Patents

Literature

116results about How to "Improve the strength of the connection structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

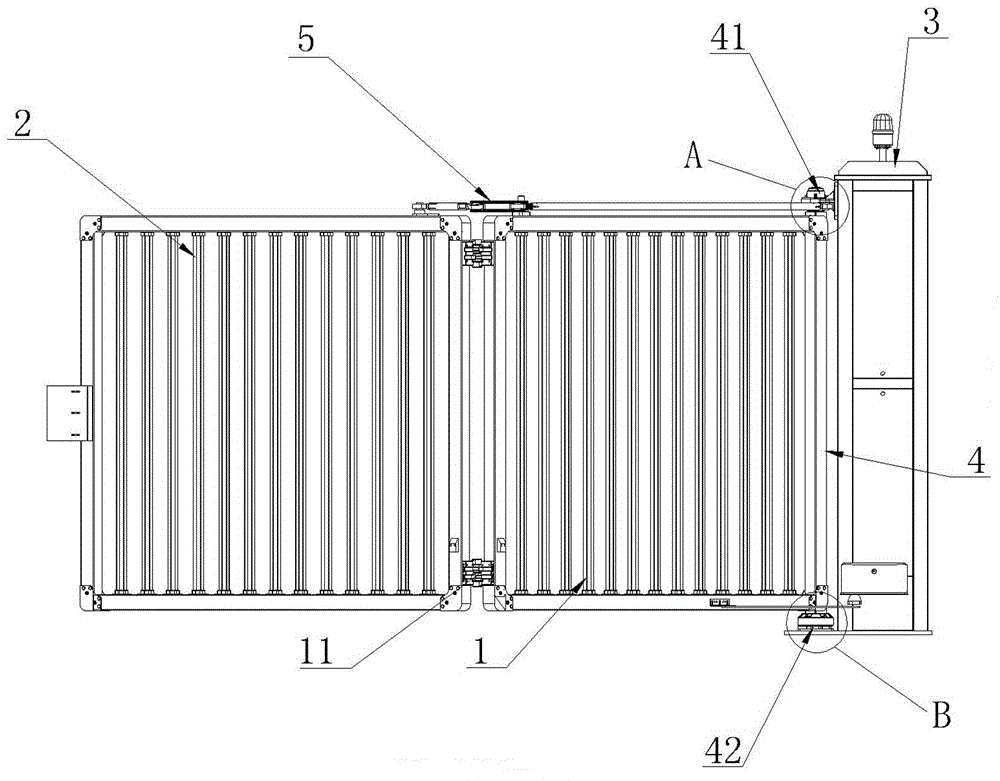

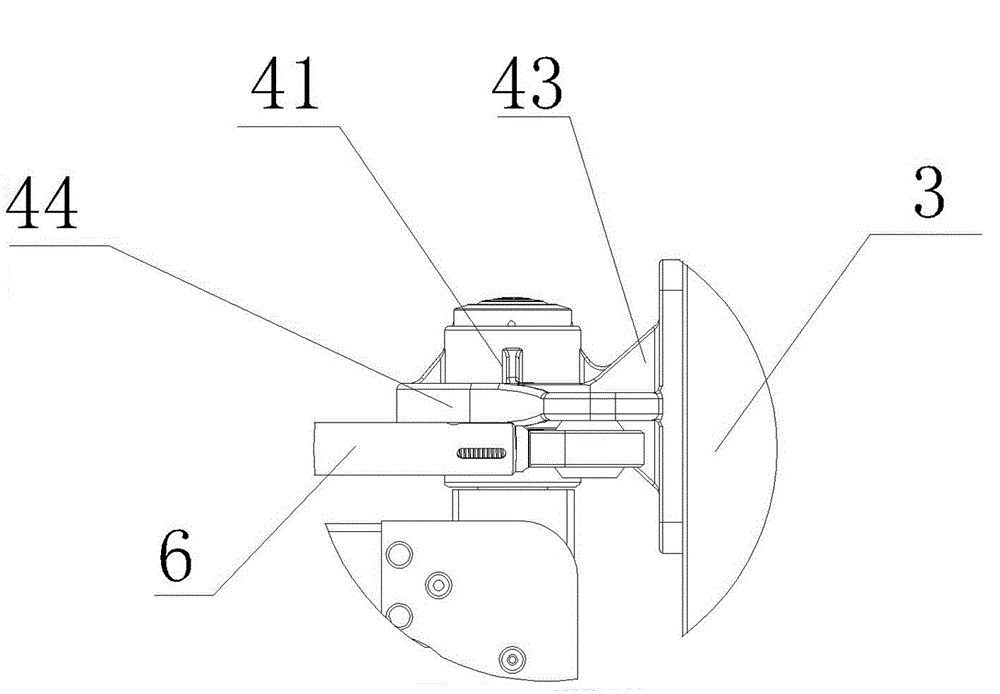

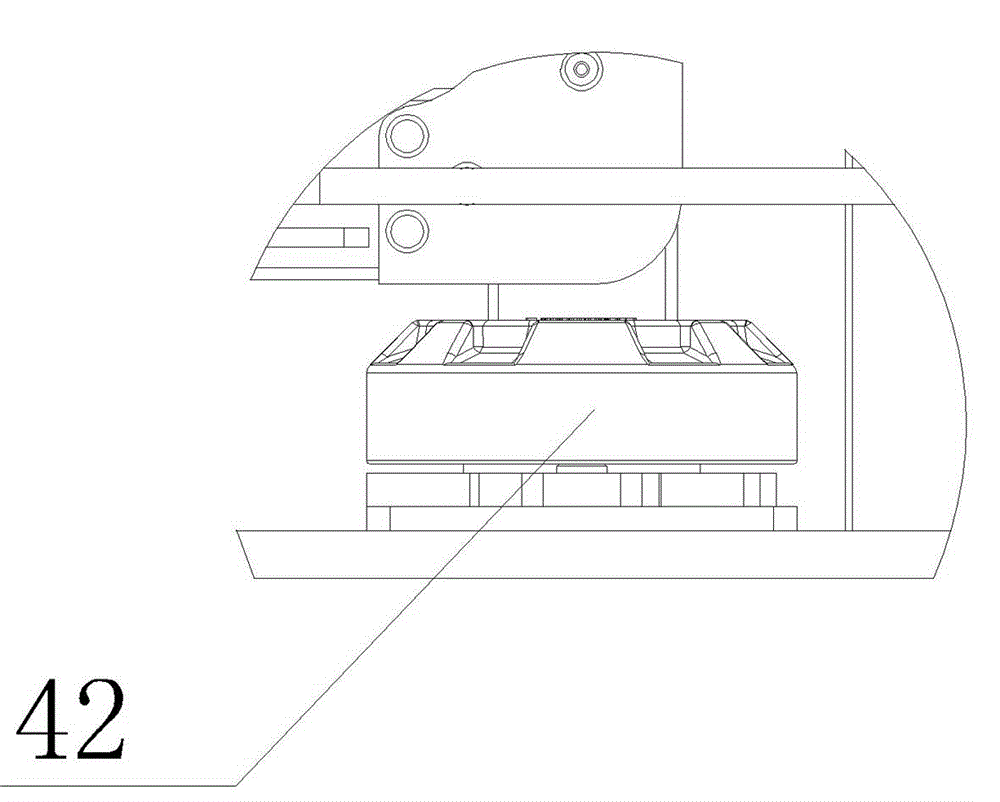

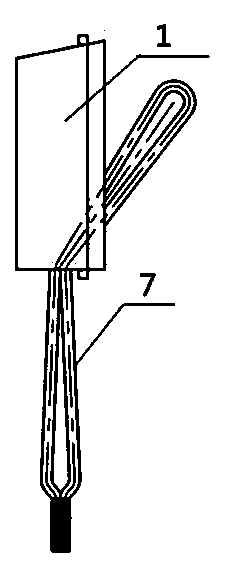

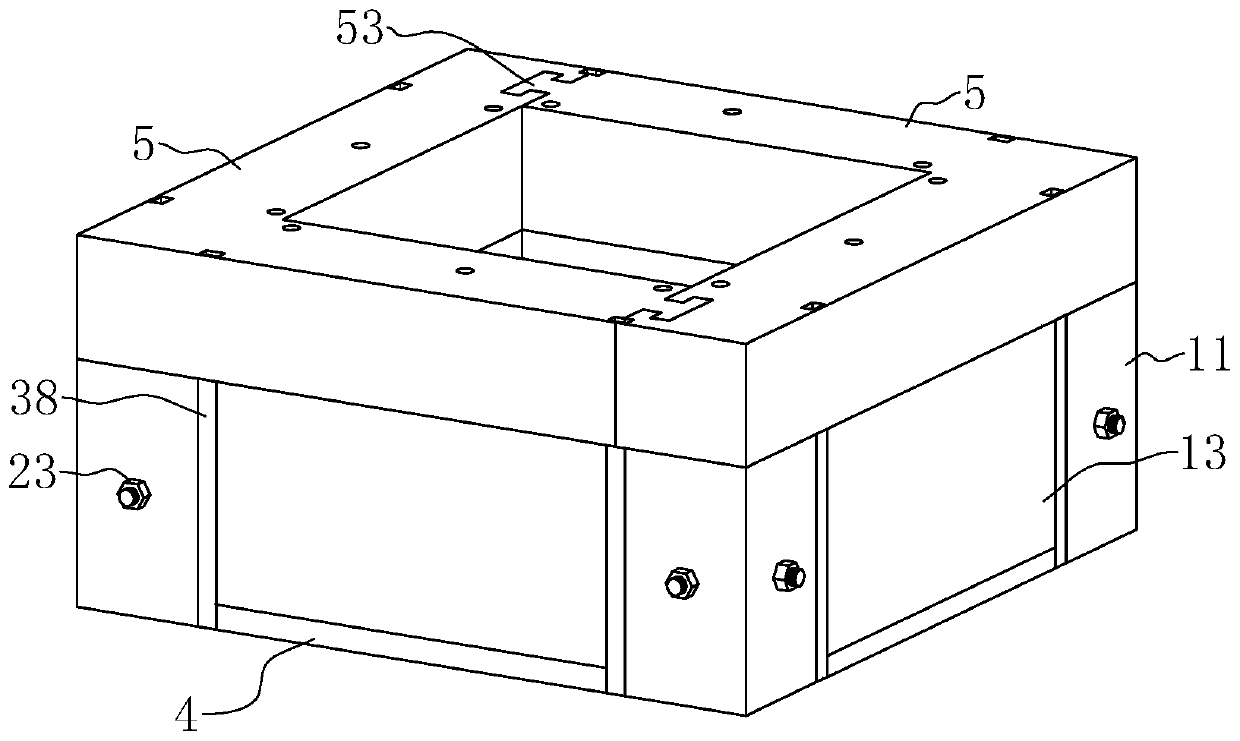

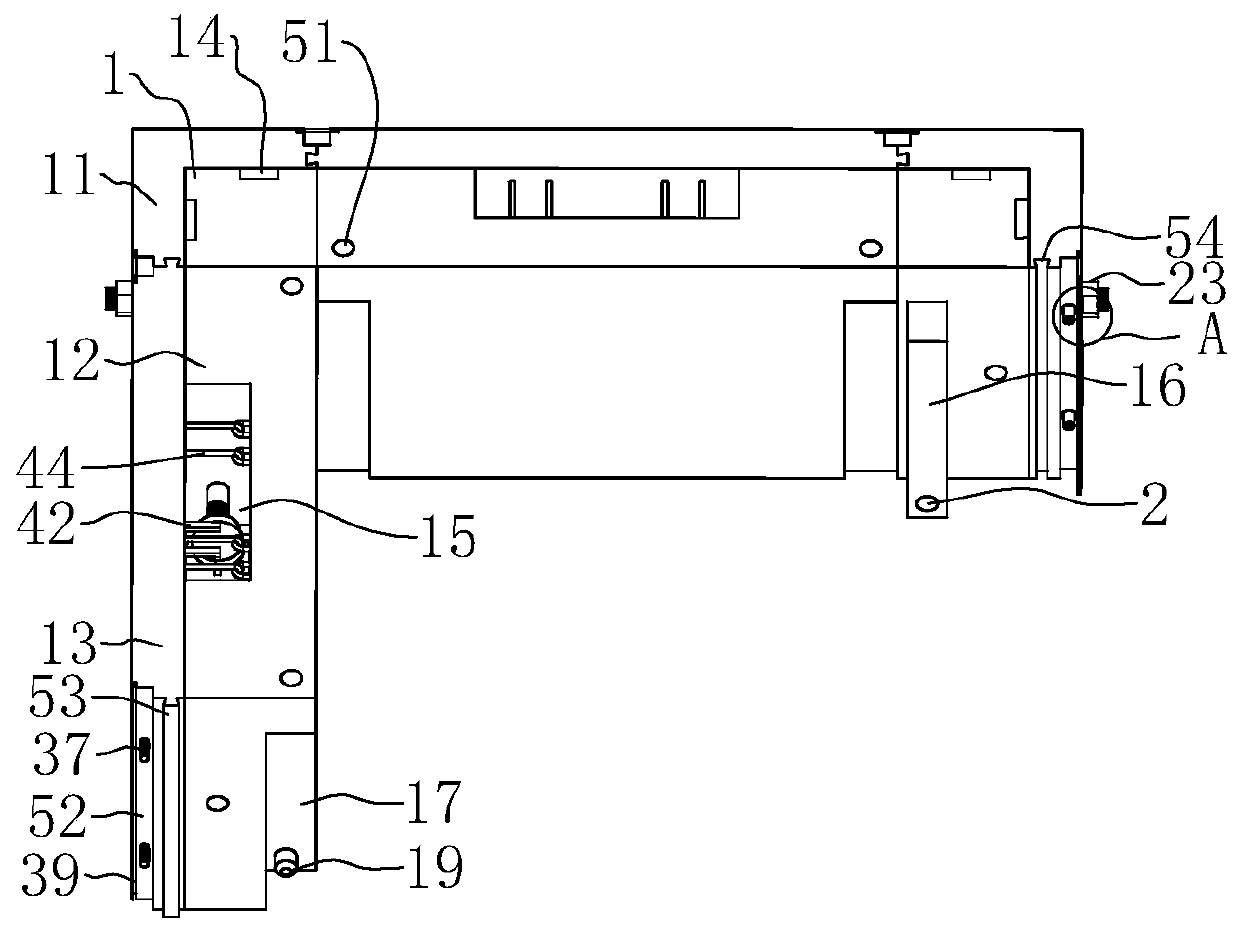

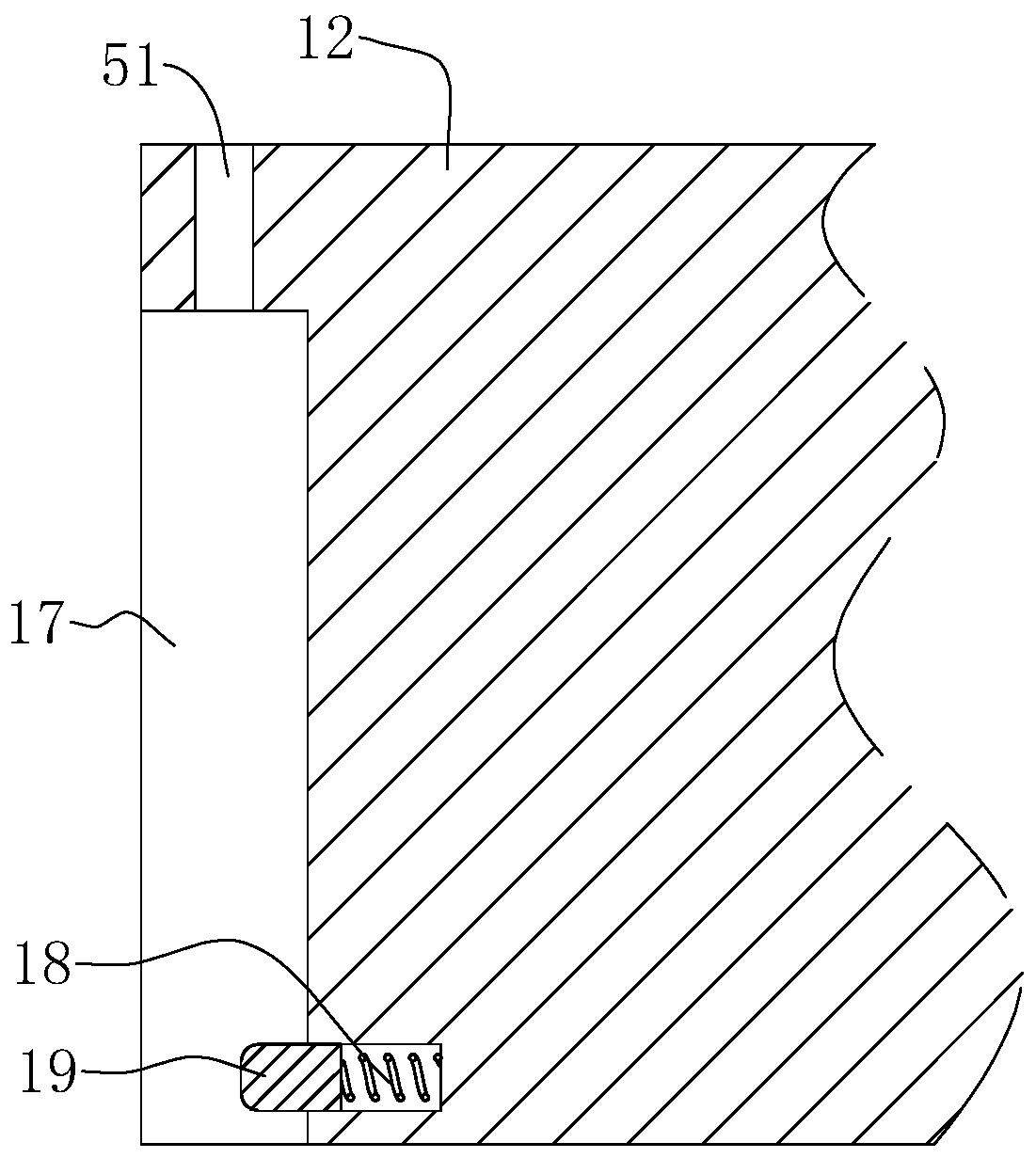

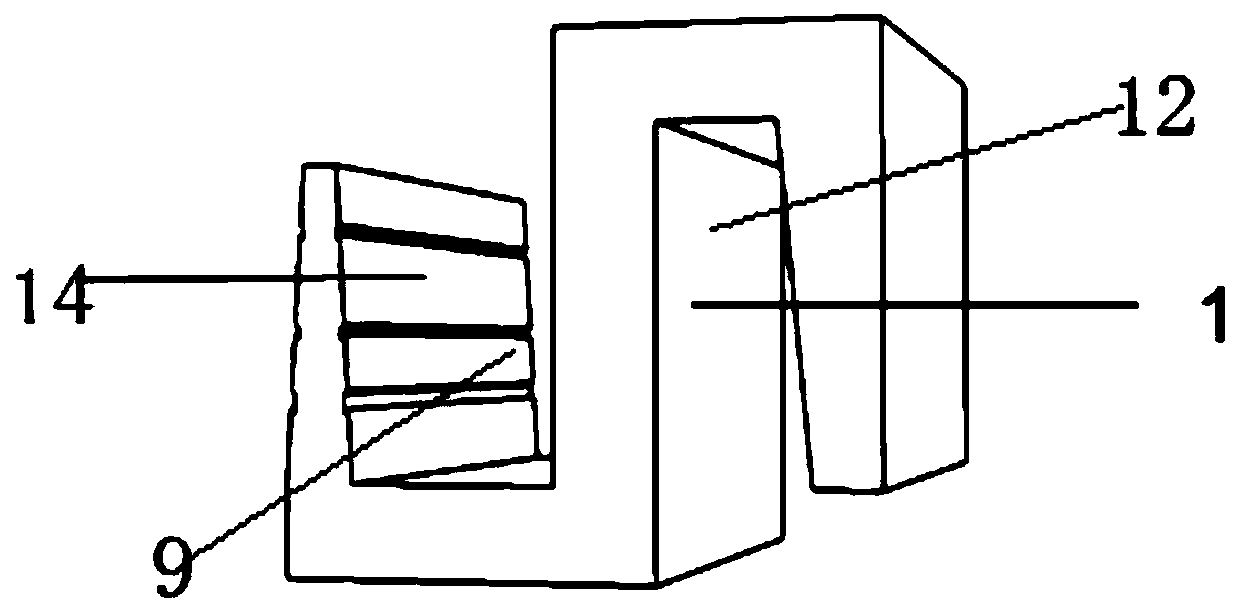

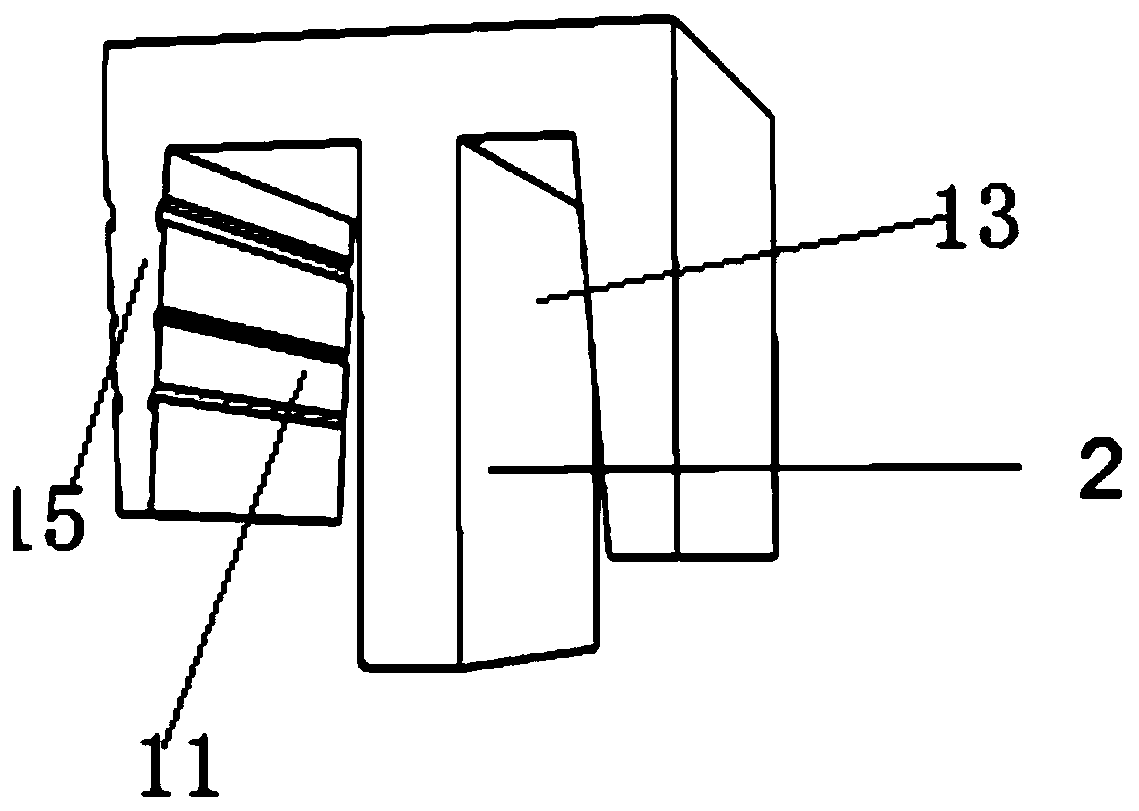

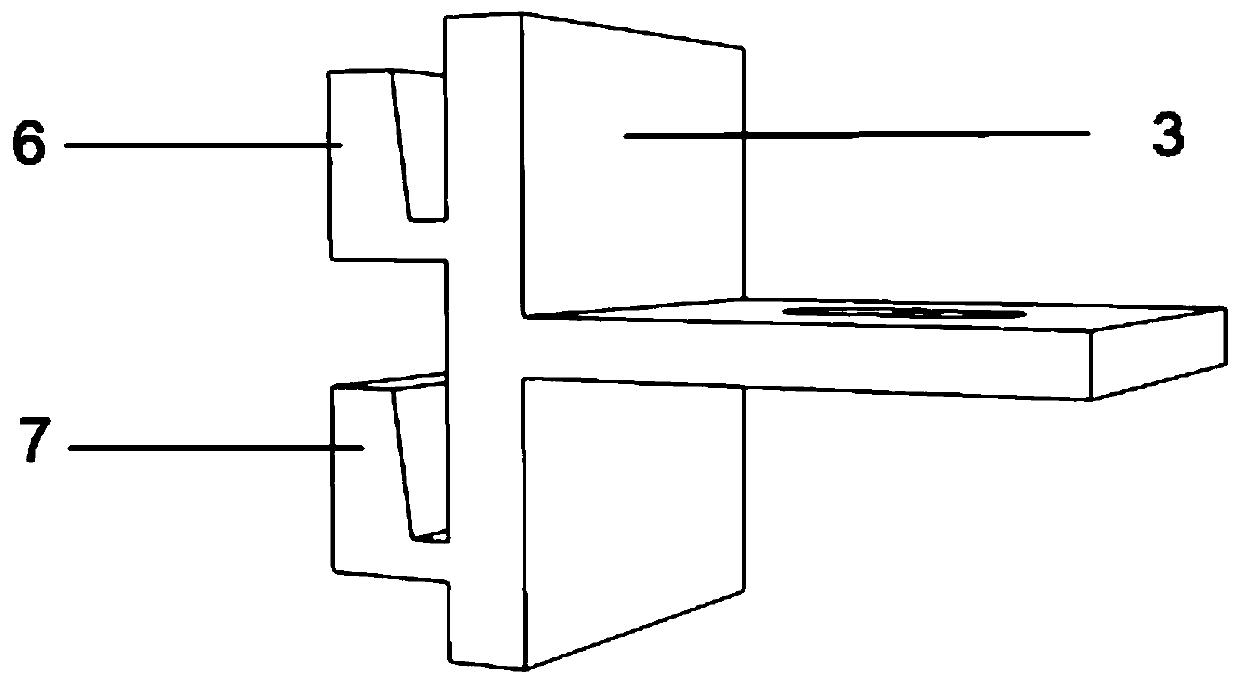

Suspended folding gate

ActiveCN102943614ALittle effortReduce power consumptionGates/doorsPower-operated mechanismRoad surfaceEngineering

