Patents

Literature

61results about How to "Improve mechanical structure strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bottom buffering metal lug structure

InactiveCN1392607AImprove mechanical propertiesImprove electrical performanceSemiconductor/solid-state device detailsSolid-state devicesCompound (substance)Alloy

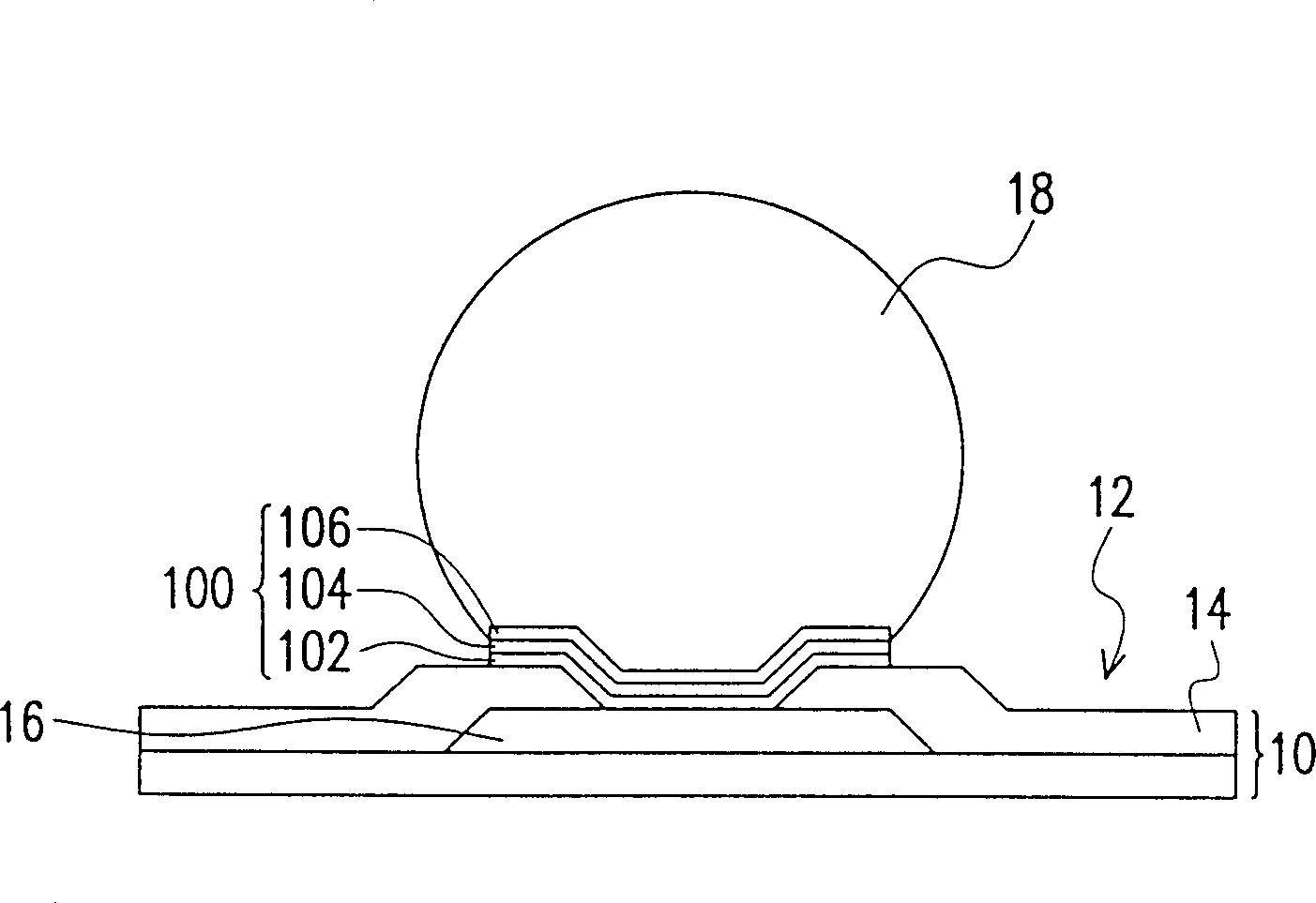

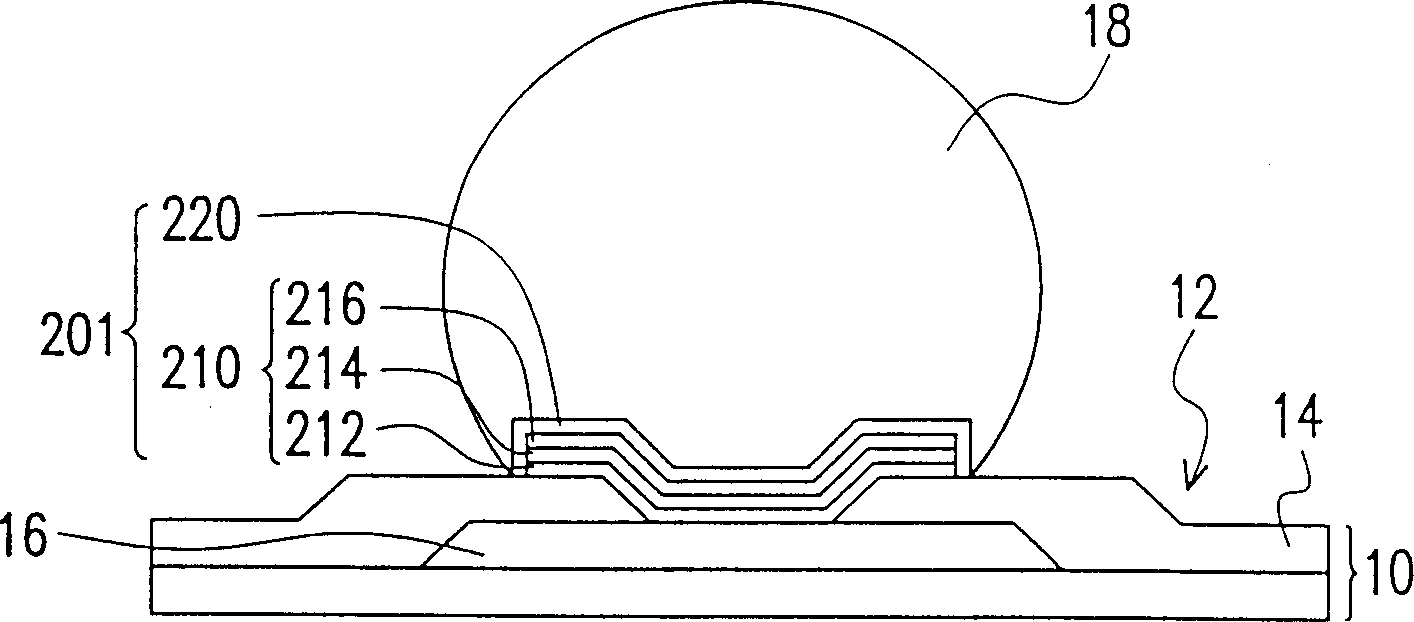

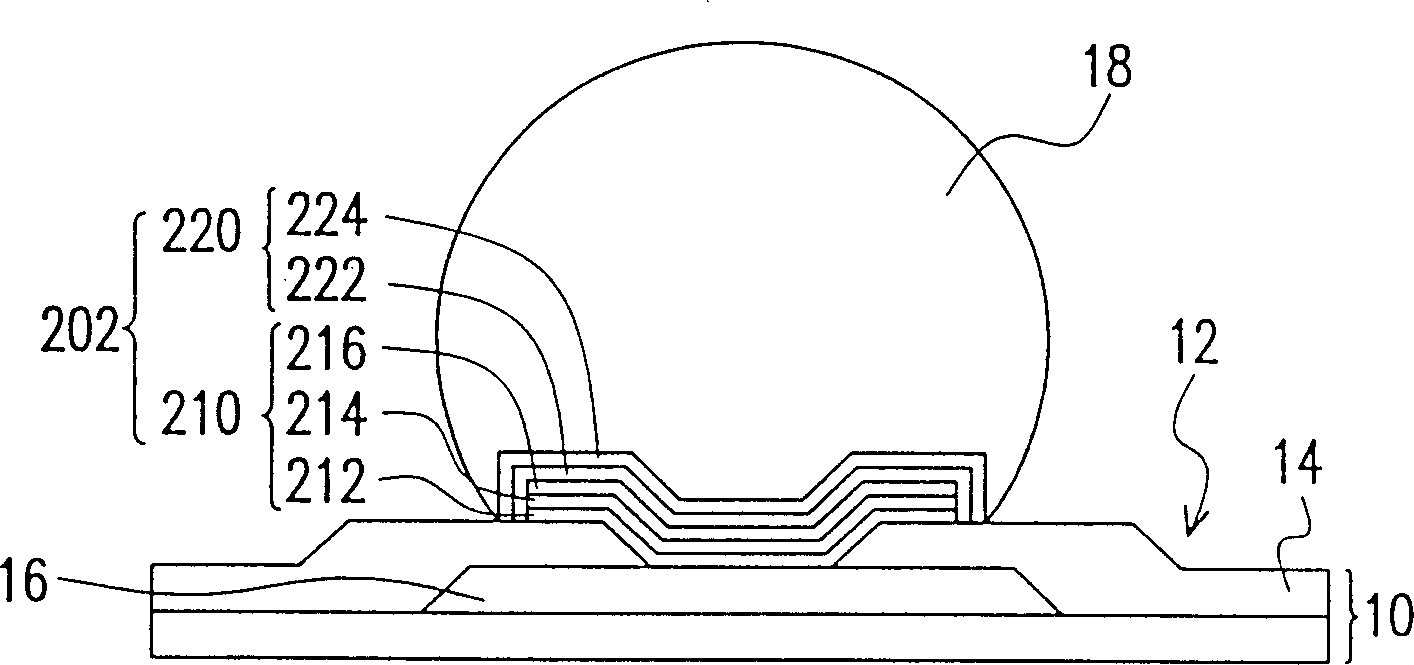

A bulge-bottom buffering metal structure is suitable for being disposed between a chip or a soldering pad for baseplate and a solder lug whose main component is tin-lead alloy. The said bulge-bottom buffering metal structure has at least one metal layer and one tuffing metal construction. This buffering metal construction can reduce or slow down the negative effect of electric and mechanical properties due to the generation of mesic metal compound when the metal layer combines with the solder lug. The metal layer disposed on the soldering pad of chip is composed of such components as Cu, Al, Ni, Ag or Au, etc. which may react on tin chemically, while the buffering construction disposed between the metal layer and the solder lug is used for reducing the possibility of generating the mesic metal compound between them.

Owner:VIA TECH INC

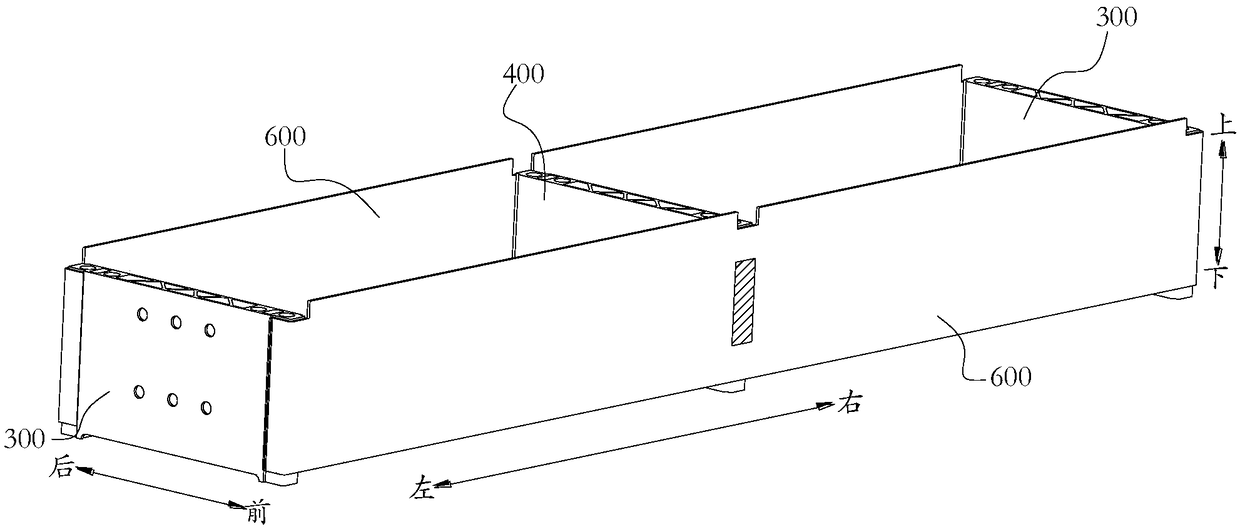

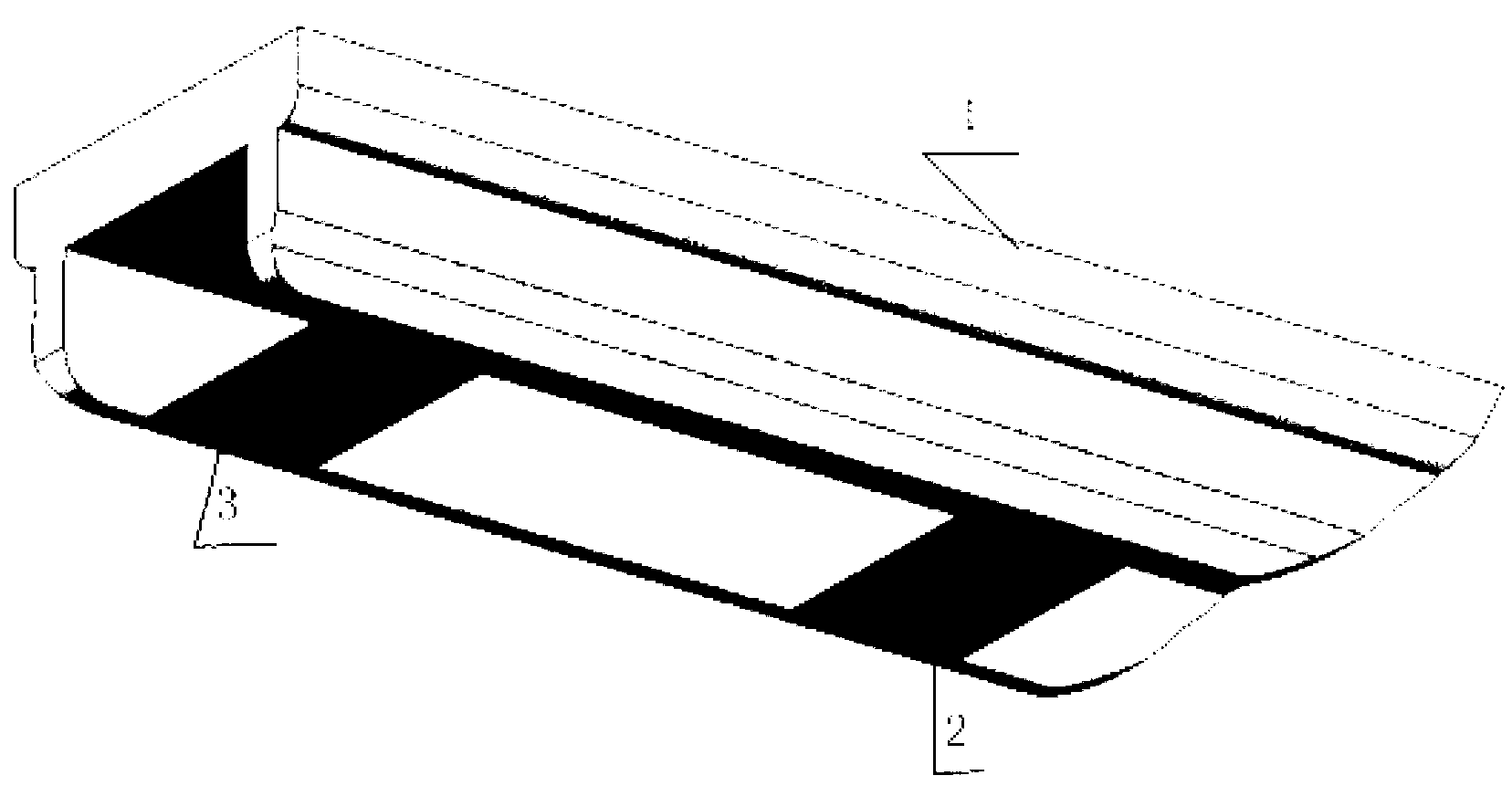

Power battery module of electric vehicle and electric vehicle

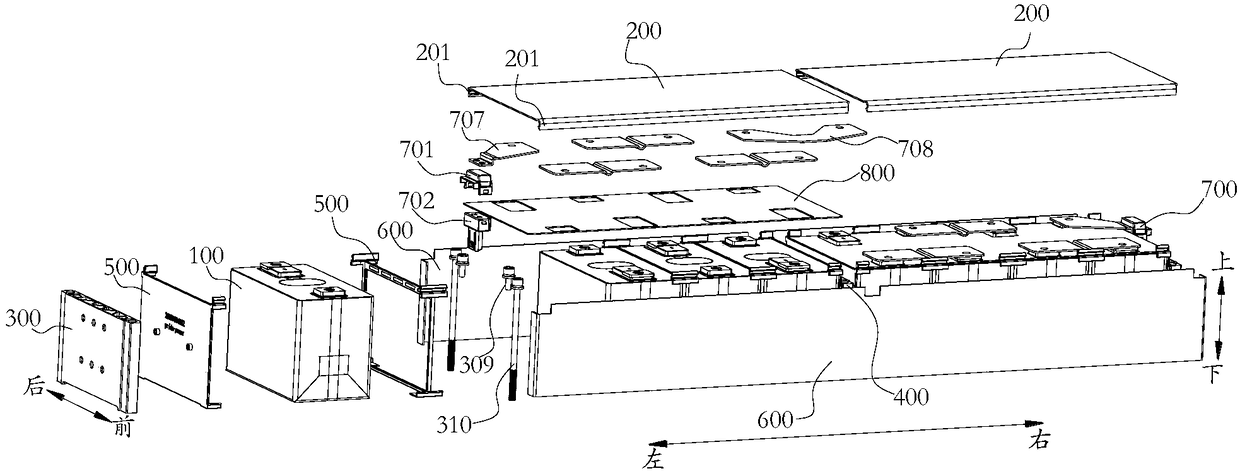

PendingCN108520928ACompact structureIncrease the lengthPropulsion by batteries/cellsCell component detailsPower batteryElectrical battery

The invention relates to a power battery module of an electric vehicle and an electric vehicle. The power battery module comprises cells, an upper cover, a middle end plate, two oppositely arranged end plates, and two oppositely arranged lateral plates. Two end plates are respectively welded to two lateral plates to form a shell without any bottom surface or a top surface. The middle end plate iswelded to two lateral plates so as to divide the interior of the shell into at least two installation cavities. Multiple cells are installed in each installation cavity. The upper cover is arranged onthe upper end of the shell. The overall installation structure is formed by connecting the middle end plate, the end plates, and the lateral plates, the number of stored cells is increased, the number of stored cells is equal to the number of cells of two or more individual modules, compared with two or more individual modules, the size is reduced in the length direction, the module length is increased, the occupied space is small, the uniformity of the module is increased, the inner space is saved, the whole structure of the module is more compact, the space utilization rate is increased, and thus the energy density and capacity of the whole battery system are both increased.

Owner:江苏和中普方新能源科技有限公司

Solidified agent for drilling well waste mud

InactiveCN1792898APrevent seepageHigh strengthSludge treatment by de-watering/drying/thickeningSludgeWell drilling

