Preparation process of sapphire photonic crystal fiber grating ultra-high temperature distributed sensor

A photonic crystal fiber, distributed sensor technology, applied in the direction of cladding fiber, optical waveguide light guide, instruments, etc., can solve high temperature instability, weak anti-electromagnetic interference, low (high temperature limit resistance temperature is generally about 1300 ℃) , the short-term ultra-high temperature limit withstand temperature is only 1600 ℃, reducing the temperature test accuracy and other problems, to achieve excellent high temperature resistance and anti-electromagnetic interference characteristics, improve structural stability and mechanical strength, improve the effect of mechanical structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

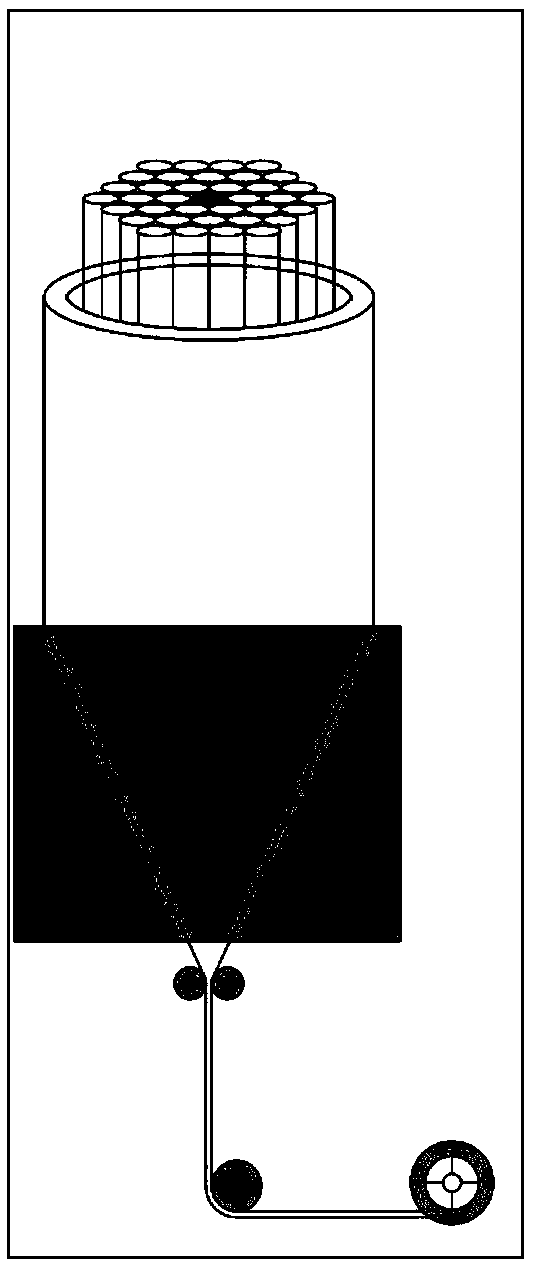

[0052] The technical solution in the present invention will be clearly and completely described below by taking a specific embodiment as an example in combination with existing equipment such as an optical fiber drawing tower and process requirements. When the relevant equipment and process parameters change, the corresponding process parameters will be changed appropriately (for example, when the temperature of the drawing furnace of the optical fiber drawing tower changes, the corresponding feeding speed and drawing speed need to be adjusted accordingly).

[0053] A preparation process of a sapphire photonic crystal fiber grating ultra-high temperature distributed sensor, comprising the following steps:

