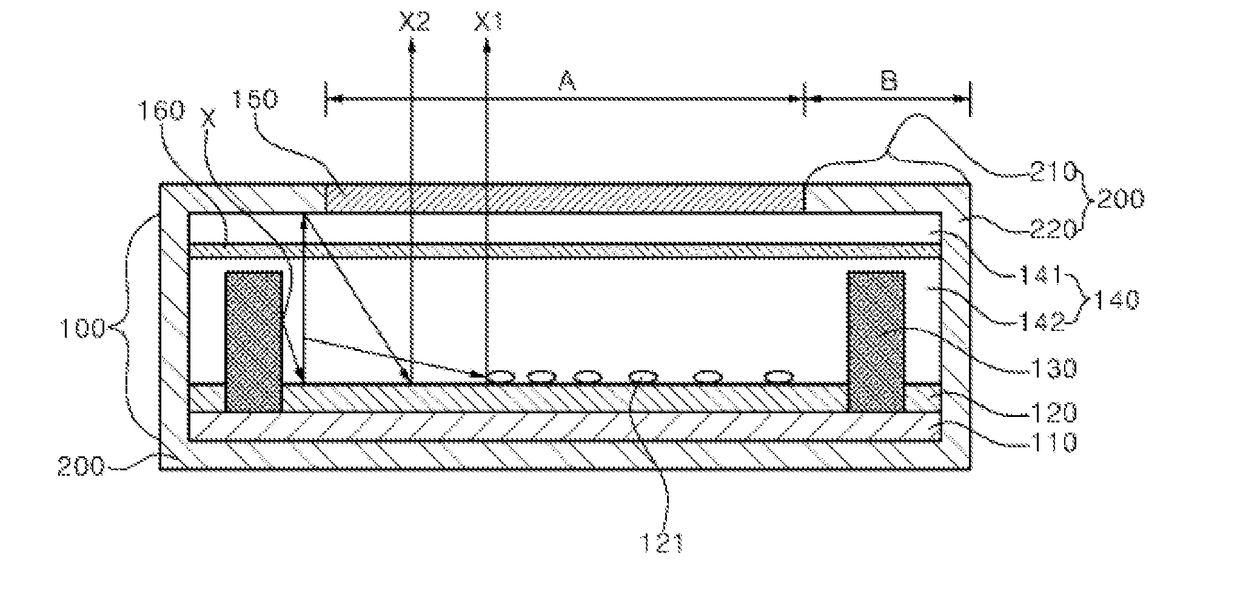

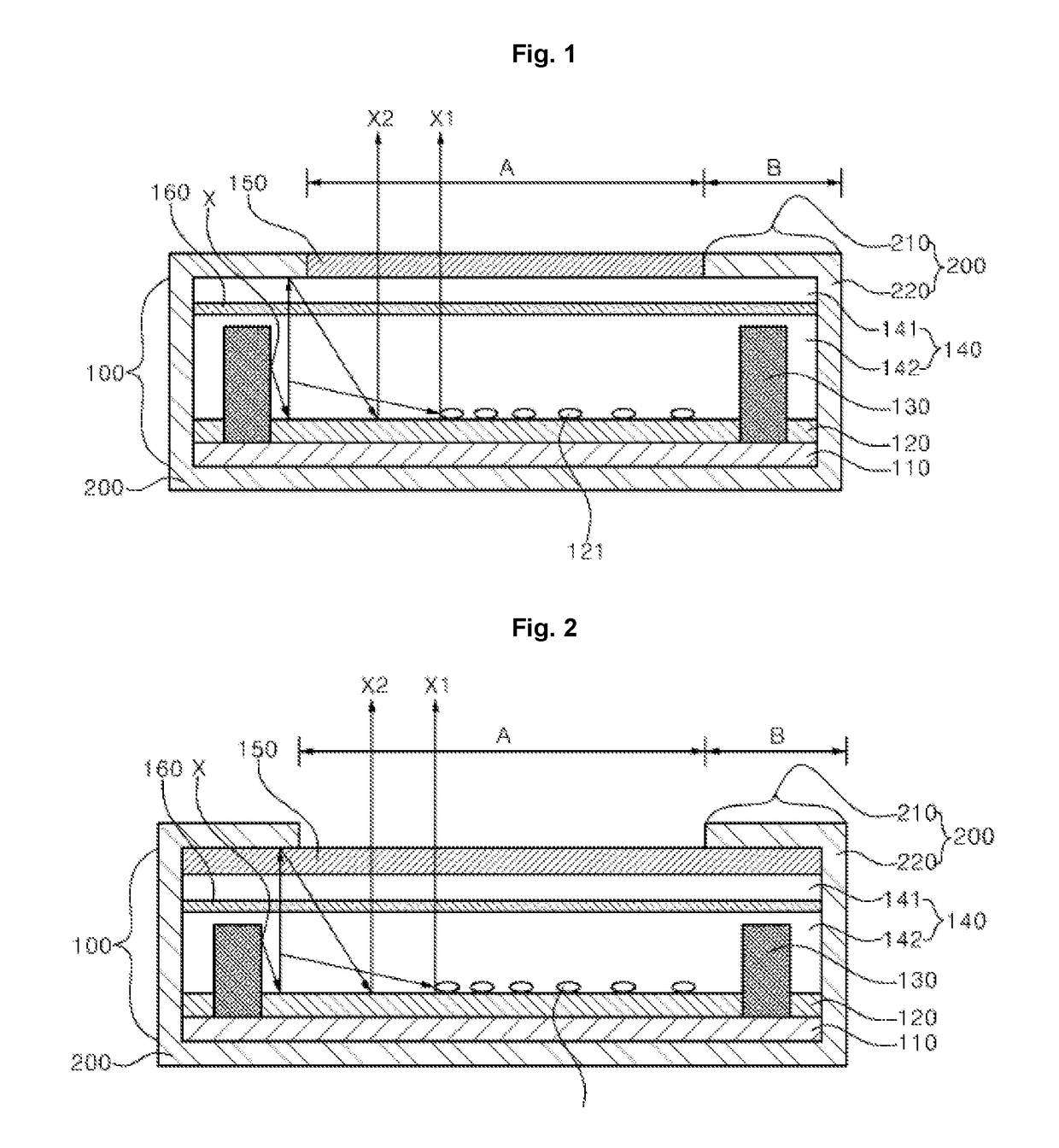

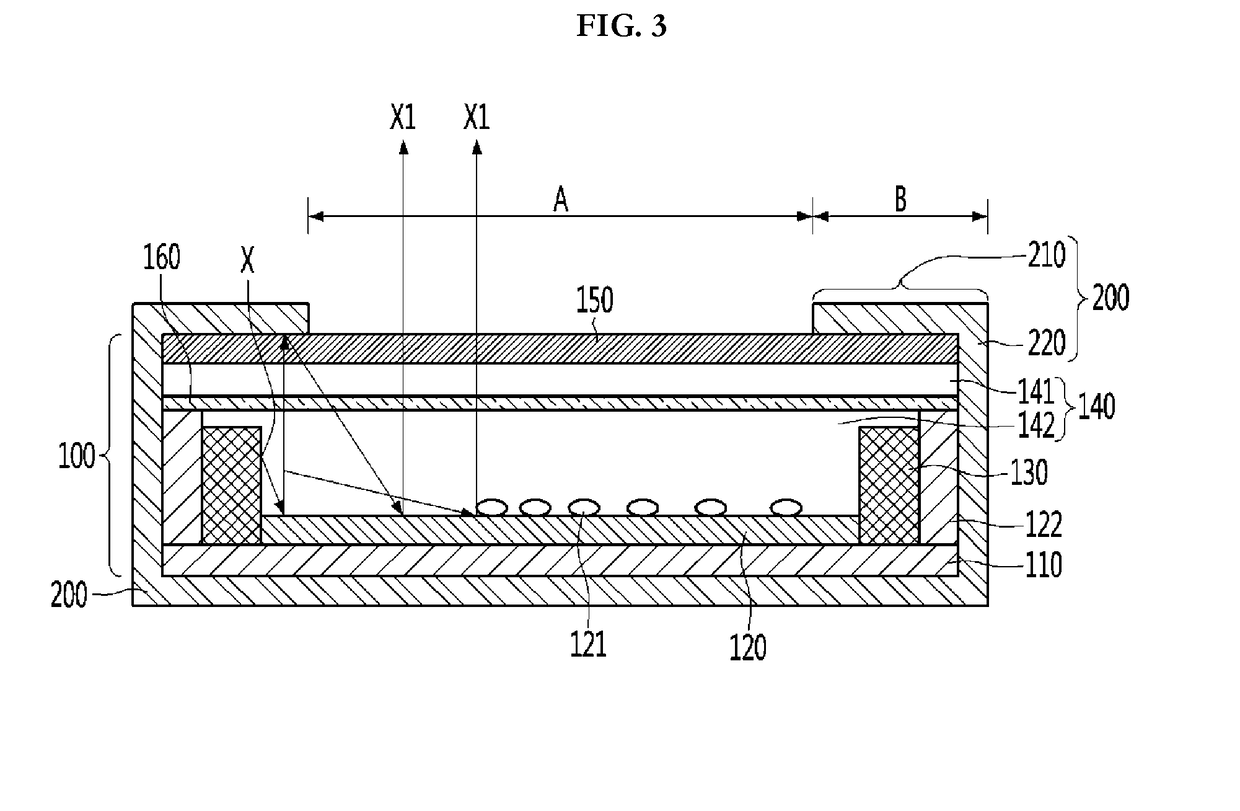

Light-emitting sign device

InactiveUS20090025264A1Reduce intensityEfficient illuminationIlluminated signsOptical light guidesVisibilityLight guide

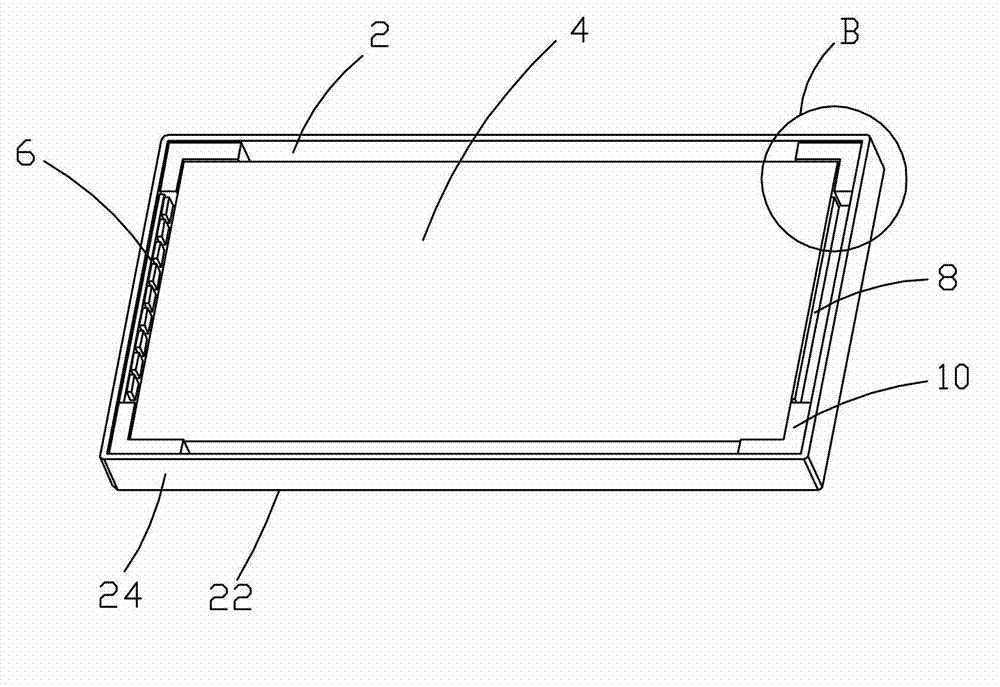

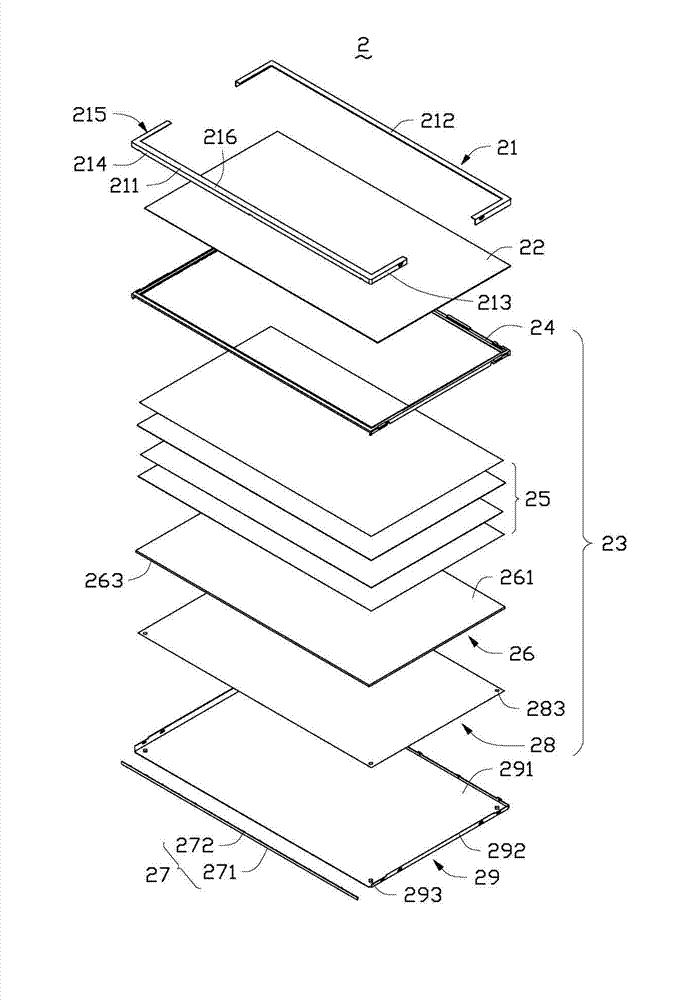

A light-emitting sign device is provided, in which optimum scattering of light from a light source is ensured, light loss can be reduced to a minimum, uniform and bright emission is made possible, and visibility and cost efficiency are improved. A sign plate having a sign surface is provided, and a light-diffusing plate, light guide plate, and white reflecting plate are arranged in this order on the rear surface of the sign plate. A light-scattering layer that scatters the light from the light source is coated on the rear surface of the light guide plate. The light-scattering layer has a binder layer composed of a coating composition using a transparent resin as a binder. A filler in the form of transparent and substantially spherical fine particles of silica is uniformly dispersed in the binder layer.

