Patents

Literature

471results about How to "Affect the use effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Macromolecule leak-proof mending material and leak-proof tyre containing the same

InactiveCN101139516APlay a leak-proof effectExtended missionTyre partsOther chemical processesElastomerDynamic balance

The invention discloses a high polymer anti-leakage dense patching material, which comprises by weight hot plastic elastomer 40-60%, thickener 40-60%, softening agent 08%, anti-aging agent 0-2%, catalyst 0-1%, and filling agent 0-15%. The invention also discloses an anti-leakage tyre containing above mentioned high polymer anti-leakage dense patching material, which can efficiently prevent tyre from air leakage and tyre bursting due to pricking of the tyre, guarantee safety in running of vehicles and prolong the service life of tyres. And the use effect of the tyres will not be affected due to the machining (for example dynamic balancing, operation, braking, comfortableness and load bearing capacity, etc.).

Owner:陈芳

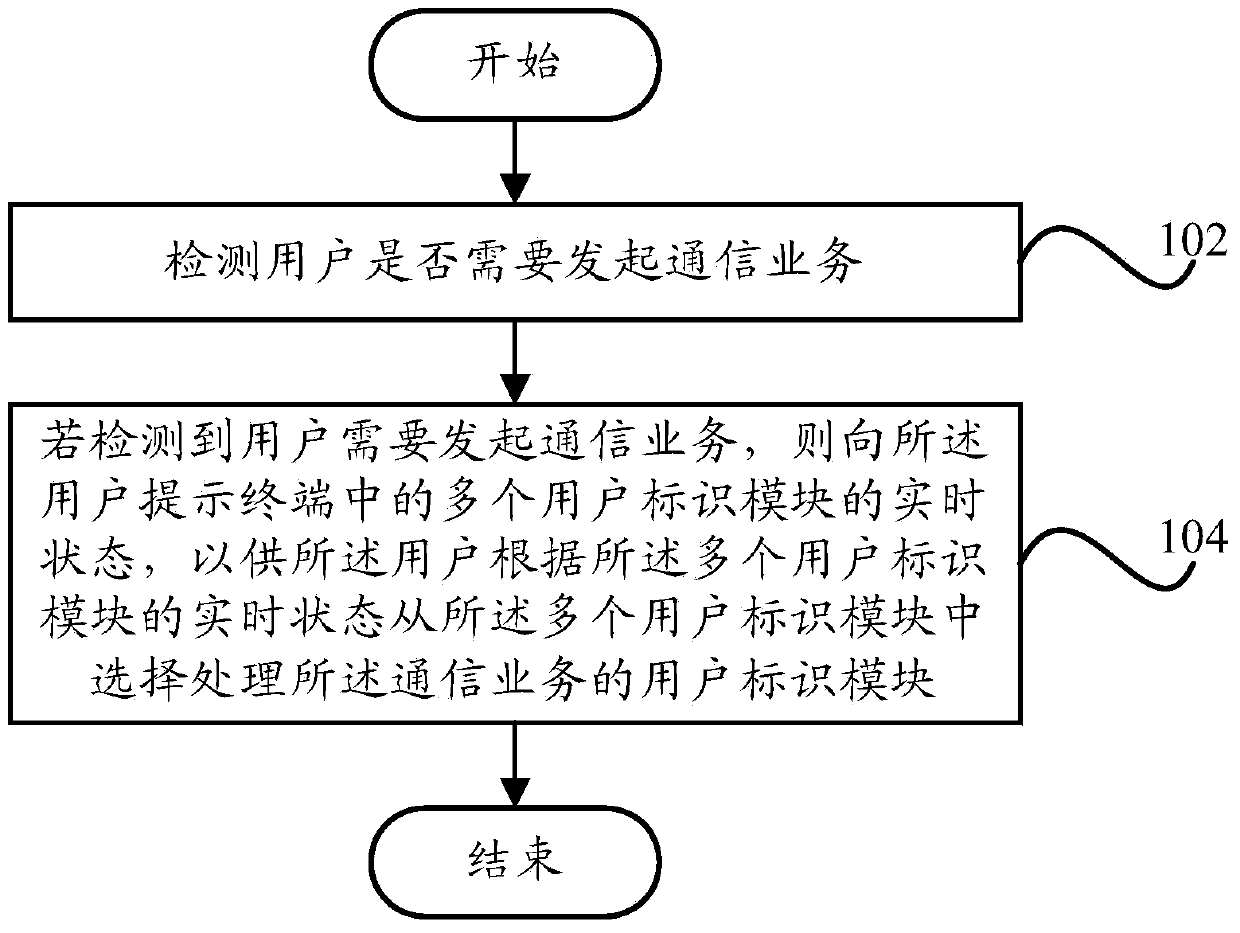

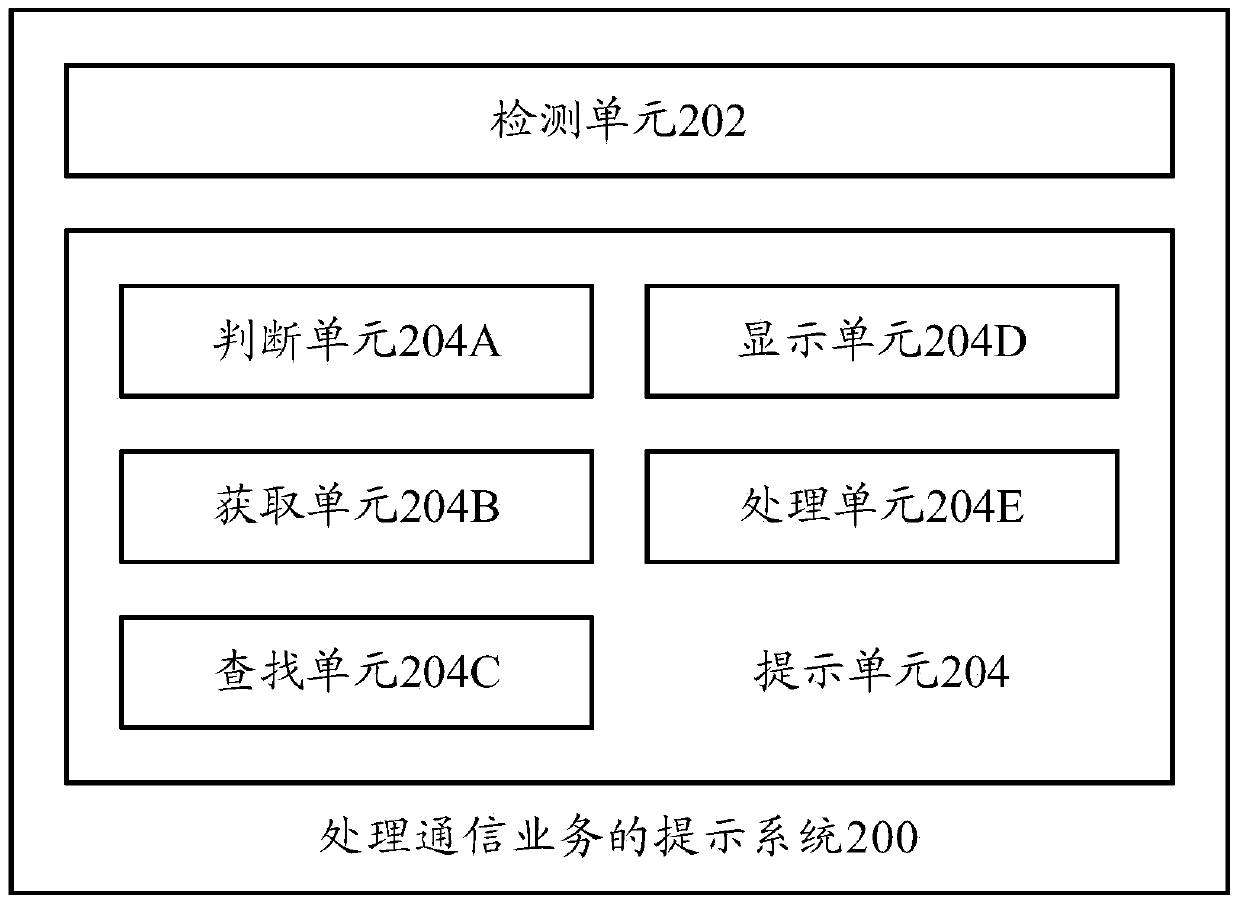

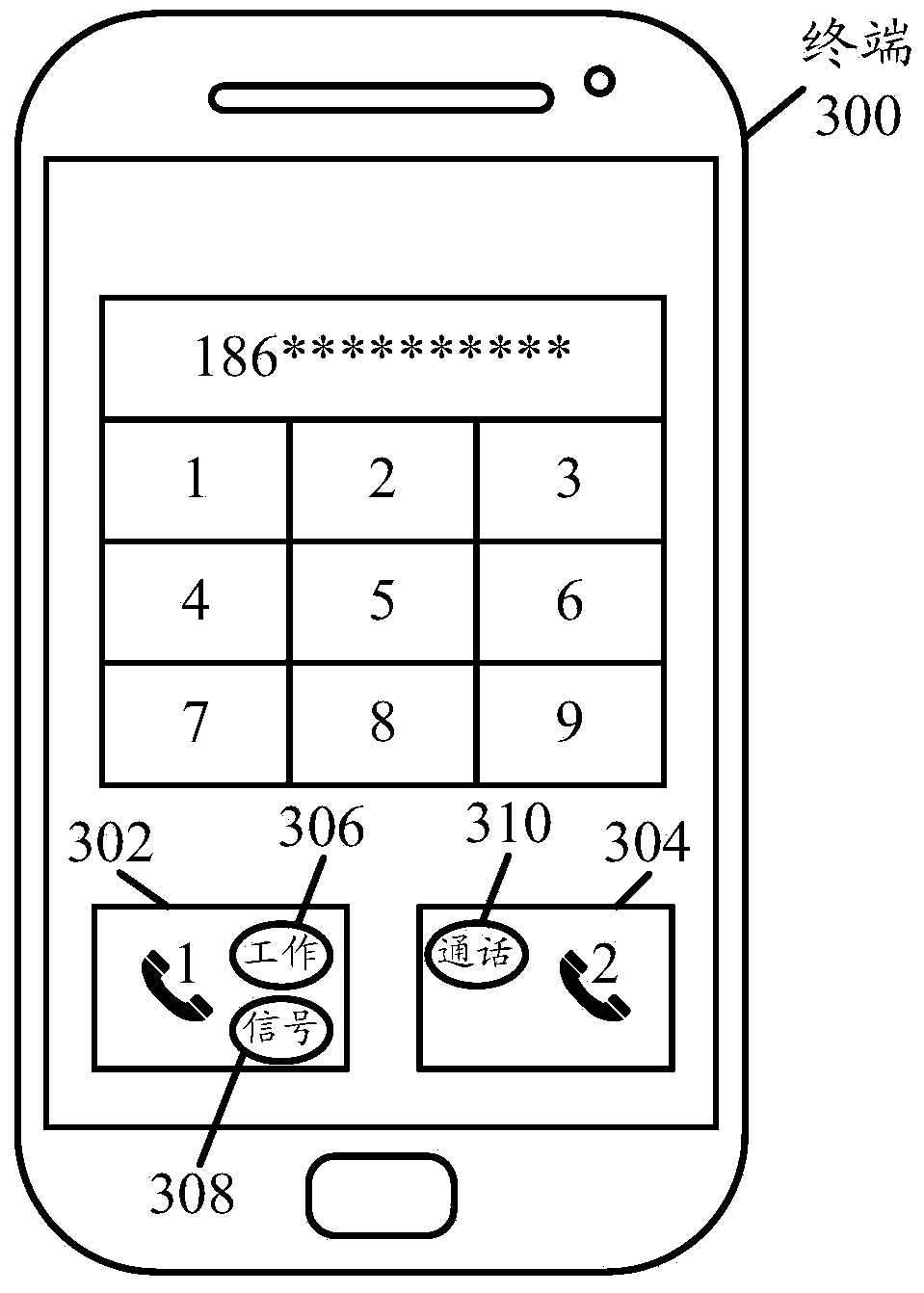

Prompting method, prompting system and terminal for processing communication service

ActiveCN103747152AAffect the use effectIntuitive graspSpecial service for subscribersUser needsComputer terminal

The invention provides a prompting method for processing communication service, a prompting system for processing the communication service and a terminal. The prompting method for processing the communication service comprises the following steps of detecting whether a user needs to initiate the communication service or not; prompting the real-time state of a plurality of user identity modules in the terminal to the user if the user needs to initiate the communication service, so that the user can select the user identity module from multiple user identity modules to process the communication service according to the real-time state of the user identity module. Through the technical scheme, the state information of each SIM (subscriber identity module) card can be intuitively and clearly controlled by the user, so that the appropriate SIM card is conveniently selected to process the communication service, and the loss caused by mistake selection of the SIM card can be avoided.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

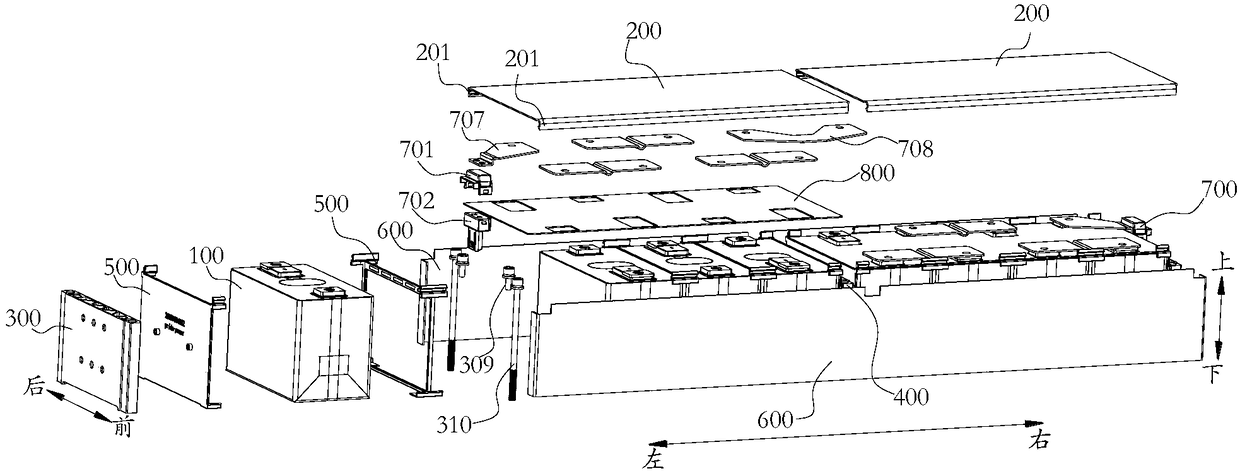

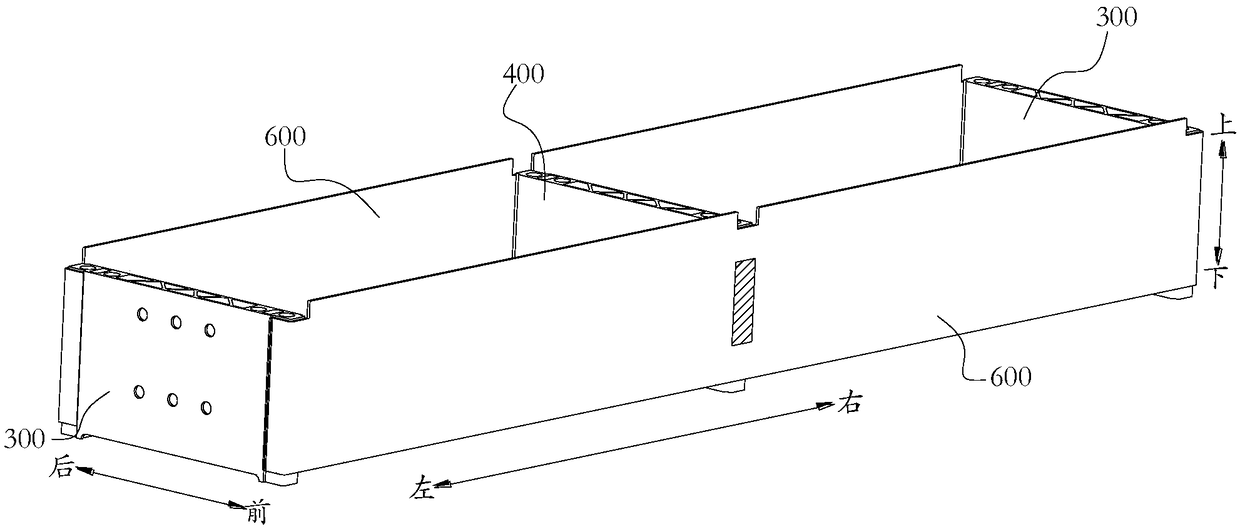

Power battery module of electric vehicle and electric vehicle

PendingCN108520928ACompact structureIncrease the lengthPropulsion by batteries/cellsCell component detailsPower batteryElectrical battery

The invention relates to a power battery module of an electric vehicle and an electric vehicle. The power battery module comprises cells, an upper cover, a middle end plate, two oppositely arranged end plates, and two oppositely arranged lateral plates. Two end plates are respectively welded to two lateral plates to form a shell without any bottom surface or a top surface. The middle end plate iswelded to two lateral plates so as to divide the interior of the shell into at least two installation cavities. Multiple cells are installed in each installation cavity. The upper cover is arranged onthe upper end of the shell. The overall installation structure is formed by connecting the middle end plate, the end plates, and the lateral plates, the number of stored cells is increased, the number of stored cells is equal to the number of cells of two or more individual modules, compared with two or more individual modules, the size is reduced in the length direction, the module length is increased, the occupied space is small, the uniformity of the module is increased, the inner space is saved, the whole structure of the module is more compact, the space utilization rate is increased, and thus the energy density and capacity of the whole battery system are both increased.