Owner:刘茂平

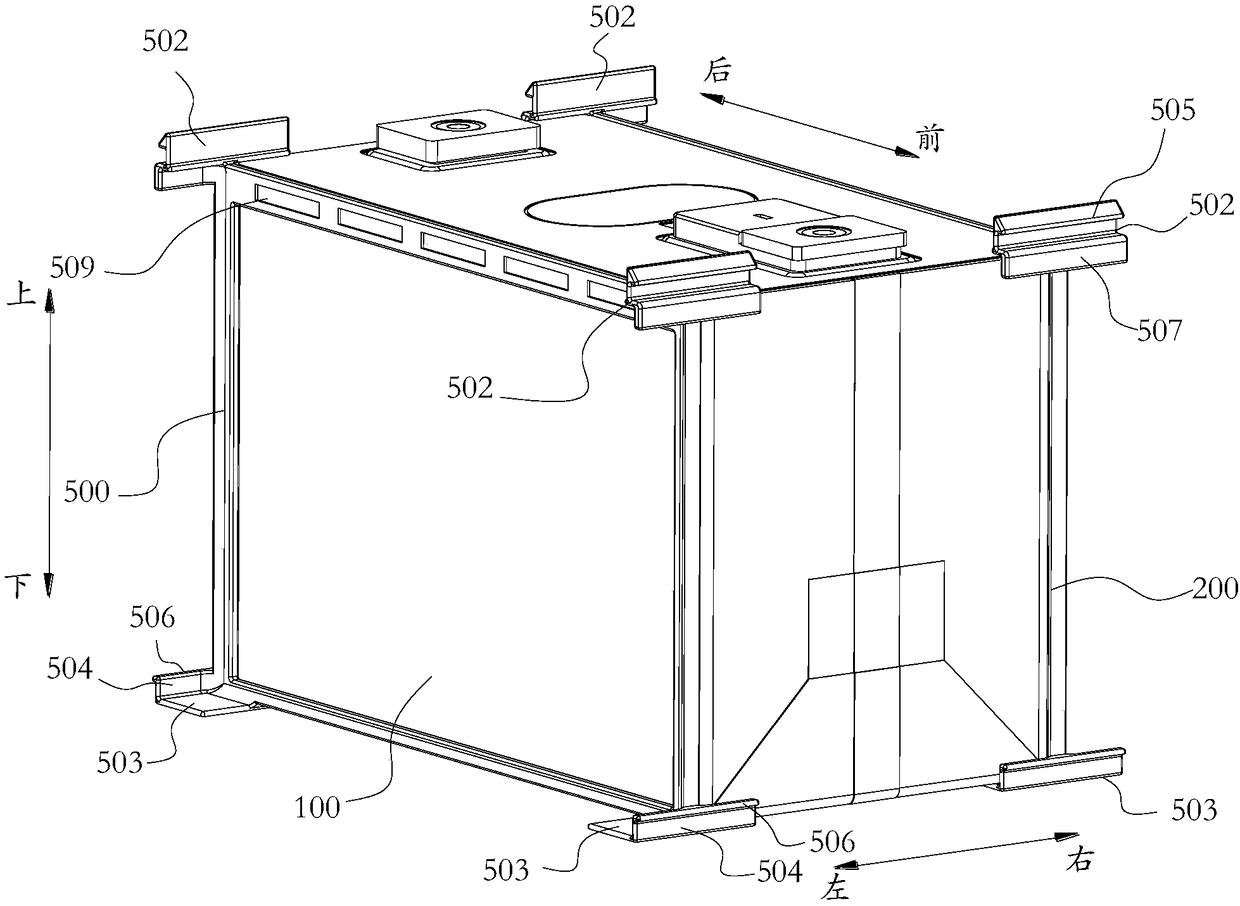

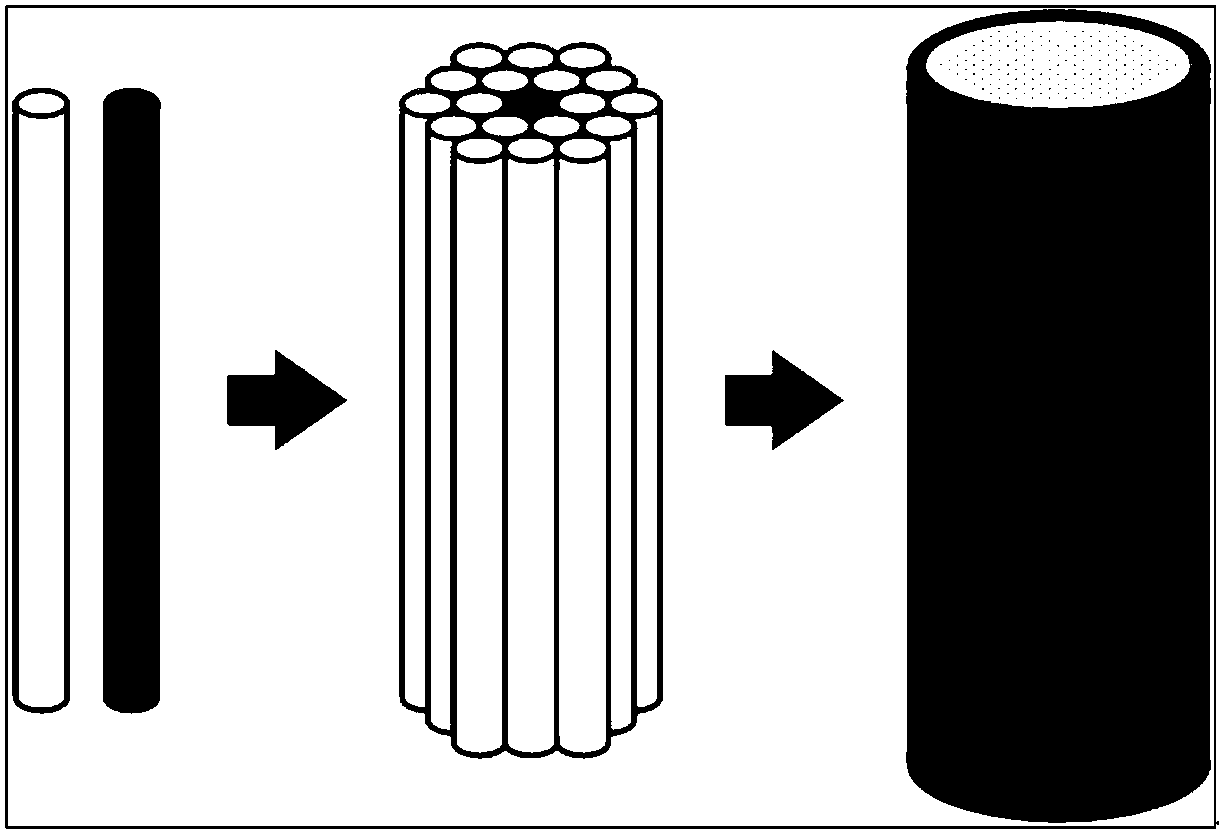

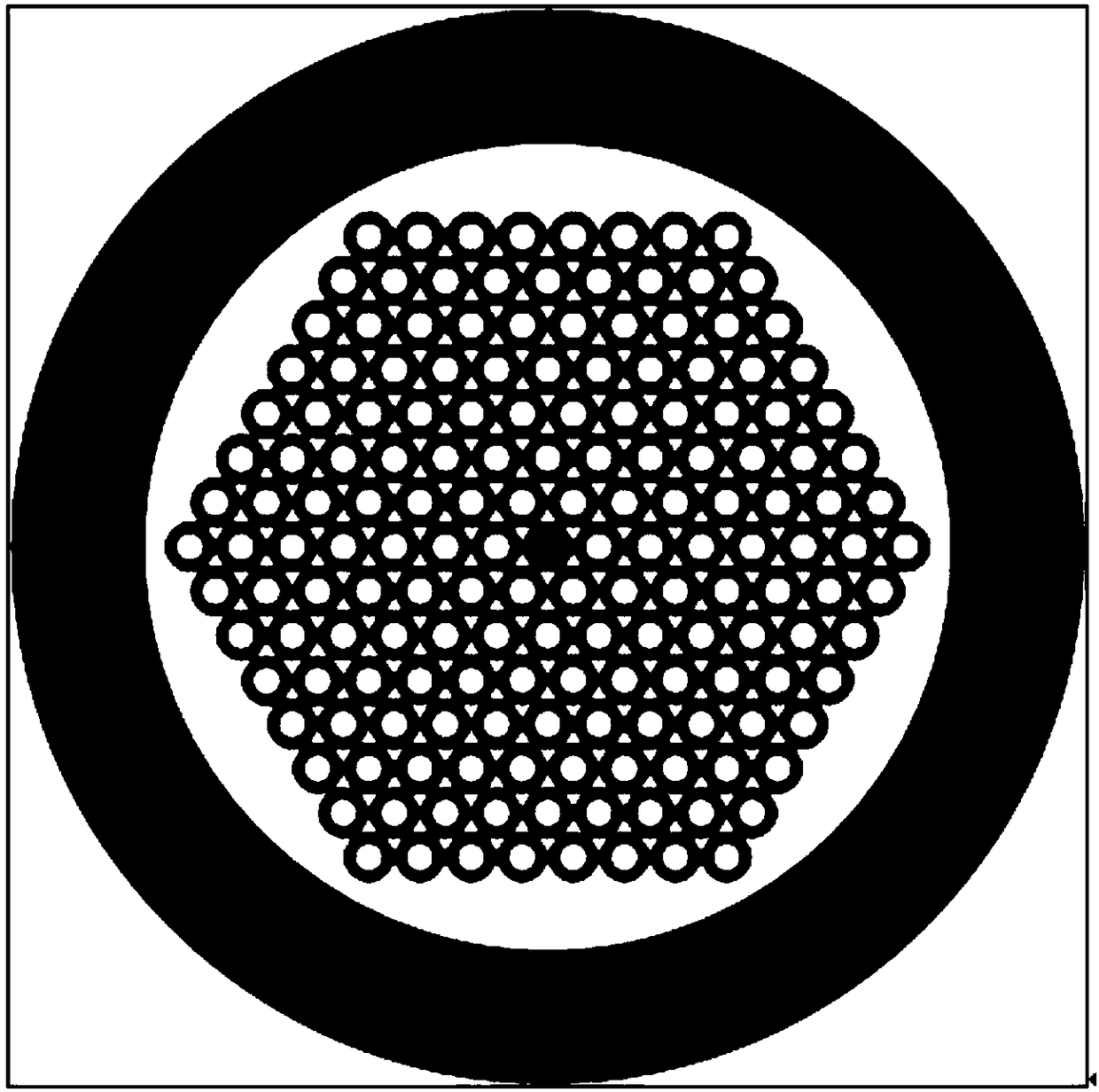

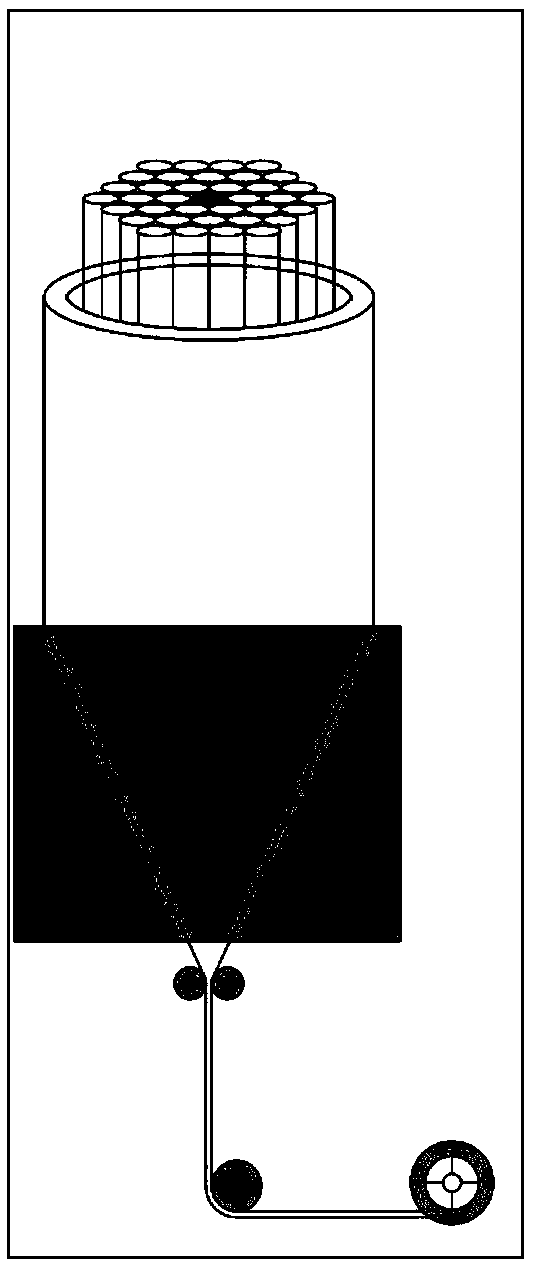

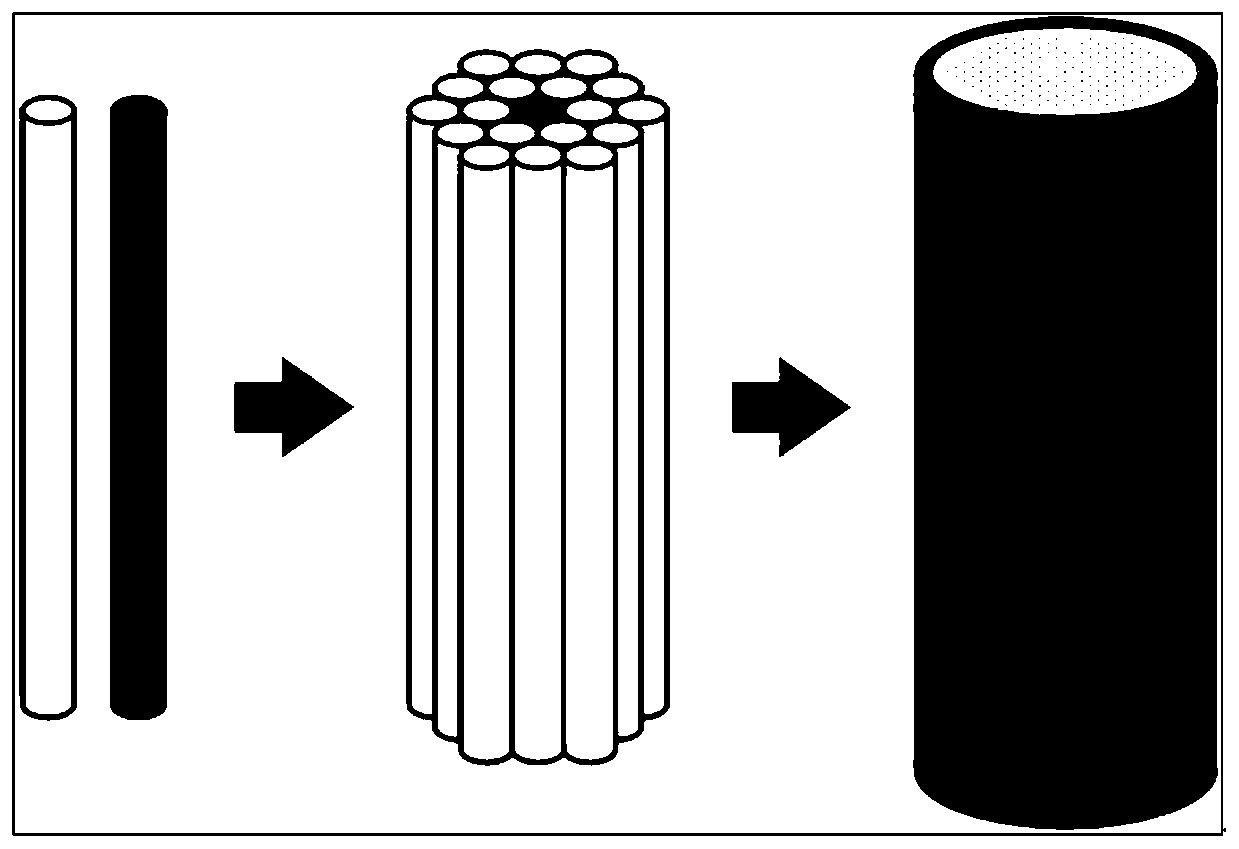

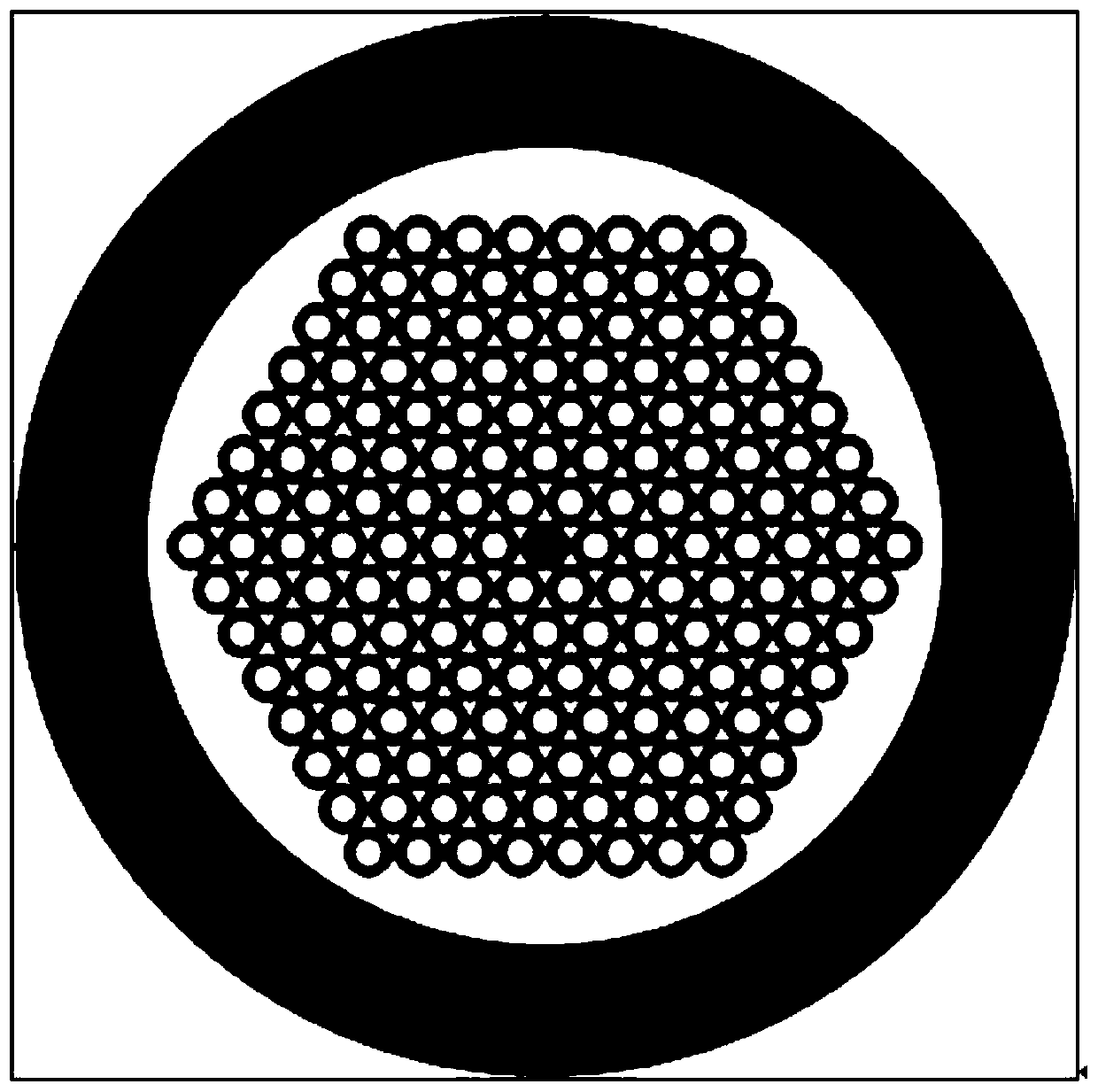

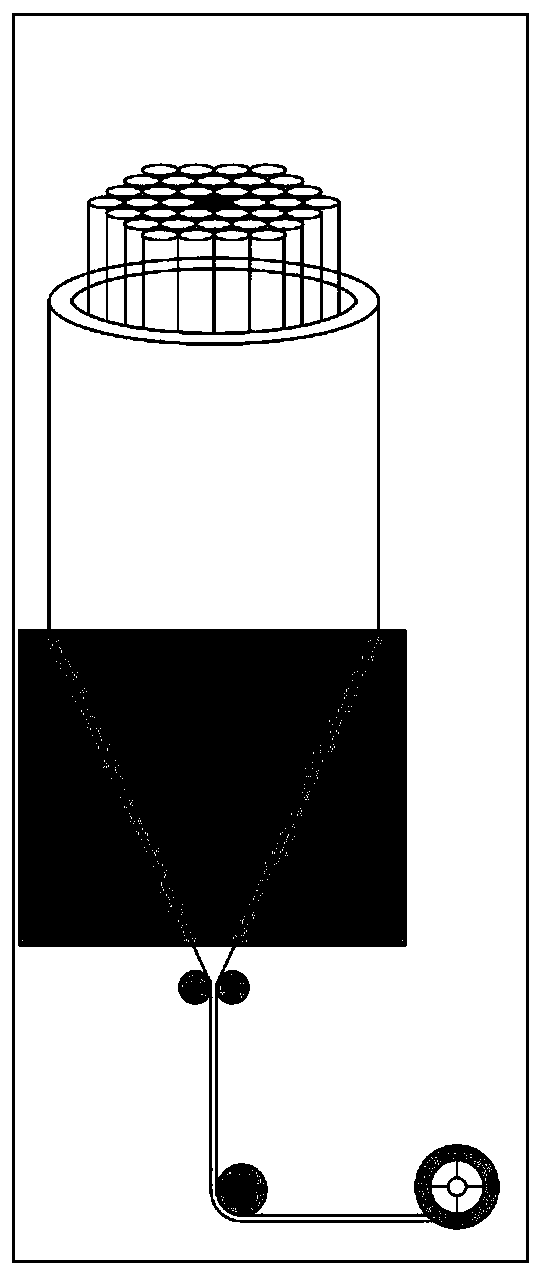

Preparation process of sapphire photonic crystal fiber grating ultra-high temperature distributed sensor

ActiveCN108106751AImprove the stable and resistant temperature of ultra-high temperature environmentImprove mechanical structure strengthThermometers using physical/chemical changesOptical waveguide light guideGratingBoron carbide

The invention provides a preparation process of a sapphire photonic crystal fiber grating ultra-high temperature distributed sensor. The preparation process comprises a first step of producing a sapphire special material rod body and a sleeve by virtue of a sapphire special material tube rod preparation process and technology; a second step of producing a sapphire photonic crystal special opticalfiber based on the sapphire special material rod body and the sleeve provided in the first step through the photonic crystal special optical fiber preparation process and technology, a third step of producing a distributed fiber grating sensing unit in the sapphire photonic crystal special optical fiber based on the sapphire photonic crystal special optical fiber provided in the second step through ultra-fast femtosecond laser engraving fiber grating preparation process and technology, and a fourth step of producing the sapphire photonic crystal fiber grating ultra-high temperature distributedsensor by packing and protecting the sapphire photonic crystal special optical fiber with the distributed fiber grating sensing unit provided in the third step through high temperature packaging based on a ceramic casing pipe with boron carbide high-temperature structure and the high-temperature sensor packaging technology based on sapphire capillary tubes.

Owner:武汉从时光瑞光电技术有限公司

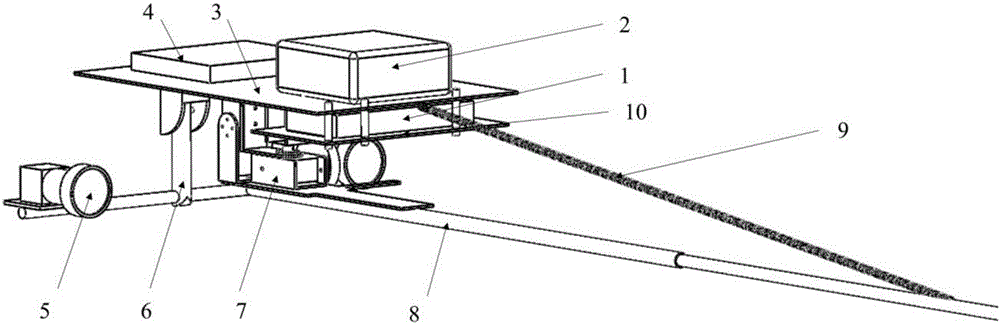

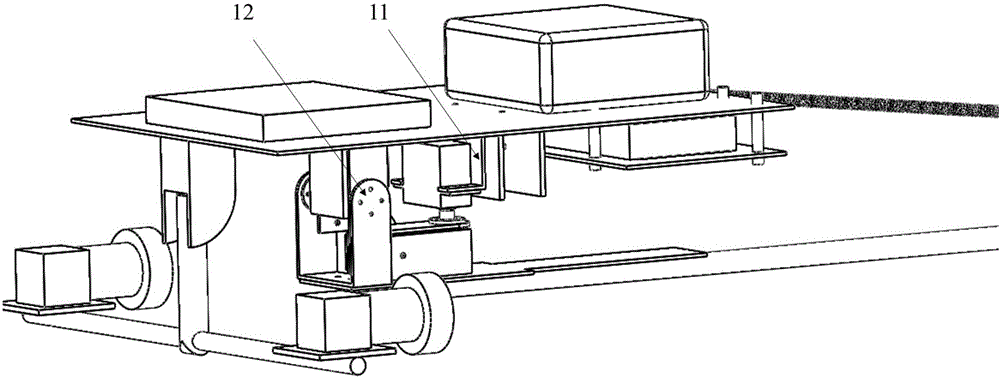

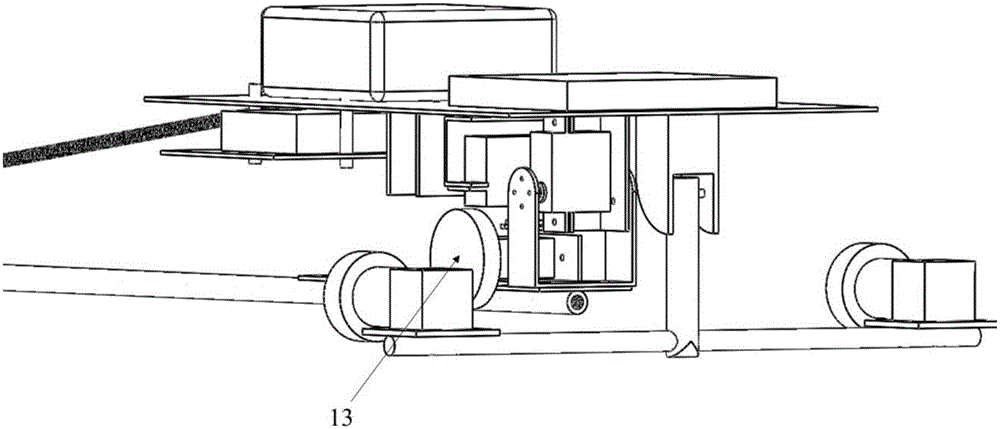

UAV three-degree-of-freedom inflight autonomous refueling device and implementation method thereof

The invention relates to a UAV three-degree-of-freedom inflight autonomous refueling device, which is used for simulating simulated refueling emulation of two eight-rotor UAV in a UAV inflight refueling semi-physical emulation platform. The implementation method comprises the steps that: a refueling aircraft obtains an image of a receiver aircraft, utilizes an internal visual processing program of Intel NUC microcomputer (hereinafter referred to as NUC) modules installed through the UAVs to solve a position and attitude relationship between the two UAVs, and then transmits the position and attitude relationship to a SCM module in a refueling rod device through a communication protocol; and the SCM module completes information output, driving and instruction execution, and finally makes a refueling rod face towards the receiver aircraft at correct angle and attitude, thereby offering support for final docking.