Owner:TAMURA KK +1

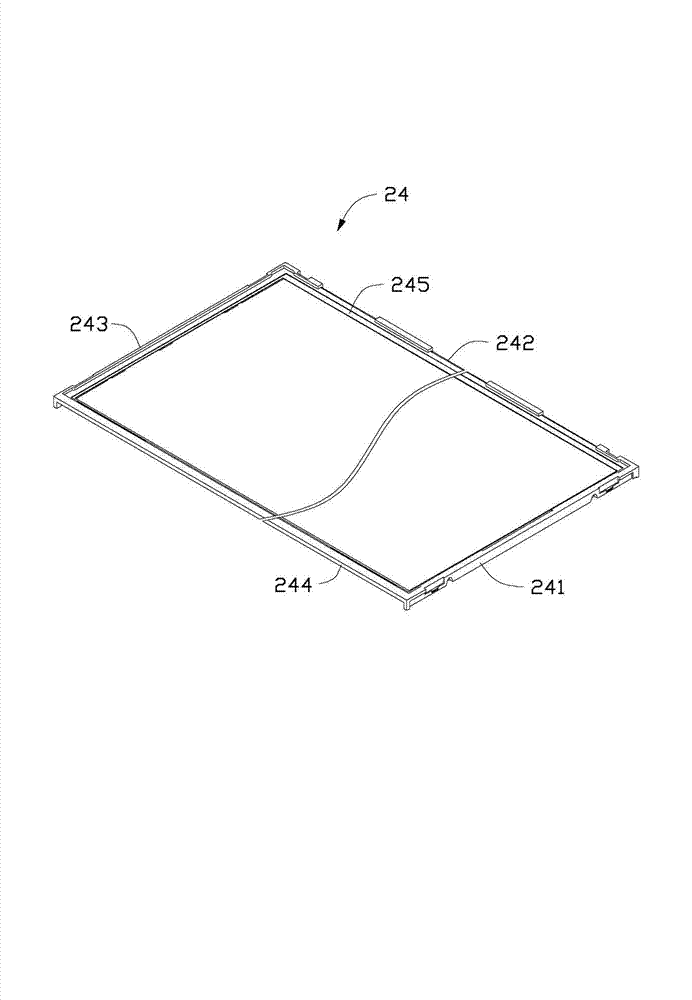

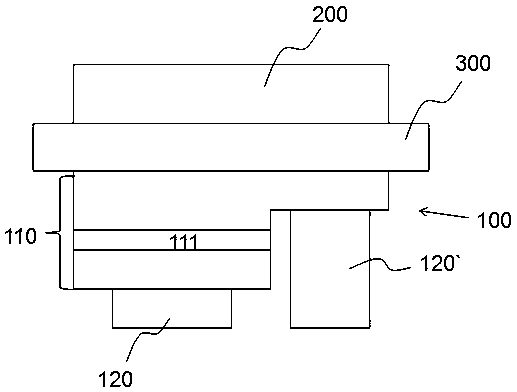

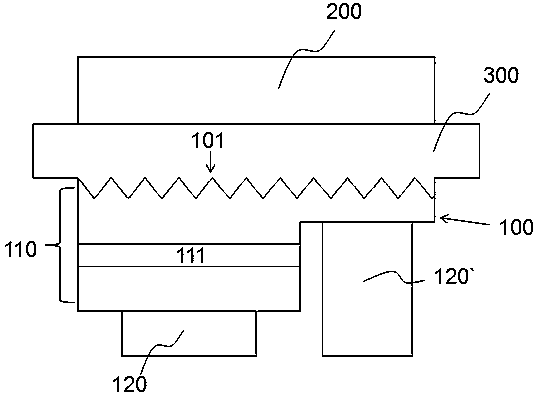

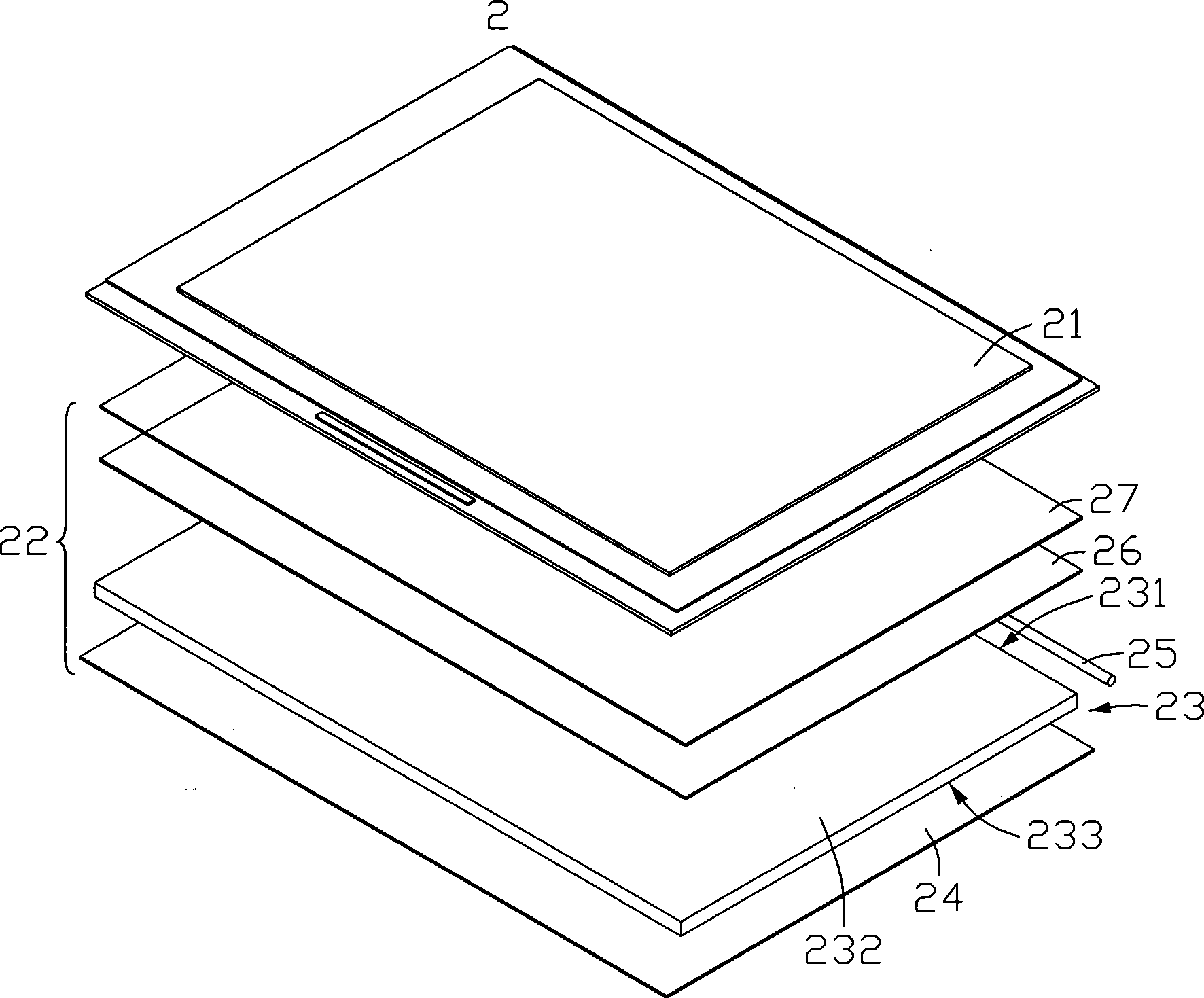

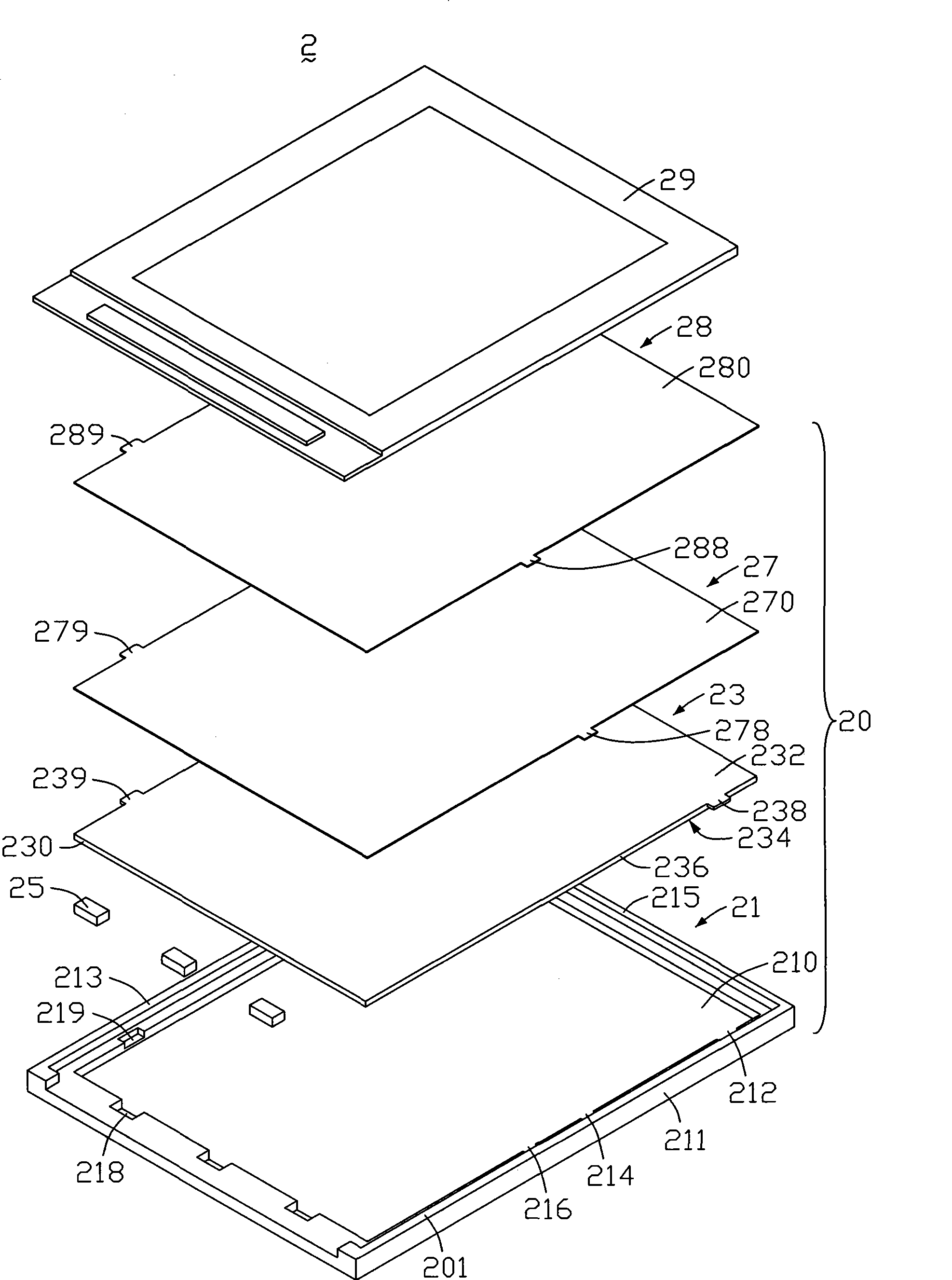

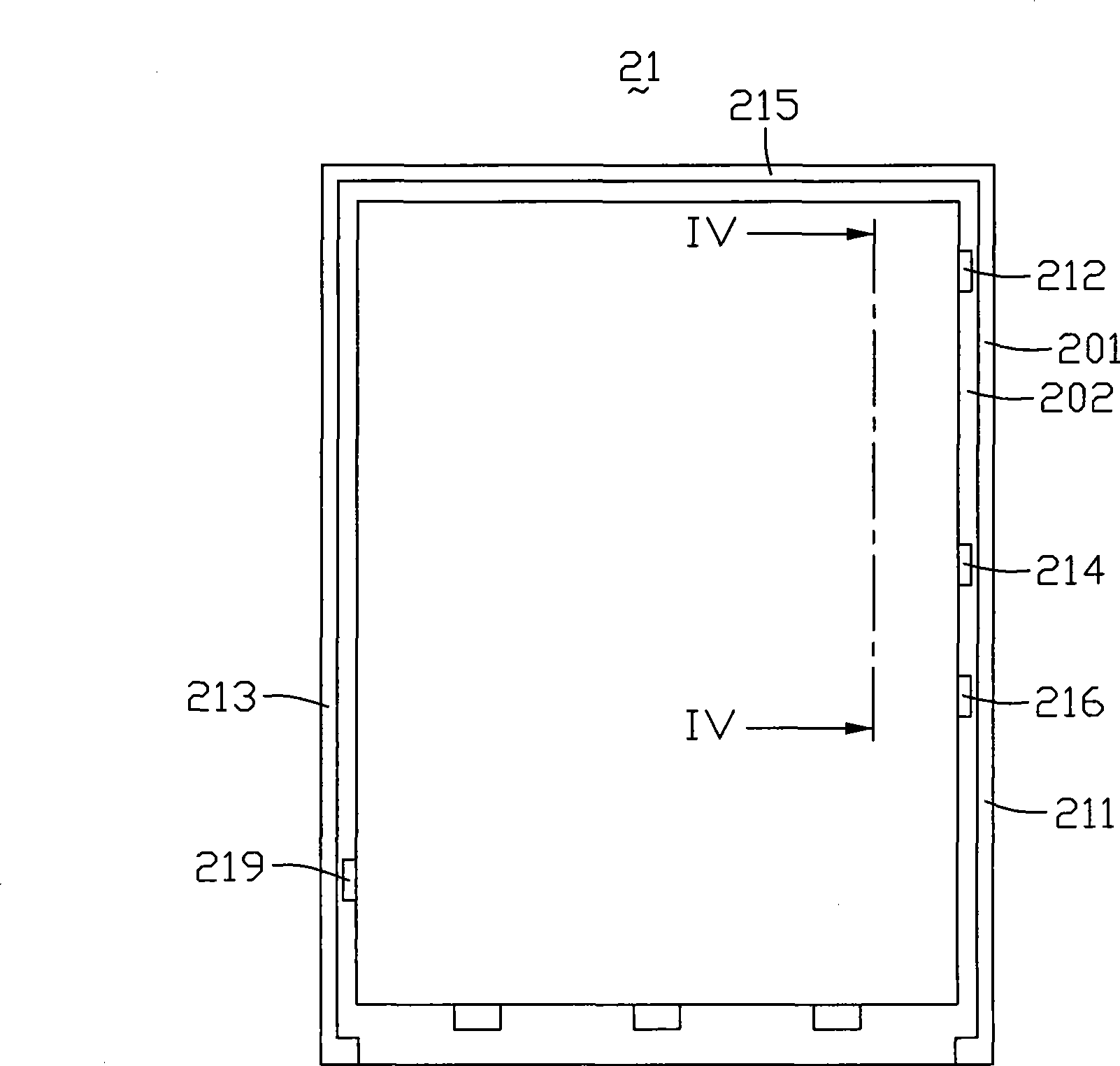

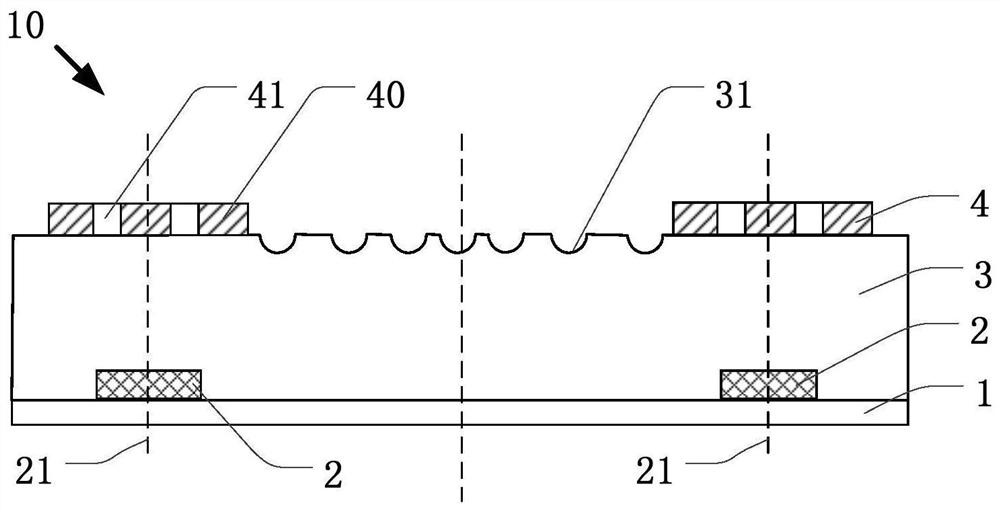

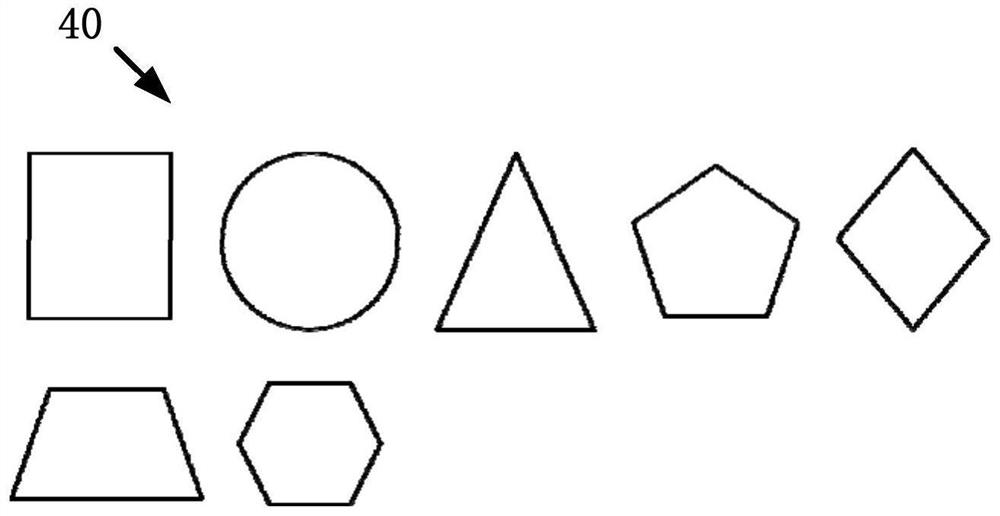

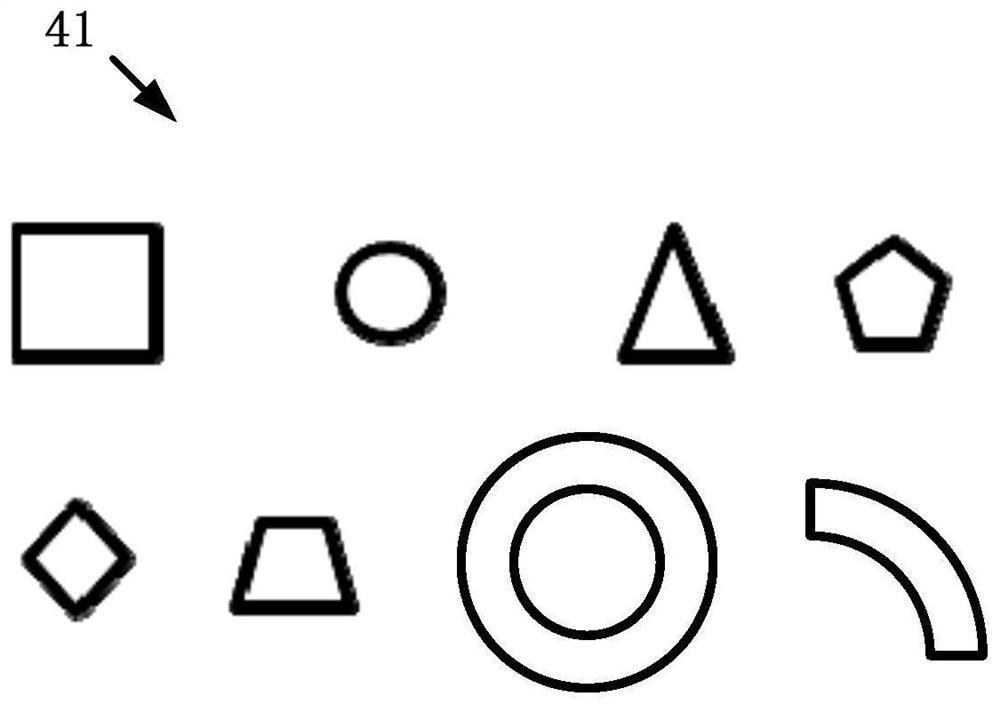

Backlight module

ActiveCN102865527AGuaranteed luminous intensityEnsure uniformity of lightPoint-like light sourceLight fasteningsRubber materialLight guide

The invention provides a backlight module which comprises a back plate, a light guide plate arranged in the back plate, a lamp bar arranged on one side of the light guide plate, a lateral reflection piece arranged on one side of the light guide plate far away from the lamp bar and four corner pieces arranged between the back plate and the light guide plate. The corner pieces are manufactured by rubber materials, the surface of the corner pieces toward the light guide plate is white, the lateral reflection piece is located between two corner pieces, and the length of the lateral reflection piece is smaller than or equal to that between the two corner pieces and further achieve separation of the lateral reflection piece and the corner pieces. The lateral reflection piece and the corner pieces used for locating the light guide plate are arranged in separation mode, separation of the light guide plate and the lateral reflection piece caused by friction between the lateral reflection piece and the corners pieces in the prior art is avoided, and corner light leakage caused by separation of the light guide plate and the lateral reflection piece is further avoided. The backlight module further ensures light intensity and light evenness of the backlight module and improves quality.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Backlight module and liquid crystal display

InactiveCN106773298AIncrease profitReduce manufacturing costNon-linear opticsLight guideRefractive index

The invention provides a backlight module and a liquid crystal display comprising the backlight module. A liquid crystal box array substrate in the prior art serves as a light guide plate, and therefore the liquid crystal display is further thinner and the production cost is reduced. A first refractor and a second refractor are deposited on the light guide plate, the refractive index of the first refractor is larger than the light guide plate and the second refractor, and therefore the light conducts total reflection on the second refractor and a faying surface of the first refractor, a good full reflection effect is achieved, and light leakage phenomenon is reduced and out-light uniformity in all positions in the crystal liquid display is guaranteed. Besides, the first refractor and the second refractor replace a low refractive index film and the manufacture cost of the backlight module is saved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Liquid crystal display device

InactiveCN103364990AIncrease distanceWell mixedLighting support devicesPlanar/plate-like light guidesLiquid-crystal displayLight guide

The invention relates to a liquid crystal display device which comprises a first frame, a liquid crystal display panel, a backlight module and a second frame. The first frame and the second frame are fastened to from an accommodation space for accommodating the liquid crystal display panel and the backlight module. A display window is defined by the first frame to be used by users for watching pictures displayed by the liquid crystal display panel. The backlight module comprises a hollow plastic frame, a light guide plate and at least two point light sources. The light guide plate and the first frame are disposed on the inner side and the outer side of the plastic frame respectively. A passage is arranged in a position of the plastic frame, which right aligns to the light guide plate, to communicate the inner side and the outer side of the plastic frame. The at least two point light sources are fixed on the inner side surface of the first frame and stretch into the passage of the plastic frame. The point light sources are arranged on the first frame of the outermost side, so that the distance from the point light sources to the light guide plate is prolonged, light emitted by the point light sources is fully mixed before entering the light guide plate, and the light emitting uniformity of the liquid crystal display device is guaranteed.

Owner:XINCHENG TECH CHENGDU +1

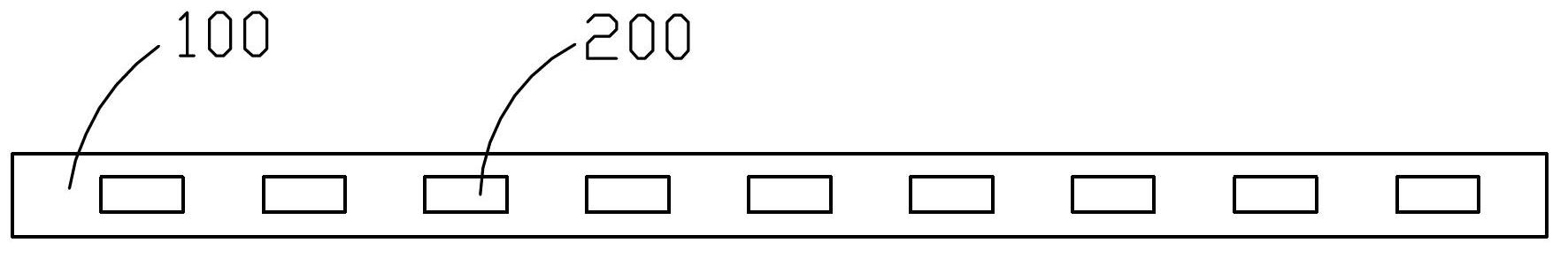

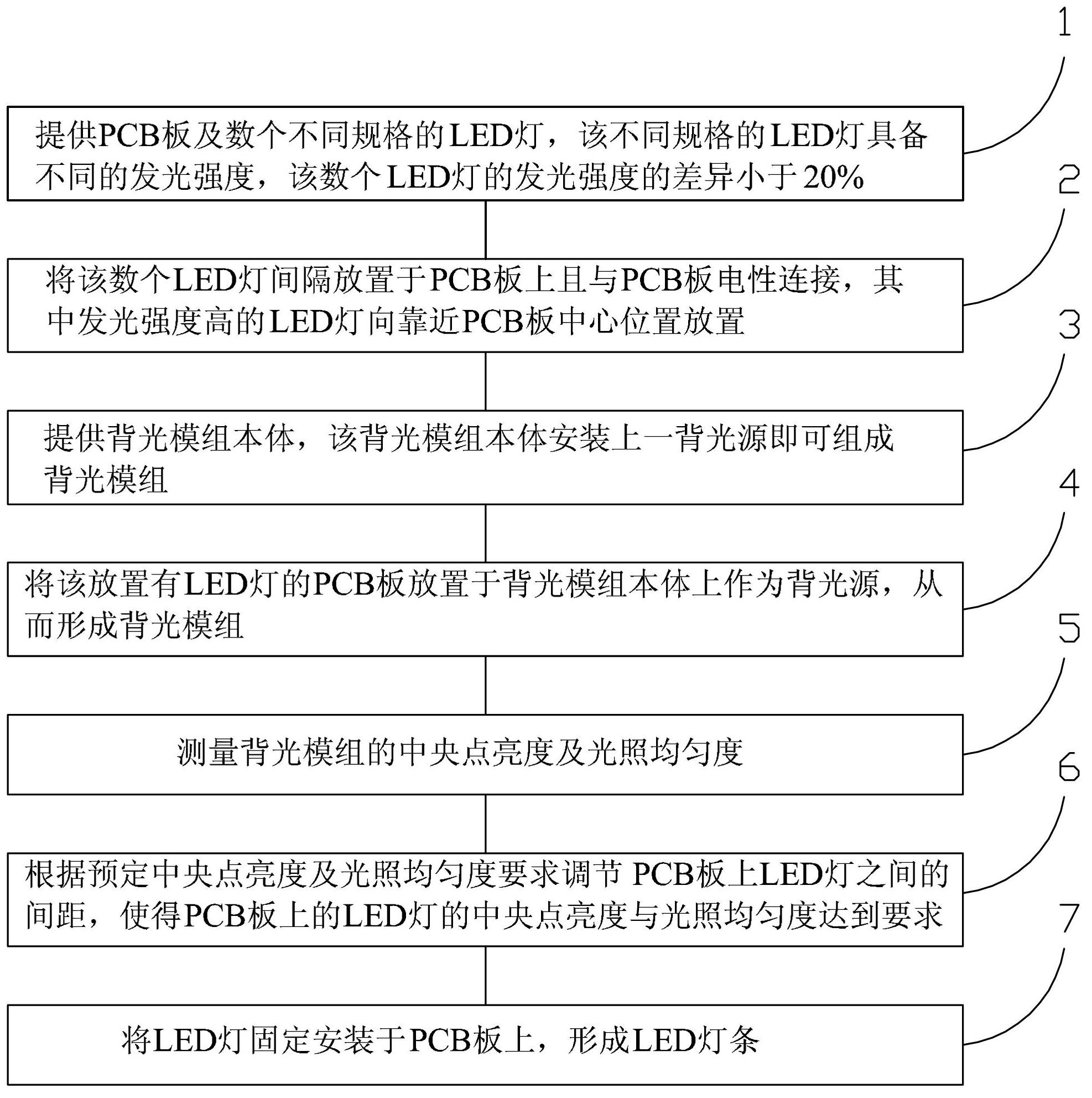

Method for manufacturing lamp strip having improvement on central point luminance of each backlight module

InactiveCN102691922AIncrease the brightness of the center pointImprove optical gradePoint-like light sourceElectric lightingLuminous intensityEngineering

The invention provides a method for manufacturing a lamp strip having an improvement on the central point luminance of each backlight module. The method comprises the steps as follows: step 1, providing a PCB (printed circuit board) and multiple different specifications of LED lamps having different luminous intensities, wherein the differences of the luminous intensities of the LED lamps are smaller than 20%; step 2, placing the LED lamps at intervals on the PCB, and electrically connecting the LED lamps with the PCB; step 3, providing a backlight module body, and mounting a backlight source on the backlight module body to form a backlight module; step 4, placing the PCB provided with the LED lamps on the backlight module body and using as a backlight source, so as to form a backlight module; step 5, measuring the central point luminance and illumination uniformity of each backlight module; step 6, regulating the distances between the LED lamps on the PCB according to preset central point luminance and illumination uniformity, and enabling the central point luminance and illumination uniformity of each LED lamp on the PCB to meet the requirements; and step 7, fixedly mounting the LED lamps on the PCB to form the LED lamp strip.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Light processing device, vehicle lamp and vehicle

ActiveCN104633572AUniform injectionImprove lighting effectsVehicle headlampsPoint-like light sourceOptoelectronicsPhysics

The invention provides a light processing device, a vehicle lamp with the light processing device and a vehicle provided with the vehicle lamp. The light processing device comprises a body, a light entering face and a light outgoing face, wherein the light entering face and the light outgoing face are arranged on the body. The body comprises a light diffusion part, a light collimation part and a light reflecting part, wherein the light diffusion part is used for diffusing light entering the light diffusion part through the light entering face, and the light entering face is arranged on the light diffusion part; the light collimation part is arranged on a transmission route of the diffused light and used for collimating the diffused light; the light reflecting part comprises a light reflecting face and a light outgoing part fixedly connected with the light reflecting face, an angle is formed between the collimated light and the light outgoing part, and the collimated light is transmitted by the light outgoing part and emitted out through the light outgoing face after being reflected by the light reflecting face. According to the light processing device, the vehicle lamp and the vehicle, a light face of the light is expanded through the light diffusion part, the emitted-out light is more even through the collimation processing of the collimation part and the processing of the light reflecting part, and the light outgoing effect is improved.