The invention relates to the field of gates with suspension characteristic and discloses a suspended folding gate. The suspended folding gate comprises a driving gate leaf, folding gate leaves and gate posts, wherein the folding gate leaves are movably connected with the driving gate leaf; the driving gate leaf is arranged on gate spindles of the gate posts; a rotary link mechanism for connecting the folding gate leaves with the driving gate leaf is arranged at the tops of the folding gate leaves and the driving gate leaf; the rotary link mechanism comprises a short rod which is movably connected with the folding gate leaves and an L-shaped hard toggle or inverted-V-shaped hard toggle of which one end is hinged on the short rod. Compared with the prior art, the suspended folding gate disclosed by the invention has the characteristics of wide gate body, simple structure and no requirement on pavement mounting.

Owner:FOSHAN NANHAI DINGXIN ELECTRICAL & MECHANICAL EQUIP

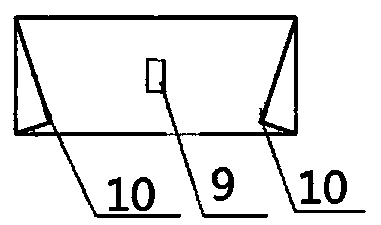

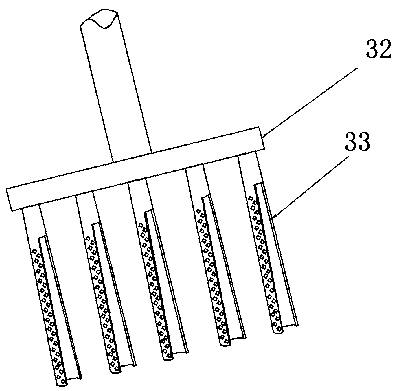

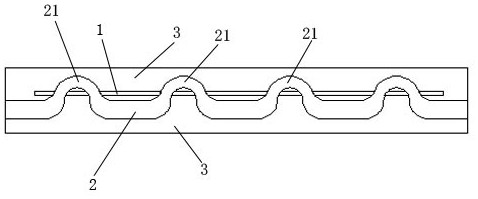

Pre-buried shear key connector box for precast facade panel and machining method of pre-buried shear key connector box

ActiveCN104074314AFacilitate standardized mass productionQuality is easy to controlBuilding reinforcementsEngineeringMachining

The invention discloses a pre-buried shear key connector box for a precast facade panel and a machining method of the pre-buried shear key connector box. The pre-buried shear key connector box comprises an upper top plate, a lower bottom plate, a box body and a connecting strand, wherein a strand penetrating hole is formed in the lower bottom plate; the box body is formed by arranging three lateral plates in a surrounding manner; the connecting strand penetrates through the strand penetrating hole; the side, where no lateral plate is arranged, of the box body is an open side; the upper top plate is inclined to the outer side of the box body; the two side plates adjacent to the open side and the lower bottom plate are inclined to the inner side of the box body; the two side plates are arranged to form ribs; the pre-buried pin of the connecting strand is pre-buried in the precast facade panel; after treated with concrete placement, the pre-buried shear key connector box, a floor and a beam together form a shear connector. The pre-buried shear key connector box has the advantages that the structure is simple; the manufacture is easy; standard batch production on a trolley can be realized; the quality is controllable; pollution and material waste are avoided; the production efficiency is high; the transportation, loading, construction and exterior wall decoration are convenient; the shear and vibration resistance of a building main body is improved.

Owner:XIANGTAN YUANDA RESIDENTIAL IND CO LTD

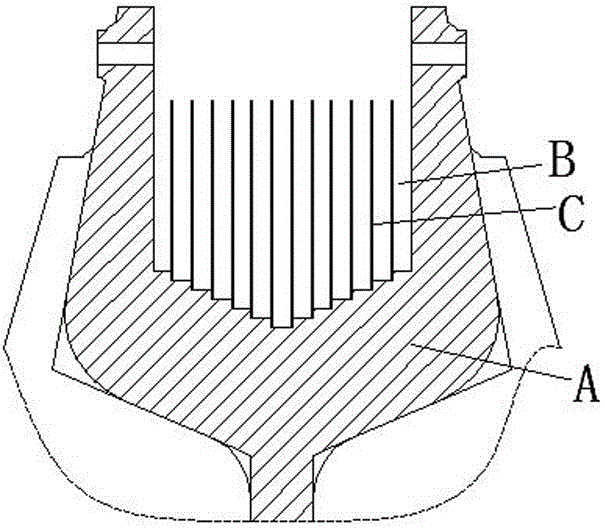

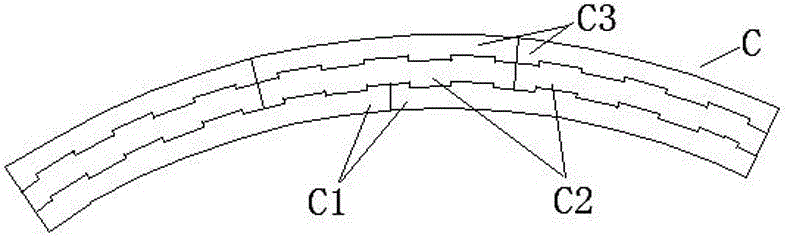

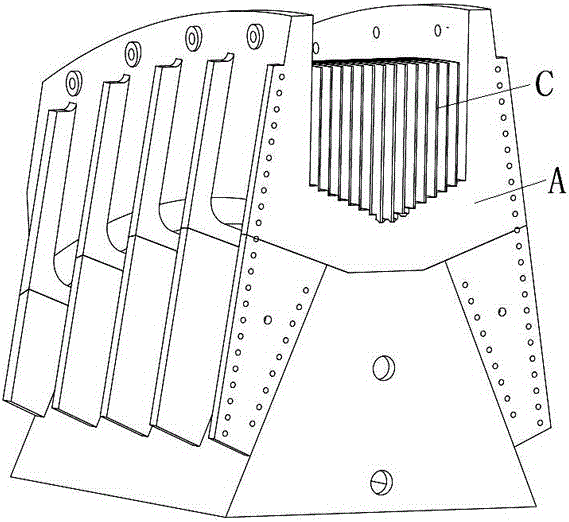

Main cable saddle head structure and forming method thereof

ActiveCN106216871AImprove the strength of the connection structureStrong shear resistanceBridge structural detailsWorkpiece edge portionsEngineeringStructural engineering

The invention discloses a main cable saddle head structure and a forming method thereof. The saddle head structure comprises a saddle head body provided with a saddle groove, multiple partition plates are vertically welded in the saddle groove in a groove weld manner, and each partition plate is of an integral structure. The forming method of the saddle head structure includes the steps that firstly, the saddle head body and the partition plates meeting design requirements are manufactured, and corresponding slope grooves are machined in the saddle groove and the partition plates correspondingly according to the design requirements; secondly, the corresponding partition plates are assembled on other welded parts, except for two to four welded parts in the center of the saddle groove, in the saddle groove one by one according to the welding sequence of conducting symmetric welding from the two sides to the center and are welded in the groove weld manner; and thirdly, the corresponding partition plates are assembled on all the welded parts in the center of the saddle groove one by one and are welded in the groove weld manner. According to the main cable saddle head structure and the forming method thereof, the strength of connecting structures between the partition plates and the saddle groove and the structural strength of the partition plates are greatly improved, and the anti-shearing capability of a whole saddle head is high.

Owner:DEYANG TIANYUAN HEAVY IND

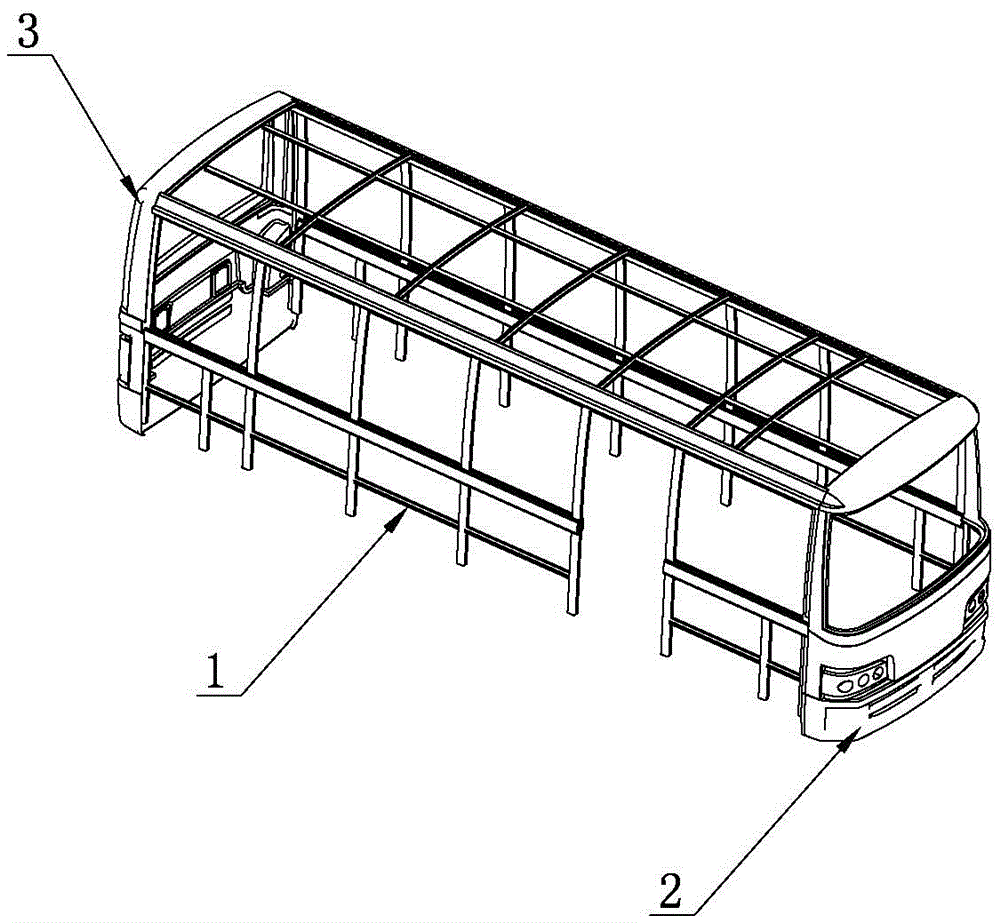

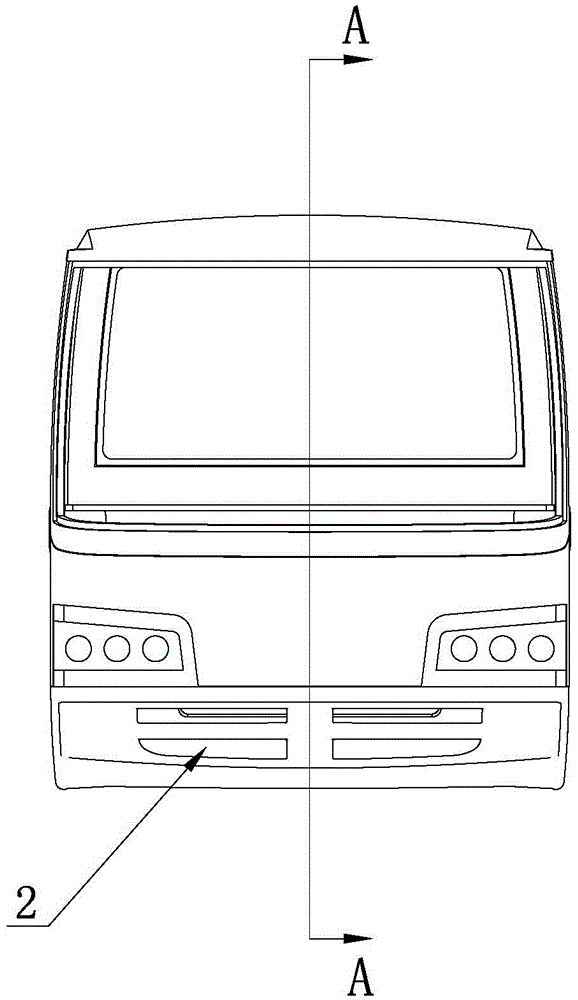

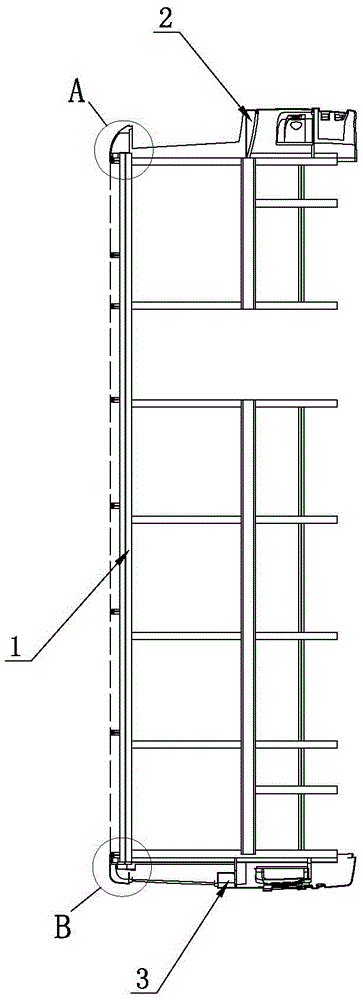

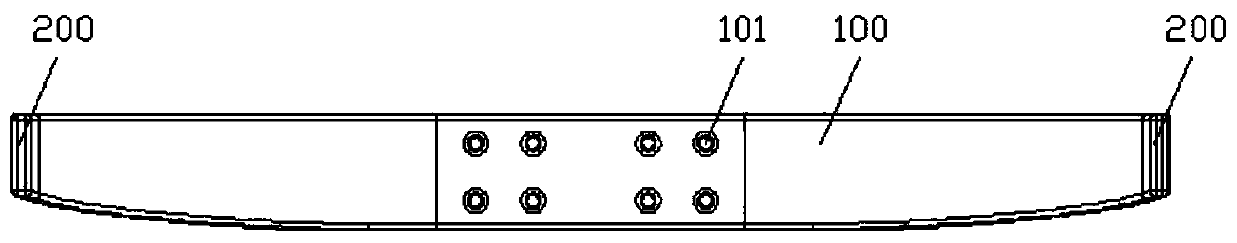

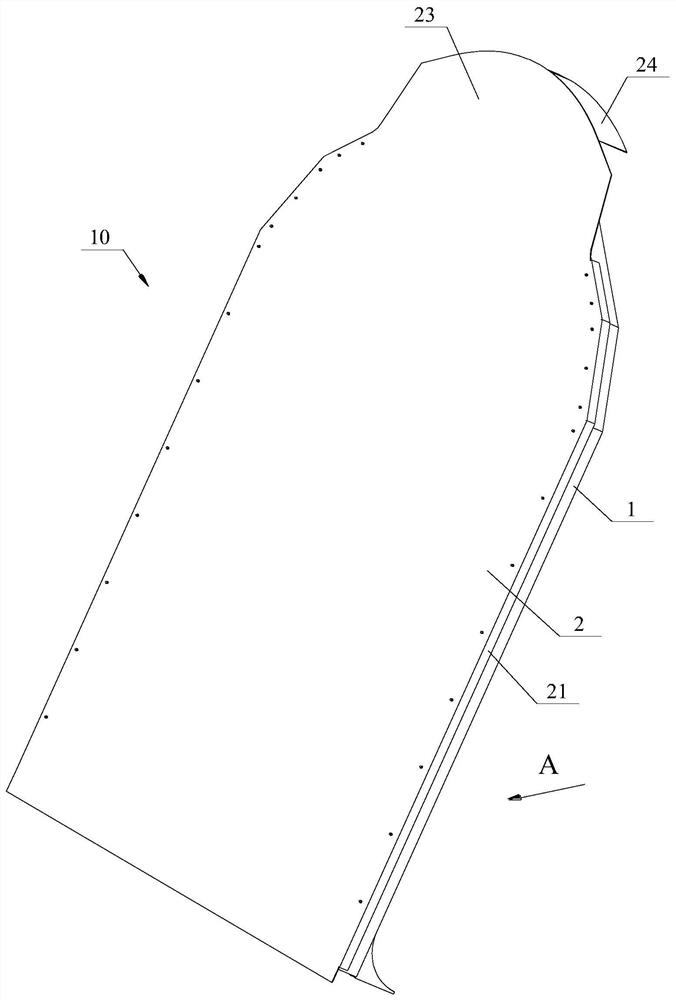

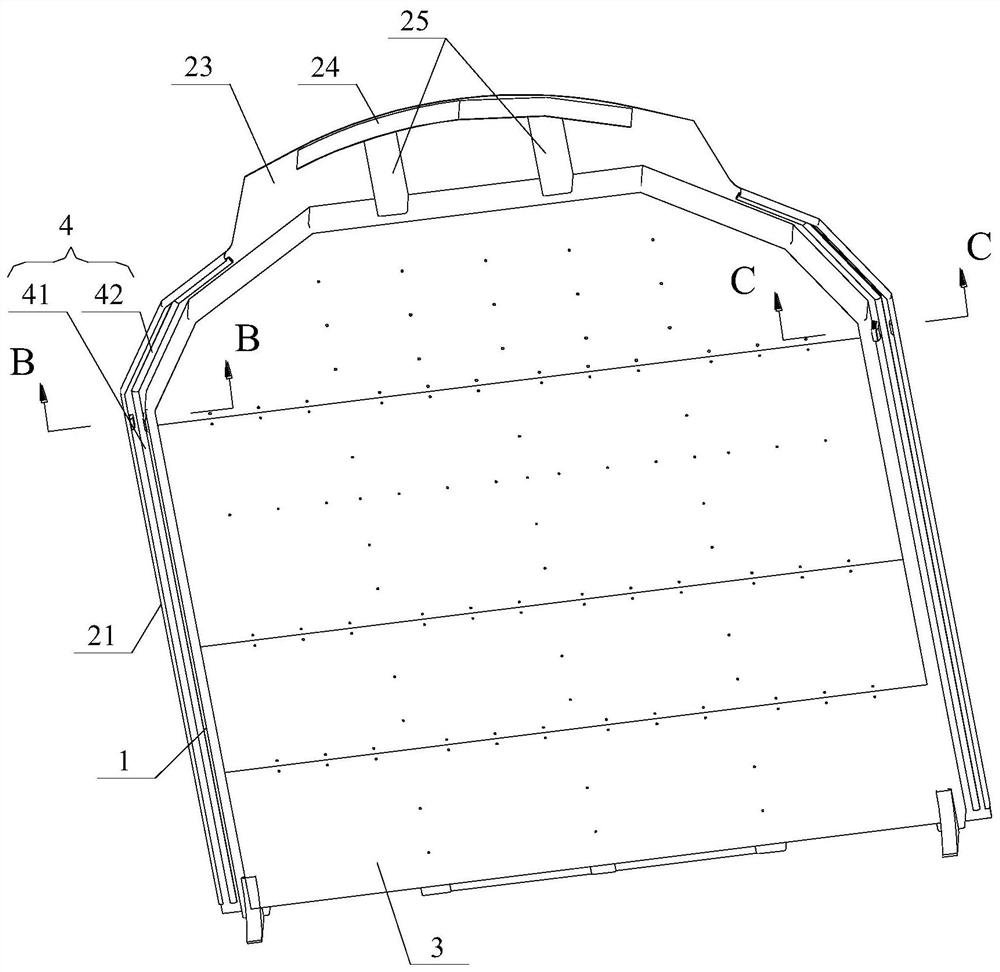

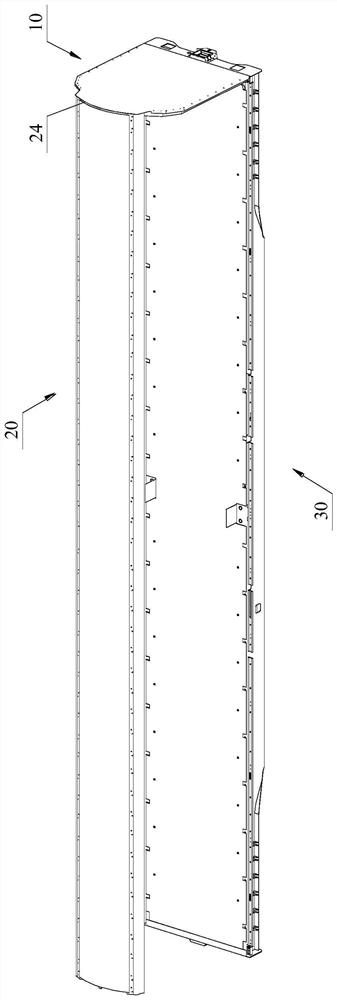

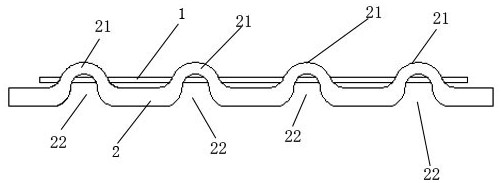

Connecting structure for front face and back face of light midbus with body frame of light midbus

InactiveCN106005047AEasy to assemble and connectHigh strengthSuperstructure connectionsButt jointEngineering

The invention relates to the technical field of automobile body structures, in particular to a connecting structure for a front face and a back faces of a light midbus and a body frame of the light midbus. An automobile front face covering part and an automobile back face covering part are fixedly installed at the front end and the back end of a body connecting end face framework through connecting flashes respectively. The connecting structure for the front face and the back face with the body frame has the following advantages that through the connecting flashes connected to the front end and the back end of the body connecting end face framework, the good connecting structure is provided for connection of the automobile front face and the automobile back face, convenience is brought to assembly and connection of the automobile front face and the automobile back face with the body frame, the process of the connecting flashes is simple, and the connecting structure strength is high; the connecting flashes can serve as reinforcing rib structures of the front end face and the back end face of the body connecting end face framework, and therefore the structural strength of the front end face and the back end face of the body connecting end face framework is greatly enhanced; the front face and the back face are connected with the body connecting end face framework by adopting the connecting structure, and therefore the waterproofness and the leakproofness are better; the surface of the front face covering part and the surface of the back face covering part achieve smooth butt-joint with the roof model surface and the side surfaces.