Owner:江苏和中普方新能源科技有限公司

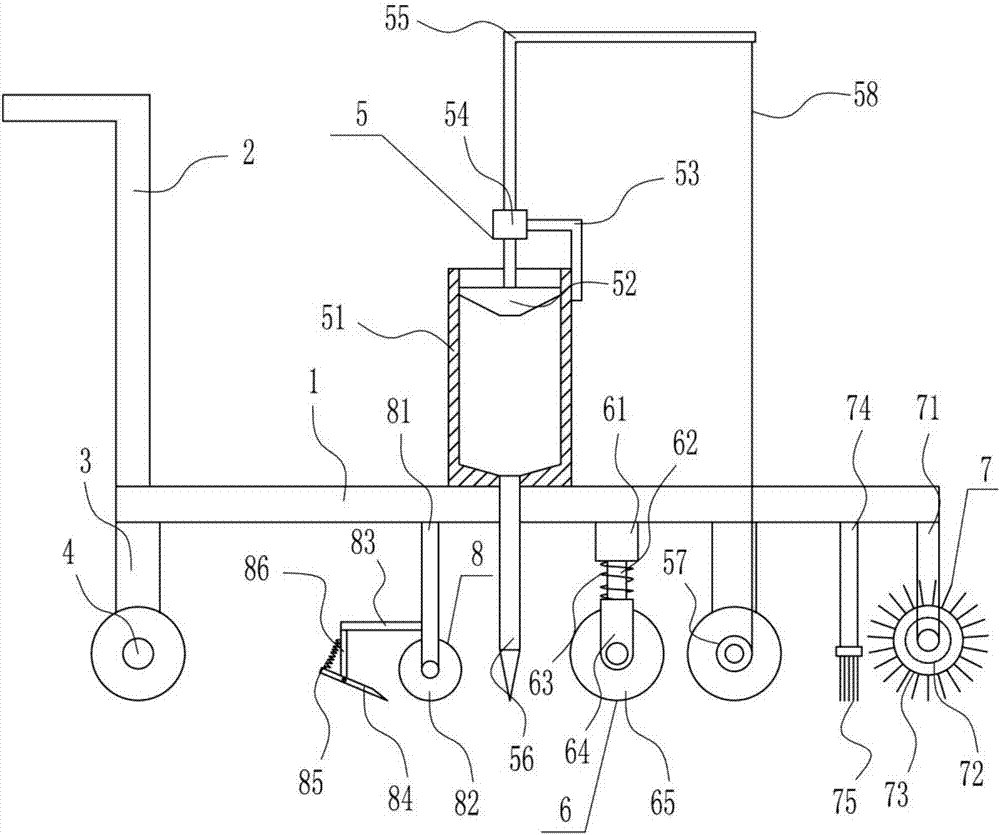

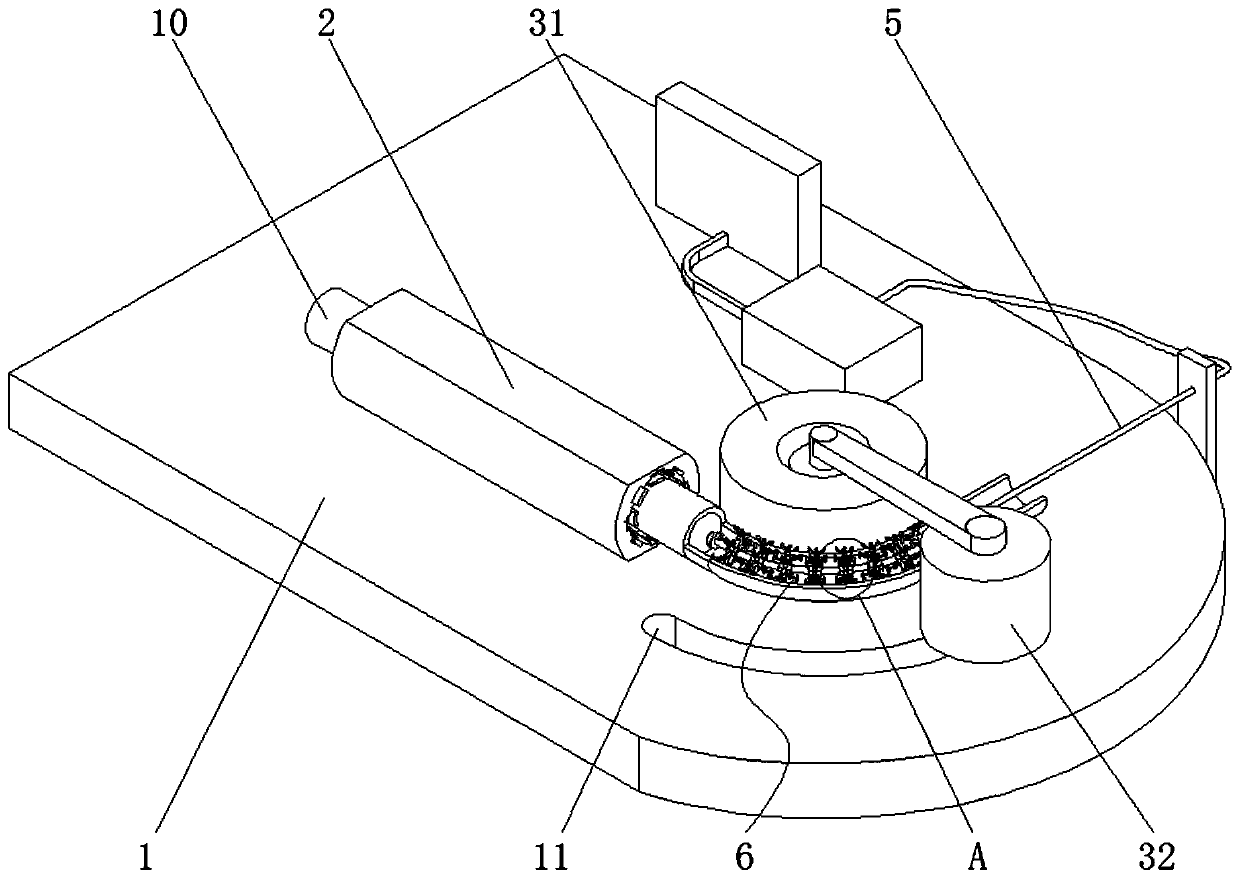

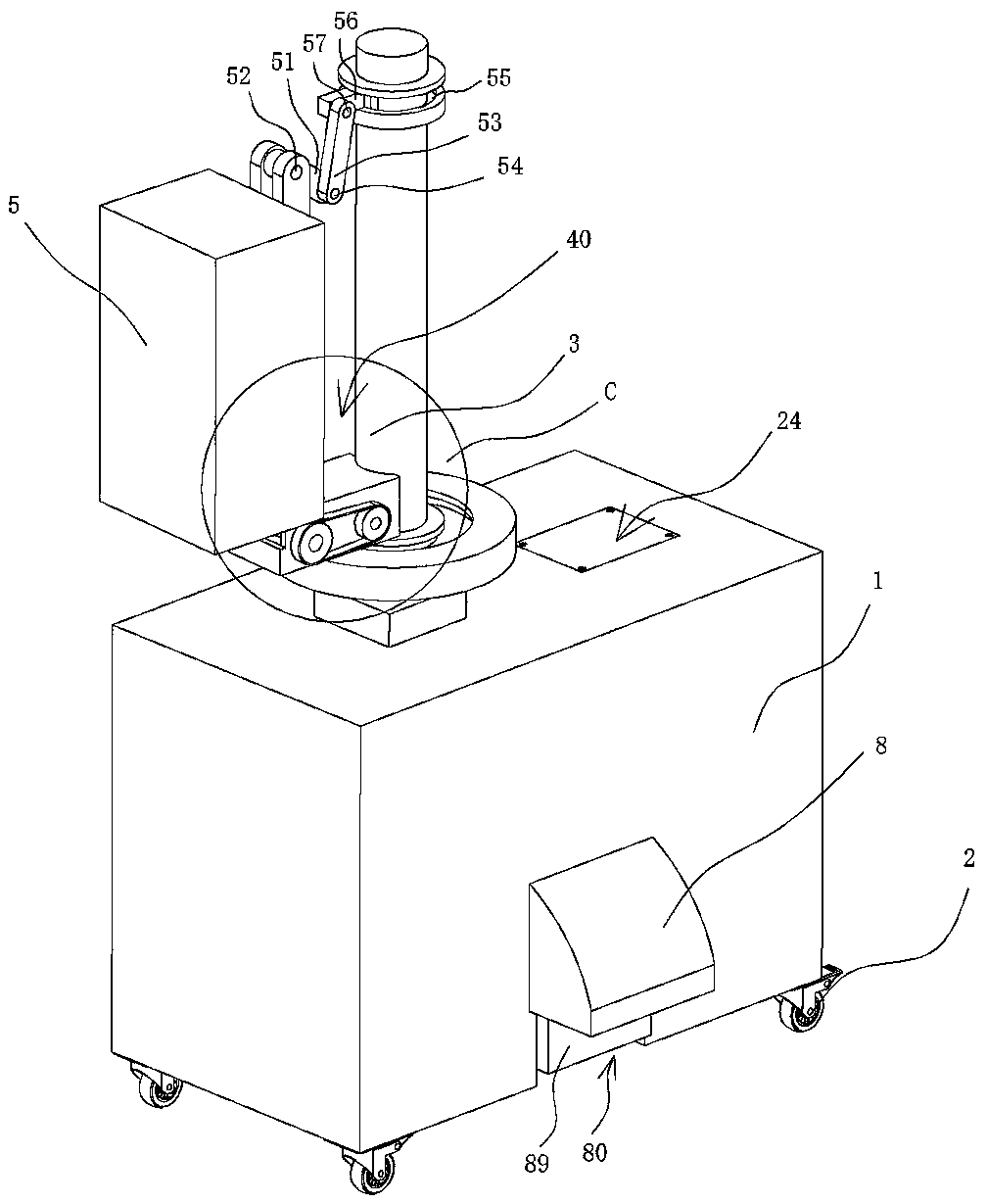

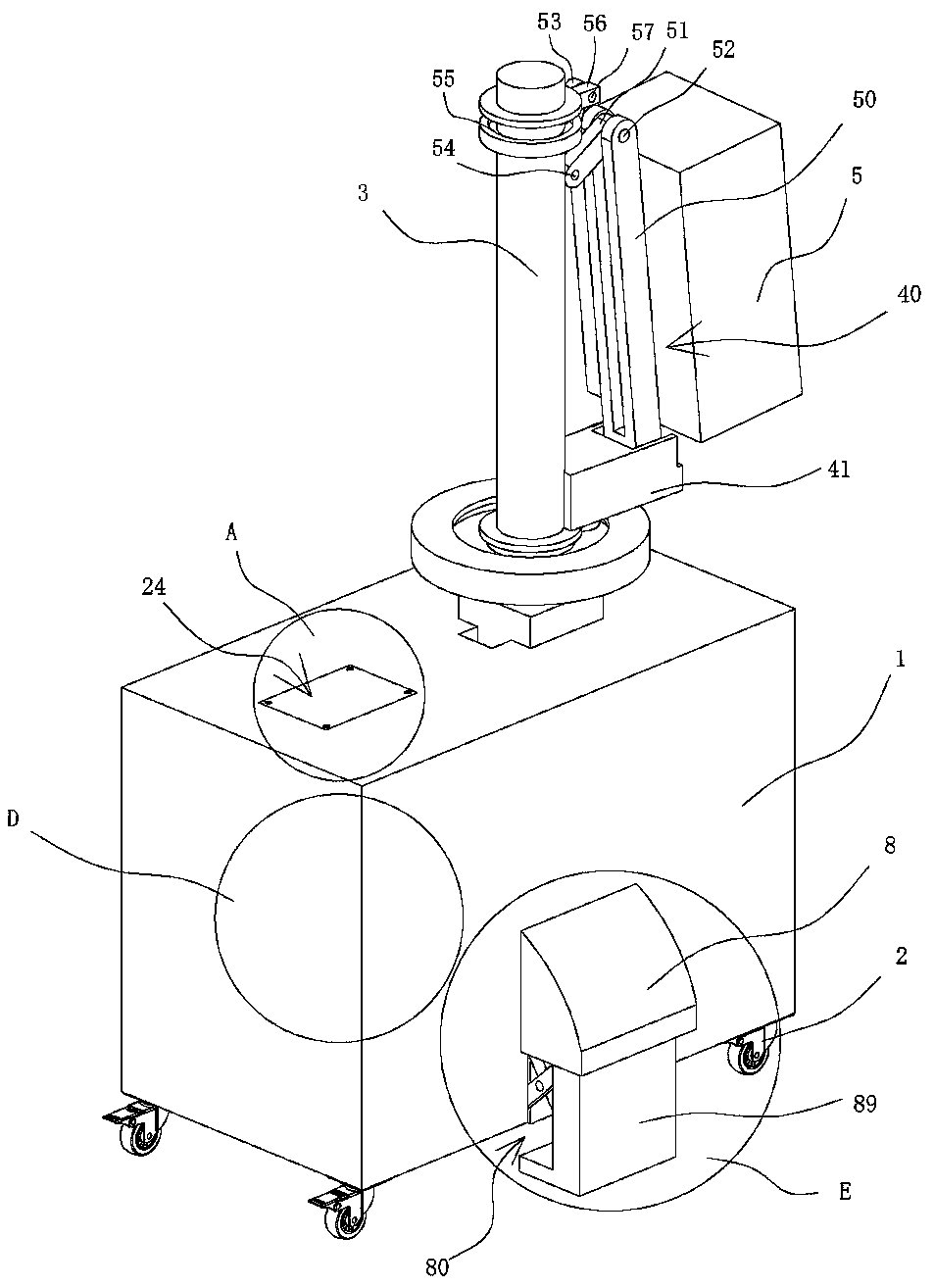

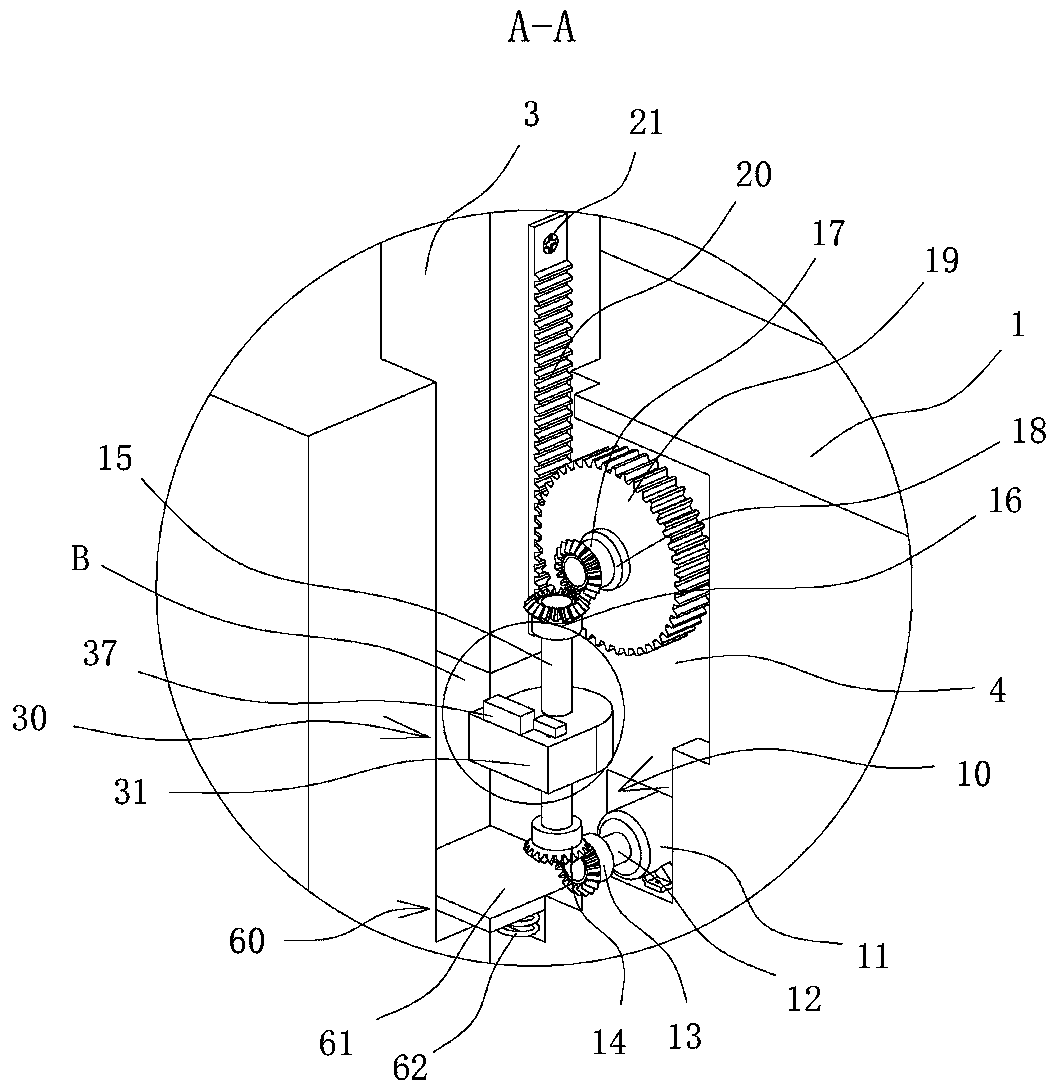

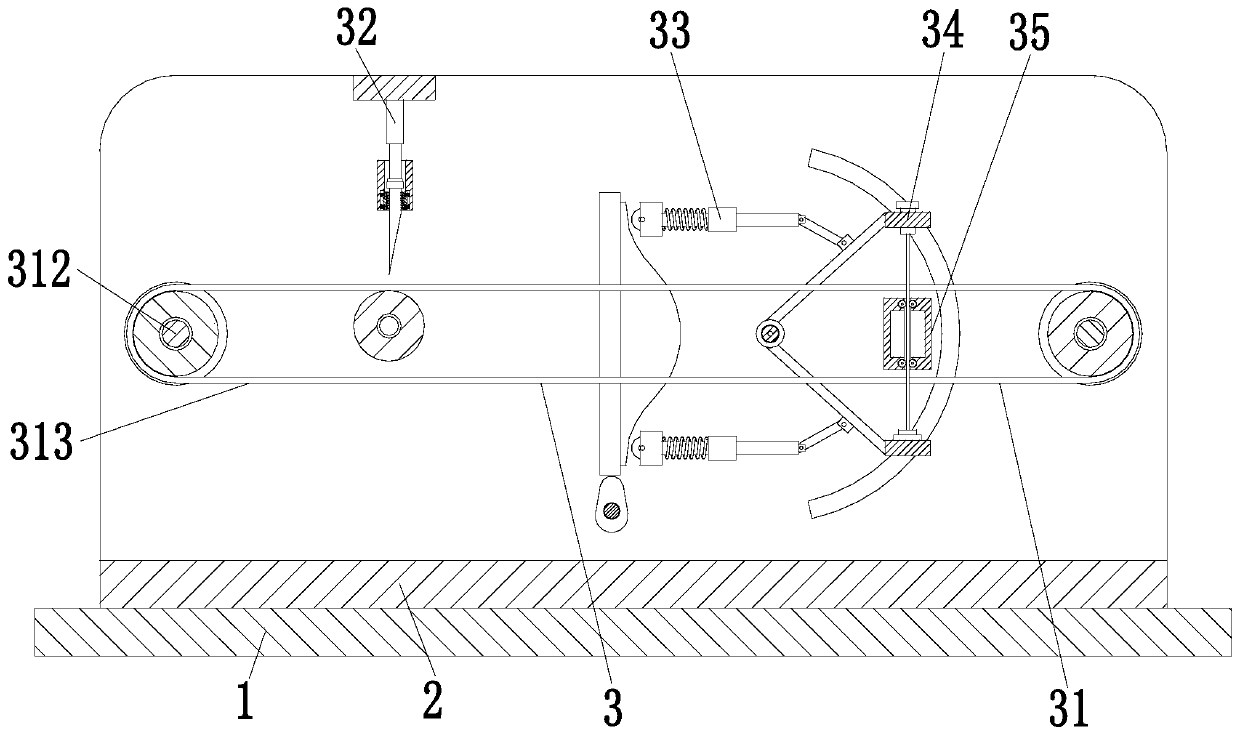

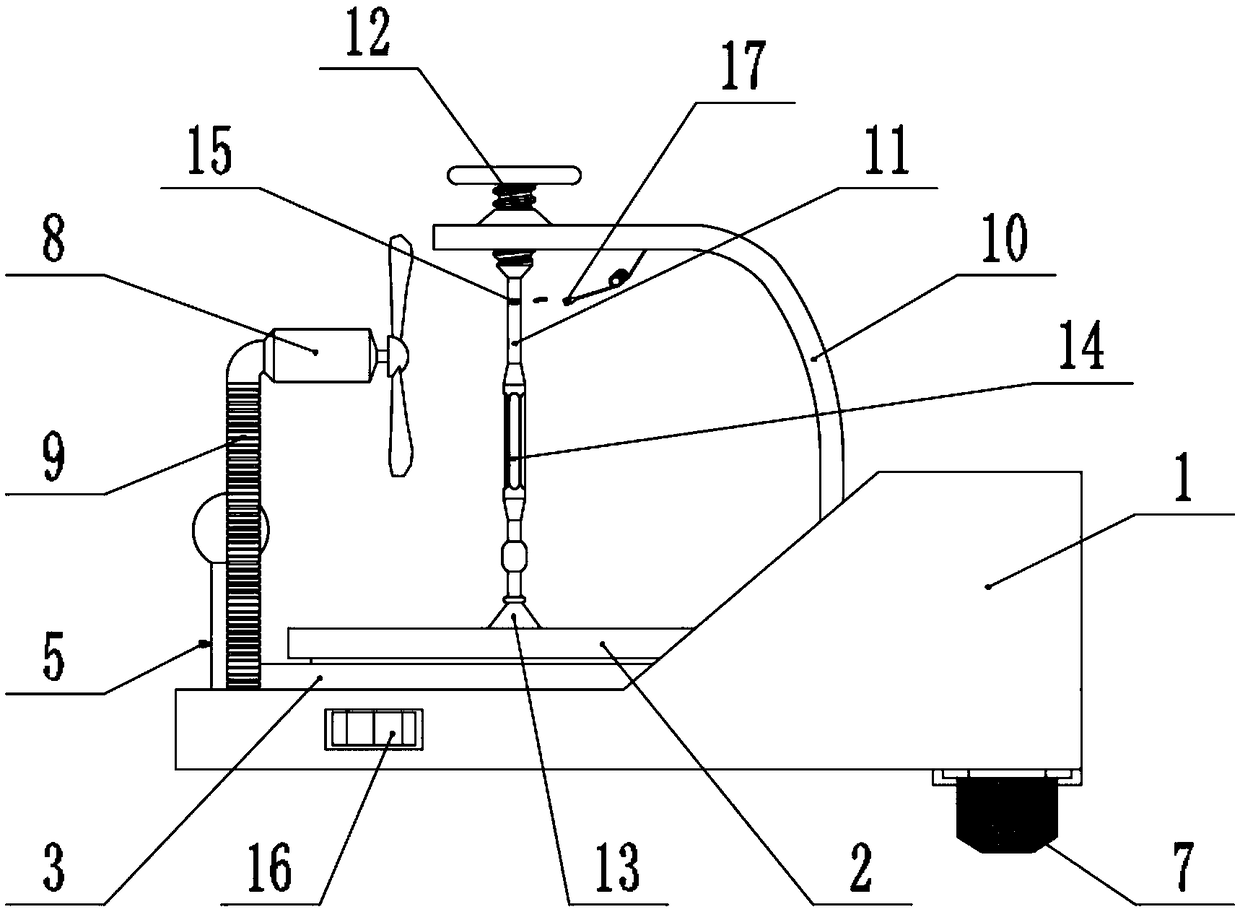

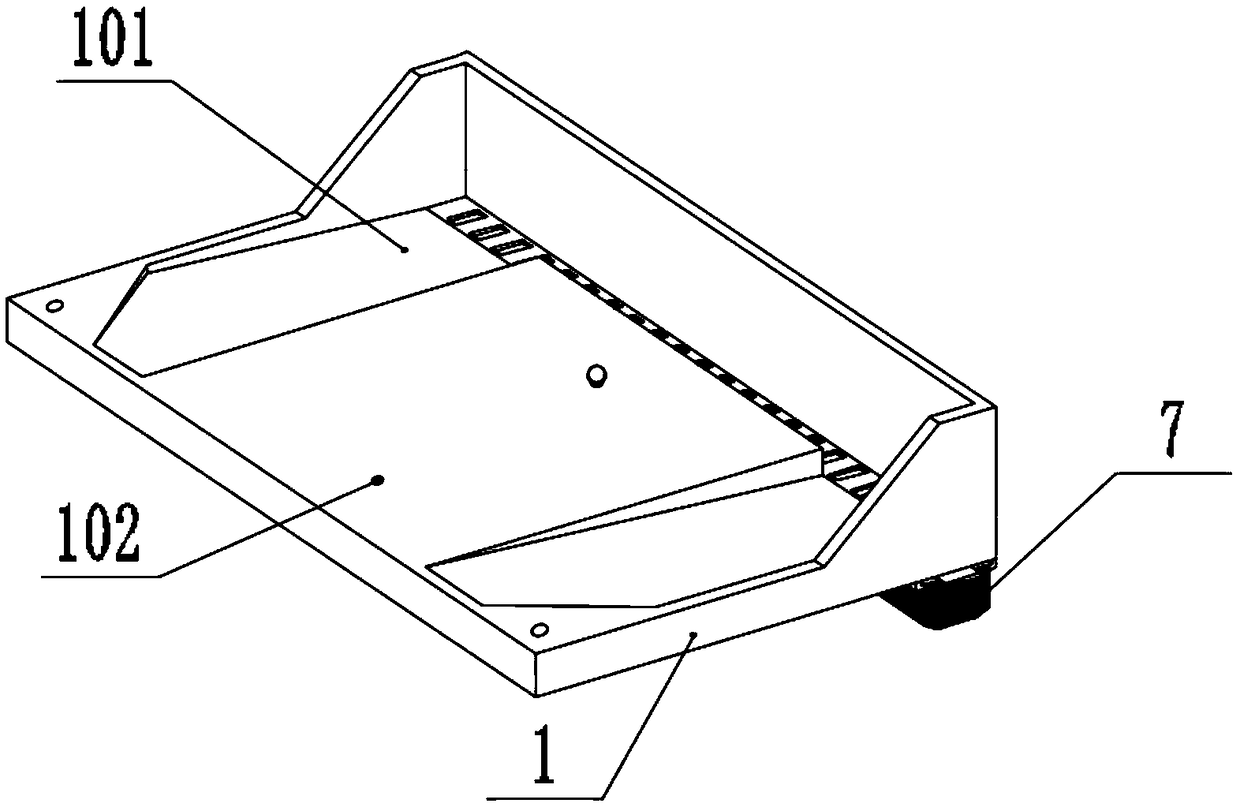

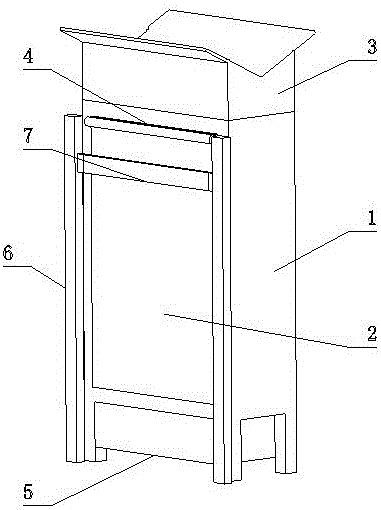

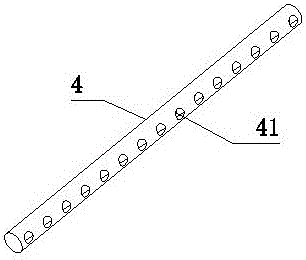

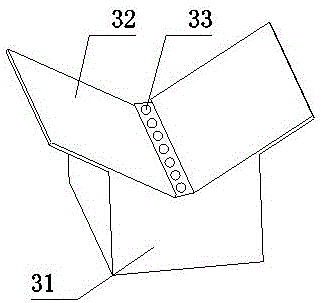

Tile base plate caulking device for house decoration

The invention relates to a caulking device, in particular to a tile base plate caulking device for house decoration. Against the technical problems to be solved, the invention provides the tile base plate caulking device for house decoration, which saves time and labor, can remove impurities in gaps, can also remove overflowing caulking adhesive without affecting attractiveness of tiles and can also make the caulking adhesive dried more quickly. In order to solve the technical problem, the invention provides the tile base plate caulking device for house decoration, which includes a base plateand the like. Vertical rods are mounted on the left side and the right side of the top of the base plate, wheels are rotatably mounted at the bottom ends of the vertical rods, a pushing hand is mounted on the left side of the top of the base plate, the right side of the bottom of the base plate is provided with a guide device, the guide device is located on the left side of the vertical rod on theright side, and the middle of the top of the base plate is provided with an adhesive-spraying device. According to the tile base plate caulking device for house decoration, through a leveling device,not only can the caulking adhesive be leveled, but also the overflowing caulking adhesive be removed. A drying device can dry the caulking adhesive to achieve effects of time saving and labor saving.

Owner:戚展鹏

Bactericidal laundry detergent containing traditional Chinese medicine components and preparation method thereof

InactiveCN104178370AAvoid stratificationChange mobilityOrganic detergent compounding agentsAmpholytes/electroneutral surface-active compoundsBetaineGlycan

The invention discloses a bactericidal laundry detergent containing traditional Chinese medicine components. The bactericidal laundry detergent containing traditional Chinese medicine components comprises the following raw materials in parts by weight: 10-20 parts of benzalkonium bromide, 20-25 parts of fatty alcohol-polyoxyethylene ether, 20-25 parts of glycine betaine, 1-6 parts of potassium sorbate, 1-4 parts of sodium alginate, 1-4 parts of glycan, 10-35 parts of deionized water, 2-10 parts of a pH adjusting agent and 2-5 parts of a traditional Chinese medicine extract, wherein the traditional Chinese medicine extract is an extract with a concentration of 2g / ml; the extract is prepared from rheum officinale and radix scutellariae according to a mass ratio of (2-3) to 1. The bactericidal laundry detergent containing traditional Chinese medicine components has the advantages of good bactericidal and antibacterial effects and strong cleaning power.

Owner:CHENGDU SHUNFA DISINFECTANT & WASHING TECH

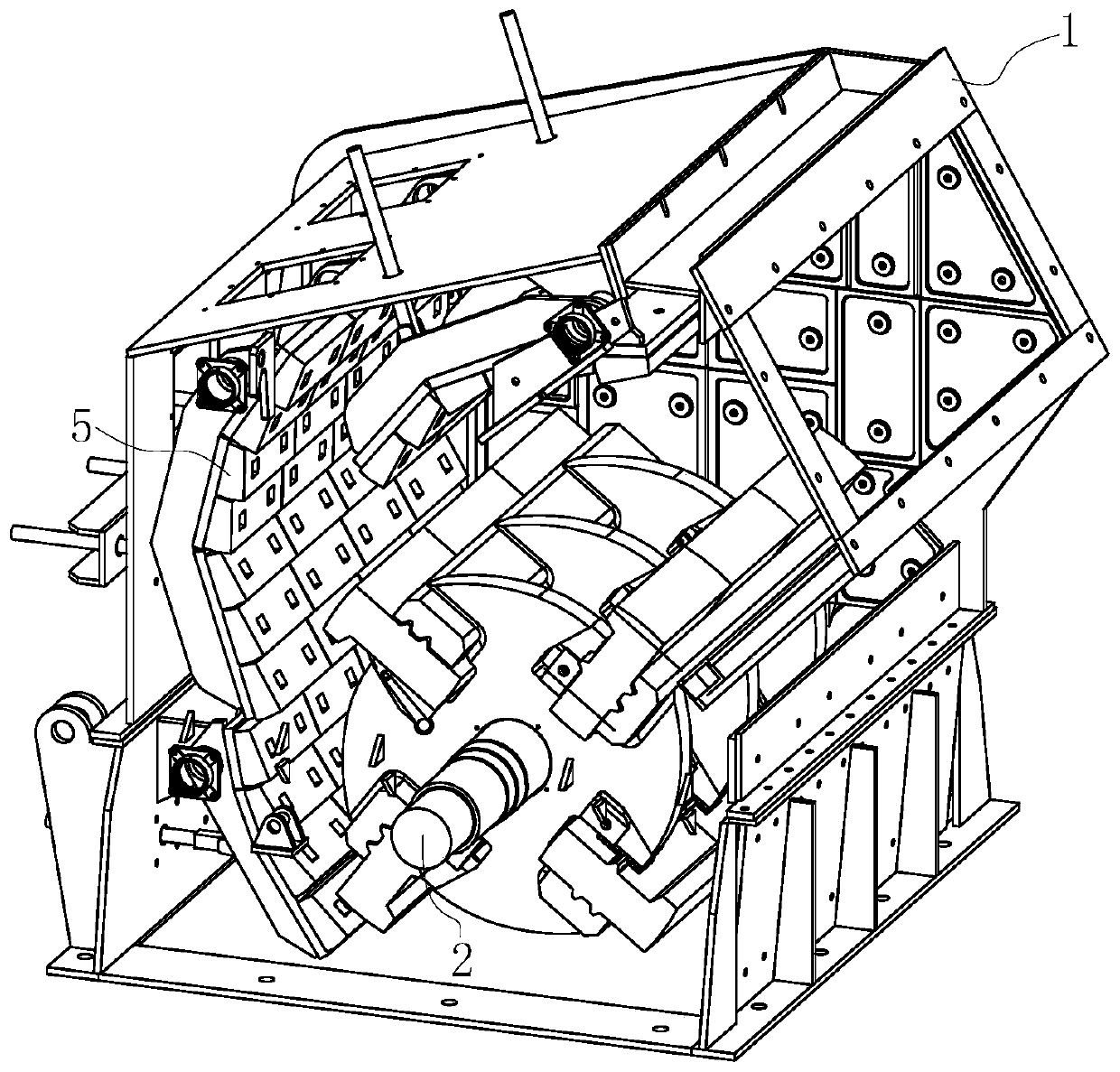

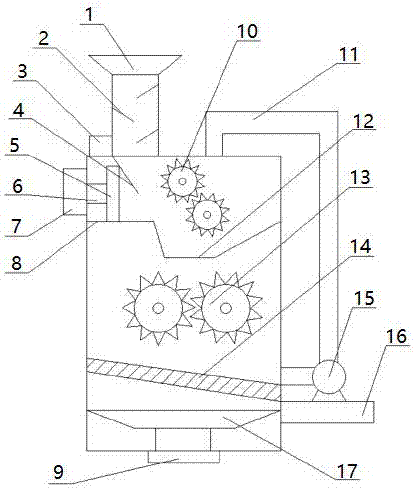

Mineral mining crusher for mine

The invention belongs to the technical field of crusher, and particularly relates to a mineral mining crusher for a mine. The mineral mining crusher comprises a rack and an impact plate, wherein a rotor is arranged in the rack, a rotating shaft frame uniformly sleeves the rotor, and plate hammers are arranged on the rotating shaft frame; the impact plate is connected with the rack through an impact frame, elastic wear-resistant blocks are uniformly arranged at the bottom end of the impact plate in the horizontal direction, elastic wear-resistant rubber plates are arranged on one side faces ofthe plate hammers, and wear-resistant steel balls are arranged in the elastic wear-resistant rubber plates; and elastic wear-resistant rods are supported on the other side surfaces of the plate hammers, the end parts of the elastic wear-resistant rods are hinged in installation grooves through hinge columns, and the end parts of the plate hammers are in extrusion contact with the elastic wear-resistant blocks during rotation. The impact force on the impact plate by materials can be increased by the upward swinging plate hammers, so that the impact crushing effect of the materials is effectively improved; the elastic wear-resistant rubber plates generates shrinkage vibration when the plate hammers swing upwards, so that the phenomenon that the viscous materials are adhered to the outer surface of the plate hammers during the crushing is effectively avoided.