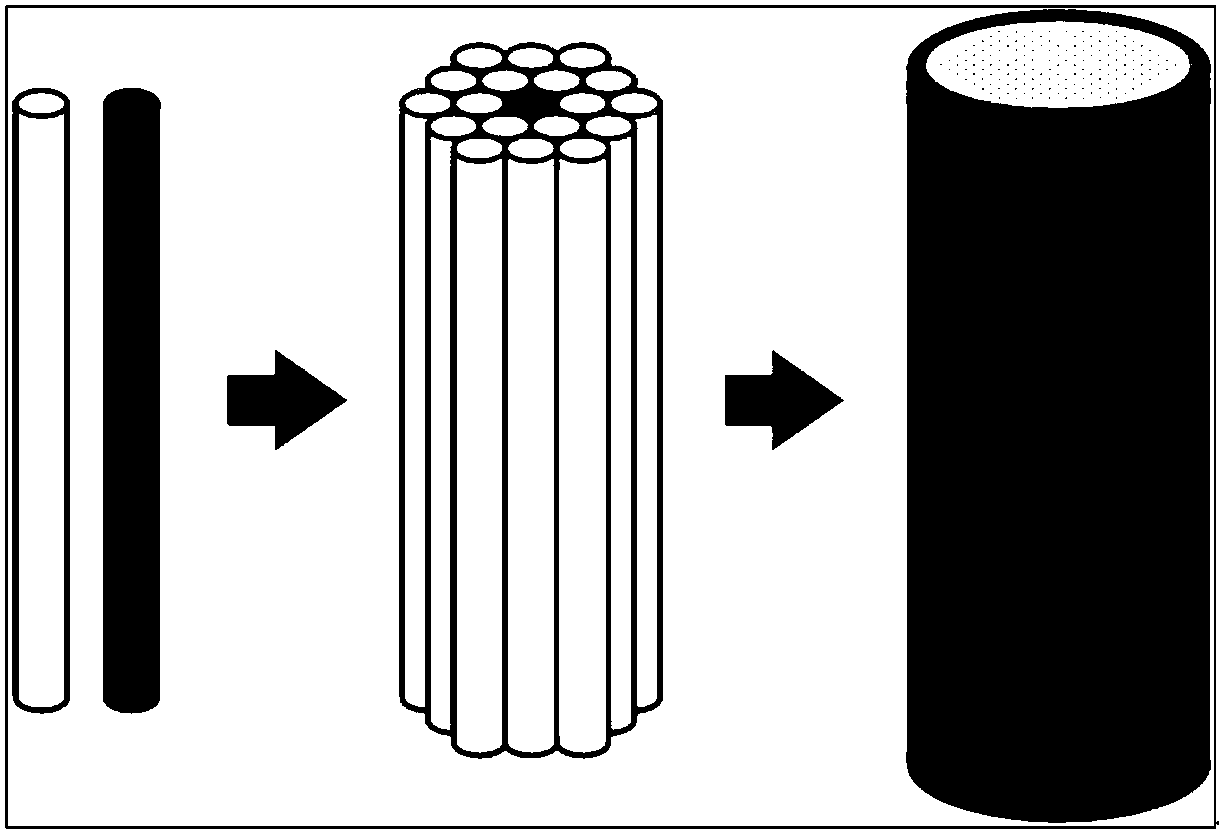

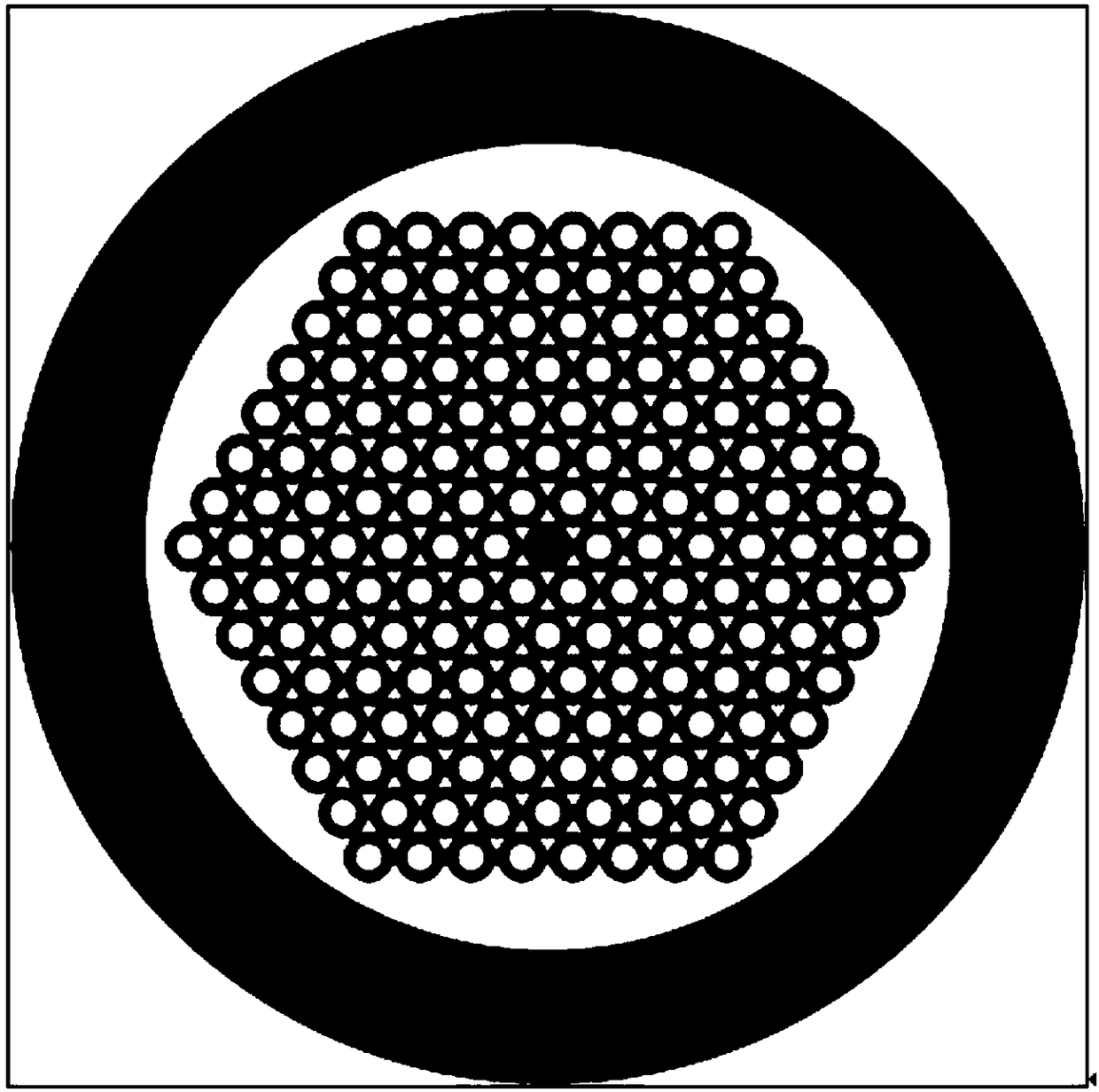

[0054] Step 1. Relying on the preparation process and technology of sapphire special material tube and rod, produce sapphire special material rod and sleeve that meet the requirements for the preparation of photonic crystal special optical fiber.

[0055] Among them, the sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com