Owner:INST OF DONGGUAN SUN YAT SEN UNIV +1

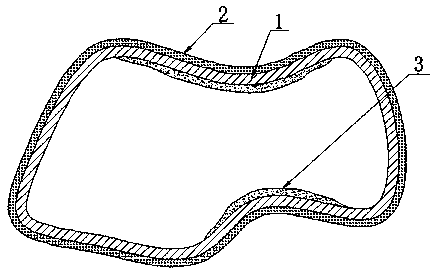

Casting method adopting dual thin shell mold process

ActiveCN108687304AEasy to soakGood removal effectAdditive manufacturing apparatusFoundry mouldsThin shells3d printer

The invention relates to the field of the 3D printing technology and the casting process, in particular to a casting method adopting a dual thin shell mold process. The casting method comprises the step of manufacturing a thin shell mold 3D printer and a corresponding computer. Specifically, a thin shell mold is printed out through the 3D printing technology, the wall thickness of the thin shell mold does not exceed 2 mm, a high temperature resisting outer shell mold is manufactured out through the immersing sizing process in the precision casting process, after filling reinforcement, the thinshell mold is removed through a physical or chemical method, casting and aftertreatment are carried out, and a finished product is manufactured. The casting method has the advantages that productioncan be standardized by manufacturing the thin shell mold through the 3D printer, the 3D printing technology and the dewaxing casting process are combined, and a manufacturing process which is easier to operate and more environment-friendly and energy-saving and reduces the production cost is obtained.

Owner:LIANYUNGANG YYU PROD

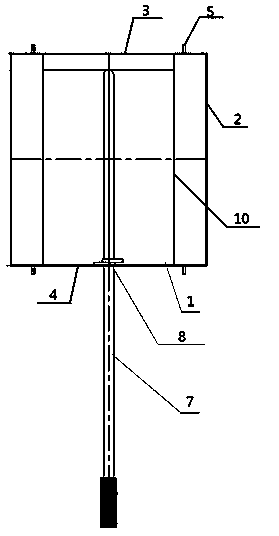

Novel solar bracket power generation column with protective cover

InactiveCN108336947AReduce failureReduce the chance of damagePhotovoltaic supportsPV power plantsElectronic componentAutomotive engineering

The invention discloses a novel solar bracket power generation column with a protective cover. The novel solar bracket power generation column comprises a column body, wherein a solar panel mounting area is formed in the peripheral side of the column body, the protective cover is arranged on the top of the column body, the protective cover is positioned above the solar panel mounting area, so thatthe solar panel mounting area is effectively protected, the relatively good functions of resisting water, dust and weathering are achieved, faults and damage rates of the solar panel bracket, solar panel and related electronic components in the solar panel mounting area are reduced, and the service life of the solar bracket power generation column is prolonged.