Owner:曼德汽车零部件(泰州)有限公司

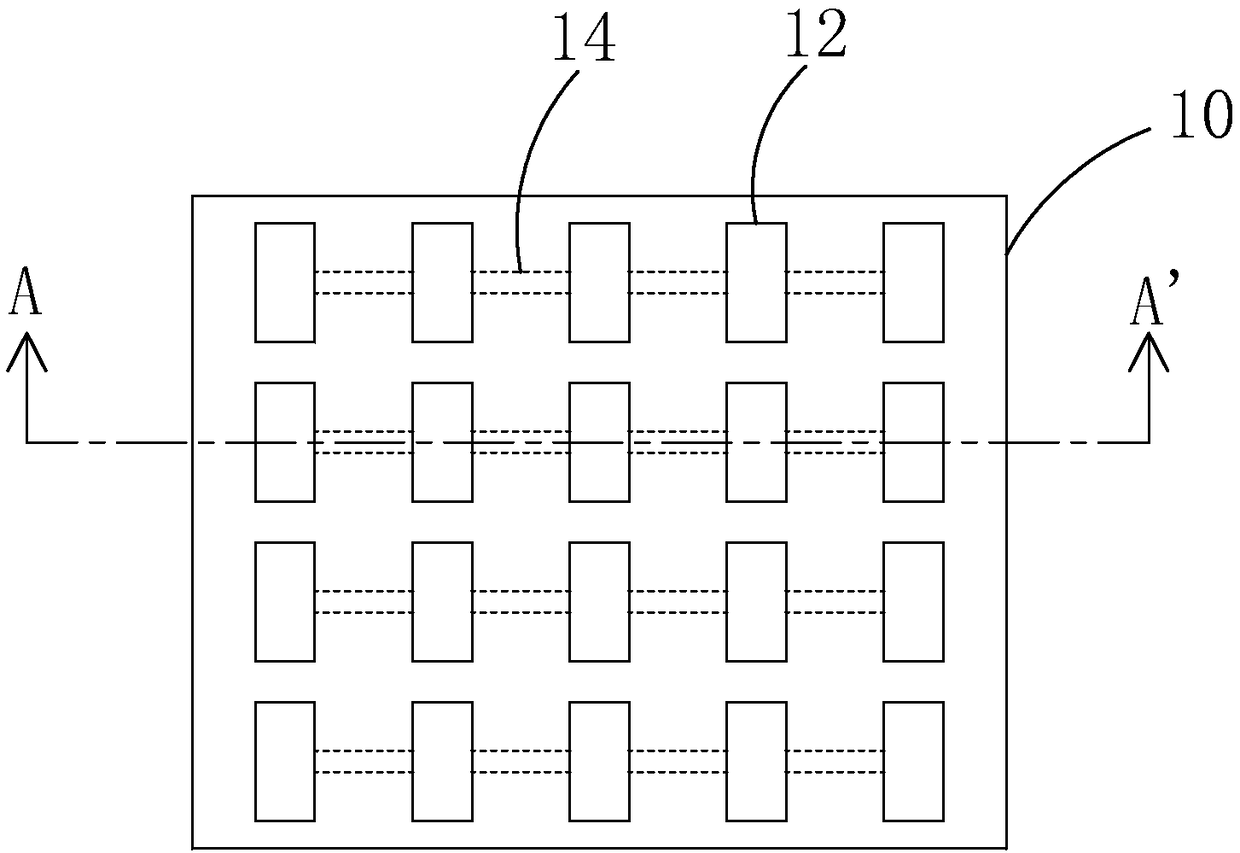

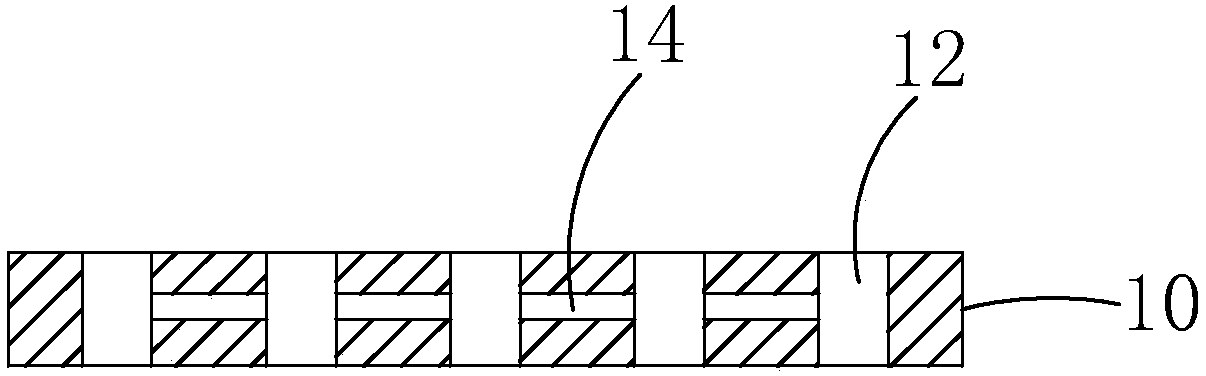

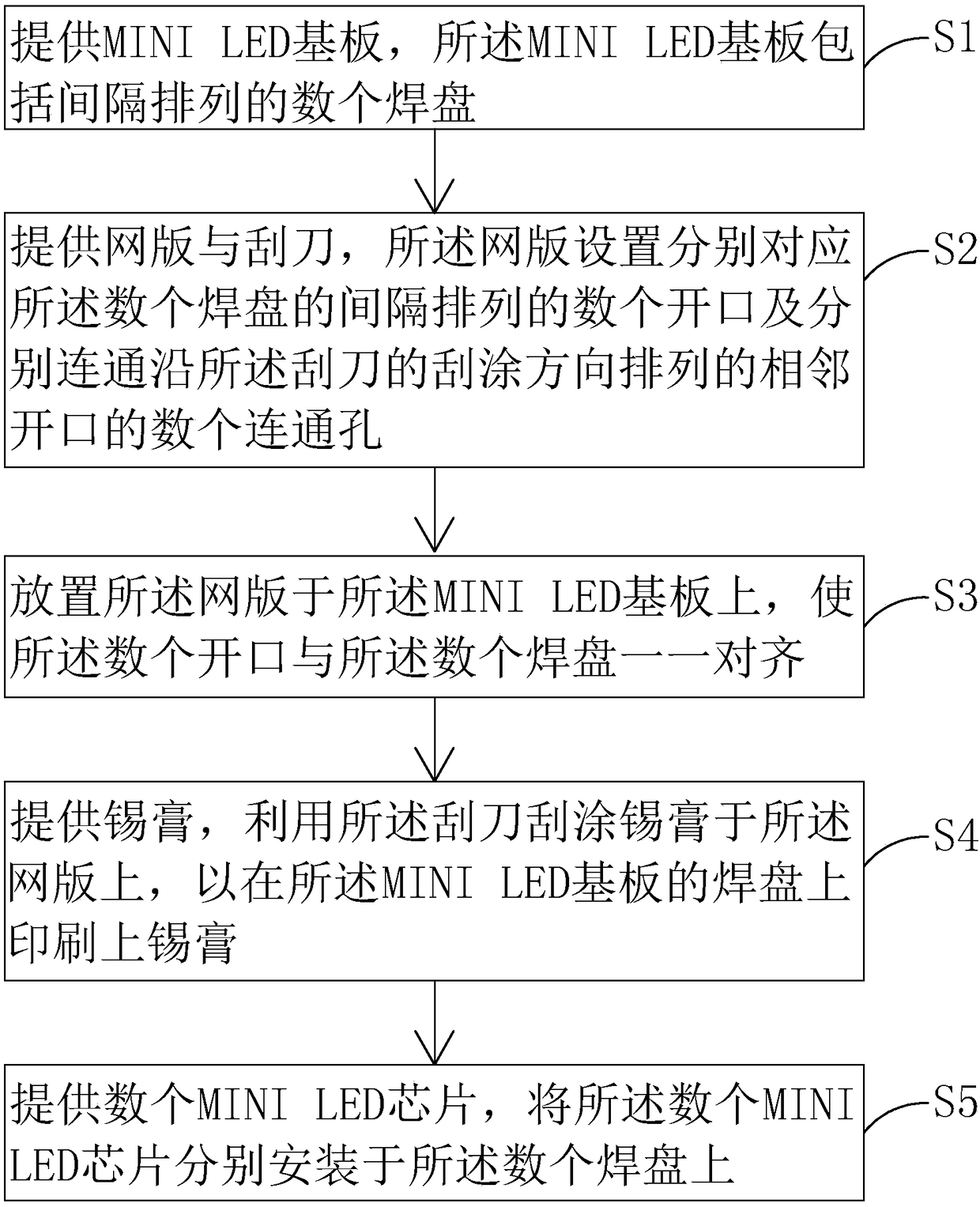

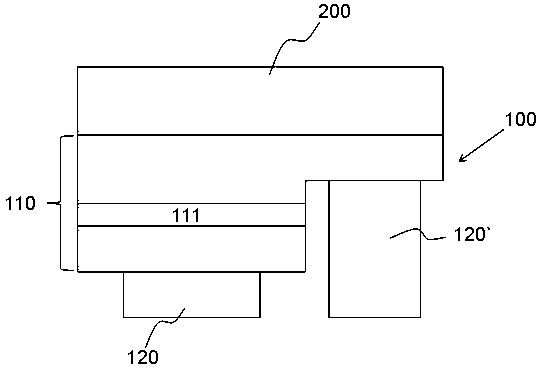

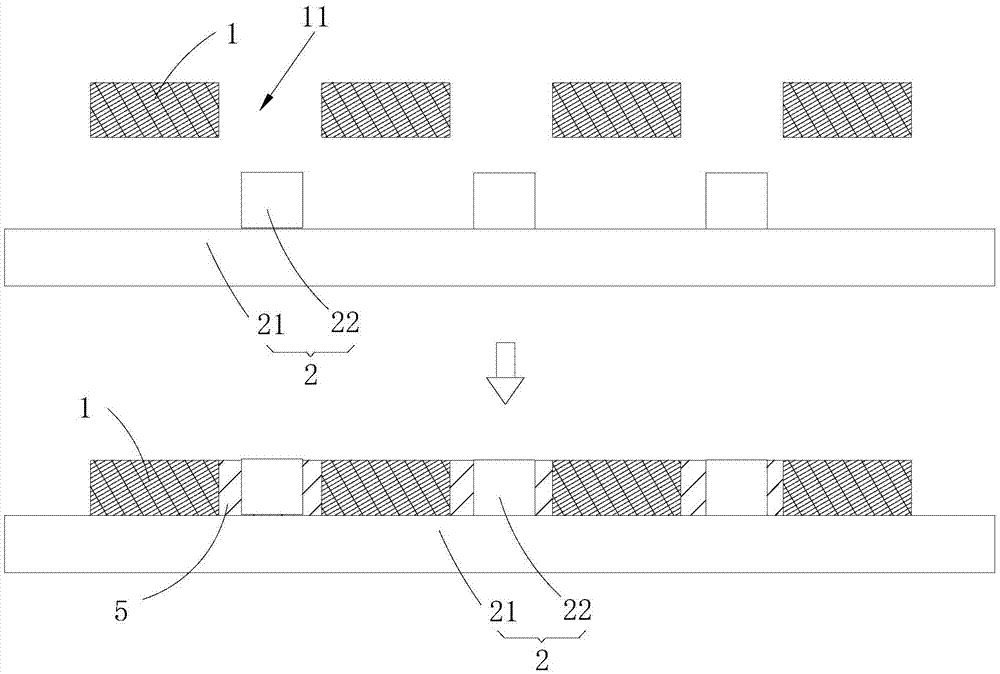

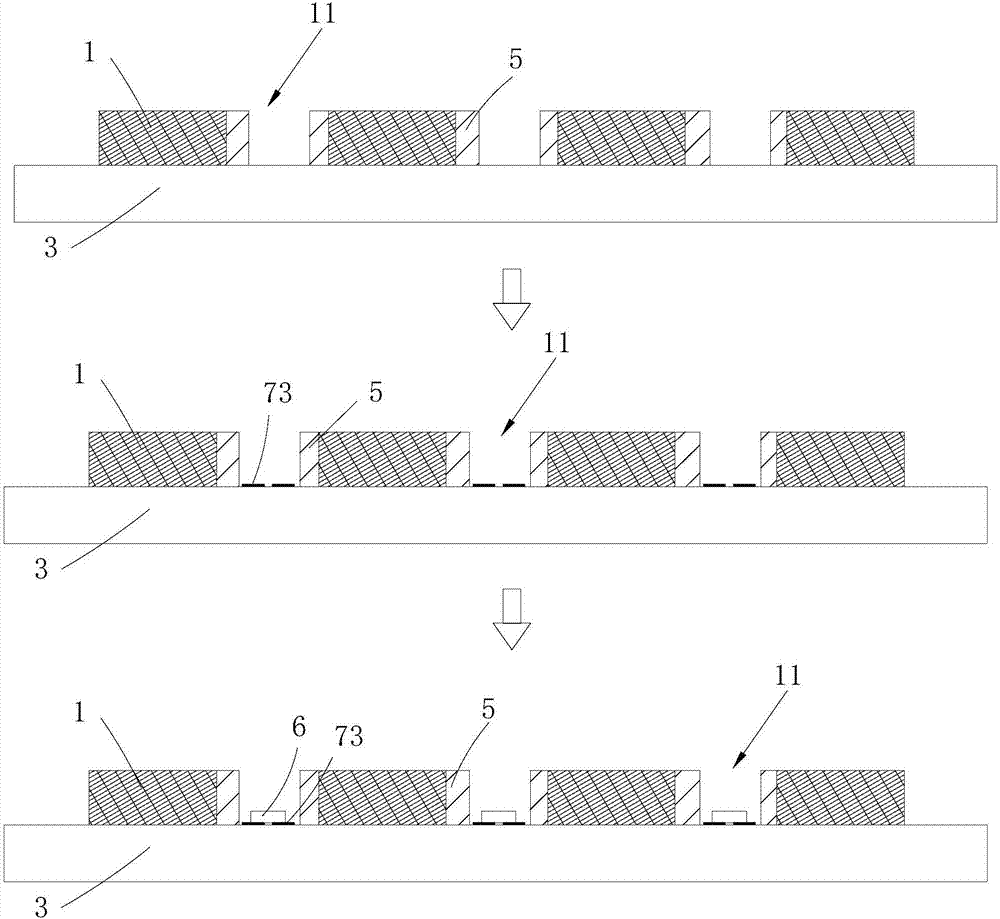

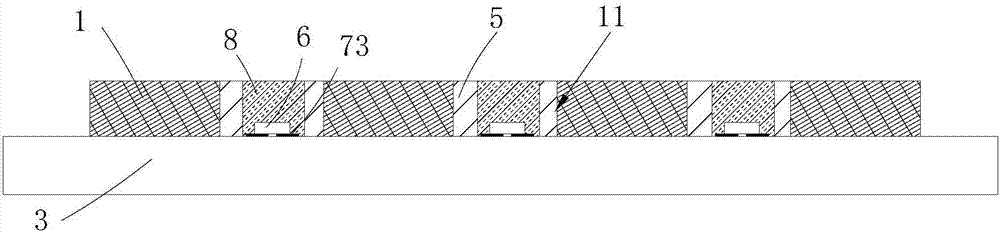

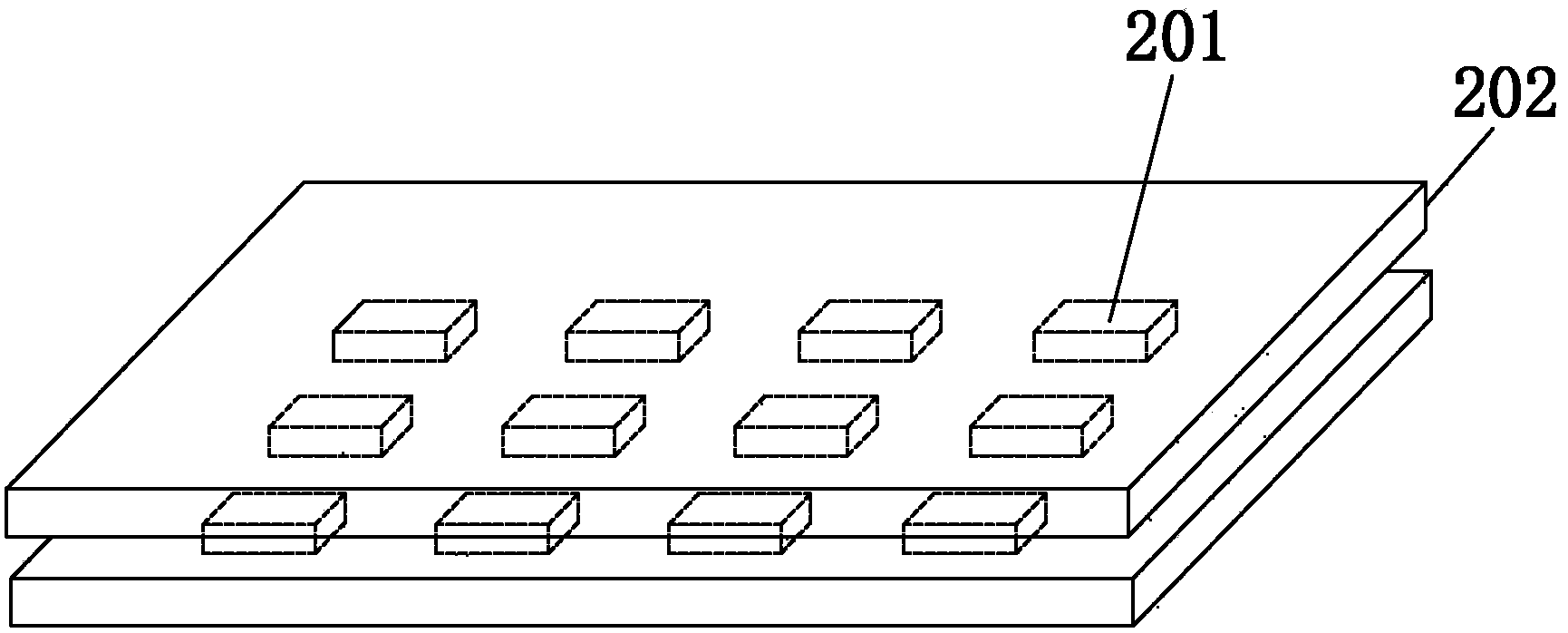

Screen, method for making area light source and method for making direct type backlight module

ActiveCN108365081AGuaranteed uniformityEnsure uniformity of lightScreen printersSemiconductor devicesEngineeringSolder paste

The invention provides a screen, a method for making an area light source and a method for making a direct type backlight module. The screen comprises a plurality of openings and a plurality of communicating holes, wherein the plurality of openings are formed at intervals; the plurality of communicating holes are respectively communicated with adjacent openings formed in a scrape coating directionof a scraper; when solder paste is coated, the solder paste height between two openings adjacent to the communicating hole can be balanced by the communicating hole, and the coating uniformity of thesolder paste is effectively ensured. The screen is used in the method for making the area light source, the communicating hole is formed between every two adjacent openings formed in the scrape coating direction of a scraper in the screen, and the moving direction of the communicating hole is the same as the scrape coating direction of the scraper, so that the solder paste amount on a bonding padof a MINI LED substrate is balanced by utilizing a principle of a similar connector, and the contact surface between the subsequent solder paste and a MINI LED chip is flat and uniform. Therefore, the arrangement uniformity and emergence uniformity of subsequent MINI LED chip arrangement are ensured, and the brightness uniformity of the whole area light source surface is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Microluminescent device and display thereof

ActiveCN109037405AMeet the needs of red lightImprove conversion efficiencySolid-state devicesSemiconductor devicesDisplay deviceLength wave

A microluminescent device and a display thereof are disclosed, the microluminescent device includes, from bottom to top: a micro light emitting diode having a light emitting semiconductor sequence that generates light of a first wavelength after excitation, A transparent adhesive layer, an antireflective antireflective film, and a light emitting layer excited by light of a first wavelength to generate light of a second wavelength, thereby realizing a microluminescent device having high efficiency and emitting only light of a second wavelength, solving the problem that the brightness of a red-light microluminescent diode in the field of microdevices does not meet the demand, and through combination with microluminescent devices of other wavelengths, a display is formed.