Owner:BEIHANG UNIV

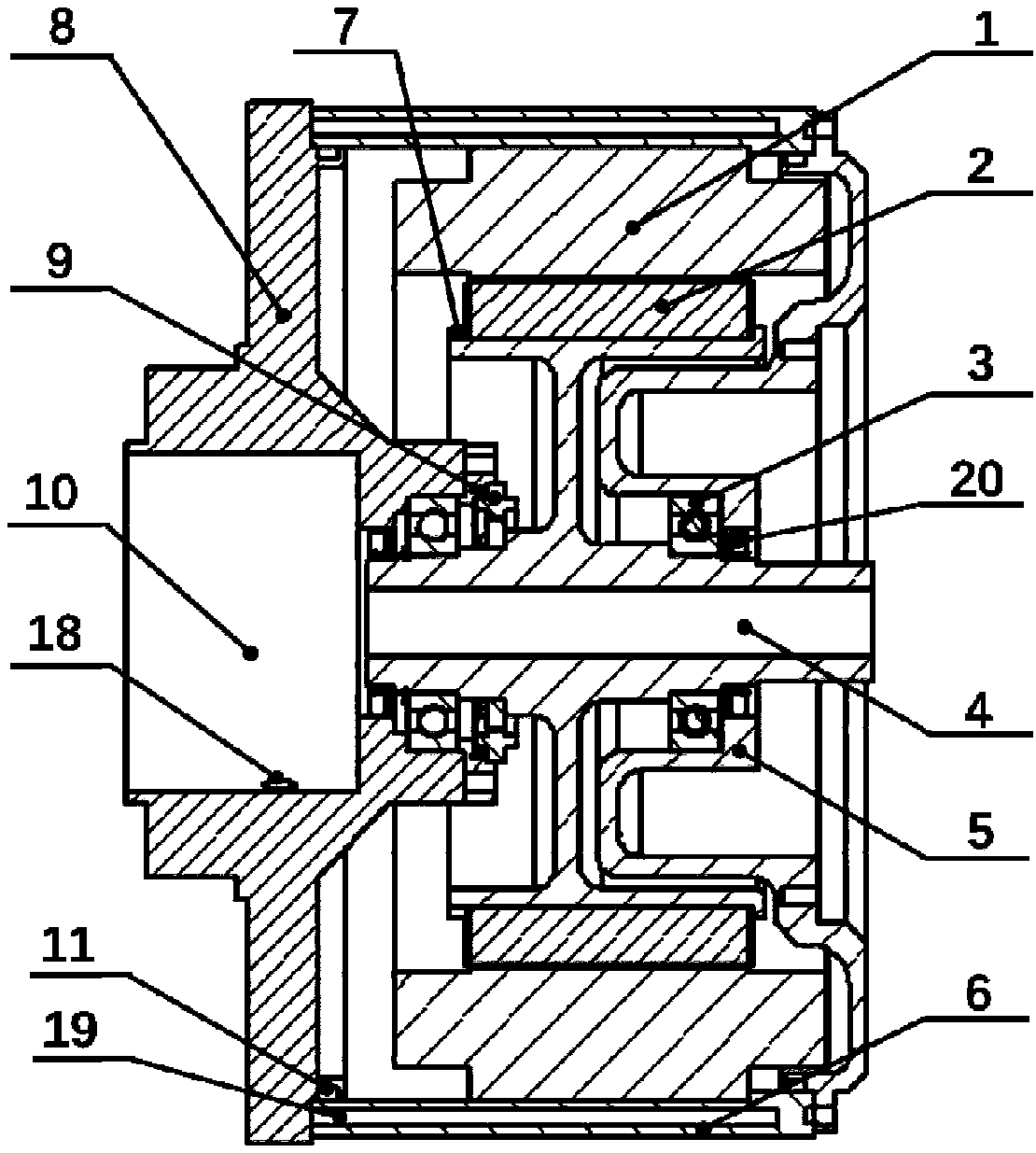

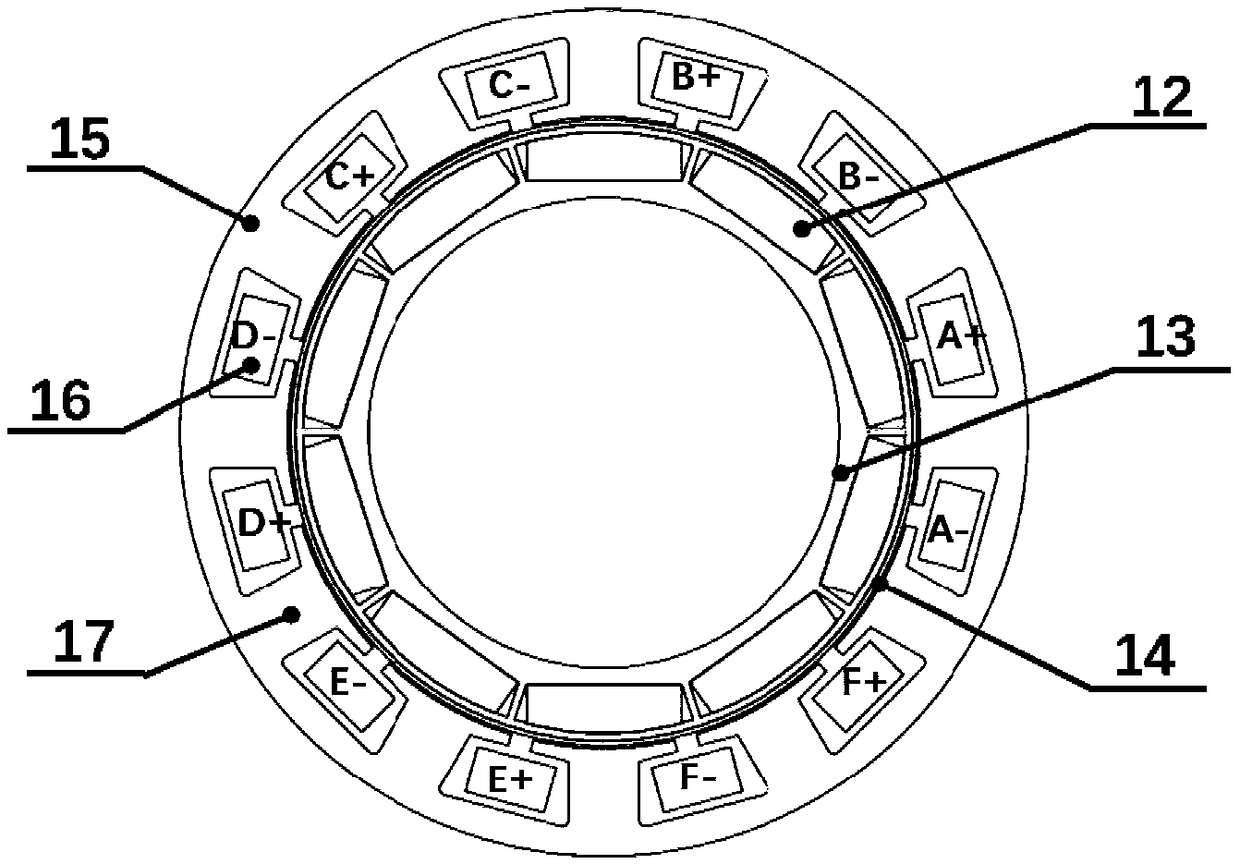

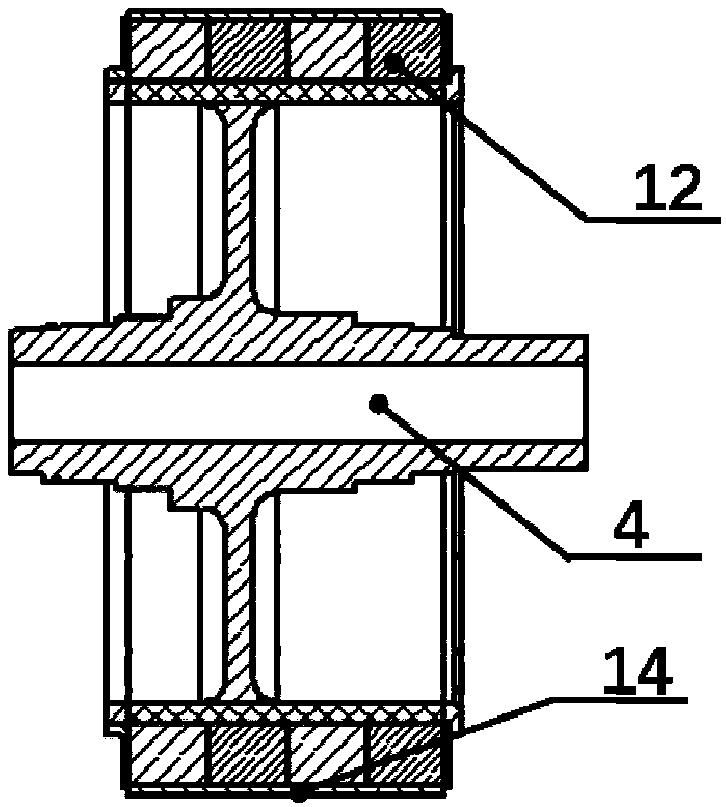

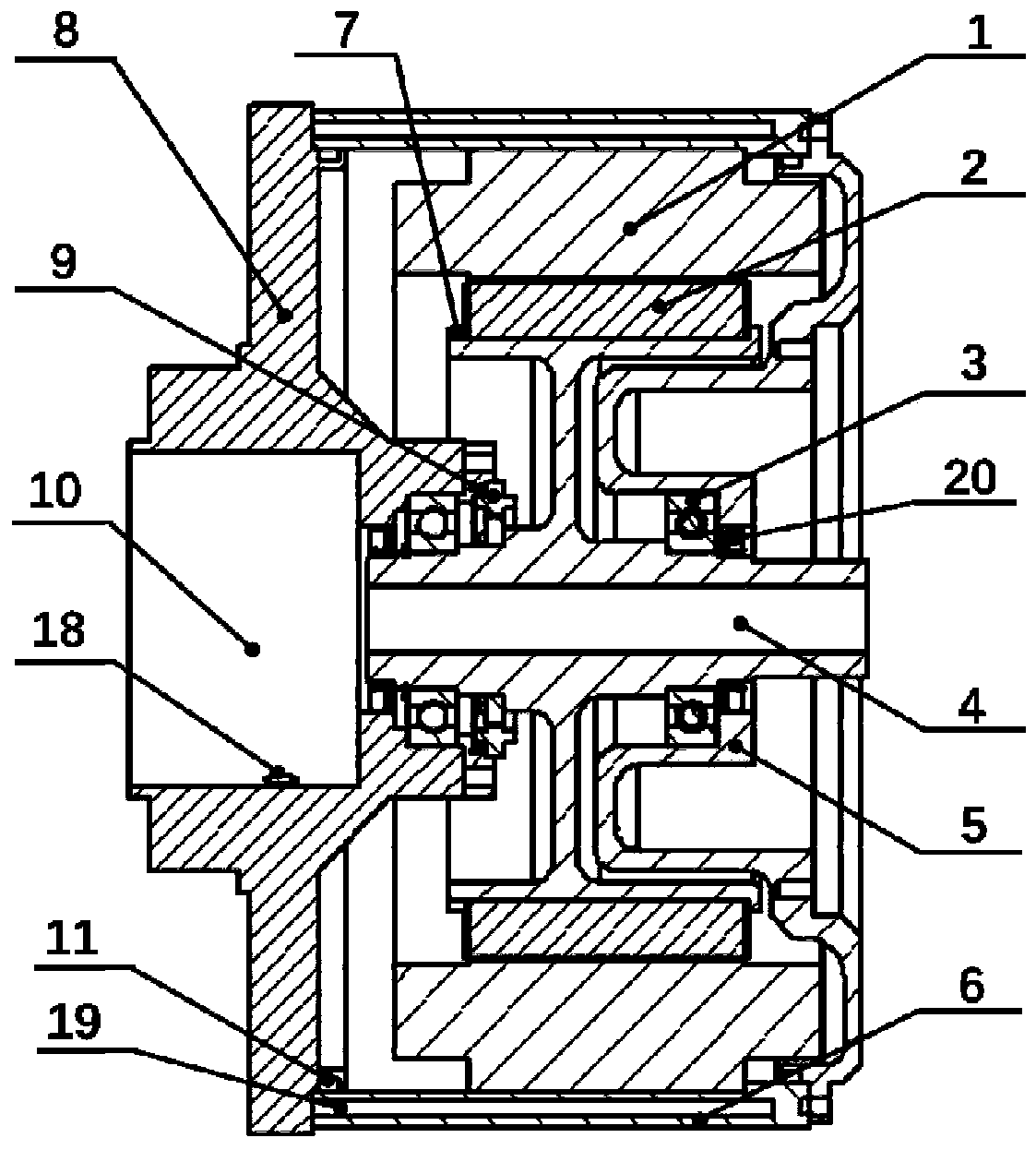

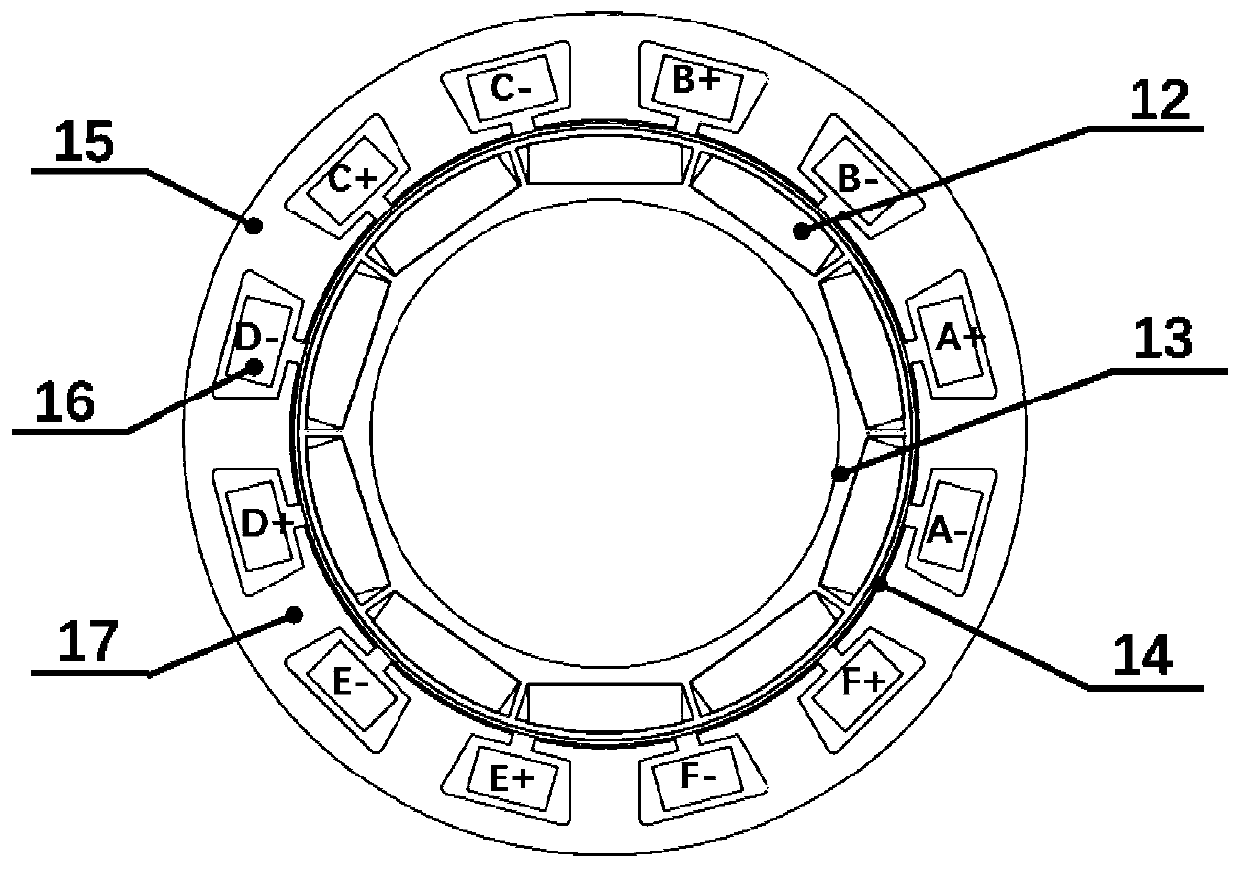

High-power high-reliability six-phase permanent magnet fault-tolerant hub motor used for electric armored vehicle

ActiveCN108631459AAdd direct axis inductanceImproving the speed-up capability of magnetic field weakeningMagnetic circuit rotating partsElectric machinesFiberPermanent magnet rotor

The invention discloses a high-power high-reliability six-phase permanent magnet fault-tolerant hub motor used for an electric armored vehicle. The high-power high-reliability six-phase permanent magnet fault-tolerant hub motor comprises a stator assembly, a rotor assembly, a rotary shaft, a bearing, a machine shell, front back end covers, and a position sensor; the six-phase windings in the stator assembly adopt a fractional-slot and concentrated single-layer winding structure embedded with partition teeth, so that an electrical fault-tolerant structure can be formed between the phase windings; meanwhile, by combination of the dimensional design of the stator toothed groove structure, the phase winding inductance of the electric motor is increased, the short circuit current is suppressedeffectively, and reliability and fault-tolerant performance of the hub motor are improved; the rotor assembly adopts an internal permanent magnet rotor structure, and the outer side of the rotor is wound with a carbon fiber protection sleeve, so that the mechanical structural strength of the rotor is improved; the stator winding adopts a monocrystal copper wire or silver wire, so that stator lossof the hub motor is lowered; the permanent magnet of the rotor assembly adopts eccentric design, and is subjected to circumferential or axial sectioning processing, so that the rotor loss of the hub motor is lowered effectively; a Z-shaped or spiral heat dissipation water path is formed in the machine shell, so that the heat dissipation capability of the hub motor is improved; and the hub motor has high fault isolation, anti-short-circuit and weak magnetic diffusion capability, so that the requirements of high reliability, high power and high rotary speed of the hub driving of the electric armored vehicle can be satisfied.

Owner:北京北航天宇长鹰无人机科技有限公司

Joint automatic control device for inner flaps/outer flaps of hydrofoil catamaran

InactiveCN103318385AConsistent flow patternImprove seakeepingVessel movement reduction by foilsHydrodynamic/hydrostatic featuresAutomatic controlEngineering

The invention aims to provide a joint automatic control device for inner flaps / outer flaps of a hydrofoil catamaran. The joint automatic control device comprises a catamaran. Two sheets are respectively mounted at the left end and the right end of the lower side of the catamaran, a front hydrofoil is mounted at the front ends of the lower sides of the two sheets, a rear hydrofoil is mounted at the rear ends of the lower sides of the two sheets, a first outer flap, a second outer flap, a first inner flap and a second inner flap are respectively mounted at the rear end of the front hydrofoil by the aid of a first connecting shaft, a third outer flap, a fourth outer flap, a third inner flap and a fourth inner flap are respectively mounted at the rear end of the rear hydrofoil by the aid of a second connecting shaft, and the first outer flap, the second outer flap, the third outer flap, the fourth outer flap, the first inner flap, the second inner flap, the third inner flap and the fourth inner flap are respectively connected with respective servo motors. The joint automatic control device has the advantages that the joint automatic control device is simple in structure and reasonable in design, multifunctional and multi-objective cooperative control is implemented, and the safety, the seaworthiness and the maneuverability of the hydrofoil catamaran are improved; the front hydrofoil and the rear hydrofoil are respectively connected with the two sheets of the hydrofoil catamaran, so that the mechanical structural strength is improved.

Owner:HARBIN ENG UNIV

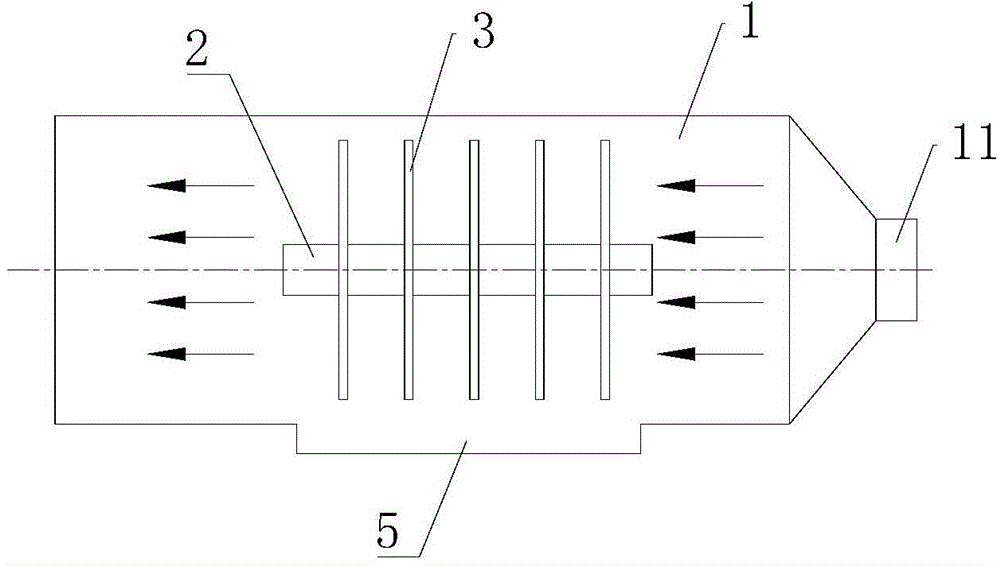

Multi-spoke-ring gas and liquid separator

InactiveCN104606965ATo achieve the purpose of defoggingIncrease the effective contact areaDispersed particle separationSpokeMotion direction

The invention discloses a multi-spoke-ring gas and liquid separator, which is used for solving the problem of low removing rate of the gas and liquid separator in the prior art. The multi-spoke-ring gas and liquid separator comprises a mist removing bin through which water mist or oil mist can pass; the mist removing bin is internally provided with a rotation shaft which is driven to rotate by a motor; the axial direction of the rotation shaft is the same with the motion direction of the water mist or oil mist; a plurality of mist removing rings which rotate synchronously with the rotation shaft are fixed side by side on the rotation shaft; the plane of each mist removing ring is perpendicular to the axial direction of the rotation shaft; a plurality of radial mist removing spokes which are peripherally and uniformly distributed are fixed on each mist removing ring; the bottom of the mist removing bin is provided with a water collecting tank. The multi-spoke-ring gas and liquid separator is simple in structure, can effectively guarantee the mist removing effect by the plurality of mist removing rings which are arranged sequentially, and the number of the mist removing rings also can be set flexibly according to the humidity of the water mist so as to remove mist completely.

Owner:BEIJING HUACHUANGLANGRUN ENVIRONMENTAL TECHCO

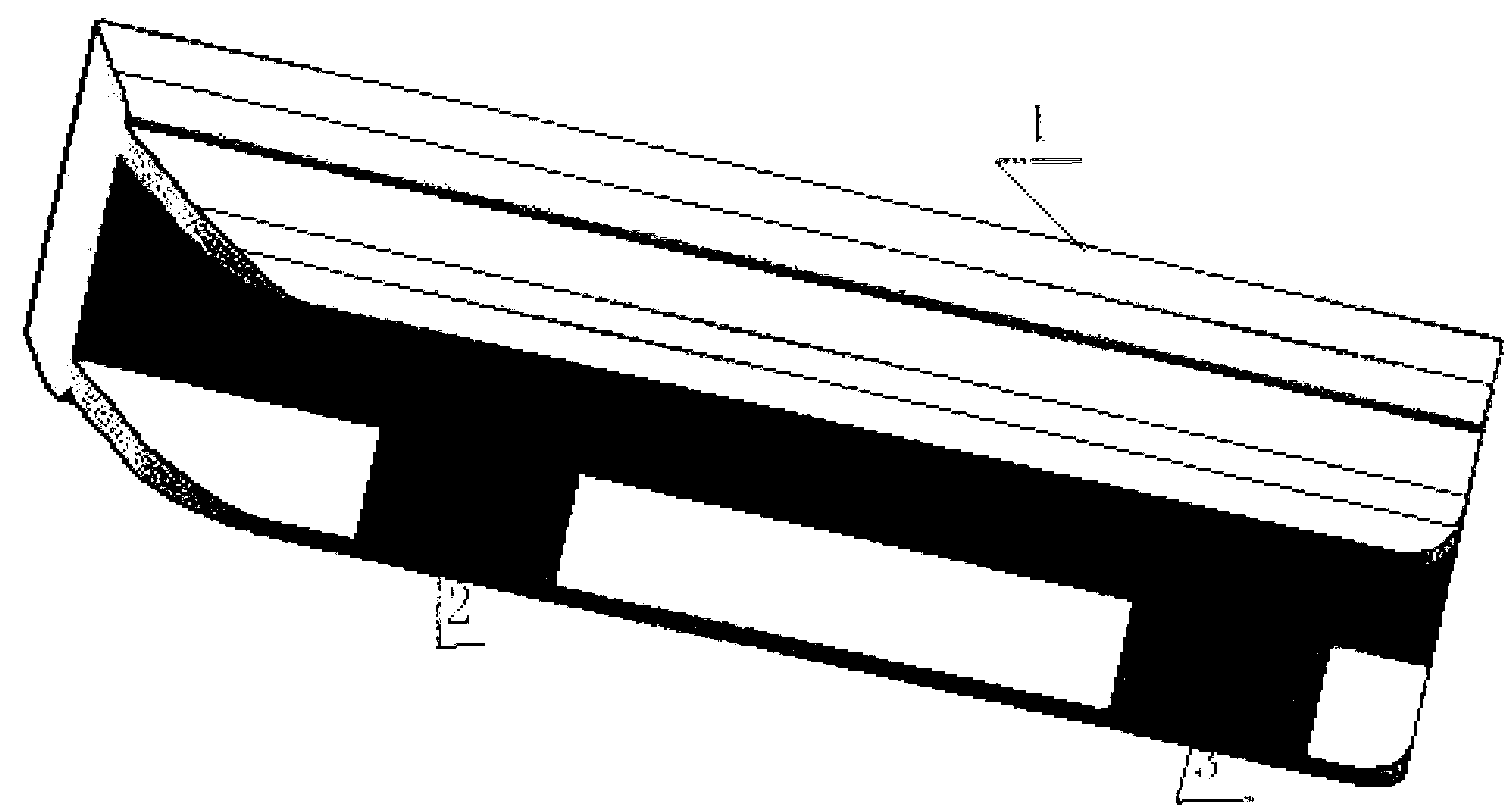

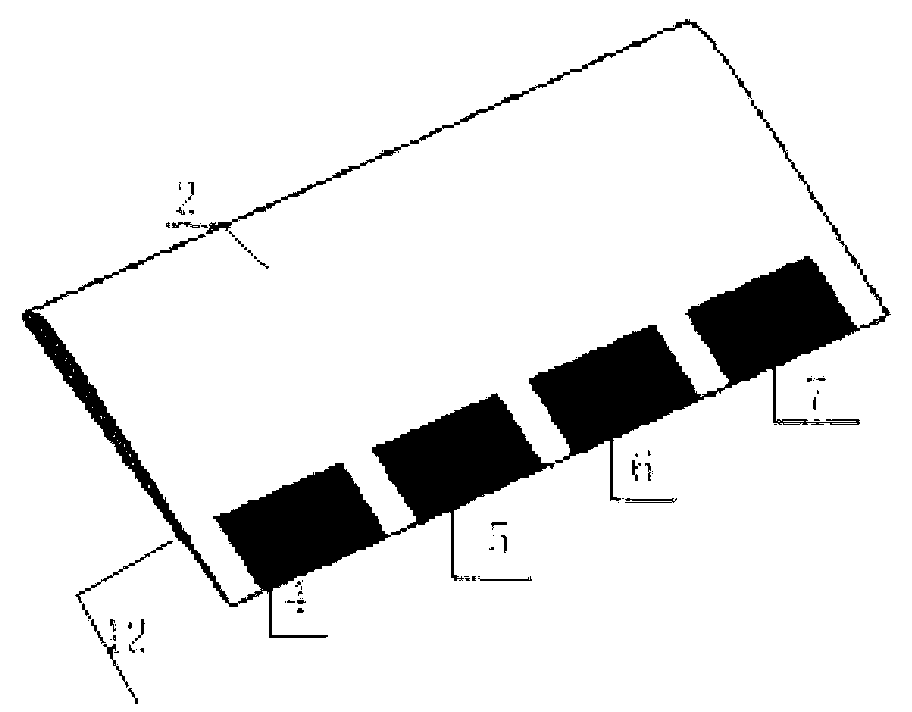

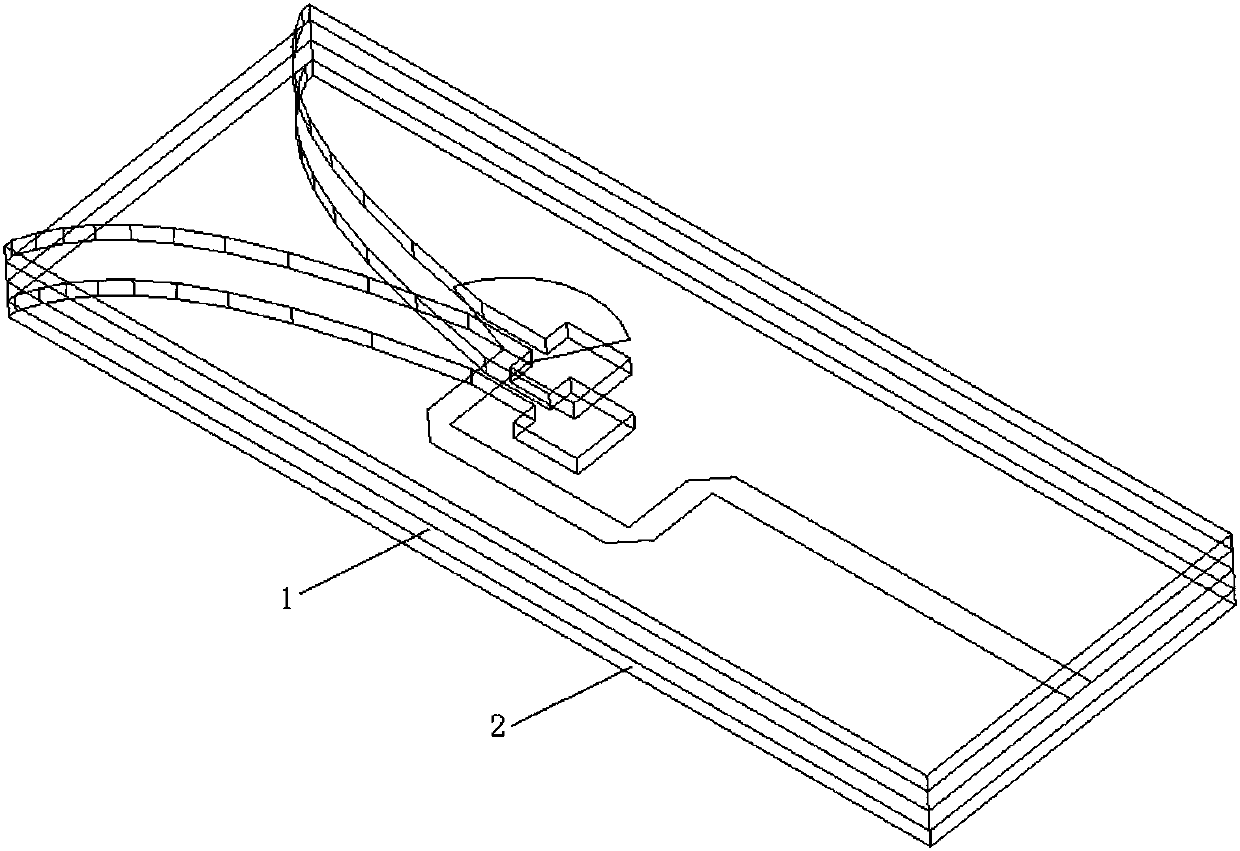

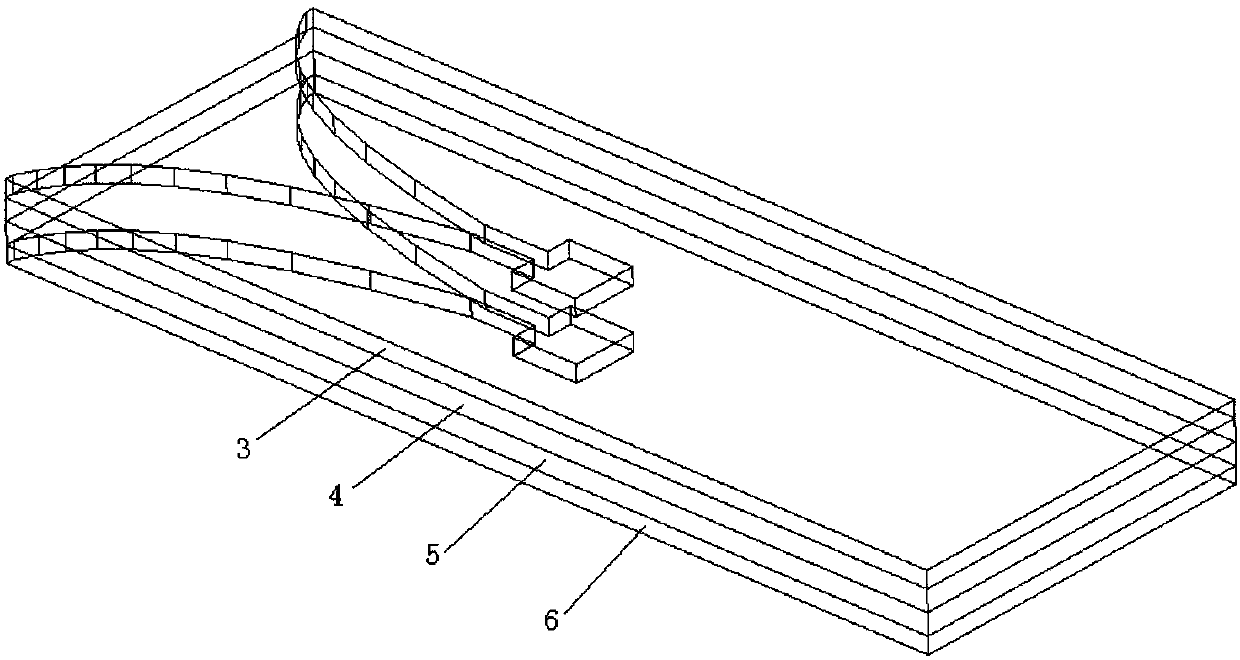

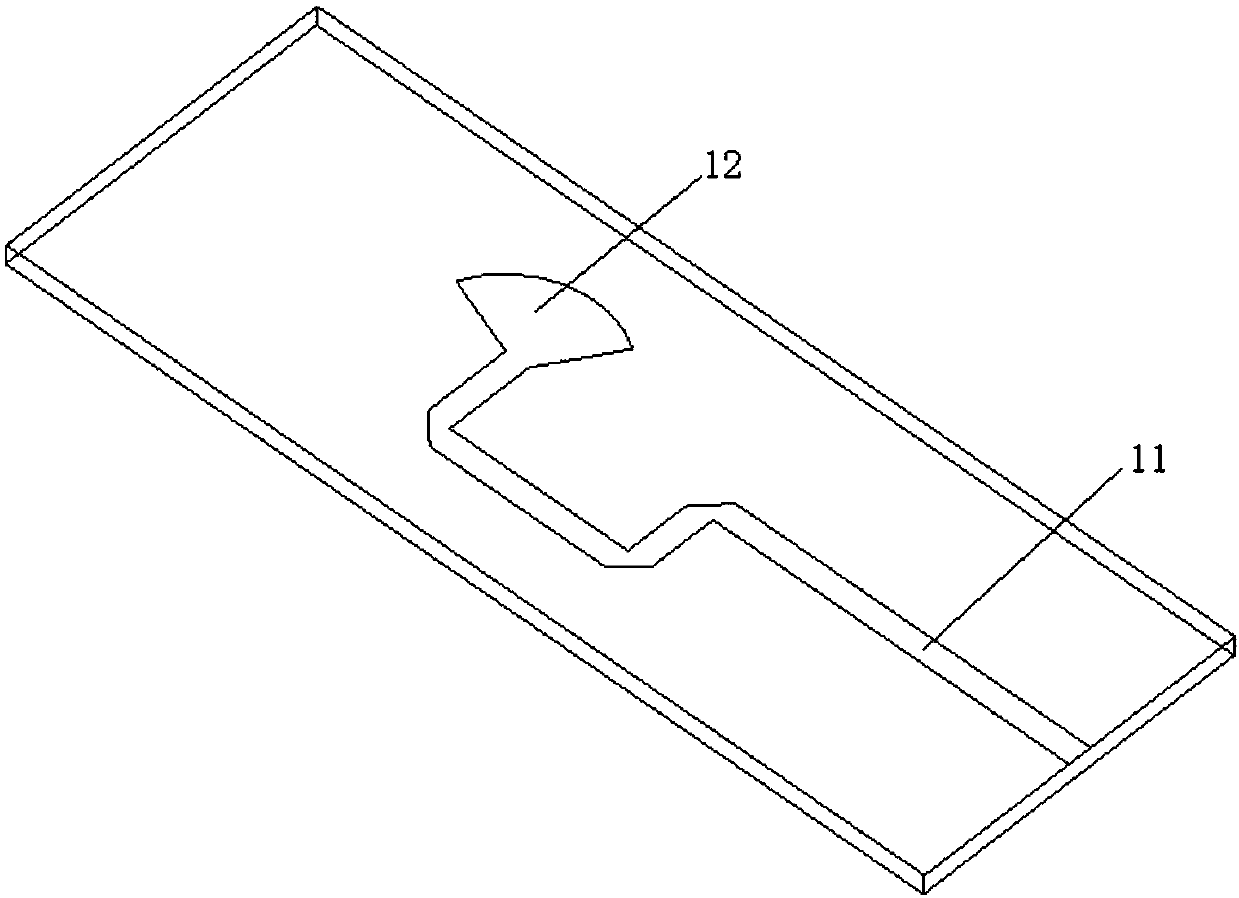

Coaxial feeding millimeter wave antenna based on thick and thin strip line conversion

InactiveCN107959107AThe solution cannot be realized by engineeringSolve the problem that its performance will seriously deteriorate during the implementation processRadiating elements structural formsAntennas earthing switches associationBand shapeAntenna feed

The invention proposes a coaxial feeding millimeter wave antenna based on thick and thin strip line conversion. The coaxial feeding millimeter wave antenna sequentially comprises a coaxial connector,a thick substrate strip line, a thin substrate strip line and a thin substrate strip line antenna from back to front, wherein the thick substrate strip line is formed by crimping four layers of substrates, and sequentially comprises the first layer substrate, the second layer substrate, the third layer substrate and the fourth layer substrate from bottom to top; the thin substrate strip line is formed by the second layer substrate, and the thin substrate strip line antenna is formed by the third layer substrate; a wide transmission line of the thick substrate strip line is positioned on the upper surface of the second layer substrate; a narrow transmission line of the thin substrate strip line is positioned on the upper surface of the second layer substrate; and side edges of the first layer substrate and the fourth layer substrate are provided with metal cladding. The coaxial feeding millimeter wave antenna solves the difficulty that a millimeter thin substrate strip line antenna feeding structure cannot be implemented by engineering or the performance thereof is about to be seriously deteriorated during the implementation process.