Owner:张宇顺

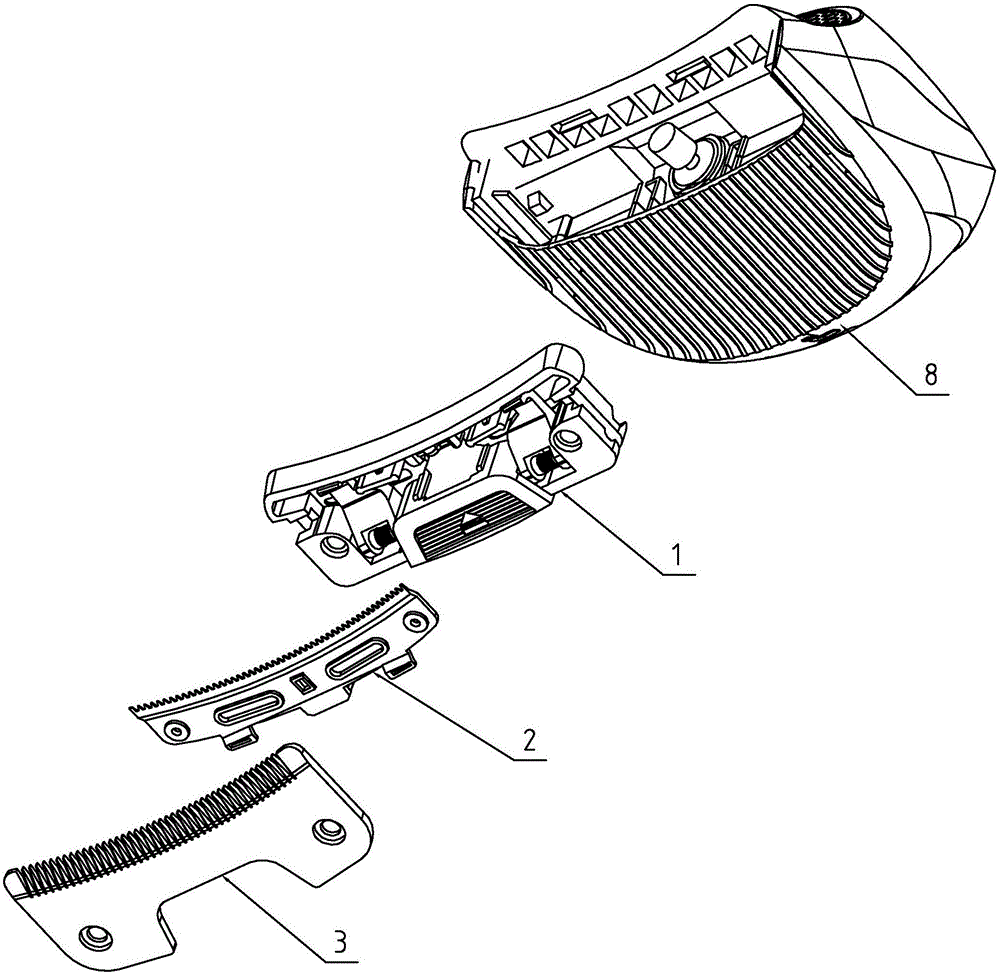

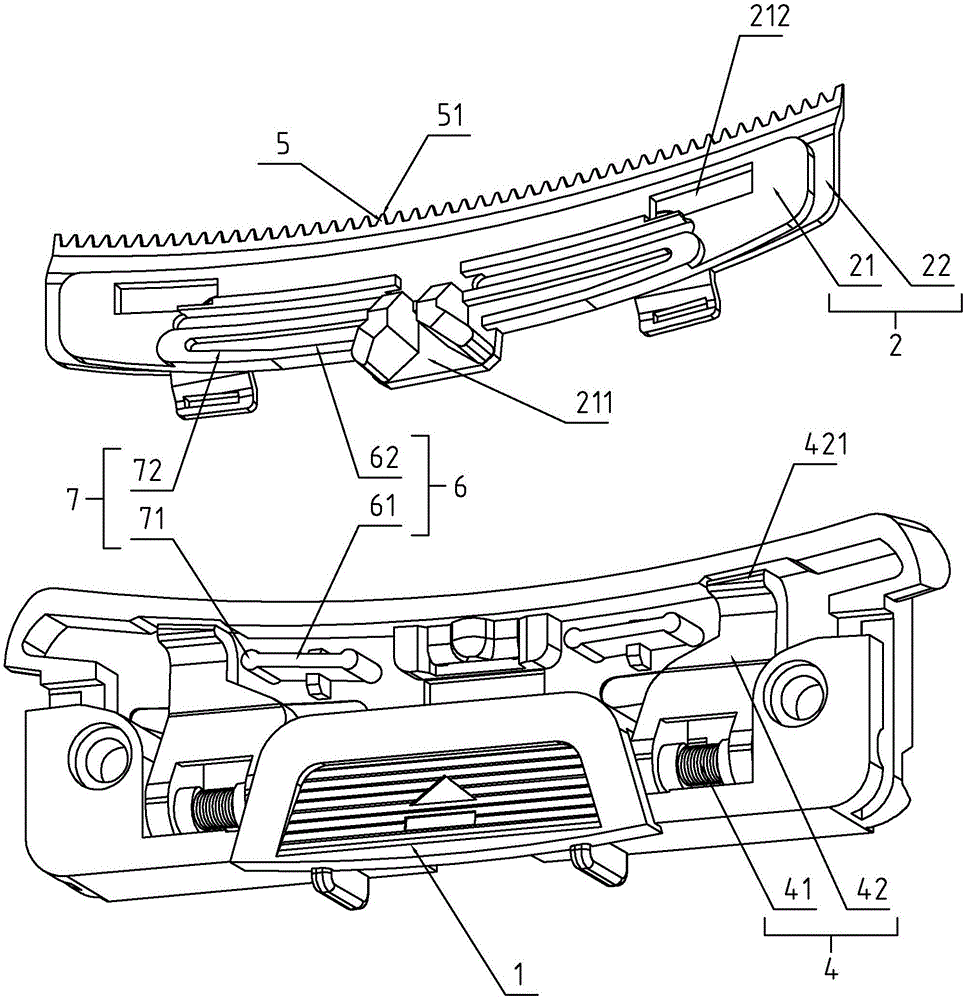

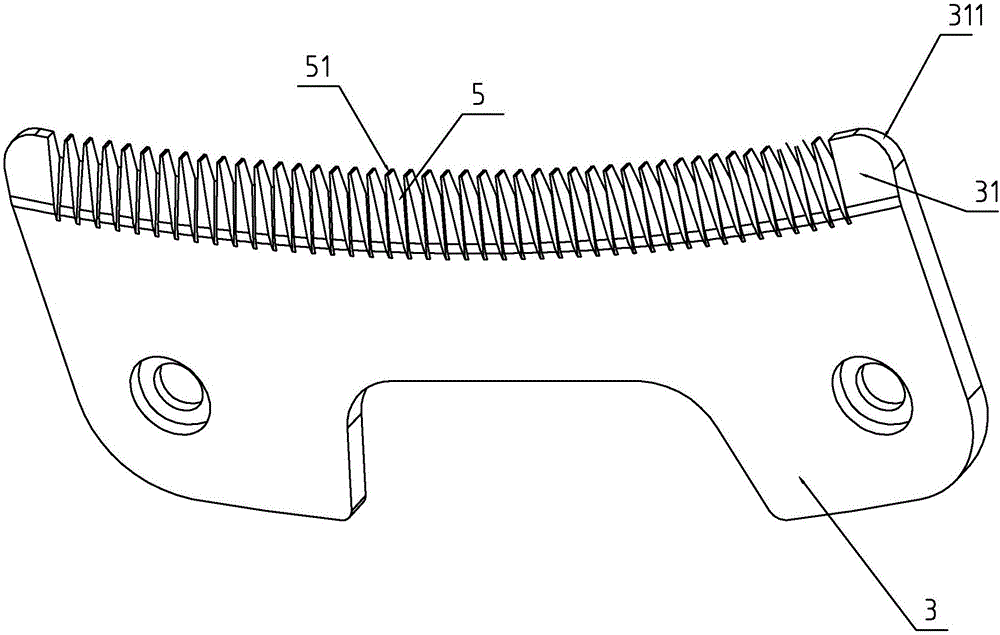

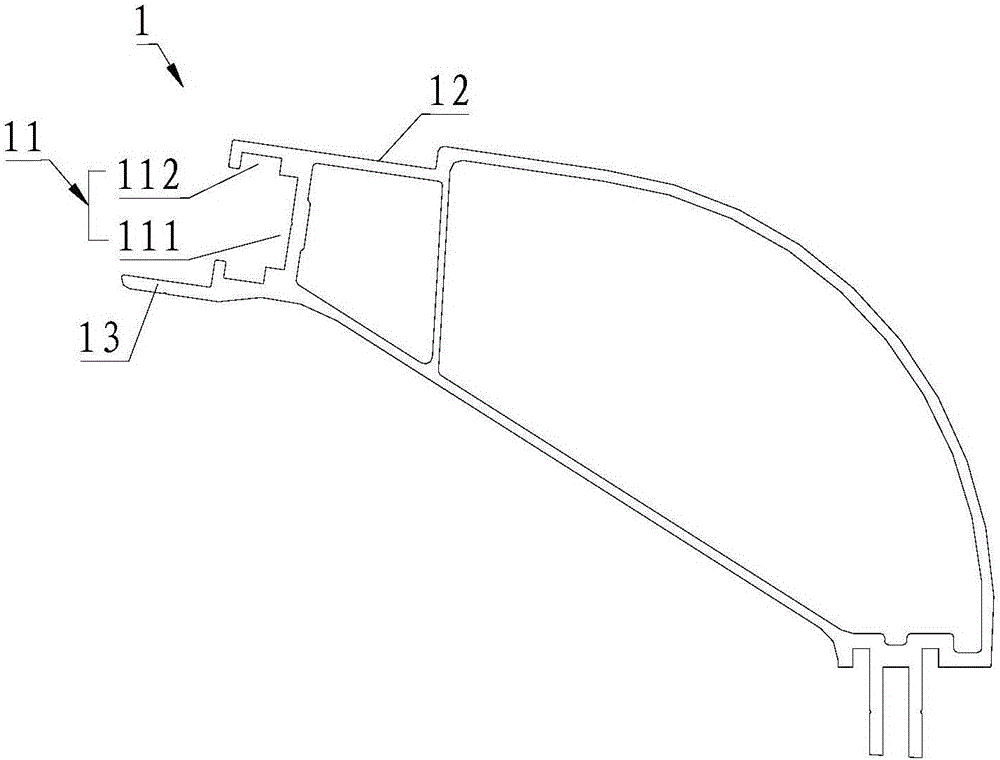

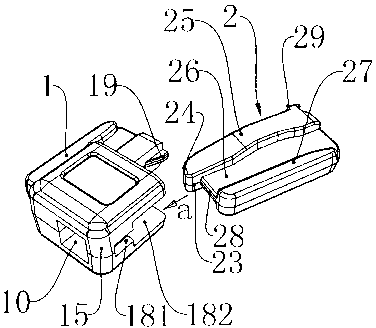

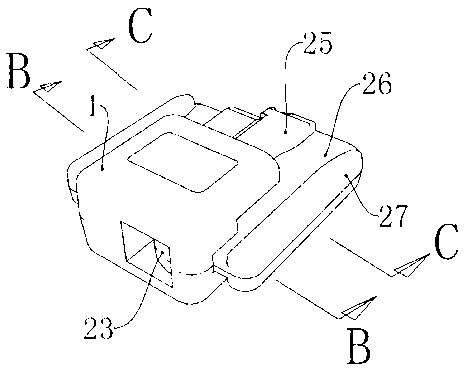

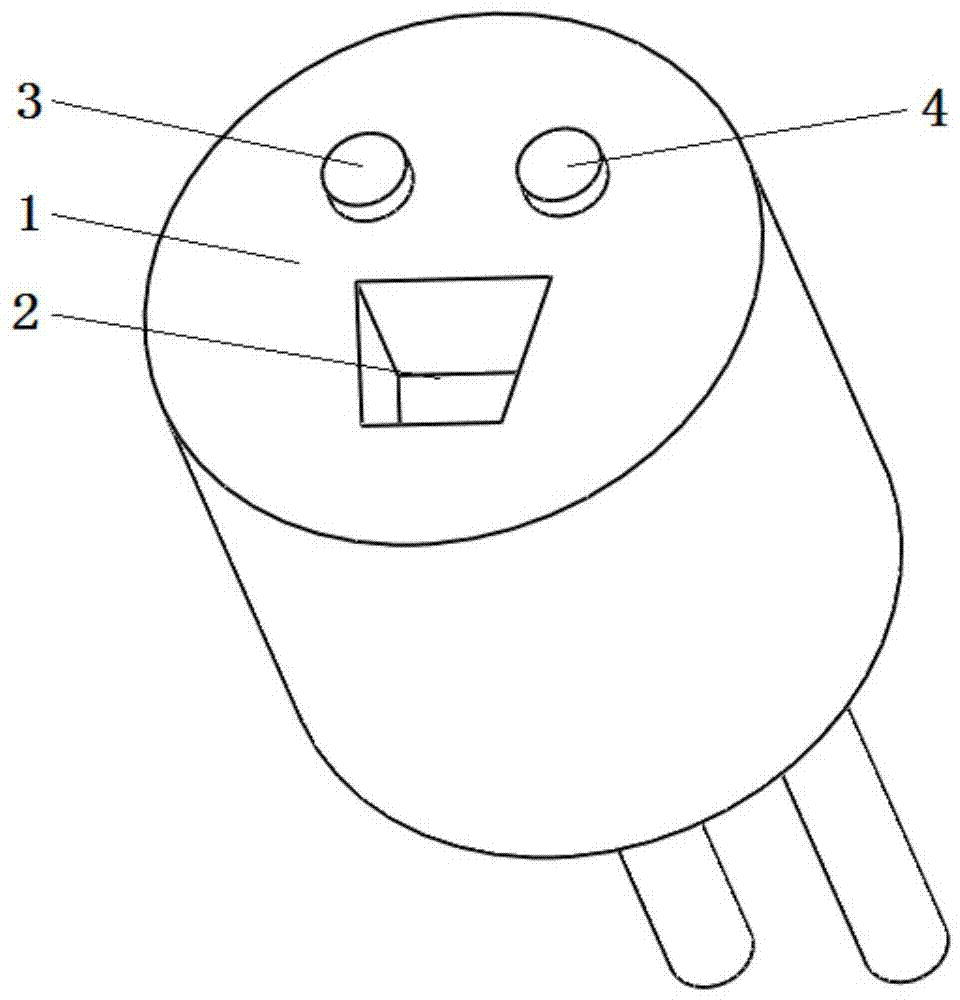

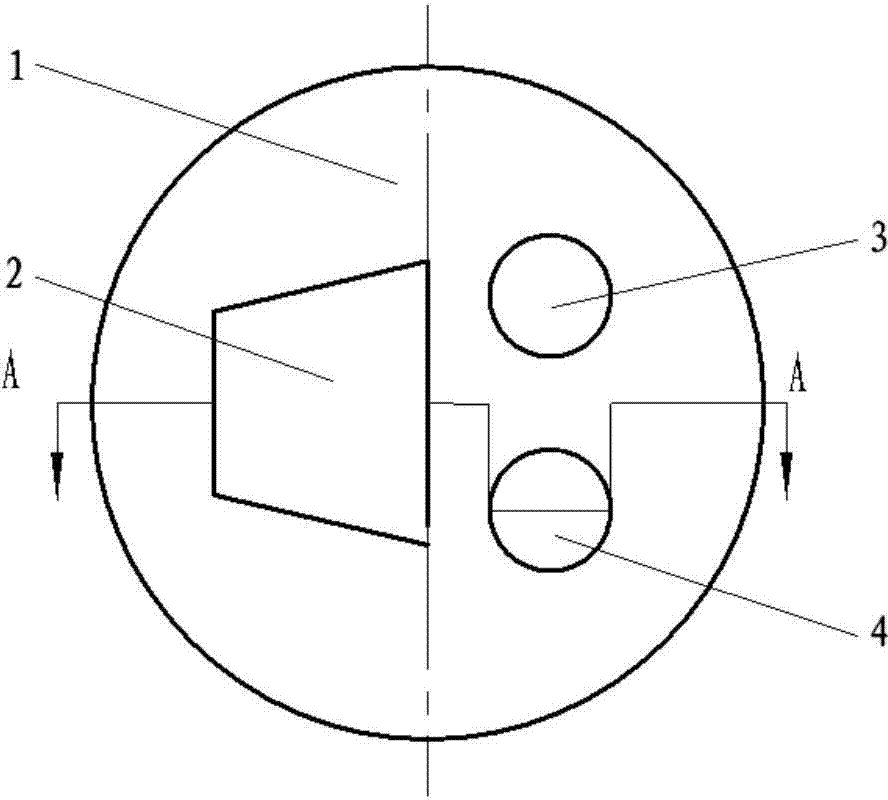

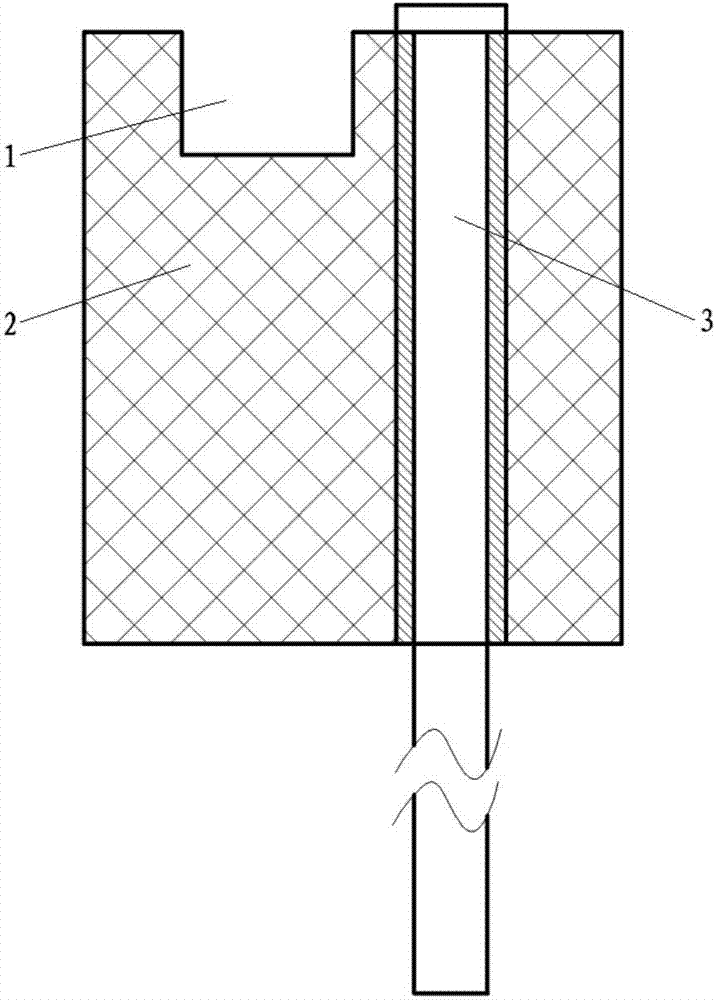

Hair clipper

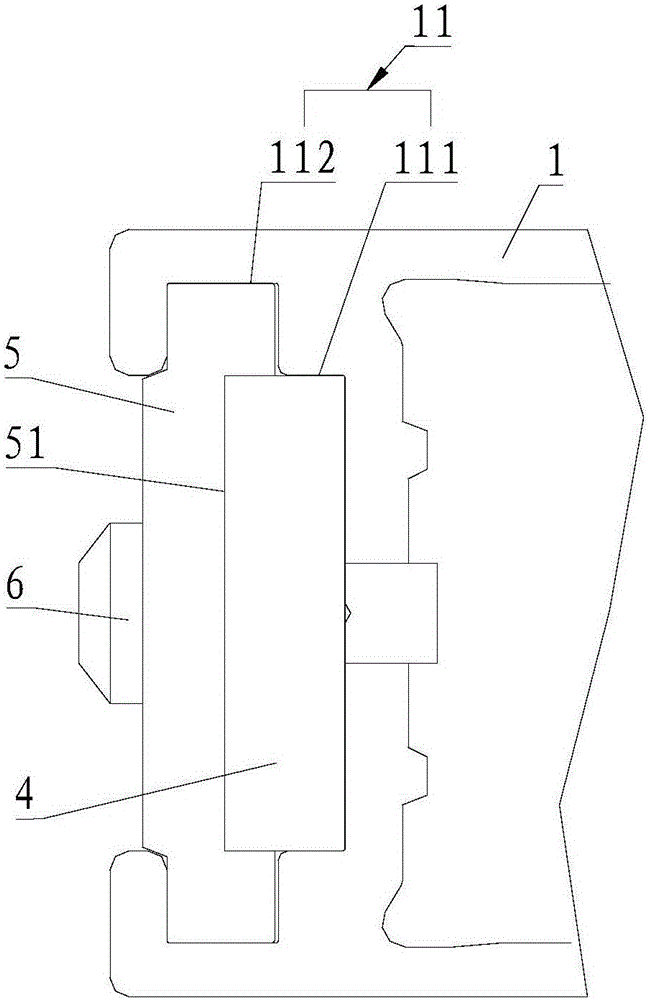

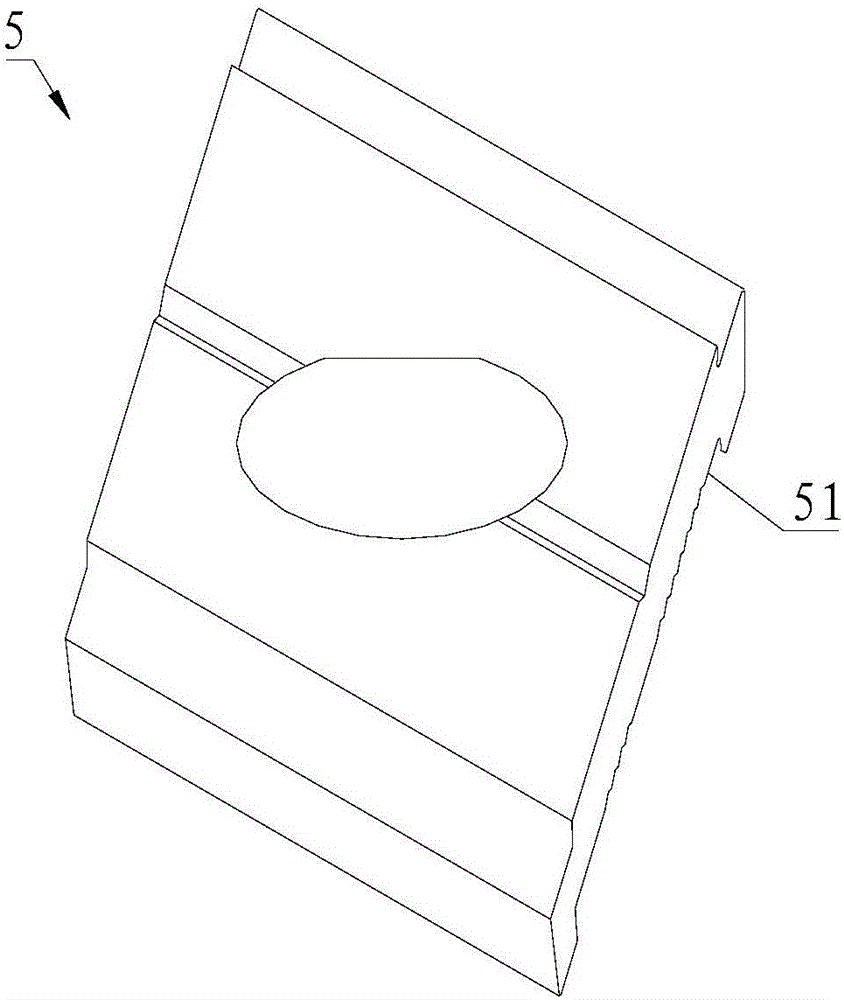

ActiveCN106625788AEasy to fixImprove the strength of the connection structureMetal working apparatusEngineeringHair clipper

The invention discloses a hair clipper. The hair clipper is characterized by including a cutter base, a movable cutter blade, a static cutter blade and a body. The movable cutter blade is movably connected between the static cutter blade and the cutter base, an elastic mechanism is arranged between the movable cutter blade and the cutter base, the side, in the backward direction of the static cutter blade, of the movable cutter blade is provided with a switching member, the body is provided with a guide rail, a slide groove is formed in the cutter base, the guide rail and the guide groove are cooperated to slidingly install the cutter base on the body, a fastener is arranged on the cutter base, a clamping member is arranged on the body, and when the cutter base is matched with the slide groove through the guide rail and slide into the body, the clamping member is fastened by the fastener so as to fix the position of the cutter base; the movable cutter blade and the static cutter blade are both provided with a plurality of cutter teeth, the cutter teeth include cutter tooth tips located at the tops of the cutter teeth, the cutter tooth tips of both the movable cutter blade and the static cutter blade are arranged along an arc structure, and the arc structure formed by the cutter tooth tips is arranged in a sunken mode and matched with the outer contour of the head. The hair clipper is high in structural strength and capable of increasing the area of contact with the hair at the time of a haircut.

Owner:WENZHOU RIDIAN ELECTRICAL APPLIANCE

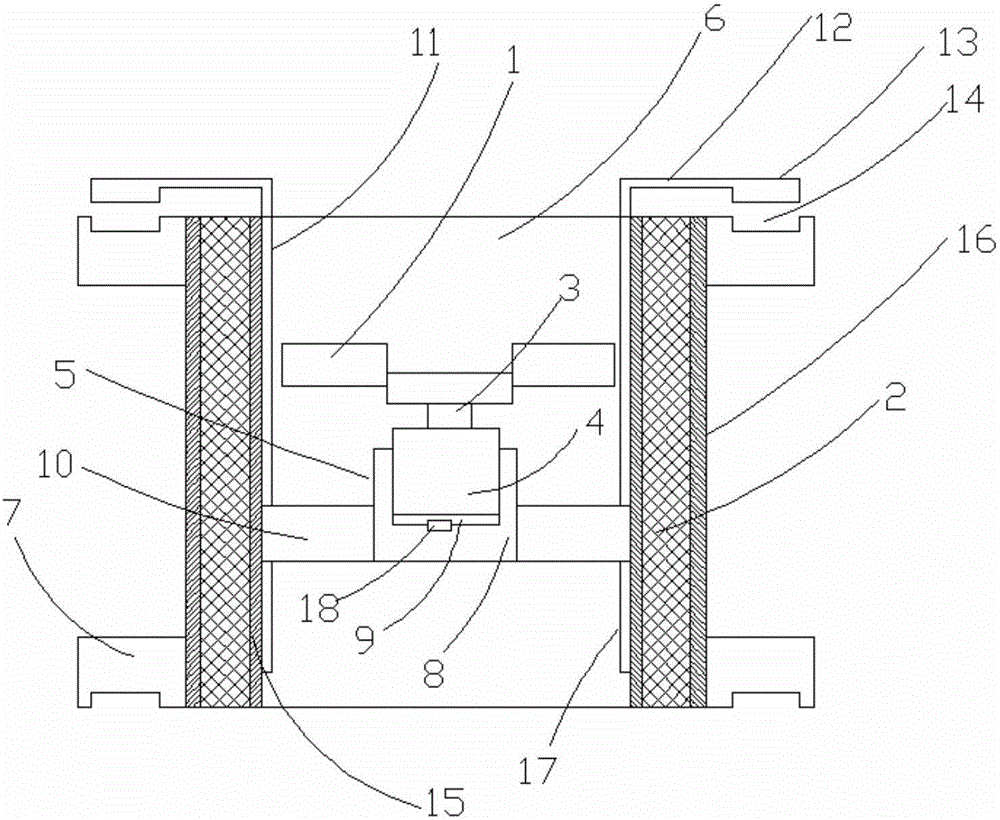

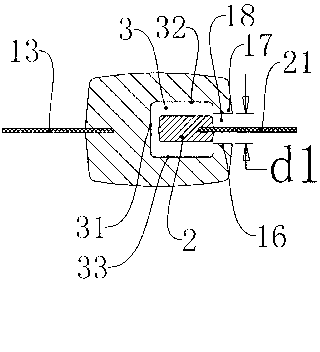

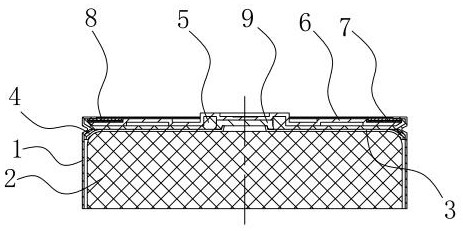

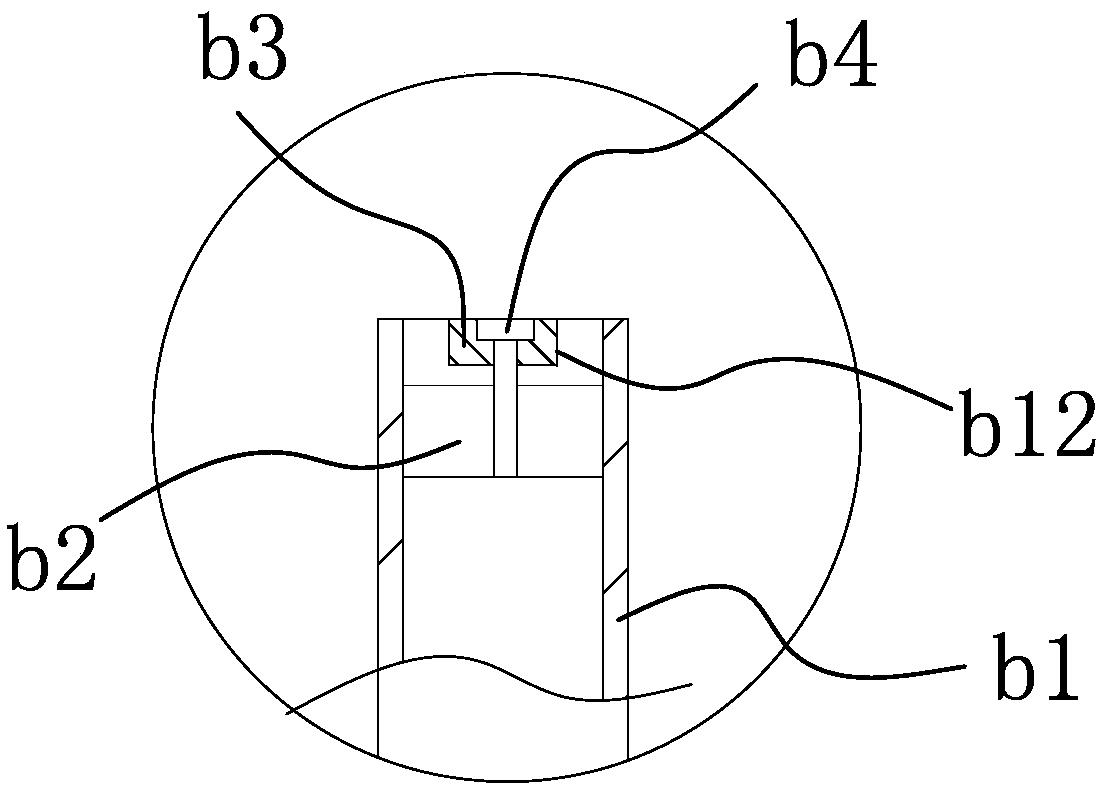

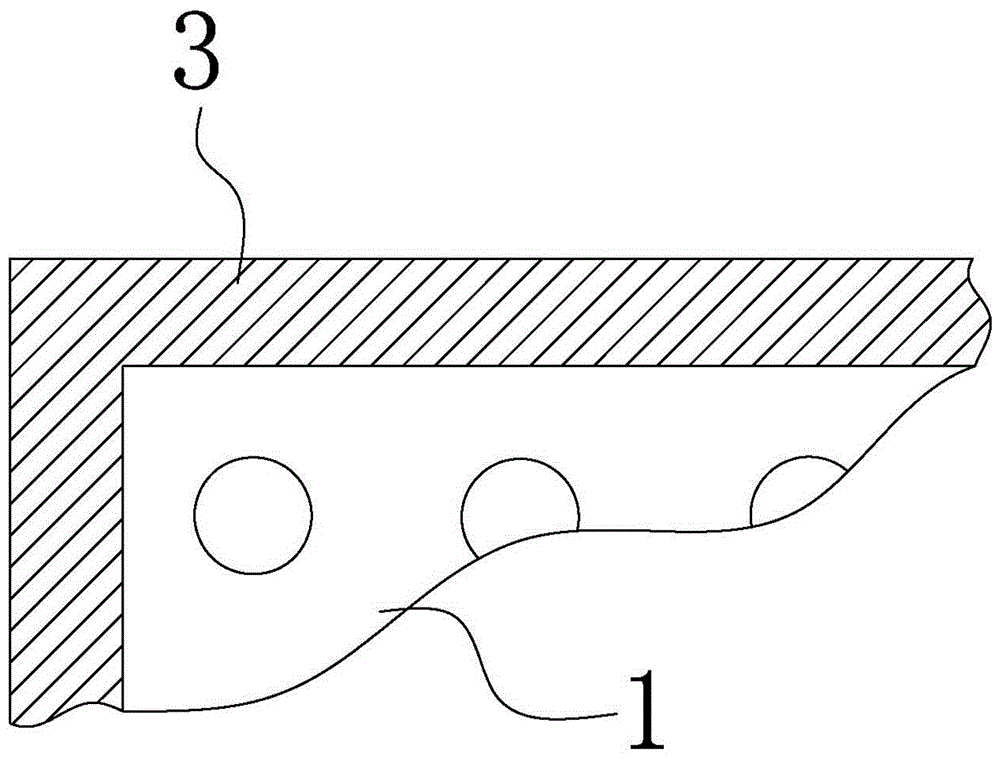

Ceiling wrapping corner and ceiling framework assembly

The invention provides a ceiling wrapping corner and a ceiling framework assembly. The ceiling framework assembly comprises two ceiling wrapping corners, at least two transverse beams, at least two longitudinal beams, connecting pieces and compressing blocks. The two ceiling wrapping corners are perforated in the front-back directions, the transverse beams are positioned between the two ceiling wrapping corners, the longitudinal beams are positioned between the adjacent transverse beams, riveting accommodating cavities are arranged on the end surfaces of the inner sides of the upper ends of the ceiling wrapping corners and comprise first grooves and second grooves, the second grooves of each riveting accommodating cavity are formed in two opposite inner side walls of the first groove of the riveting accommodating cavity, the shapes of the first grooves are matched with those of the connecting pieces, and the shapes of the second grooves are matched with those of the compressing blocks.