Owner:HUNAN XIANGQIAN IND

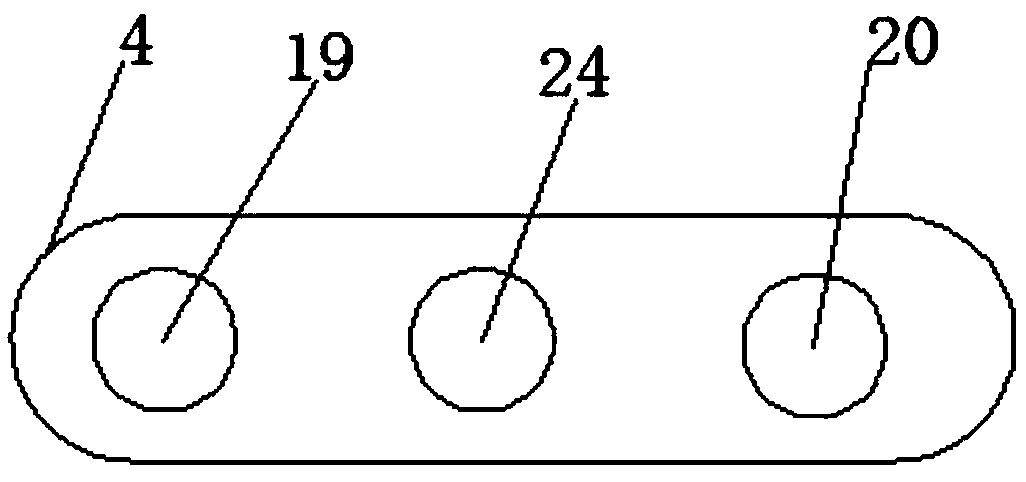

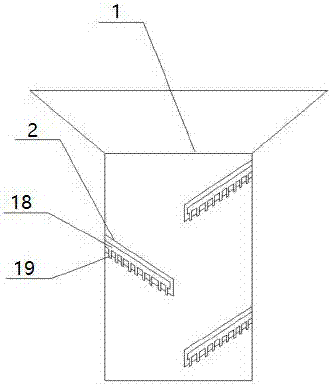

Dust removal device for spring production

The invention discloses a dust removal device for spring production. The dust removal device comprises a dust removal chamber, a dust collection hopper and an air inlet, wherein an air inlet pipe is arranged at the bottom of the air inlet; an air blower is arranged on the air inlet pipe; the air inlet pipe penetrates through the air blower; one end of the air inlet pipe is connected with the dustremoval chamber; a control panel is arranged at the left middle of the dust removal chamber; a first filter screen and a second filter screen are arranged on the left and right sides of the top of thedust removal chamber respectively; a dust falling port is formed in the bottom of the dust removal chamber; a valve A is arranged on the dust falling port; an air outlet is formed in the middle of the right side of the dust removal chamber. According to the dust removal device disclosed by the invention, relatively large metal dust particles are subjected to primary filtration through the firstfilter screen and the second filter screen in the dust removal chamber; adsorption settlement is formed at the moment of sufficient contact between metal dust and water through a water storage tank atone end of the air guide pipe, thus, thorough removal of the metal dust is facilitated, the using effect of the dust removal effect is improved, and the dust removal device is relatively practical and suitable for wide popularization and application.

Owner:NANJING LISHUI LIHUA SPRING FACTORY

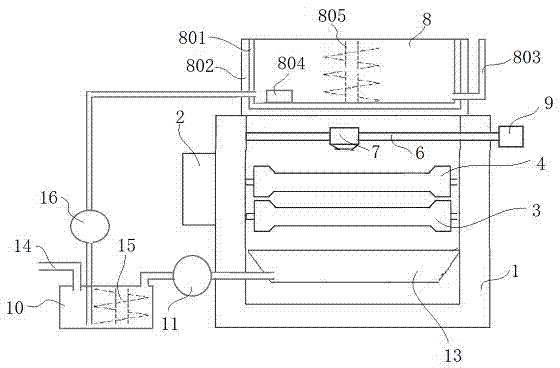

Soundproof-cotton gluing machine application method

ActiveCN104722450AImprove uniformityQuality improvementLiquid surface applicatorsCoatingsAdhesive glueLeather belt

The invention discloses a soundproof-cotton gluing machine application method and belongs to the technical field of gluing machines. The soundproof-cotton gluing machine application method includes the steps of 1), equipment starting, namely respectively starting a gluing mechanism, a glue discharging mechanism, a recycling mechanism and a belt conveying mechanism on a soundproof-cotton gluing machine; 2), gluing, namely allowing glue flowing out from a glue discharging device to flow down along a gap between a gluing roller and a glue mixing roller and a to-be-glued rubber skin to be driven by the gluing roller to move sequentially in gaps of between a glue applying roller and the glue roller as well as between the glue applying roller and the glue mixing roller for gluing; 3), gluing completion, namely allowing the rubber skin coated with the glue to be conveyed to the tail portion of a conveying platform through a conveying belt, wherein the lower surface of the rubber skin is in friction contact with the upper surface of a cushion block, movement speed of the rubber skin is reduced, the rubber skin is taken away by workers, and gluing is completed. With the method, problems that gluing is uneven, waste glue cannot be effectively recycled and the like are solved.

Owner:河北蓝格隔音材料有限公司

Material rapid crushing device

The invention discloses a material rapid crushing device, which includes a crushing shell, a crushing group and a small crushing roller arranged inside the inner body, the small crushing roller is arranged at the upper end of the casing, and a material bearing plate is arranged on the left side of the small crushing roller. A pusher plate is placed above the material plate, the left side of the pusher plate is connected to the push rod, the push rod is connected to the cylinder outside the shell, the upper end of the shell is provided with a feed hopper, and a hot air blower is installed at the connection between the feed hopper and the shell. There is a guide hopper in the middle of the material bearing plate, the crushing group in the shell is located under the guide hopper, the inclined vibrating sieve plate is arranged under the crushing group, the receiving funnel is provided under the vibrating sieve plate, and the receiving funnel is provided under the receiving hopper. At the discharge port, the device of the present invention has an excellent material crushing effect, and is not easy to be blocked during the feeding process. An anti-rust coating is provided on the surface of the crushing parts, which is beneficial to ensure the quality of the crushing materials and the service life of the crushing parts.

Owner:浦江县协盈动物饲料技术开发有限公司

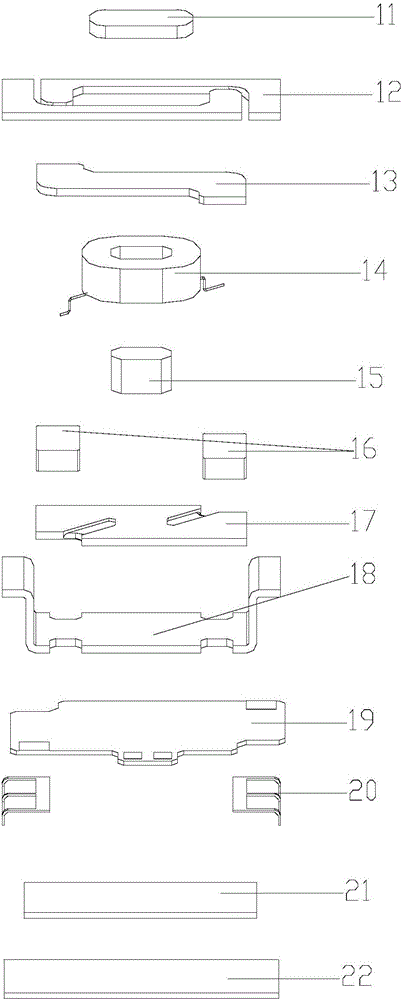

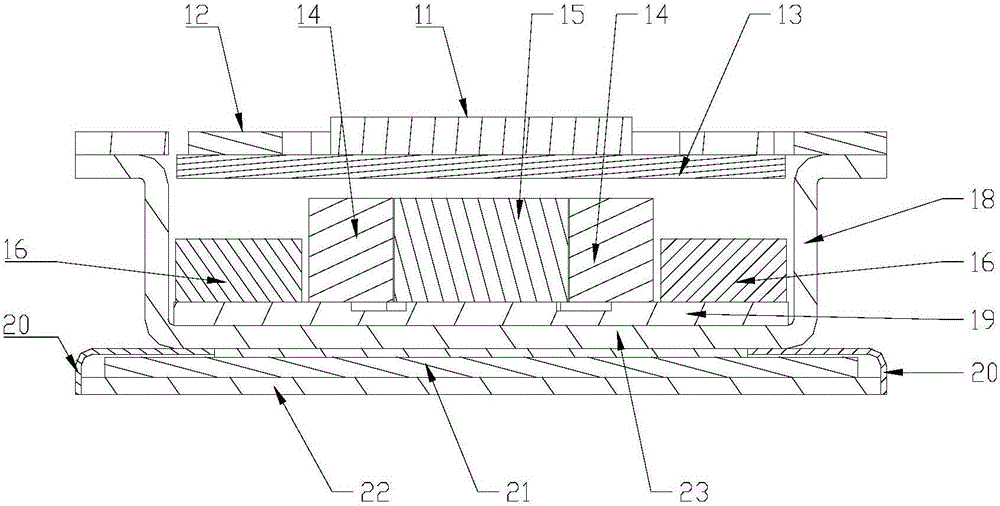

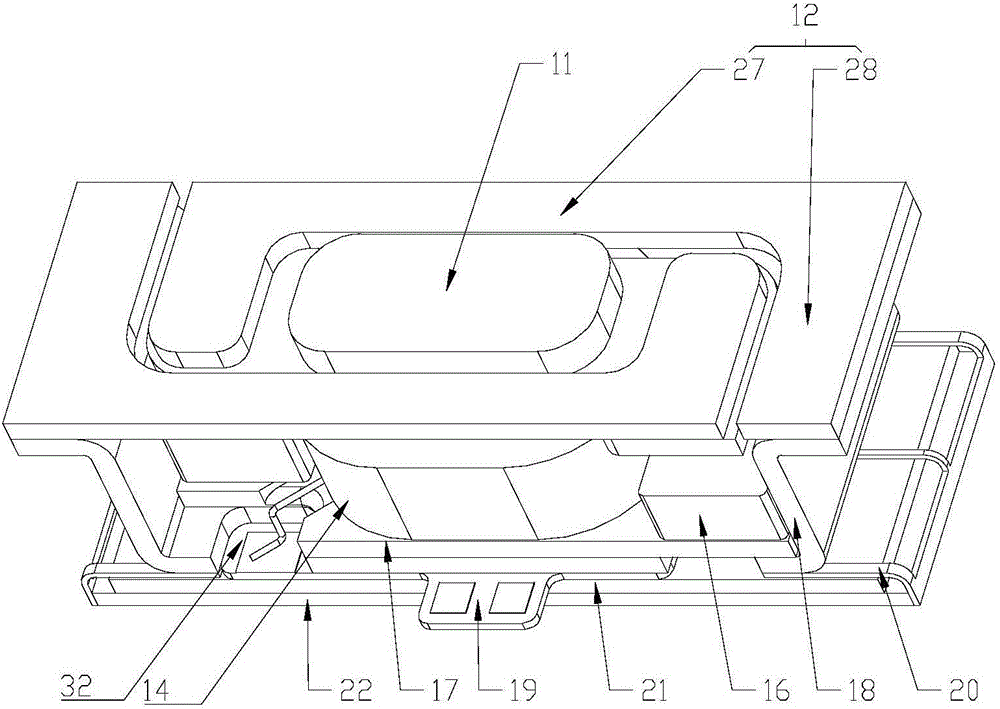

Osteoconductive loudspeaker unit of multi-resonance system

ActiveCN106507252ABroaden the frequency response curveGood sound performanceFrequency/directions obtaining arrangementsLoudspeakerEngineering

The invention discloses an osteoconductive loudspeaker unit of a multi-resonance system. The loudspeaker unit comprises a support, a magnetic circuit system and a vibration system, wherein the magnetic circuit system is arranged on the support; the vibration system comprises a first vibration system and at least one second vibration system, the first vibration system comprises a first elastic sheet, a first washer and a first permanent magnet, the first elastic sheet is connected with the support, the washer is arranged on the first elastic sheet, and the first permanent magnet is arranged on the first washer; and the second vibration system comprises an elastomer and a fixing potion connected together, and the second vibration system is suspended outside a space encircled by the support and the first vibration system. The loudspeaker unit has the characteristic of good low frequency effect.

Owner:GOERTEK INC

Mask plate, organic light-emitting display panel and display device

PendingCN108559948AAffect the use effectAvoid formingVacuum evaporation coatingSolid-state devicesLoudspeakerTransmittance

The invention discloses a mask plate, an organic light-emitting display panel and a display device, so as to improve the problem that transmittance is low at the position where a loudspeaker, a camera, a sensor and other parts are arranged in the AA area because of a light emitting layer of the AA area. The mask plate comprises a shielding part, a frame surrounding the shielding part, and a plurality of first connecting parts for connecting the shielding part and the frame. When the mask plate carries out mask shielding on the light emitting layer of the organic light-emitting display panel, the shielding part is used for shielding a preset area of a display area of the organic light-emitting display panel.

Owner:BOE TECH GRP CO LTD +1

Surface machining device and method aiming at bending metal pipes of small specifications

ActiveCN111346955AAffect the use effectAchieve sanding effectEdge grinding machinesRevolution surface grinding machinesPolishingStructural engineering

The invention provides a surface machining device and method aiming at bending metal pipes of small specifications and relates to the field of metal pipes. The surface machining device aiming at bending the metal pipes of the small specifications is used for bending pipe bodies and comprises a working table, a placing groove, a bending mechanism, a supporting rod, a cable and multiple polishing mechanisms. The placing groove is formed in the working table. The bending mechanism is arranged on one side of the placing groove. According to the surface machining device aiming at bending the metalpipes of the small specifications, by means of cooperation of the cable, a fixing sleeve, a tiny electric pushing rod and a scraper, the whole polishing mechanism extends into the metal pipes to be bent. The function of filler is achieved, and the interiors can be stressed uniformly when the pipes are bent. After the pipes are bent, the cable is pulled to drive the scraper on the polishing mechanism to move while the scraper makes contact with pipe walls. Thus wrinkles generated on the inner walls of bent portions of the pipes are milled flatly, the effect of polishing the inner walls of the metal pipes of the small specifications is achieved, and the situation that due to existence of the wrinkles, the use effect of the pipes is influenced.

Owner:绍兴市菲尔乐管业有限公司

Mobile micro base station

PendingCN110798758AStable supportPrevent rolloverWireless communicationSelection arrangementsRatchetControl engineering

The invention discloses a mobile micro base station. The station comprises a machine body. A control mechanism is arranged on one side of the machine body. A support rod is arranged at the other end of the body. A first cavity is formed in the machine body. One end of the supporting rod extends into the first cavity and is provided with a first lifting mechanism; the first lifting mechanism is connected with the control mechanism through a circuit; a ratchet mechanism is arranged in the middle of the first lifting mechanism; the ratchet mechanism is connected with the control mechanism througha circuit; a buffer mechanism is arranged on one side of the supporting rod; an adjusting mechanism capable of changing the angle and the position is arranged at the other end of the supporting rod;the adjusting mechanism is connected with the control mechanism through a circuit; a micro base station is arranged at one end of the adjusting mechanism. The invention has the beneficial effects thatthe stable fixing effect can be provided in the working state, the side turning phenomenon is not likely to happen, and the reliability of the stable fixing device is effectively improved.

Owner:互联互想(杭州)教育科技有限公司

High-temperature-resistance infrared-radiation-attenuation-resistance energy-saving coating

InactiveCN110117457AImprove mechanical propertiesSolve crackingFireproof paintsChemical industryFull waveAdhesive

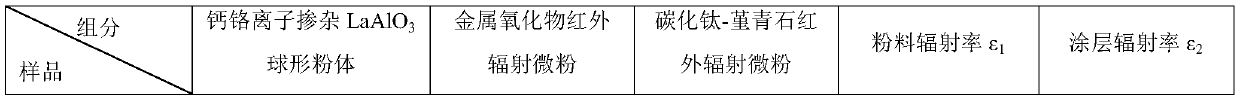

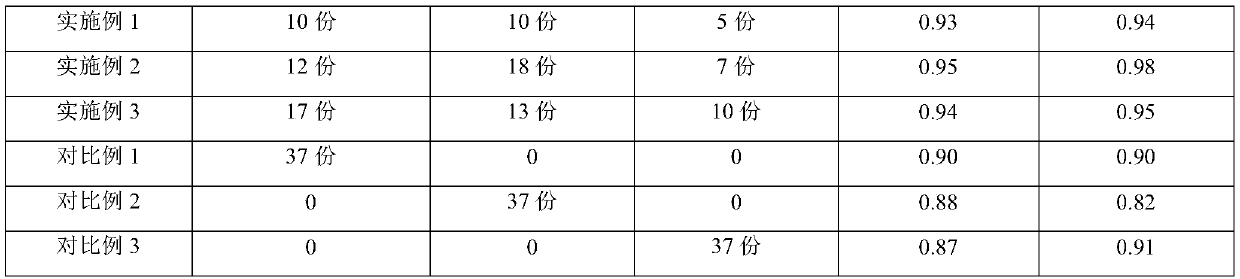

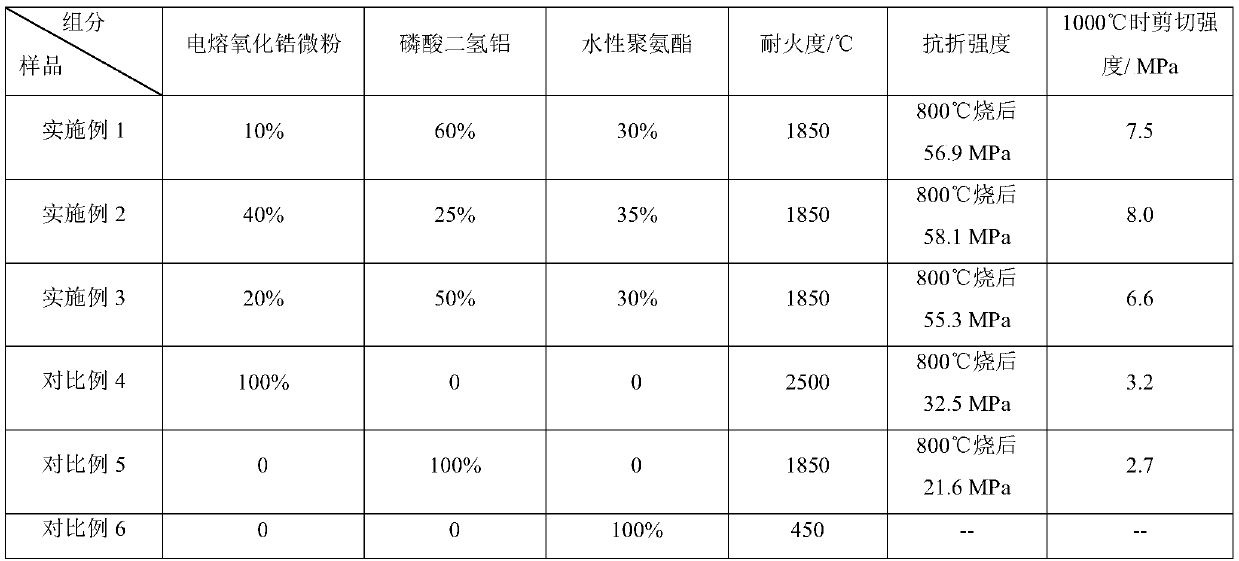

The invention discloses a high-temperature-resistance infrared-radiation-attenuation-resistance energy-saving coating. The coating is prepared from, by weight, 10-20 parts of LaAlO3 spherical powder doped with calcium and chromium ions, 10-20 parts of metallic oxide infrared radiation micro powder, 5-10 parts of titanium carbide-cordierite infrared radiation micro powder, 15-25 parts of filler, 0.1-0.2 part of a retardant, 30-50 parts of an adhesive, 10-20 parts of a solvent, 0.15-0.25 part of a dispersion agent, 0.1-0.35 part of a coupling agent and 0.05-0.15 part of a defoaming agent. The invention further discloses a preparation method of the coating. The coating comprises the following steps of step one, raw material preparation; step two, high temperature treatment; step three, high shearing dispersion; step four, coating preparation. The infrared radiation rate of the full-wave band of the provided energy-saving coating is 0.94-0.98, infrared radiation attenuation can be effectively prevented, after long-time using of the coating, the phenomena of cracking and coating shedding cannot occur, and the thermal shock resistance is high.