Owner:XIAMEN SANAN OPTOELECTRONICS CO LTD

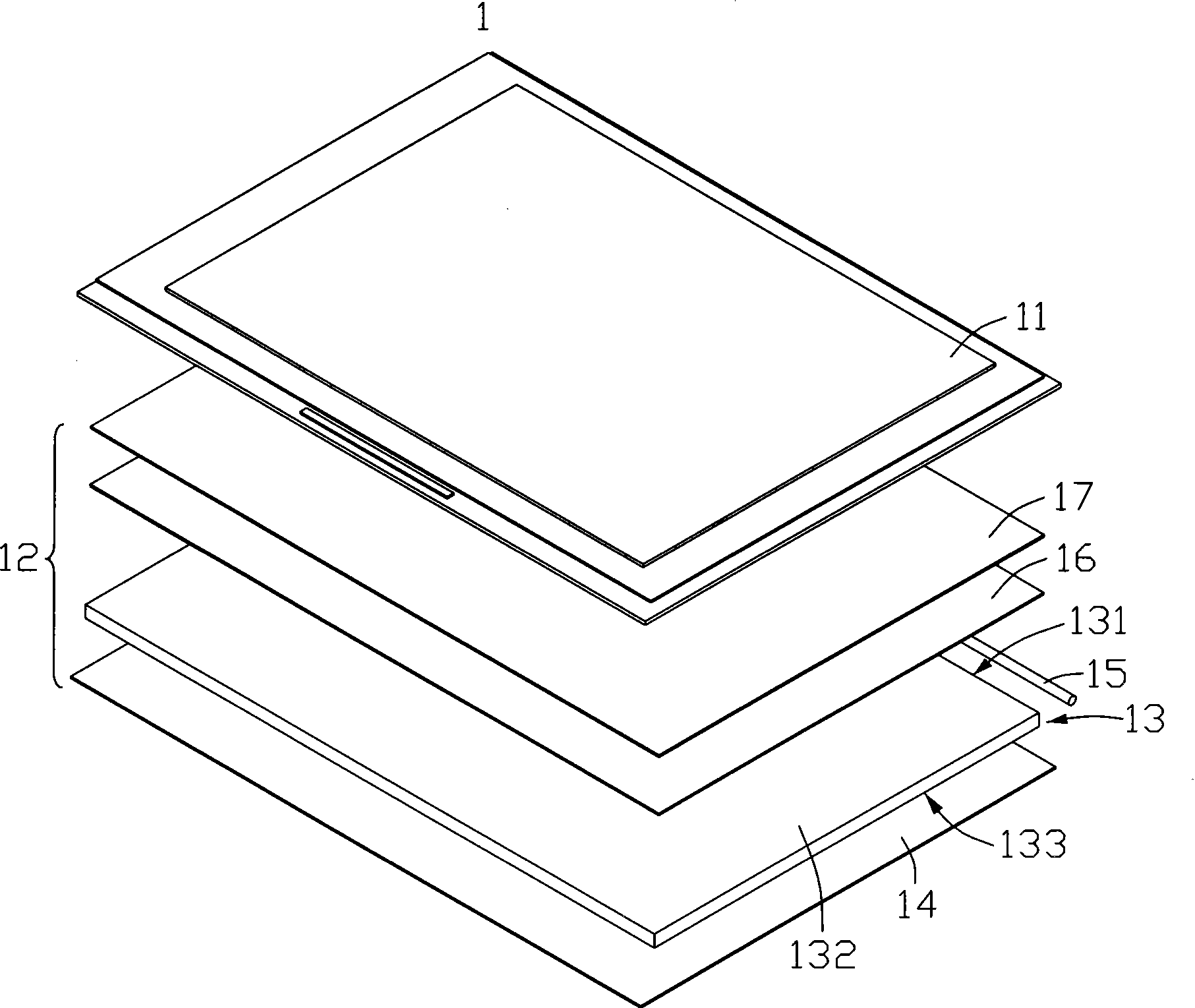

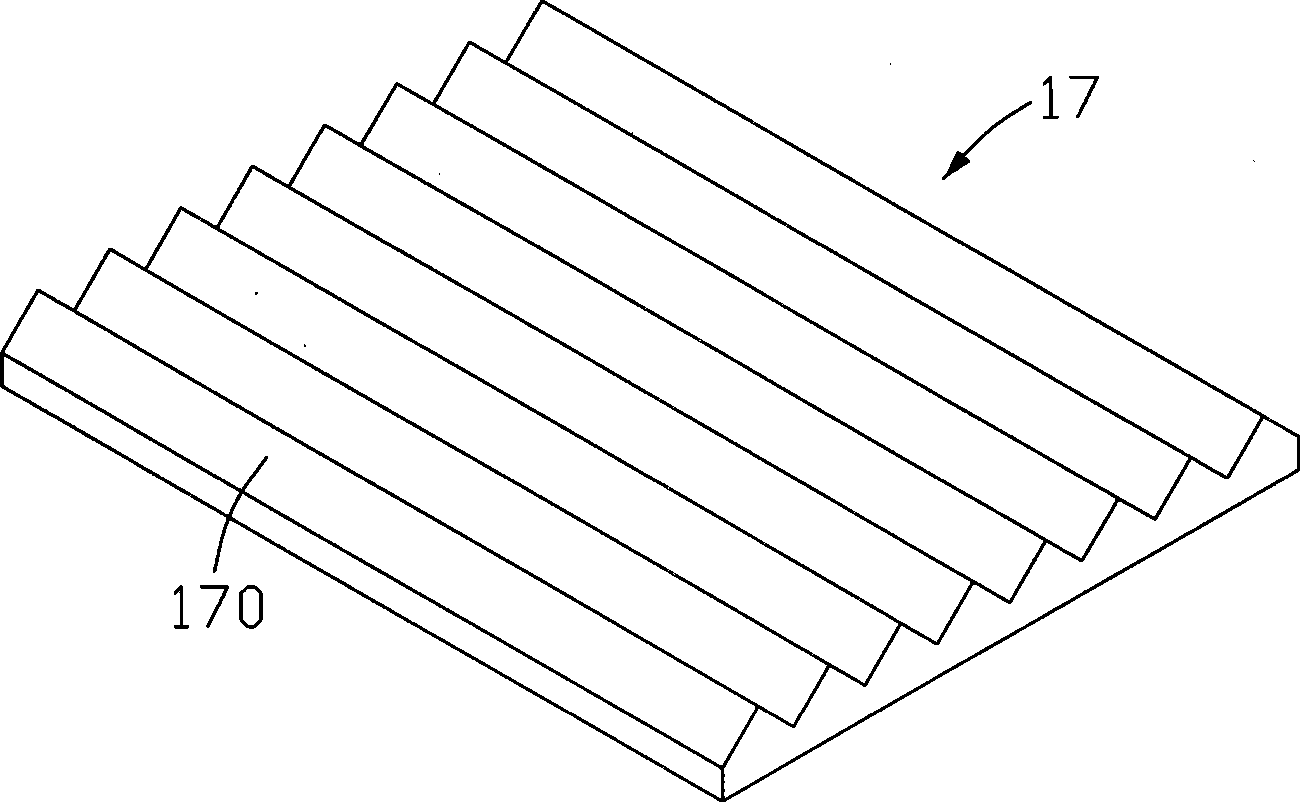

Prismatic lens, back light module unit and LCD device

InactiveCN101452086AGuaranteed brightnessEnsure uniformity of lightPrismsNon-linear opticsMicro structureLiquid-crystal display

The present invention relates to a prism sheet, a backlight module unit and a liquid crystal display device. One surface of prism sheet comprises a plurality of light collecting units. The plurality of light collecting units comprise a plurality of light radiating surfaces which comprises a plurality of micro-structures for diffusing light. The light radiating homogeneity degree of prism sheet is high.

Owner:INNOCOM TECH SHENZHEN +1

Packaging component and manufacturing method thereof

PendingCN107275459AAvoid exceedingEnsure uniformity of lightSemiconductor devicesWaferingMold removal

The invention provides a manufacturing method of a packaging component. The manufacturing method comprises the steps of dam installation, wafer fixing, packaging colloid injecting and packaging and mold removing. The invention further provides a packaging component which is manufactured by applying the packaging component manufacturing method. The packaging component is used for being mounted on a circuit board. The packaging component comprises a wafer, a bonding pad assembly arranged at one side of the wafer, packaging colloid packaging outside the wafer and the bonding pad assembly and a dam enclosing outside the packaging colloid, wherein the bonding pad assembly comprises a positive bonding pad, a negative bonding pad and metal pieces used for connecting the circuit board and the positive bonding pad and the negative bonding pad, the metal pieces are connected with the positive bonding pad and the negative bonding pad in a one-to-one correspondence manner, and the area of the metal piece is greater than or equal to the area of the positive bonding pad or the negative bonding pad. Batch production is performed by adopting cooperation of various molds, so that mass production can be carried out more conveniently. In addition, the positions of the wafer and the packaging colloid relative to the dam can be better limited, and the light emitting angle and the light color uniformity of an optical design are effectively ensured.

Owner:深圳市科艺星光电科技有限公司

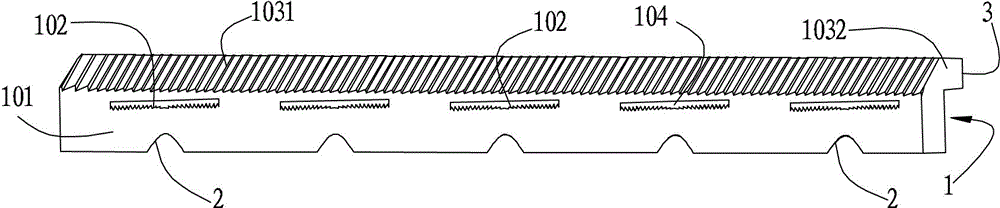

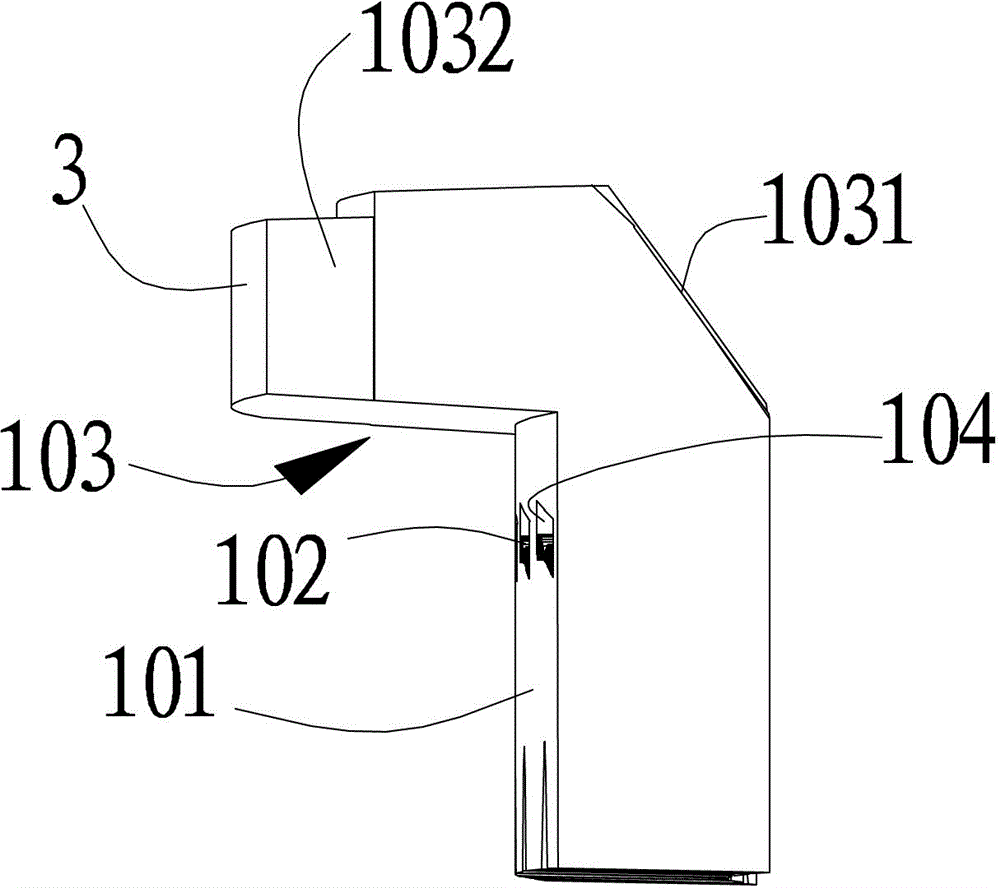

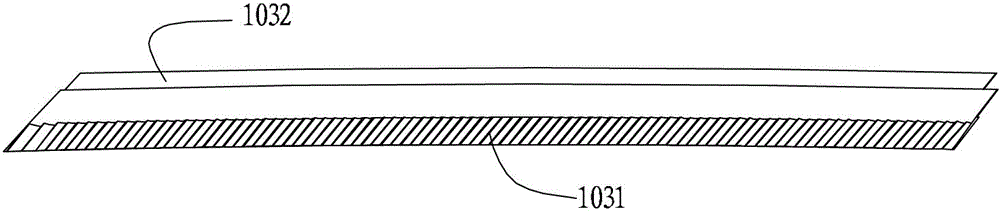

Light guide plate and backlight mould provided with same

InactiveCN102661574AGuaranteed light intensityEnsure uniformity of lightMechanical apparatusPlanar/plate-like light guidesLight guideLength wave

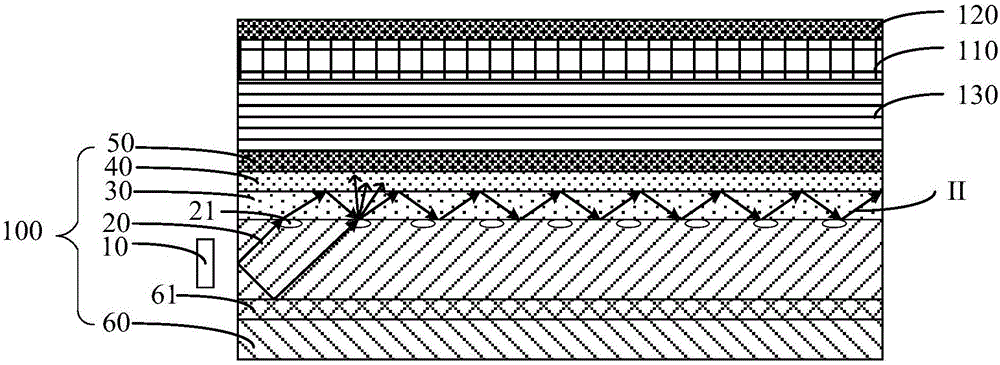

The invention provides a light guide plate and a backlight mould provided with the same. The light guide plate comprises a body and a metal layer arranged on the body, wherein the body comprises a bottom surface and a top surface corresponding to the bottom surface as well as a plurality of side faces positioned between the bottom surface and the top surface; and the metal layer is arranged on at least one side edge of the top surface, and the difference of the reflectivity of the metal layer on light with the wavelength of 380-780mm is less than 20%. In the light guide plate provided by the invention, the metal layer is arranged on the top surface, thus the light which is shined from the light-inlet surface of the light guide plate and spread to the top surface of the light guide plate is reflected back to the light guide plate, so that the light can spread in the light guide plate, the light leakage is prevented, and then the illumination intensity and uniformity of the light guide plate are guaranteed; and the manufacture is simple, and the cost is low.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

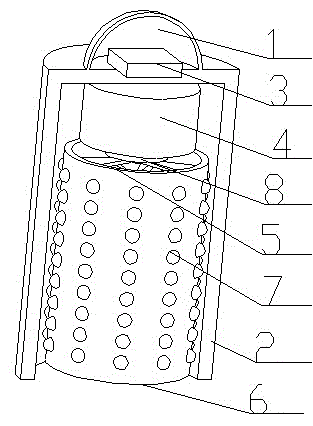

Rotary LED lamp

InactiveCN104154480AConvenient lightingImprove cooling efficiencyPoint-like light sourceElectric circuit arrangementsEngineeringLED lamp

The invention discloses a rotary LED lamp. The rotary LED lamp comprises a lamp holder, a shell, a power source, a motor, a heat dissipation device, a circuit board, LEDs and a connecting ring. The power source is arranged in the lamp holder. The shell is arranged below the lamp holder. The motor is coaxially arranged on the central axis of the lamp holder. The connecting ring is coaxially arranged at the upper end of the heat dissipation device. The heat dissipation device is connected to the lower end of the motor. The circuit board is designed on the heat dissipation device. The LEDs are attached to the circuit board. In this way, the rotary LED lamp has the advantages that the reliability is high, the structure is compact, the heat dissipation performance is good, electric conduction is stable, cost is low, and the service life is long. In addition, the rotary LED lamp has wide market prospect on the illumination market.

Owner:JIANGSU DALEN ELECTRONICS CO LTD

Light-emitting diode (LED) fluorescence lampshade

InactiveCN103162230ASimple manufacturing processEnsure mixing uniformityPoint-like light sourceGlobesEpoxyMicrometer

The invention discloses a light-emitting diode (LED) fluorescence lampshade. The LED fluorescence lampshade is characterized in that liquid stateful epoxy resin or silica gel serves as basic materials, yellow fluorescent powders serve as filling materials, the proportion is that 0.3-10 parts by weight of the yellow fluorescent powders are added into every 100 parts by weight of the basic materials so that raw materials for preparing the fluorescence lampshade are formed, wherein the raw materials are used for manufacturing the fluorescence lampshade, then the needed formative fluorescence lampshade is formed after injection moulding and solidifying demoulding are conducted. The grain sizes of fluorescent powder grains are 5-25 micrometers. The epoxy resin is double epoxy resin. The LED fluorescence lampshade has the advantages of being simple in moulding process, good in light transmission homogenization and long in service life.

Owner:SHANGHAI JIATANG ELECTRONICS DEV

Display module and display device

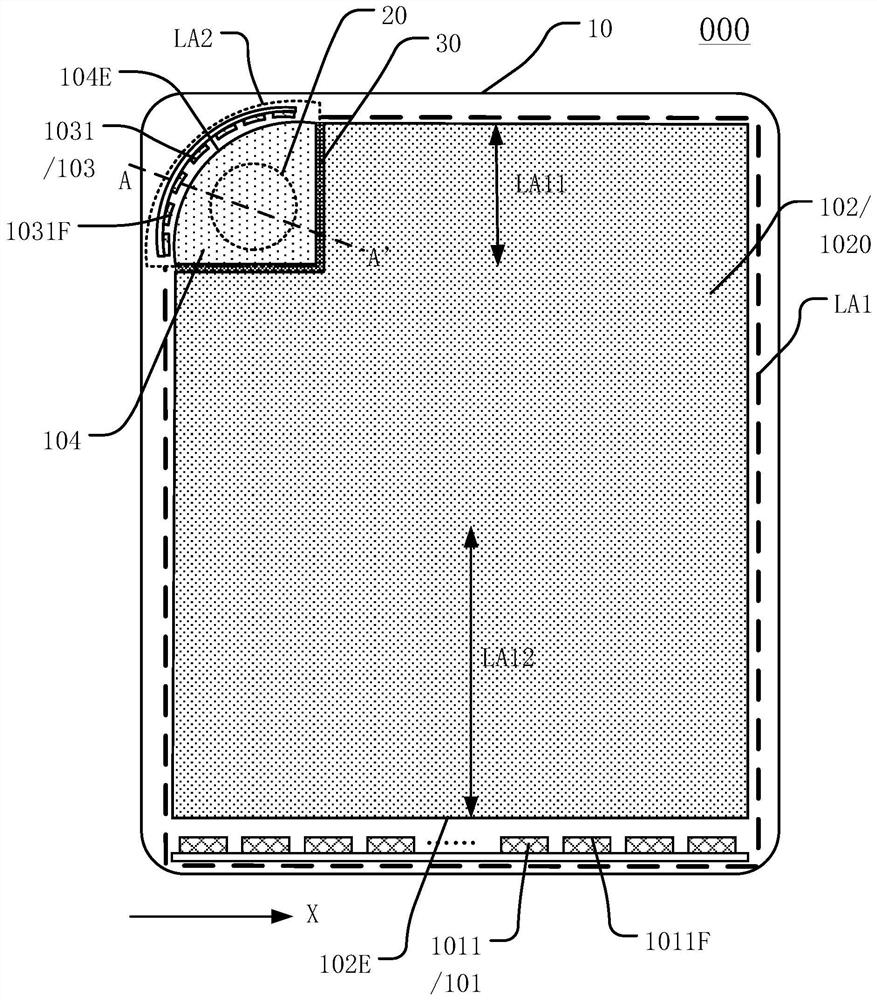

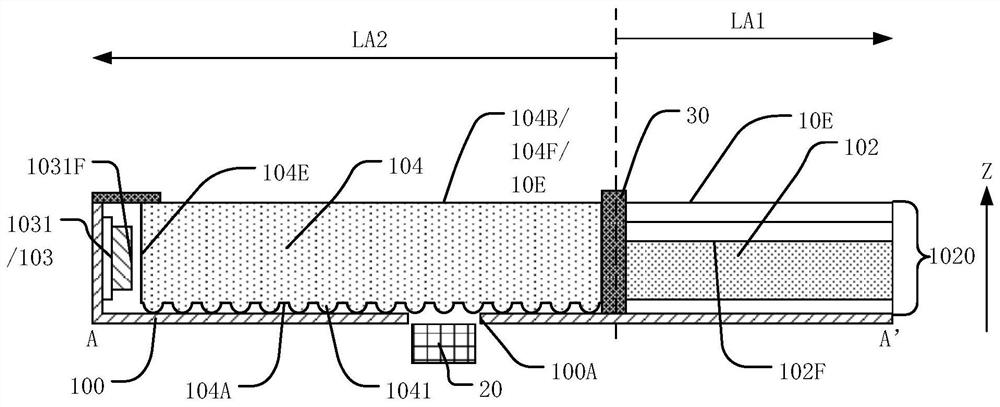

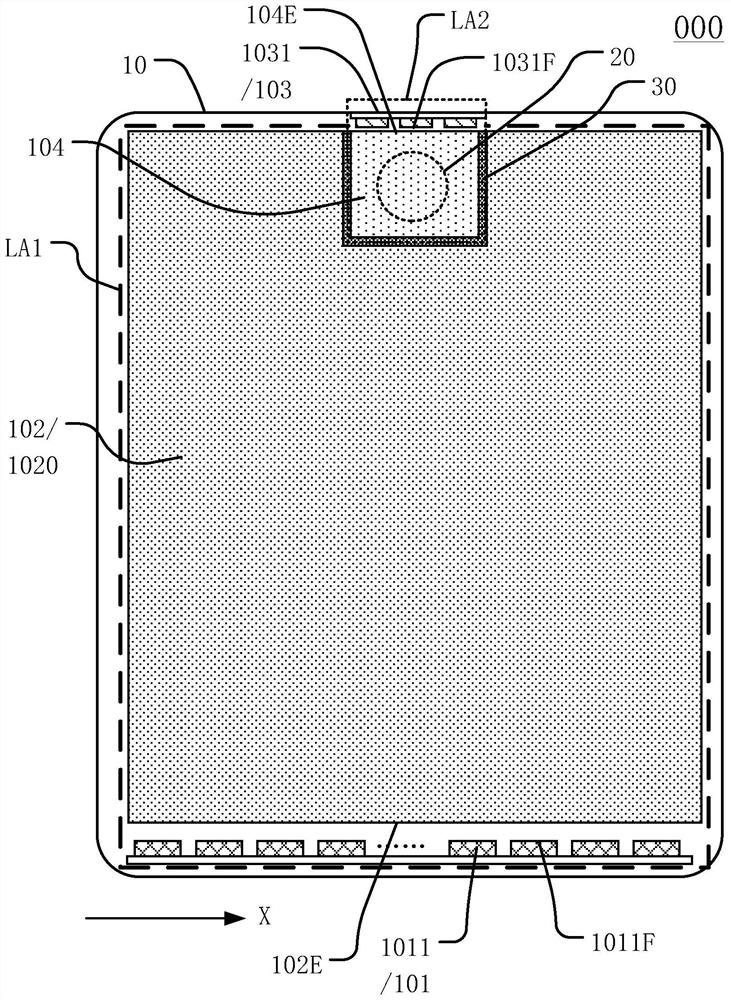

ActiveCN113296314AAffect the use effectAvoid affecting the light effectPlanar/plate-like light guidesNon-linear opticsLight guideDisplay device

