A kind of manufacturing method of white light led chip

A technology of LED chip and manufacturing method, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of poor color reproduction, low excitation efficiency, and inability to achieve high power density of white LEDs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

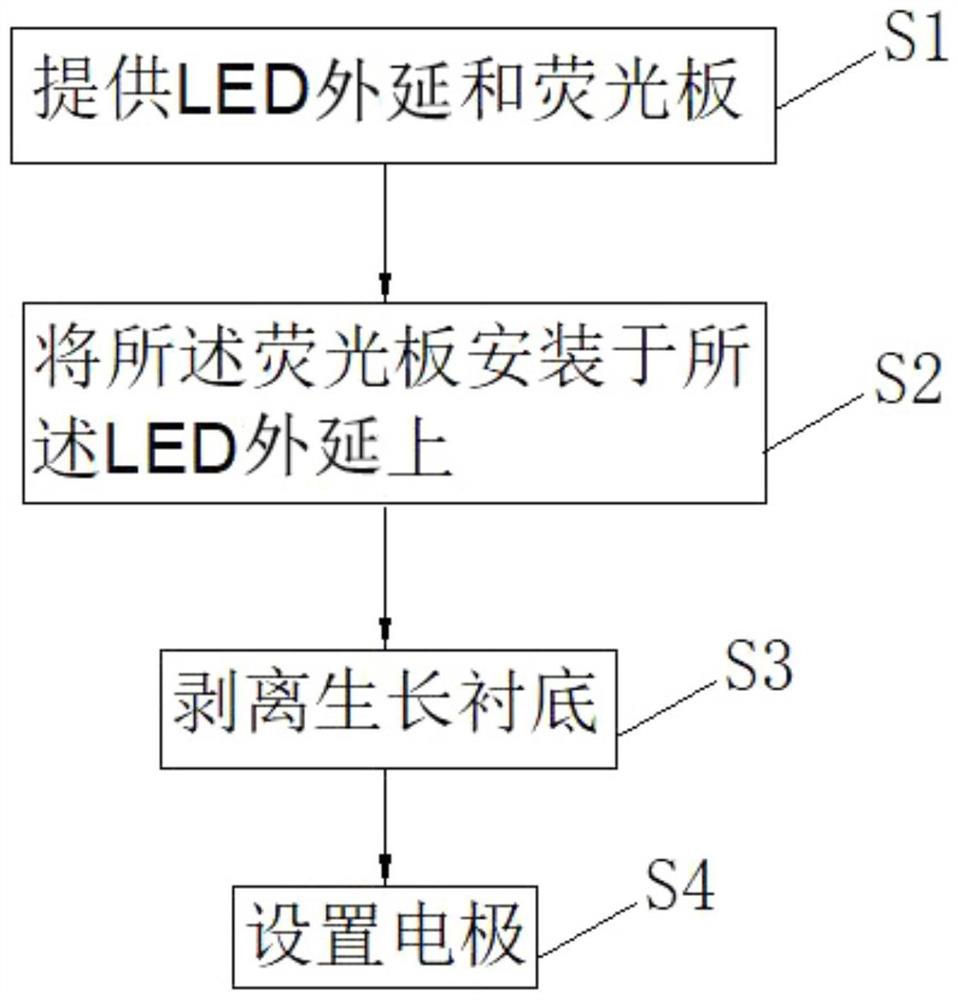

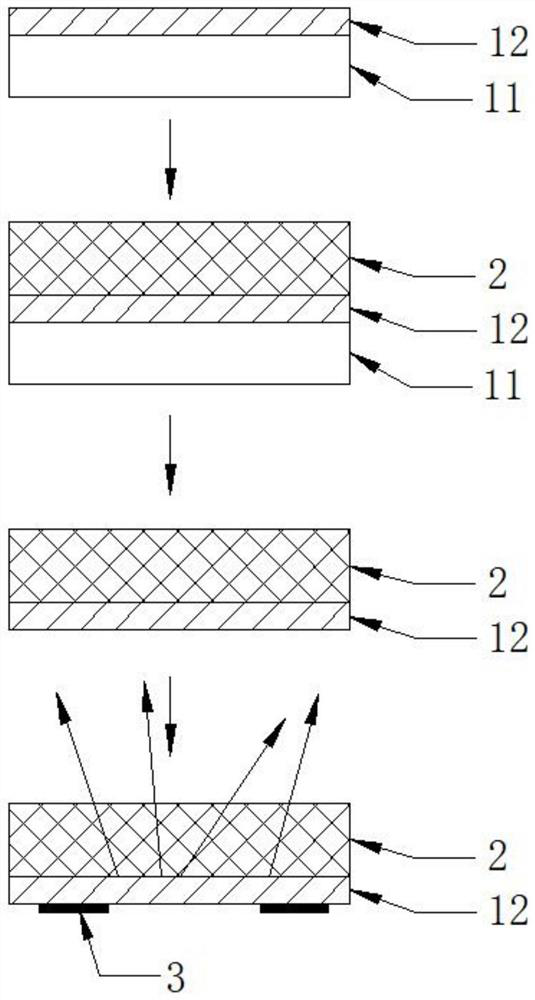

[0054] Such as Figure 1-2 Shown, a kind of manufacturing method of white light LED chip comprises the following steps:

[0055] S1. Provide an LED epitaxy 1 and a phosphor plate 2, the LED epitaxy 1 includes a growth substrate 11 and a light-emitting layer 12 grown on the growth substrate 11, wherein the light-emitting layer 12 includes N-GaN layers 121 arranged in sequence , a quantum well layer 122 and a P-GaN layer 123, wherein the N-GaN layer 121 is connected to the growth substrate 11.