Owner:中国船舶重工集团公司第七二三研究所

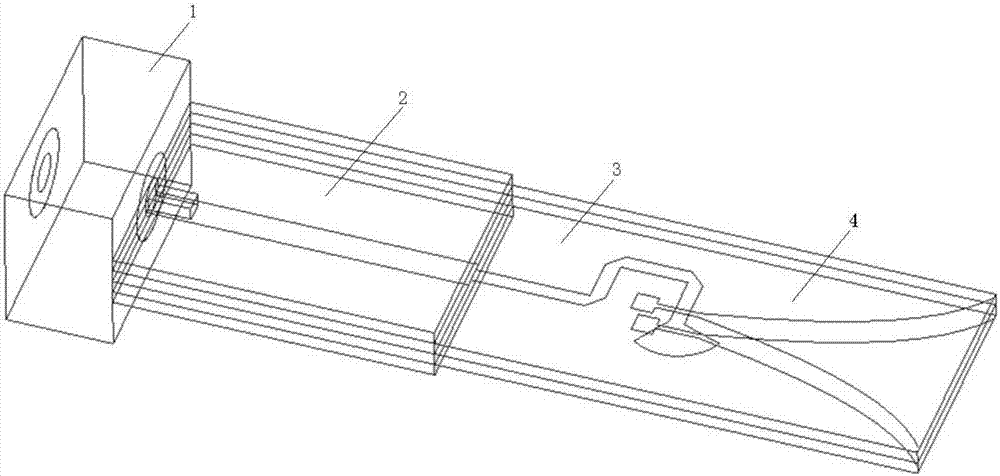

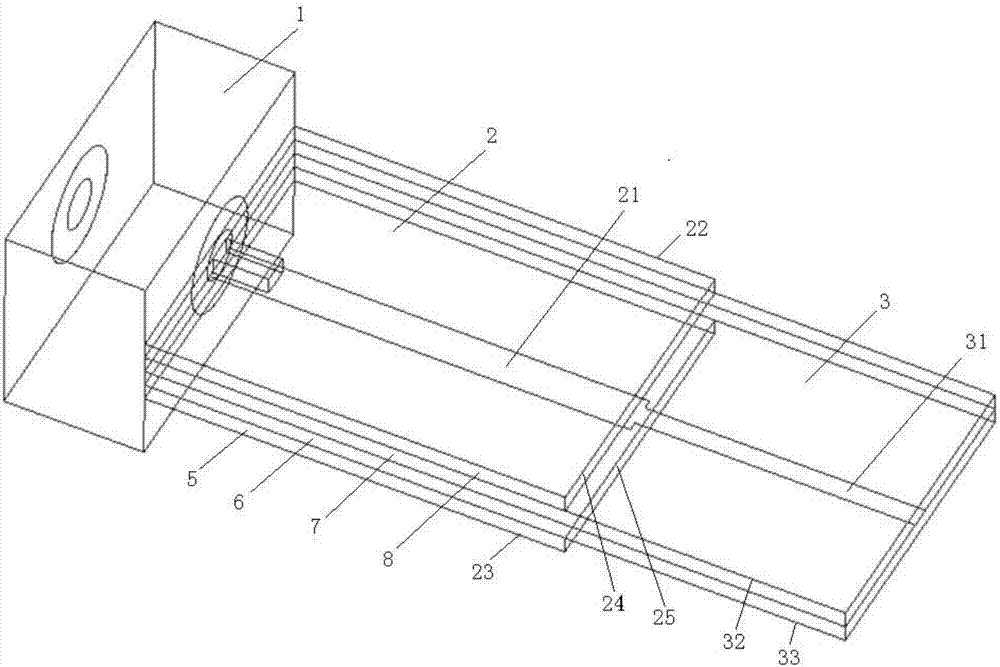

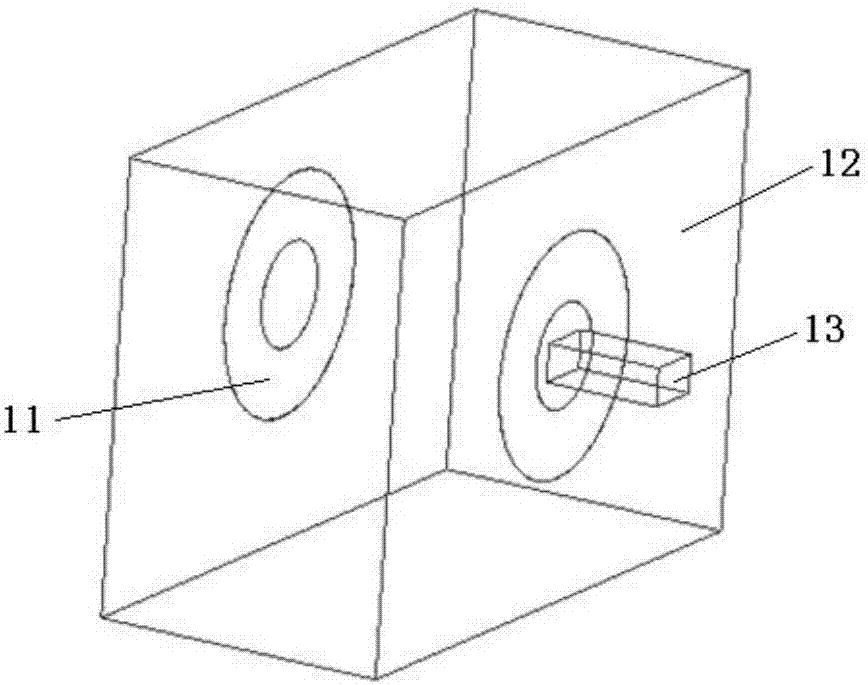

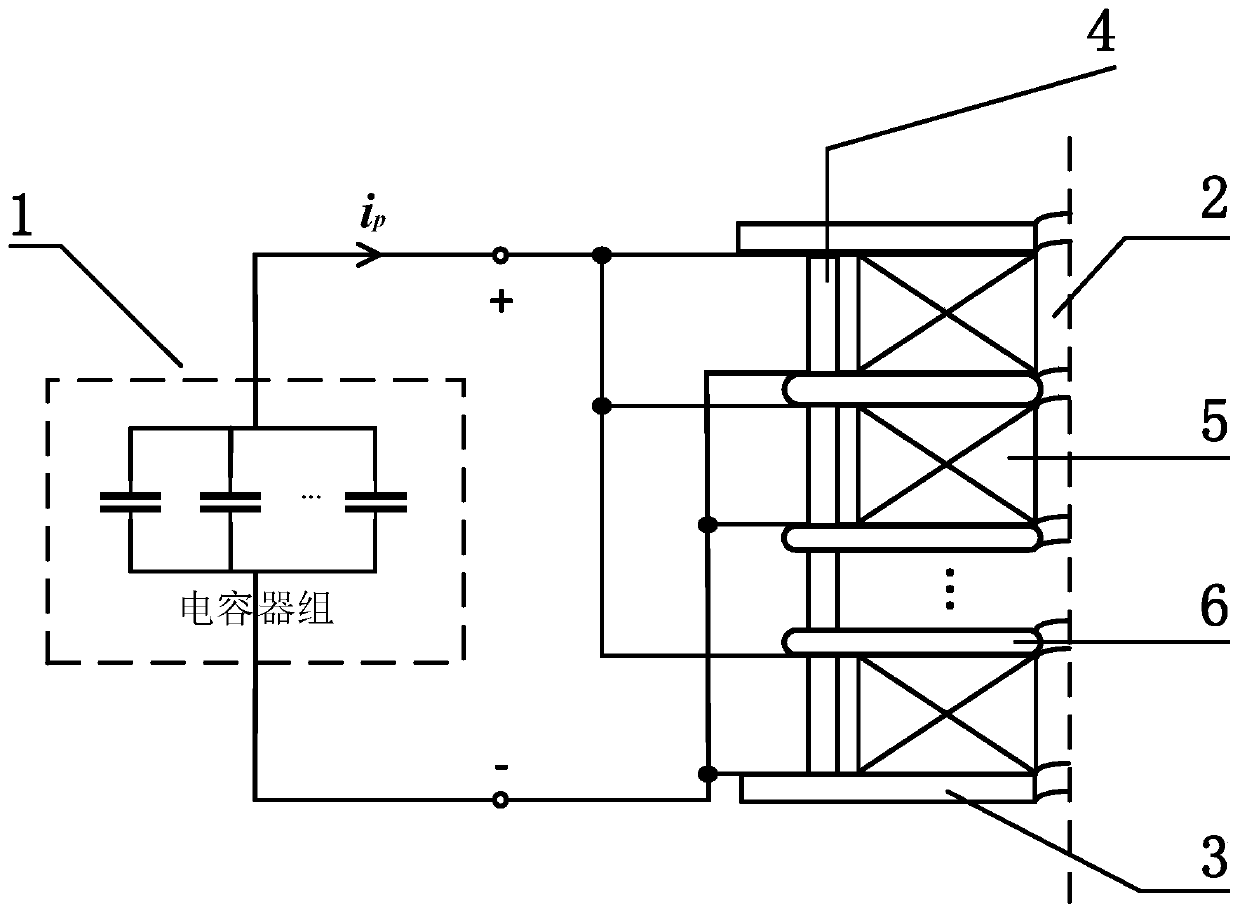

High-strength parallel pulse magnet device

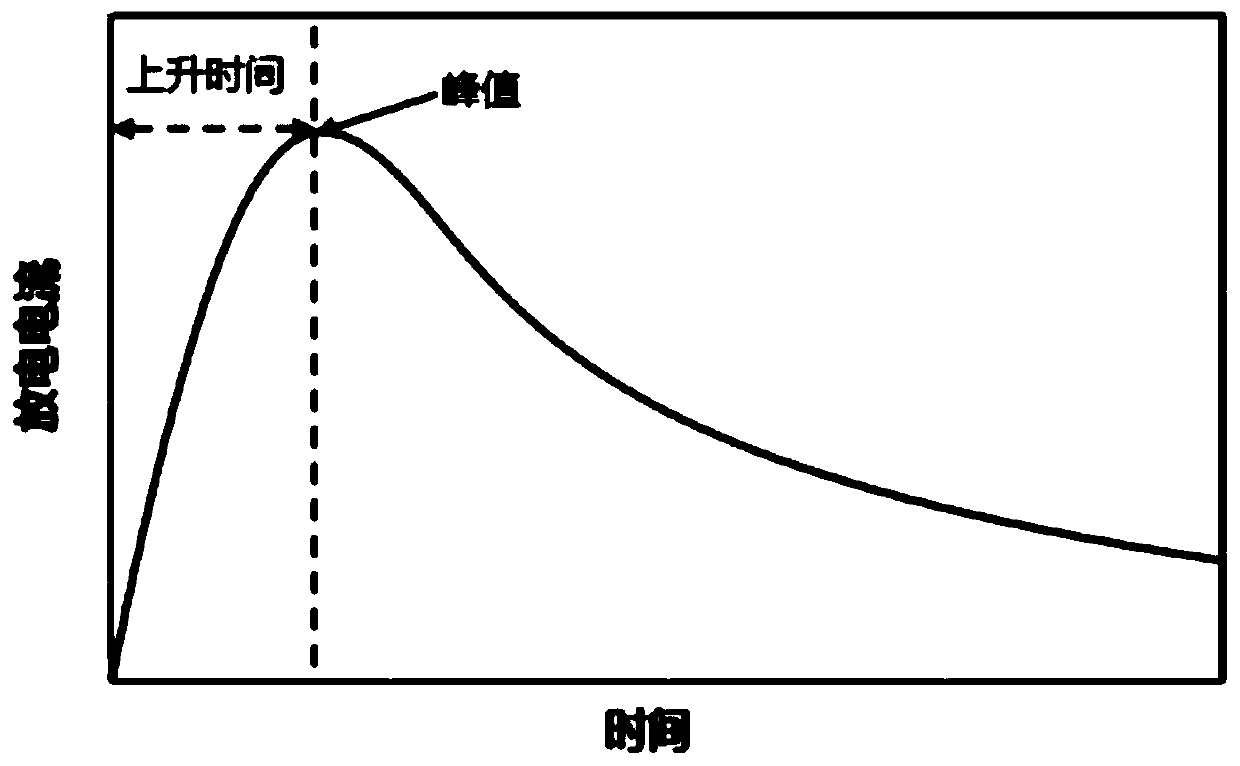

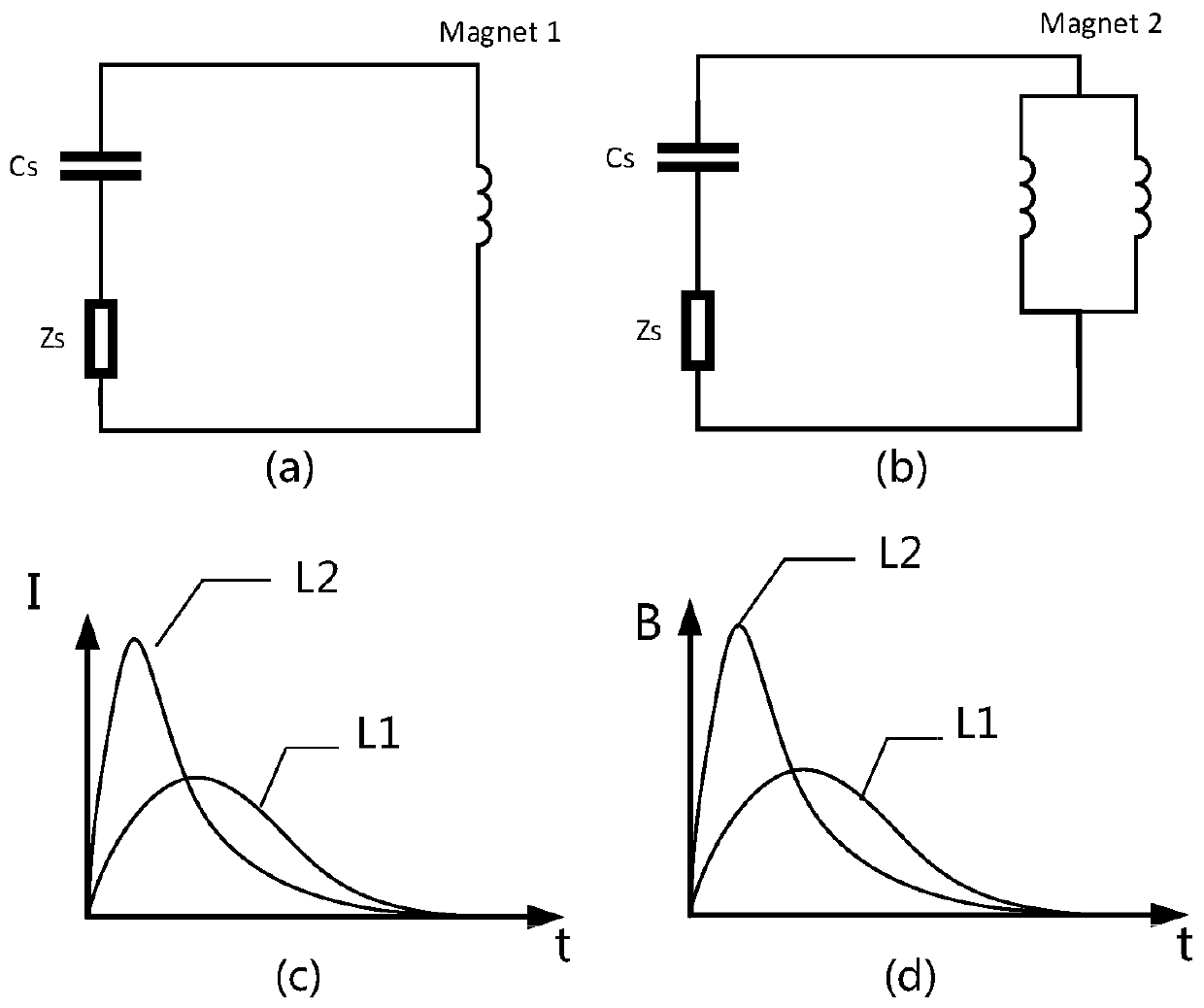

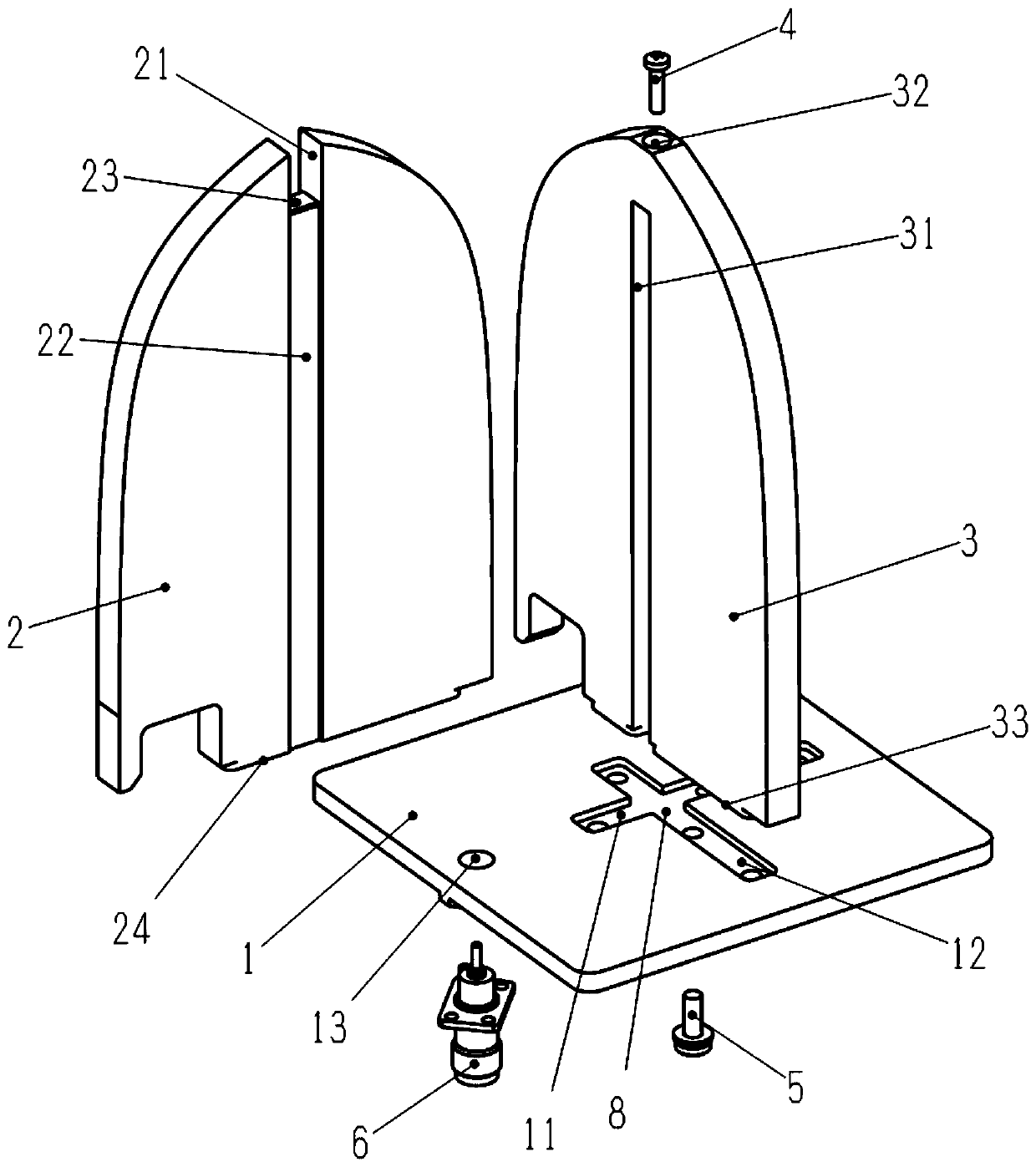

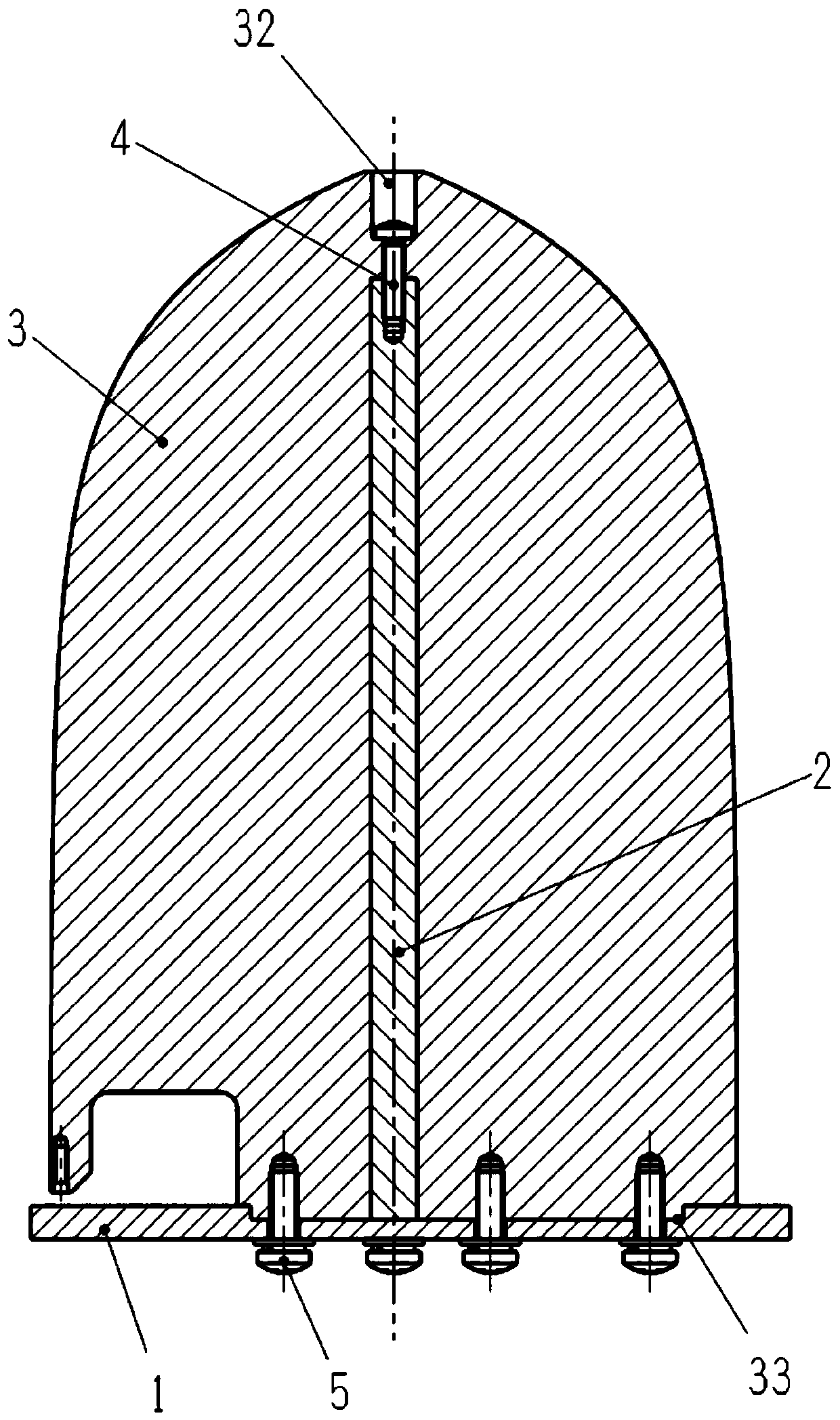

InactiveCN111009378ALower impedanceHigh strengthElectromagnets without armaturesMagnet deviceMagnet coil

The invention belongs to the technical field of electromagnetism, and particularly discloses a high-strength parallel pulse magnet device which comprises a power supply module and a pulse magnet module. The pulse magnet module comprises a magnet unit, a supporting rod and two first reinforcing plates arranged at two ends of the supporting rod respectively. The magnet unit is arranged between the two first reinforcing plates and is electrically connected with the power supply module, and the supporting rod is arranged on a periphery of the magnet unit and is used for limiting and fixing plate layers with different heights so that the plate layers are coaxial and do not generate relative displacement. The magnet unit is composed of n groups of magnet coils connected in parallel. During work,an impedance of the pulse magnet module is reduced to 1 / n of the original impedance by the magnet coils connected in parallel under a condition that the number of turns of the coils is the same, a pulse current with higher intensity is obtained, and a magnetic field with higher intensity is induced. The magnet unit is axially separated through a second reinforcing plate, an axial stress of the magnet unit is shared, and mechanical structural strength of the whole pulse magnet device is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

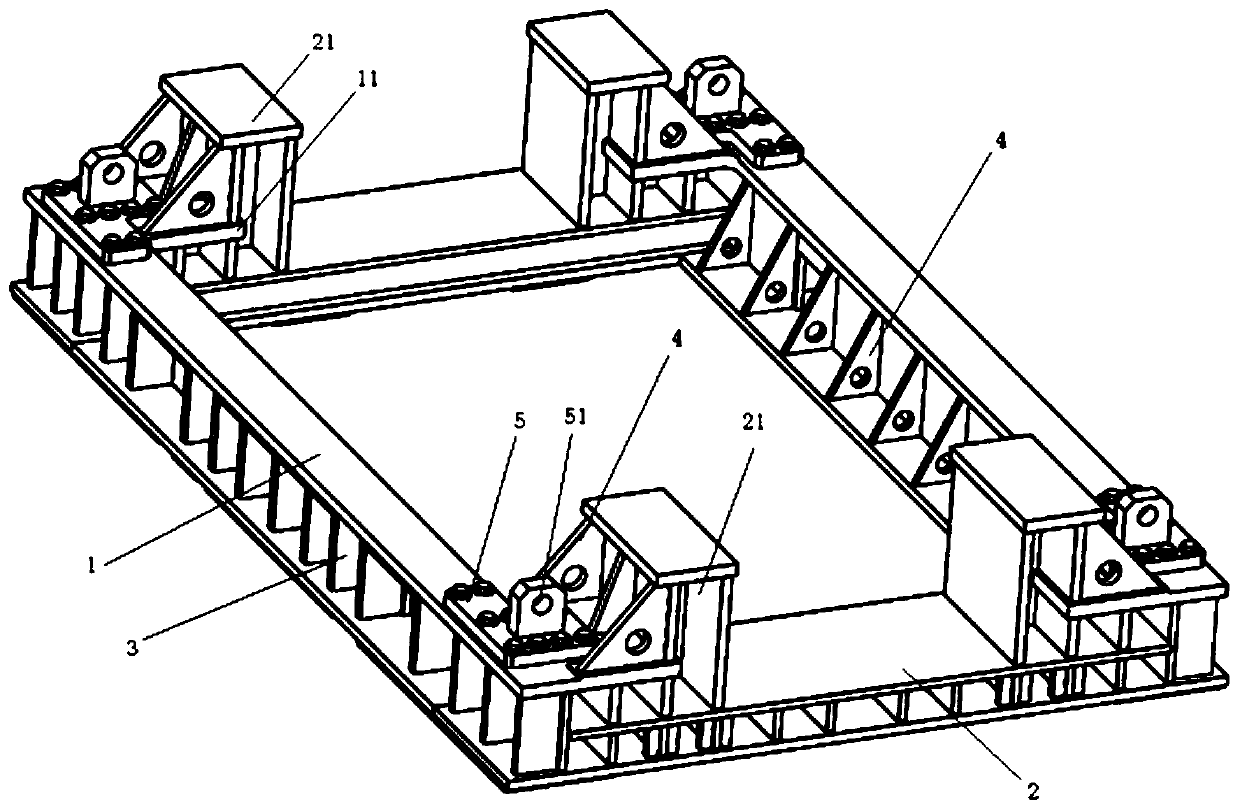

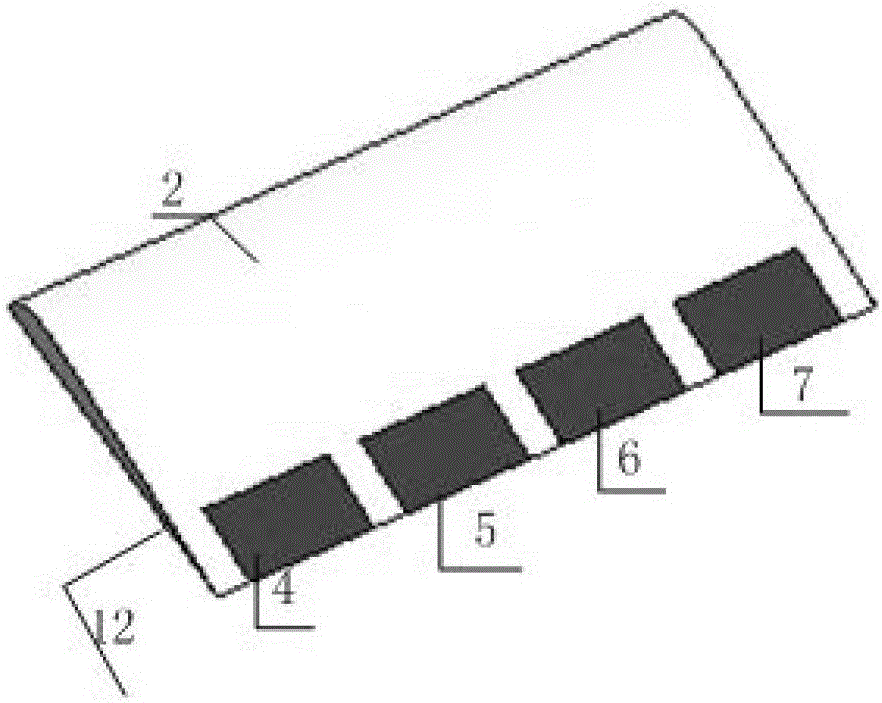

Orthogonal dual-polarized metal slot antenna array structure and antenna array containing the structure

ActiveCN109904587AGuaranteed accuracyGuaranteed electromagnetic performanceAntenna supports/mountingsRadiating elements structural formsUltimate tensile strengthRadiating element

The invention discloses an orthogonal dual-polarized metal slot antenna array structure and an antenna array containing the structure, and solves the problem in the prior art that high-temperature welding formation is adopted to cause poor antenna precision, resulting in reducing the yield, limiting by the welded aluminum alloy material and reducing the mechanical strength of the antenna, or the assembly formation of spare parts is adopted, resulting in increasing the weight of the antenna, reducing the mechanical strength of the antenna and increasing the number of structural parts that are independent of electromagnetic properties, so as to narrow the scope of application. The antenna array structure comprises an antenna bottom plate, and a sub-structure unit mounted on the antenna bottom plate and interposed by horizontal radiating unit pieces and vertical radiating element pieces. The antenna array includes an antenna array structure. The antenna array structure and the antenna array have the advantages of simple structure, scientific and reasonable design and convenient use, and can effectively ensure the accuracy of the antenna to improve the production yield, effectively improve the mechanical structure strength, reduce the weight of the antenna, and ensure the electromagnetic performance of the antenna array to expand the applicable range.