Owner:河南嘉和节能科技有限公司

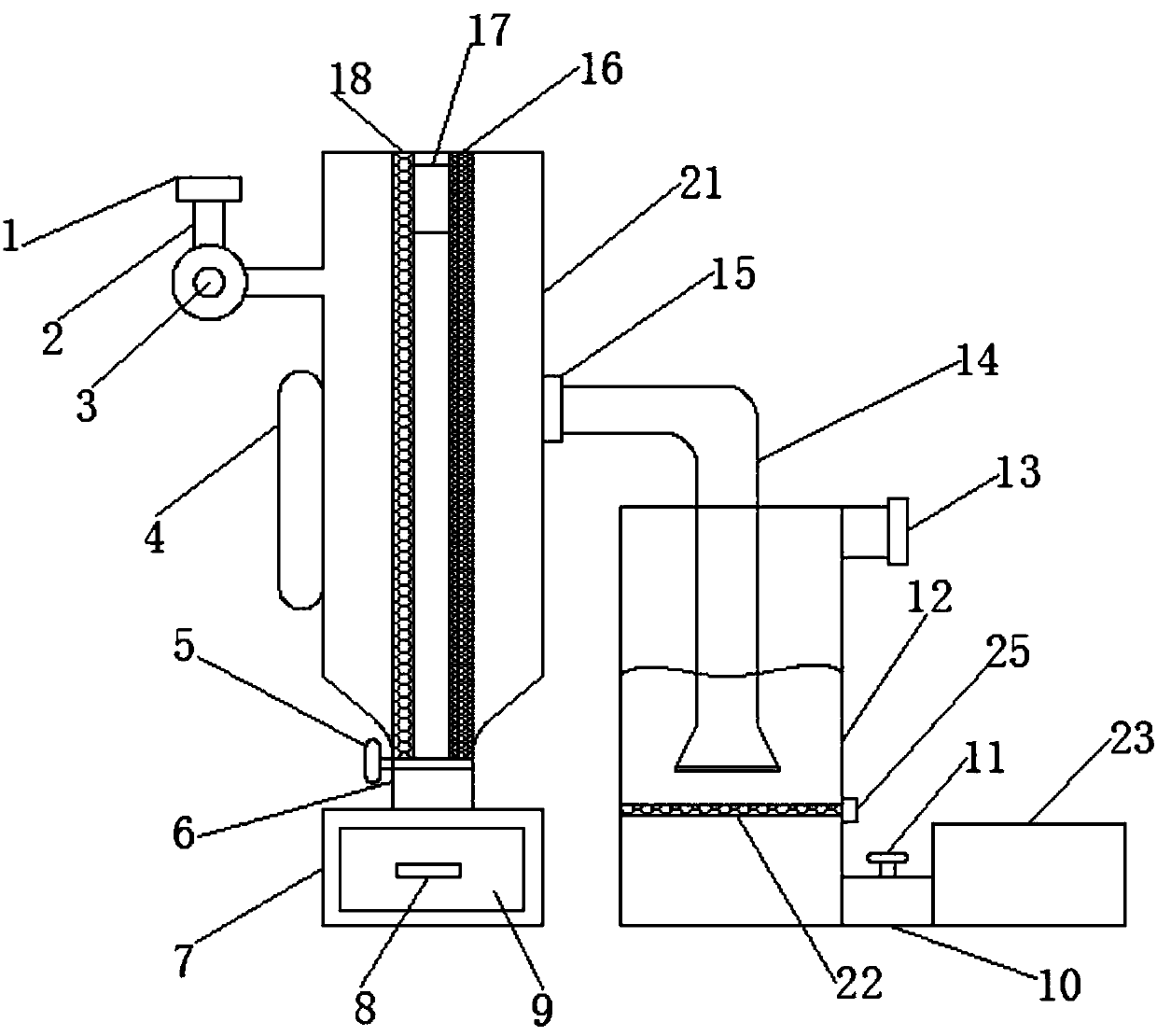

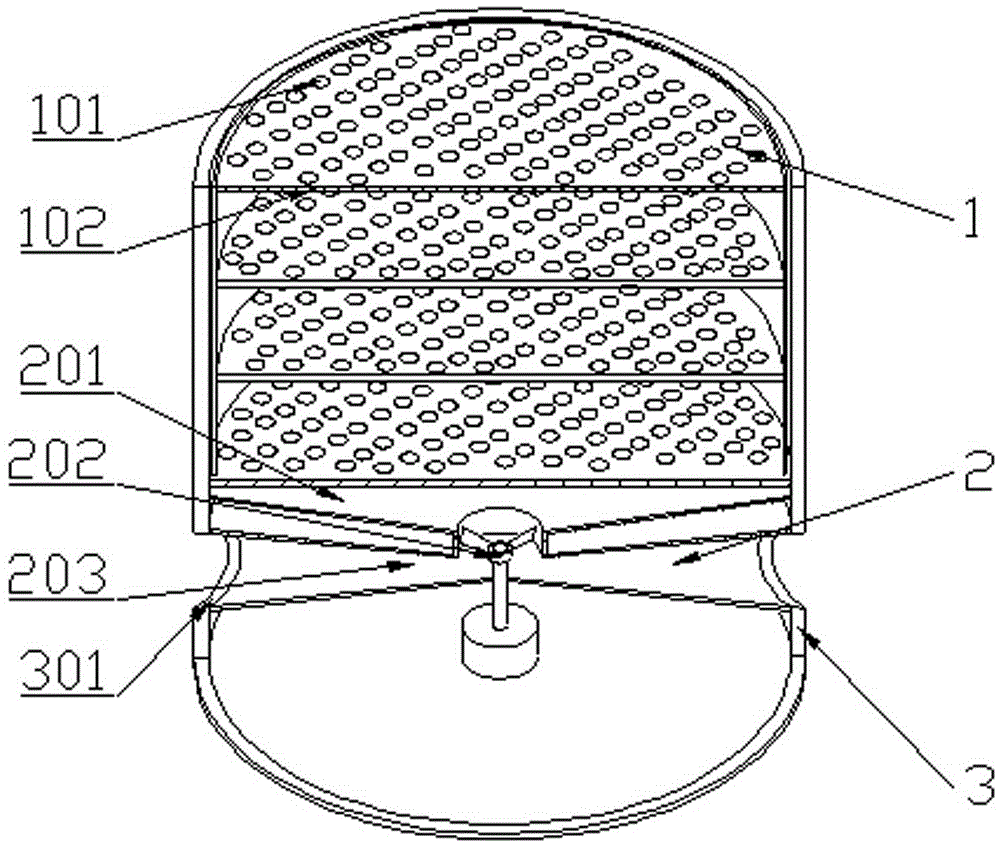

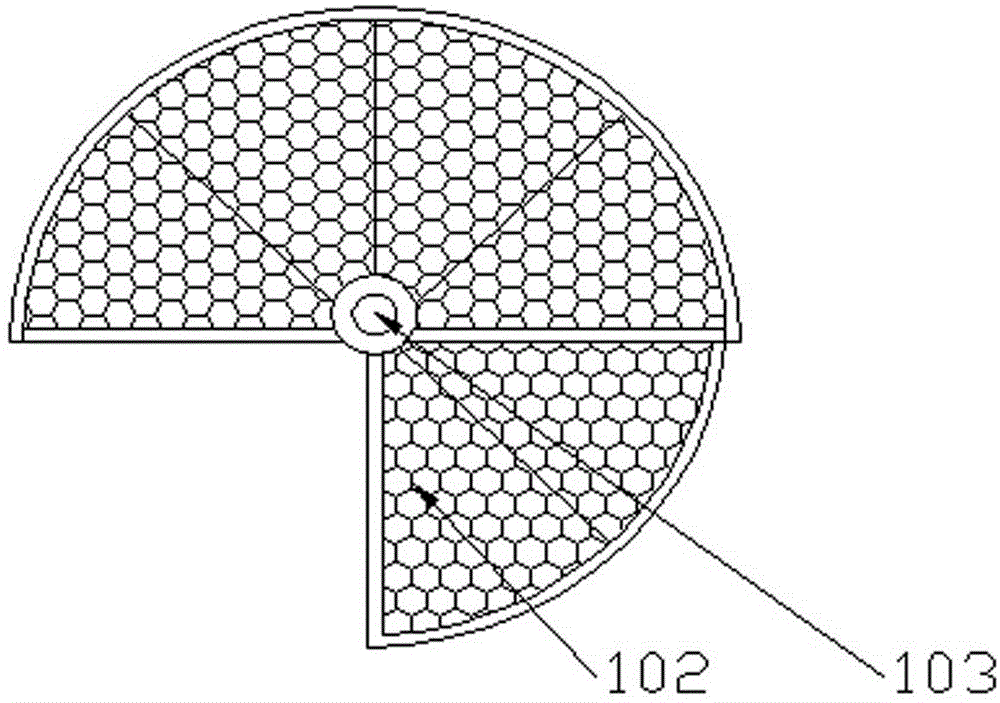

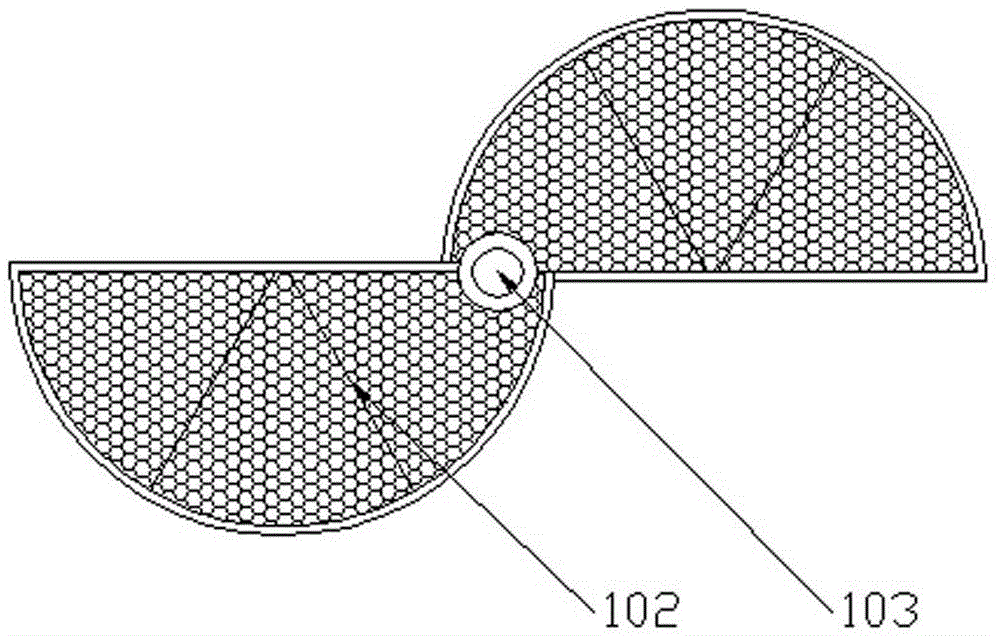

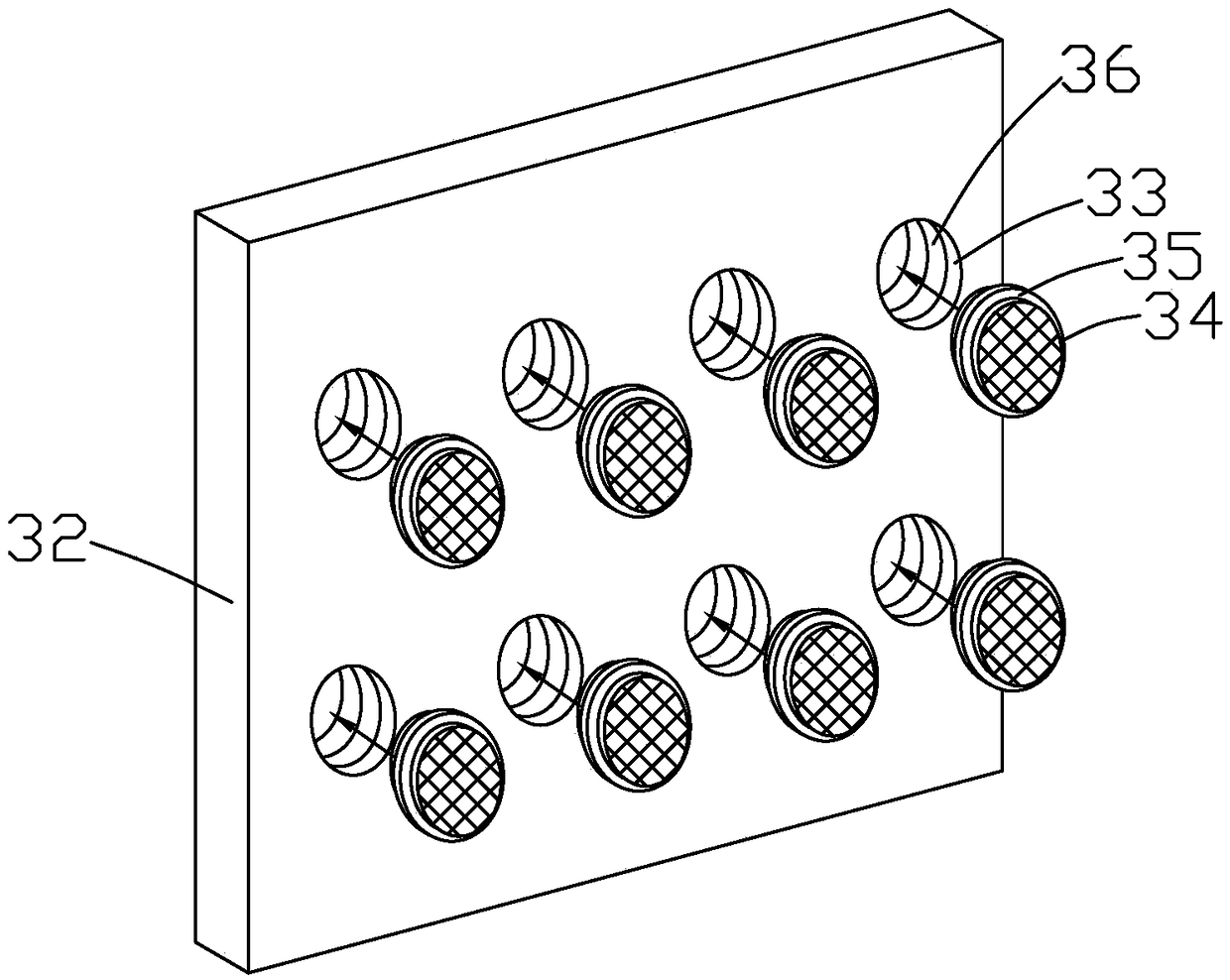

Rainproof insect pest situation forecasting lamp

ActiveCN106973877AAffect the use effectImpact measurementGeneral water supply conservationInsect catchers and killersTrappingInsect pest

The invention discloses a rainproof insect pest situation forecasting lamp and particularly relates to an insect pest situation forecasting lamp. The rainproof insect pest situation forecasting lamp comprises a lamp body, wherein the lamp body is provided with a light-emitting device emitting light for trapping insect pests and is provided with a rain sheltering component used for rain sheltering, capable of making light transmitted and reserved with gaps for insect pests to enter the lamp body and a filter device for filtering non-target insect pests, the rain sheltering component is located on the outer wall of the lamp body, and the filter device faces the position enabling insect pests to enter from the rain sheltering component and is located on the inner side of the rain sheltering component. The rainproof insect pest situation forecasting lamp has the advantages that the rainproof insect pest situation forecasting lamp can work in rainy days and the service life of the lamp is not affected.

Owner:ZHEJIANG TUOPUYUN AGRI SCI & TECH CO LTD

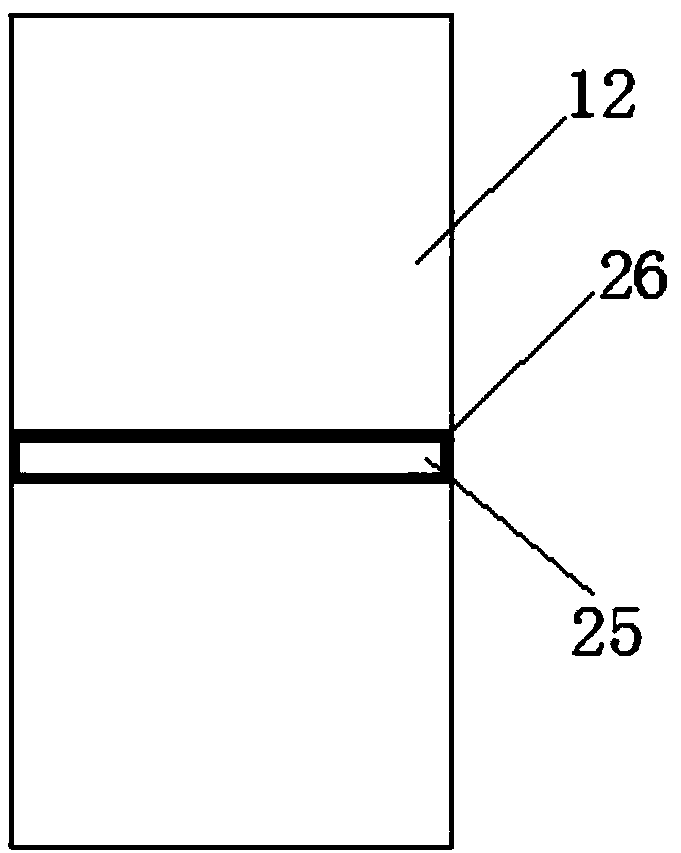

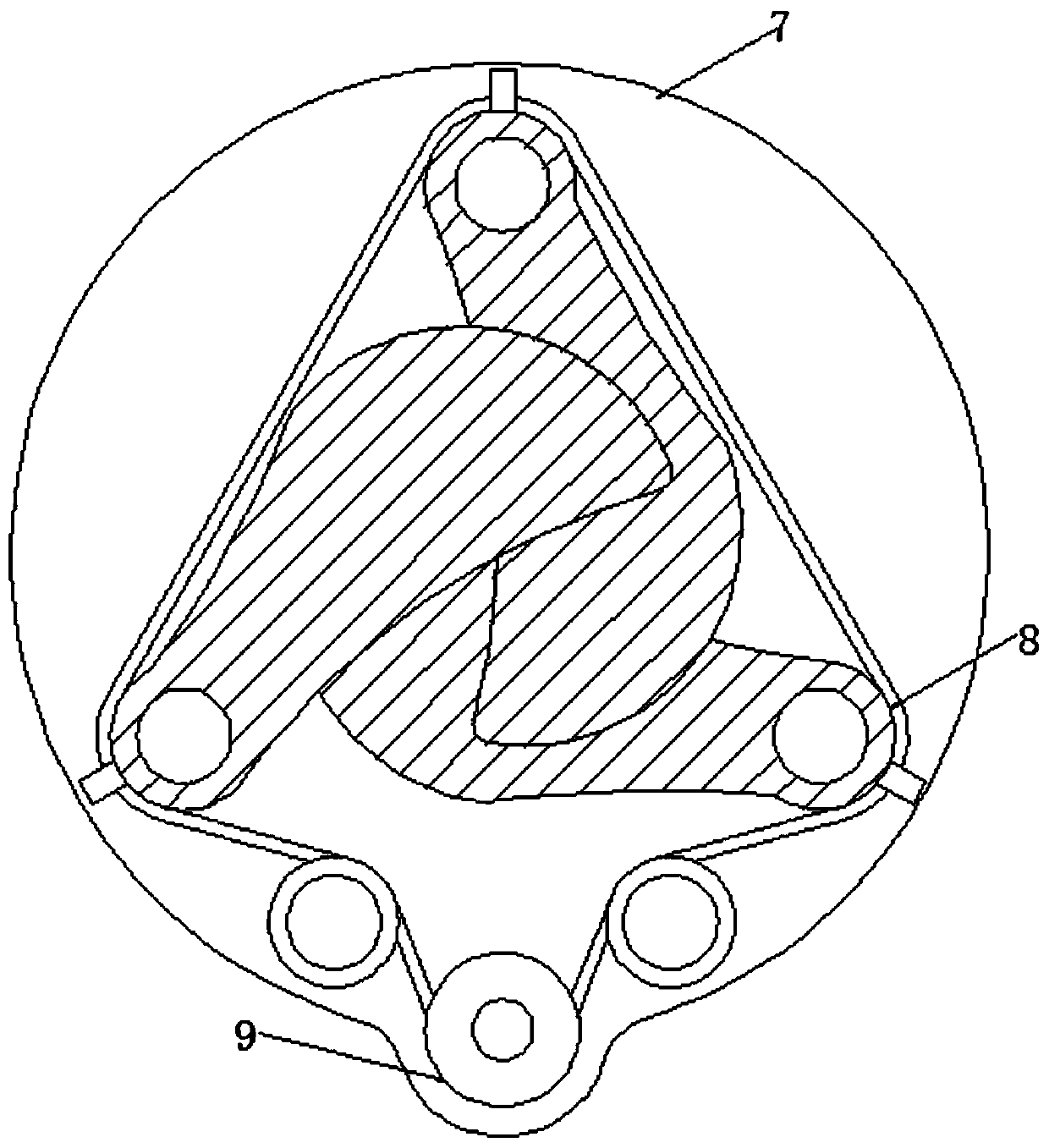

Construction coating stirring device capable of preventing precipitation and automatically replacing filter tool

InactiveCN111389279AAffect the use effectIncrease linkageTransportation and packagingMixer accessoriesStructural engineeringComposite material

The invention relates to the technical field of buildings, and discloses a construction coating stirring device capable of preventing precipitation and automatically replacing a filter tool, the construction coating stirring device comprises a shell, and the outer side of the shell is fixedly connected with a discharge pipe; the gears rotate to enable the stirring rods to get close and away; the coating in a stirring bin is stirred; precipitation of the coating is avoided, and the use effect of the coating is influenced, a first turntable rotates to enable the three baffle plates to get away from each other and get close; an outlet of the stirring bin is opened and closed; the coating falls onto a sieve plate of the vertical pipe of the discharge pipe; the falling condition of the coatingis automatically controlled; the coating is filtrated, excessive falling amount of the coating is avoided, large particles of paint are precipitated on the surface of the sieve plate, the sieve holesare blocked and effective sieving is prevented. The rotating rod rotates to enable the sieve plate to rotate synchronously, so that the sieve plate is replaced automatically, the sieve plate is cleaned conveniently, and the phenomena that a large amount of large-particle paint is accumulated on the surface of the sieve plate, flowing of the paint is hindered and the sieving efficiency of the coating is reduced can be avoided.

Owner:姚龙祥

Refrigerator odor remover

InactiveCN104874003AUnimpeded accessSimple structureDispersed particle separationDeodrantsEngineeringRefrigerated temperature

The invention discloses a refrigerator odor remover which comprises a box shell, a filtering device and an air guiding device, wherein the filtering device and the air guiding device are wrapped by the box shell; the filtering device is arranged above the air guiding device; the size of the filtering device is matched with that of the air guiding device; the filtering device comprises three or more filtering layers; one or more odor removing agents are arranged in all the filtering layers; each odor removing agent is granulose; every two adjacent filtering layers are separated by a screen, and communicated with each other; the air guiding device comprises an air guiding machine, an air inlet and an exhaust outlet; the air inlet of the air guiding machine is arranged at the bottom of the lowest filtering layer; the exhaust outlet is communicated with an air outlet formed in the box shell of the air guiding device. The refrigerator odor remover is simple in structure and ingenious in design; under the action of the air guiding machine, the refrigerator odor remover initiatively introduces air into the filtering layers for adsorption, thereby removing odor and achieving a faster and better odor removing effect; meanwhile, a sterilization and disinfection function can be additionally realized as required.

Owner:GUIYANG GAOXIN FENGHUA ELECTRICAL APPLIANCE

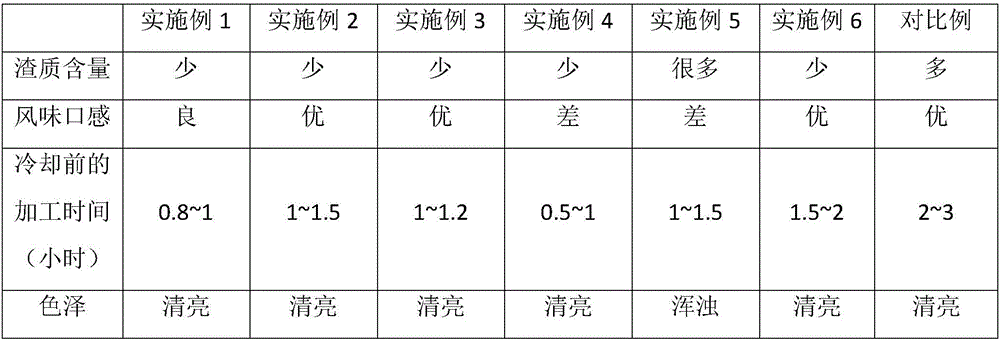

Processing technology of dreg-free hotpot condiment

The invention belongs to the field of food processing, and discloses a processing technology of a dreg-free hotpot condiment. According to the processing technology, chili and Sichuan pepper are fried with animal oil, and a main material oil is obtained via filtering; animal oil and plant oil are mixed for frying of rhizoma kaempferiae, poria cocos, Chinese yam, radix angelicae, fructus tsaoko, momordica grosvenori, amomum cardamomum, fructus gardenia, fructus amomi, and rhizome alpiniae officinarum, an obtained mixture is decocted with water, and spice dreg is removed via filtering so as to obtain a first auxiliary material oil; animal oil and plant oil are mixed for frying of cassia bark, star anise, myrcia, fennel, cinnamon skin, lemongrass, cumin particle, fructus piperis longi, rhizoma chuanxiong, parsley seed, and liquorice, an obtained mixed material is decocted with water, dreg is removed via filtering so as to obtain a second auxiliary material oil; sesame oil and lindera glauca oil are mixed so as to obtain a third auxiliary material oil; the main material oil, the first auxiliary material oil, the second auxiliary material oil, and the third auxiliary material oil are mixed at a mass ratio of 10:7:6:1 so as to obtain the dreg-free hotpot condiment. The processing technology is capable of maintaining the flavor of the spices, relatively excellent local flavor is achieved, dreg content is low, dreg-free degree is high, animal oil content is low, and the dreg-free hotpot condiment is good for health.

