Controller shell assembly

A controller and housing technology, applied in the field of controller housing assembly, can solve problems affecting the quality of use, achieve better sealing effect, prolong service life, and ensure the effect of using effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

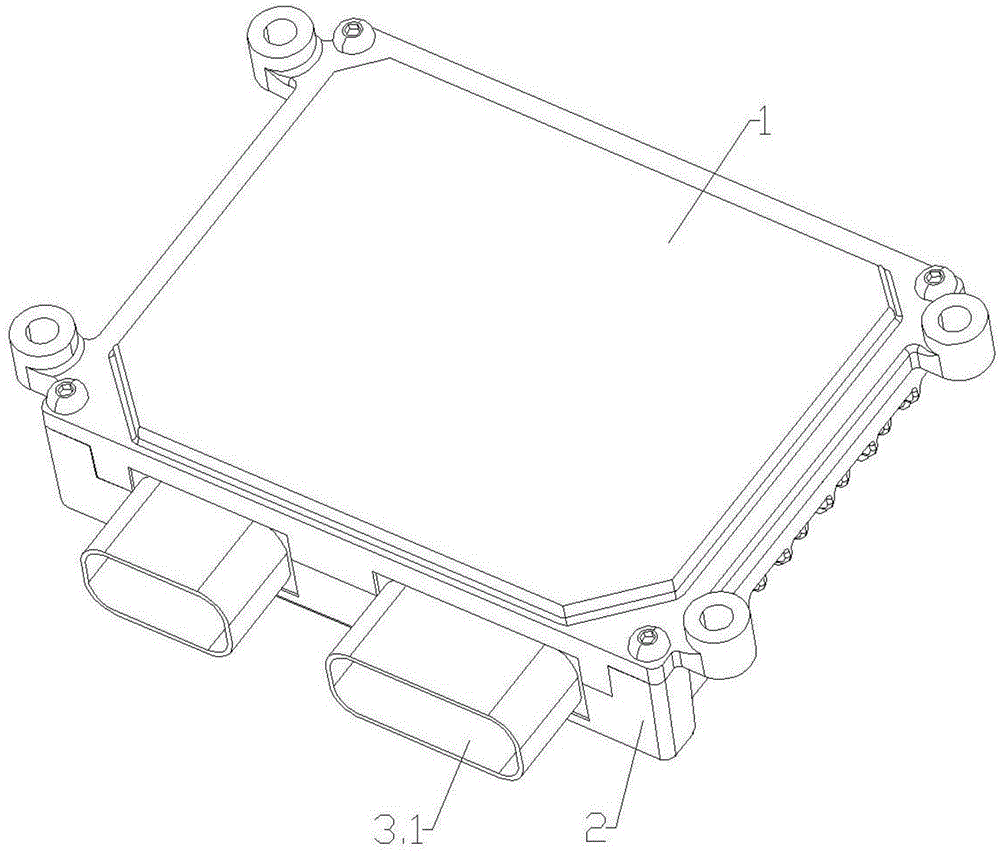

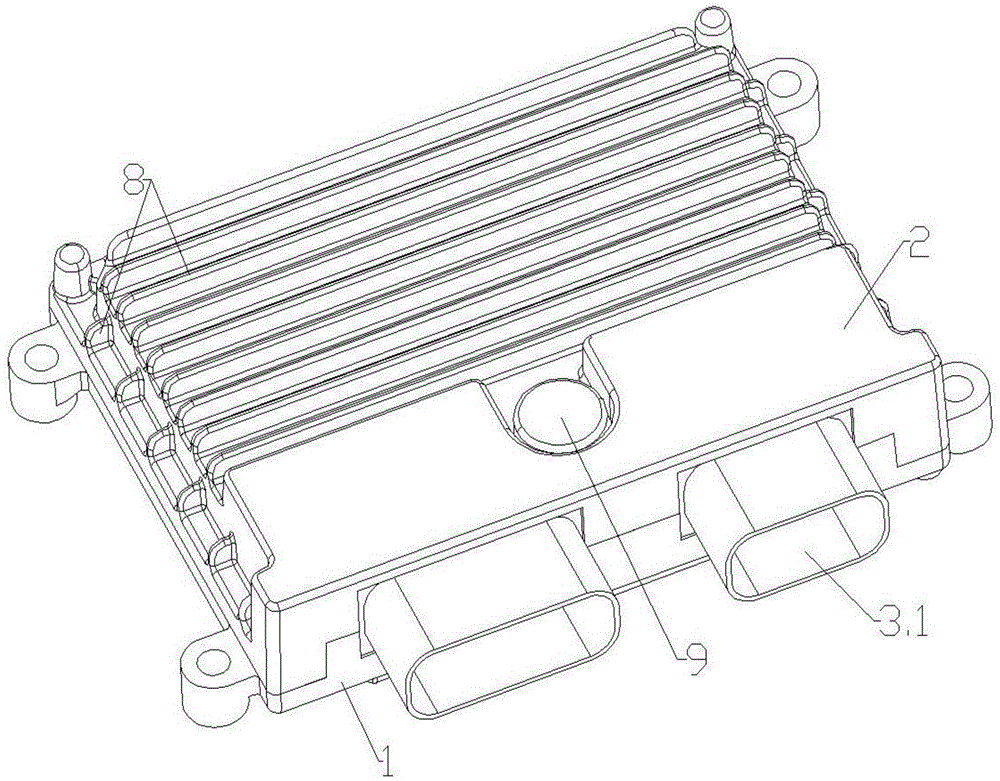

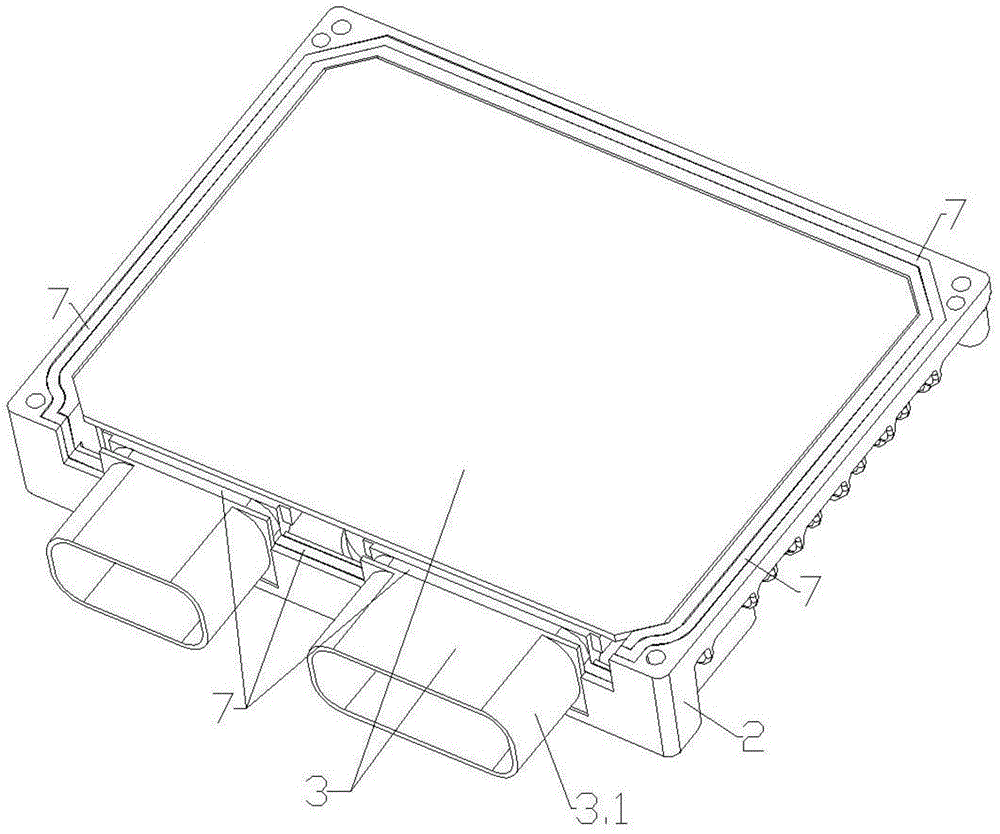

[0021] As shown in the figure, the controller housing assembly of the present invention includes a matching upper cover 1 and a lower cover 2. In this embodiment, the upper cover 1 and the lower cover 2 are fastened and connected by bolts to realize two outfit of the wearer.

[0022] An accommodating area 4 is formed between the assembled upper cover 1 and the lower cover 2 , where the component mounting plate 3 of the power supply is placed horizontally.

[0023] The top surface of the lower cover 2 close to the accommodation area 4 sticks to the bottom surface at the edge of the electrical component mounting plate 3 , and the bottom surface of the upper cover 1 close to the accommodation area 4 sticks to the top surface at the edge of the electrical element mounting plate 3 . Of course, the top surface of the lower cover 2 close to the accommodation area 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com