Combined cool storage plate

A cold storage plate and combined technology, which is applied to impact-sensitive items, types of packaging items, special packaging items, etc., can solve the problems of irregular placement, thickness of the cold storage plate, uneven cooling transmission, etc., to ensure quality, Reduced volatility, cooling release and uniform transfer effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below with reference to the drawings and examples.

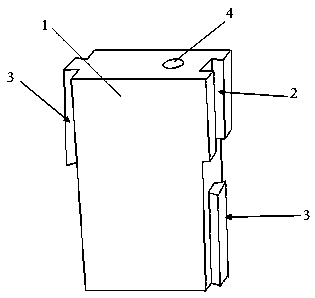

[0019] like figure 1 As shown, in the combined cold storage plate of the present invention, it includes: a shell body 1, which constitutes the main body of the cold storage plate; the above shell body is a hollow plate structure, forming a hollow cold storage agent filling space inside the shell body; The arrangement structure of the guide groove 2 and the guide rail 3 is set on the side, and the arrangement structure of the guide rail and the guide groove whose shape, size and position are matched with the above-mentioned arrangement is set on the other side of the shell body; the top end of the side of the shell body The width is greater than the width of the base, forming a wedge-shaped structure. An acute angle is formed between the front and back of the cold storage plate, so that the cold storage plate can be inserted into the article.

[0020] The guide groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com