Owner:重庆汤嫂食品有限公司

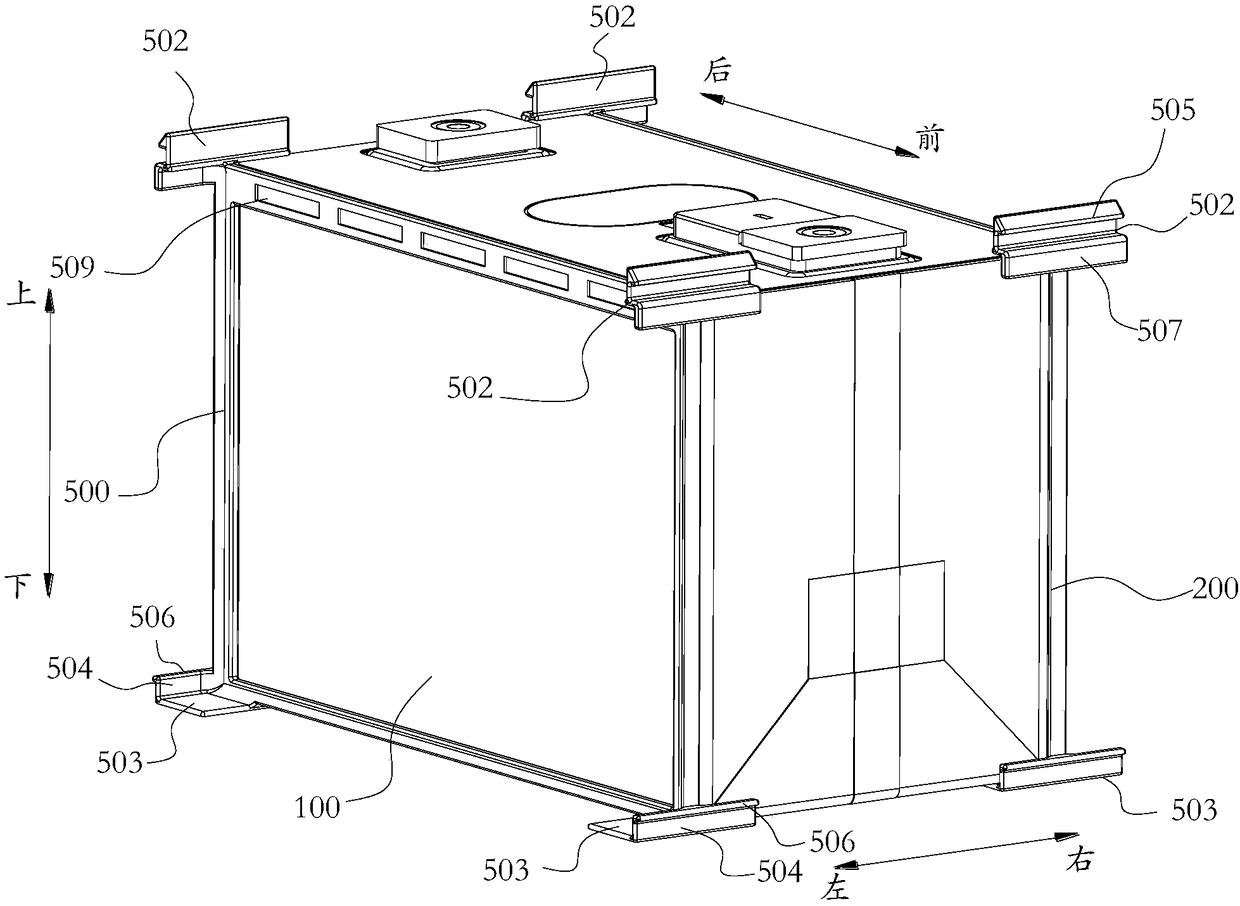

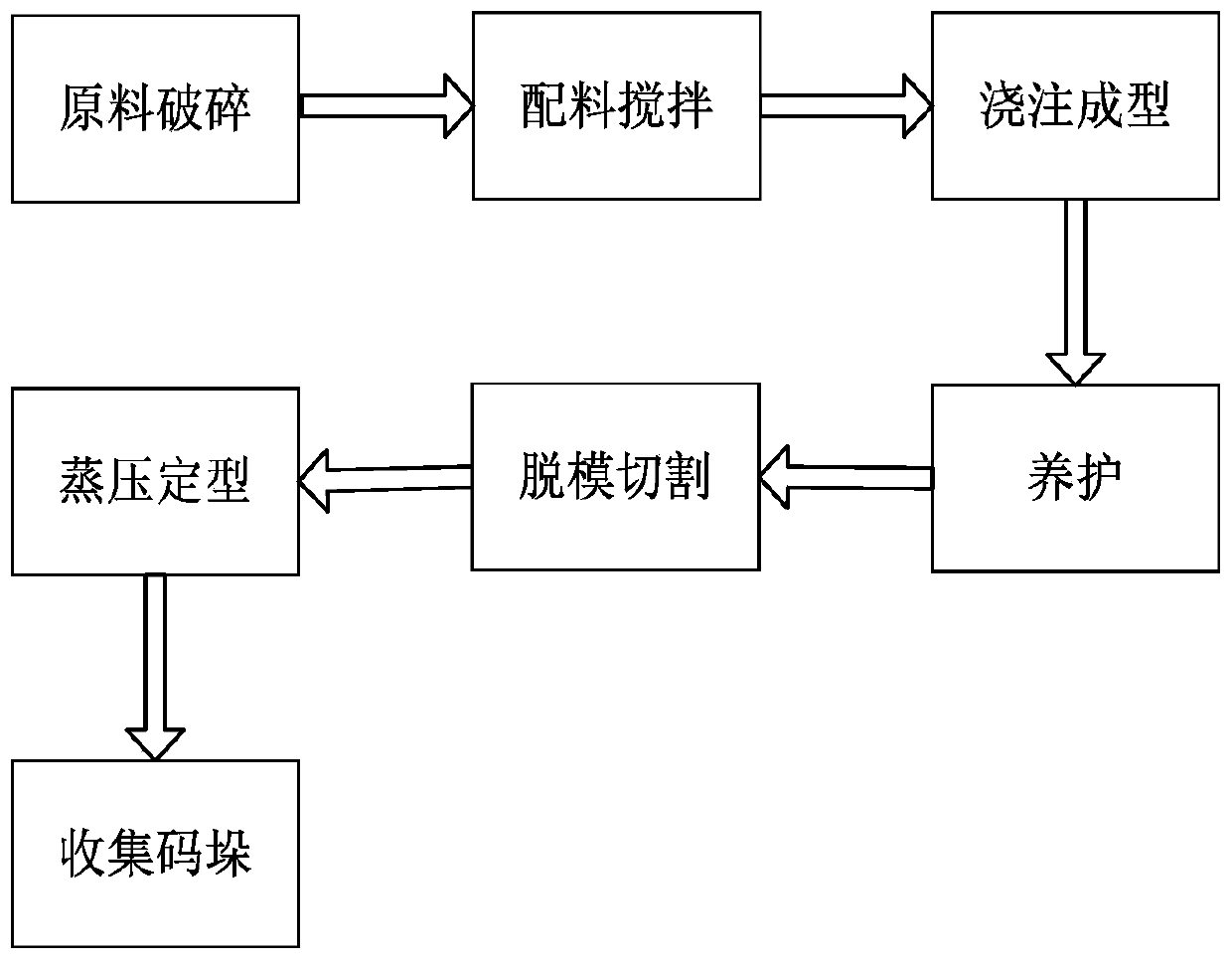

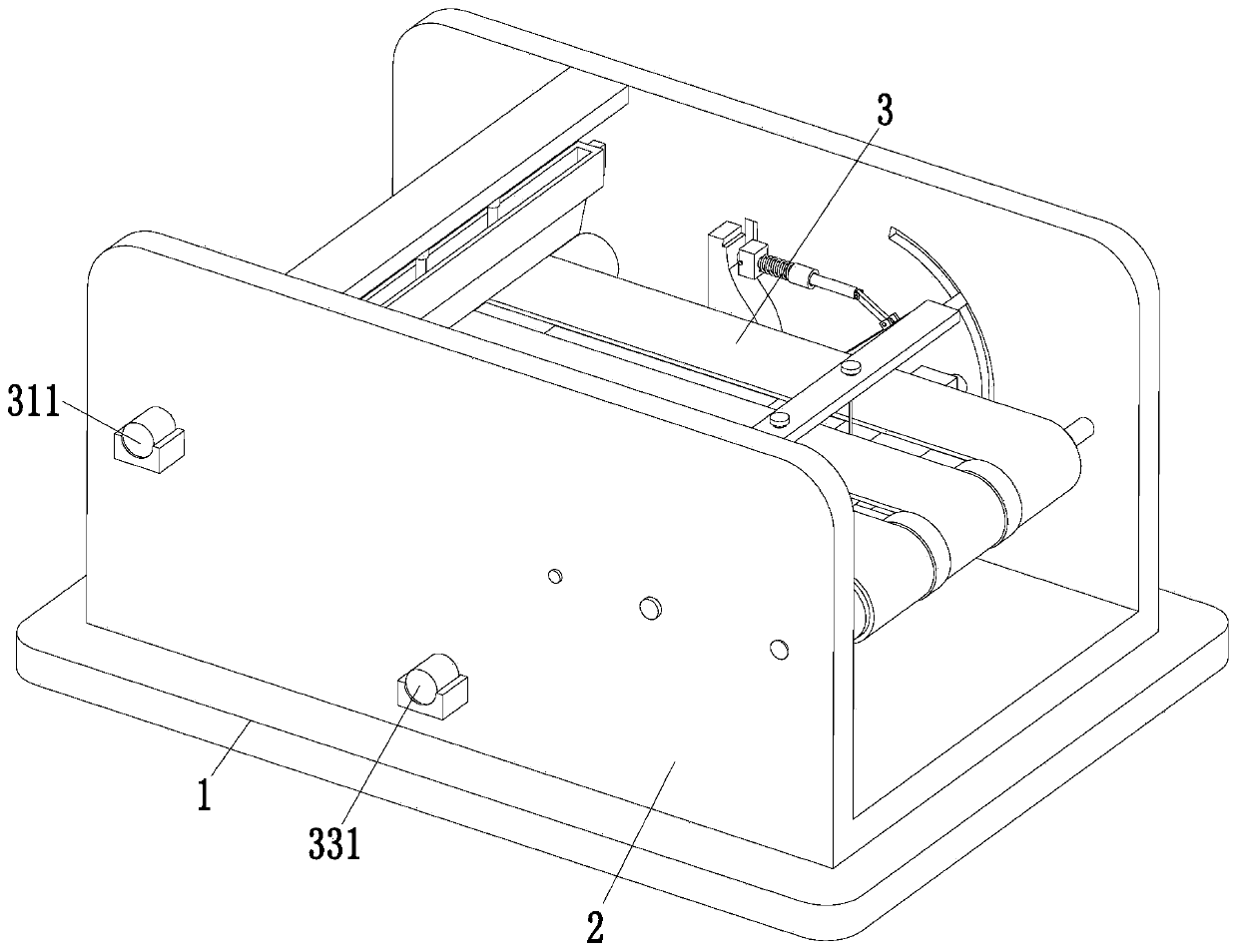

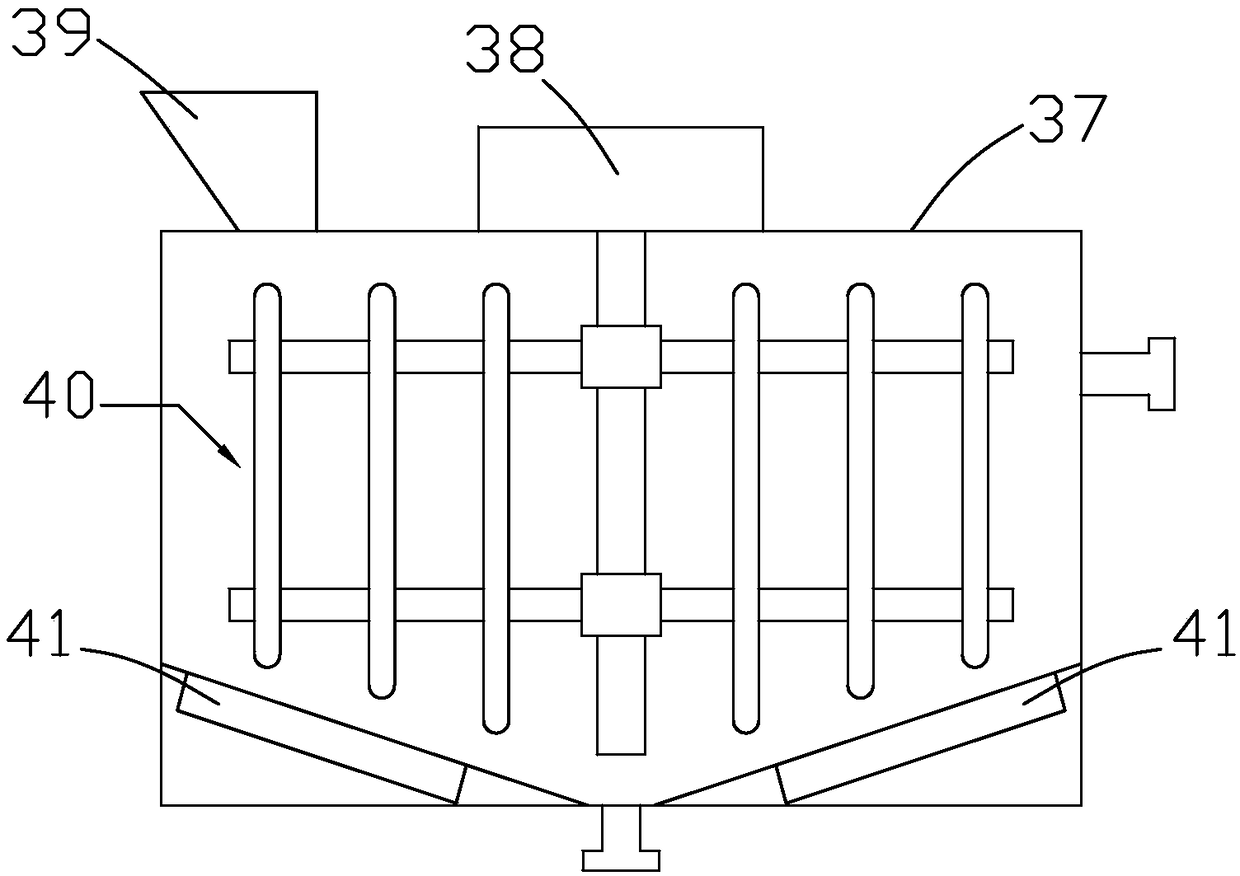

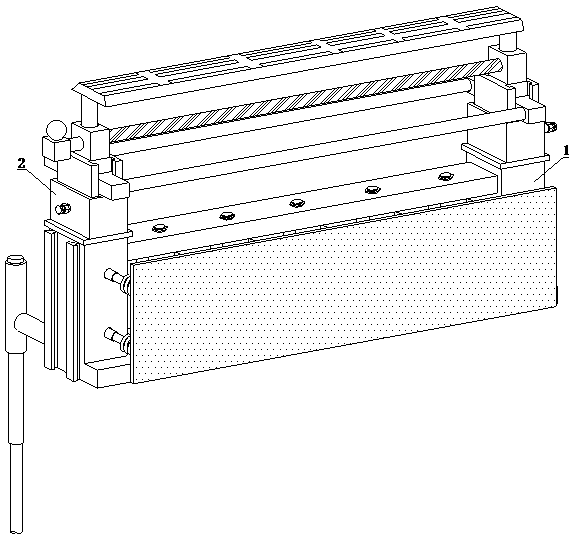

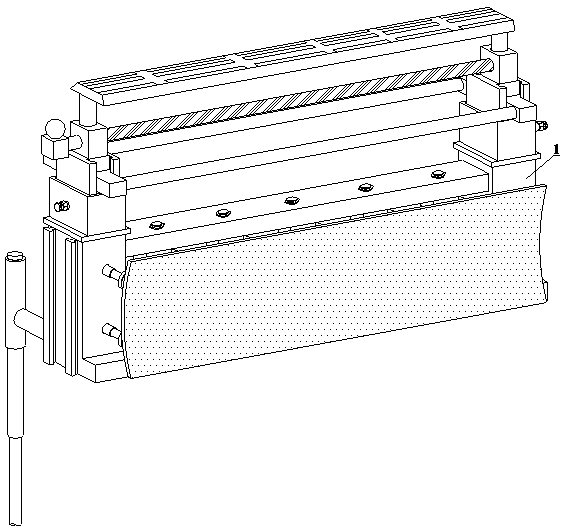

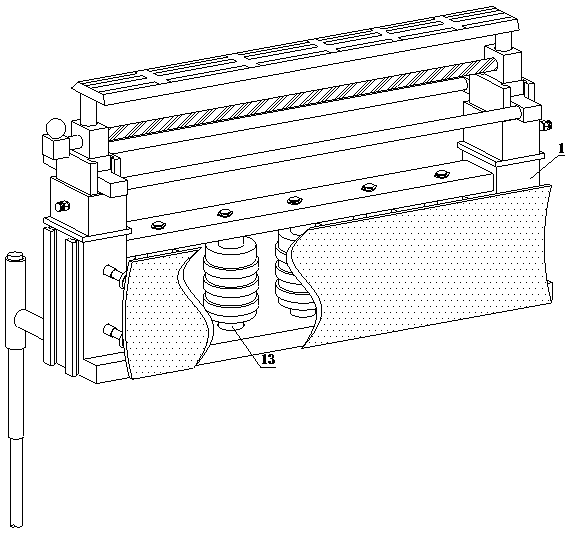

Technology for preparing, forming and processing aerated concrete blocks

ActiveCN111438809AAffect the use effectSo as not to damageDischarging arrangementFeeding arrangmentsArchitectural engineeringWire cutting

The invention relates to a technology for preparing, forming and processing aerated concrete blocks. A bottom plate, a supporting frame and a cutting device are included, the supporting frame is installed in the middle of the upper end of the bottom plate, the section of the supporting frame is of a U-shaped structure, and the cutting device is installed in the supporting frame. The technology cansolve the problems that when existing equipment cuts a concrete green body, the cutting effect is poor, edge cutting is uneven, during cutting, the concrete green body is prone to damage, the subsequent using effect of the concrete green body is affected, and when the existing equipment conducts linear cutting on the concrete green body, impurities adhering to the surface of a cutting steel wirecannot be effectively and rapidly removed, consequently, the section of the cut green body is uneven, and the surface quality of the block is affected.

Owner:安徽阜阳富龙建筑材料有限责任公司

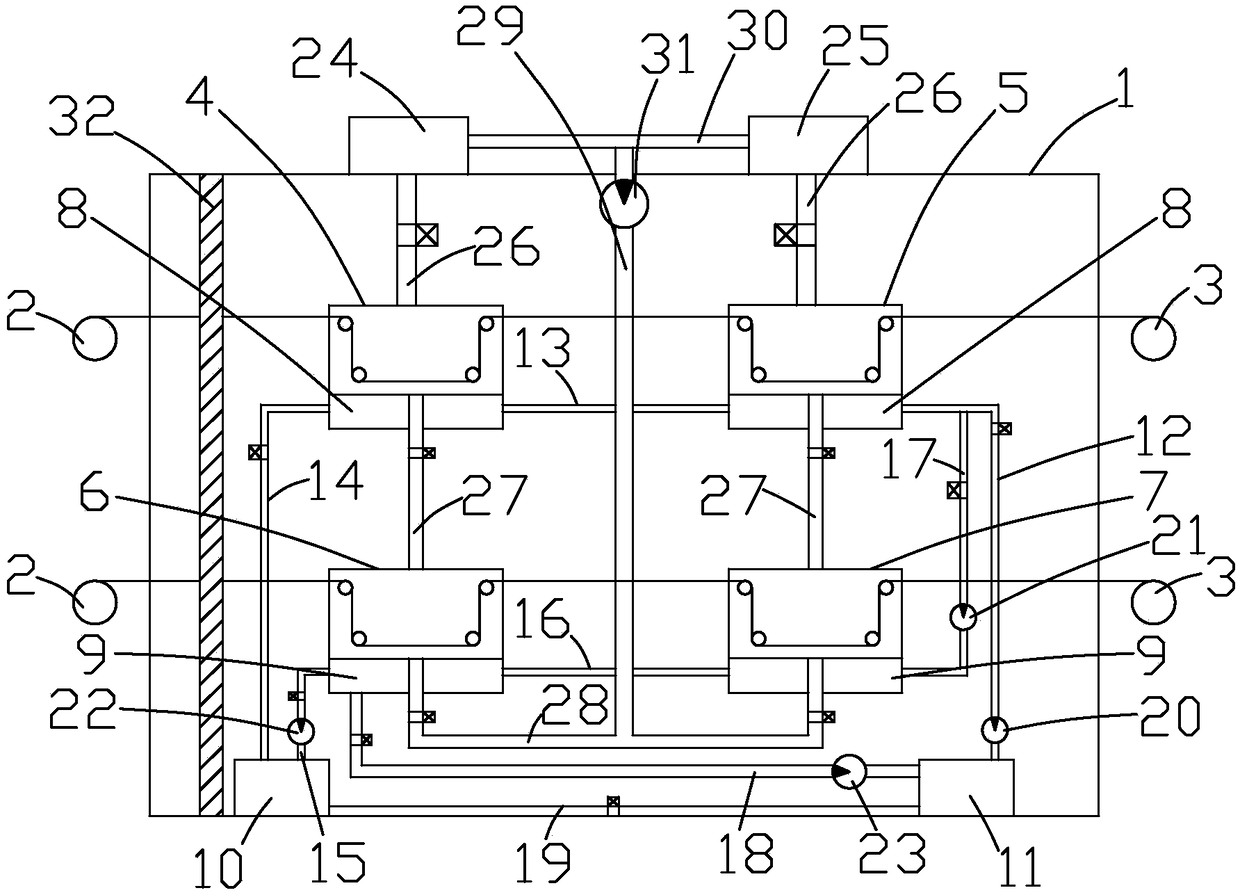

Yarn waxing device for textile machinery

The invention discloses a yarn waxing device for textile machinery. The yarn waxing device comprises a box body, yarn feeding rollers and yarn receiving rollers; the box body is internally provided with a first main waxing box, a first auxiliary waxing box, a second main waxing box, a second auxiliary waxing box, a wax supply device and a cold and hot water system; the wax supply device is separately communicated with the first main waxing box, the first auxiliary waxing box, the second main waxing box and the second auxiliary waxing box; the cold and hot water system is separately connected to the first main waxing box, the first auxiliary waxing box, the second main waxing box and the second auxiliary waxing box; baffles are arranged between the first main waxing box and the yarn feedingrollers and between the second main waxing box and the yarn feeding rollers. The yarn waxing device is simple in structure and high in practicability, not only are the waxing effect and quality of yarn improved, but also recycling of wax can be realized, waste of the wax is reduced, the wax is transformed between a solid state and a liquid state, and the automation degree of the yarn waxing device is greatly increased.

Owner:桂林市盛茏纺织有限公司

Protective bridge elastic guardrail structure and mounting method

InactiveCN111395161AAvoid casualtiesAvoid damageBridge structural detailsBridge erection/assemblyArchitectural engineeringStructural engineering

The invention discloses a protective bridge elastic guardrail structure and a mounting method, the protective bridge elastic guardrail structure comprises a bearing mechanism and a fixing mechanism, and the fixing mechanism is mounted at the upper end of the bearing mechanism. According to the guardrail structure, an elastic sleeve is connected between a mounting plate and the bottom surface of abearing frame; the outer wall of the side, away from a rescue rod assembly, of the bearing frame is connected with a plurality of buffer columns. A buffer plate is mounted at the front ends of the buffer columns; so that when a vehicle is out of control and collides with the guardrail, the out-of-control vehicle can be buffered for the first time by utilizing the buffer plate and the buffer columns; the impact force is prevented from directly acting on the guardrail to damage the guardrail; meanwhile, when the impact force is too large, a rubber gasket on the elastic sleeve can be used for conducting secondary buffering on the out-of-control vehicle, the head of the out-of-control vehicle can be deflected through a center rotary drum, the direction of the out-of-control vehicle head is turned to a front rail, and casualties caused by the fact that the vehicle easily breaks through the guardrail and falls into a river after colliding with the guardrail are avoided.