[0056] The growth substrate 11 is one of a sapphire substrate, a silicon carbide substrate, a silicon substrate or a gallium nitride substrate, and the growth substrate is selected according to actual needs.

[0057]Wherein, the fluorescent plate 2 is formed by mixing fluorescent powder and a transparent high-temperature-resistant material. Specifically, the transparent high-temperature-resistant material is sapphire, glass, quartz crystal or silicon carbide. The phosphor is one or mor...

Embodiment 2

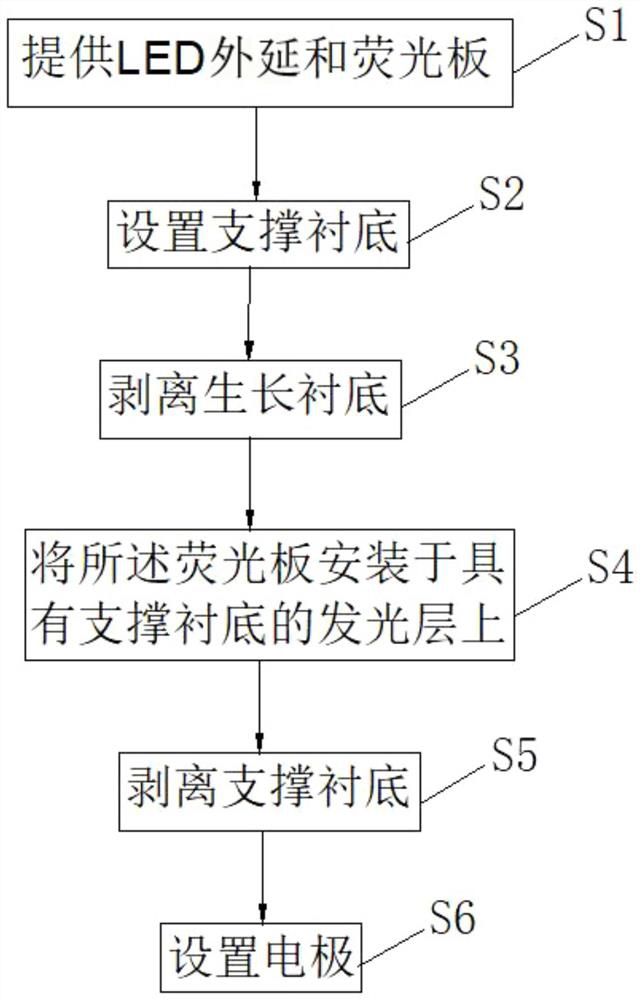

[0065] Such as Figure 3-5 As shown, this embodiment, as an improved implementation of the first embodiment, solves the problem that the luminous efficiency and the light uniformity of the white LED chip cannot be maximized.

[0066] A method for manufacturing a white light LED chip, comprising the following steps:

[0067] S1. Provide an LED epitaxy 1 and a phosphor plate 2, the LED epitaxy 1 includes a growth substrate 11 and a light-emitting layer 12 grown on the growth substrate 11, wherein the light-emitting layer 12 includes N-GaN layers 121 arranged in sequence , a quantum well layer 122 and a P-GaN layer 123, wherein the N-GaN layer 121 is connected to the growth substrate 11.

[0068] The growth substrate 11 is one of a sapphire substrate, a silicon carbide substrate, a silicon substrate or a gallium nitride substrate, and the growth substrate is selected according to actual needs.

[0069] Wherein, the fluorescent plate 2 is formed by mixing fluorescent powder and ...

Embodiment 3

[0078] Such as Figure 6-7 As shown, this embodiment serves as an improved implementation of the above-mentioned embodiment, and solves the problem of low production efficiency of white light LED chips.

[0079] A method for manufacturing a white light LED chip, comprising the following steps:

[0080] S1. Provide an LED wafer 5 and a phosphor plate 2, the LED wafer 5 includes a growth substrate 51, a light emitting layer 52, an ohmic contact layer 53, an insulating layer 53, and an electrode layer 55 arranged in sequence, wherein the light emitting layer The number of 52 is at least one, which includes an N-GaN layer, a quantum well layer and a P-GaN layer arranged in sequence, wherein the N-GaN layer is connected to the growth substrate.

[0081] The growth substrate 51 is one of a sapphire substrate, a silicon carbide substrate, a silicon substrate or a gallium nitride substrate, and the growth substrate is selected according to actual needs.

[0082] Wherein, the fluores...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com