Owner:FUJIAN MINLU LIGHTWEIGHT AUTOMOBILE MFG CO LTD

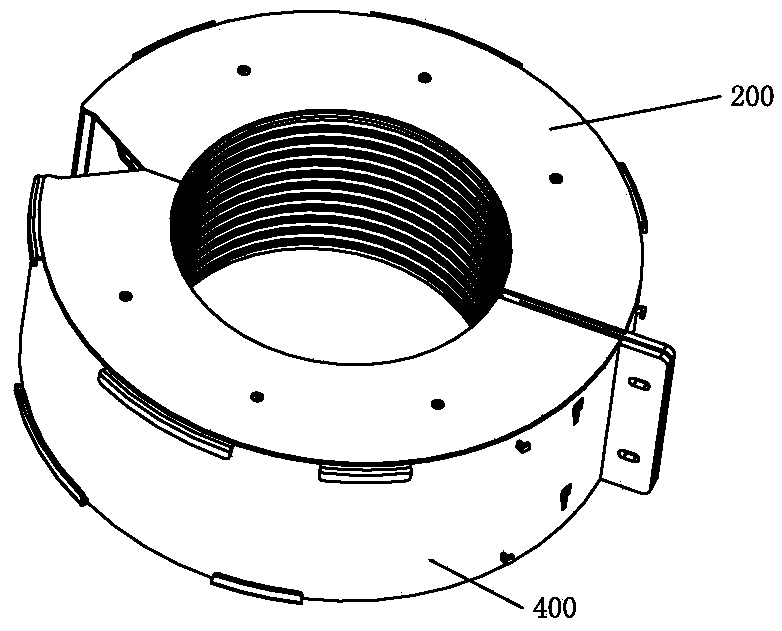

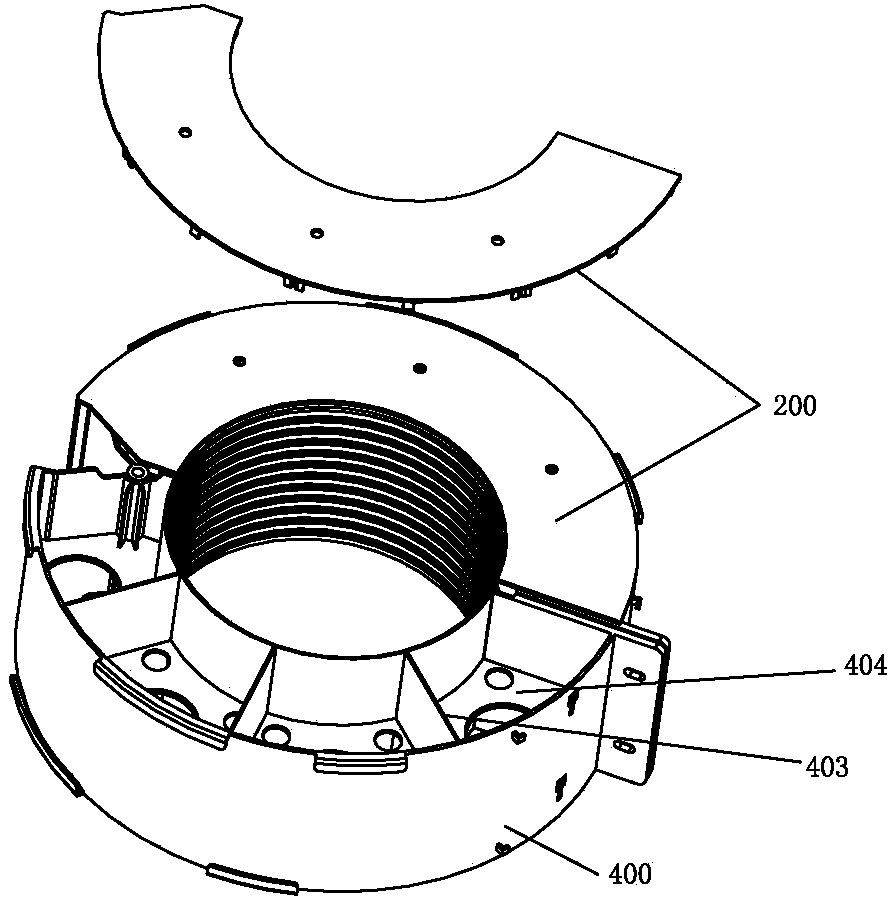

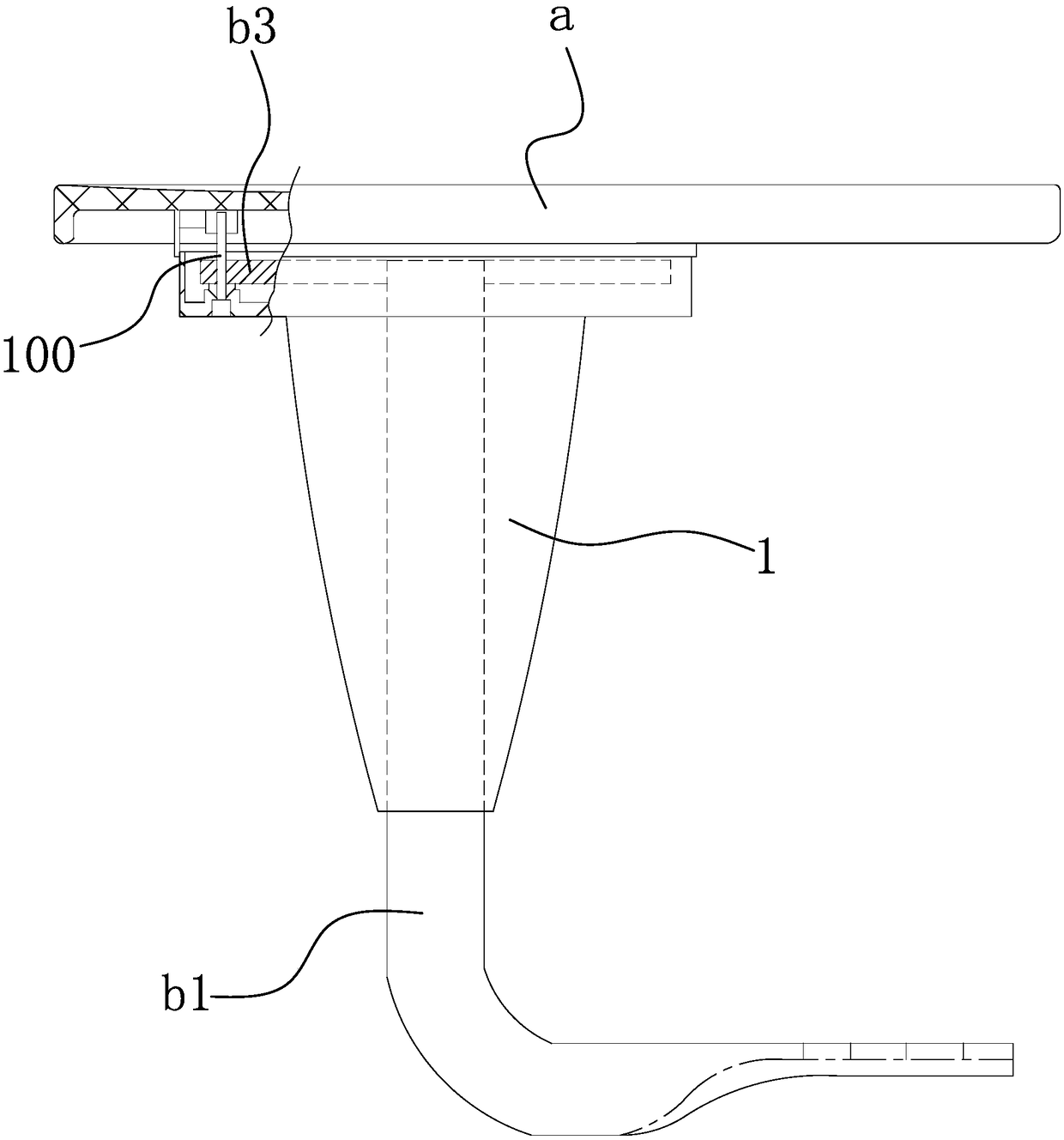

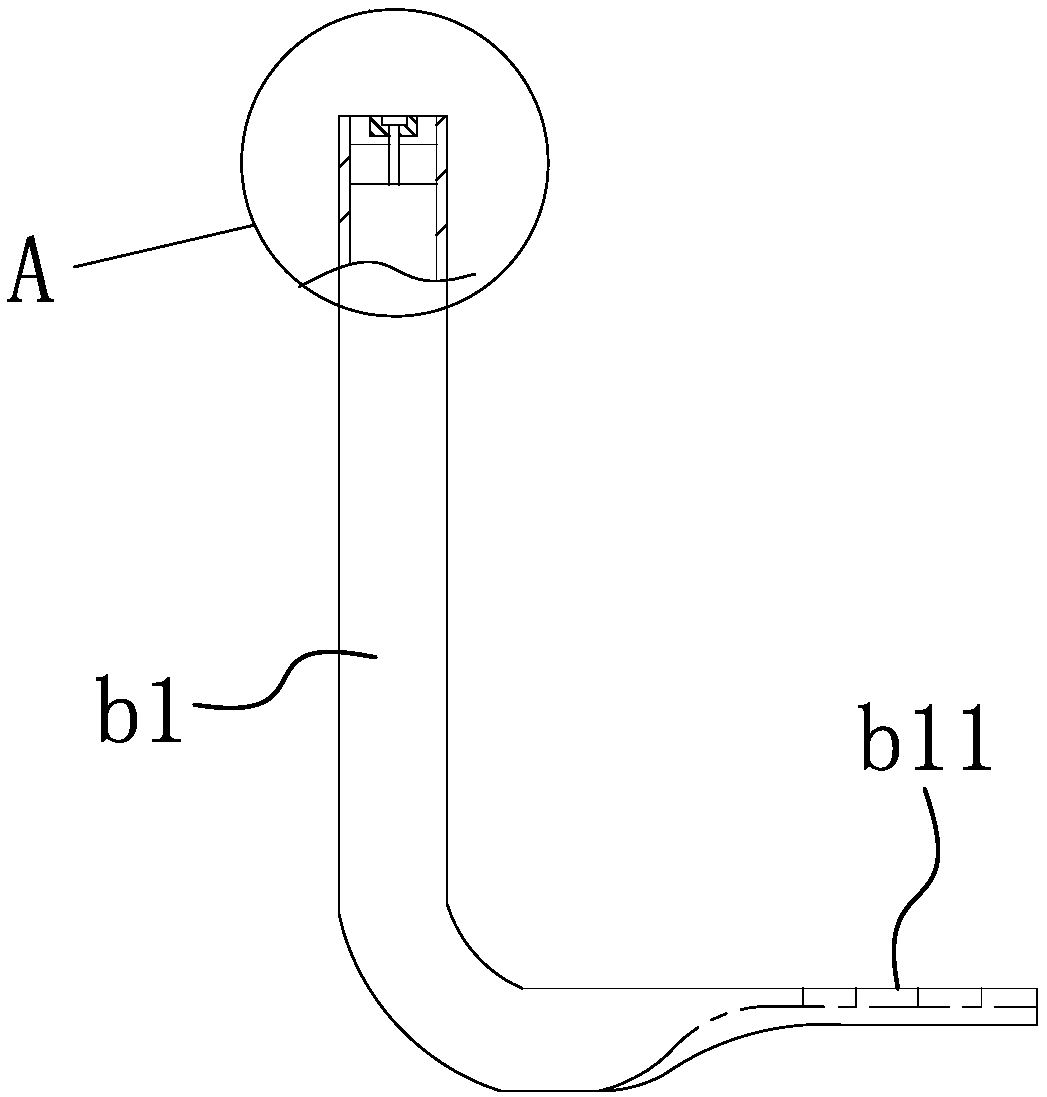

Axial flow fan convenient to install and adjust

InactiveCN107435663AEasy to installImprove installation efficiencyPump componentsPump installationsEngineeringFan blade

The invention provides an axial flow fan which is easy to install and adjust, including fan blades and wind guide rings, the fan blades have a mounting end, the mounting end has a motor, and the motor has a mounting frame. The inner shaped strip cavity of the wind guide ring, the upper and lower ends of the cavity form ring-shaped fixed sides respectively, the mounting frame includes a mounting seat, and an mounting cavity is formed in the middle of the mounting seat, and the mounting cavity is used for installing Fixing the motor; a plurality of equally spaced extension plates are arranged on the peripheral edge of the mounting seat, the end of the extension plate is provided with a positioning bar extending vertically upward, and the end of the positioning bar has a horizontally extending outward The fixed strip has a fixed plate at the end of the fixed strip; an annular groove is formed on the upper end surface of the annular fixed edge, the fixed plate is matched with the annular groove, and the fixed plate is arc-shaped. The invention can solve the problems existing in the prior art, improves the installation structure between the fan and the wind guide ring, is convenient and flexible to install, and can improve the strength of the overall connection structure.

Owner:新昌县鑫诺制冷设备有限公司

Bottom stop assembly of zipper fast to take off

ActiveCN103271518AImprove structural strengthImprove the strength of the connection structureSlide fastenersEngineering

A bottom stop assembly of a zipper comprises a left stop part and a right stop part, wherein the outer side of the left stop part and the outer side of the right stop part are connected with a left zipper chain and a right zipper chain respectively. A right inserting groove and an annular hole are formed in the inner side of the right stop part and extend in the inner side direction, the annular hole is located in the front end of the right inserting groove and is straightly communicated with a groove hole of the right inserting groove, and the left stop part can be movably inserted into the groove hole of the right inserting groove and can be taken off from the side edge port of the right inserting groove. When the left stop part is inserted into the groove hole of the right inserting groove, the top end portion of the left stop part can be inserted into the annular hole. As the left stop part can be inserted into the groove hole of the right inserting groove, the left stop part can be vertically positioned; as the left stop part can be taken off from the side edge port, when the left stop part is withdrawn from the right inserting groove, the left stop part can be driven by the left zipper chain to rotate around the outer side wall of the annular hole to be capable of rotating out, and withdrawing is very convenient and fast. The bottom stop assembly has the characteristics and the advantages, thereby being capable of being applied to bottom stop assemblies of zippers.

Owner:KEE (GUANGDONG) GARMENT ACCESSORIES LTD

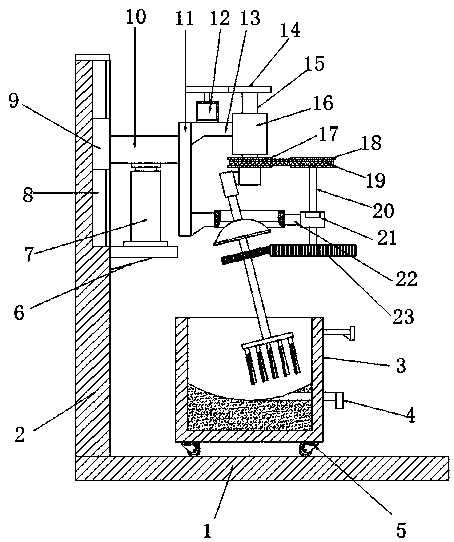

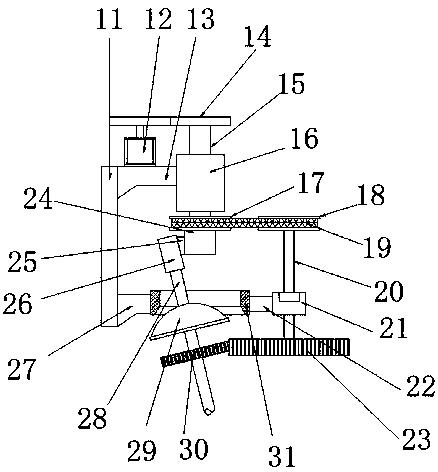

Stirrer for continuously mixing oily fluid

InactiveCN111151174AImprove stabilityPlay a guiding roleRotary stirring mixersTransportation and packagingGear driveGear wheel

The invention discloses a stirrer for continuously mixing oily fluid. The stirrer comprises a bottom plate, and a side plate is fixed to the left side of the outer wall of the top of the bottom plate.A lifting mechanism is fixed on the outer wall of one side of the side plate; the lifting mechanism is fixedly connected with a connecting plate; a first connecting block and a second connecting block are fixed on one side of the connecting plate; a shaft sleeve is fixedly connected to the first connecting block; a rotating shaft is rotationally inserted into the shaft sleeve; the top end of therotating shaft is in transmission connection with a driving mechanism, a driving block is fixed to the bottom end of the rotating shaft, a wedge block is fixed to one side of the driving block, a fixing shaft is fixed to the slope of the wedge block, a stirring shaft is fixed to the bottom end of the fixing shaft, a stirring mechanism is fixed to the bottom end of the stirring shaft, a fixing ringis fixed to the second connecting block, and a fixing block is fixed on one side of the fixing ring. Autorotation of the stirring shaft and the stirring mechanism can be achieved, overall rotation ofthe stirring mechanism can be achieved while autorotation is conducted, the stirring and mixing effect is improved, in addition, belt transmission and gear transmission are conducted at the same time, and the double-transmission effect is more stable.

Owner:丁许

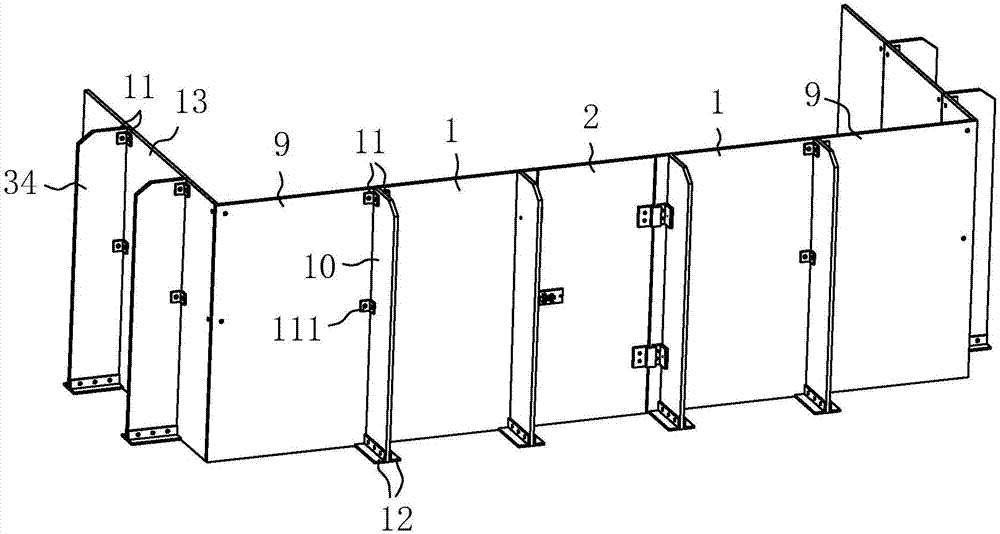

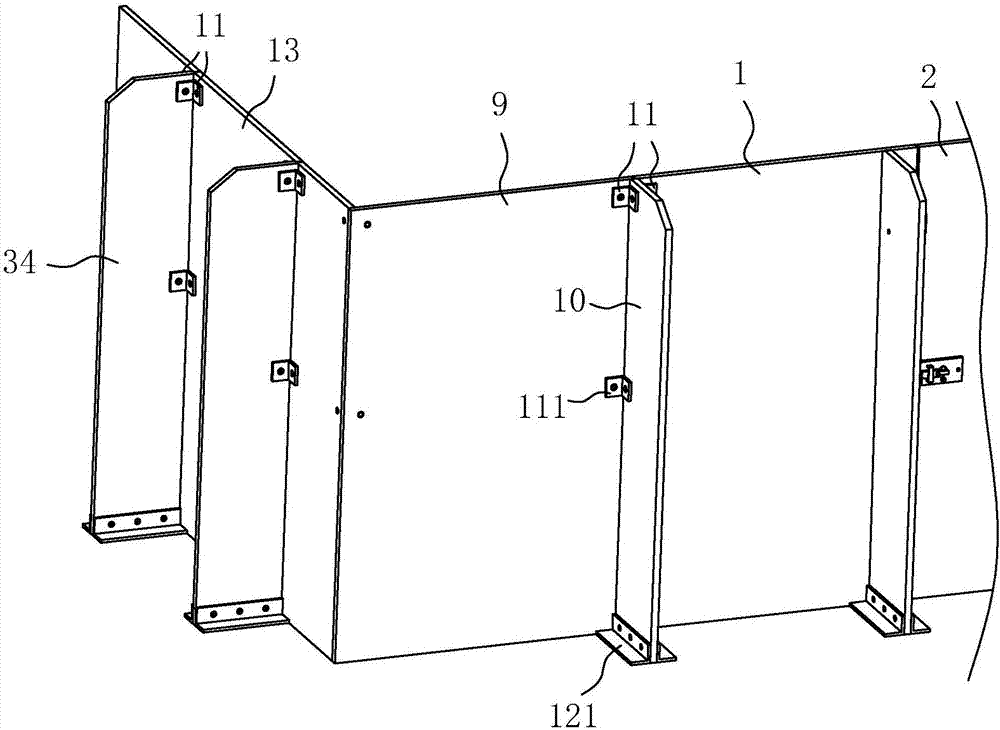

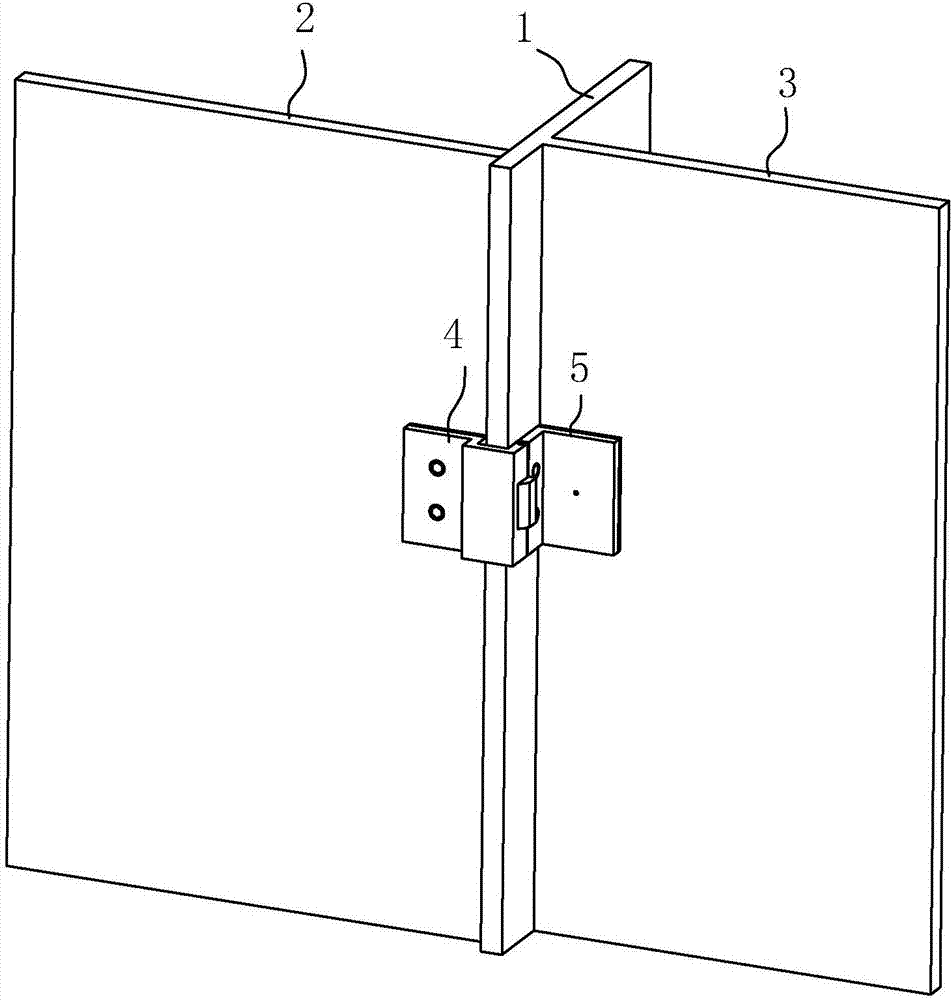

Squash court glass assembly body

InactiveCN107044213AImprove connection strengthImprove stabilityWallsWing fastenersSquash courtUltimate tensile strength

The invention discloses a glass assembly for squash courts. The key point of the technical solution is to include at least two first glass units fixed on the ground, and hinged joints for entering and exiting the squash court are arranged between the adjacent first glass units. A glass door, a hinge assembly is installed between the glass door and one of the first glass units, a door lock assembly is installed between the glass door and the other first glass unit, the squash hall glass assembly of the present invention, The structural connection strength is high, and it has excellent structural stability, which can resist the impact of squash balls and reduce the loosening of glass assemblies.