Owner:SOUTHWEST CHINA RES INST OF ELECTRONICS EQUIP

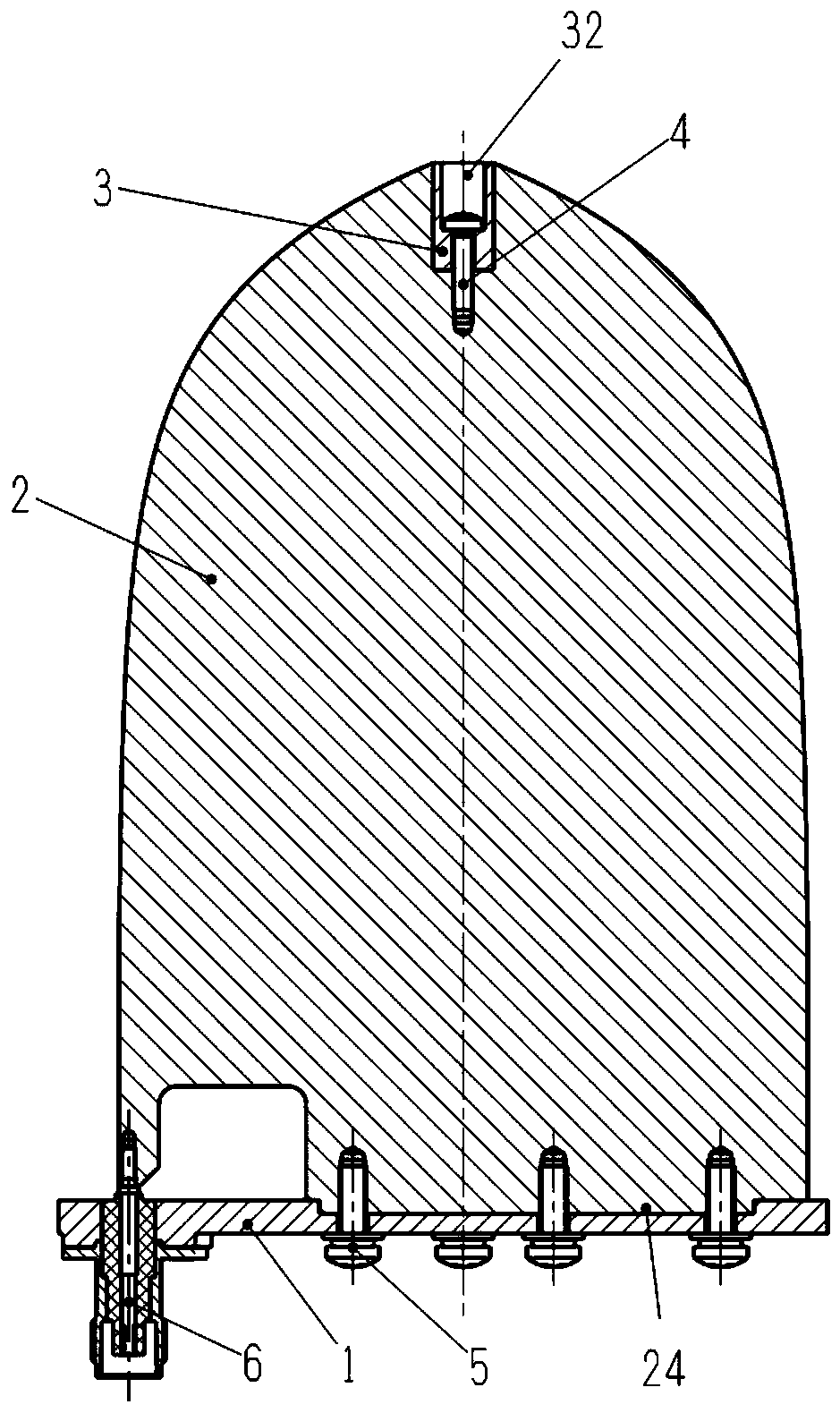

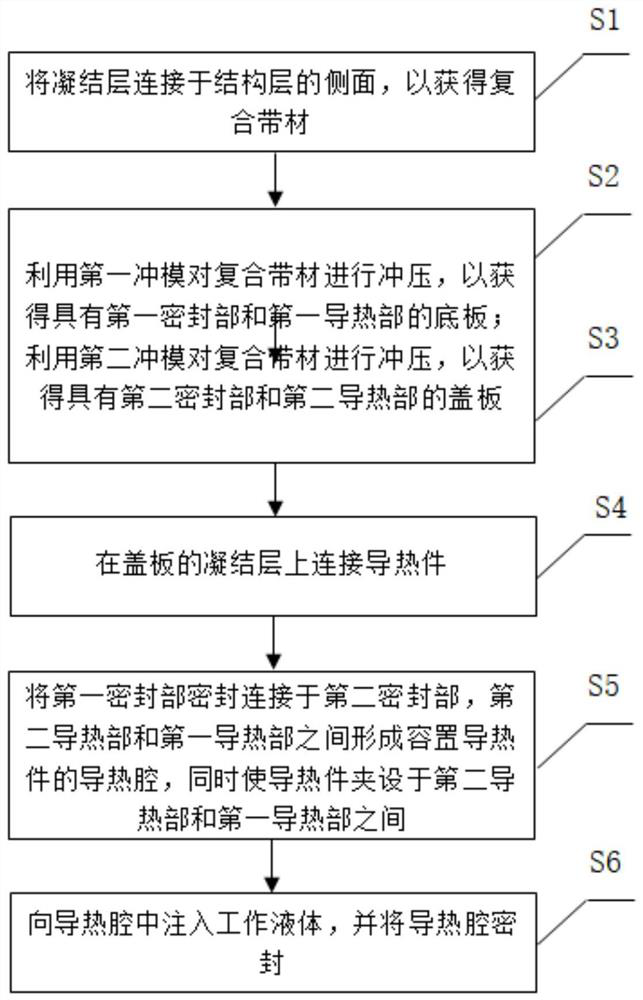

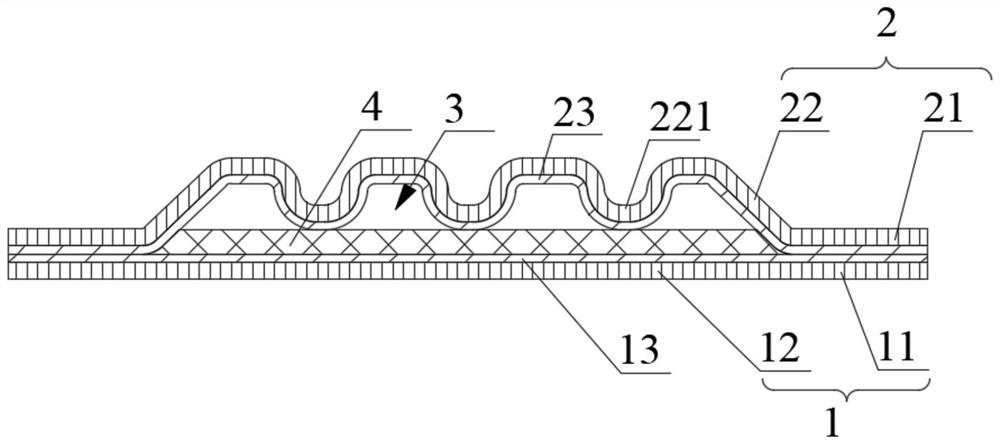

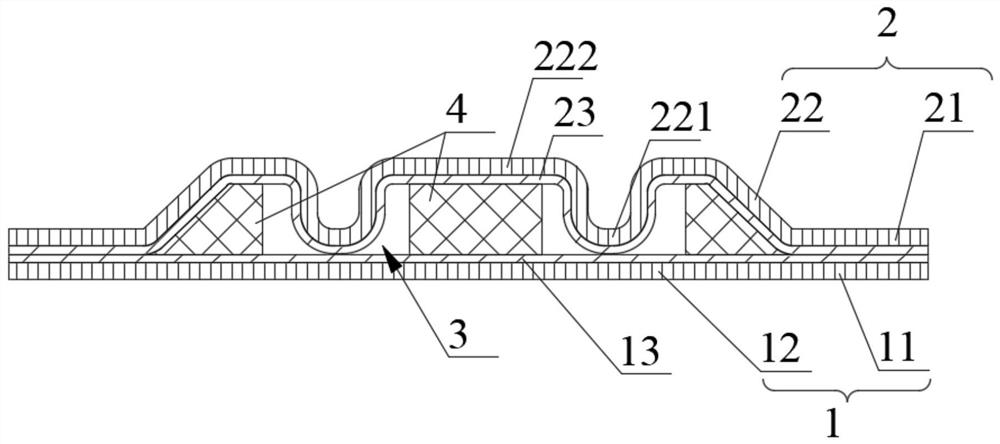

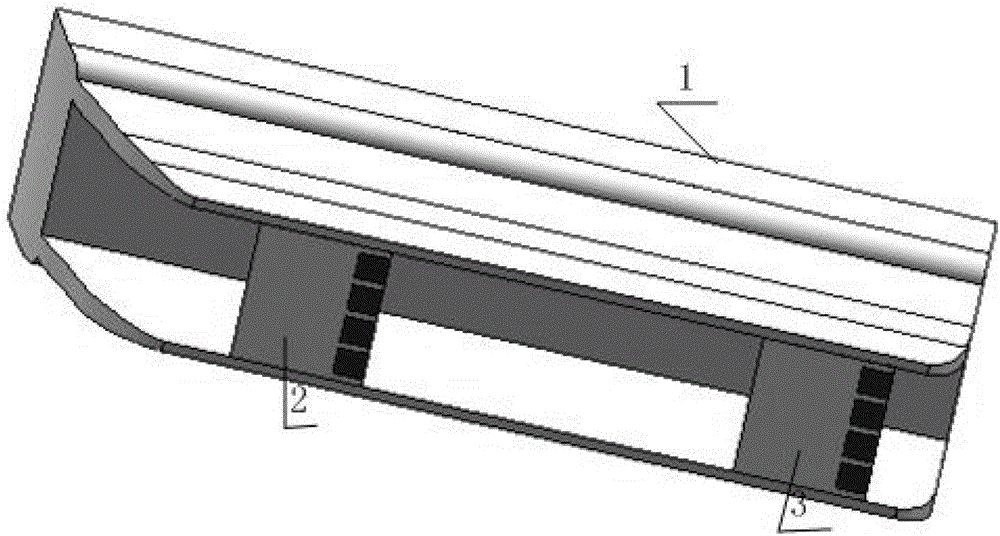

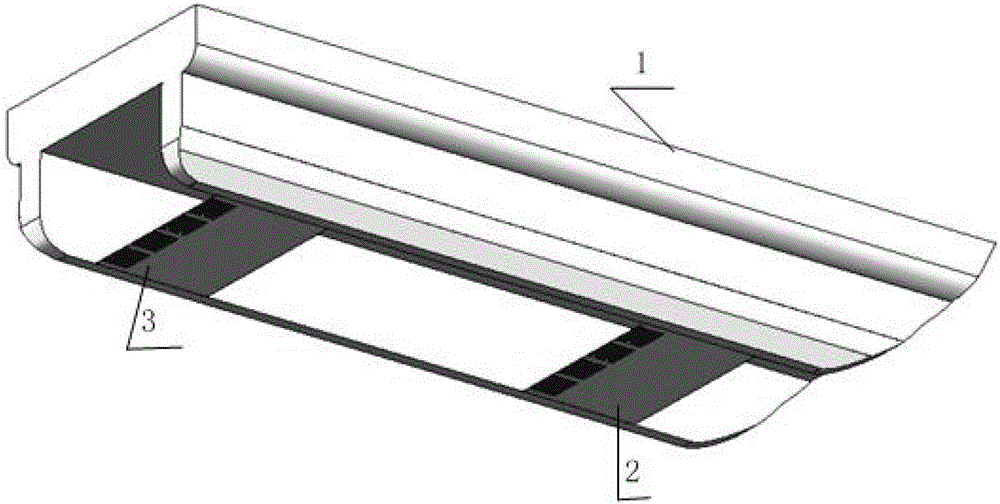

Manufacturing process for lightweight vapor chamber and vapor chamber

PendingCN112648870AImprove mechanical structure strengthReduce weightIndirect heat exchangersThermodynamicsEngineering

The invention relates to the technical field of heat dissipation, and discloses a manufacturing process for a lightweight vapor chamber and the vapor chamber. The manufacturing process comprises: connecting a condensation layer to the side surface of a structural layer to obtain a composite strip; stamping the composite strip to obtain a bottom plate with a first sealing portion and a first heat conduction portion; stamping the composite strip to obtain a cover plate with a second sealing portion and a second heat conduction portion, forming a support portion on the second heat conduction portion, and enabling the support portion to abut against the second heat conduction portion or other parts of the vapor chamber; connecting a heat conduction member to the condensation layer of the cover plate; sealedly connecting the first sealing portion to the second sealing portion, forming a heat conduction cavity for containing the heat conduction member between the second heat conduction portion and the first heat conduction portion, and meanwhile, clamping the heat conduction member between the second heat conduction portion and the first heat conduction portion; injecting working liquid into the heat conduction cavity, and sealing the heat conduction cavity. The vapor chamber manufactured by the manufacturing process for the lightweight vapor chamber not only has enough structural strength, but also is light in weight.