The invention discloses a display module and a display device, and belongs to the technical field of display. The display module comprises a backlight module and a photosensitive element; the backlight module at least comprises a first light emitting area and a second light emitting area; the photosensitive element and the second light emitting area are overlapped in the direction perpendicular to the light emitting surface of the backlight module; in the second light emitting area, the backlight module comprises a second light source assembly and a second light guide plate; the second light source assembly is a side entry type light source assembly; the second light guide plate comprises a first side and a second side in the direction perpendicular to the light emitting surface of the backlight module; and the first side of the second light guide plate comprises a plurality of first lattice points, and the second side of the second light guide plate is of a plane structure. The display device comprises a display panel and the display module. The light-emitting brightness of the second light emitting area can be improved, and the light-emitting uniformity is ensured; and the use effect of the photosensitive element in the second light emitting area can be improved when the photosensitive element is used.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

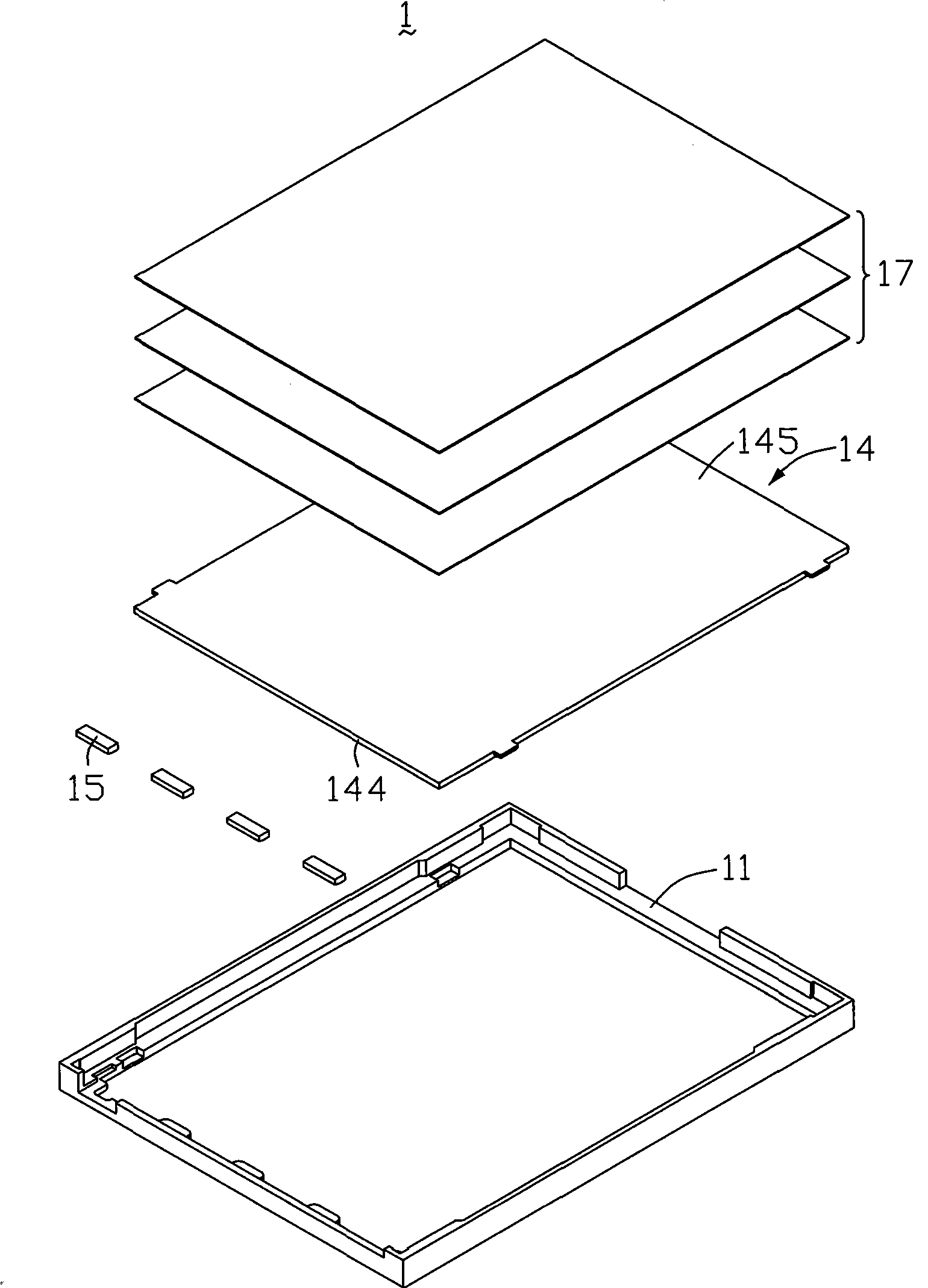

Back light module unit and LCD device

InactiveCN101458419AImprove assembly recognitionImprove lighting qualityLighting support devicesNon-linear opticsEngineering

The invention relates to a backlight module and an LCD device adopting the backlight module. The backlight module comprises a frame and at least two optical elements, wherein, the frame includes a side frame which includes at least two containing grooves with an interval arrangement, and the two optical elements which include at least a lug respectively are contained in the frame, besides, the lugs are contained correspondingly in the two containing grooves. The assembly identification level of the backlight module and the LCD device adopting the backlight module of the invention is very high.

Owner:INNOCOM TECH SHENZHEN +1

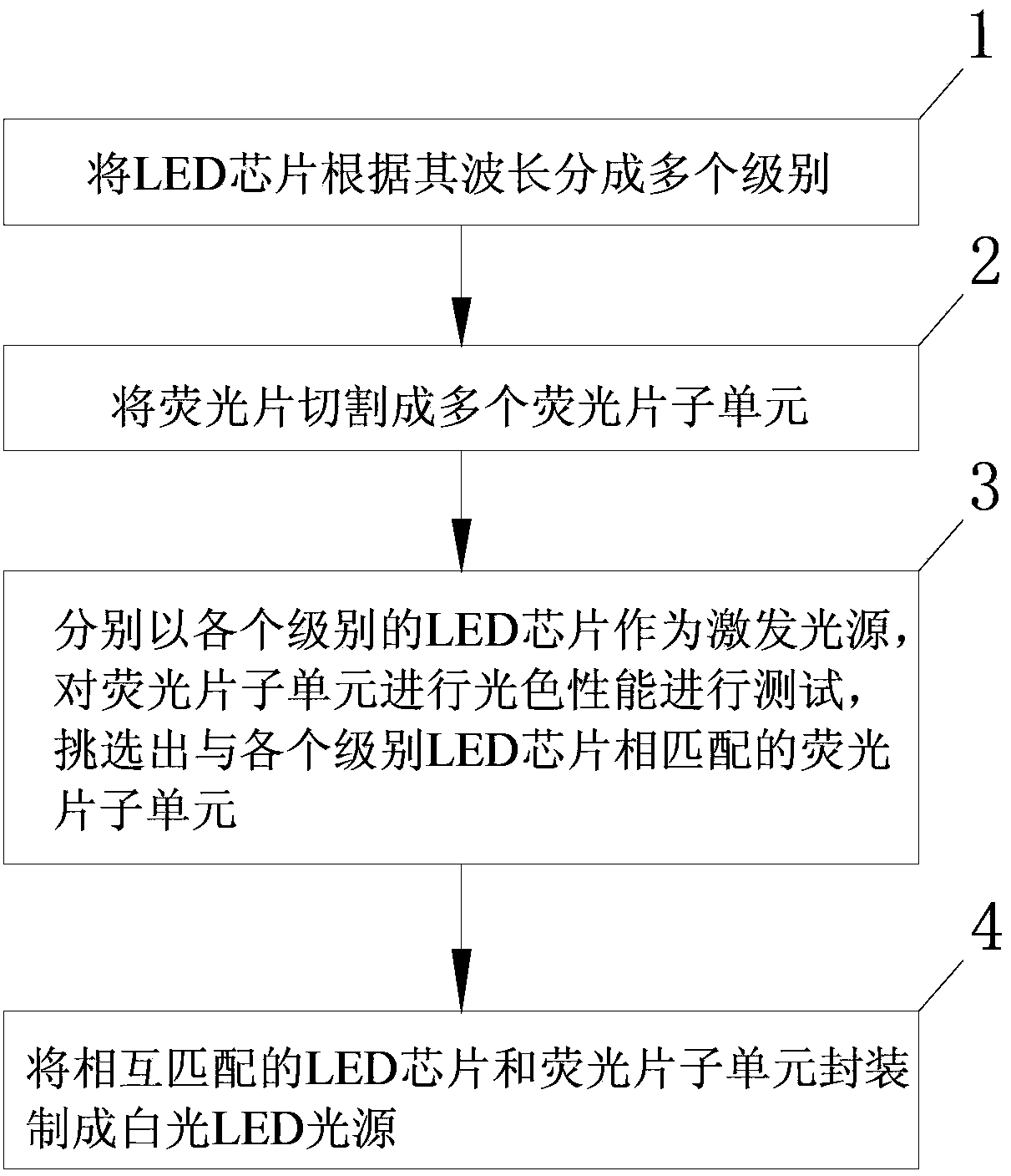

Method for manufacturing white light LED light sources

InactiveCN103413870AEnsure uniformity of lightGuaranteed compatibilitySemiconductor devicesFluorescenceWavelength

The invention discloses a method for manufacturing white light LED light sources. The white light LED light sources are made of LED chips and a fluorescent piece. The method for manufacturing the white light LED light sources comprises the following steps of dividing the LED chips into a plurality of grades according to the wave length of the LED chips, cutting the fluorescent piece into a plurality of fluorescent piece subunits, using the LED chips of all the grades as excitation light sources respectively, carrying out photochromic performance tests on the fluorescent piece subunits, selecting the fluorescent piece subunits matched with the LED chips of all the grades, and packaging mutually matched LED chips and the fluorescent piece subunits to form the white light LED light sources. The method for manufacturing the white light LED light sources can ensure the matching between the fluorescent piece subunits and the LED chips, and guarantees the uniformity of light emitted by the white light LED light sources, therefore, the qualified rate of products is improved, and production cost is reduced.

