Damping sleeve for metal pipe vibration and noise reduction and coating method

A vibration and noise reduction, metal pipe technology, applied in the direction of pipes/pipe joints/fittings, pipe elements, springs, etc., can solve problems such as complex construction, reduced vibration and noise reduction effects, complex production processes, etc., to achieve construction quality and Improve construction efficiency, ensure vibration reduction effect, and ensure the effect of coverage area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The invention relates to a damping sleeve used for vibration and noise reduction of metal pipelines and a cladding method.

[0026] The outer diameter of the metal pipeline is set as D, and the diameter of D can reach Φ30-Φ300mm.

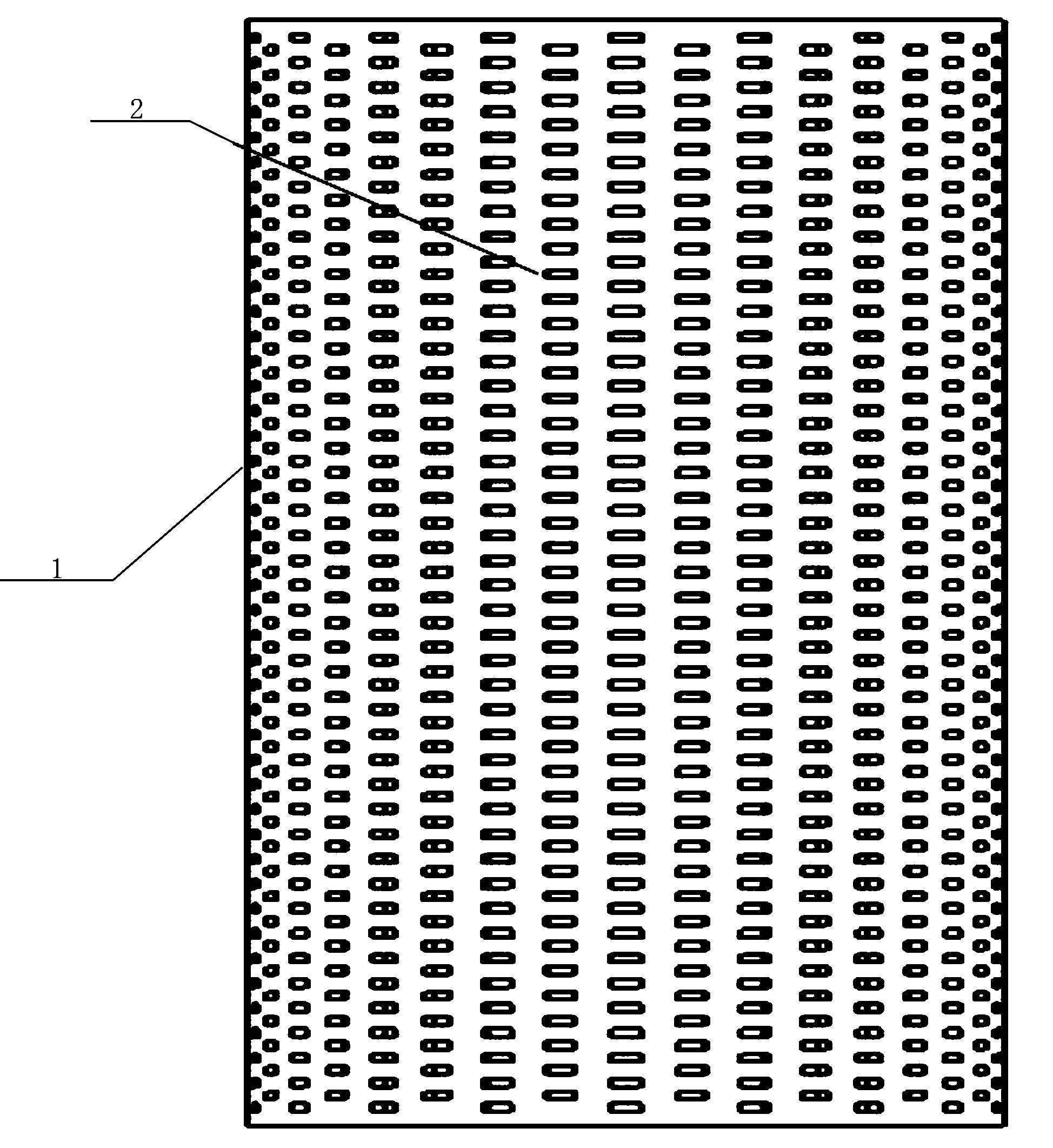