Owner:宝德华南(深圳)热能系统有限公司

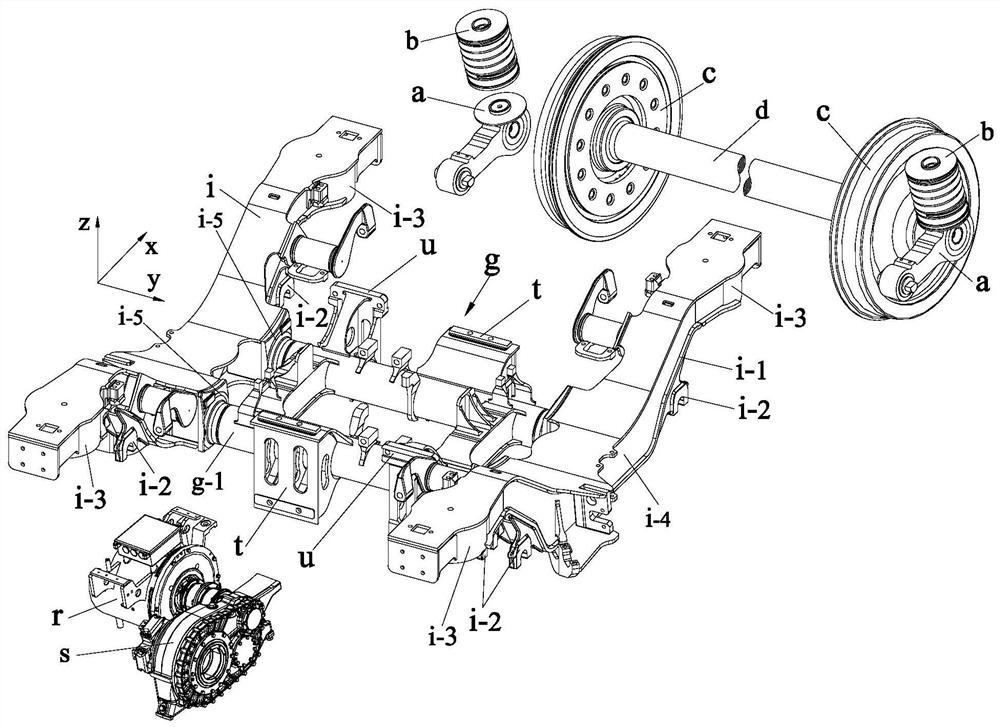

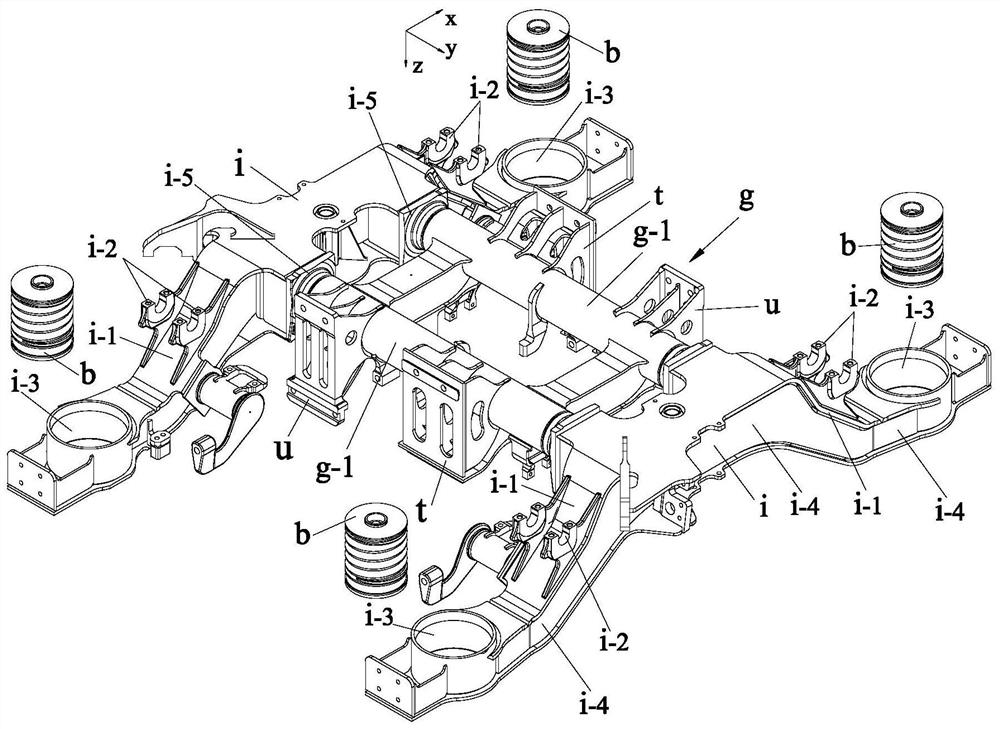

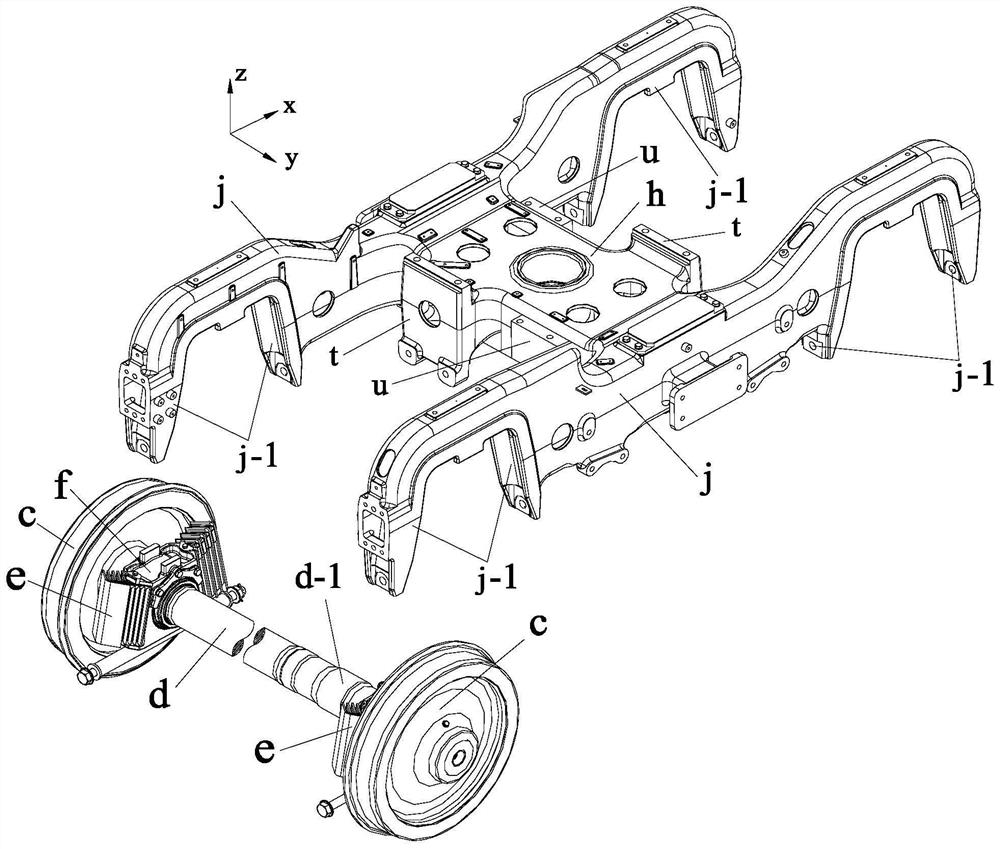

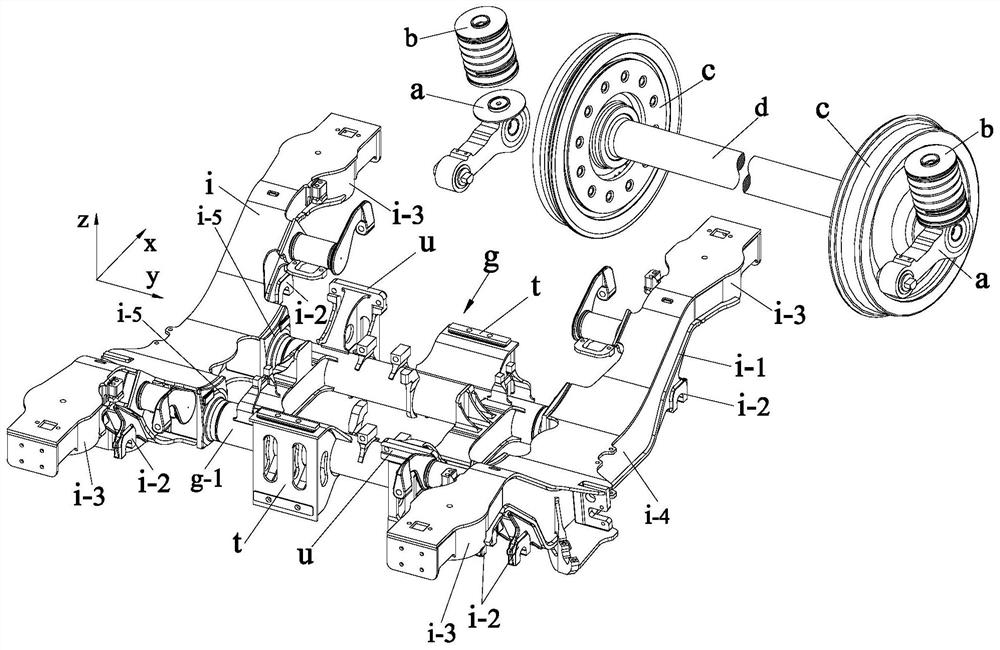

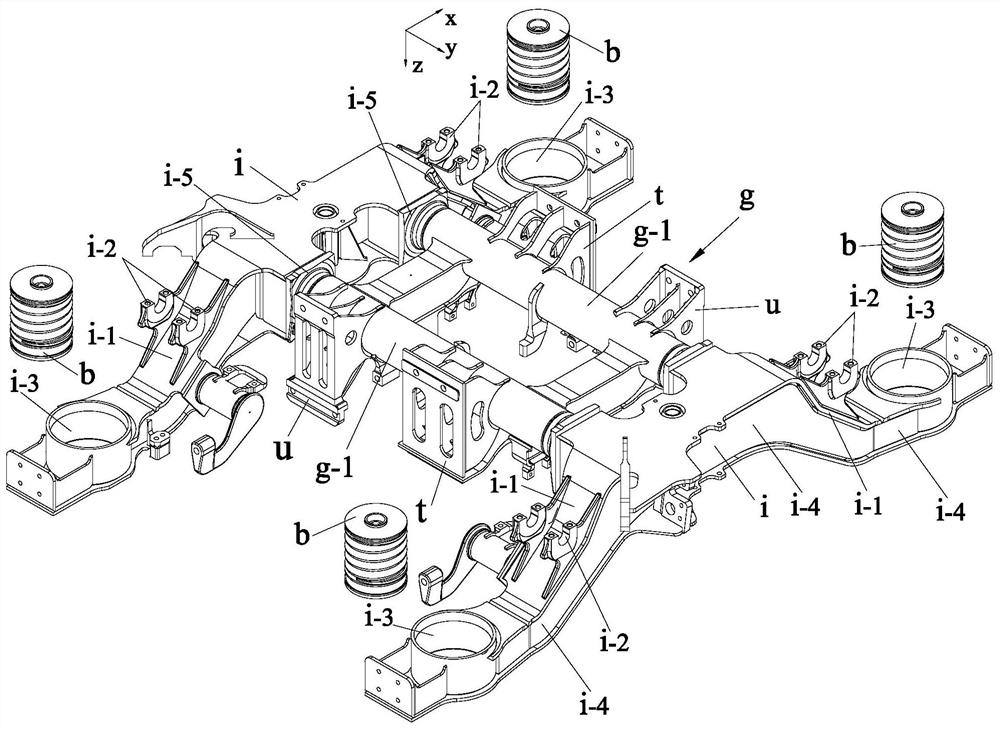

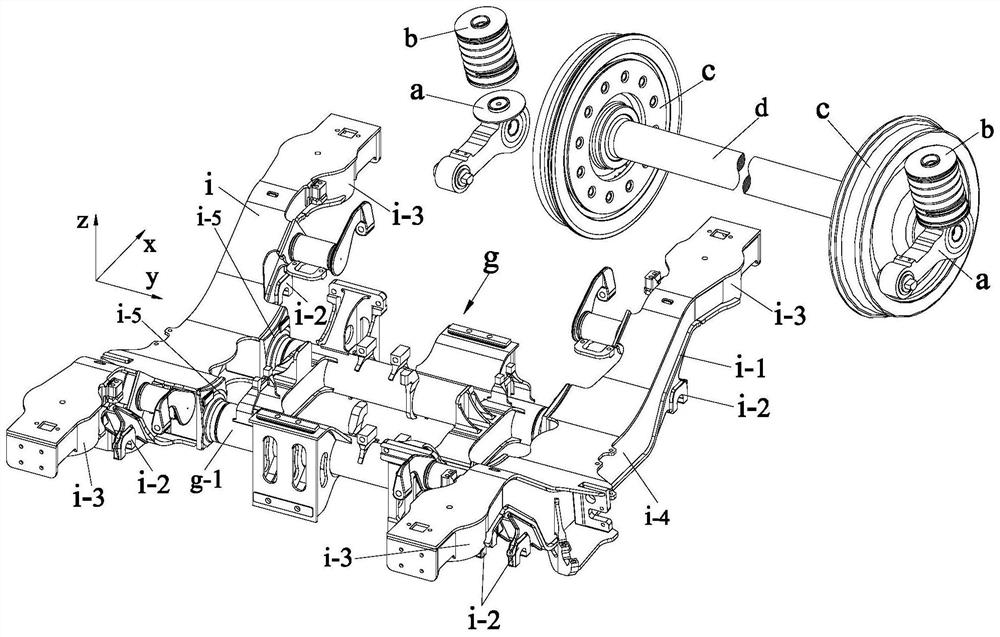

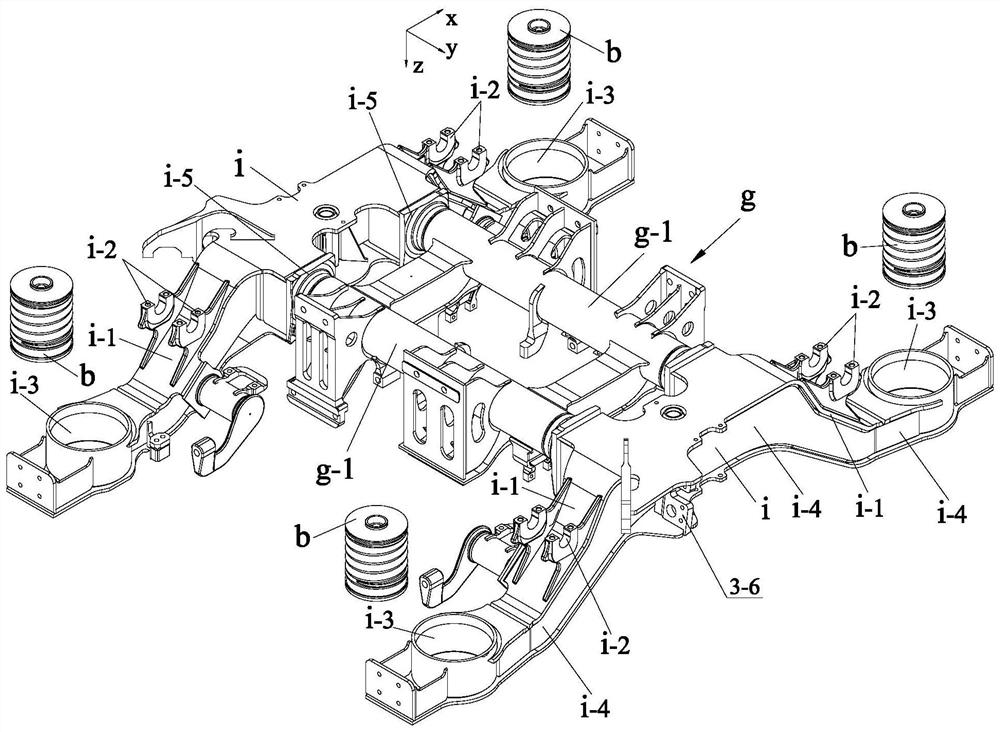

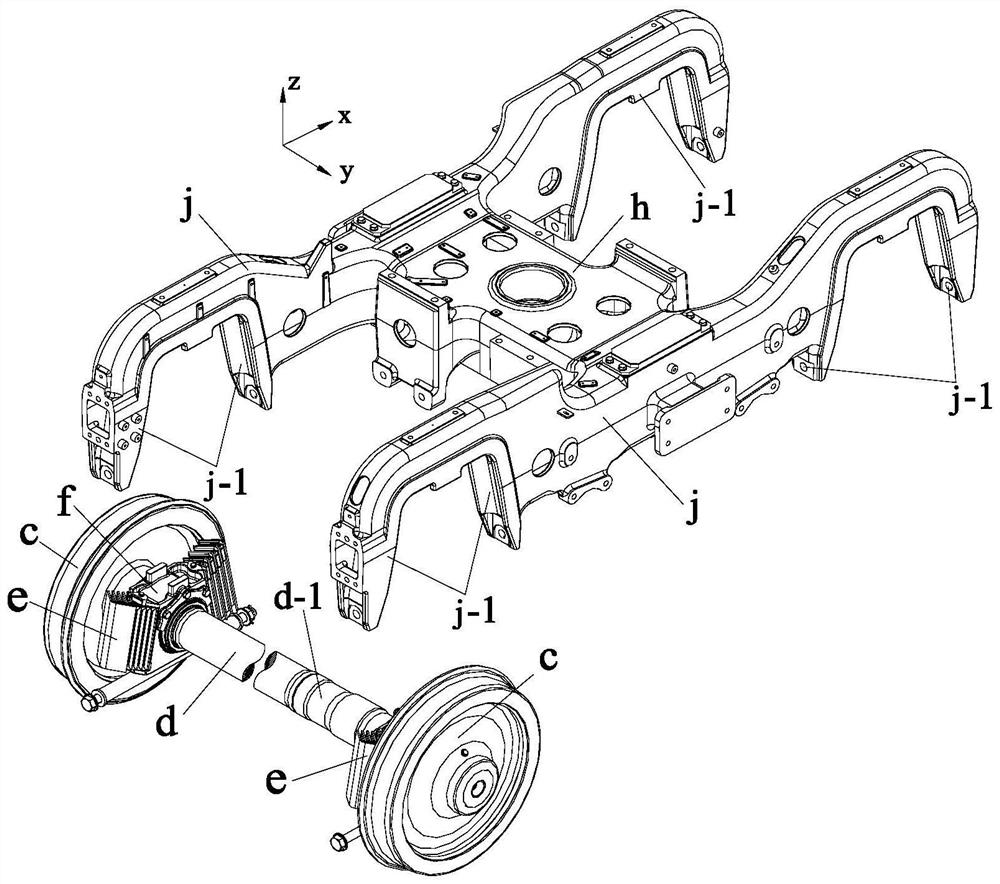

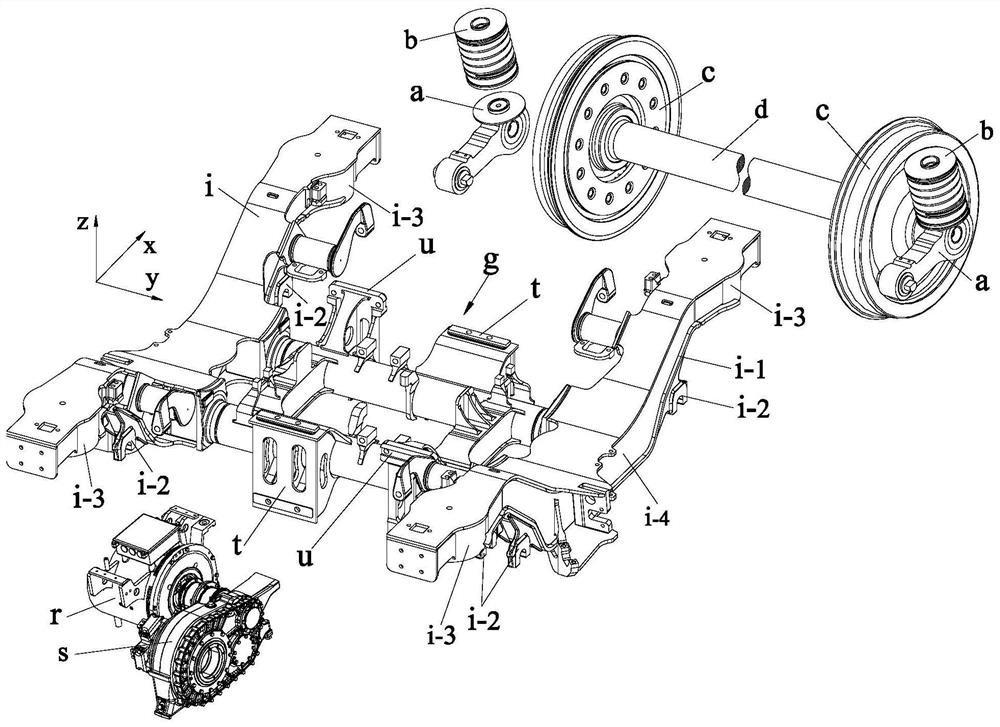

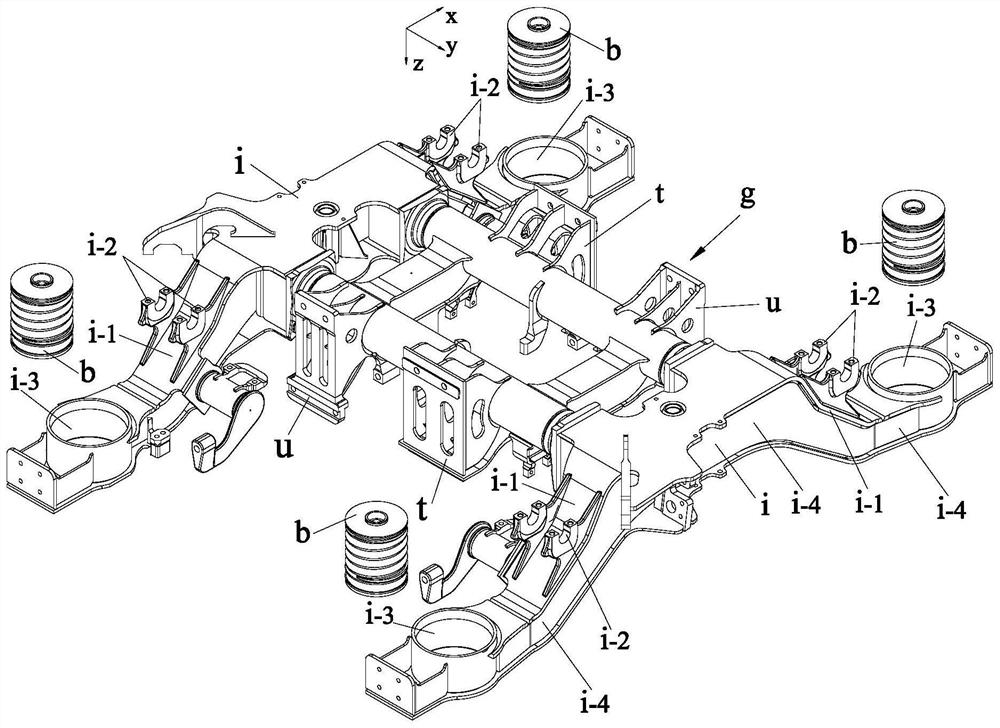

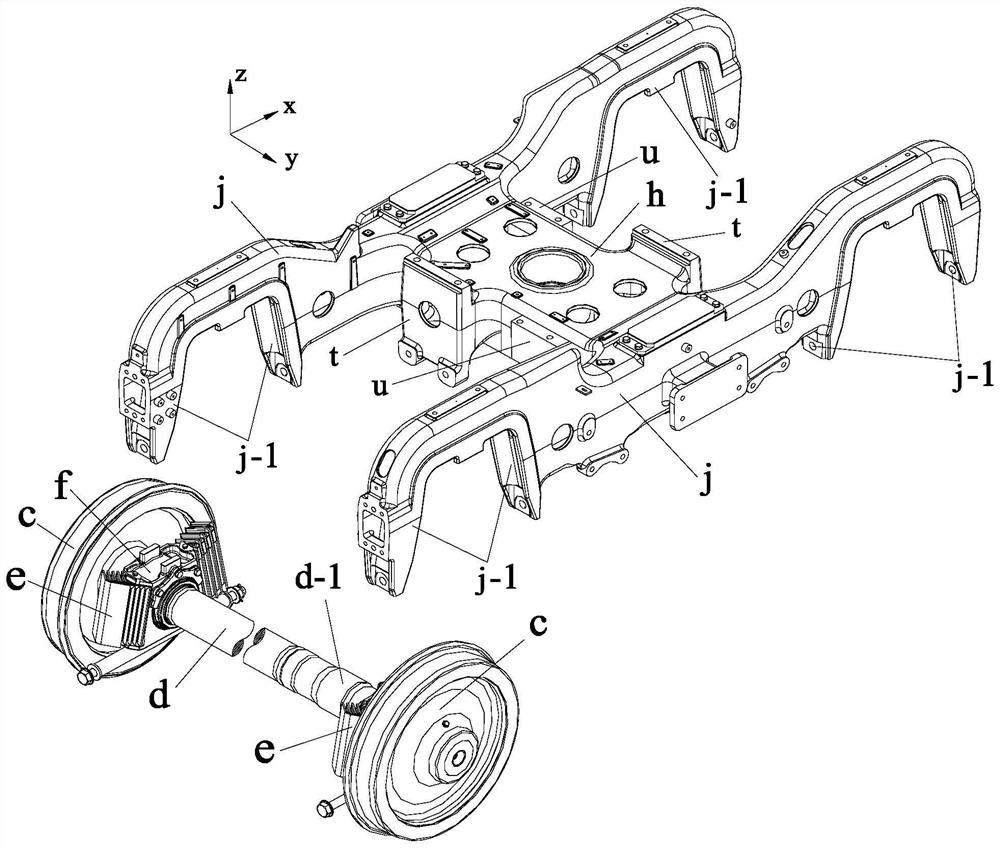

Axle box built-in subway bogie based on flexible interconnection framework and upper swing bolster

PendingCN113022622AReduce the impact of vibrationLow degree of vibration influenceElectric motor propulsion transmissionAxle-boxesBogieFailure rate

The invention discloses an axle box built-in subway bogie based on a flexible interconnection framework and an upper swing bolster, and belongs to the field of railway vehicle power bogie devices. The flexible interconnection frame comprises a wheel set device composed of wheels and axles, a horizontal and longitudinal integrated flexible interconnection frame, four annular vibration reduction axle boxes, an easy-to-withdraw shaft type gearbox, a side beam single-point suspension type motor, an integrated vibration reduction type swing bolster and a secondary suspension system. The damping requirement for the whole framework is greatly reduced, and the effects of reducing the number of parts, reducing the failure rate, releasing the layout space of a motor and a gearbox and releasing the maintenance operation allowance are achieved; on the premise of ensuring the mounting position and the vibration reduction index of the primary suspension axle box device, the transverse width size and the turning radius of the whole bogie are effectively reduced, the curve passing capacity of the bogie is further improved, and the annular vibration reduction axle box is convenient to mount, dismount and maintain; and after four fastening bolts are respectively dismounted, the side beam single-point suspension type motor can be directly and independently dismounted from the lower part of the vehicle body through the maintenance trench.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

Transverse and longitudinal integrated non-power framework device with temperature-measurable axle boxes

PendingCN112046538AGet rid of partitionAccurate measurementAxle-boxesBogiesBogieSuspension (vehicle)

The invention discloses a transverse and longitudinal integrated non-power framework device with temperature-measurable axle boxes, and belongs to the field of railway vehicle framework devices. The transverse and longitudinal integrated non-power framework device comprises a transverse and longitudinal integrated interconnection framework and four annular vibration reduction axle boxes. The transverse and longitudinal integrated interconnection framework comprises two transverse and longitudinal integrated frameworks, and each transverse and longitudinal integrated framework comprises an integrated side beam and an integrated cross beam which are integrally formed. Each integrated side beam comprises a side beam middle section which serves as two bird wing connecting parts and is locatedat a lower position, and two bird-wing-shaped side beam cantilever sections which are symmetrically and fixedly connected to the two ends of the side beam middle section. On the premise that the installation position and the vibration reduction index of a primary suspension axle box device are guaranteed, the overall transverse width size and the turning radius of the bogie are effectively reduced, the curve passing capacity of the bogie is further improved, the vibration influence degree of the bogie on a vehicle body is reduced to the minimum, the balance stability and comfort of the vehiclebody are enhanced, the fatigue loss of the overall structure is effectively reduced, and the overall service life of the bogie and the vehicle body is greatly prolonged.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

Substrate metal combined Vivaldi phased array antenna

InactiveCN109818140AImprove the array environmentExpand the scanning airspaceAntenna arraysRadiating elements structural formsMetal sheetAntenna substrate

The invention relates to a substrate metal combined Vivaldi phased array antenna. The antenna sequentially comprises an upper-layer metal sheet antenna, an upper-layer substrate, a lower-layer substrate and a lower-layer metal sheet antenna from top to bottom. A Vivaldi substrate antenna is formed by crimping the upper-layer substrate and the lower-layer substrate, and comprises a micro-strip feeder line printed on the upper surface of the lower-layer substrate, a micro-strip fan-shaped stub line at the tail end of the micro-strip feeder line, and printing matching grooves and printing taperedslot lines which are printed on the lower surface of the lower-layer substrate and the upper surface of the upper-layer substrate; the upper-layer metal sheet antenna and the lower-layer metal sheetantenna are provided with metal matching grooves and metal tapered slot lines; the structural shapes of the metal matching grooves and the metal tapered slot lines are the same as those of the printing matching grooves and the printing tapered slot lines of the Vivaldi substrate antenna; the upper-layer metal sheet antenna is crimped to the upper surface of the upper-layer substrate; and the lower-layer metal sheet antenna is crimped to the lower surface of the lower-layer substrate. According to the invention, the unit directional diagram in the array is improved, the scanning airspace of thephased array antenna is expanded, the mechanical structure strength of the antenna substrate is improved, and the antenna deformation is reduced.

Owner:中国船舶重工集团公司第七二三研究所

Array bolt hoisting underframe

InactiveCN110713109AImprove mechanical structure strengthStable supportLoad-engaging elementsElectric machineBearing (mechanical)

Owner:上海电气集团上海电机厂有限公司

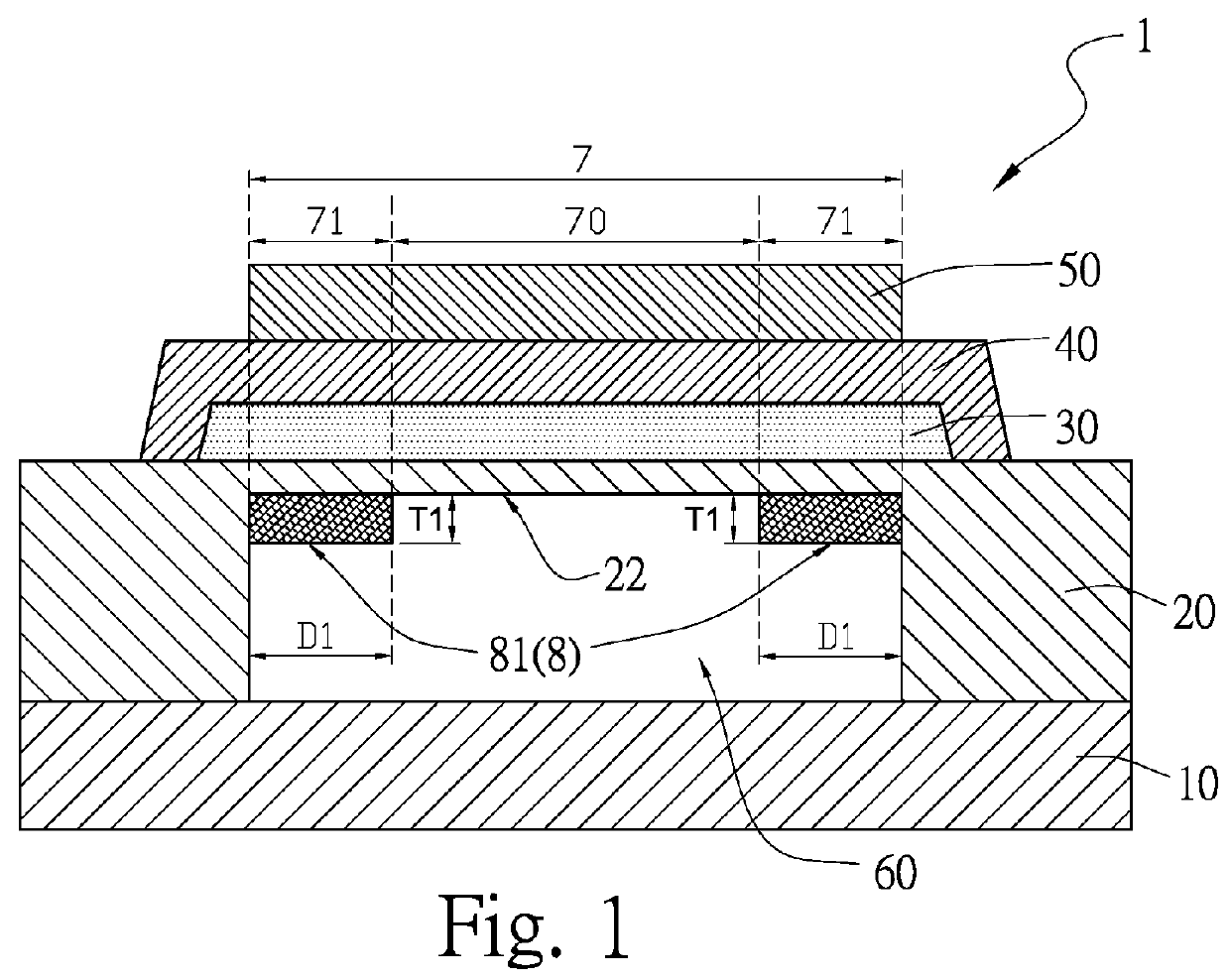

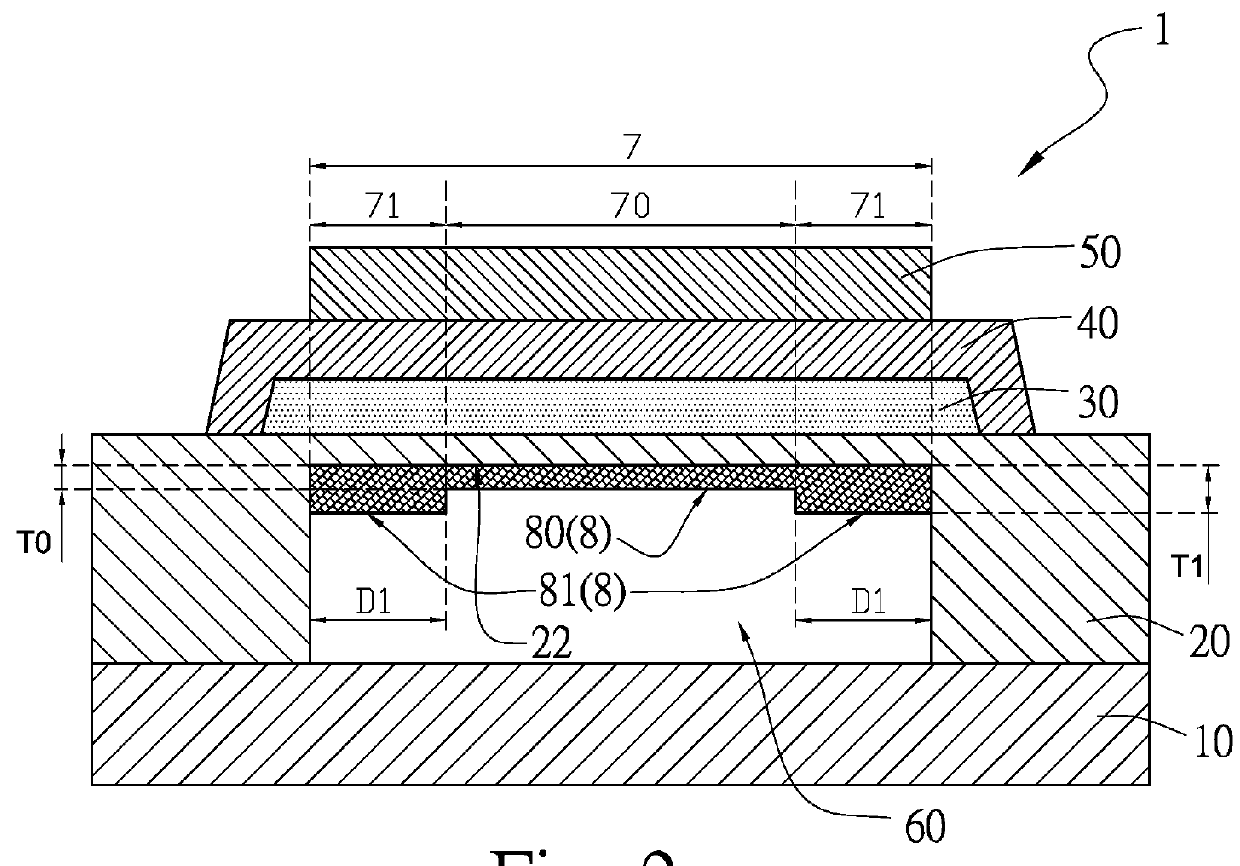

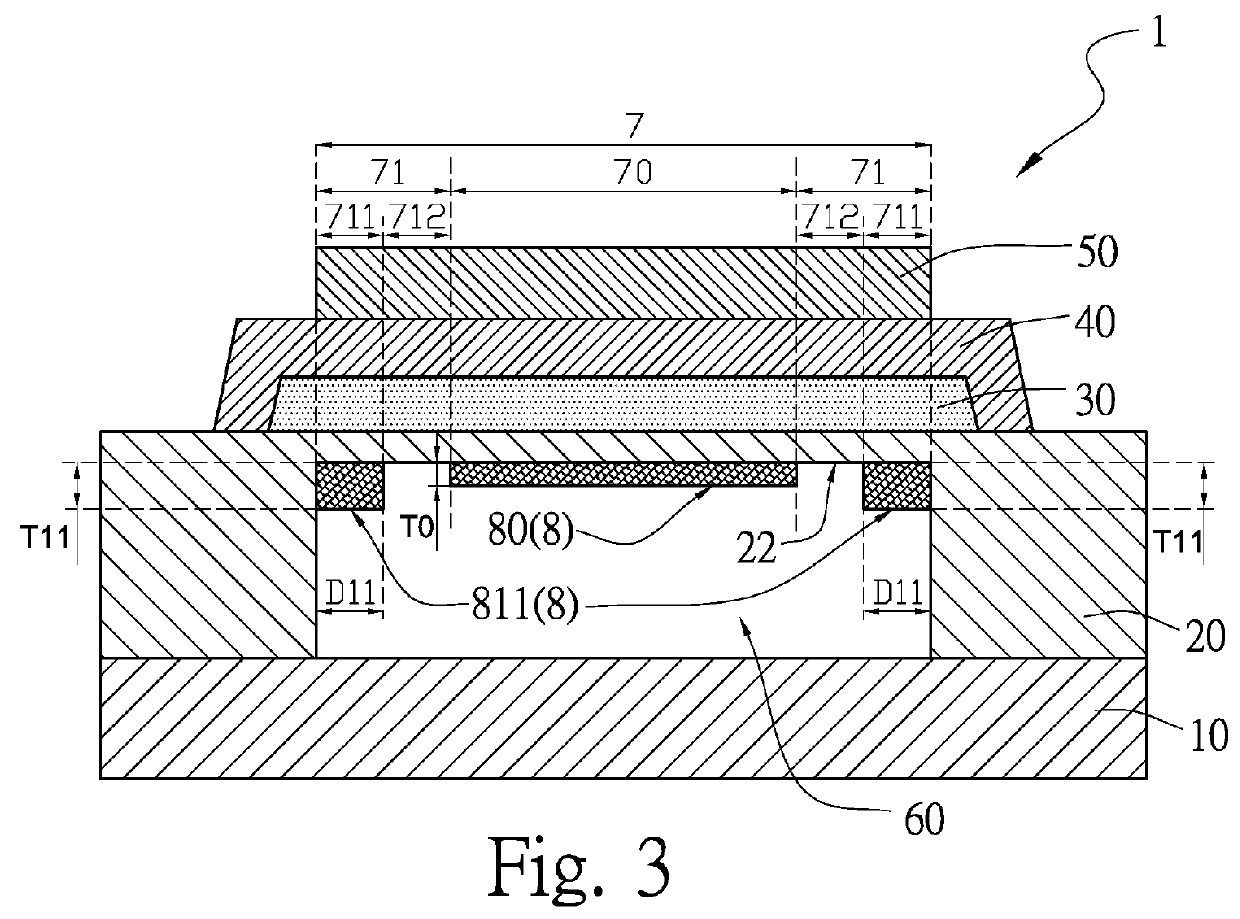

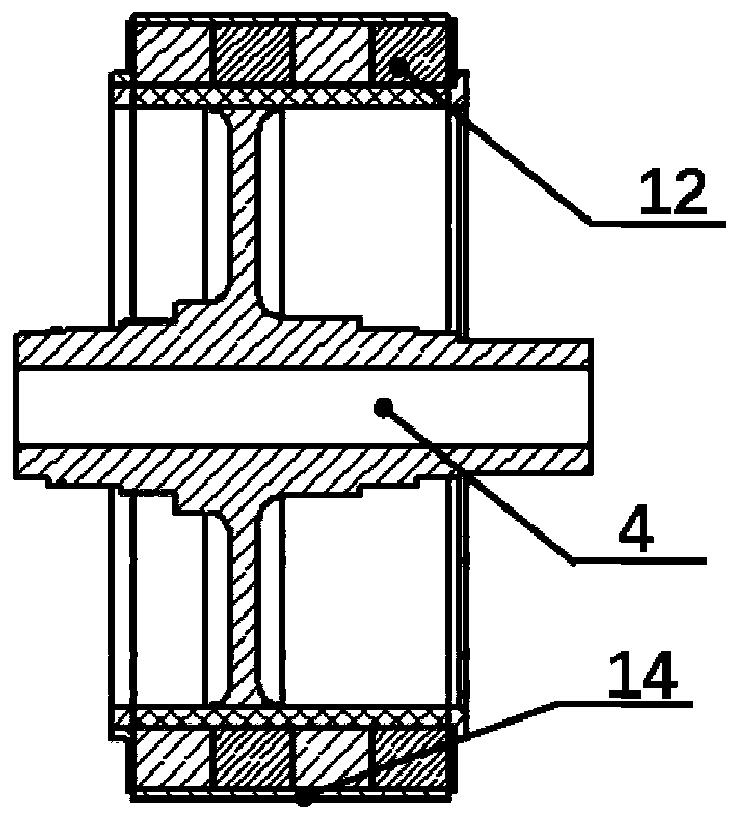

Bulk acoustic wave resonator with a mass adjustment structure and its application to bulk acoustic wave filter

ActiveUS20180109240A1Increase mechanical strengthSuppress spurious modeImpedence networksAcoustic waveCentral region

A bulk acoustic wave resonator with a mass adjustment structure comprises a supporting layer, a lower metal layer, a piezoelectric layer, an upper metal layer and a mass adjustment structure. The supporting layer is formed on a substrate. The supporting layer has a cavity, and the cavity has a top-inner surface. The lower metal layer is formed on the supporting layer. The piezoelectric layer is formed on the lower metal layer. The upper metal layer is formed on the piezoelectric layer. An acoustic wave resonance region is defined by an overlapping region of projections of the upper metal layer, the piezoelectric layer, the lower metal layer, the supporting layer and the cavity. The acoustic wave resonance region is divided into a peripheral region and a central region. The mass adjustment structure comprises a peripheral mass adjustment structure formed on the top-inner surface within the peripheral region.