Owner:NANJING HANWEI SPORT ENG IND

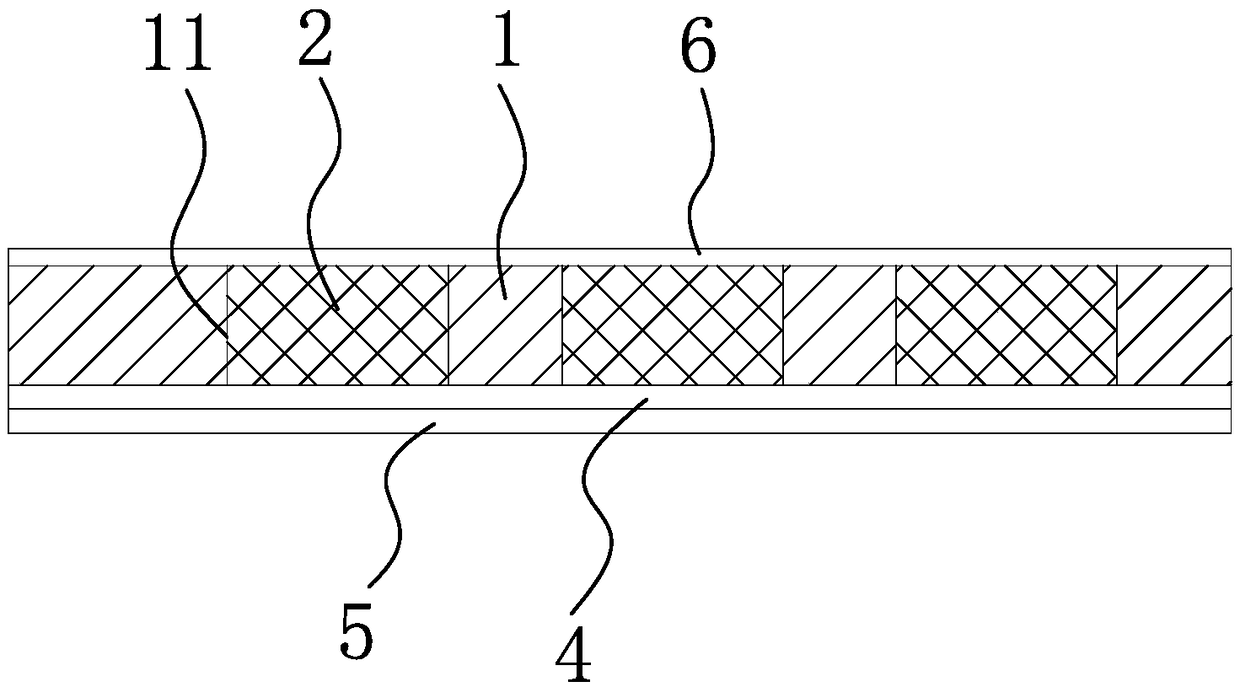

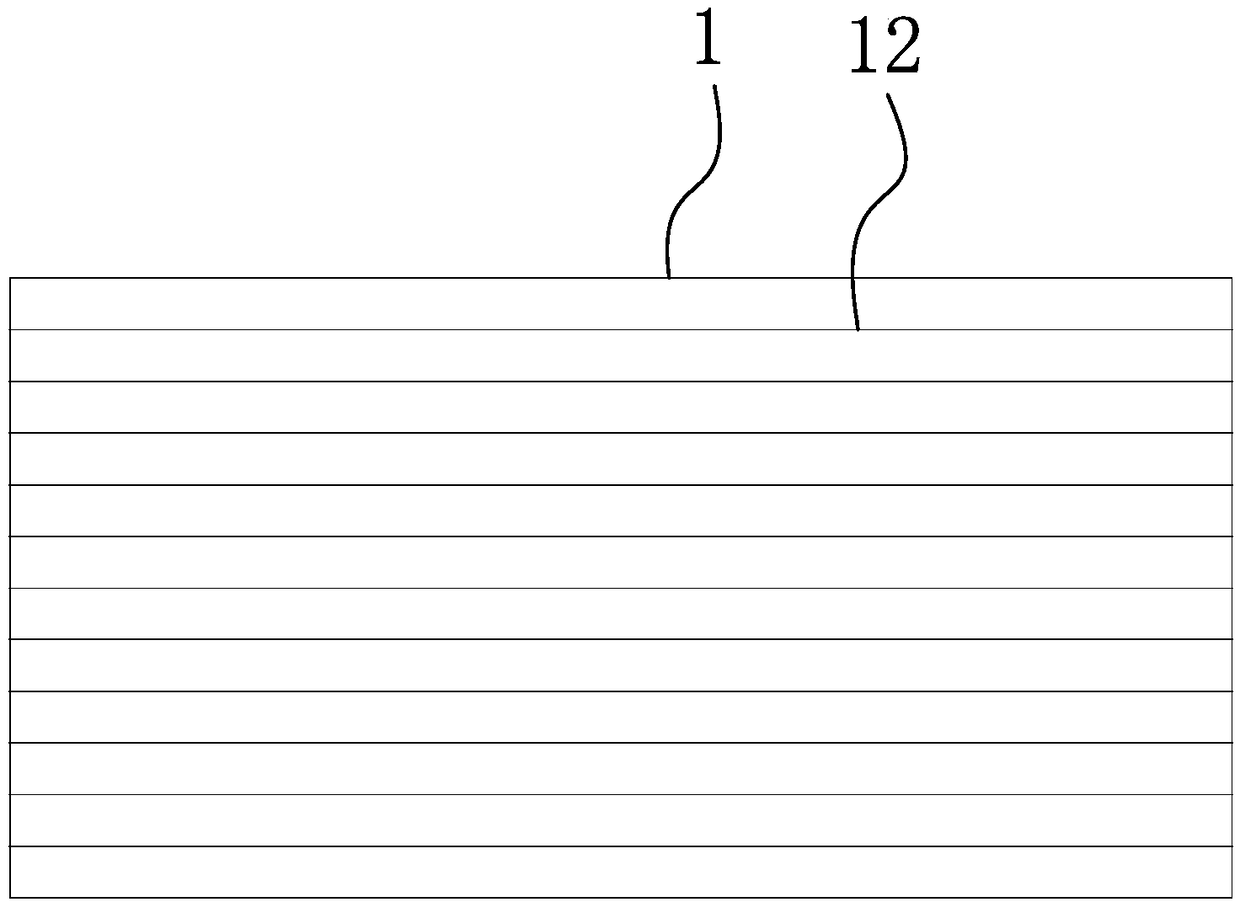

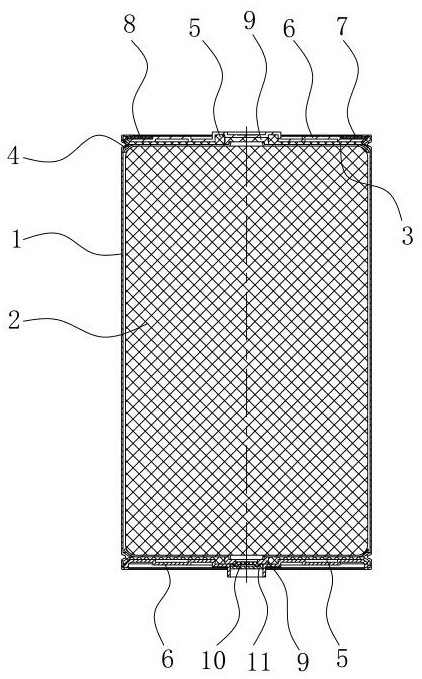

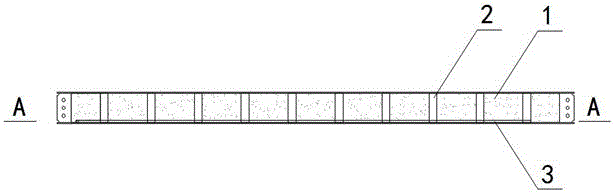

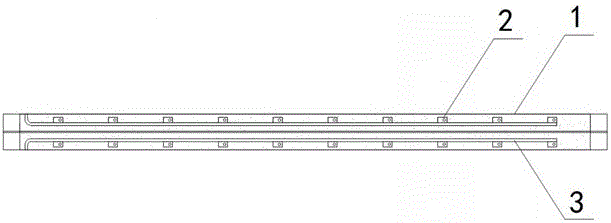

Composite aluminum substrate, production technology thereof, and LED circuit board

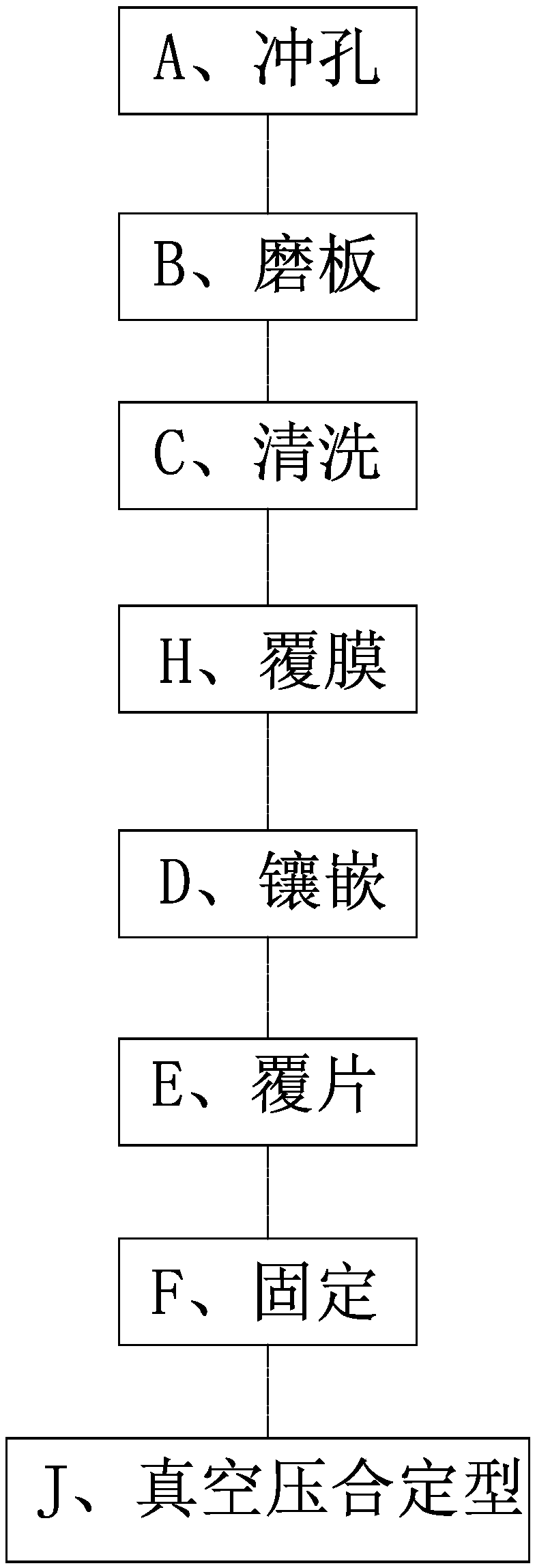

ActiveCN108848619AIncrease productivityReduce manufacturing costInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentPunchingOptoelectronics

The invention belongs to the technical field of circuit boards, and particularly relates to a production technology of a composite aluminum substrate, and an LED circuit board. The problems of unreasonable design and the like in the prior art are solved. The production technology of the composite aluminum substrate comprises the following production steps of A, punching, B, plate grinding, C, cleaning, D, inlaying, E, sheet cladding, and F fixing. The production technology of the composite aluminum substrate has the advantages that the bonding strength can be improved, the cost can be reduced,and the production efficiency is improved.

Owner:俊萱新材料(杭州)有限公司

Lithium battery end structure and manufacturing method

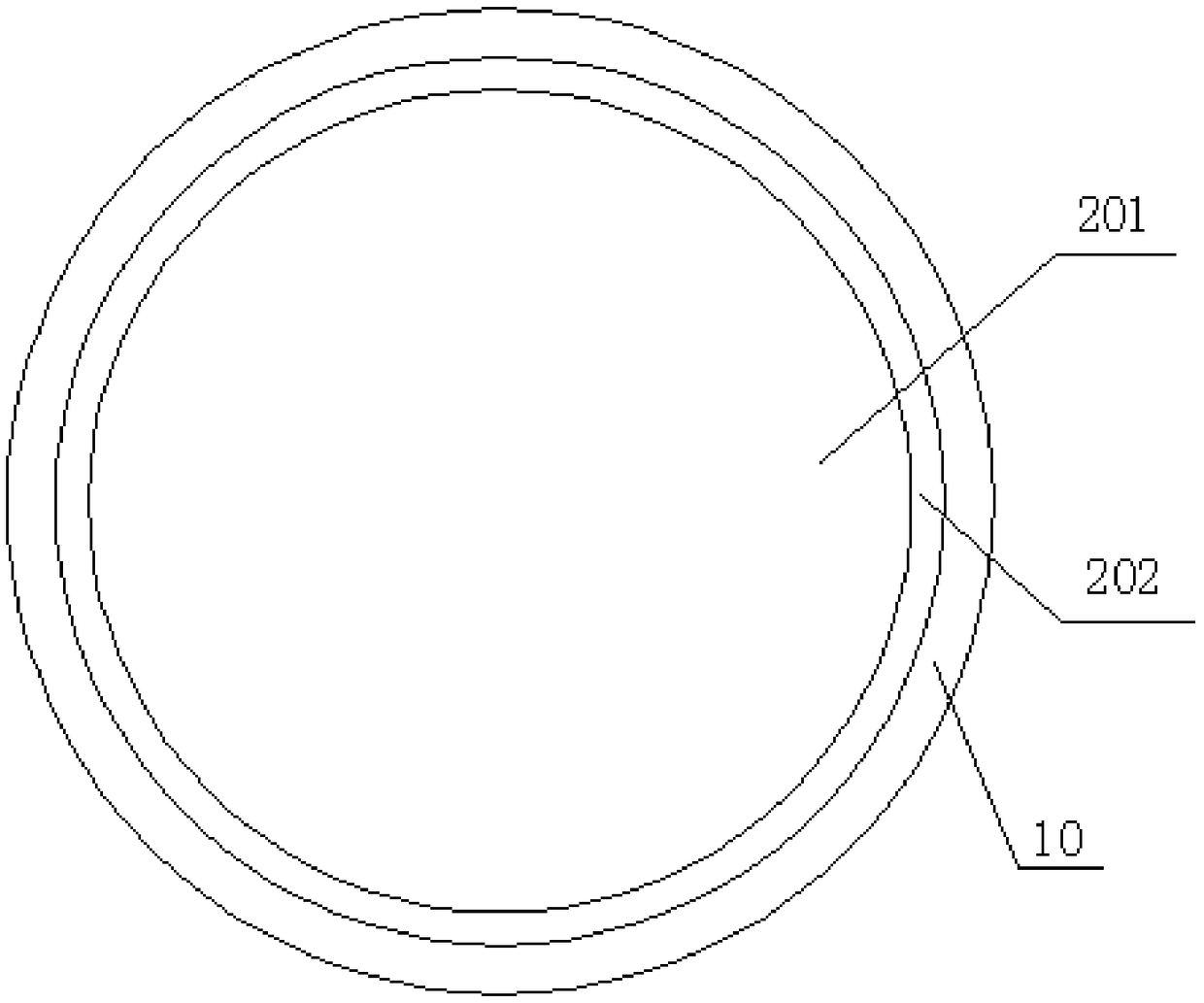

PendingCN113745715ASimple structureCompact designFinal product manufactureSmall-sized cells cases/jacketsAutomatic processingElectrically conductive

The invention discloses a lithium battery end structure and a manufacturing method, the lithium battery end structure comprises a shell, a battery cell, a current collector and the like, a current collector cap and a sealing ring sleeved outside the current collector cap are arranged outside the current collector, the current collector cap covers a liquid injection hole of the current collector and is conductively connected with the current collector, an inner circumference seal is formed between the sealing ring and the current collector cap. Outer circumferential sealing is formed between the sealing ring and the shell, a cover cap is arranged outside the sealing ring and the current collecting cap, the cover cap and the current collecting cap are in conductive connection, and the outer edge of the cover cap is peripherally pressed and conductively fixed by an outer turned edge at the end part of the shell; obviously, the port structure of the whole shell also achieves the conductive sealing effect under the condition of fewer parts, and has the use advantages of simple structure, compact design, capability of better improving the capacity of the lithium battery, simplification of the automatic processing procedure and the like; Meanwhile, the outer turned edge is circumferentially pressed and conductively fixed, so that the structural connection strength is improved, the structural compactness is ensured, and the use is safer.

Owner:宁波久鼎新能源科技有限公司

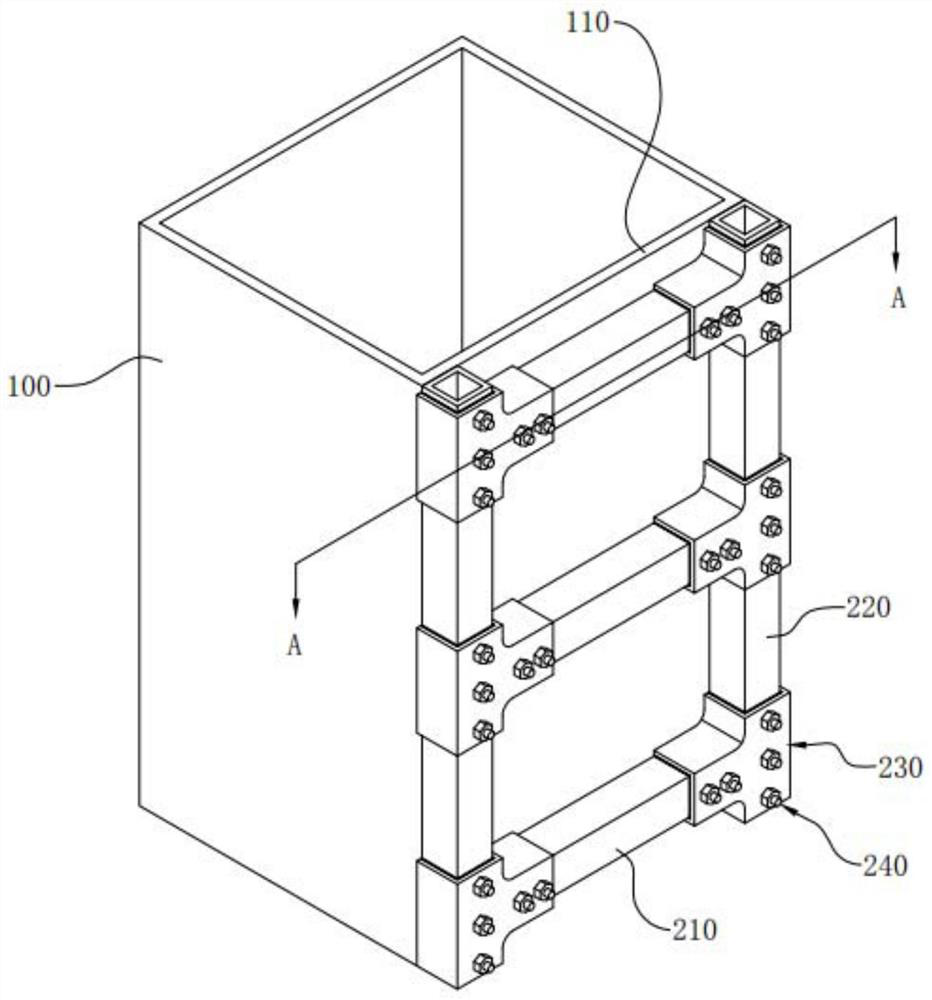

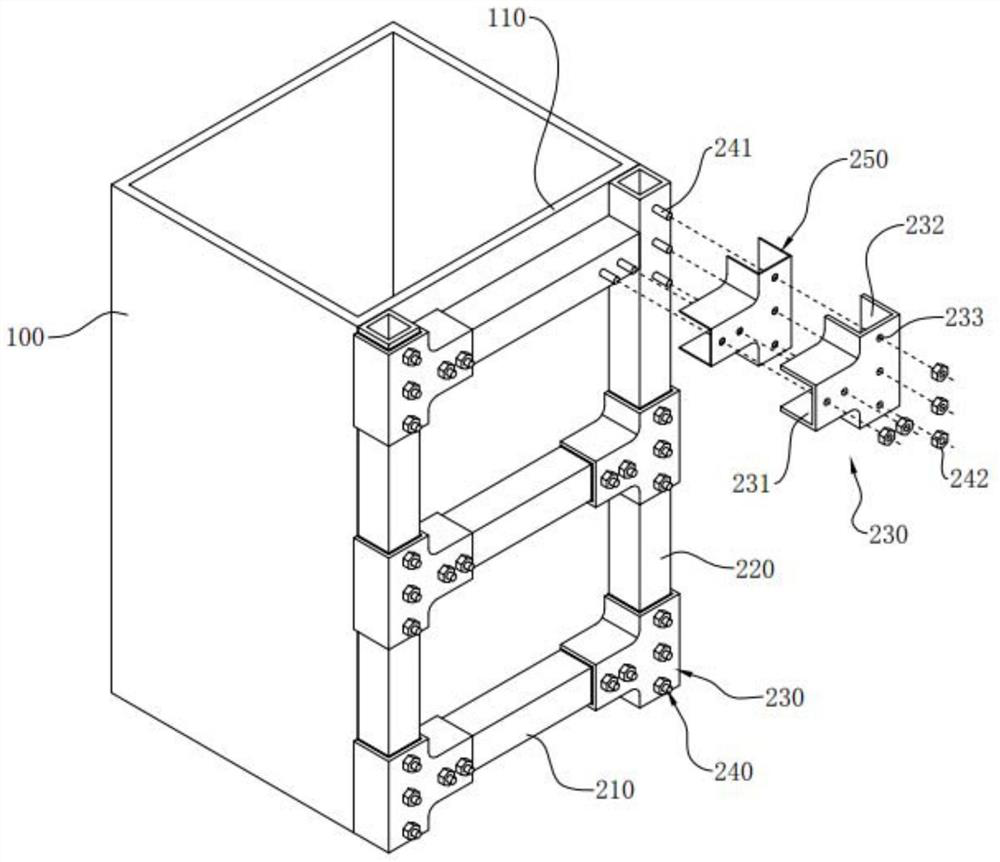

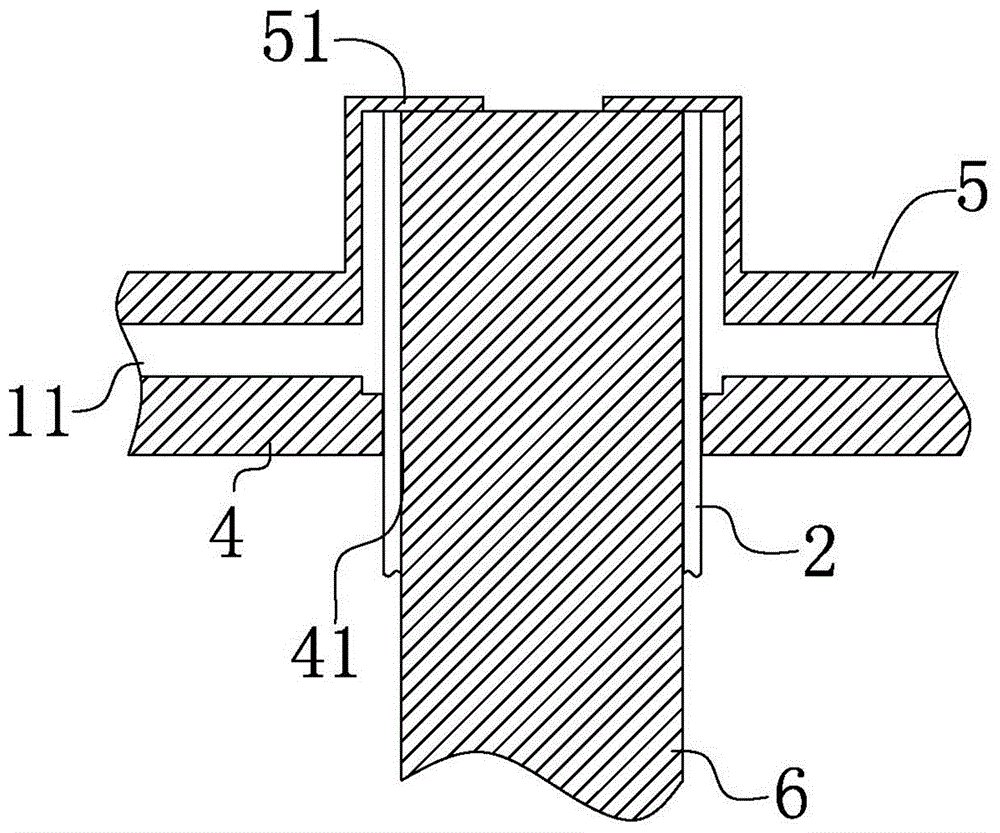

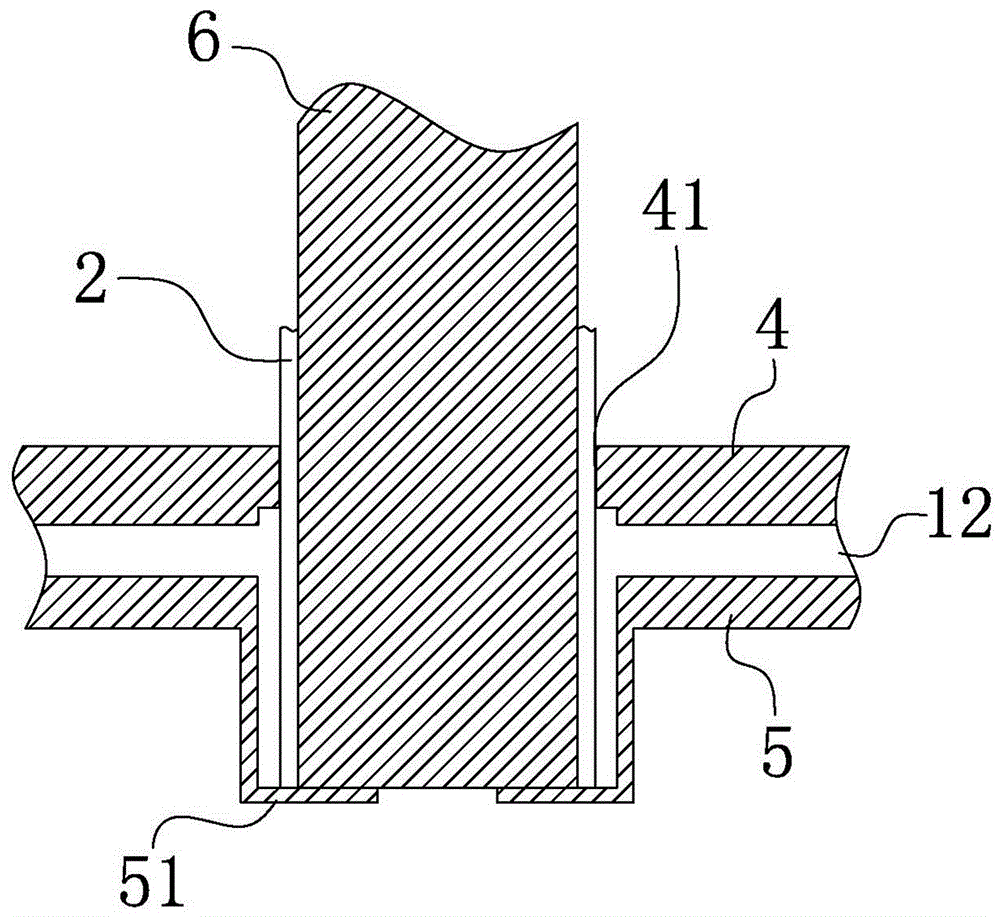

A light steel structure rectangular tube beam-column connection node

ActiveCN106836481BShorten the construction periodWork lessBuilding constructionsEngineeringUltimate tensile strength