Owner:APT ELECTRONICS

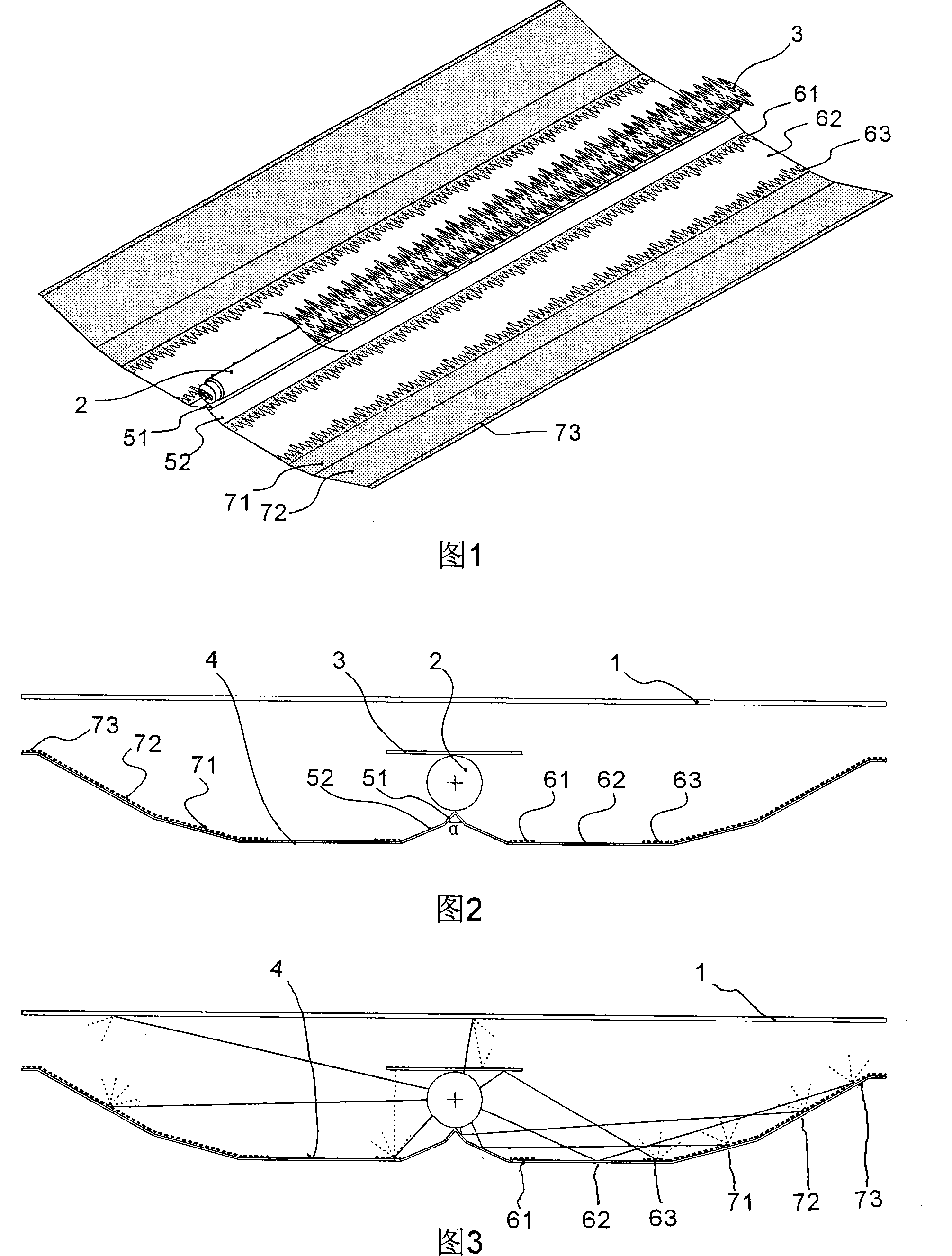

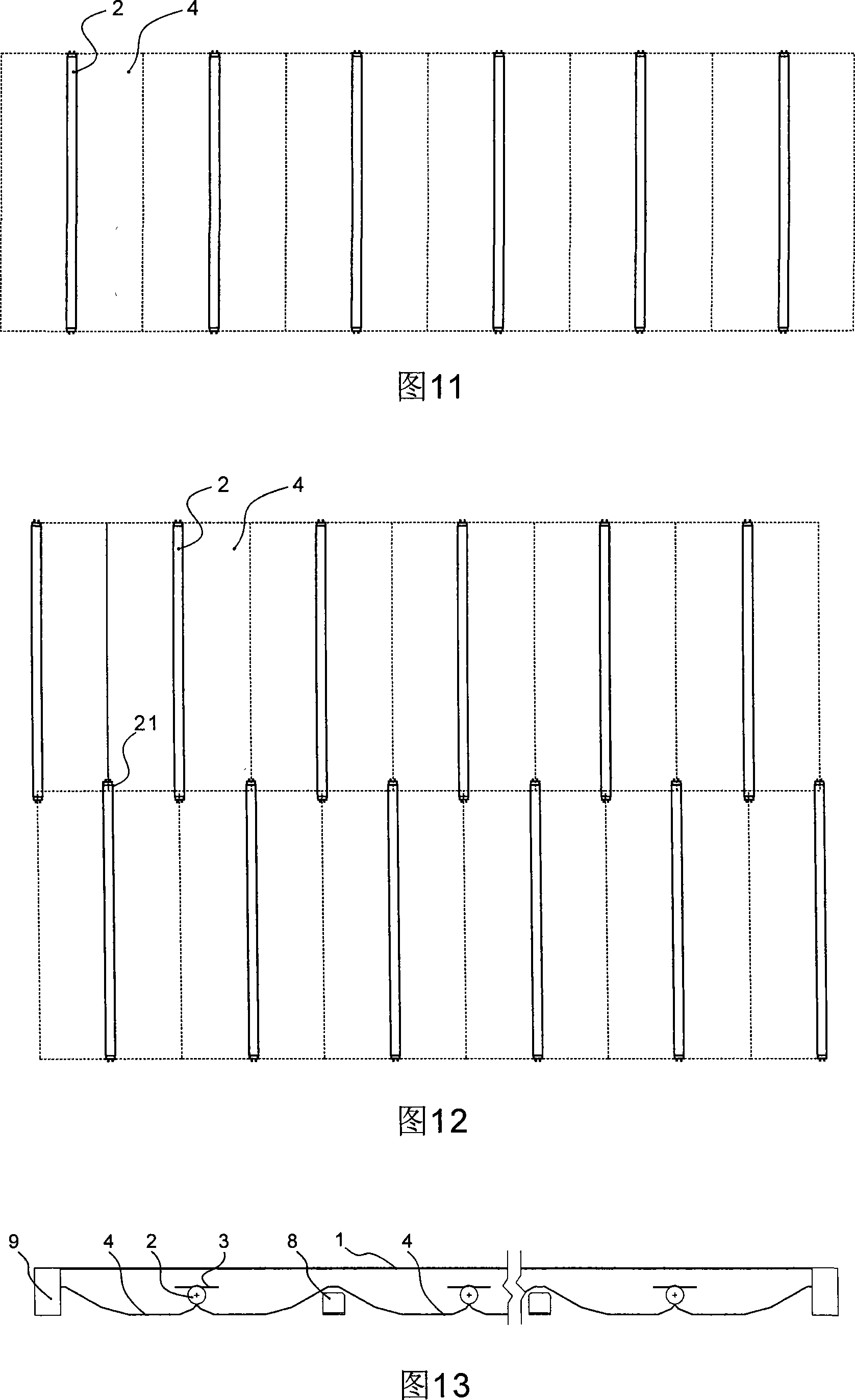

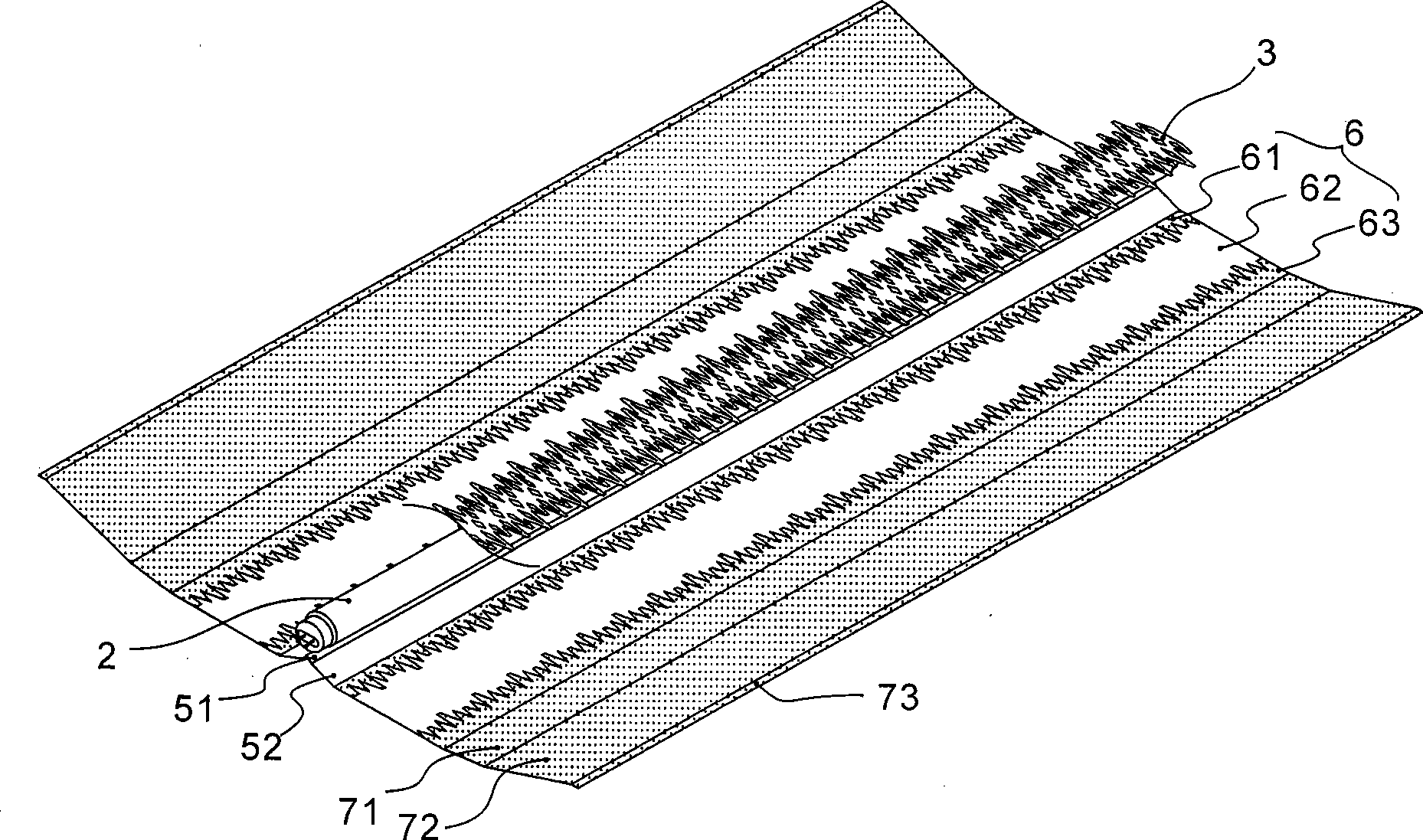

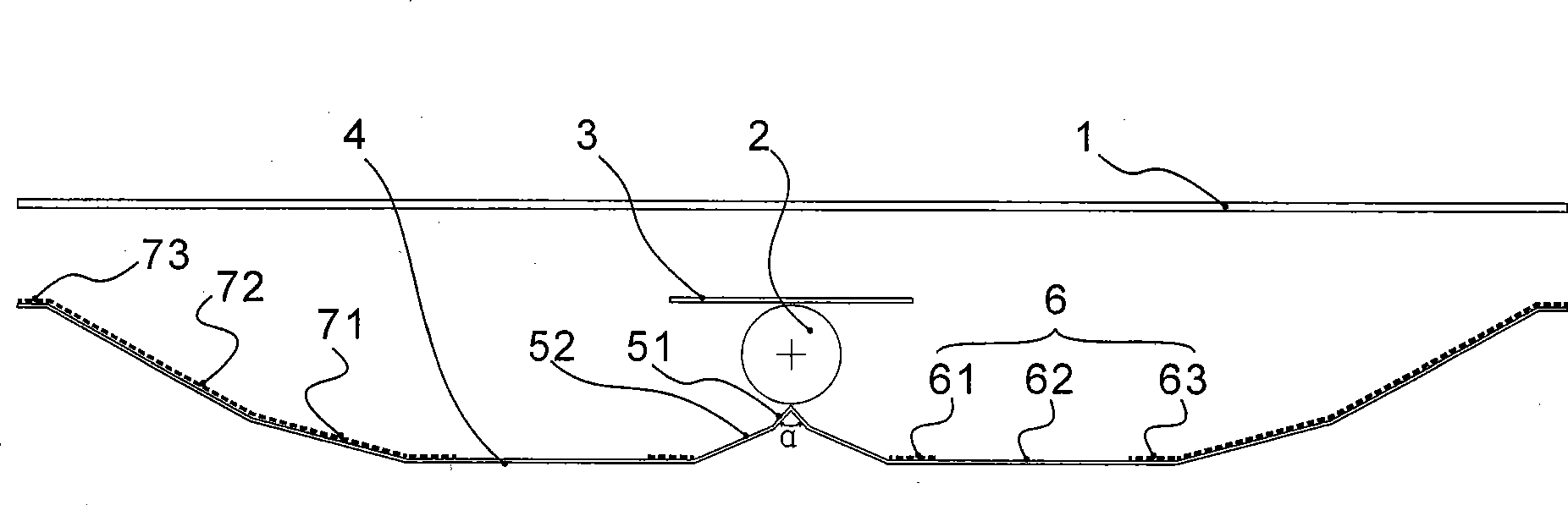

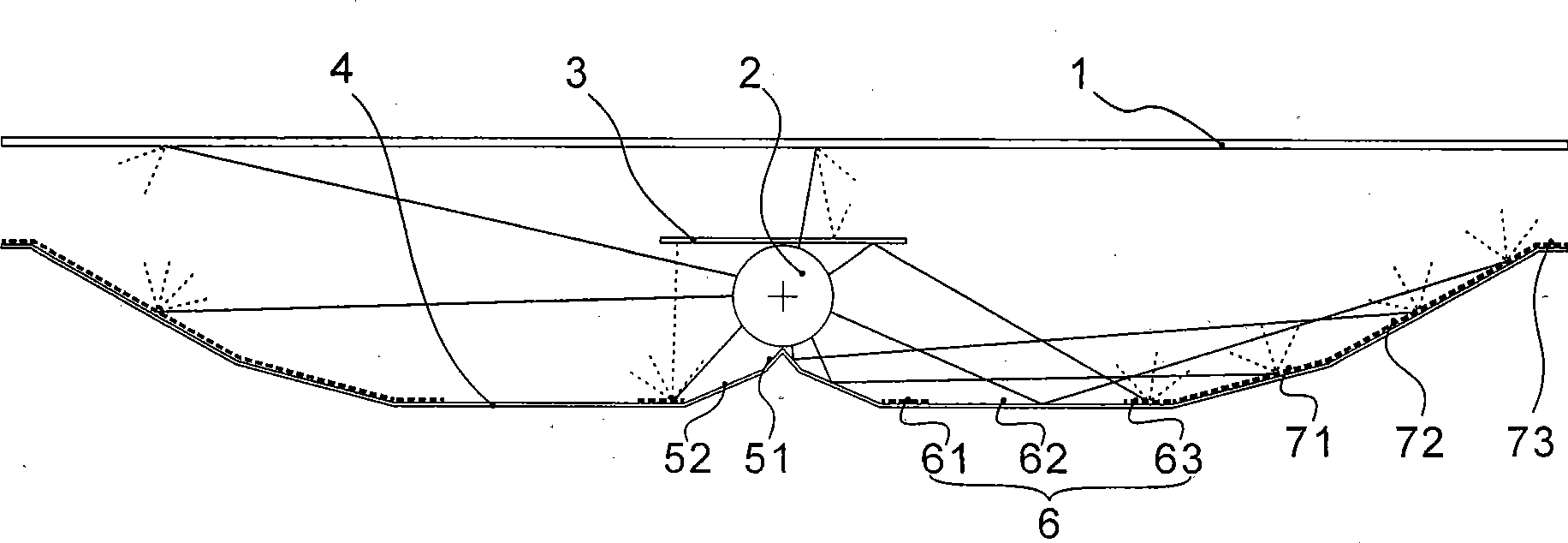

Broad width light evening backlight source module and backlight source applying the module

InactiveCN101418929AEnsure uniformity of lightLow installation accuracy requirementsElongate light sourcesElectric lightingMirror reflectionLight reflection

The invention relates to a wide light evening backlight module, which comprises a line light source (2), a light evening reflective plate (4) and a reflex housing (3), wherein the line light source (2) is arranged between the light evening reflective plate (4) and the reflex housing (3). The wide light evening backlight module is characterized in that the light evening reflective plate (4) is provided with mirror reflecting zones (51 and 52), mirror diffuse mixed reflecting zones (6 and 6') and diffuse reflecting zones (71, 72 and 73), wherein the mirror reflecting zones (51 and 52) are positioned on a central position of the light evening reflective plate (4); the longitudinal direction of the mirror reflecting zones (51 and 52) is basically parallel to the line light source (2); two sides of the mirror reflecting zones (51 and 52) are provided with the mirror diffuse mixed reflecting zones (6 and 6') respectively; and the outside of at least one of the mirror diffuse mixed reflecting zones (6 and 6') is provided with the diffuse reflecting zones (71, 72 and 73). The wide light evening backlight module improves the light evening effect and light utilization rate through reasonable division and arrangement of the reflecting zones of the light evening reflective plate, thereby the distribution and control problems of reflex are effectively solved and a wide reflective plate can also guarantee illuminating evenness degree of a display surface.

Owner:刘俊波

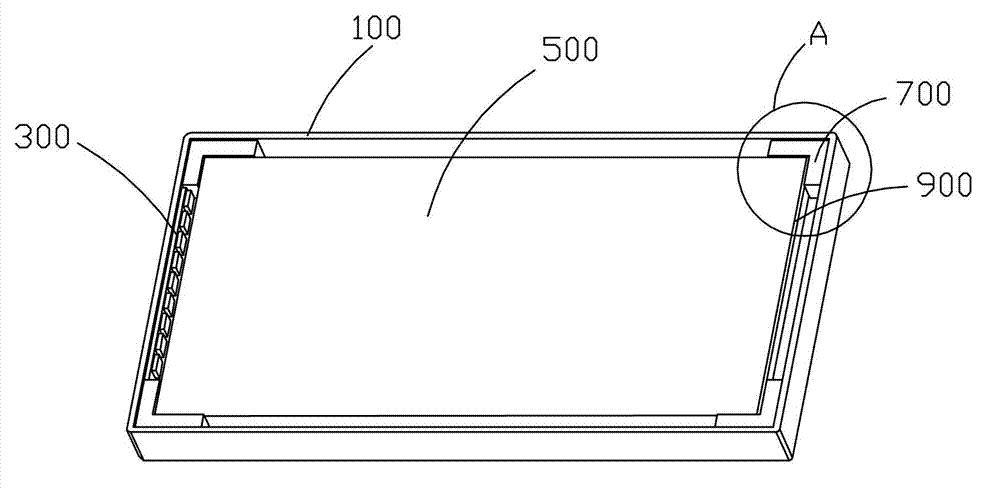

Backlight module and display device

InactiveCN113138494AGood viewing angle uniformityTaking into account the uniformity of light outputNon-linear opticsLight guideDisplay device

The invention provides a backlight module and a display device. The backlight module comprises a substrate, a plurality of light-emitting units, a light guide layer and a light reflecting layer. The design of the ultrathin flexible backlight module is achieved, and it is guaranteed that the overall thickness of the backlight module does not exceed 0.3 mm; a direct type light emitting mode is adopted, it is guaranteed that backlight has good visual angle uniformity when bent at different angles, no uniform light film structure exists in the backlight module, a net point structure is manufactured on the surface film surface of the lamp panel, light emitting uniformity at different positions of the front face is achieved through the combined action of the optical waveguide and the net point structure, the thinning of backlight and the light emitting uniformity of the whole surface are guaranteed, the light emitting uniformity and the bending characteristic of the backlight are considered, the light emitting uniformity of the whole surface is achieved, meanwhile, the overall lighting effect of the lamp panel can be improved, and the ultrathin flexible backlight with the higher lighting effect is achieved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

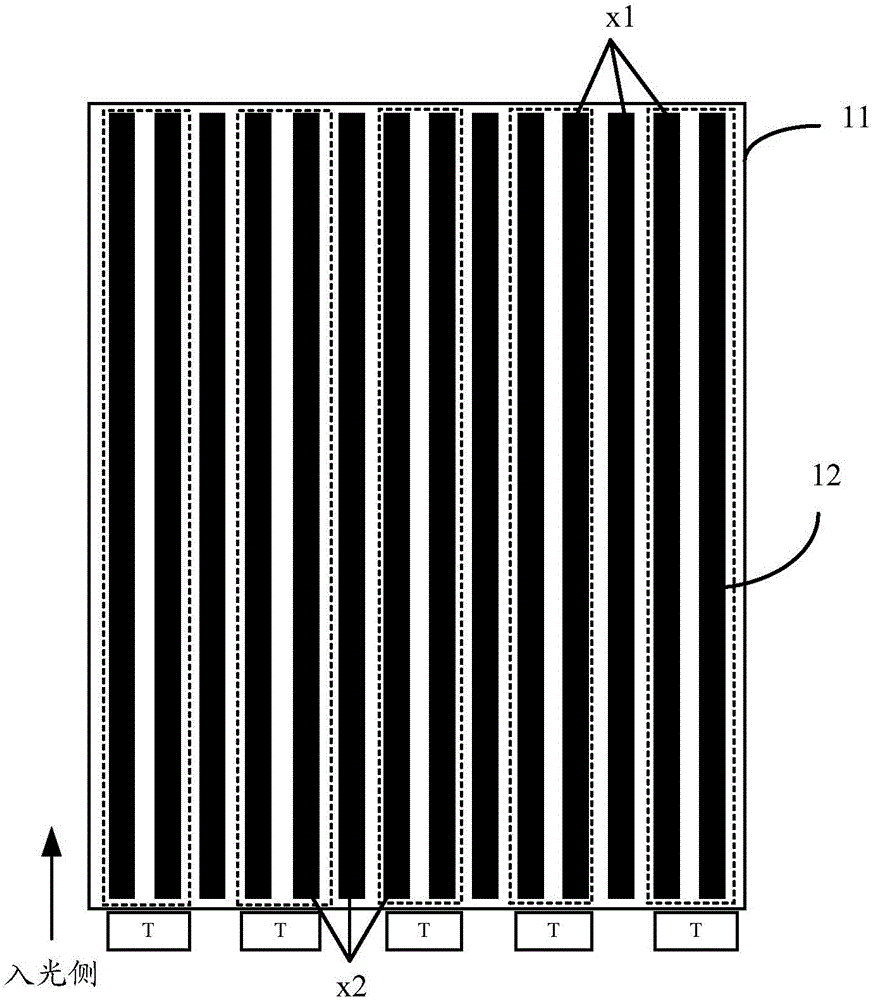

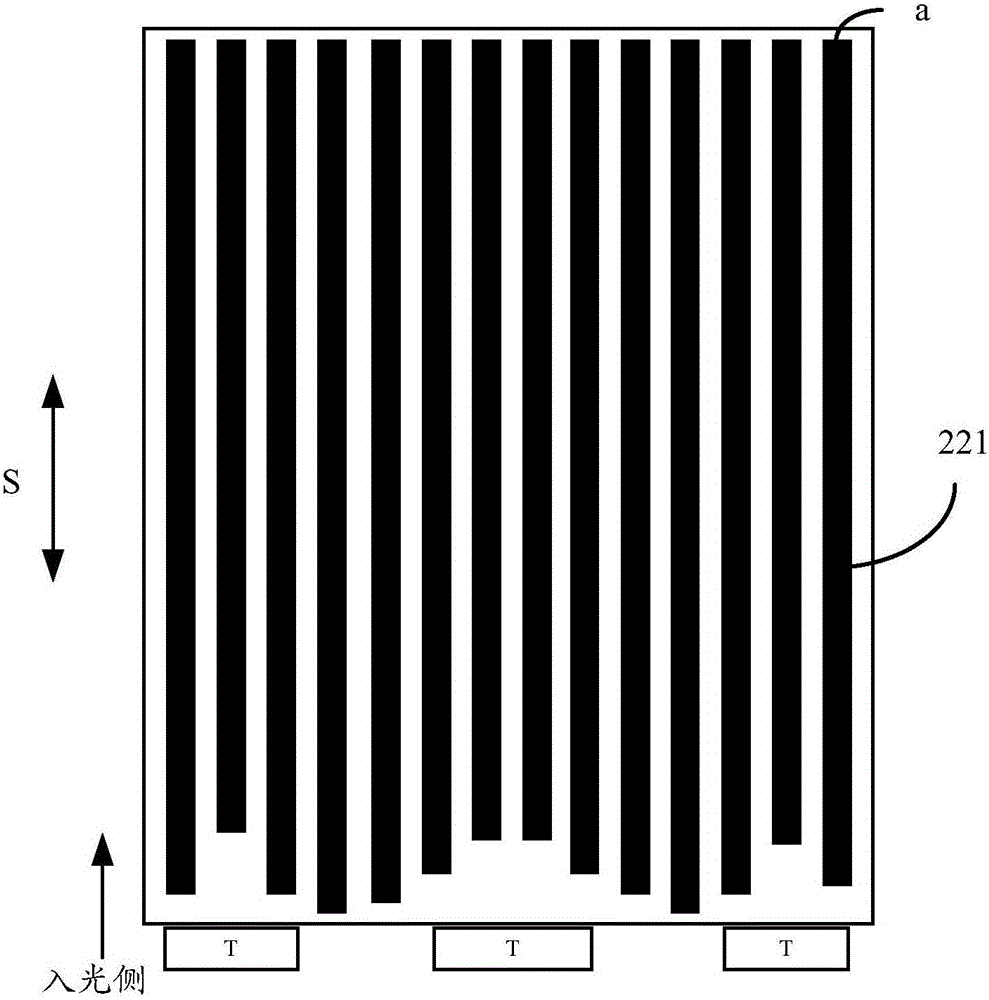

Light guide plate, backlight source module and display device

InactiveCN105891940AEnsure uniformity of lightImprove qualityOptical light guidesLight guideDisplay device

The invention relates to the technical field of backlight, in particular to a light guide plate, a backlight source module and a display device which are used for solving the problem of non-uniform light rays emitted by the conventional light guide plate due to the distribution design of a light emitting strip in the prior art. The light guide plate in the embodiment of the invention comprises a light guide main body part and a light emitting part positioned on one surface of the light guide main body part, wherein the light emitting part comprises a plurality of optical units arranged in the light guide direction; the lengths of the optical units in the light emitting part in the light guiding direction are unequal; each optical unit corresponding to a position where the light emitting strip is designed is shorter than an optical unit corresponding to a position where the light emitting strip is not designed, and one end surfaces, away from the light incident side of the light guide plate, of the optical units are flush with one another. Therefore, the light guide performances of the optical units at the light incident side of the light guide plate are ensured to be nearly consistent, the uniformity of scattering and reflection is improved, the light guide performances are improved, the light emitting uniformity of the light guide plate is ensured, and the quality of the light guide plate is improved.