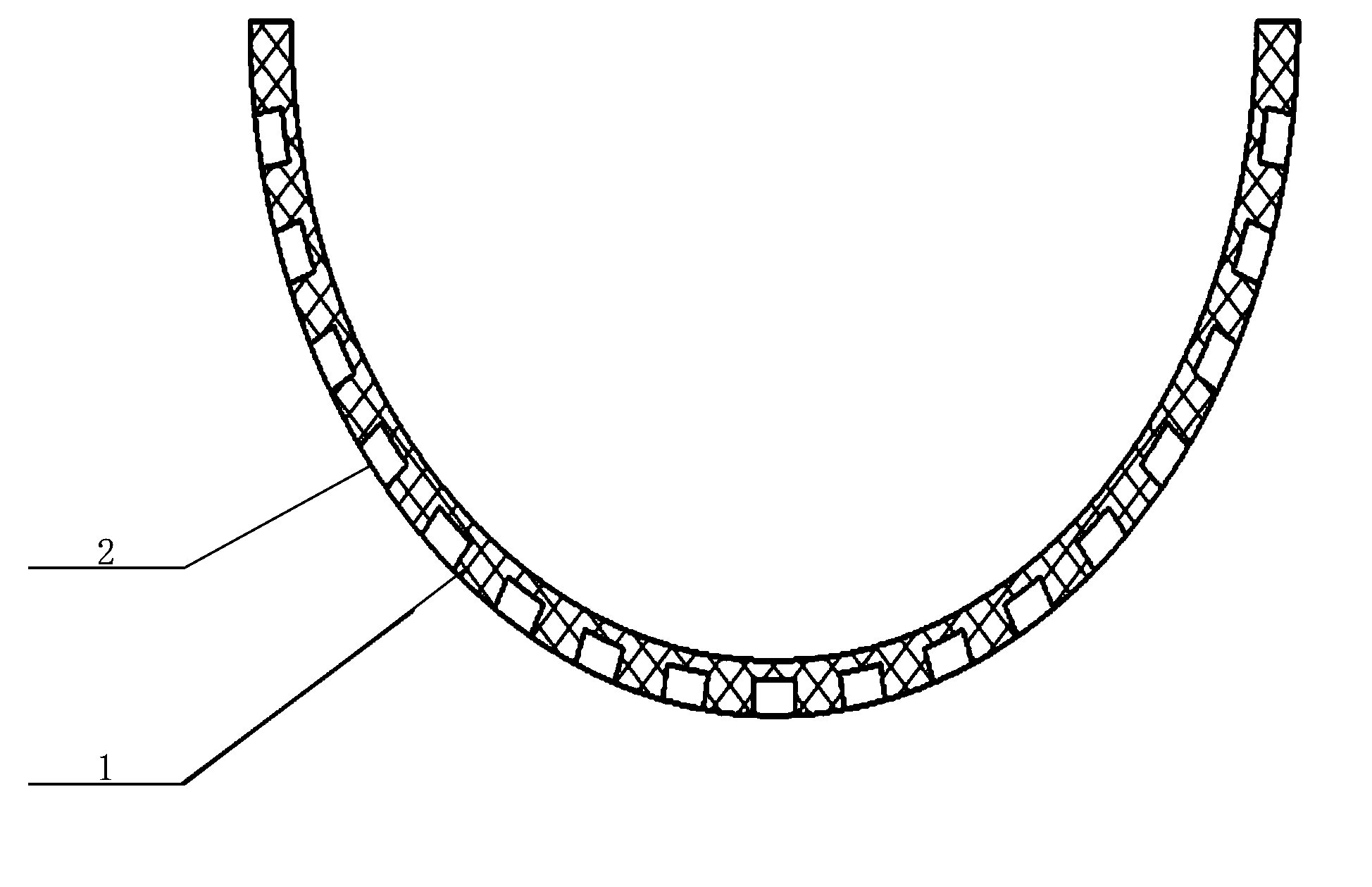

[0027] combine Figure 1-2 , the damping sleeve 1 with a thickness of T is mostly semi-cylindrical and made of rubber material. The material is either neoprene, nitrile rubber, or polyurethane rubber, and an anti-aging agent is added to the rubber material.

[0028] The inner diameter of the multi-semi-cylindrical shape matches D, the expanded width of the multi-semi-cylindrical shape is ≥3лD / 4, and several cavity holes 2 are arranged on the outer surface of the damping sleeve, and several cavity holes 2 are arranged along the damping sleeve The axial direction of the pipe 1 is arranged in several rows, the distance between two adjacent cavity holes in each row is equal to K, and the distance between the cavity holes in adjacent rows is als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com