Method for manufacturing white light LED light sources

A technology of LED light source and manufacturing method, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., and can solve problems such as inconsistent matching between fluorescent sheets and LED chips, low product yield, and uneven light output from LED light sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

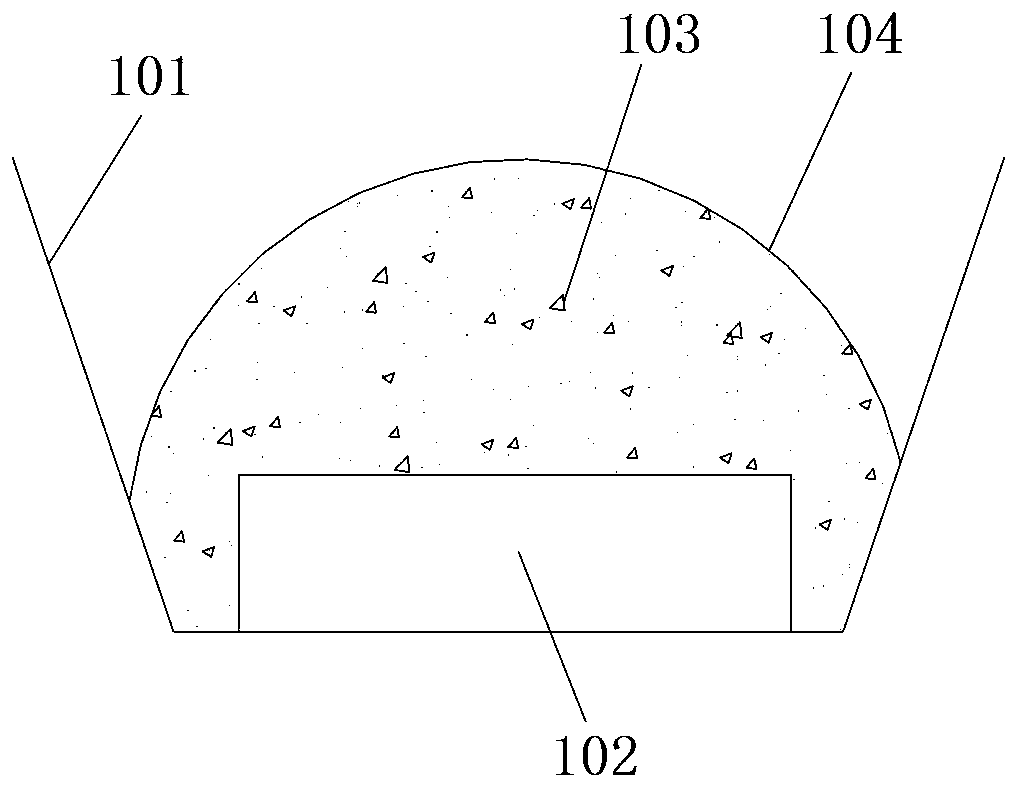

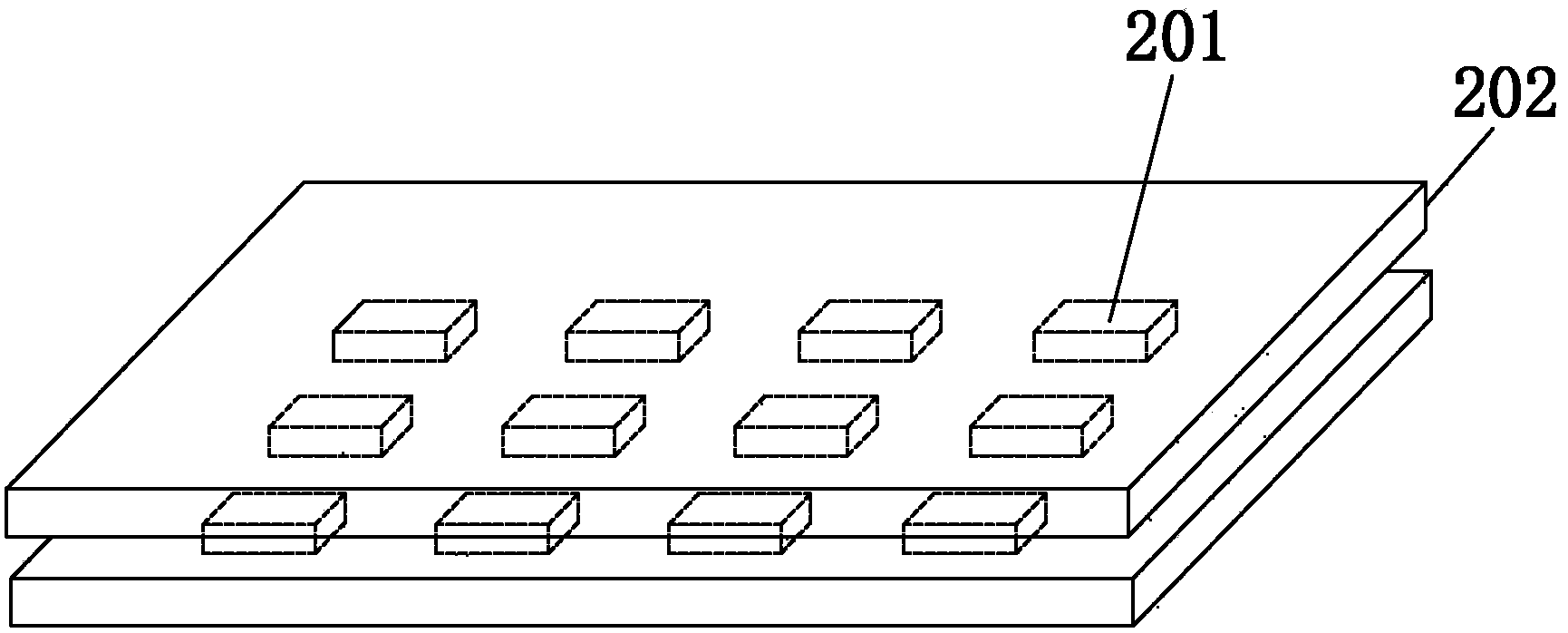

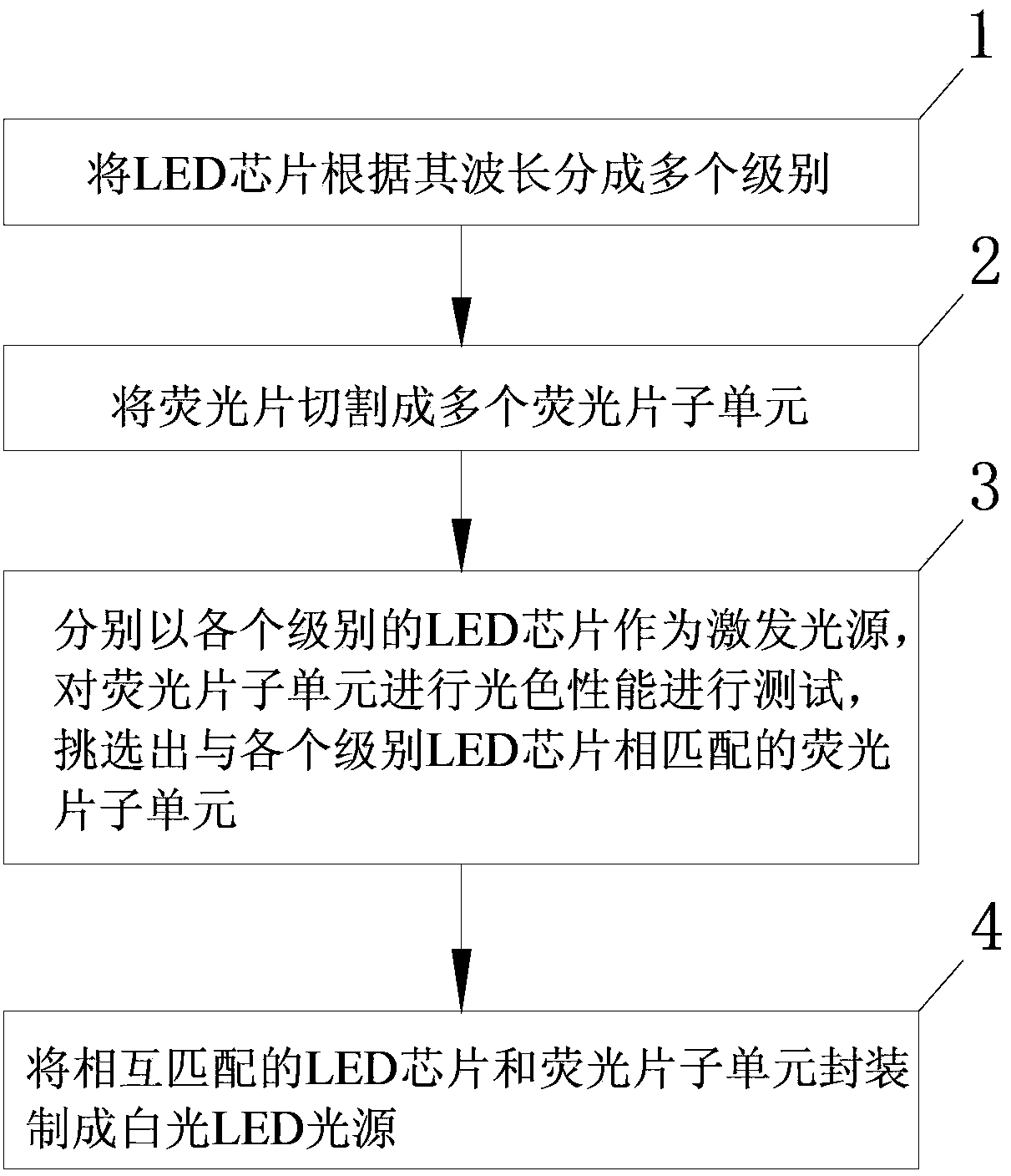

[0037] Such as image 3 As shown, this embodiment discloses a method for manufacturing a white LED light source, the white LED light source is made of LED chips and fluorescent sheets, including the following steps:

[0038] (1) Divide the LED chips into multiple levels according to their wavelengths; among them, the LED chips in this embodiment preferably have blue LED chips with a wavelength of 440-465 nanometers; Figure 4 As shown, the LED chips are divided into multiple levels according to their wavelengths, specifically: the 440-465 nm blue LED chips are divided into ten levels with 2.5 nm as the wavelength difference, the first level in the figure is 440 -442.5, that is, blue LED chips with a wavelength greater than or equal to 440 nanometers and less than or equal to 442.5 nanometers are class 1, blue LED chips with a wavelength greater than 442.5 nanometers and less than or equal to 445 nanometers are class 2, and so on. The blue-light LED chip is the 10th level; aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com