Owner:张俊中

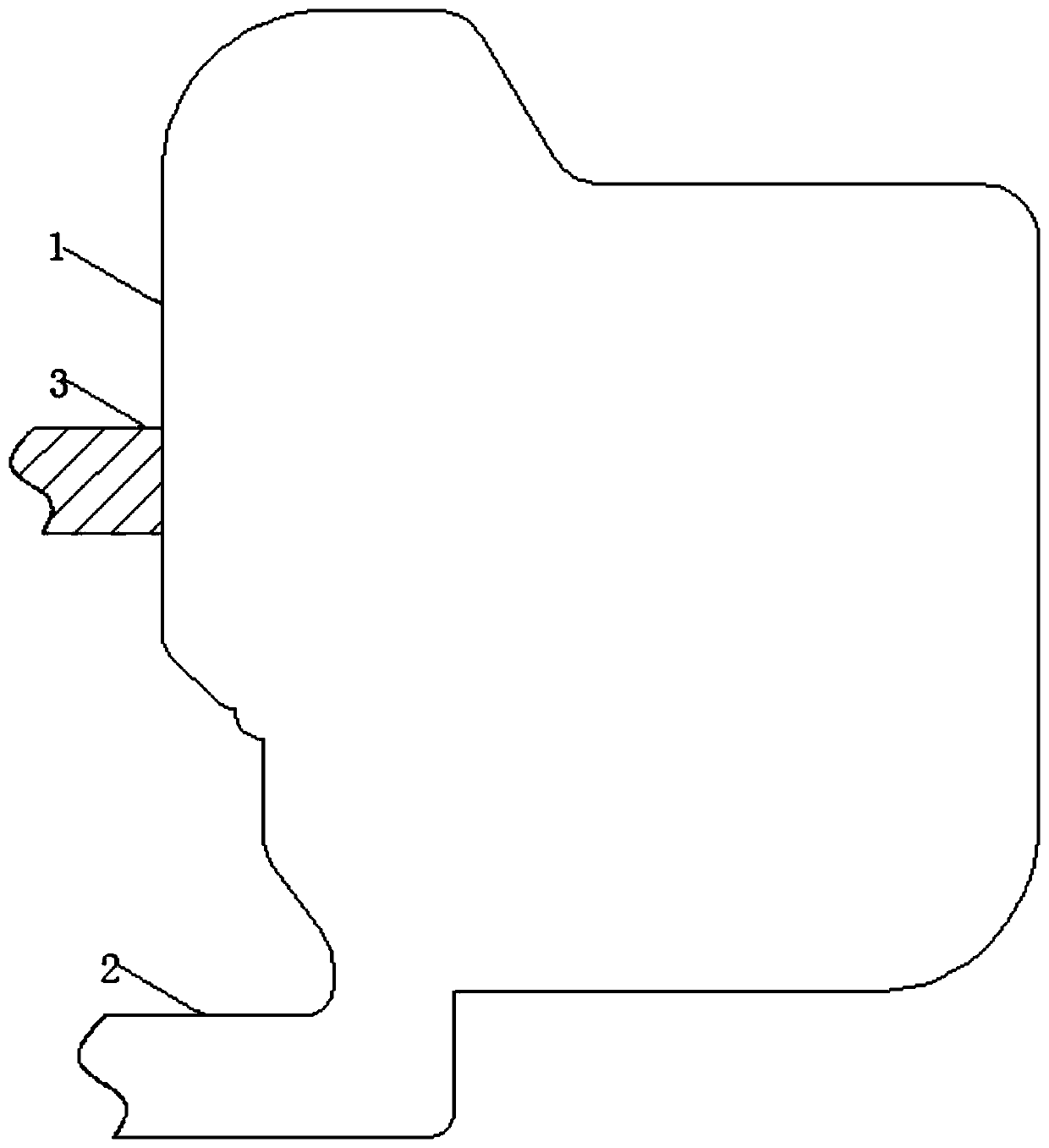

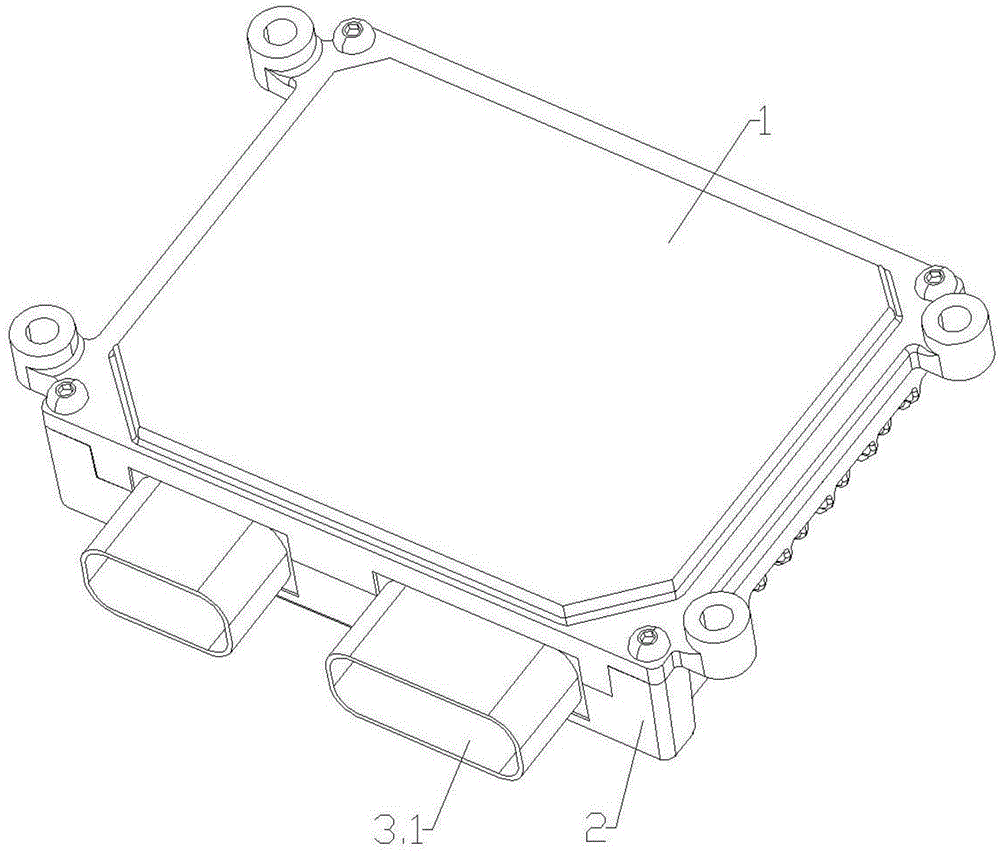

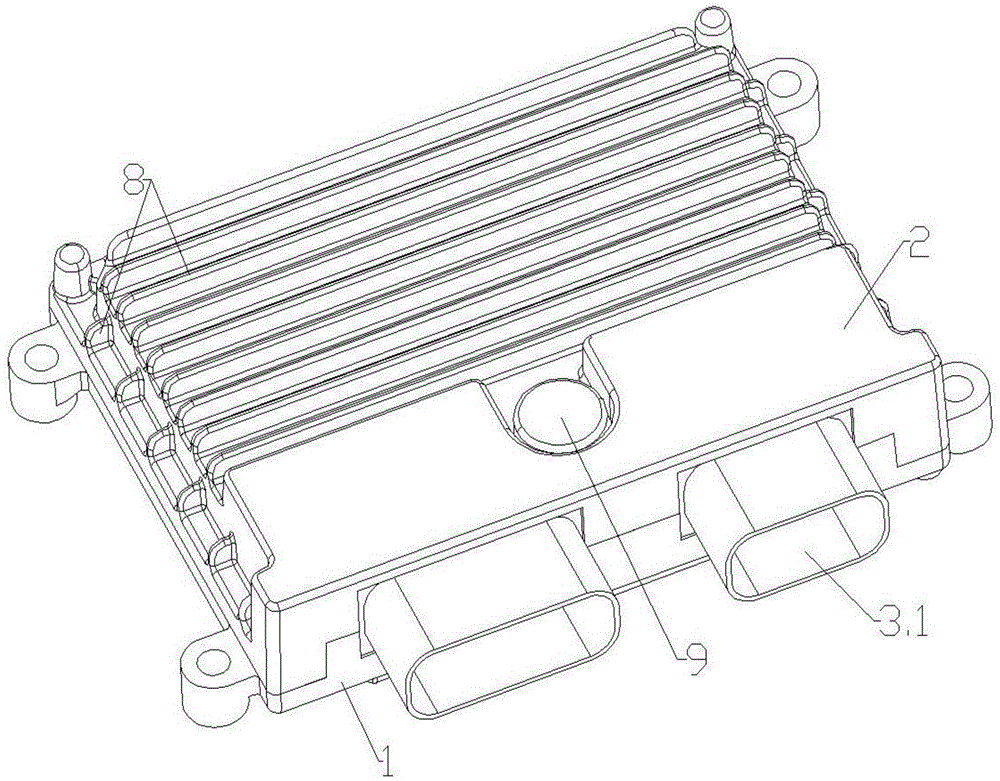

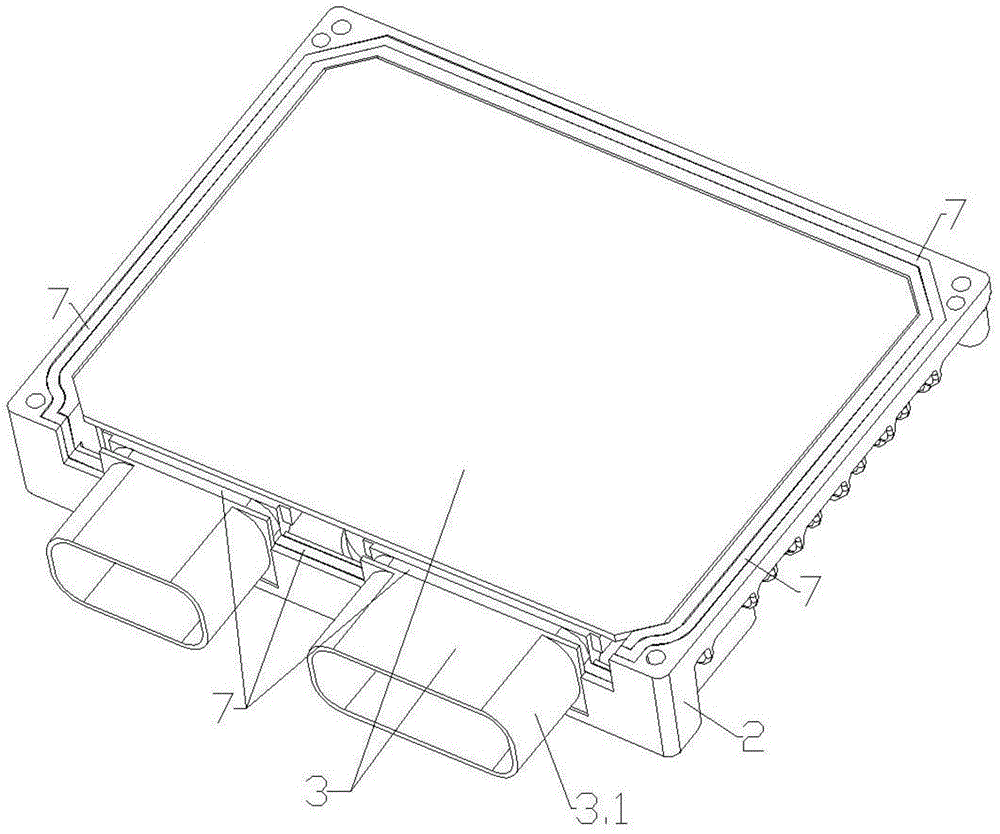

Controller shell assembly

ActiveCN104394671AEasy to fixNot easy to loosen and shiftCasings/cabinets/drawers detailsSupport structure mountingEngineeringMechanical engineering

The invention discloses a controller shell assembly which comprises an upper cover (1) and a lower cover (2) matched with each other, wherein an accommodating region (4) for horizontally placing a power supply element installation plate (3) is formed between the assembled upper cover (1) and the lower cover (2); the top end surface close to the lower cover (2) of the accommodating region (4) is resisted against the bottom surface on the edge of the power supply element installation plate (3); the bottom end surface close to the upper cover (1) of the accommodating region (4) is adhered with the top surface on the edge of the power supply element installation plate (3); an installation hole (5) for extending out an electrical joint (3.1) of the power supply element installation plate is further formed in the front side wall of the assembled upper cover (1) and the lower cover (2); and the inner wall of the installation hole (5) is adhered with the outer wall of the electrical joint (3.1) of the power supply element installation plate. The controller shell assembly can be used for accommodating the installation plate with the electrical appliance element and can be used for preventing the using quality of the electrical appliance element from being affected due to direct exposure of the electrical appliance element.