Owner:BEIJING KUANGJIAN CONSTR GRP CO LTD

Front cabin structure of off-road vehicle body

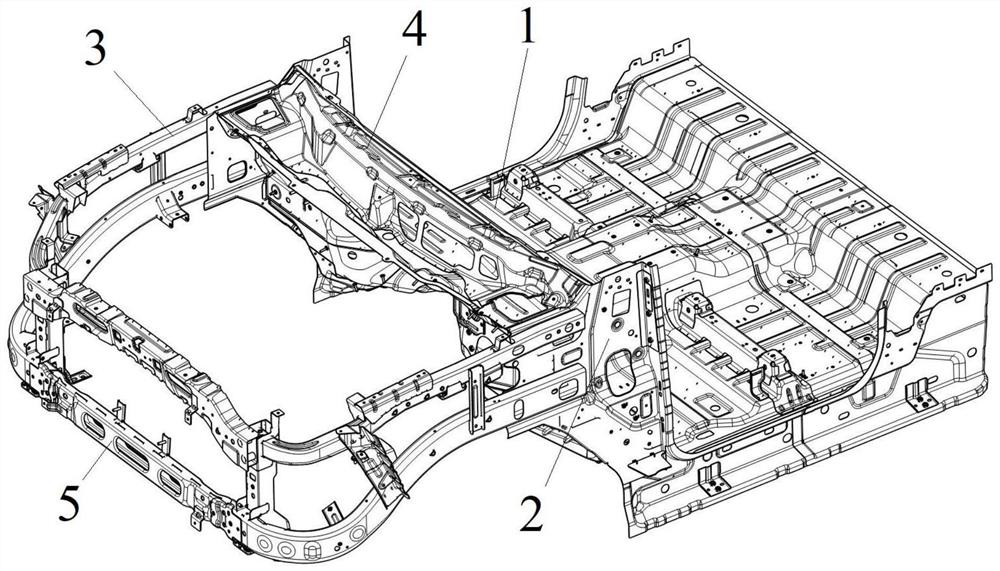

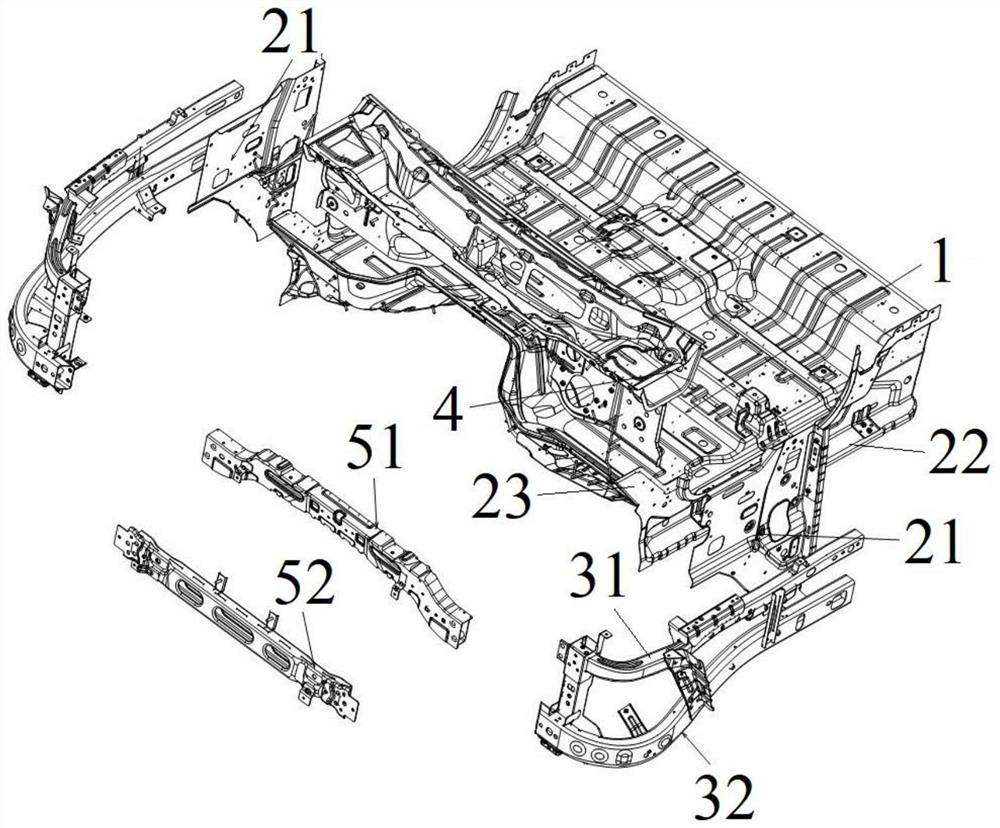

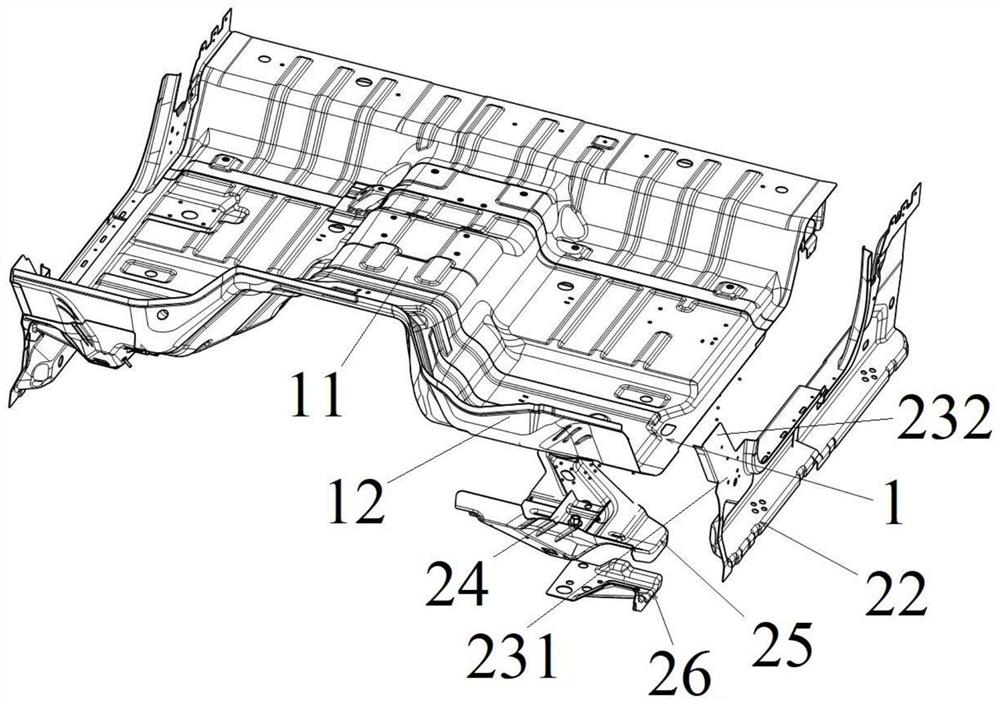

ActiveCN113968285AControl force transmissionSimple structureSuperstructure subunitsBumpersClassical mechanicsEngineering

The invention relates to the technical field of automobile structures, in particular to a front cabin structure of an off-road vehicle body. The structure comprises a floor assembly, side reinforcing assemblies are arranged on the two transverse sides of the floor assembly in the vertical direction, and the lower ends of the side reinforcing assemblies are fixed to the transverse sides of the floor assembly; a cabin longitudinal beam assembly which is arranged in the longitudinal direction, and the end, close to the floor assembly, of the cabin longitudinal beam assembly is fixed to the upper end of the side reinforcing assembly; a front wall assembly which is arranged in the transverse direction, and the two ends of the front wall assembly are fixedly connected with the side reinforcing assemblies on the two sides respectively; a water tank cross beam assembly which is transversely arranged, and the two ends of the water tank cross beam assembly are fixedly connected with the cabin longitudinal beam assemblies on the two sides; the lower end of the front wall assembly is fixed to the floor assembly, and the lower end of the front wall assembly, the side reinforcing assemblies on the two sides and the floor assembly form a stress cavity space for dissipating the bending moment and torque of the cabin longitudinal beam assembly. The front cabin is simple in structure, can bear large longitudinal stress by constructing a frame type structure, and is good in structural stability and high in lightweight degree.

Owner:DONGFENG OFF ROAD VEHICLE CO LTD

A kind of casting method using double thin shell mold technology

ActiveCN108687304BGood removal effectReduce intensityAdditive manufacturing apparatusFoundry mouldsThin shellsManufacturing technology

The invention relates to the field of the 3D printing technology and the casting process, in particular to a casting method adopting a dual thin shell mold process. The casting method comprises the step of manufacturing a thin shell mold 3D printer and a corresponding computer. Specifically, a thin shell mold is printed out through the 3D printing technology, the wall thickness of the thin shell mold does not exceed 2 mm, a high temperature resisting outer shell mold is manufactured out through the immersing sizing process in the precision casting process, after filling reinforcement, the thinshell mold is removed through a physical or chemical method, casting and aftertreatment are carried out, and a finished product is manufactured. The casting method has the advantages that productioncan be standardized by manufacturing the thin shell mold through the 3D printer, the 3D printing technology and the dewaxing casting process are combined, and a manufacturing process which is easier to operate and more environment-friendly and energy-saving and reduces the production cost is obtained.

Owner:LIANYUNGANG YYU PROD

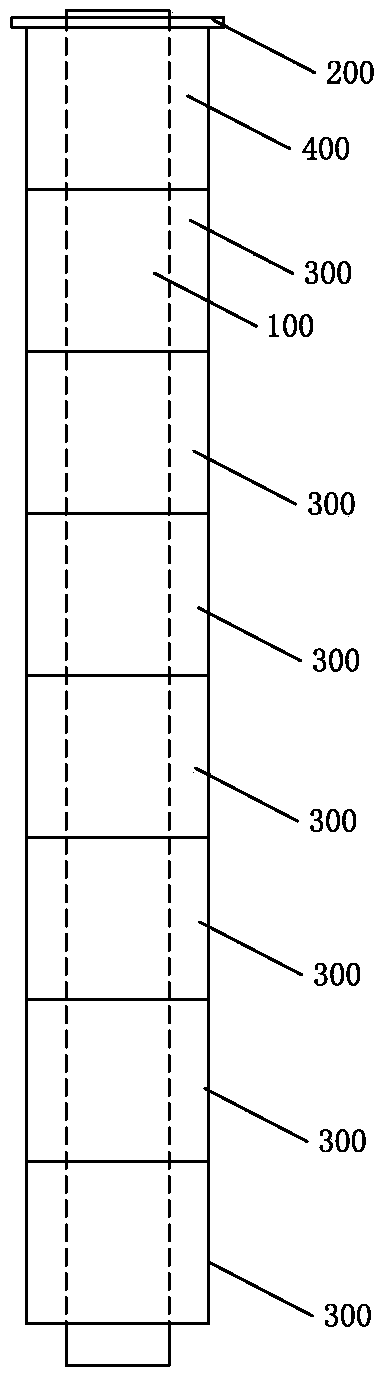

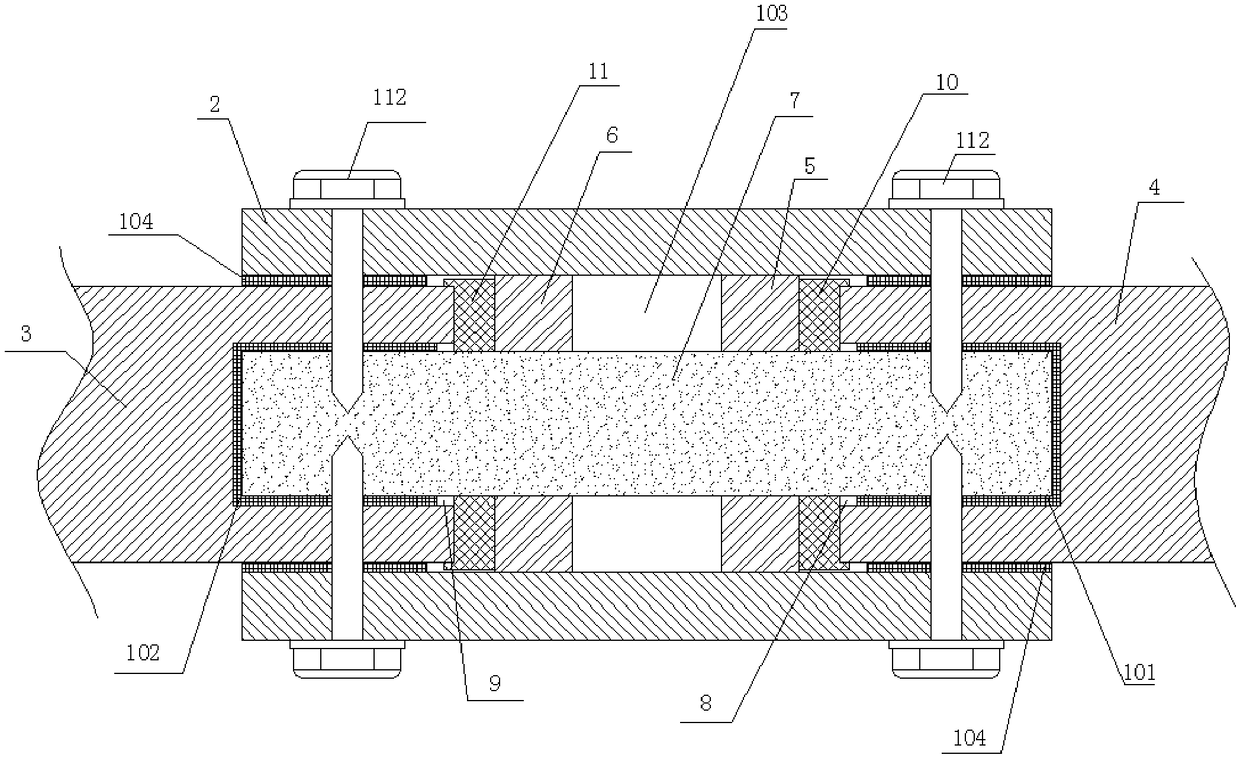

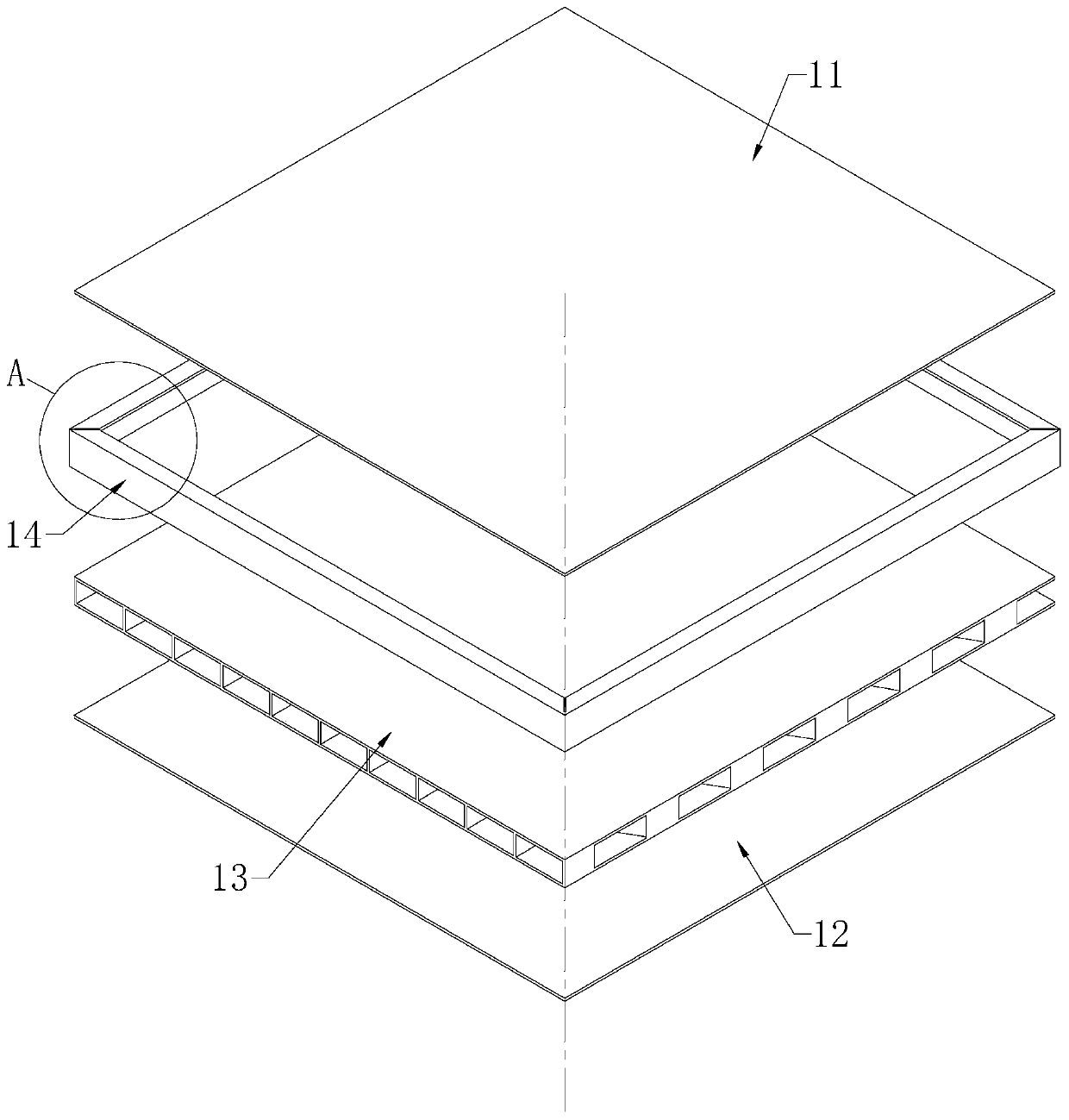

Assembly-type concrete frame shear wall structure

ActiveCN111561072AStrengthen the connection structureImprove the strength of the connection structureWallsBuilding reinforcementsArchitectural engineeringGrout

The invention relates to an assembly-type concrete frame shear wall structure. The assembly-type concrete frame shear wall structure comprises a precast column, a precast beam and a precast wall. Theprecast column comprises rectangular positioning columns and connecting plates which are in butt joint with the two adjacent side faces of the positioning columns. The precast wall comprises an innerside wall body matched with the positioning columns and an outer side wall body matched with the connecting plates. A first connecting mechanism is arranged between the positioning columns and the inner side wall body, and a second connecting mechanism is arranged between the positioning columns and the connecting plates. A third connecting mechanism is arranged between the outer side wall body and the inner side wall body, and a fourth connecting mechanism is arranged between the outer side wall body and the connecting plates. First grouting grooves are formed in the side face, close to the positioning columns, of the connecting plates, and second grouting grooves are formed in the side face, close to the outer side wall body, of the inner side wall body. The connecting plates and the outer side wall body are matched to encircle the inner side wall body and the positioning columns. The assembly-type concrete frame shear wall structure has the effects that the connecting structure between the precast column and the precast wall is additionally arranged, so that connection strength is good, and separation happening under the external force action cannot occur easily.

Owner:广东中都建筑集团有限公司

Clean water concrete decorative panel mounting assembly of interior mall decoration

The invention discloses a clean water concrete decorative panel mounting assembly of an interior mall decoration. The clean water concrete decorative panel mounting assembly of the interior mall decorationcomprises a connecting master piece, a pressurized pre-embedded socket mounting block, and a tensioned pre-embedded socket mounting block, wherein a first opening slot and a second opening slot are formed in theconnecting master piece, the first opening slot and the second opening slot are both connected to the connecting master piece, the pressurized pre-embedded socket mounting block is provided with a pressurized pre-embedded socket, the pressurized embedded socket mounting block is detachably connectedwith the connecting masterpiece through the pressurized pre-embedded socket is tightly inserted into the first opening slot, the tensioned pre-embedded socket mounting block is provided with a tensioned pre-embedded socket, and the tensioned pre-embedded socket mounting block is detachably connected with the connecting master piece through the tensioned pre-embedded socket is tightly inserted into the second opening slot; and according to the characteristics of concrete as casting material, the pre-embedded dry link combination system is used in mold casting,and under the premise of simplifying the process and lowering the cost, the structural joint strength are improved.

Owner:GOLD MANTIS CONSTR DECORATION

Light aluminum alloy chassis of light rail vehicle body

The invention discloses a light aluminum alloy chassis of a light rail vehicle body which comprises a transverse beam and a longitudinal beam and further comprises a splicing piece and a fastening piece, the splicing piece is provided with a transverse clamping groove and a longitudinal clamping groove, the longitudinal beam is inserted into the longitudinal clamping groove, the end of the cross beam is inserted into the transverse clamping groove, and the splicing piece is connected with a floor of the vehicle body in a fastened mode through the fastening piece. The cross beam, the longitudinal beam and the splicing piece are made of aluminum alloy materials. The cross beam and the longitudinal beam are restrained through the inner walls of the transverse clamping groove and the inner walls of the longitudinal clamping groove, compared with welding in the prior art, a certain relative movement range can exist between the traverse beam and the longitudinal beam instead of rigid connection, the situation that the connecting positions are cracked due to repeated stretching and compression is avoided, and the structural strength of the bottom frame is improved; and the train is saferin the running process.