Owner:WIN SEMICON

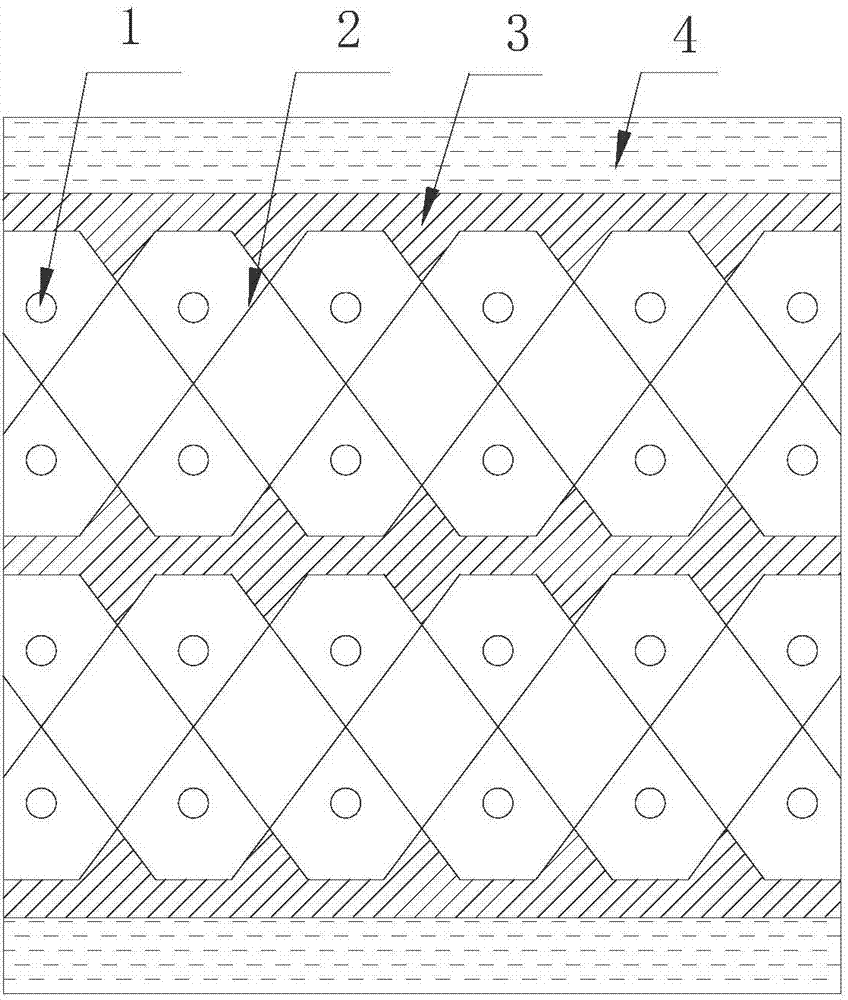

Weaving framework for conveying belt

InactiveCN107164866AReduce thicknessAvoid opening glueWoven fabricsEngineeringUltimate tensile strength

The invention discloses a weaving framework for a conveying belt. The weaving framework comprises warp threads and weft threads, wherein the weft threads include upper-layer weft threads and lower-layer weft threads, the strand number of the warp threads is four, two strands of warp threads are alternatively woven with an uneven number of weft threads in the lower-layer weft threads and an even number of weft threads in the upper-layer weft threads in an opposite-direction mode, the other two strands of warp threads are alternatively woven with an uneven number of weft threads in the lower-layer weft threads and an even number of weft threads in the upper-layer weft threads in an opposite-direction mode, and two strands of warp threads are mutually staggered with the other two strands of warp threads to form a network. Compared with a framework structure in the prior art, the weaving framework for the conveying belt is higher in structural structure strength, the conveying belt including the framework can be connected by using the mode of a mechanical joint, is economic, convenient and quick, repeated calendaring and rubberizing in the conveying belt manufacturing process are not needed, the thickness of the conveying belt can be remarkably decreased, and the phenomenon that the conveying belt produces interlaminar glue failure after the joint forms an annular shape is avoided. The invention also discloses the conveying belt.

Owner:YANKUANG DONGHUA HEAVY IND CO LTD +1

Method for processing inner surface of solar-thermal power generation thermal storage device

InactiveCN104315734AImprove mechanical structure strengthImprove wear resistanceSolar heat devicesSolar thermal energy generationGrapheneProcessing cost

The invention relates to a method for processing the inner surface of a solar-thermal power generation thermal storage device. A layer of graphene nanofilm is formed on the inner surface of a structural material forming the solar-thermal power generation thermal storage device, is 0.05-2mu m in thickness, and is formed with a mechanical method, a chemical method and a surface spraying method. The mechanical structural strength of the thermal storage device is improved, the wear resistance and the corrosion resistance of the thermal storage device are improved, the material cost and the processing cost are reduced, and the service life of the thermal storage device is prolonged.

Owner:殷苏

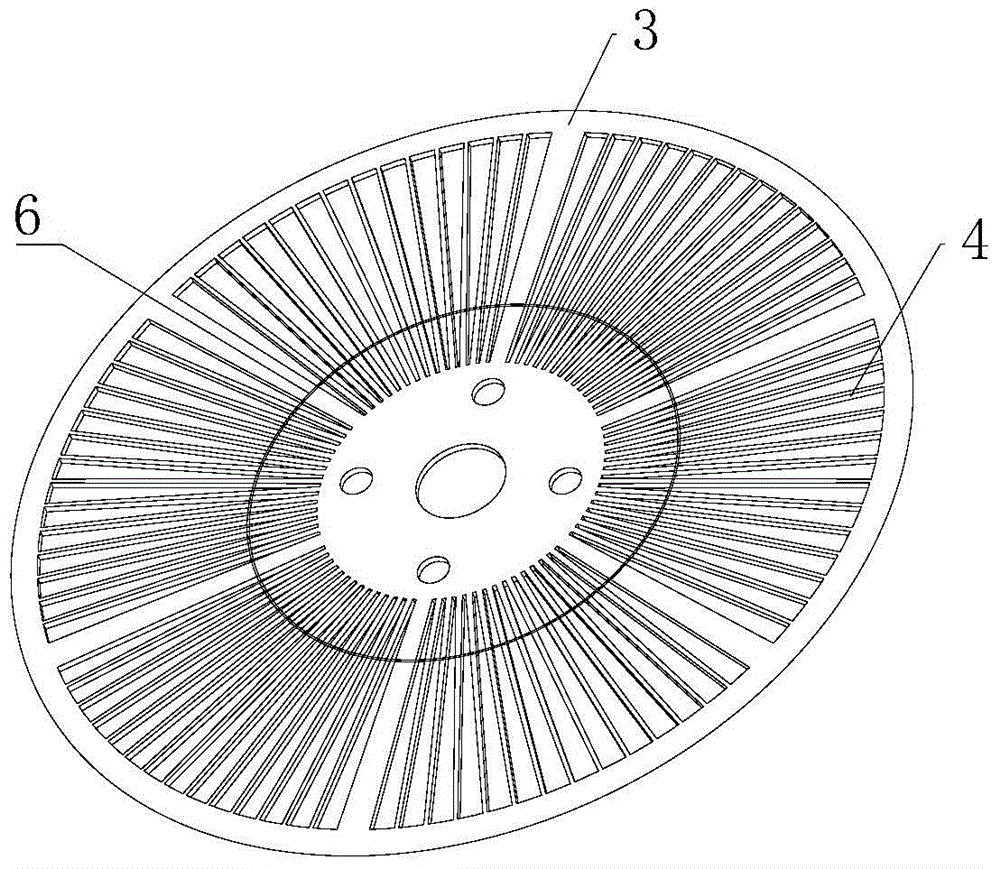

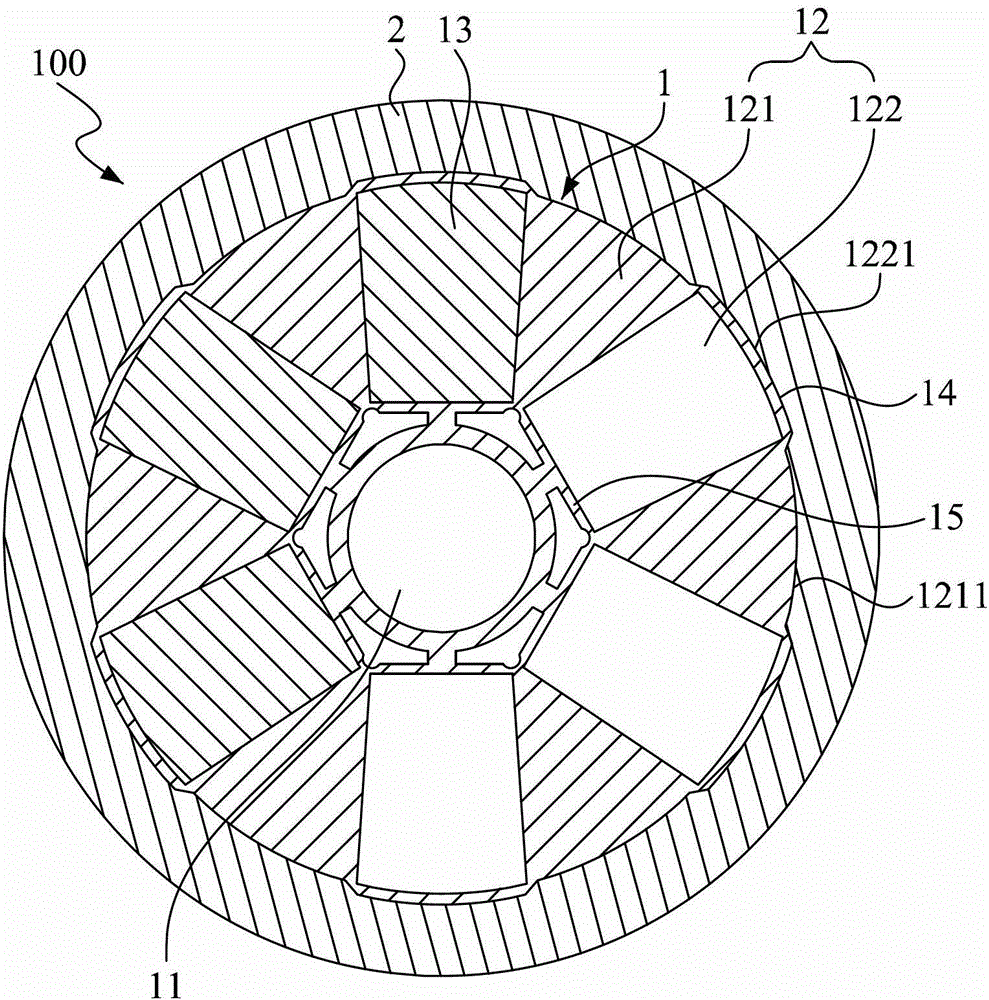

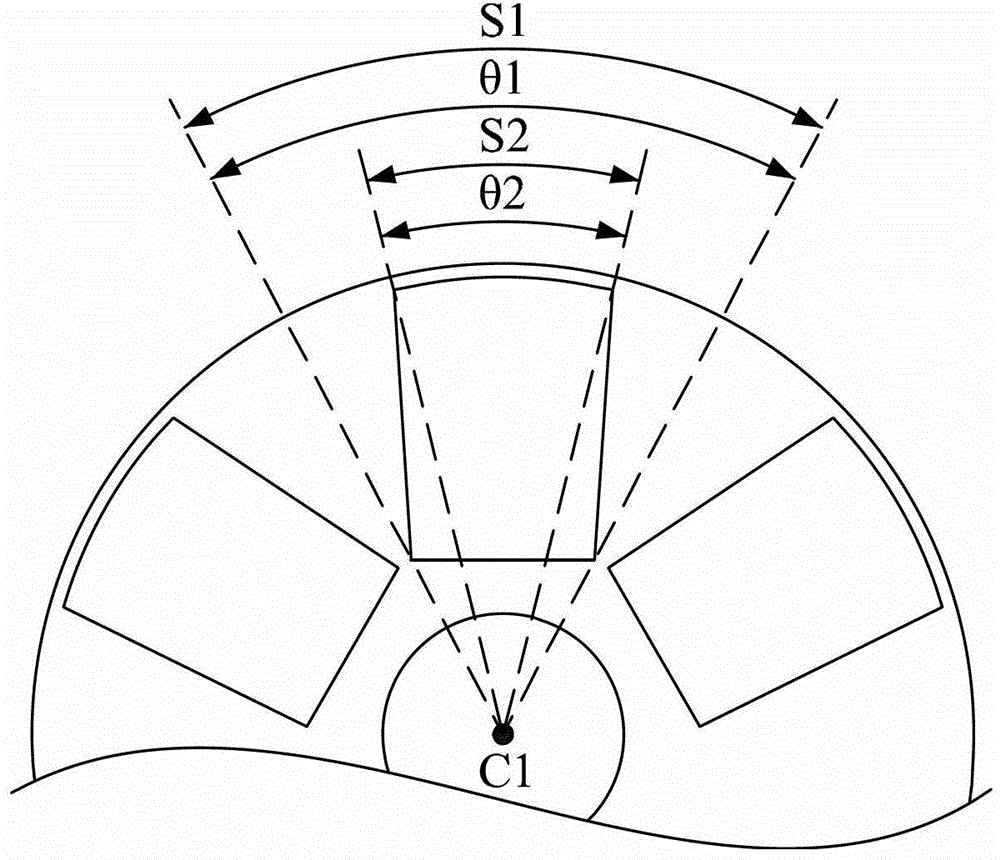

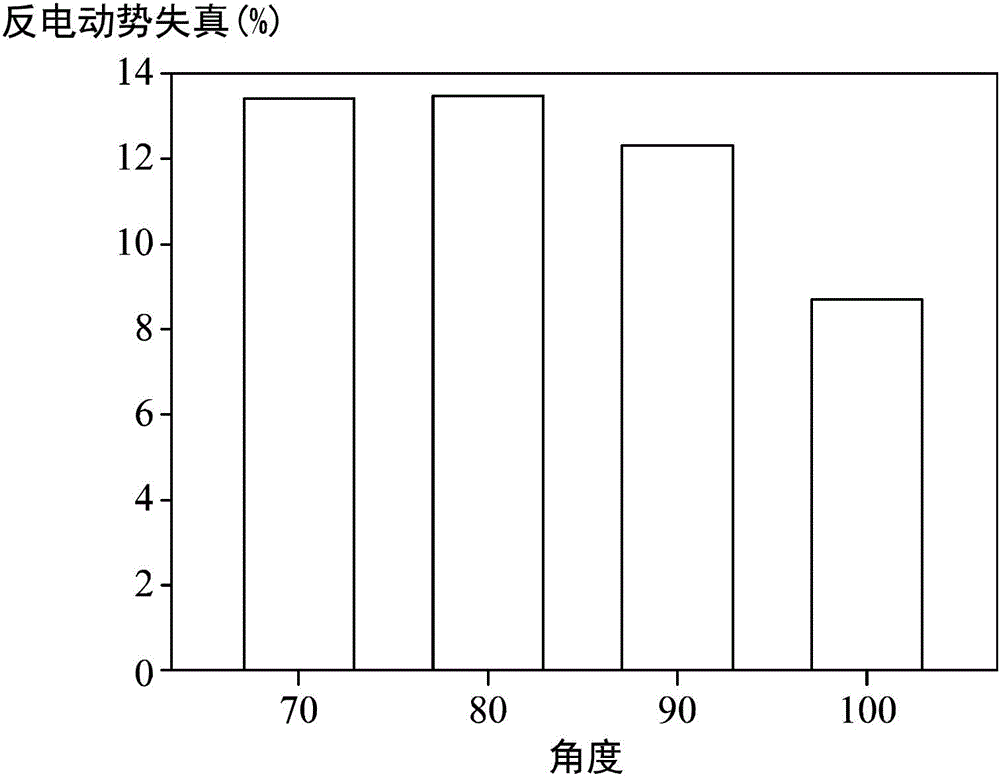

Rotor having arc cutting structure

InactiveCN103944295AIncreased durabilityImprove back EMFMagnetic circuit rotating partsEngineeringMagnet

The invention relates to a rotor having an arc cutting structure. The rotor is used for being arranged in a stator of a motor, and comprises a rotating shaft, a rotor core and a plurality of sector-shaped magnets. The rotor core comprises a plurality of iron core parts and a plurality of magnet accommodating grooves, the iron core parts are mutually connected and integrally formed, and have a first circular arc, and the first circular arc corresponds to a first centre of curvature. The magnet accommodating grooves are sector-shaped, arranged among the iron cores parts, and correspond to a second circular arc, the second circular arc is connected to the first circular arc, and corresponds to a second centre of curvature, and the second centre of curvature is different from the first centre of curvature. The sector-shaped magnets are correspondingly accommodated in the magnet accommodating grooves.

Owner:TECO ELECTRIC AND MACHINERY

A high-power and high-reliability six-phase permanent magnet fault-tolerant hub motor for electric armored vehicles

ActiveCN108631459BAdd direct axis inductanceImproving the speed-up capability of magnetic field weakeningMagnetic circuit rotating partsElectric machinesPermanent magnet rotorCarbon fibers

The invention discloses a high-power high-reliability six-phase permanent magnet fault-tolerant hub motor used for an electric armored vehicle. The high-power high-reliability six-phase permanent magnet fault-tolerant hub motor comprises a stator assembly, a rotor assembly, a rotary shaft, a bearing, a machine shell, front back end covers, and a position sensor; the six-phase windings in the stator assembly adopt a fractional-slot and concentrated single-layer winding structure embedded with partition teeth, so that an electrical fault-tolerant structure can be formed between the phase windings; meanwhile, by combination of the dimensional design of the stator toothed groove structure, the phase winding inductance of the electric motor is increased, the short circuit current is suppressedeffectively, and reliability and fault-tolerant performance of the hub motor are improved; the rotor assembly adopts an internal permanent magnet rotor structure, and the outer side of the rotor is wound with a carbon fiber protection sleeve, so that the mechanical structural strength of the rotor is improved; the stator winding adopts a monocrystal copper wire or silver wire, so that stator lossof the hub motor is lowered; the permanent magnet of the rotor assembly adopts eccentric design, and is subjected to circumferential or axial sectioning processing, so that the rotor loss of the hub motor is lowered effectively; a Z-shaped or spiral heat dissipation water path is formed in the machine shell, so that the heat dissipation capability of the hub motor is improved; and the hub motor has high fault isolation, anti-short-circuit and weak magnetic diffusion capability, so that the requirements of high reliability, high power and high rotary speed of the hub driving of the electric armored vehicle can be satisfied.

Owner:北京北航天宇长鹰无人机科技有限公司

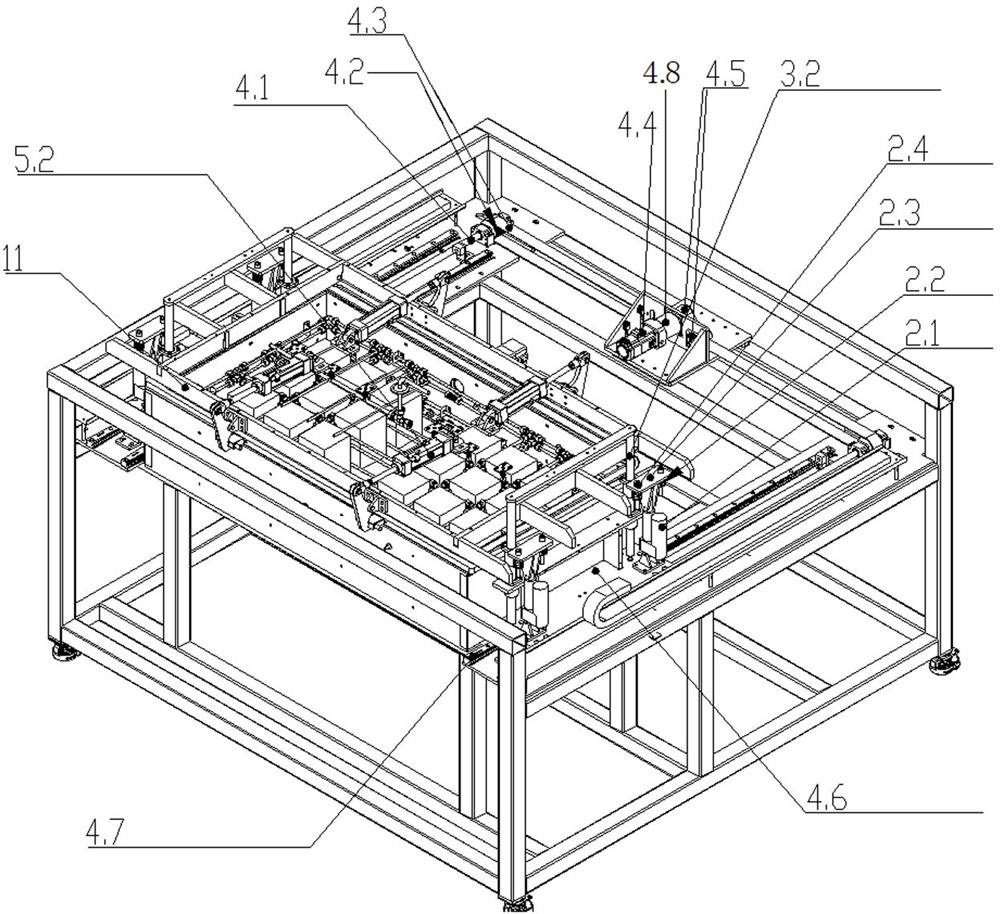

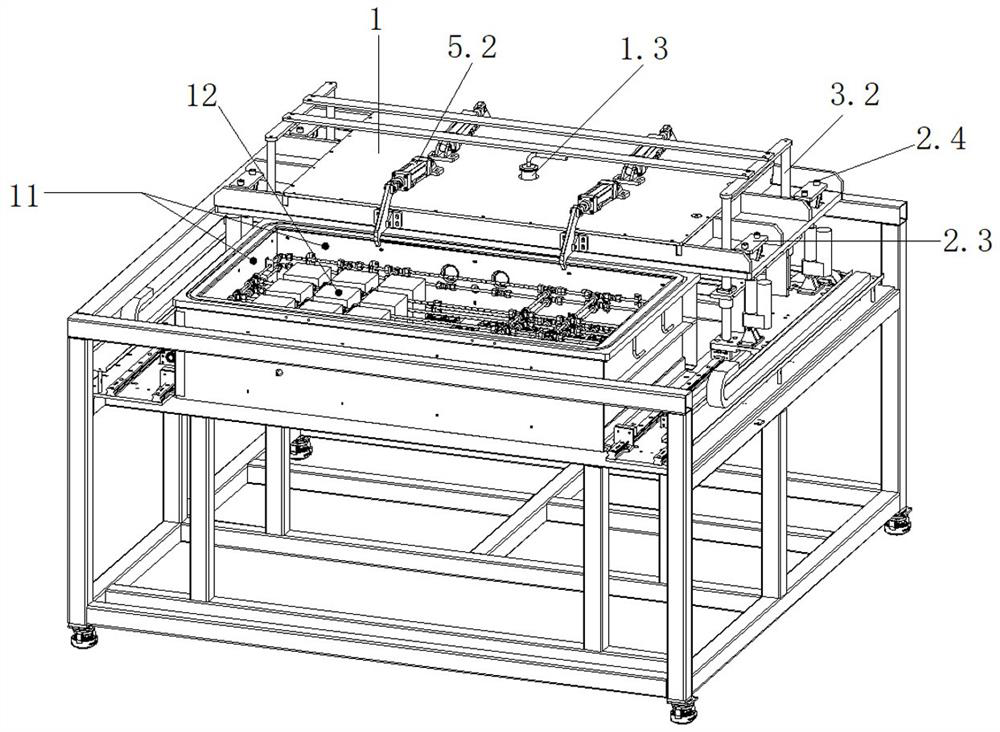

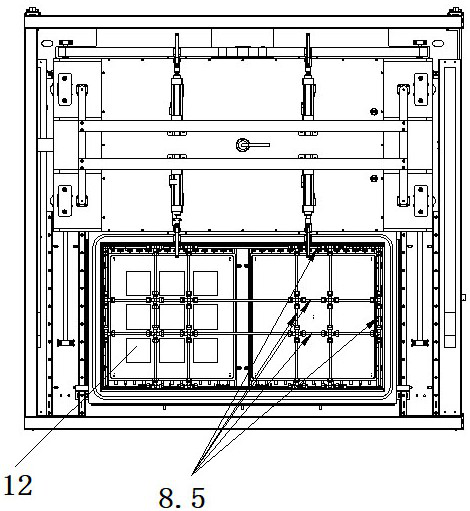

Vacuum equipment for vacuum welding or annealing of semiconductor chip

ActiveCN112103225AEasy for automatic loadingConvenient for automatic loading and unloadingSemiconductor/solid-state device manufacturingRobot handSemiconductor chip

The invention relates to vacuum equipment for vacuum welding or annealing of a semiconductor chip, and the equipment comprises a vacuum cabin and a vacuum cabin upper cover, and further comprises a translation mechanism, wherein the translation mechanism is connected with the vacuum cabin upper cover and can drive the vacuum cabin upper cover to horizontally move relative to the vacuum cabin; Theequipment also comprises a lifting mechanism which is connected with the vacuum cabin upper cover and can drive the vacuum cabin upper cover to move up and down relative to the vacuum cabin. The vacuum chamber upper cover can move up and down and horizontally relative to the vacuum chamber, the opening and closing door does not occupy the position of an input port, robot automatic feeding is moreconvenient, products can be vertically and automatically input, the top space of a welding area in the vacuum chamber can be increased, robot or mechanical arm automatic feeding and discharging are convenient, and the problem that horizontal input of heavy-load products easily causes scratching of the jig carrying table is effectively solved.

Owner:北京仝志伟业科技有限公司

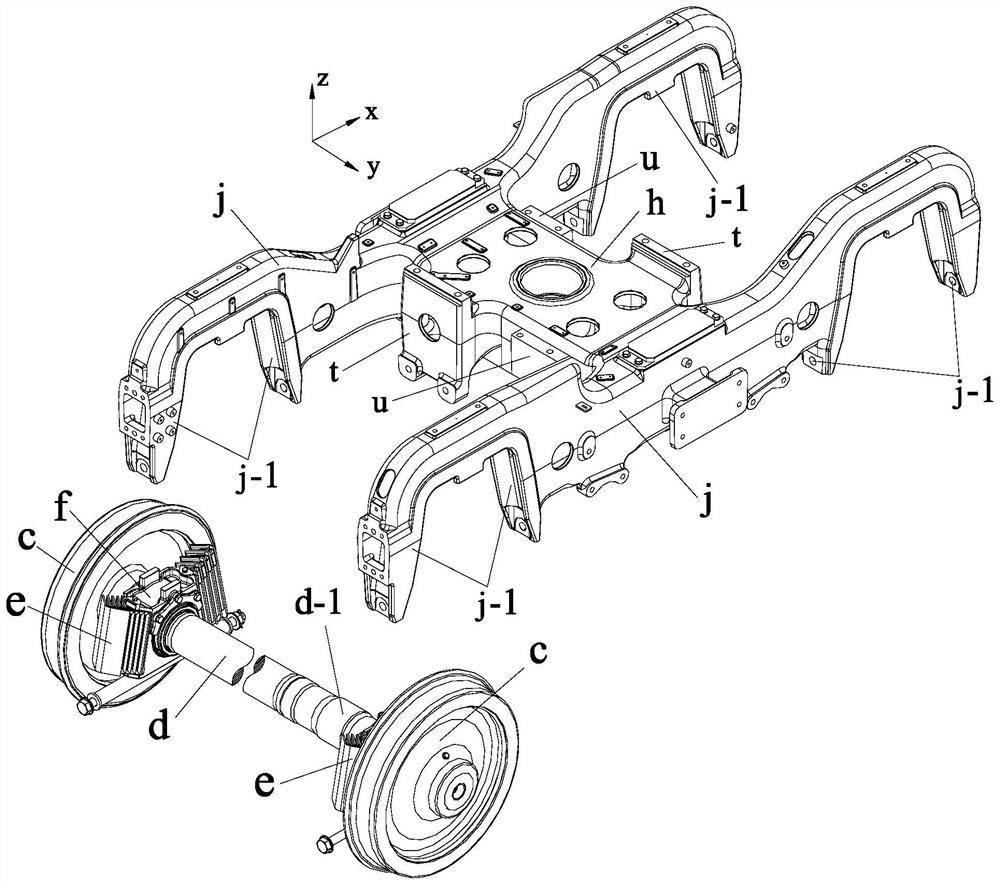

Non-powered bogie with axle boxes capable of measuring temperature and flexible interconnection framework

PendingCN113022625AImprove curve passabilityReduce wheel load shedding rateAxle-boxesBogiesBogieFailure rate

The invention discloses a non-power bogie with axle boxes capable of measuring temperature and a flexible interconnection framework, and belongs to the field of rail vehicle non-power bogie devices. The non-power bogie comprises a wheel set device composed of wheels and axles, a transverse-longitudinal integrated flexible interconnection framework and four annular vibration reduction axle boxes. The damping requirement for the whole framework is greatly reduced, and the effects of reducing the number of parts and the failure rate, releasing the layout space and maintenance operation allowance of a motor and a gearbox, simplifying the framework size and simplifying the manufacturing process are achieved; and on the premise that the mounting position and the vibration reduction index of the primary suspension axle box device are ensured, the transverse width size and the turning radius of the whole bogie are effectively reduced, the curve passing capacity of the bogie is further improved, and the annular vibration reduction axle box is convenient to mount, dismount and maintain.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

Power bogie based on novel motor suspension structure and temperature-measurable axle box

PendingCN112046537AAvoid structural size deviationsGuarantee welding qualityElectric motor propulsion transmissionAxle-boxesSuspension (vehicle)Electric machinery

The invention discloses a power bogie based on a novel motor suspension structure and a temperature-measurable axle box, and belongs to the field of railway vehicle power bogie devices. The power bogie comprises a framework, a wheel set device composed of wheels and axles, four annular vibration reduction axle boxes, an easy-to-retreat axle type gear box and a side beam single-point suspension type motor. On the premise that the installation position and the vibration reduction index of a primary suspension axle box device are guaranteed, the transverse width size and the turning radius of thewhole bogie are effectively reduced, the curve passing capacity of the bogie is further improved, and the annular vibration reduction axle boxes are convenient to install, detach and maintain; and after the four fastening bolts are disassembled respectively, the side beam single-point suspension type motor can be directly and independently disassembled from the lower portion of a vehicle body through an overhauling trench.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

Fabrication process of sapphire photonic crystal fiber grating ultra-high temperature distributed sensor

ActiveCN108106751BImprove the stable and resistant temperature of ultra-high temperature environmentImprove mechanical structure strengthThermometers using physical/chemical changesOptical waveguide light guidePhotonic crystalFiber gratings

The invention provides a preparation process of a sapphire photonic crystal fiber grating ultra-high temperature distributed sensor, comprising: Step 1, relying on the preparation process and technology of sapphire special material pipe rods to produce sapphire special material rods and sleeves; Step 2, based on The sapphire special material rod and sleeve provided in step 1 rely on the photonic crystal special fiber preparation process and technology to produce sapphire photonic crystal special fiber; step 3, based on the sapphire photonic crystal special fiber provided in step 2, rely on ultra-fast femtosecond Laser-engraved fiber grating preparation process and technology, manufacturing distributed fiber grating sensing units in sapphire photonic crystal special optical fibers; step 4, using high-temperature sensor packaging based on boron carbide high-temperature structural ceramic sleeves and high-temperature sensor packaging based on sapphire capillary tubes Technology, package and protect the sapphire photonic crystal special optical fiber with distributed fiber Bragg grating sensing unit provided in step 3, and prepare a sapphire photonic crystal fiber grating ultra-high temperature distributed sensor.