Owner:NINGBO HUASHENG AUTOMOBILE PARTS

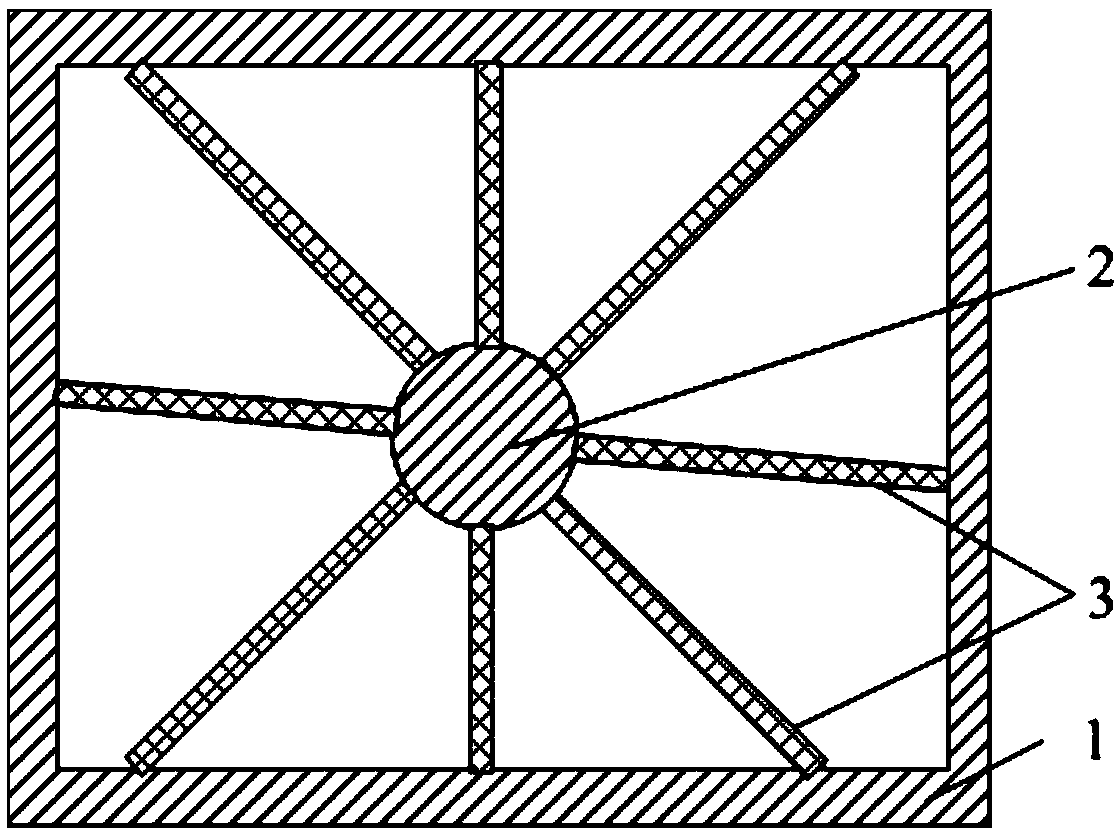

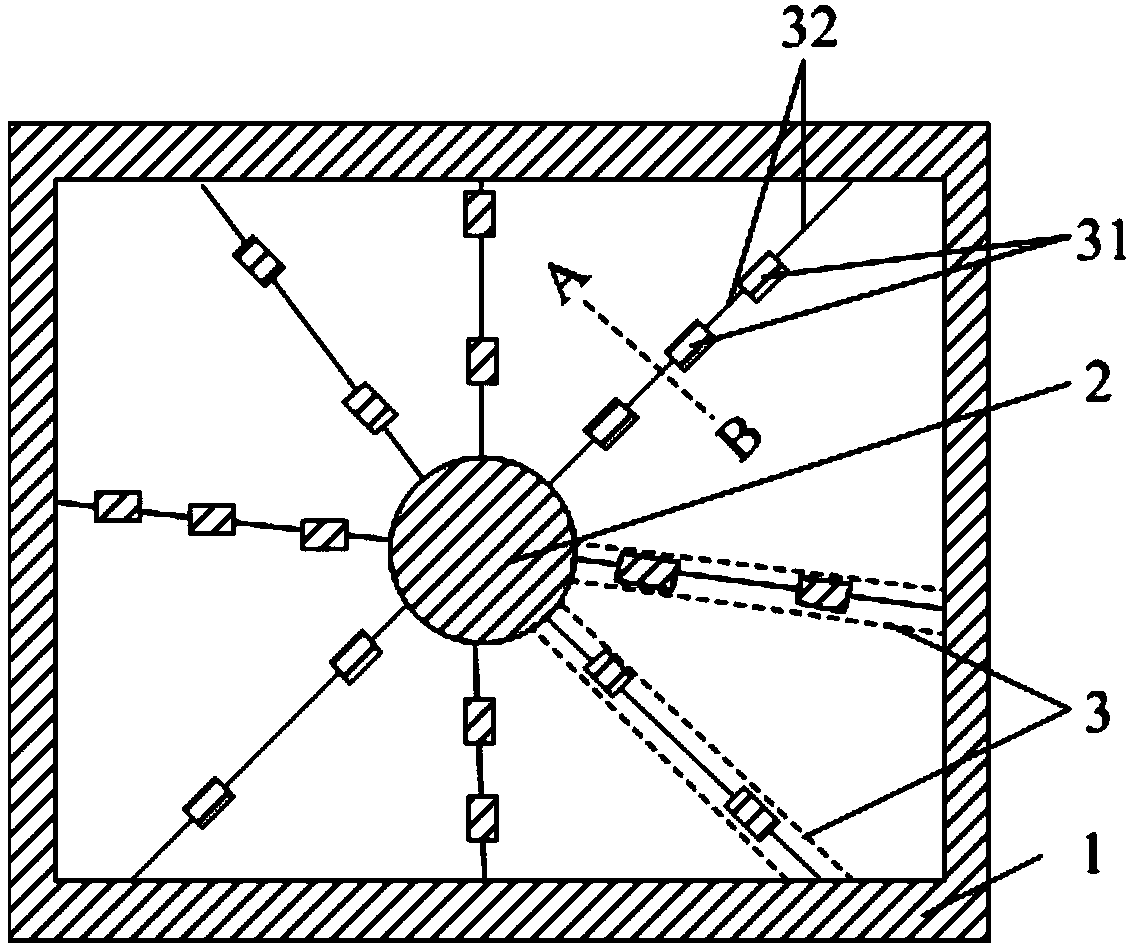

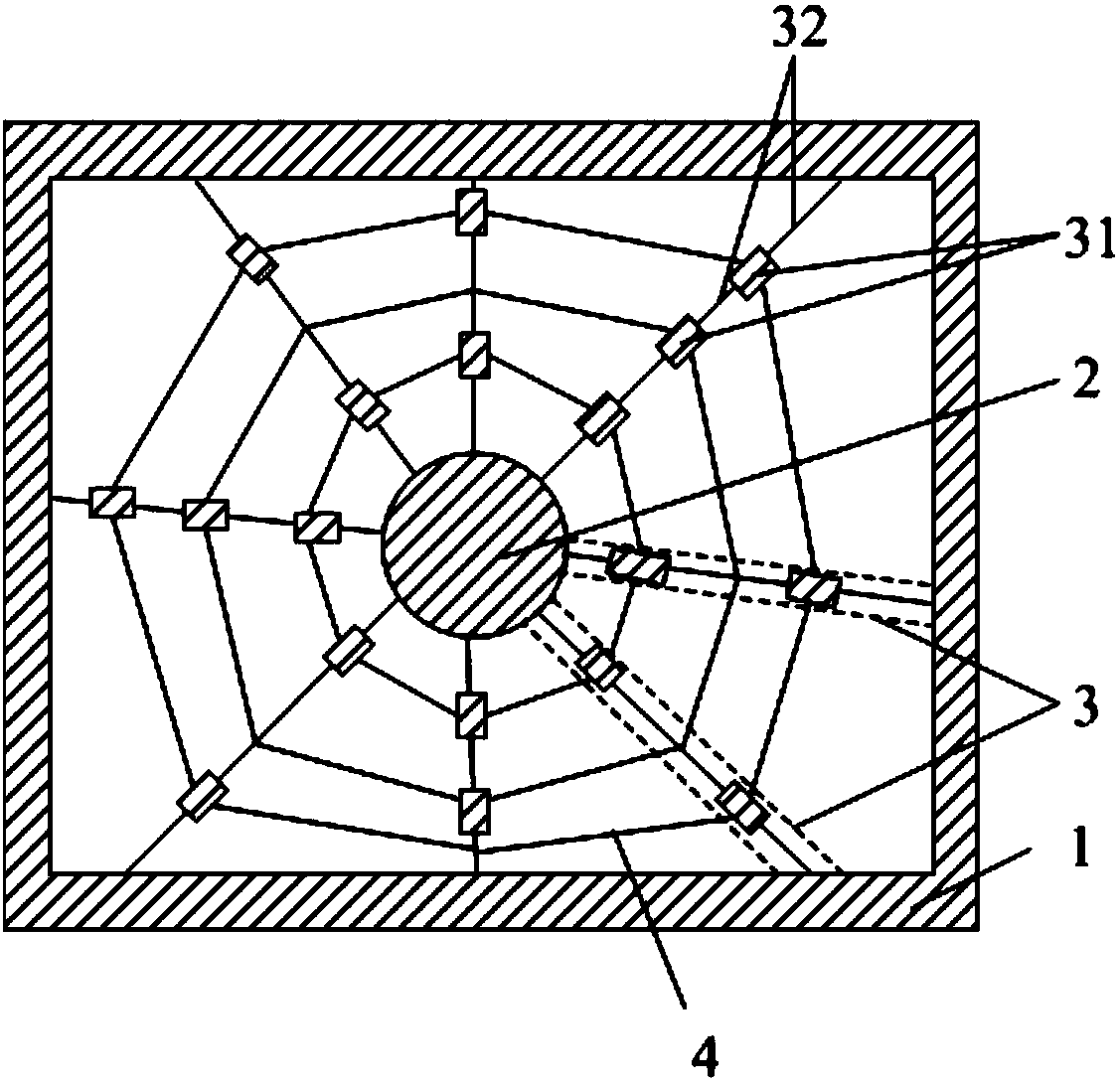

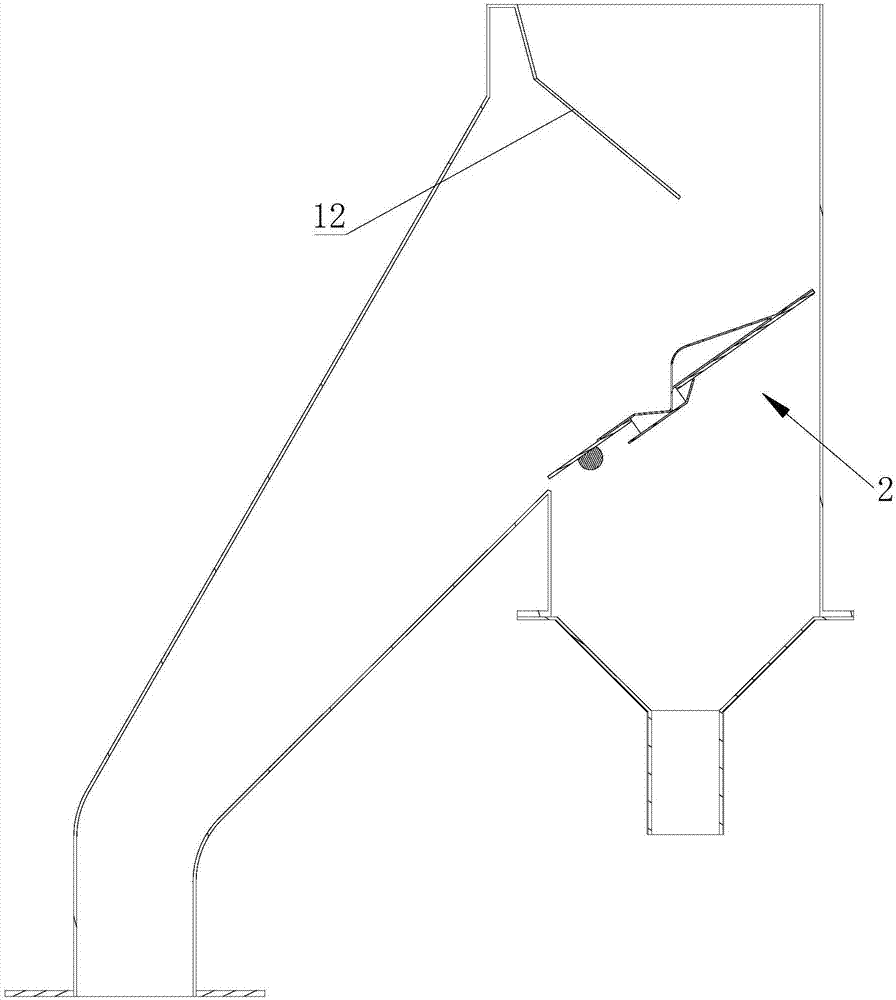

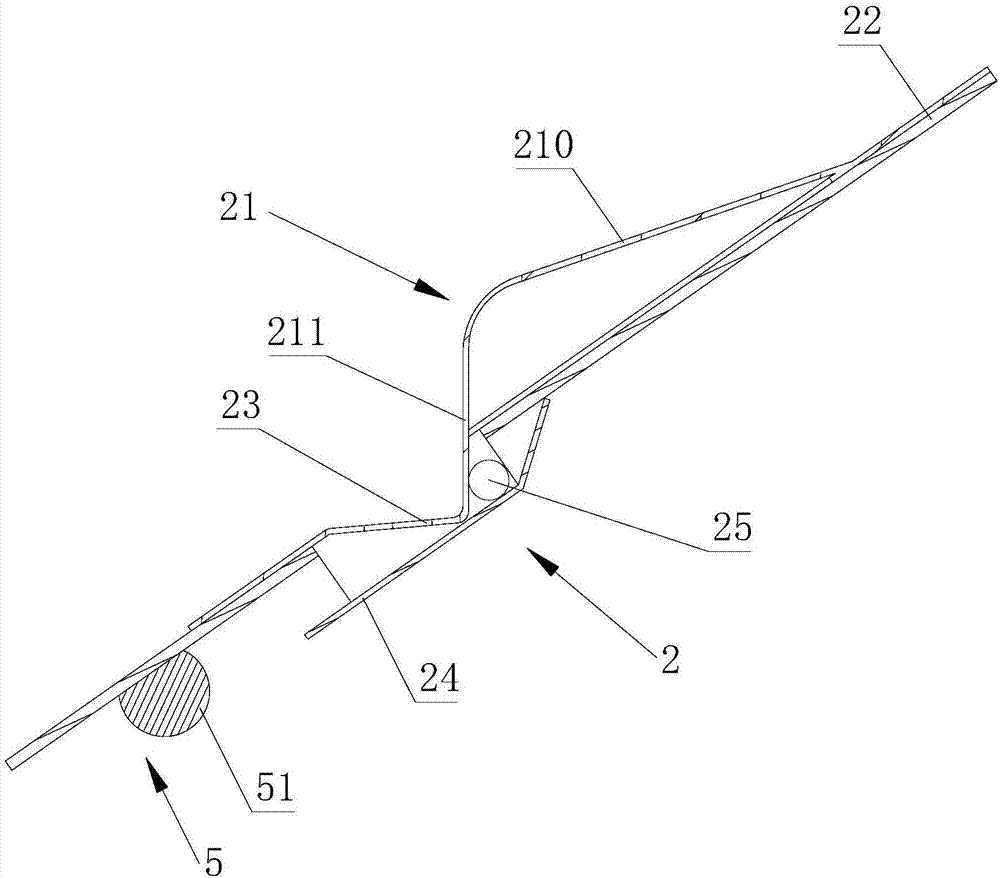

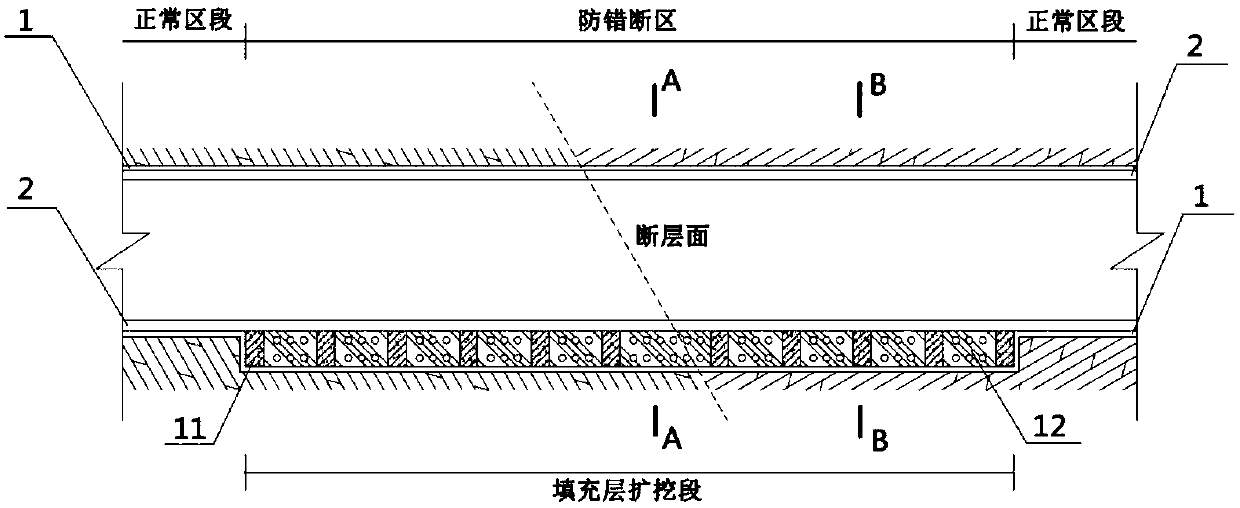

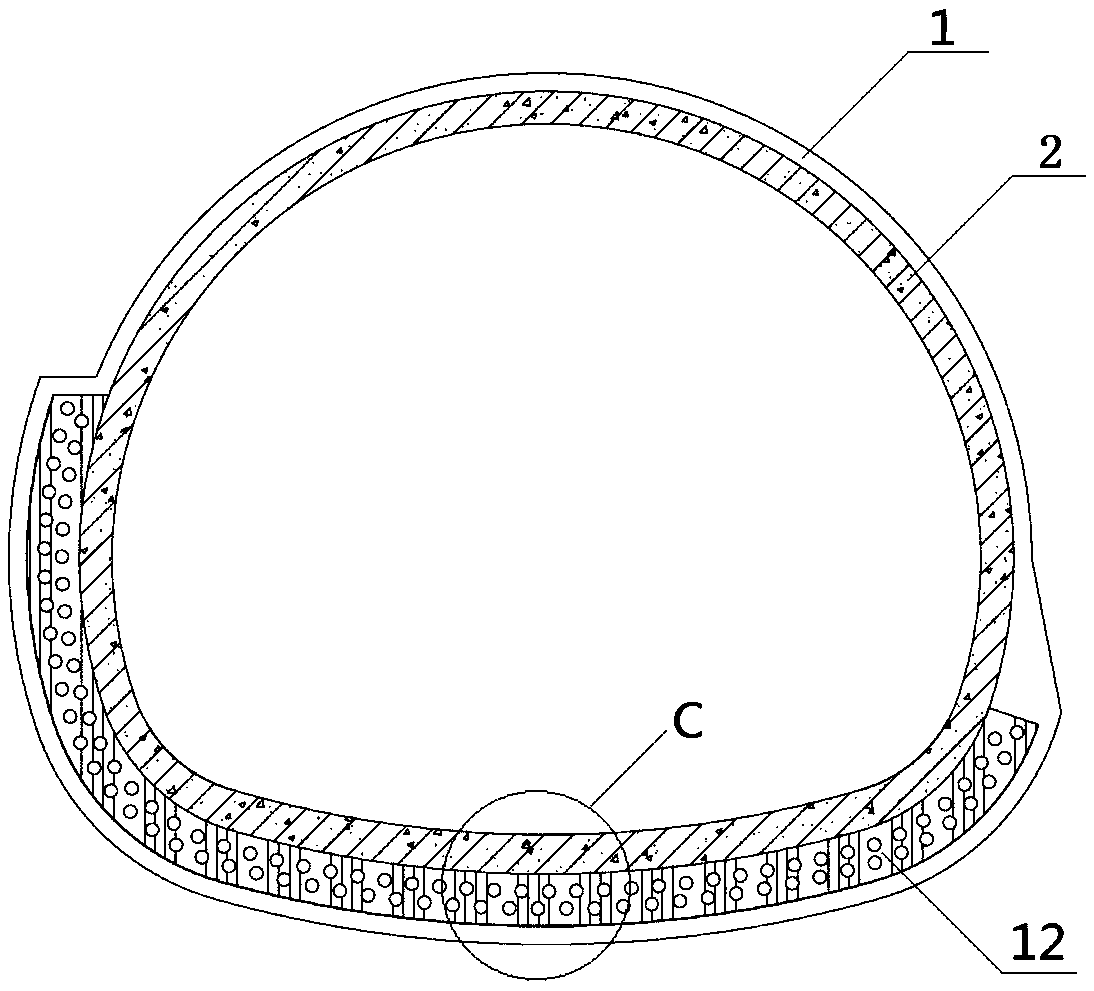

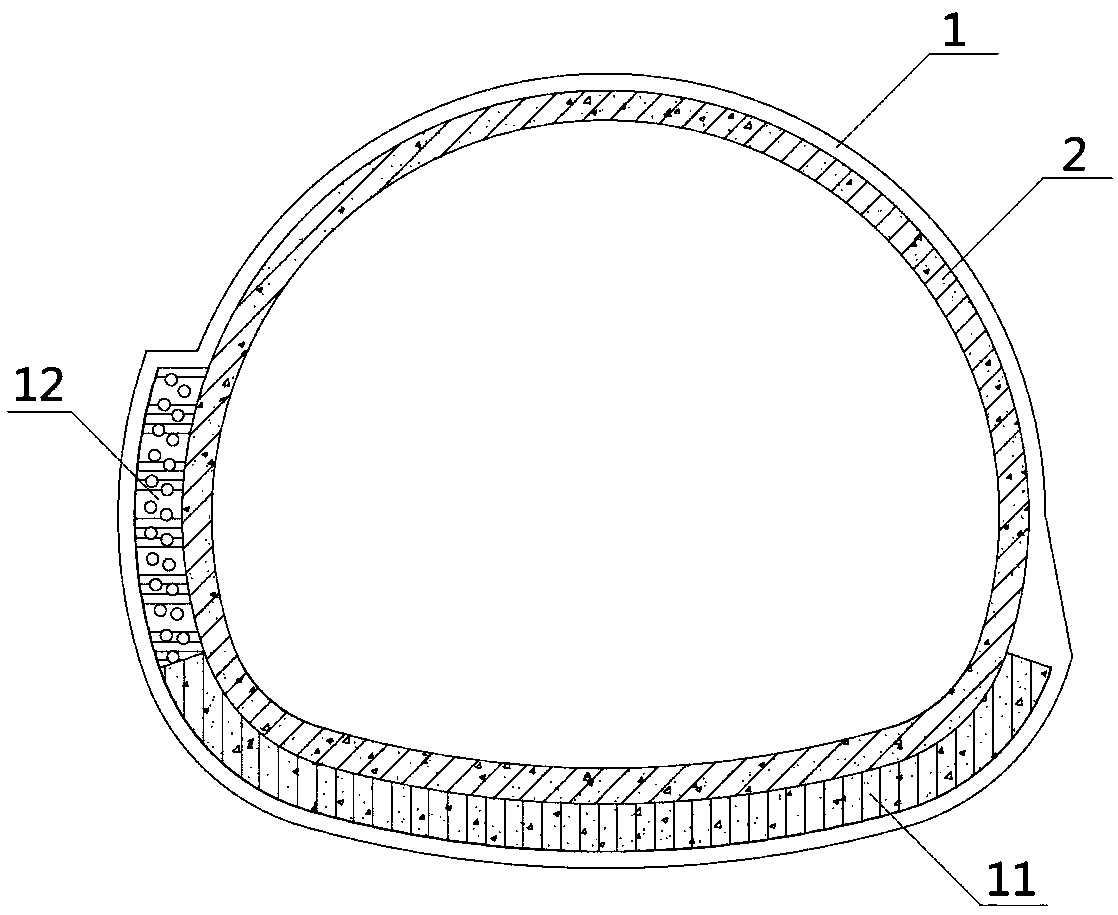

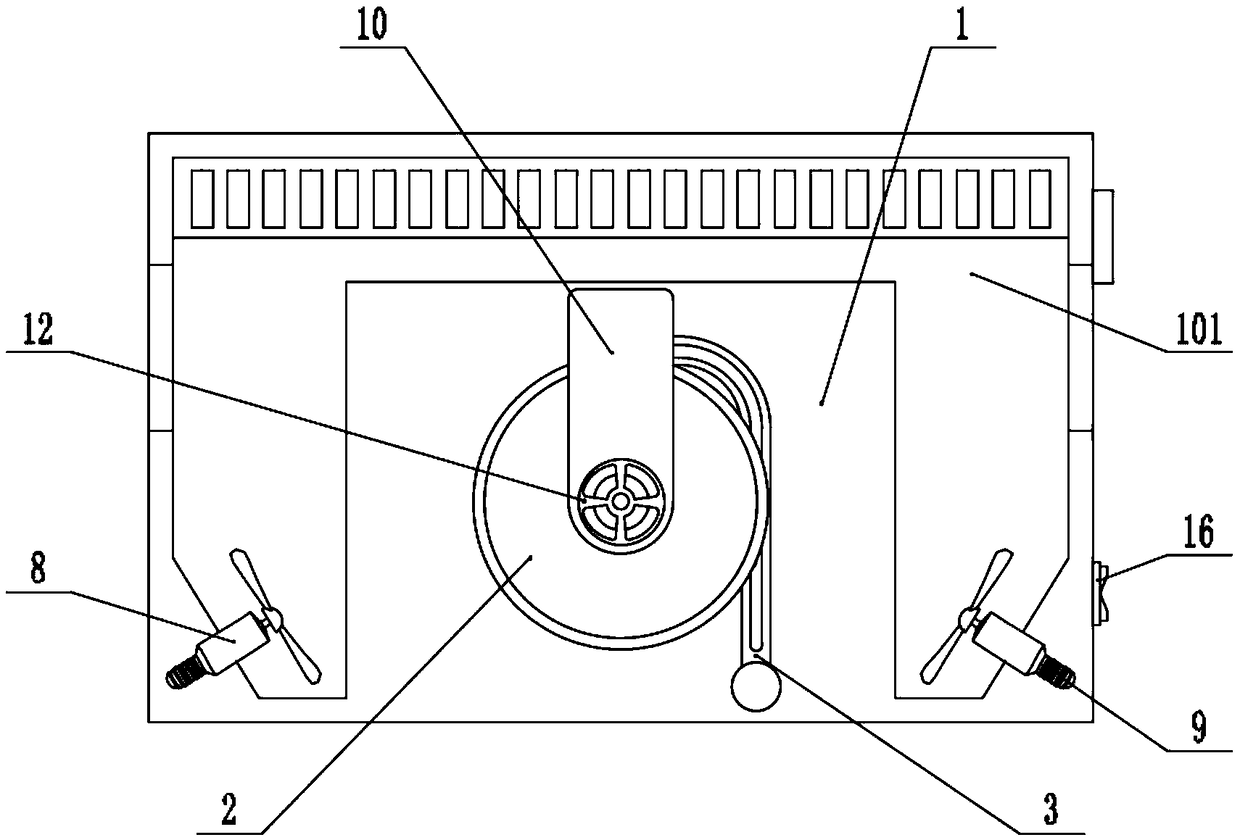

Self-adaptive structure for displacement of tunnel by active fault sectional mining method and installation method

PendingCN109681231AAvoid mistakesReduce the amount of structural misalignmentGeometric CADUnderground chambersActive faultShotcrete

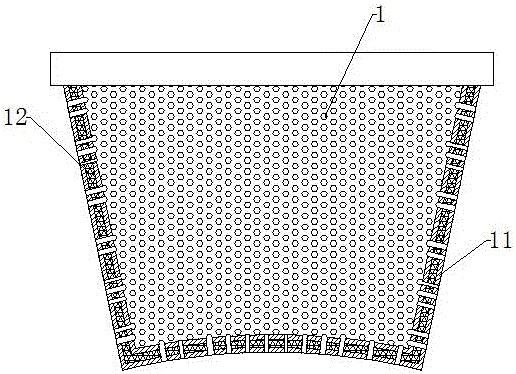

The invention discloses a self-adaptive structure for displacement of a tunnel by an active fault sectional mining method. An anti-offset area is arranged at a section, longitudinally crossing the active fault, of the tunnel, and comprises sprayed concrete (1), secondary lining (2) and a filling layer, wherein the filling layer is arranged between the sprayed concrete (1) and the secondary lining(2) and is of a half-coating structure; the filling layer comprises a bottom filling section and side filling sections, the bottom filling section is arranged at the bottom part of the tunnel, and theside filling sections are arranged at the side edges of the tunnel; porous rubber (12) is filled into each side filling section, a plurality of support piers (11) are arranged in the bottom filling section at intervals, the porous rubber (12) is arranged between the adjacent support piers (11), and the porous rubber (12) is of a pre-compressed structure. The invention also discloses an installation method of the self-adaptive structure for displacement of the tunnel by the active fault sectional mining method. The displacement self-adaptive structure provides by the invention provides supportfor the tunnel structure, and is capable of reducing the offsetting quantity of the structure.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Engraving fixing device for ceramic processing

ActiveCN108909329AConvenient post-engraving workAvoid scatterLighting applicationsMechanical apparatusEngravingWorking environment

The invention provides an engraving fixing device for ceramic processing. The engraving fixing device comprises a power source switch and a miniature power source plug, wherein the top part of an engraving table is provided with a material leaking groove; the bottom part of the material leaking groove is of a hollow structure; the front end of the end surface of the top part of the engraving tableis provided with a circular positioning groove, and the bottom part of an inserting bolt is glidingly connected with the interior of the positioning groove; the top part of a rotary disc is of a circular plate-shaped structure, and the rotary disc is positioned at the end surface of the top part of the engraving table; a rotary handle is of an L-shaped strip structure, and the bottom part of therotary handle is glidingly connected with the end surface of the top part of the engraving table; a rubber gasket is attached to the inside sawtooth-shaped structure of the rotary handle. The engraving fixing device has the advantages that when an operator engraves a bottled magnetic blank, the crushed residue of porcelain clay from the engraving is blown away from the surface of the magnetic blank, the exterior of the magnetic blank is cleaner, and the operator can conveniently perform the engraving operation lately; by arranging the material leaking groove and a net cage, the previous blowncrushed residue of porcelain clay away from the surface of the magnetic blank can be collected, so as to avoid the pollution to working environment due to scattering of the crushed residue of the porcelain clay.

Owner:陈春燕

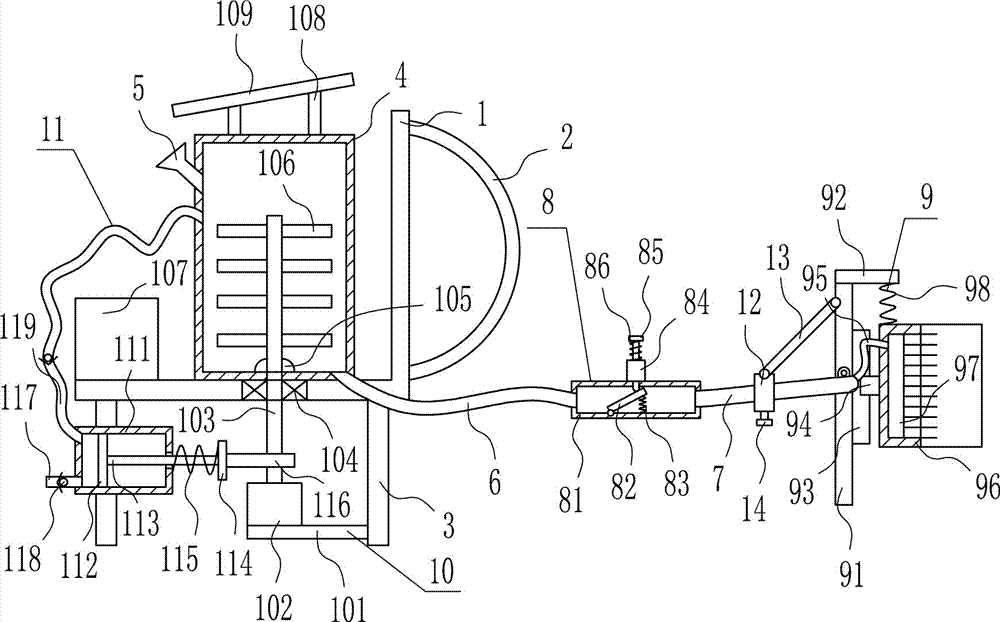

Automatic cleaning type advertisement cabinet

InactiveCN106057078AAffect the use effectSave human effortCleaning using toolsCleaning using liquidsEngineeringWater spray

The invention provides an automatic cleaning type advertisement cabinet. The automatic cleaning type advertisement cabinet comprises a cabinet body, a transparent display board is arranged at the front end of the cabinet body, and two vertical driving mechanisms are arranged on left and right sides of the transparent display board respectively; left and right ends of a cleaning rod in horizontal arrangement are connected with the two vertical driving mechanisms respectively; the cleaning rod is provided with a brush head which contacts with the transparent display board; a water spray rod is horizontally arranged at the top end of the transparent display board and provided with water spray holes. The automatic cleaning type advertisement cabinet has advantages that the advertisement cabinet can be regularly cleaned and prevented from being dirty in long-term outdoor application, influences on utilization of the advertisement cabinet are avoided, and manpower is greatly saved.

Owner:SHENZHEN YIHAOGUI TECH CO LTD

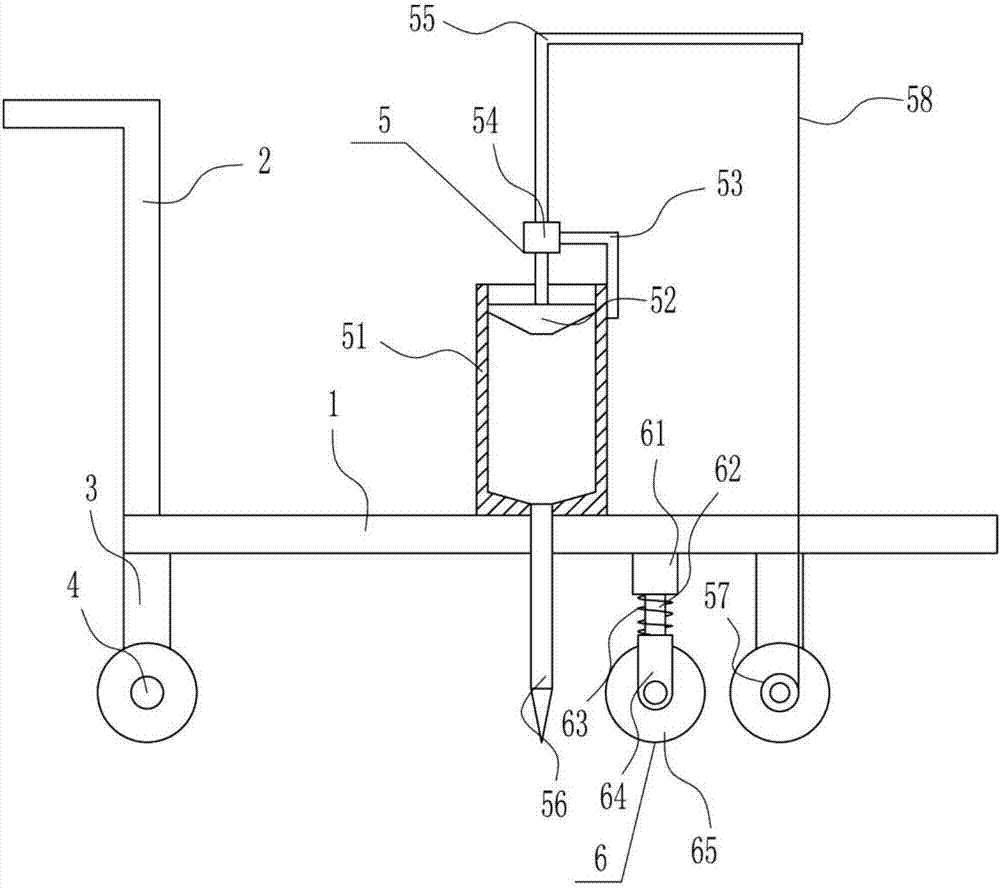

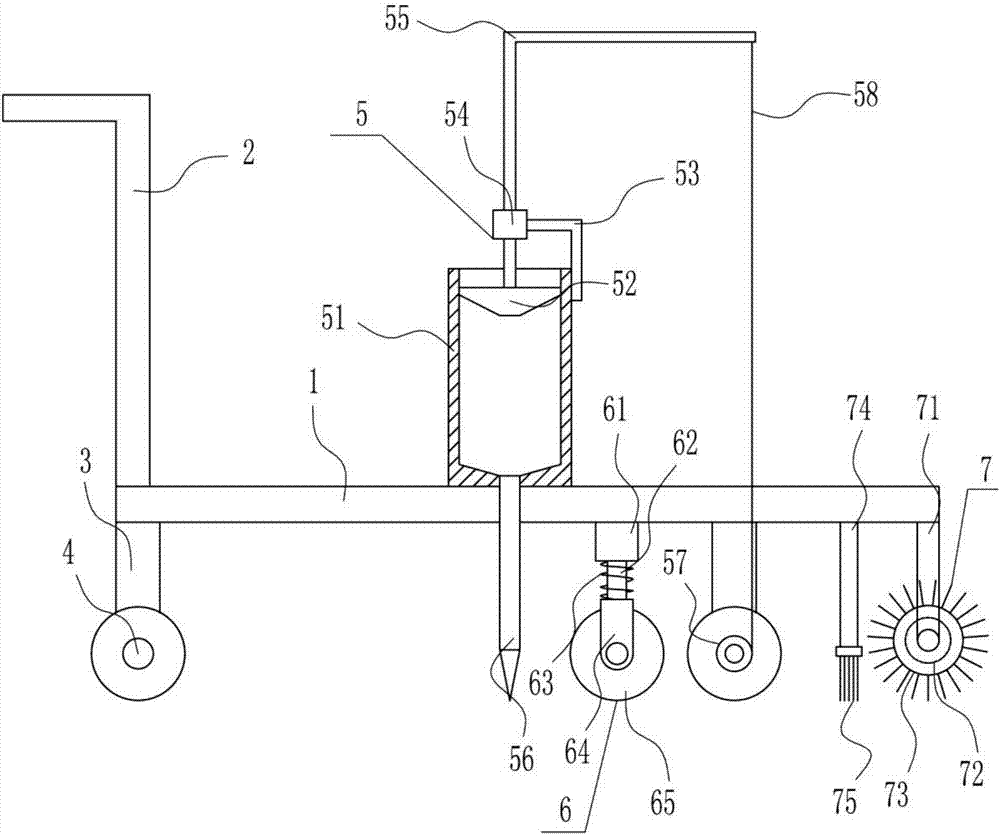

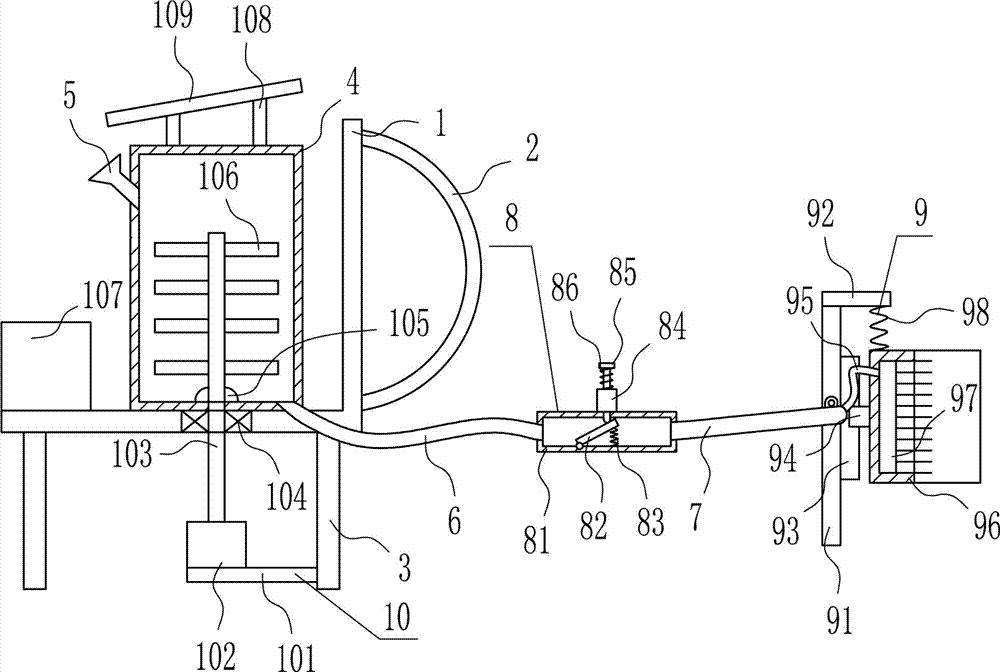

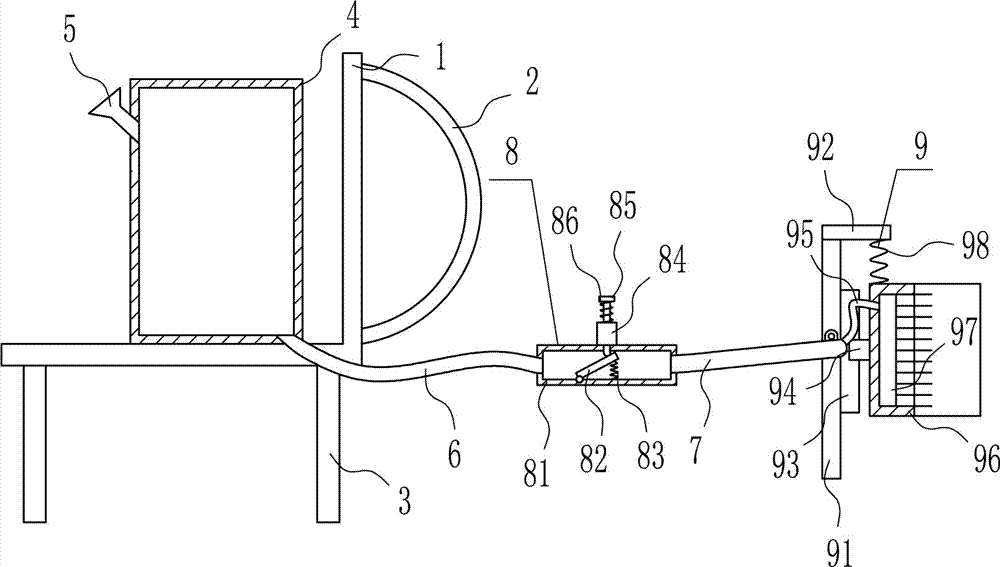

Whitewash spraying equipment for gardens

InactiveCN107999344AAffect the use effectEasy dischargeLiquid surface applicatorsLiquid spraying apparatusTree trunkEngineering

The invention relates to spraying equipment, in particular to whitewash spraying equipment for gardens. The whitewash spraying equipment has the advantages that the time-saving and labor-saving effects can be achieved, the spraying effect is good, whitewash can be spayed and stirred at the same time, and precipitation is not liable to occur. In order to solve the technical problem, the invention provides the whitewash spraying equipment for the gardens. The whitewash spraying equipment comprises an L-shaped plate, a strap and the like; the strap is connected to the right side surface of the L-shaped plate; supporting legs are symmetrically arranged on the left side and the right side of the bottom of the L-shaped plate; a box body is arranged on the right side of the bottom of the L-shapedplate; a feeding hopper is arranged on the upper portion of the left side of the box body and communicates with the interior of the box body; and a discharging pipe is connected to the right side ofthe bottom of the box body. According to the whitewash spraying equipment, the whitewash can be stirred through a stirring device so that the phenomenon that the use effect of the whitewash is influenced due to precipitation of the whitewash can be avoided, the whitewash can be better discharged from the box body into the discharging pipe to be sprayed on tree trunks through a pressurizing device,and therefore the time-saving and labor-saving effects can be achieved, and the spraying effect is good.