Owner:BOE TECH GRP CO LTD +1

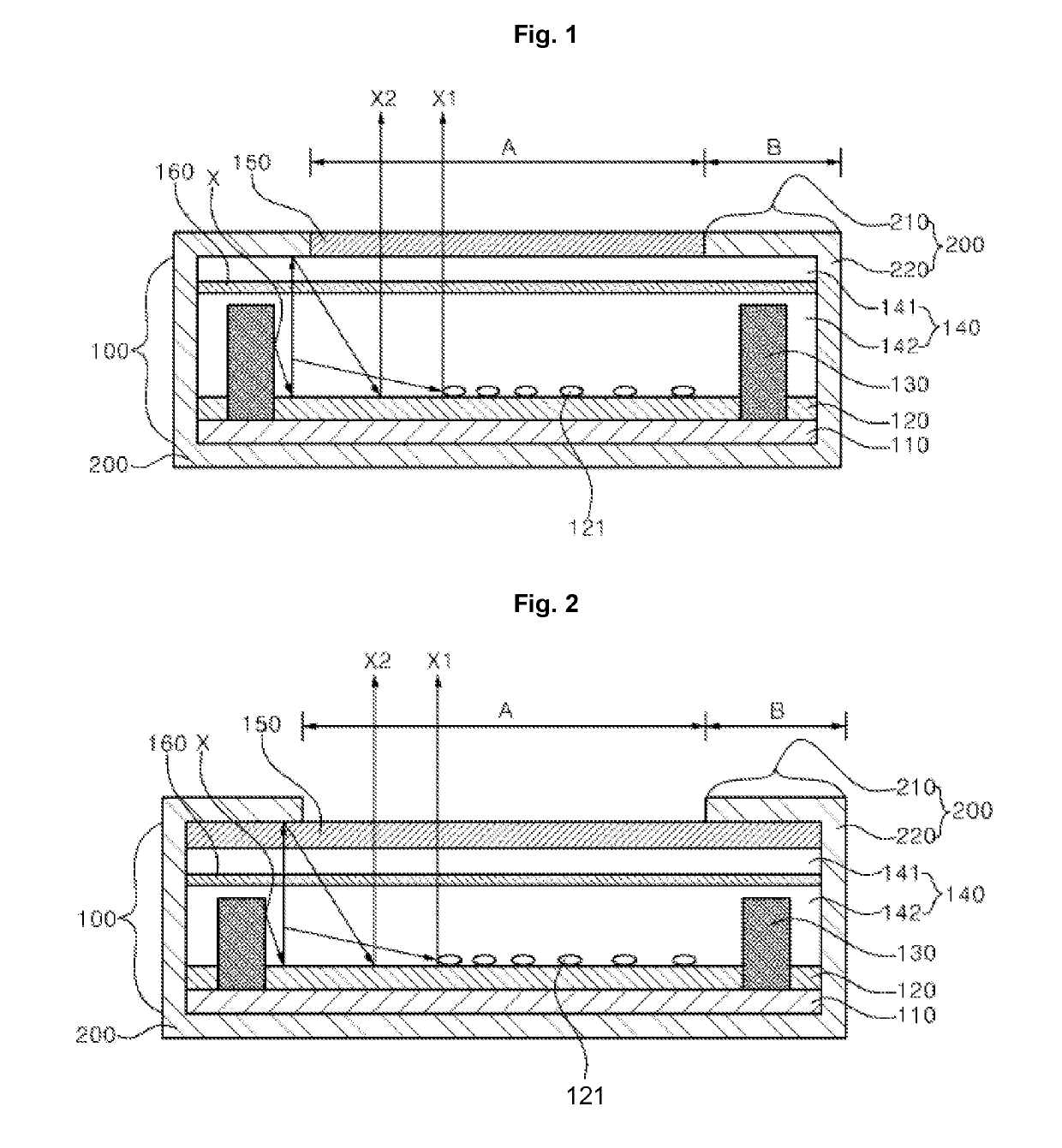

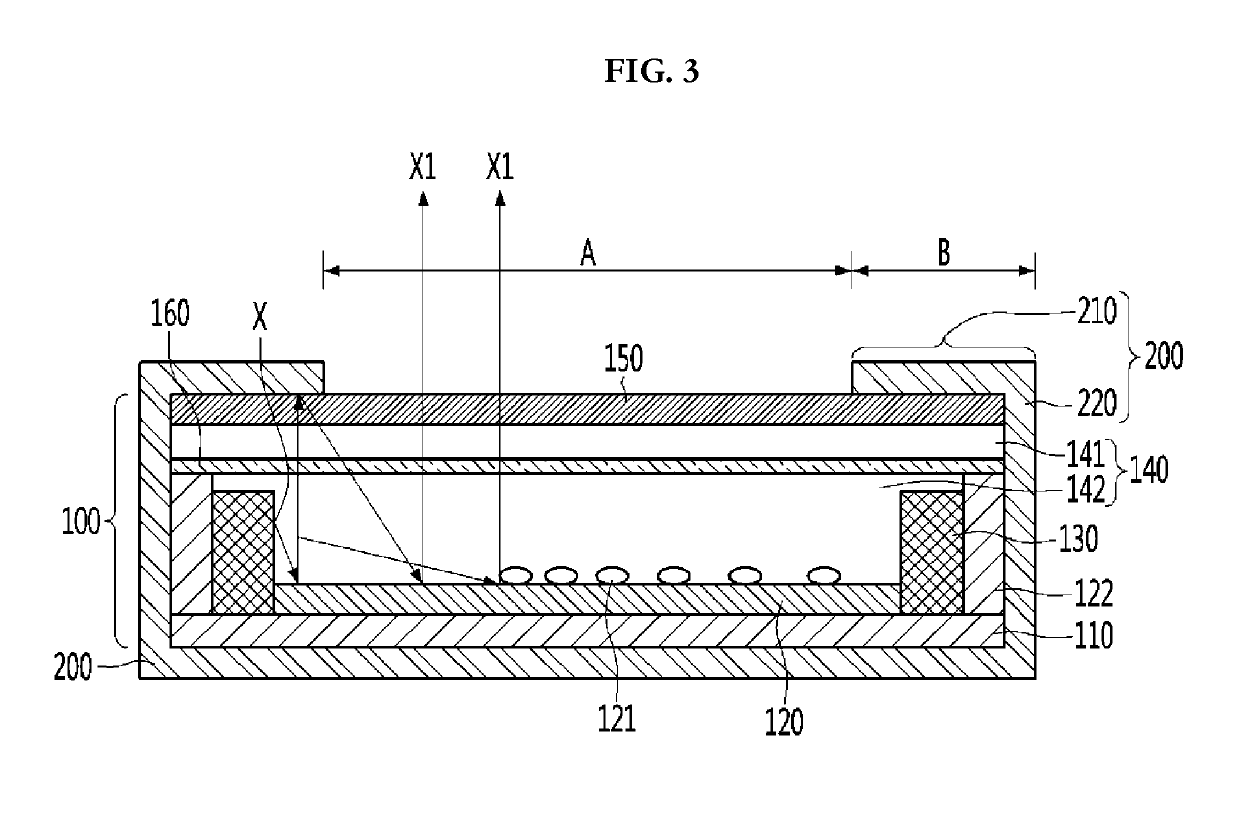

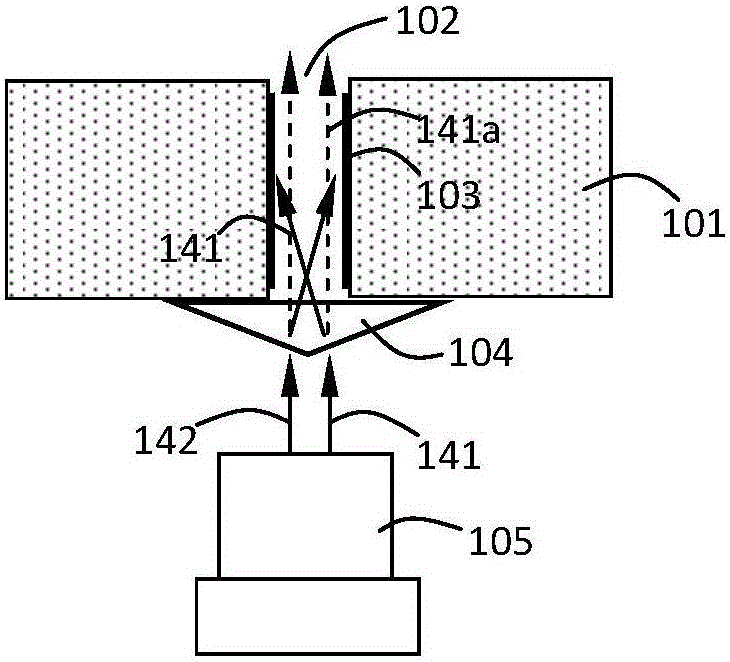

Lighting apparatus and vehicular lamp comprising the same

ActiveUS10300836B2Ensure uniformity of lightReduce thicknessMechanical apparatusVehicle headlampsLight guideEffect light

In the present invention, there is provided a lighting device including: a light source module including at least one light source and a light guide member that buries the light source; a shielding module accommodating the light source module therein, the shielding module having an opening region and a shielding region, which are provided above the light guide member; and a diffusion member disposed in the light guide member.

Owner:LG INNOTEK CO LTD

Lighting apparatus and vehicular lamp comprising the same

ActiveUS20180326895A1Uniform lightReduce thicknessMechanical apparatusVehicle headlampsLight guideEffect light

In the present invention, there is provided a lighting device including: a light source module including at least one light source and a light guide member that buries the light source; a shielding module accommodating the light source module therein, the shielding module having an opening region and a shielding region, which are provided above the light guide member; and a diffusion member disposed in the light guide member.

Owner:LG INNOTEK CO LTD

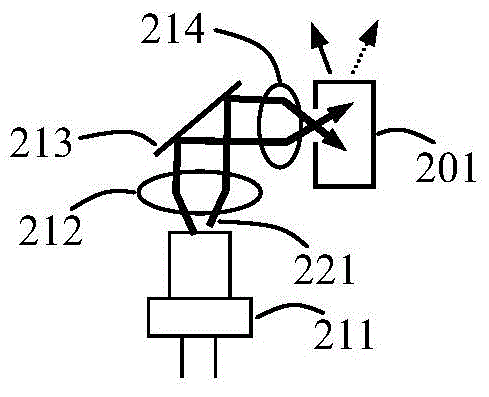

Light emitting device, lamp and projection display device

InactiveCN106527025ALimit aperture sizeGuaranteed light efficiencyProjectorsLighting device detailsLight spotLuminous flux

Disclosed are a light emitting device, a lamp and a projection display device. The light emitting device comprises a wavelength conversion device which comprises a perforated substrate and a wavelength conversion layer attached to the inner wall of a hole. The light emitting device also comprises a laser source and a light processing element. A laser emitted from the laser source is incident on the light processing element and processed, and the angular distribution of the laser is in the first angular range, so that the laser can all be incident on the wavelength conversion layer of the inner wall of the hole and the wavelength conversion layer is excited to emit a stimulated laser. The light processing element enables all of the laser to be incident on the wavelength conversion layer of the inner wall of the hole without direct injection from the hole, so that the luminous efficiency and uniformity can be guaranteed. At the same time, the size of the hole limits the size of the aperture of the emitted light, small holes can make the exit light spot become small, and the luminous flux is prevented from being affected, so that relatively higher brightness can be achieved.

Owner:杨毅

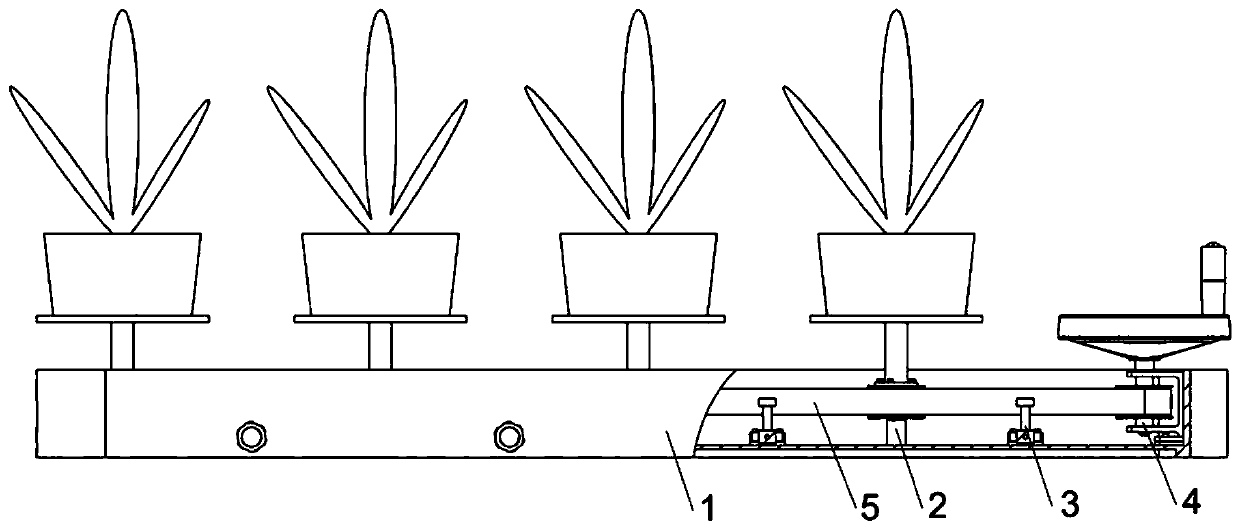

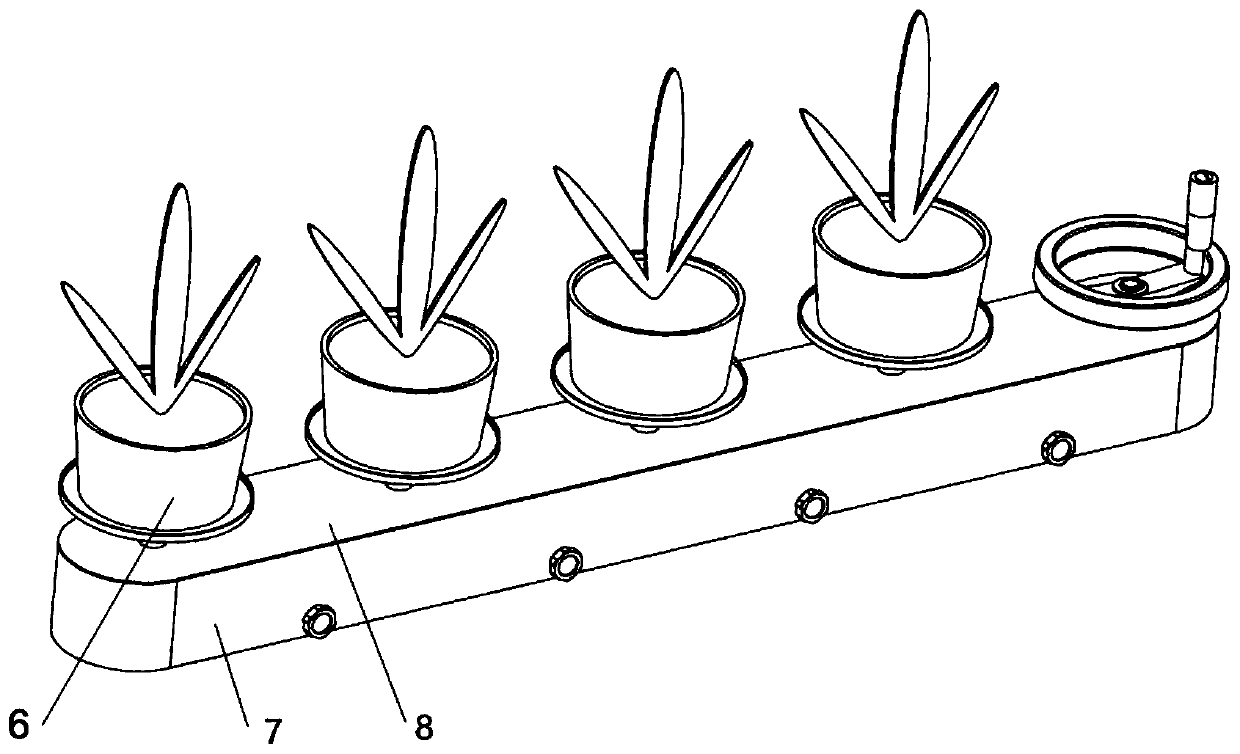

Horizontal flowerpot rotary support

InactiveCN109845529AEnsure uniformity of lightSimple structureFlower tablesReceptacle cultivationAgricultural engineeringEngineering

The invention discloses a horizontal flowerpot rotary support, comprising a casing, a rotation unit, a tension unit, a handwheel unit, a synchronous belt and flowerpots. The rotation unit is mounted on the bottom surface of the inside of the casing; the handwheel unit is arranged at one end of the casing; the rotation unit and the handwheel unit are connected through the synchronous belt; the tension unit is arranged on the bottom surface of the inside of the casing and fits the outer side of the synchronous belt; the flowerpots are arranged on the top surface of the rotation unit; thus, whenusers turn the handwheel, users can enjoy the sight of plant landscape at different angles, plants can receive full sunshine to complete photosynthesis along with angle change of rotary discs, and further healthy growth of the plants is guaranteed. The horizontal flowerpot rotary support is simple in structure and convenient to operate; operating efficiency is improved, while operation of the horizontal flowerpot rotary support becomes much interesting.

Owner:NANJING VOCATIONAL UNIV OF IND TECH

Optical assembly, backlight module and display device

PendingCN114217479AGuaranteed brightnessEnsure uniformity of lightPlanar/plate-like light guidesNon-linear opticsLight guideDisplay device

The invention discloses an optical assembly, a backlight module and a display device. The optical assembly comprises a light guide plate, at least one first light source and at least one second light source. At least one avoiding hole penetrating to the top is formed in the bottom of the light guide plate; the first light sources are arranged at the bottom of the light guide plate, and each first light source is opposite to one avoiding hole; the second light source is arranged on the side edge of the light guide plate, and the light-emitting surface of the second light source faces the side edge of the light guide plate. According to the technical scheme, the problems that the overall brightness of a side-in type display device is not high, and the overall picture of a direct-down type display device is not uniform can be solved.

Owner:SHENZHEN SKYWORTH RGB ELECTRONICS CO LTD

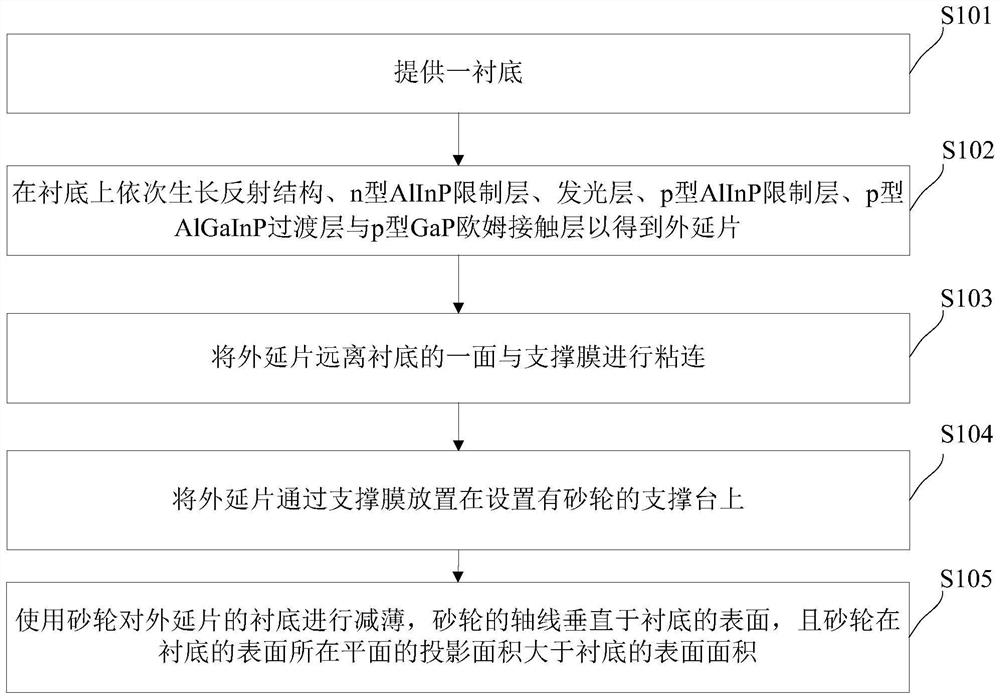

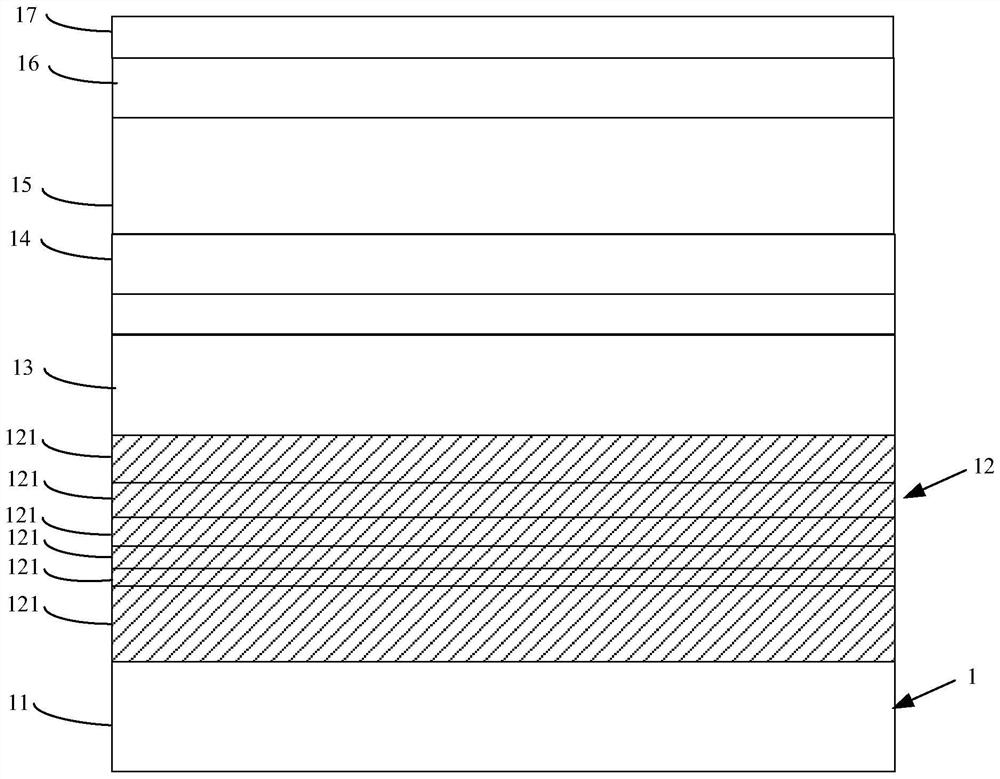

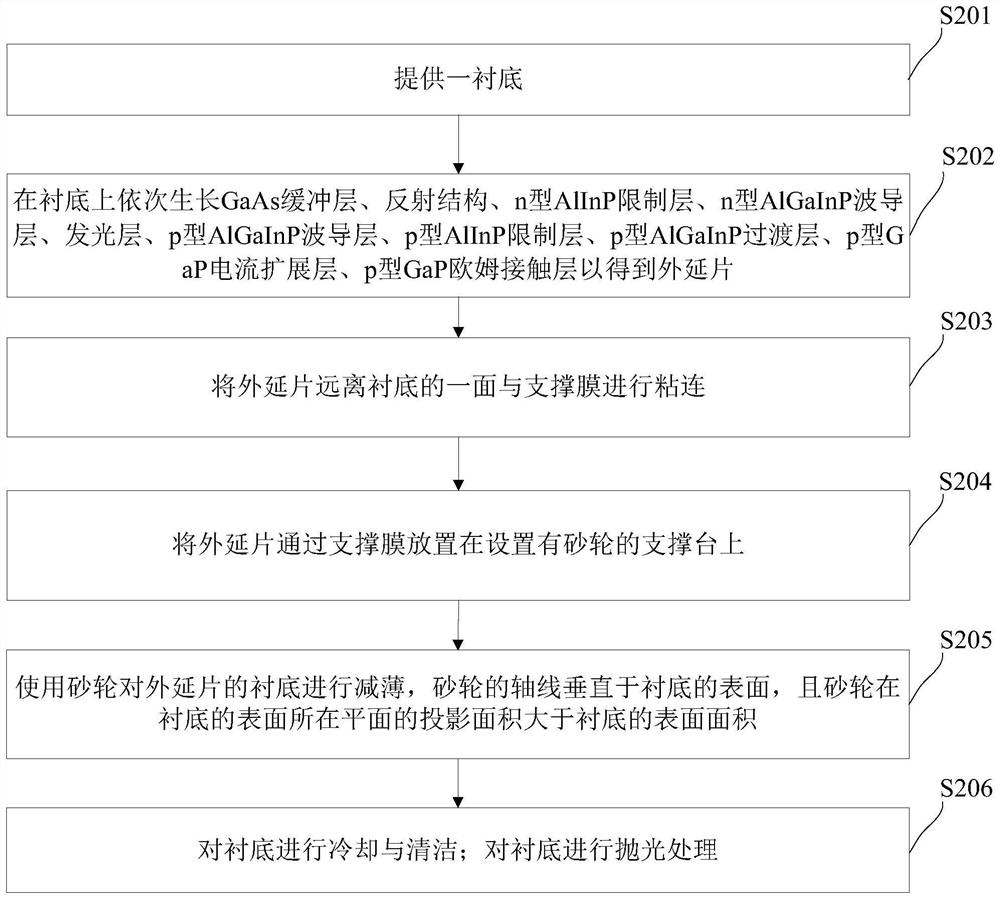

Preparation method of red and yellow light emitting diode epitaxial wafer

PendingCN114551652AEvenly ThinningImprove uniformitySemiconductor/solid-state device manufacturingSemiconductor devicesPhysical chemistryGrinding wheel

The invention provides a preparation method of a red and yellow light emitting diode epitaxial wafer, and belongs to the technical field of diode preparation. The surface, far away from the substrate, of the epitaxial wafer, namely the surface, far away from the epitaxial layer, of the substrate is adhered to the supporting film, the supporting film can play a role in uniformly supporting the whole epitaxial wafer and can be stably adhered to the epitaxial wafer, and the surface, far away from the epitaxial layer, of the substrate can be uniformly thinned while operation is facilitated. An epitaxial wafer is placed on a supporting table through a supporting film, a substrate of the epitaxial wafer is thinned through a grinding wheel, the axis of the grinding wheel is perpendicular to the surface of the substrate, the projection area of the grinding wheel on the plane where the surface of the substrate is located is larger than the surface area of the substrate, it is guaranteed that the face, away from the epitaxial wafer, of the substrate is thinned stably through the grinding wheel, and the thickness of the substrate is evenly reduced; and the uniformity of the thickness of the finally obtained substrate is improved, so that the light emitting uniformity of the finally obtained red and yellow light emitting diode is ensured.