Owner:武汉从时光瑞光电技术有限公司

Hydrofoil catamaran inner flap/outer flap combined automatic control device

InactiveCN103318385BImprove seakeepingShorten takeoff timeVessel movement reduction by foilsHydrodynamic/hydrostatic featuresAutomatic controlEngineering

The invention aims to provide a joint automatic control device for inner flaps / outer flaps of a hydrofoil catamaran. The joint automatic control device comprises a catamaran. Two sheets are respectively mounted at the left end and the right end of the lower side of the catamaran, a front hydrofoil is mounted at the front ends of the lower sides of the two sheets, a rear hydrofoil is mounted at the rear ends of the lower sides of the two sheets, a first outer flap, a second outer flap, a first inner flap and a second inner flap are respectively mounted at the rear end of the front hydrofoil by the aid of a first connecting shaft, a third outer flap, a fourth outer flap, a third inner flap and a fourth inner flap are respectively mounted at the rear end of the rear hydrofoil by the aid of a second connecting shaft, and the first outer flap, the second outer flap, the third outer flap, the fourth outer flap, the first inner flap, the second inner flap, the third inner flap and the fourth inner flap are respectively connected with respective servo motors. The joint automatic control device has the advantages that the joint automatic control device is simple in structure and reasonable in design, multifunctional and multi-objective cooperative control is implemented, and the safety, the seaworthiness and the maneuverability of the hydrofoil catamaran are improved; the front hydrofoil and the rear hydrofoil are respectively connected with the two sheets of the hydrofoil catamaran, so that the mechanical structural strength is improved.

Owner:HARBIN ENG UNIV

Anti-impact structure and anti-impact equipment

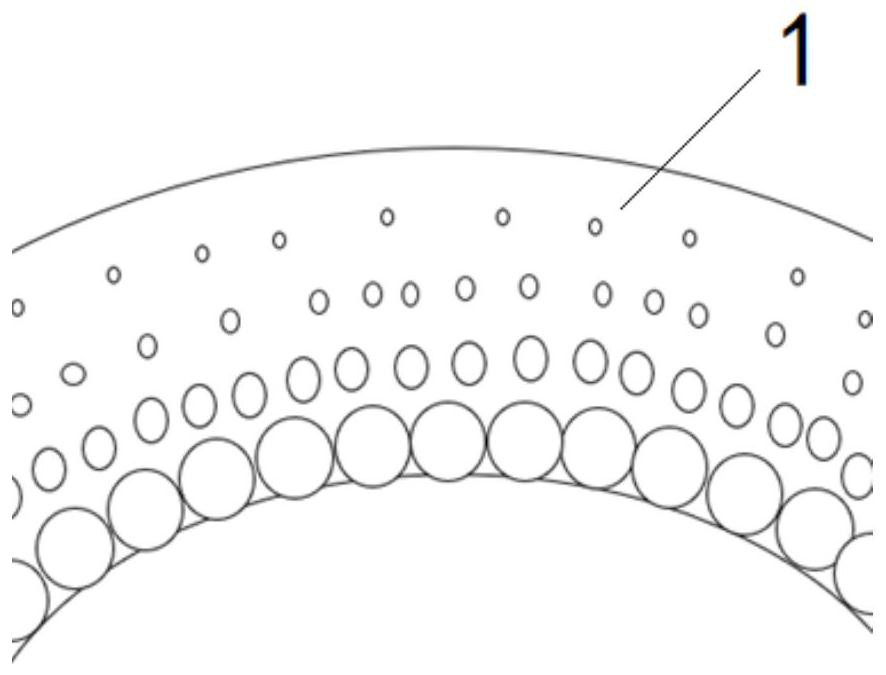

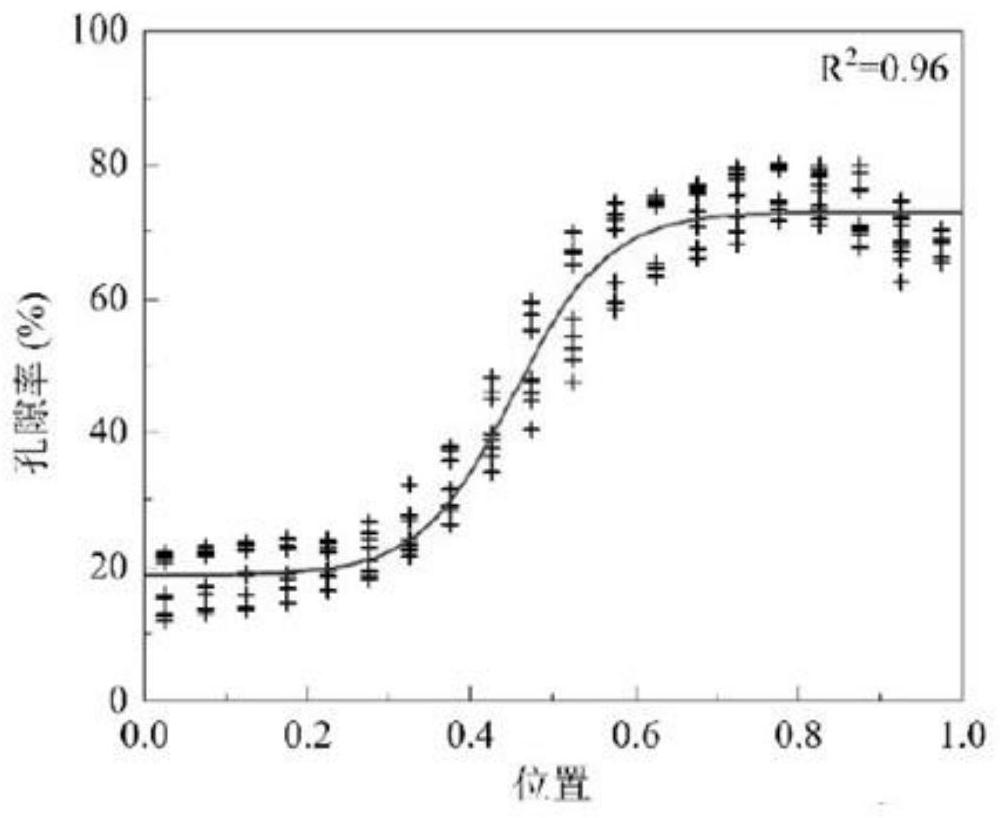

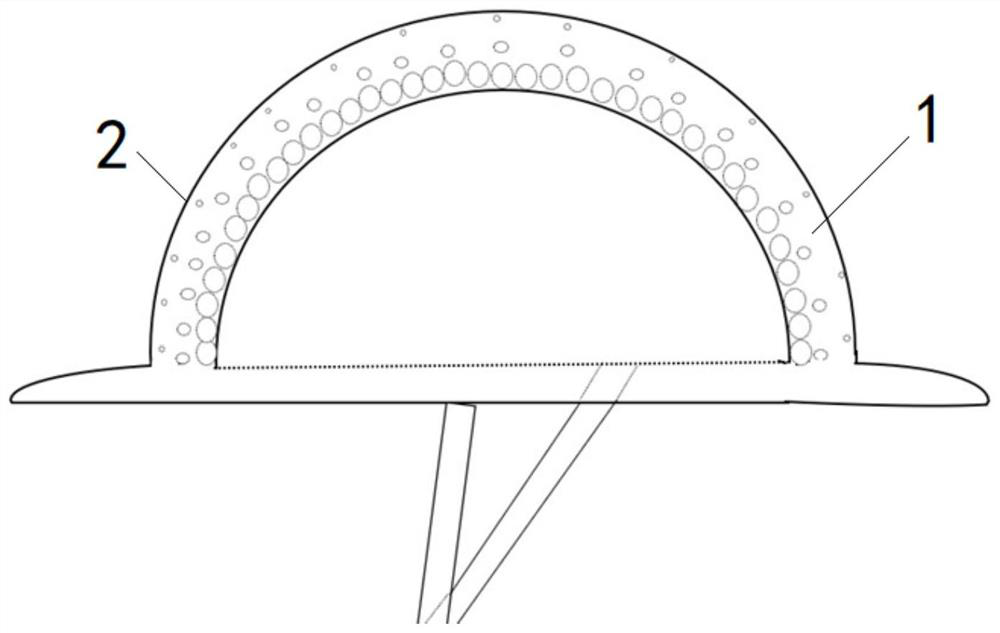

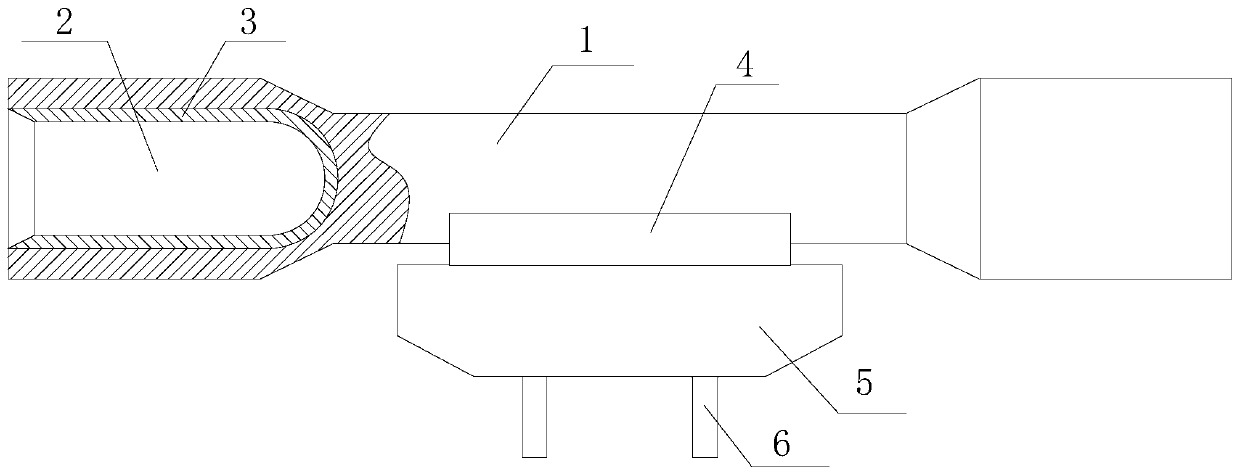

ActiveCN114485271AReduce weightHigh porositySolesClimate change adaptationClassical mechanicsStructural engineering

The invention provides an anti-impact structure and anti-impact equipment. The porosity of the anti-impact structure is gradually increased inwards along the outer surface; in a direction inward along the outer surface, a gradient of a porosity-position distribution function at an intermediate location of the impact resistant structure is greater than a gradient of a porosity-position distribution function at start and end segment locations. According to the anti-impact structure, the outer layer has lower porosity and higher elastic modulus and can bear larger stress, the inner layer has higher porosity and can have larger deformation space and can bear larger strain, the buffering effect of the inner layer is facilitated, and the overall strength of anti-impact protection equipment is guaranteed.

Owner:BEIHANG UNIV

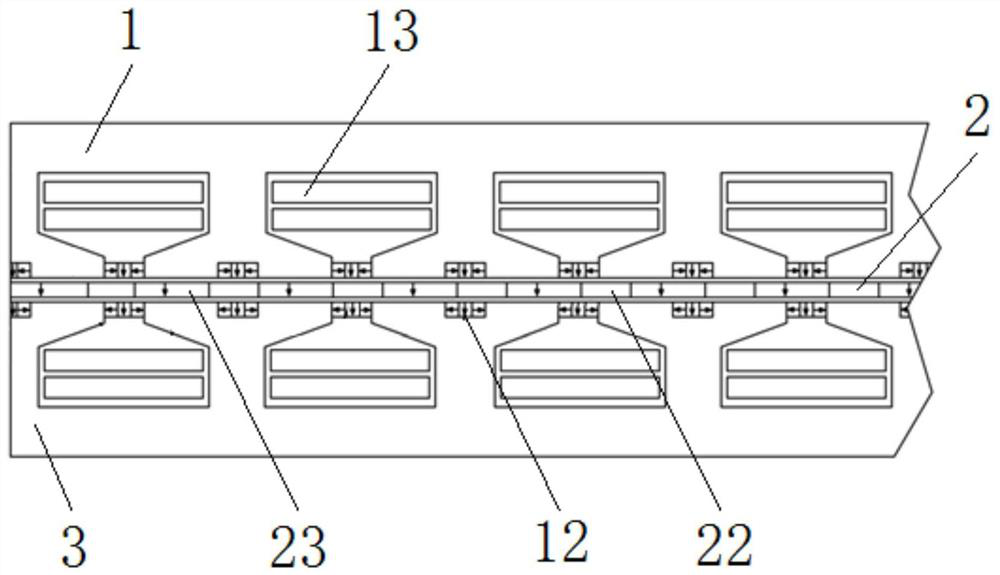

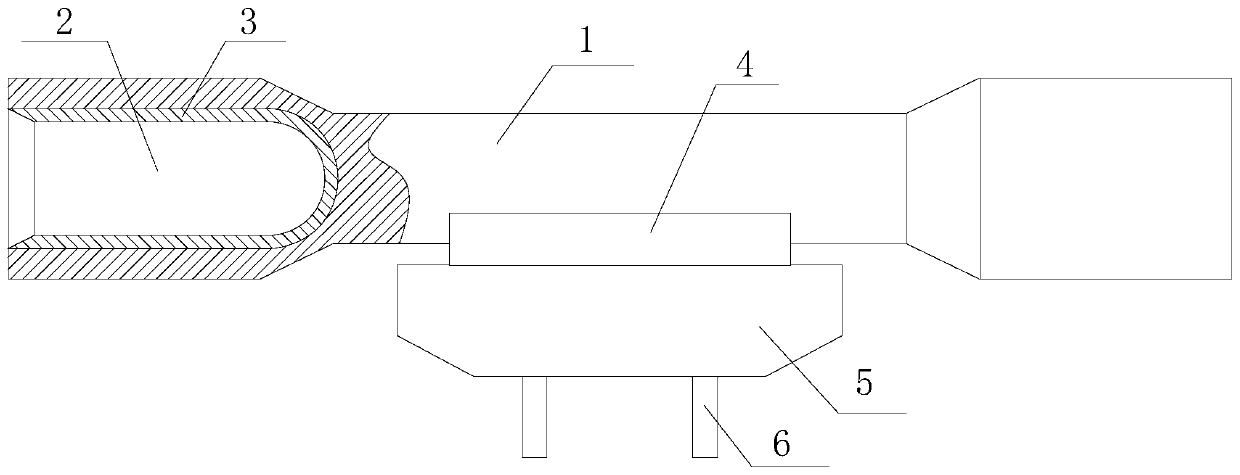

An aluminum alloy high-voltage cable aluminum-copper composite terminal

ActiveCN108615985BImprove the strength of the connection structureImprove impact resistanceElectric connection structural associationsMetal/alloy conductorsHigh pressureElectric power

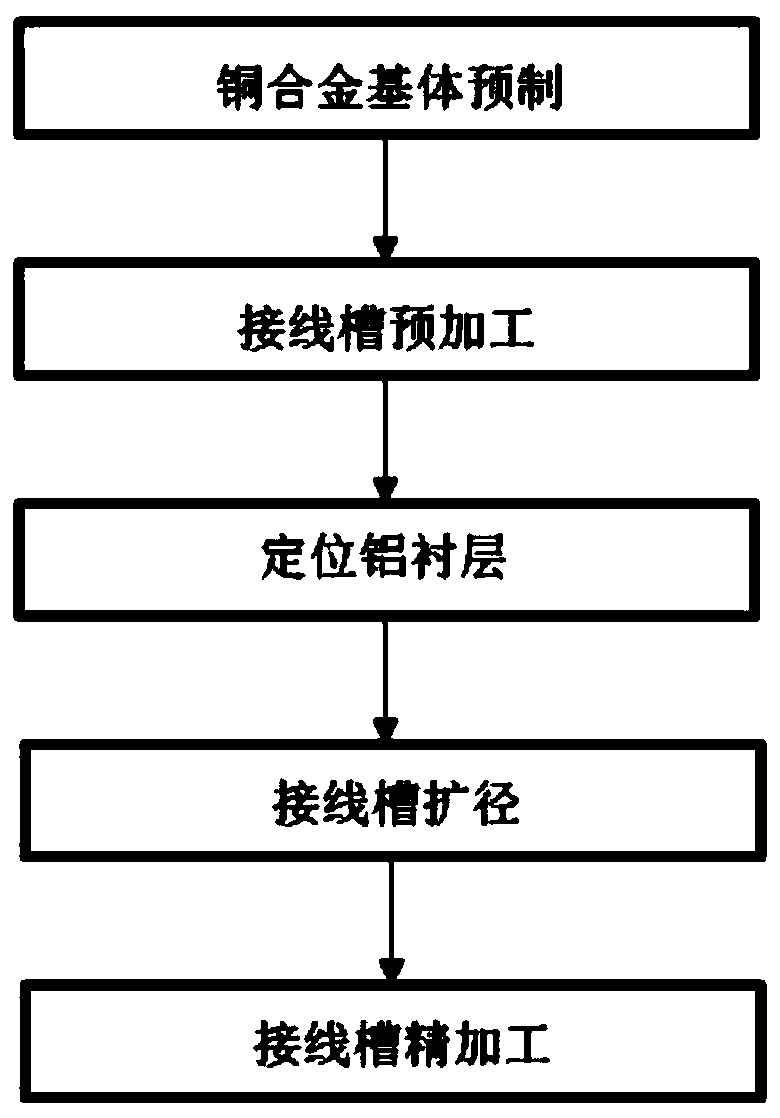

The invention discloses an aluminum-copper composite wiring terminal for an aluminum alloy high voltage cable, which comprises a copper alloy base body and wiring slots located at two ends of the copper alloy base body, wherein the connecting slots are of a U-shaped slot structure in cross section and symmetrically distributed about an axis of the copper alloy base body, the length of the connecting slots is 1 / 5-1 / 2 of the length of the copper alloy base body, the inner surface of each wiring slot is uniformly provided with an aluminum alloy lining, and the thickness of the aluminum alloy lining is 1 / 4-3 / 4 of the thickness of the side wall of the wiring slot. The preparation method comprises four steps such as copper alloy base body prefabrication, wiring slot preprocessing, aluminum lining positioning and wiring slot diameter expansion and wiring slot fine machining. On the one hand, the connecting structure strength, impact resistance, corrosion resistance and high temperature resistance between the wiring terminal and the cable can be effectively improved, and the mechanical structural strength of the wiring terminal is greatly improved; and on the other hand, the overload capacity of the wiring terminal can be effectively improved, the uniformity of current distribution is improved, so that the reliability and operation stability of power cable connection are greatly improved.

Owner:上海永固电力器材有限公司

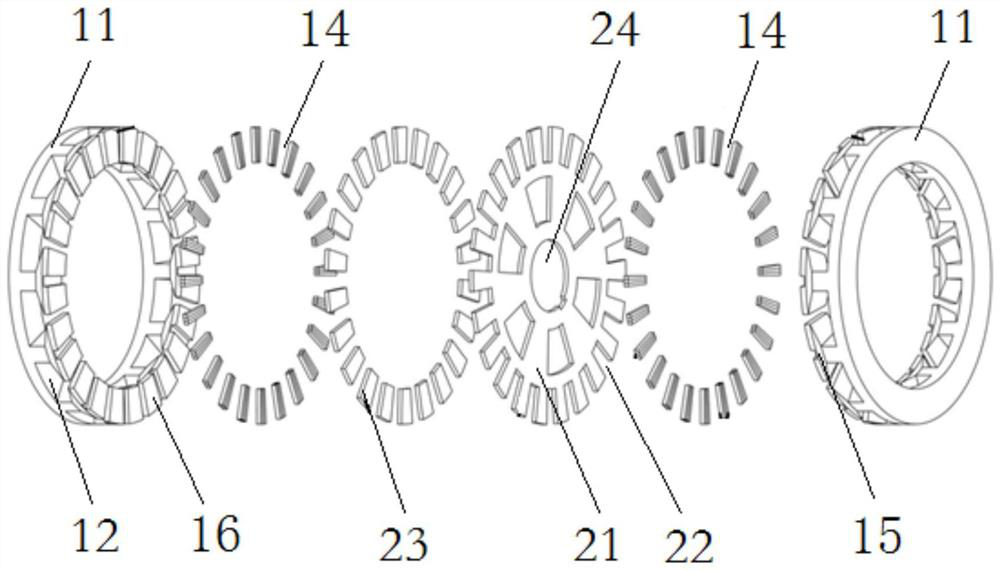

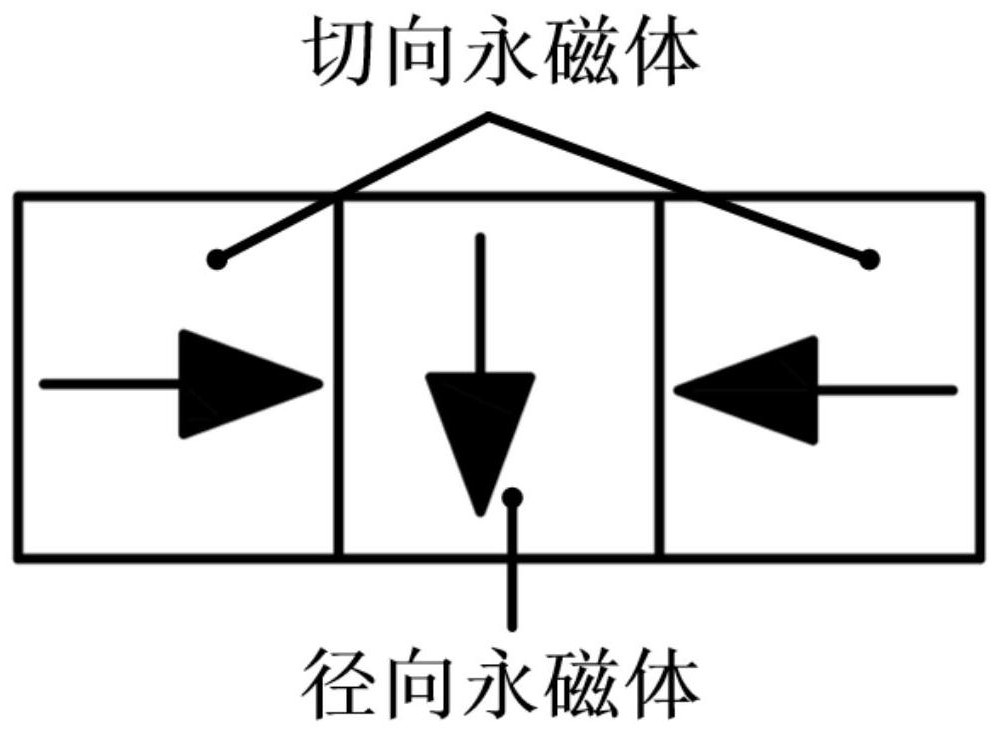

A New Double Stator Halbach Alternating Pole Permanent Magnet Vernier Motor

ActiveCN110808673BImproved air gap flux densityImprove mechanical structure strengthElectric machinesMagnetic circuit stationary partsElectric machineEngineering

The invention discloses a novel dual-stator Halbach alternating pole permanent magnet vernier motor, comprising a first stator structure, a second stator structure and a rotor structure, wherein the rotor structure is arranged on the first stator structure and the second stator structure In the middle; the first stator structure and the second stator structure are stator structures with the same structure, and both include a stator core, and the stator core is provided with stator slots and stator teeth at uniform intervals in the circumferential direction, and the stator slots are embedded in the There is an armature winding, the tooth end of the stator is split into two modulation poles, and a Halbach permanent magnet array is arranged between the modulation poles; the rotor structure includes a rotor iron core, and the rotor iron core is provided with rotor slots at equal intervals in the circumferential direction , rotor permanent magnets are embedded between the rotor slots. The invention improves the air-gap magnetic density of the motor, effectively reduces magnetic flux leakage, and simultaneously achieves the purpose of reducing the amount of permanent magnets and enhancing the mechanical structure strength of the rotor.

Owner:WUHAN UNIV OF TECH

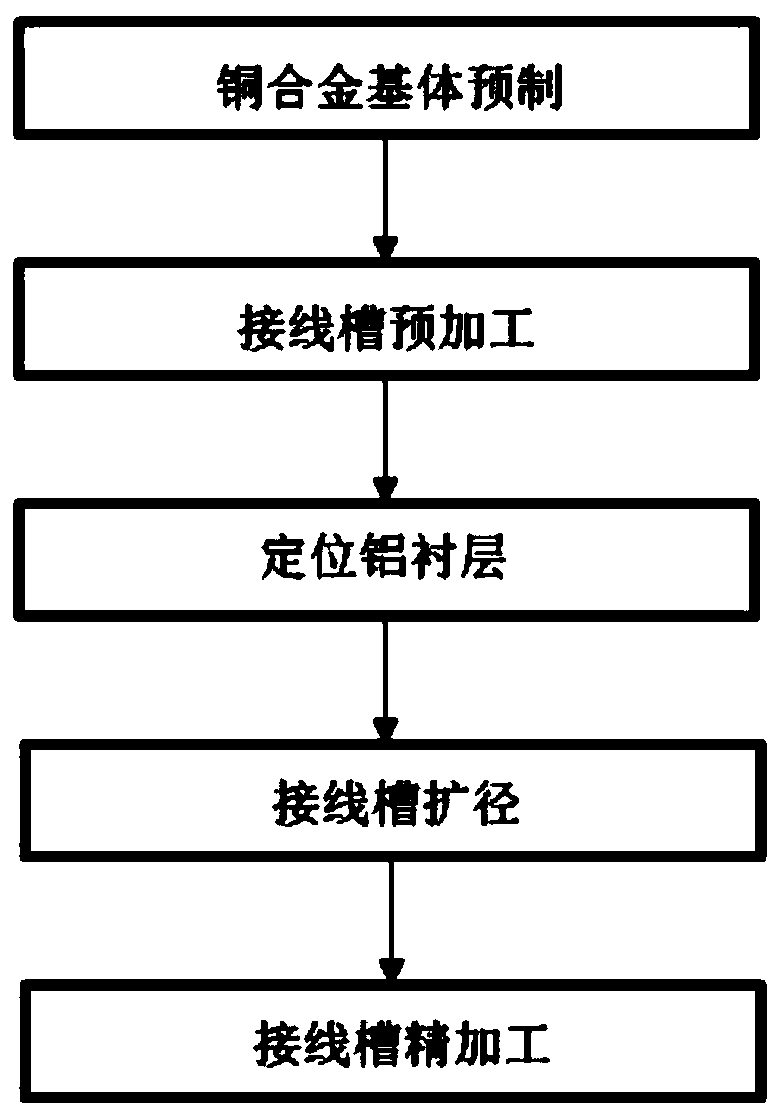

Preparation method of aluminum-copper composite terminal for aluminum alloy high-voltage cable

ActiveCN108493735BImprove the strength of the connection structureImprove impact resistanceContact member manufacturingMetal/alloy conductorsTemperature resistanceHigh pressure

The invention discloses an aluminum alloy high-voltage cable aluminum copper composite terminal. The aluminum alloy high-voltage cable aluminum copper composite terminal comprises a copper alloy substrate and connecting grooves formed in the two ends of the copper alloy substrate; the connecting grooves adopt a U-shaped groove-shaped cross section and are symmetrically distributed along the axis of the copper alloy substrate; the length of the connecting grooves is 1 / 5-1 / 2 of that of the copper alloy substrate; the inner surfaces of the connecting grooves are both distribute with aluminium alloy lining layers; and the thickness of the aluminium alloy lining layers is 1 / 4-3 / 4 of that of the connecting groove side wall; and the preparation method comprises four steps of copper alloy substrate prefabrication, connecting groove pre-processing, aluminum lining layer positioning, connecting groove diameter expansion and connecting groove fine processing. By virtue of the aluminum alloy high-voltage cable aluminum copper composite terminal and the preparation method thereof, the connecting structural strength, the impact resistance performance, the corrosion resistance performance and thehigh temperature resistance performance between the terminal and the cable can be improved effectively, so that the mechanical structural strength of the terminal is highly improved; and in addition,the overload capacity of the terminal is improved effectively, and current distribution uniformity is improved, thereby highly improving reliability and operational stability of the power cable connection operation.

Owner:江西杰洋科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com