Owner:郑瑞文

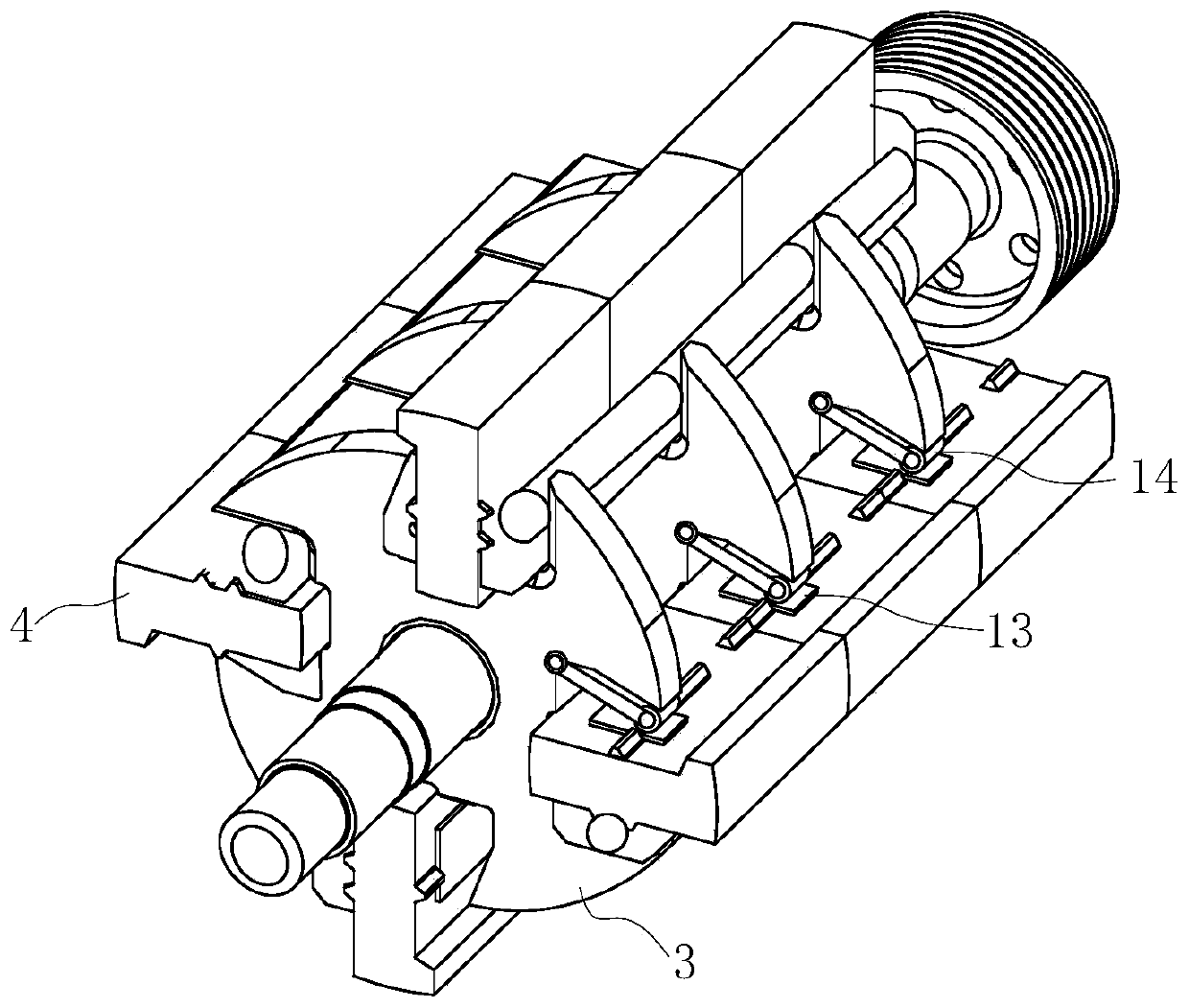

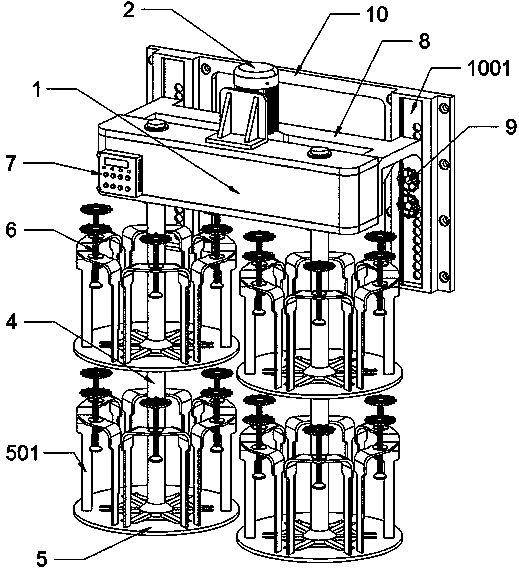

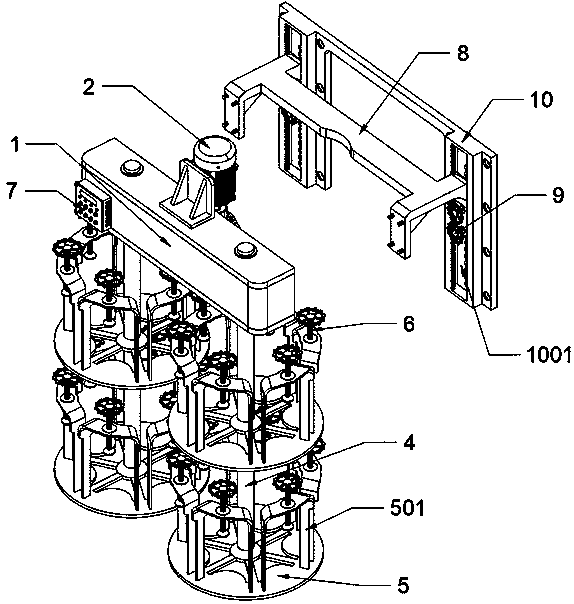

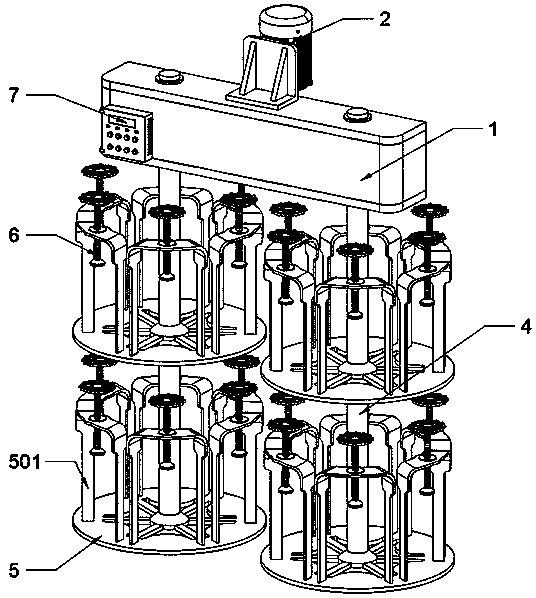

Multi-station hanging tool for automatic machining sand blasting equipment

ActiveCN110405638AGuaranteed stabilityImprove sandblasting efficiencyAbrasive machine appurtenancesAbrasive blasting machinesSand blastingDrive motor

The invention provides a multi-station hanging tool for automatic machining sand blasting equipment. The tool comprises station ring plates, N-shaped limiting frames and fixing screws, wherein a mainbody is hollow, and the main body is mounted at the front end of a connecting seat through a support frame; the drive motor is mounted at the top end of the rear side of the main body inversely, and is connected with a control electric box through a power line; a rotating shaft at the bottom of the driving motor is rotationally connected with the outside of the rear side of the main body through abearing, and a driving pulley is arranged on the outer side of the rotating shaft at the bottom of the driving motor; a synchronous belt is rotationally connected inside the main body. Workpieces tobe sandblasted can be placed in the N-shaped limiting frames arranged on the tops of the station ring plates, the fixing screws on the tops of the N-shaped limiting frames are rotated, so that the bottoms of the fixing screws are moved and pressed on the end surfaces of the tops of the workpieces to clamp and fix the workpiece inside the N-shaped limiting frames, and stability of the workpieces during sandblasting is guaranteed.

Owner:GUANGZHOU XINSAIERTE TENT TECH CO LTD

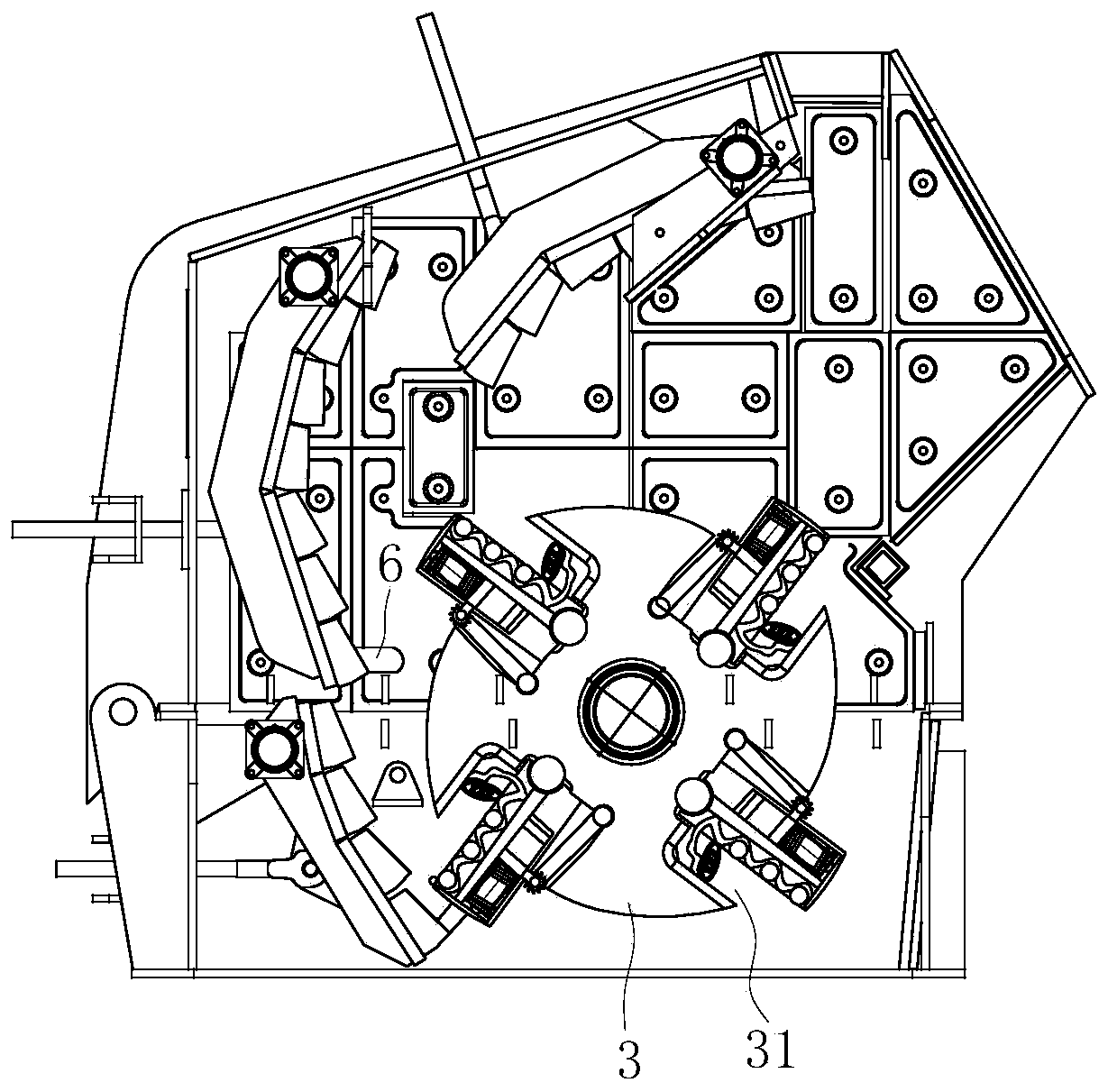

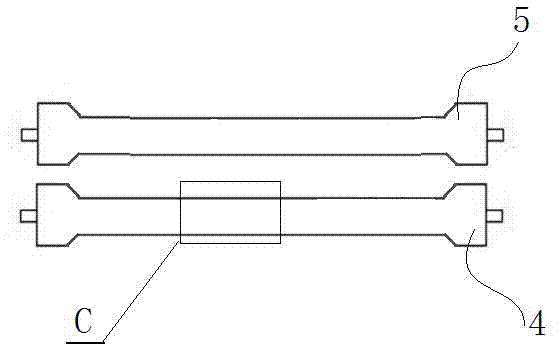

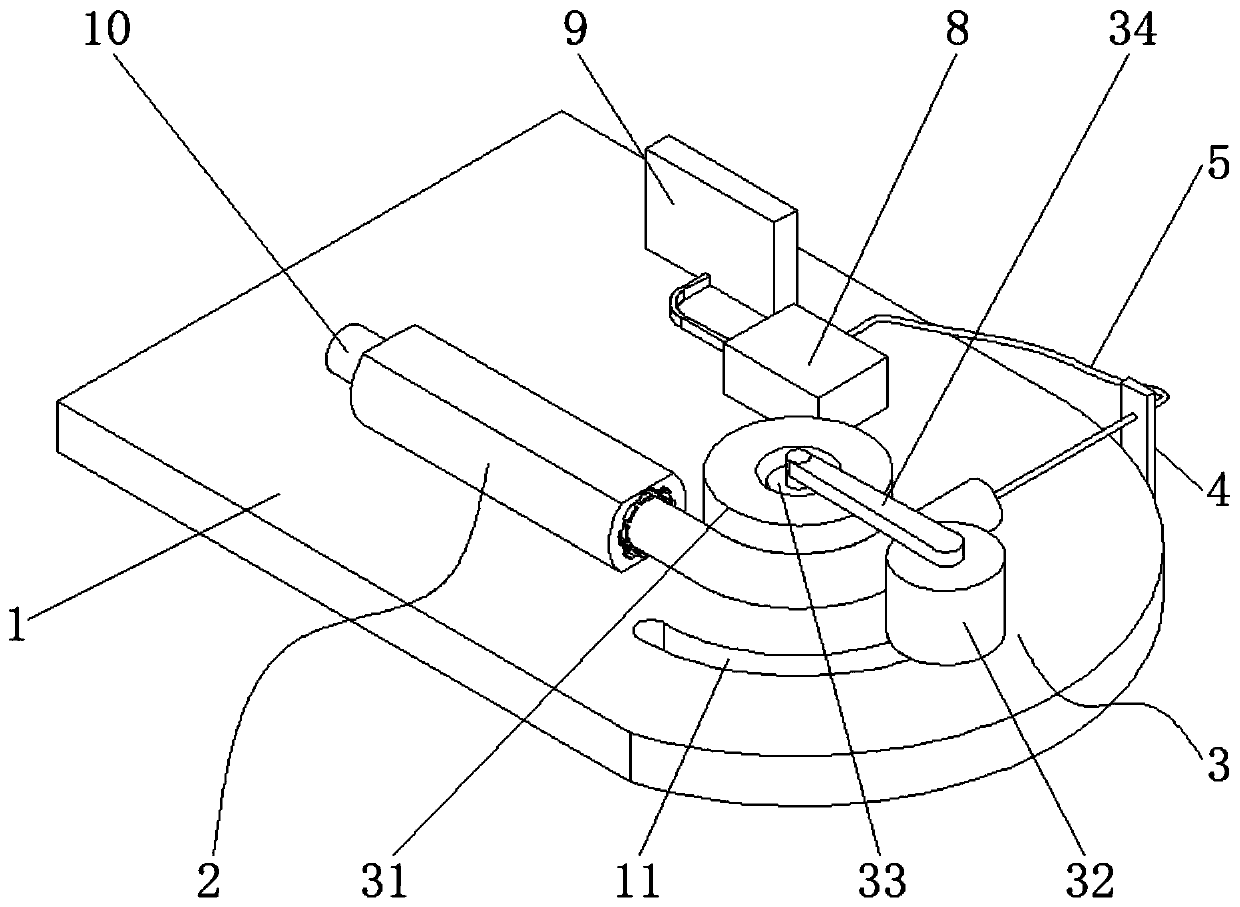

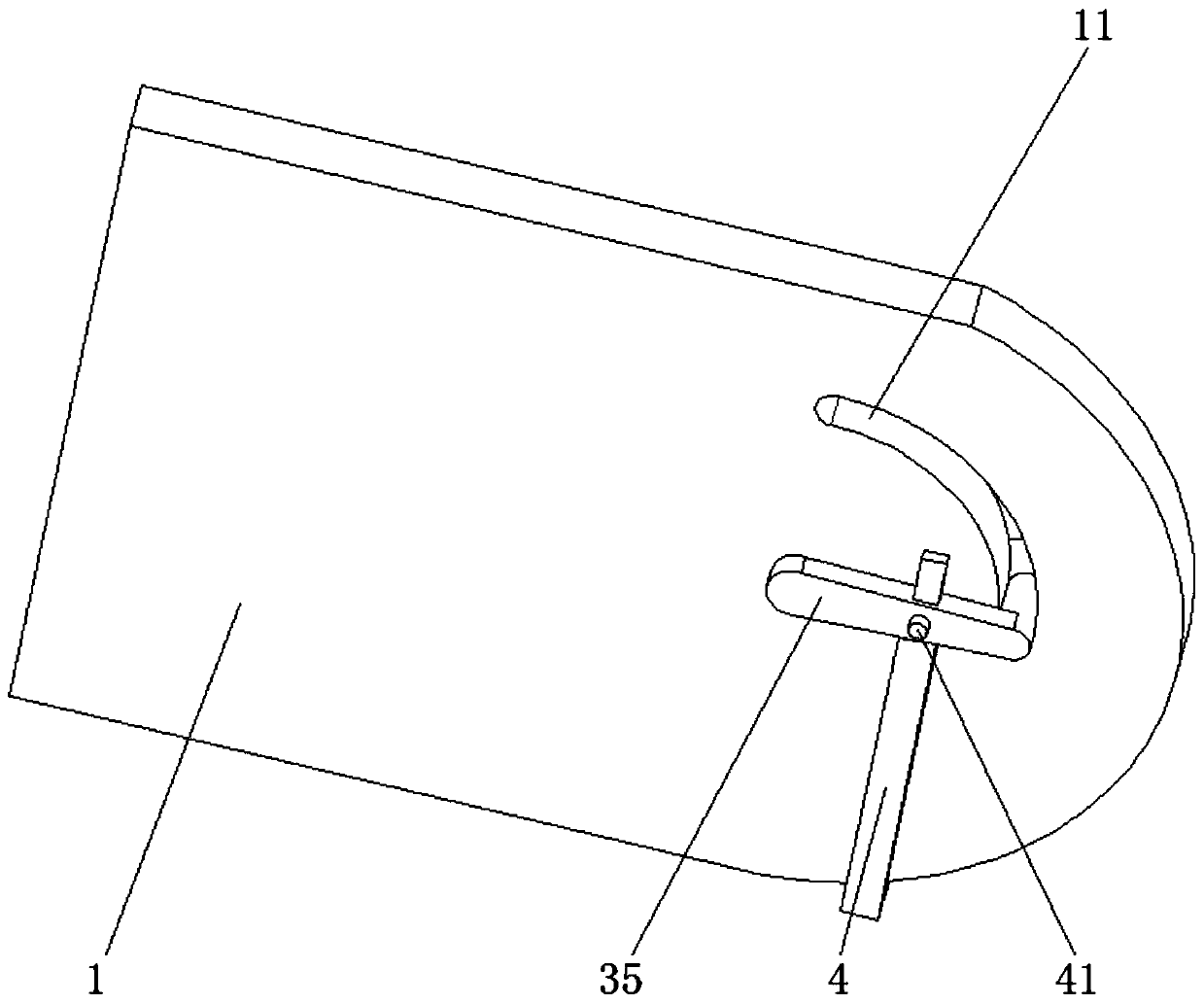

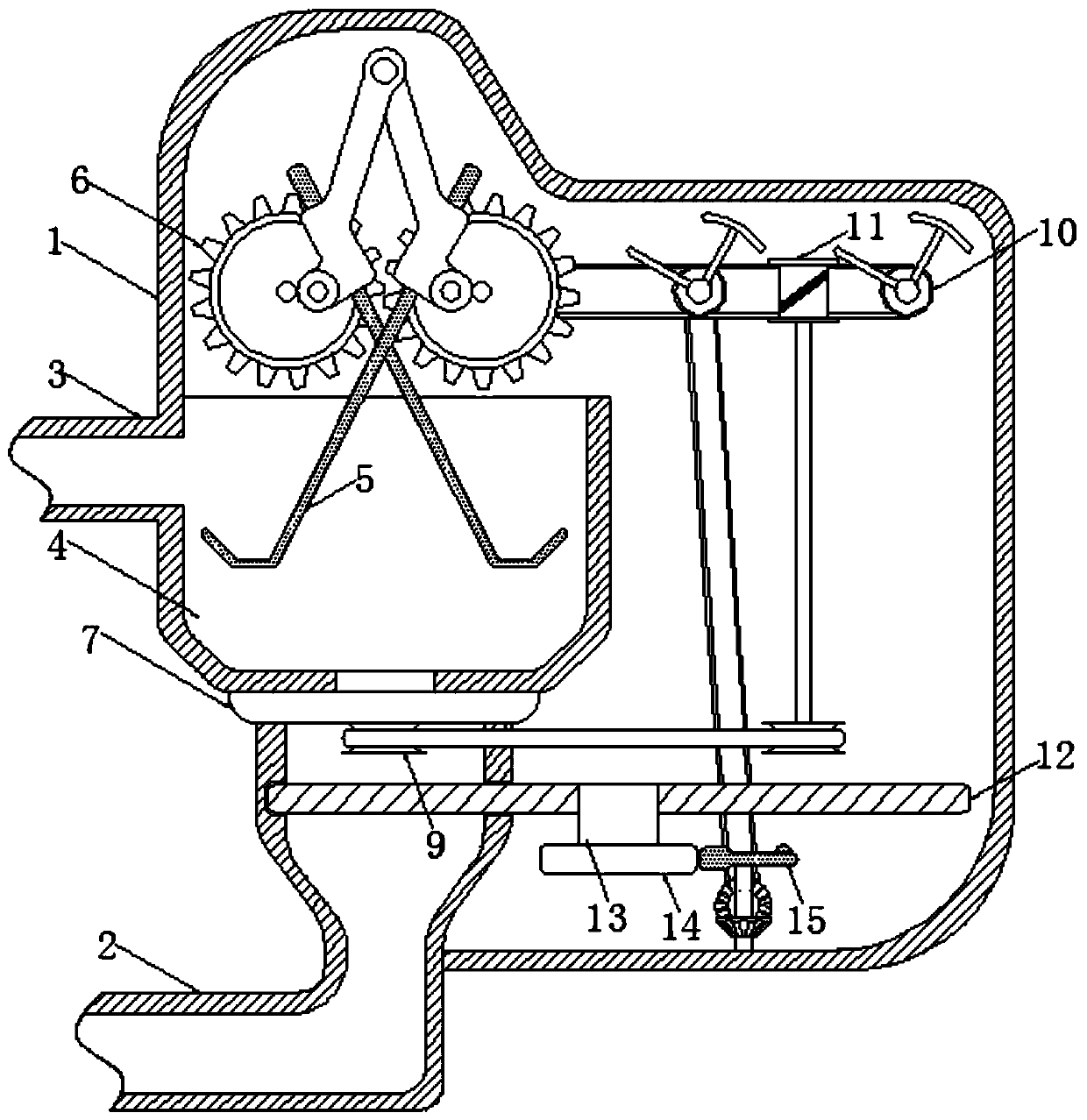

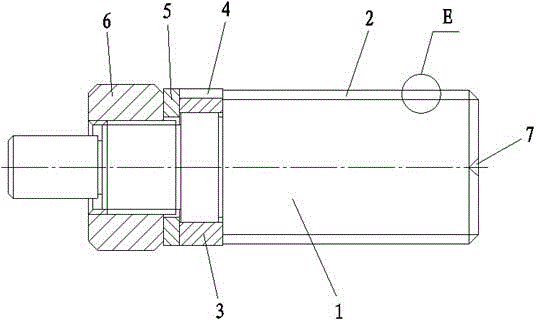

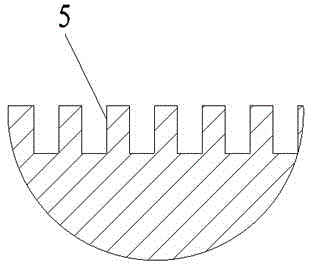

Multi-layer wave spring winding device and winding method

The invention discloses a multi-layer wave spring winding device and winding method. The multi-layer wave spring winding device comprises a mandrel (1) and is characterized in that a rectangular spiral groove (2) is formed in the surface of one end of the mandrel (1), a clamp ring (3) sleeves the end near the rectangular spiral groove (2), an axial through slot (4) is formed in the circumference of the clamp ring (3), a nut (6) compresses the clamp ring (3) and fixes the clamp ring on the mandrel (1) through a gasket (5), and the through slot (4) in the clamp ring (3) is aligned to the initial end of the rectangular spiral groove (2). The multi-layer wave spring winding device is simple in structure, convenient and fast to process and capable of shortening the gaps between circles of the multi-layer wave spring and guaranteeing the coaxiality of the multi-layer wave spring so as to enable the multi-layer wave spring to meet use requirements.

Owner:GUIZHOU HONGLIN MACHINERY

Method for inhibiting in-vivo BmNPV viral multiplication of silkworms

ActiveCN103947614AAffect digestionAffect absorbencyAnimal feeding stuffAccessory food factorsBiotechnologyMicrobiology

The invention discloses a method for inhibiting in-vivo BmNPV viral multiplication of silkworms. The method comprises the following steps: firstly preparing nano-titanium dioxide into an additive solution with the concentration of 4.5-5.5 mg / L; spraying the solution on mulberry leaves according to the use dosage that 1.0L of solution is added to 100kg of mulberry leaves; feeding to the silkworms after the mulberry leaves are dried, so that the in-vivo BmNPV viral multiplication of the silkworms can be obviously inhibited. According to the method, the nano-titanium dioxide is fed to the silkworms to inhibit the in-vivo BmNPV viral multiplication, and thus a theoretical support can be provided for the preventing and curing of BmNPV disease of silkworms. The disclosed method is high in practicability, convenient in operation and obvious in effect, and is suitable for popularization and application in sericultural areas of our country.

Owner:JIANGSU HUAJIA SILK

Antibacterial mildew-proof synthetic leather production process

The invention discloses an antibacterial mildew-proof synthetic leather production process in the technical field of synthetic leathers. The process includes the following steps: step I. preparing anorganic silicon / aqueous polyurethane interpenetrating network polymer emulsion containing zinc phthalocyanine, a foaming slurry material and a surface treatment agent; step II. sending release paper into a preheating oven for heating; step III. coating the organic silicon / aqueous polyurethane interpenetrating network polymer emulsion containing the zinc phthalocyanine on the release paper to forma surface layer, and sending the surface layer into a first oven; step IV. uniformly coating the foaming slurry material on the surface layer to form a foaming layer, and sending the foaming layer into a second oven; step V. uniformly coating glue on the foaming layer, coating a polyester cloth on the foaming layer, and sending the foaming layer into a third oven; step VI. peeling the release paper and the surface layer after cooling to obtain a semi-finished product of the antibacterial mildew-proof synthetic leather; step VII. coating the surface treatment agent on the surface of the semi-finished product of the antibacterial mildew-proof synthetic leather, and sending the surface treatment agent into a fourth oven to prepare the antibacterial mildew-proof synthetic leather. The processhas the advantages of safe use and obvious antibacterial and mildew-proof effects.

Owner:YANGZHOU DERWINS PLASTICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com