Owner:HC SEMITEK ZHEJIANG CO LTD

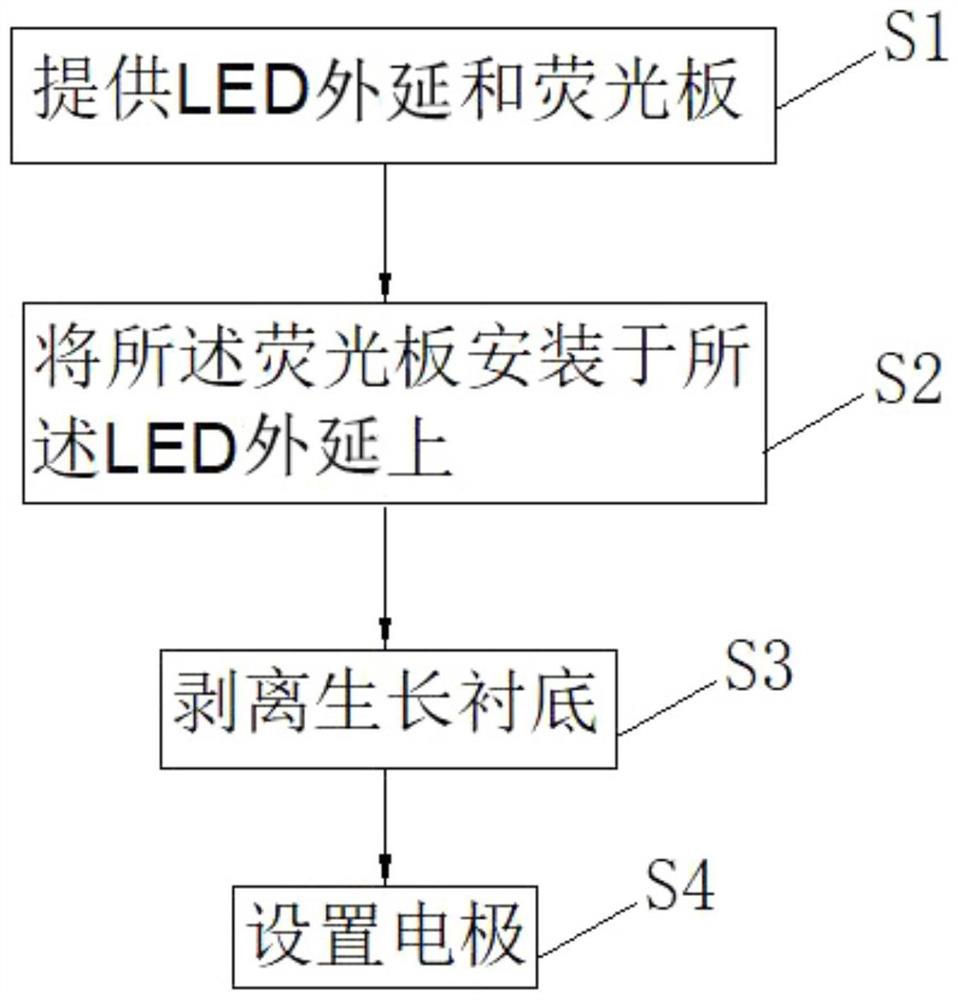

A kind of manufacturing method of white light led chip

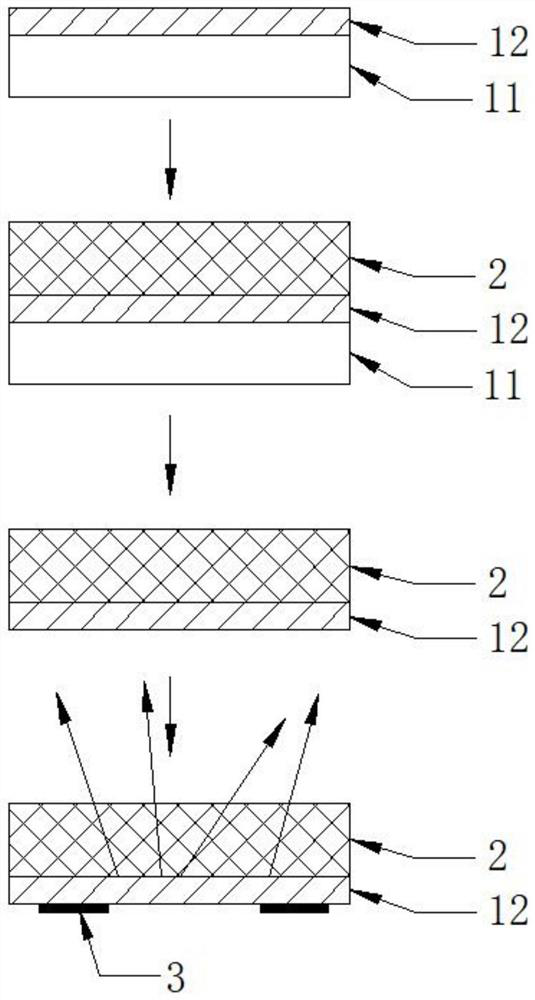

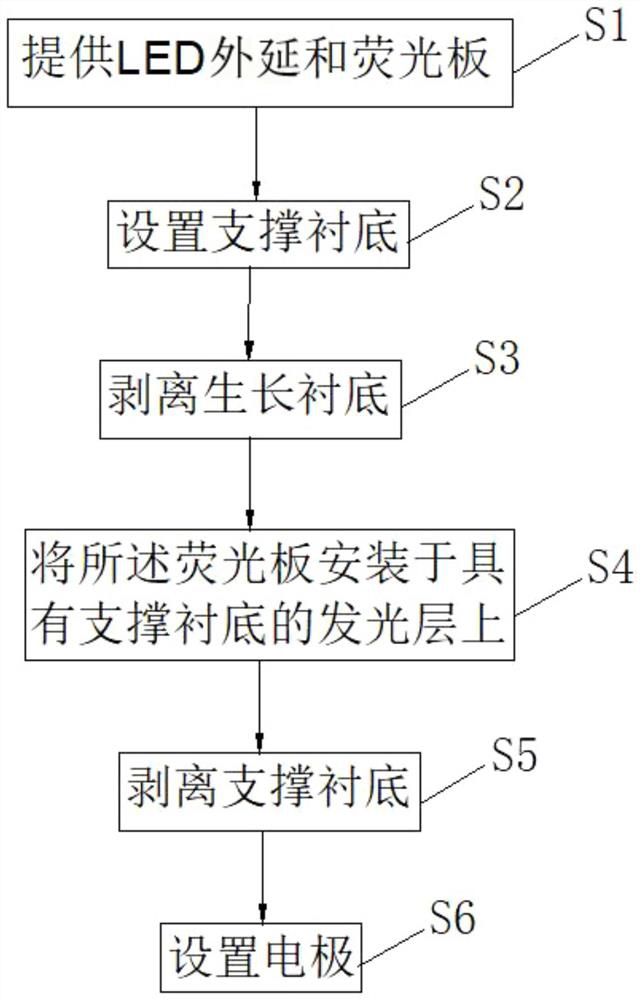

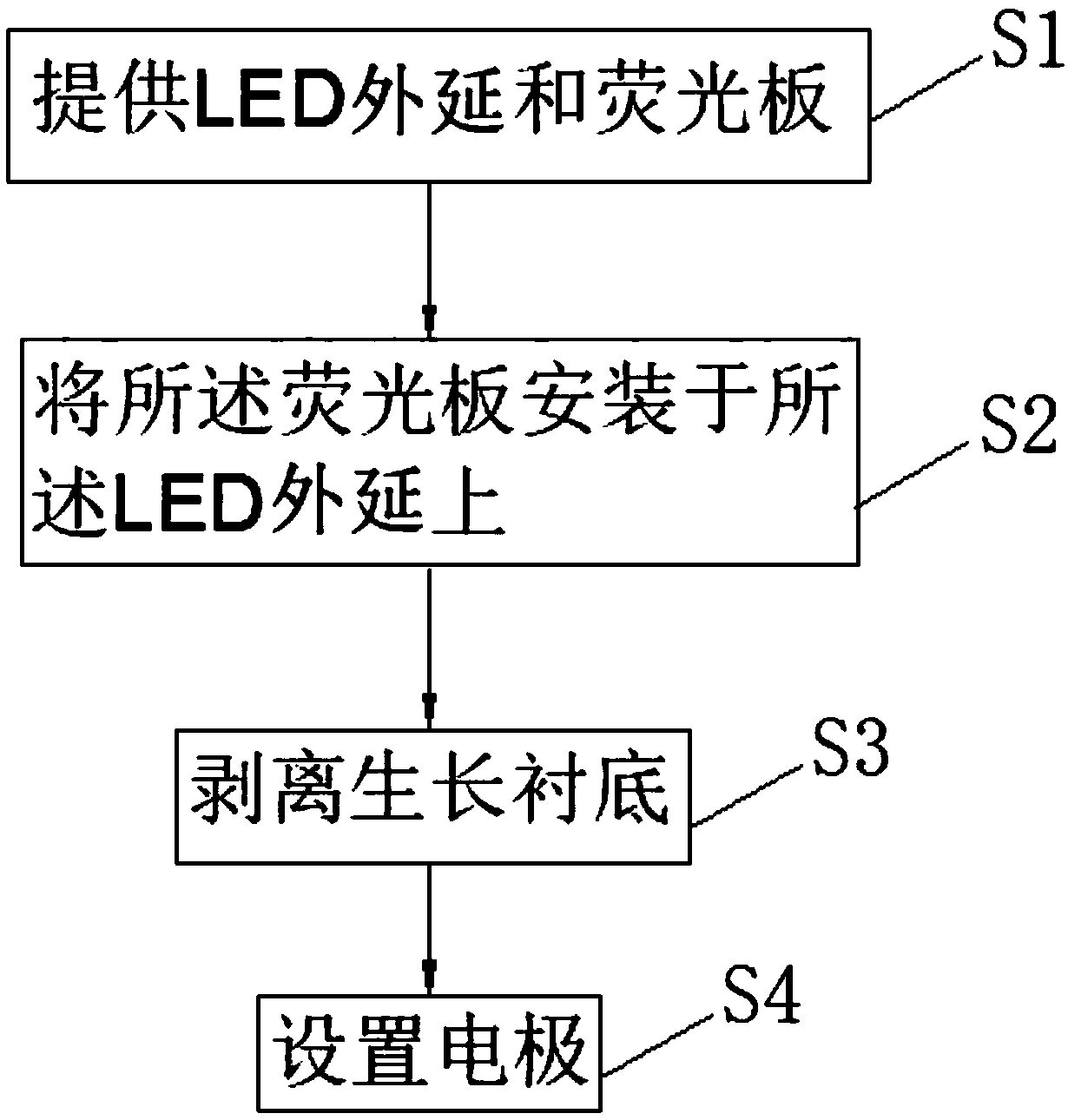

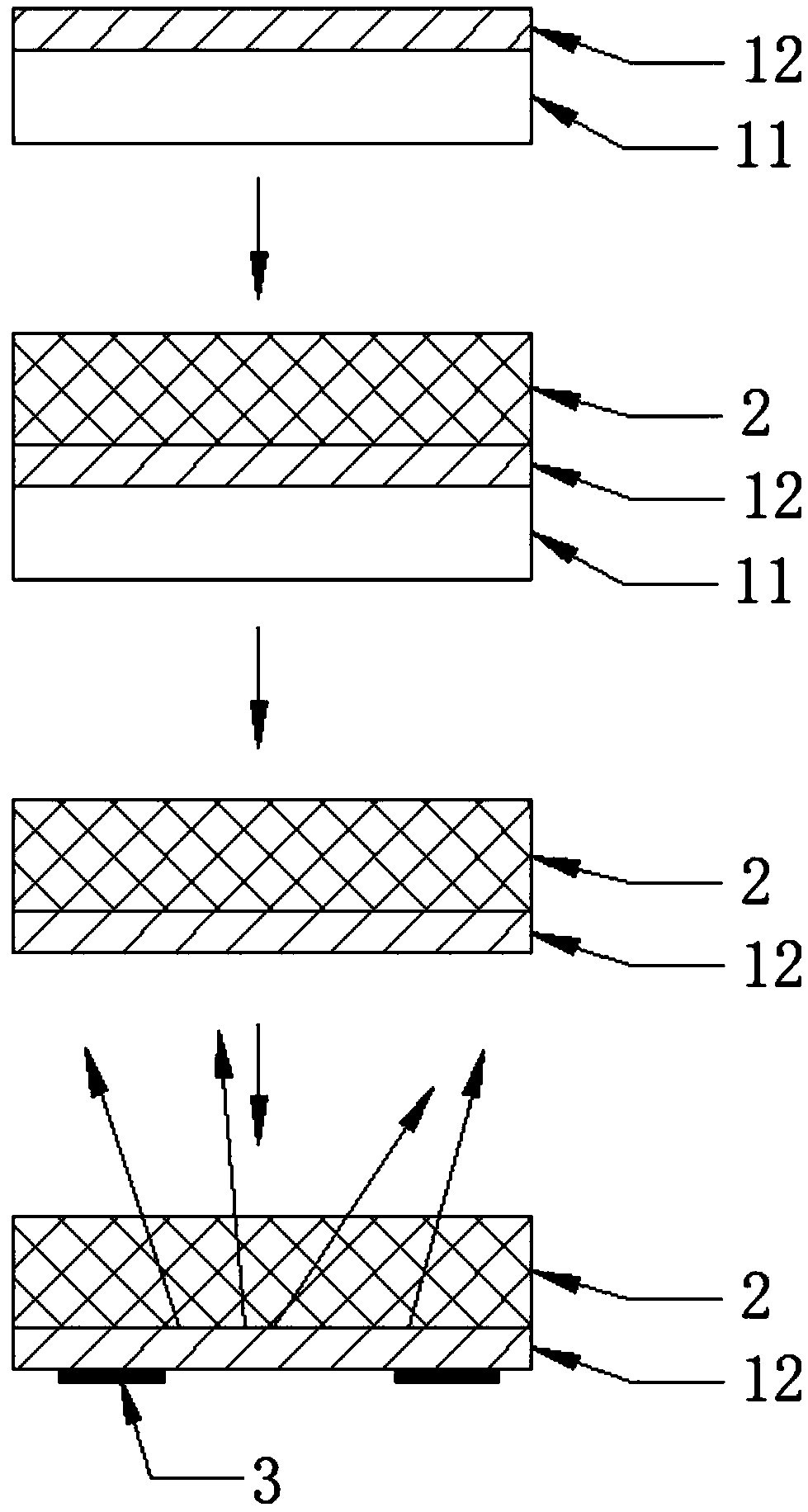

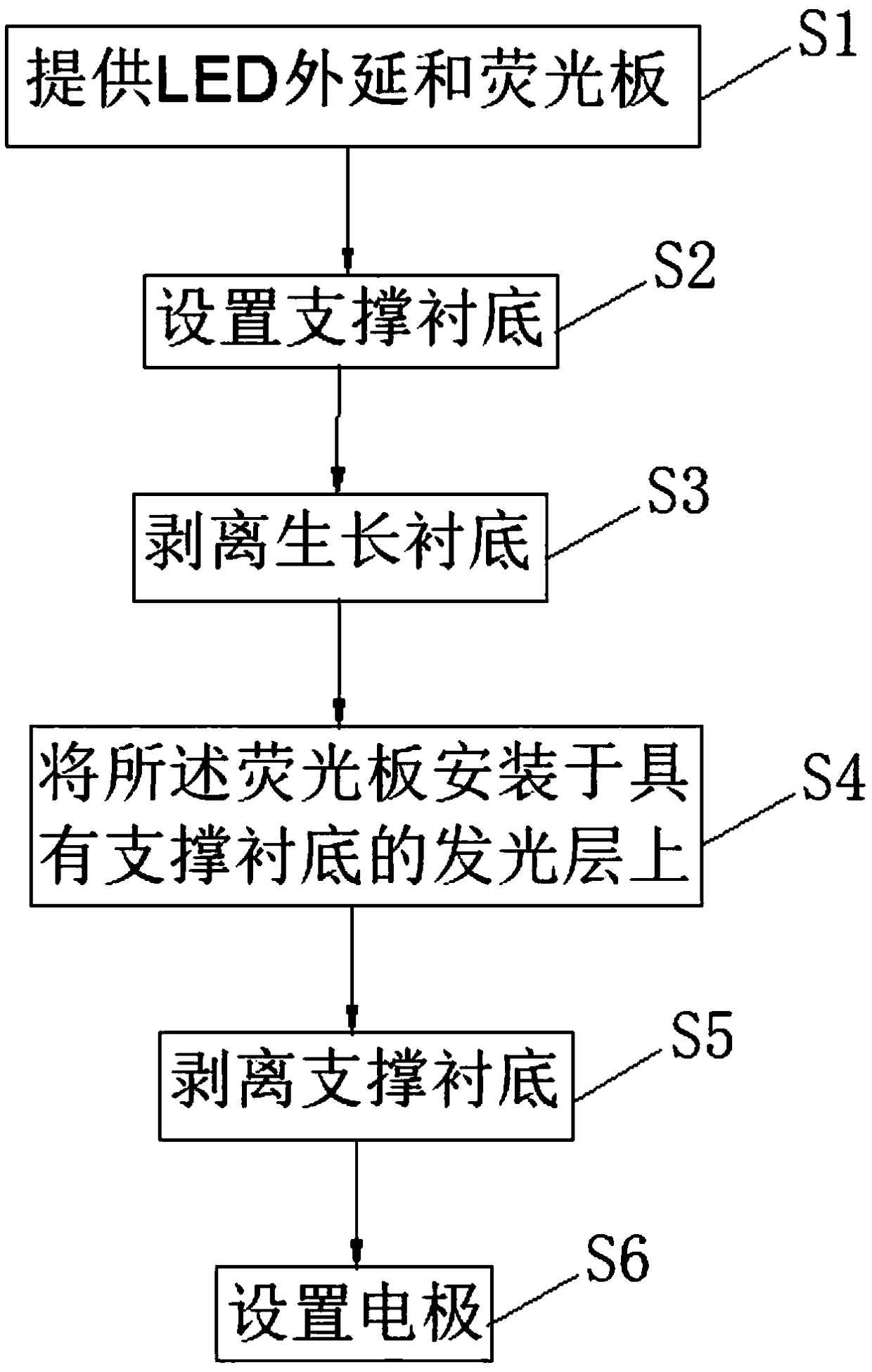

ActiveCN109244195BReliability impactImprove excitation efficiencySemiconductor devicesFluorescencePhysical chemistry

The invention relates to a manufacturing method of a white light LED chip, comprising the following steps: S1, providing an LED epitaxial and fluorescent plate; 2, mounting that fluorescent plate on the LED epitaxy to obtain a white LED epitaxy with a growth substrate; 3, stripping that growth substrate to obtain white LED epitaxy to be formed; S4, arranging an electrode- to obtain a molded whiteLED chip. The invention provides a white LED epitaxial manufacturing method, The LED epitaxial light-emitting layer is mounted on the fluorescent plate, and the formed white LED chip can emit white light directly, and the fluorescent plate is made of high-temperature resistant transparent material and fluorescent powder, and the high-temperature generated in the working process will not affect thereliability of the fluorescent plate, and the LED chip can be made into high-power LED chip. On the other hand, the luminescence principle of the white light LED chip is that the monochromatic lightLED chip excites phosphor to form white light, the production cost is low, the package is not needed, the excitation efficiency is high, the wavelength is continuous, and the color reducibility is high.

Owner:FOSHAN EVERCORE OPTOELECTRONICS TECH

A manufacturing method of a white light LED chip

ActiveCN109244195AReliability impactImprove excitation efficiencySemiconductor devicesPhosphorLength wave

The invention relates to a manufacturing method of a white light LED chip, comprising the following steps: S1, providing an LED epitaxial and fluorescent plate; 2, mounting that fluorescent plate on the LED epitaxy to obtain a white LED epitaxy with a growth substrate; 3, stripping that growth substrate to obtain white LED epitaxy to be formed; S4, arranging an electrode- to obtain a molded whiteLED chip. The invention provides a white LED epitaxial manufacturing method, The LED epitaxial light-emitting layer is mounted on the fluorescent plate, and the formed white LED chip can emit white light directly, and the fluorescent plate is made of high-temperature resistant transparent material and fluorescent powder, and the high-temperature generated in the working process will not affect thereliability of the fluorescent plate, and the LED chip can be made into high-power LED chip. On the other hand, the luminescence principle of the white light LED chip is that the monochromatic lightLED chip excites phosphor to form white light, the production cost is low, the package is not needed, the excitation efficiency is high, the wavelength is continuous, and the color reducibility is high.

Owner:FOSHAN EVERCORE OPTOELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com