Owner:安徽鑫铂科技有限公司

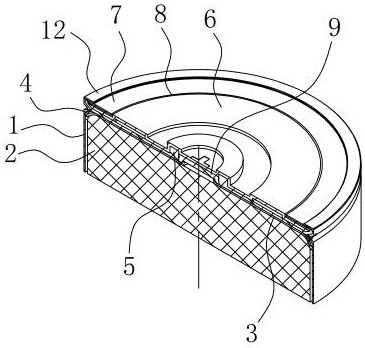

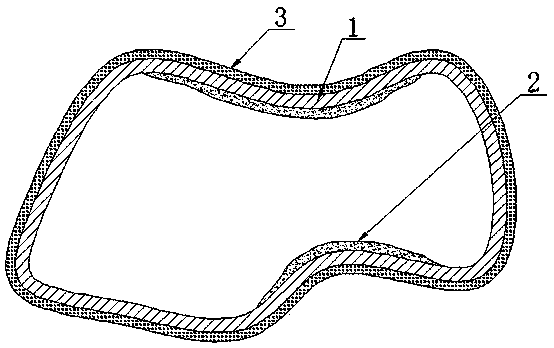

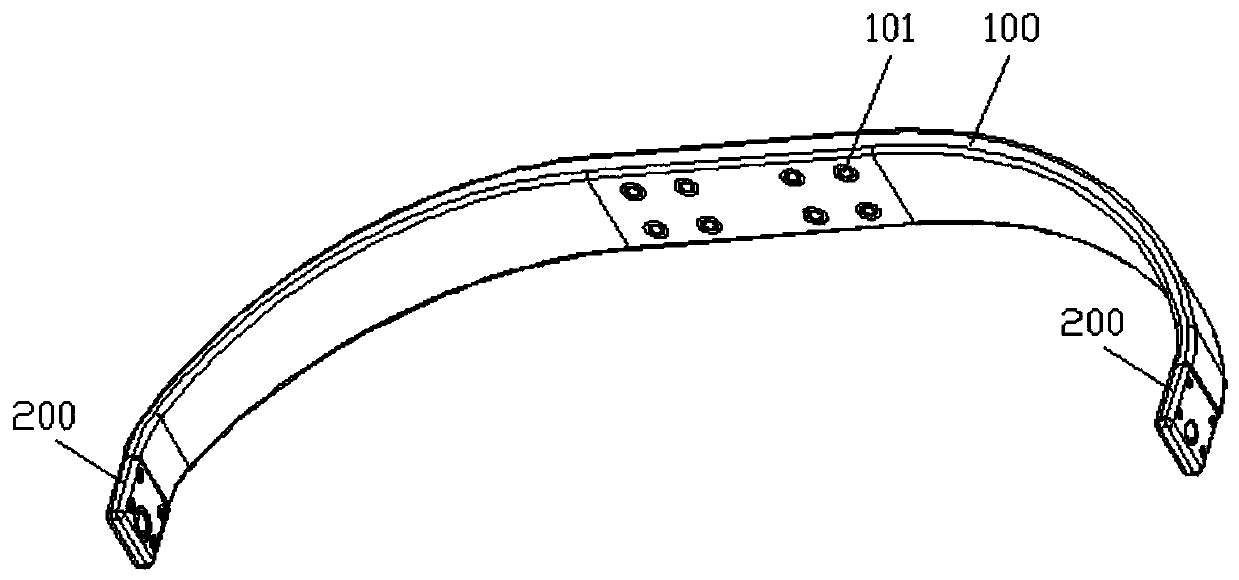

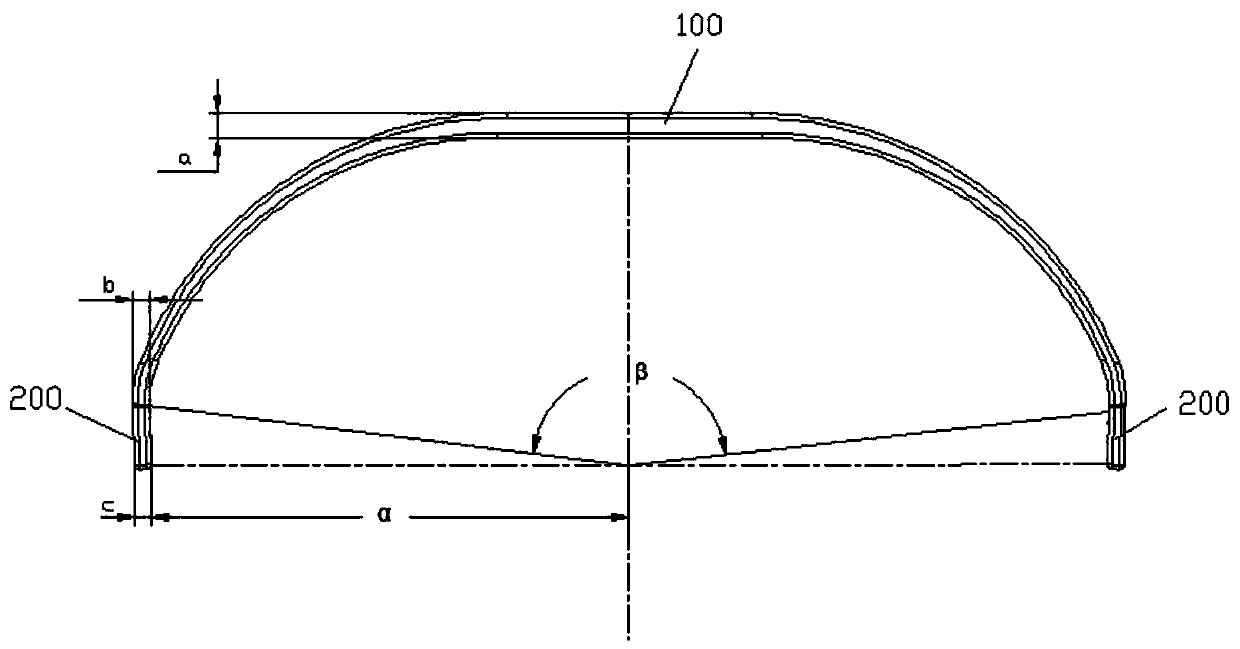

Composite material main lifting support and manufacturing and assembling method thereof

InactiveCN111038686AReduce weightImprove the strength of the connection structureAircraft assemblyFuselagesFlight vehicleStructural engineering

The invention discloses a composite material main lifting support and a manufacturing and assembling method thereof, and belongs to the technical field of aviation aircraft accessories. The compositematerial main lifting support comprises an arc-shaped plate and two side supporting plates; the arc-shaped plate and the side supporting plates are made of composite materials, and the arc-shaped plate and the side supporting plates are integrally formed; the arc-shaped plate is used for being connected with the lower portion of a fuselage of an aircraft, and the two side supporting plates are connected to the two end faces of the arc-shaped plate respectively and used for being connected with two hubs respectively. The problems that in the prior art, a main lifting support is made of a metalmaterial, and the overall weight is large; and two hydraulic rods and a hub supporting mode are adopted, the weight of a main lifting support is large, operation is strenuous, and the universality ispoor are solved. The arc-shaped plate and the side support plates are made of composite materials, so that the overall weight is light; the two ends of the arc-shaped plate are each connected with onecorresponding side supporting plate, each side supporting plate is connected with a corresponding hub, and the whole support is light in weight and good in universality.

Owner:天津爱思达新材料科技有限公司

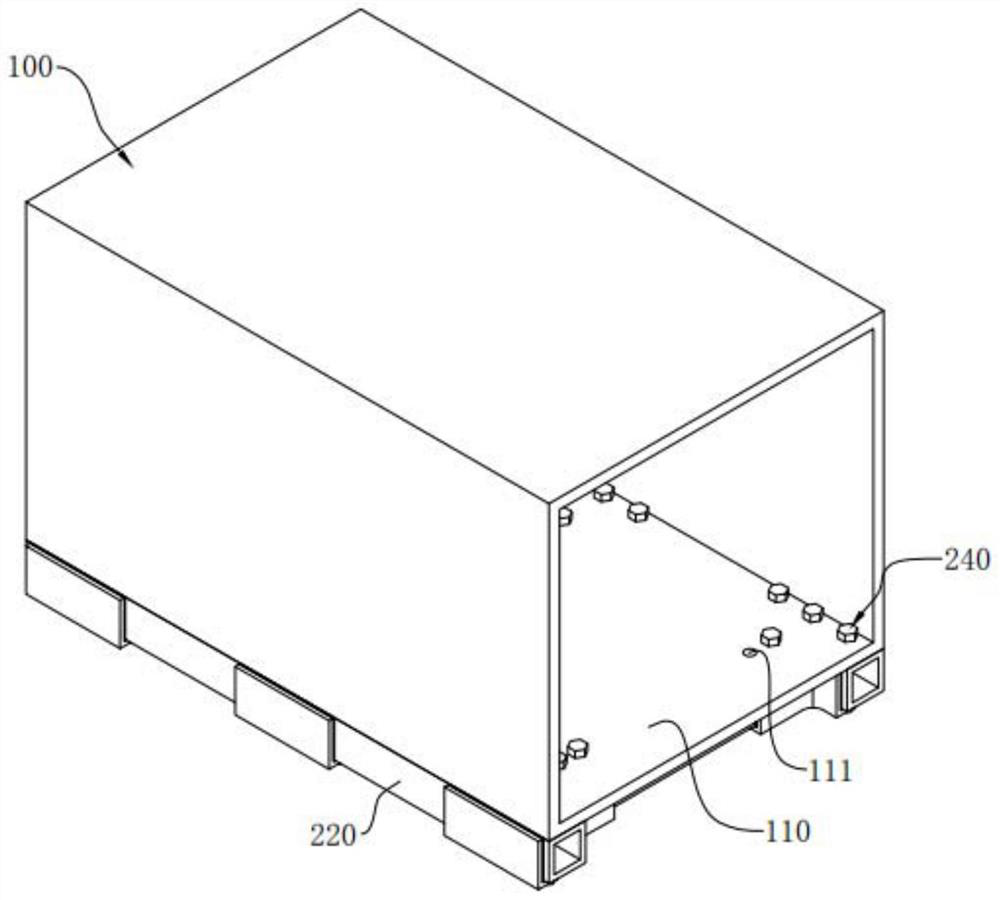

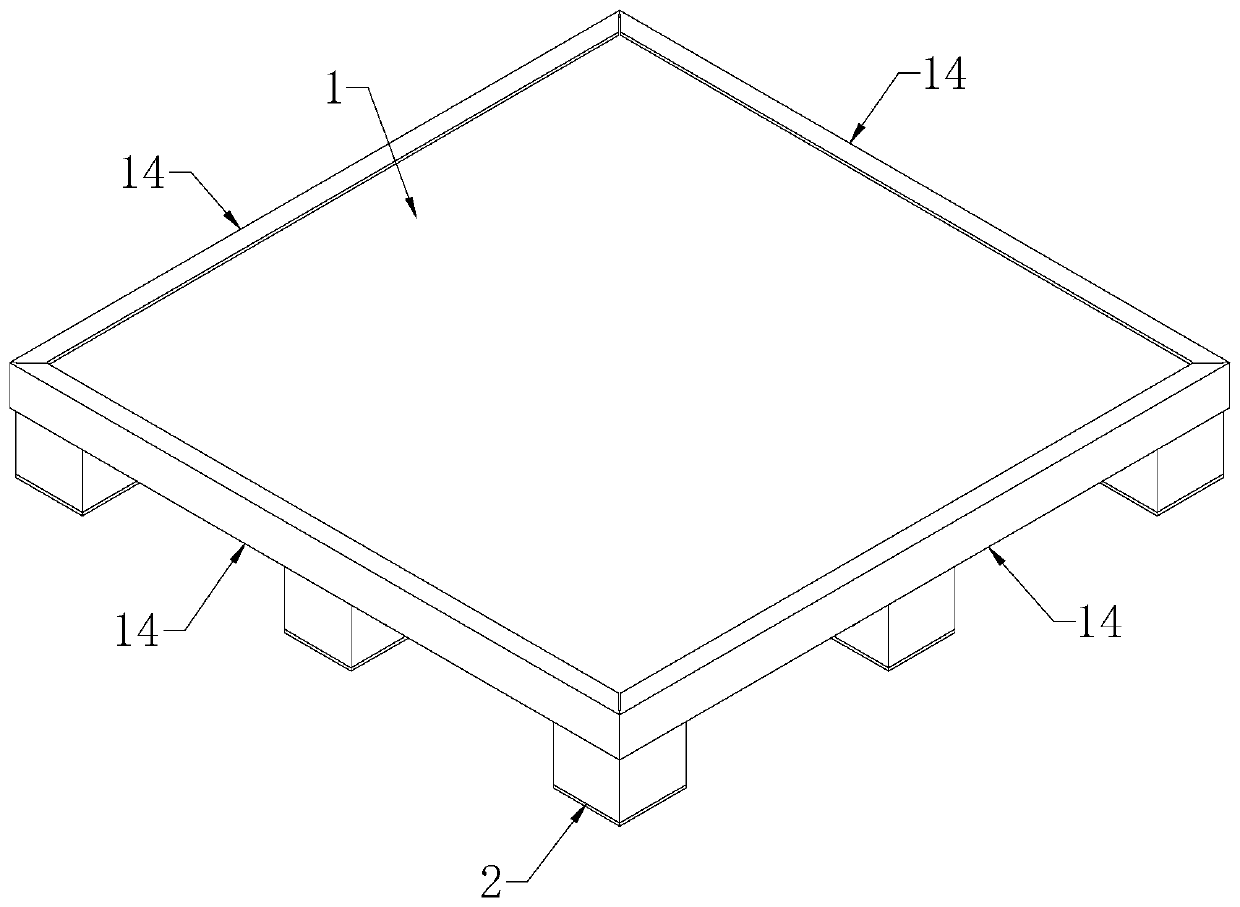

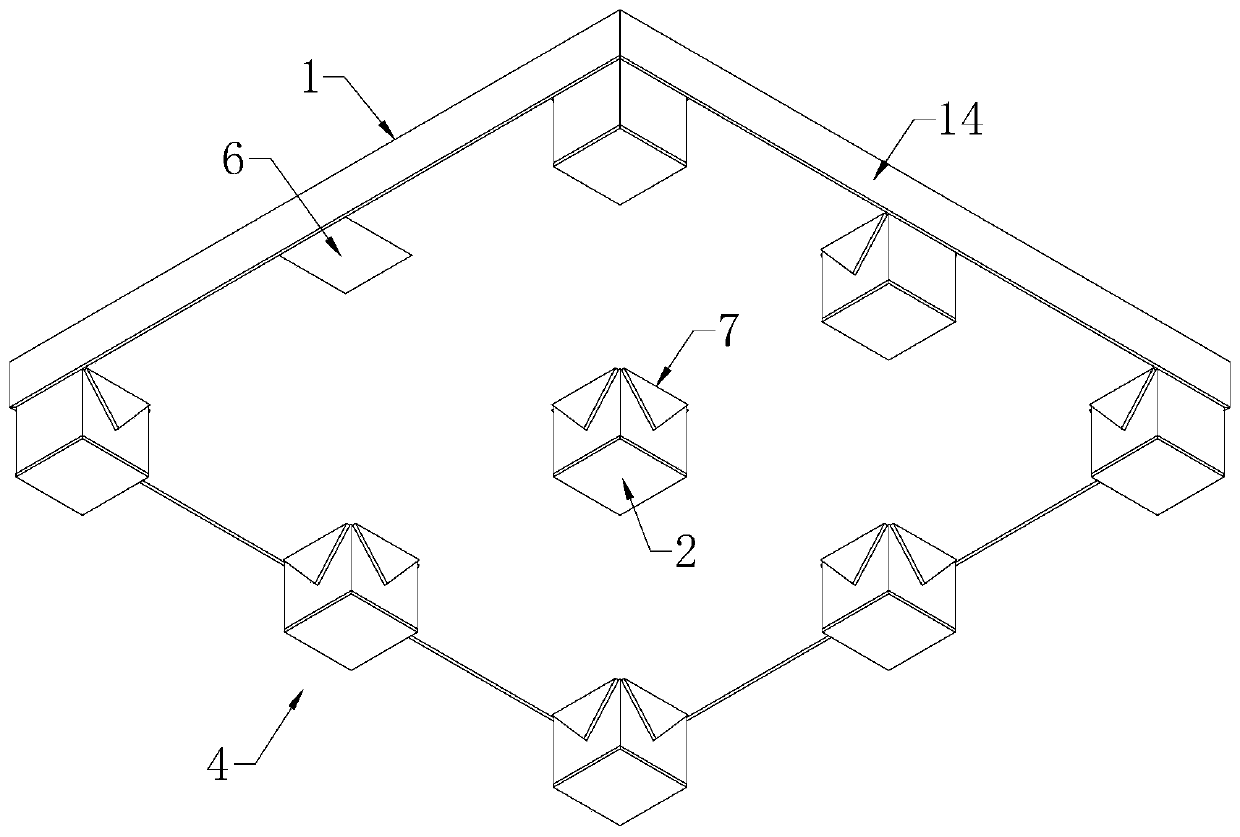

Paper tray and processing technology thereof

ActiveCN110127165AShorten production and processing operation timeImprove structural strengthBox making operationsPaper-makingBiochemical engineeringUltimate tensile strength

The invention discloses a paper tray and a processing technology thereof, and relates to the technical field of tray. A digital model pre-design mode and a component unit standardized production assembly mode are adopted to cooperate to produce a paper tray, the respective structural strength of a tray body and foot columns are improved, meanwhile, the structural strength of connection between thefoot columns and the tray body and the transmission uniformity of a load between the foot columns and the tray body are improved, the production operation of the tray body, the production operation of the foot columns and the combining production operation of the tray body and the foot column are completed step by step in an adhesive hot pressing operation manner, which is not only helpful to shorten the production and processing operation time of the paper tray, but also helpful to improve the structural strength and the use stability of the paper tray, so that the problem that the paper tray split easily or even deform when the paper tray support heavy articles is solved.

Owner:景晖包装(上海)股份有限公司

Railway vehicle and end wall thereof

ActiveCN112172851AReduce longitudinal impactEnhanced end seal performanceRailway transportAxle-box lubricationCar doorChassis

The invention discloses a railway vehicle and an end wall thereof, wherein the end wall is used for being matched with a roof, an underframe and a side-pull vehicle door of a vehicle body, and comprises an end wall body and a buffer pad, wherein the inner end surface and the outer end surface of the framework of the end wall body are respectively coated with a skin, two side plate edges of the outer skin are respectively provided with bent sections, the bent sections are formed by extending outwards along the plate surface of the outer skin and then longitudinally extending inwards, and the bent sections and the corresponding side surfaces of the framework are encircled to form accommodating grooves for accommodating the side edges of the end parts of the side-pulling vehicle door; the buffer pad is arranged in the groove bottom of the accommodating groove so as to be matched with the side edge of the side-pulling vehicle door in an abutting mode. According to the scheme, through structural optimization, vibration of the vehicle door can be effectively reduced, and a good technical guarantee is provided for improving the running performance of the whole vehicle.

Owner:CRRC QIQIHAR ROLLING CO LTD

Non-woven fabric with stable structure and preparation method thereof

InactiveCN112080947AStable structureImprove the strength of the connection structureVegetal fibresYarnPolymer science

The invention discloses a non-woven fabric with a stable structure and a preparation method thereof. The non-woven fabric comprises a non-woven fabric core layer, skeleton twisted fiber yarns and a surface coating; the skeleton twisted fiber yarns are formed by spirally winding spandex elastic fibers on the surfaces of bamboo fiber yarns, and due to the elastic characteristic of the spandex elastic fibers, after the bamboo fiber yarns are connected to multiple connecting protruding strips and multiple connecting strip-shaped grooves in a penetrating mode, the spandex elastic fibers can be elastically tightened to be connected to the multiple connecting protruding strips in a penetrating mode, in this way, the structures of the multiple connecting protruding strips of the non-woven fabric core layer are in the tendency of being elastically tightened and expanded, and then the structures of the multiple connecting protruding strips of the non-woven fabric core layer are more stable.

Owner:盐城恒天无纺布科技有限公司

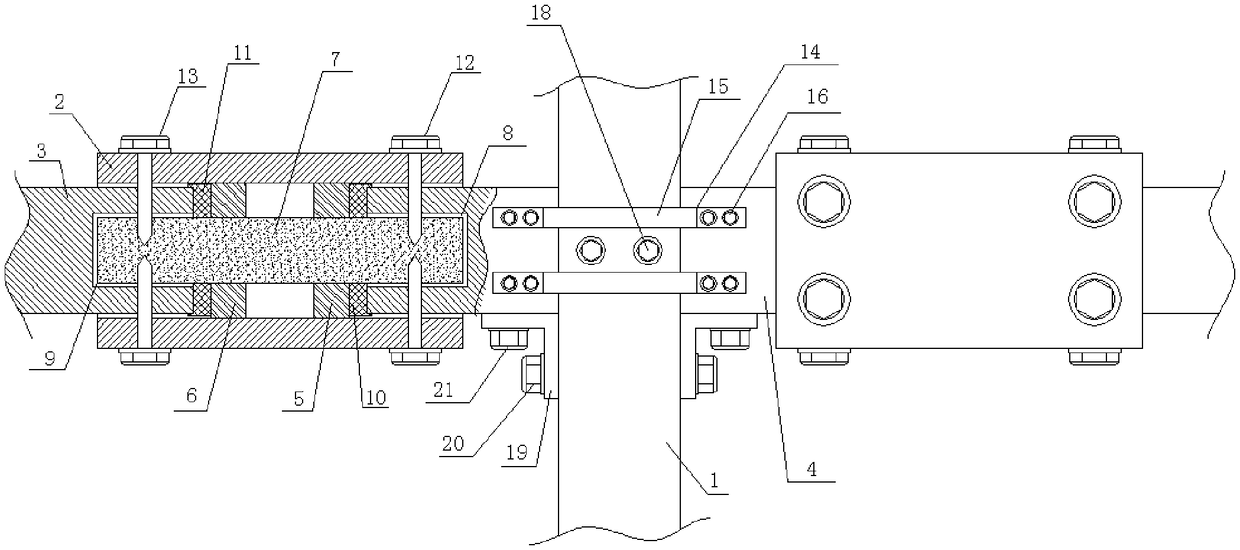

Grouting device for steel shear structure assembling type building and construction method of grouting device

ActiveCN106401191AHigh strengthImprove seismic performanceWallsBuilding material handlingSteel barMaterials science

The invention discloses a grouting device for a steel shear structure assembling type building and a construction method of the grouting device. The grouting device comprises grouting sleeves arranged in an H steel beam web, grouting communication pipes, reinforcing steel bar inserting holes, reinforcing steel bar stretching-out holes, and lower layer reinforcing steel bar inserting holes, wherein the reinforcing steel bar inserting holes and the reinforcing steel bar stretching-out holes are formed in an upper wing edge plate of an H steel beam, the lower layer reinforcing steel bar inserting holes are formed in a lower wing edge plate of the H steel beam, the two ends of the grouting sleeves are welded to the upper wing edge plate and the lower wing edge plate of the H steel beam; the reinforcing steel bar inserting holes and the reinforcing steel bar stretching-out holes of the upper wing edge plate and the lower layer reinforcing steel bar inserting holes of the lower wing edge plate are all communicated with the interiors of the grouting communication pipes, the grouting communication pipes are arranged on the inner upper side of the lower wing edge plate of the H steel beam, the grouting sleeves and the grouting communication pipes are communicated, and the aim that slurry is grouted into the grouting sleeves through one-position connection is achieved. The grouting device is simple in structure and novel in design, and facilitates industrialized production, the structural layout and the grouting method of interlayer reinforcing steel bar connecting sleeves are expanded, and the grouting construction speed and the grouting quality are improved.

Owner:曲周县和盛新型建筑材料有限公司

Method for manufacturing metal composite plate

InactiveCN108312686ALow manufacturing costImprove the strength of the connection structureLamination ancillary operationsLaminationExplosion weldingMetal

The invention discloses a method for manufacturing a metal composite plate. The method for manufacturing the metal composite plate comprises the following steps: 1) forming sawtooth-shaped waves on the surfaces of a metal plate A and a metal plate B; 2) correspondingly adhering the waved surface of the metal plate A to the waved surface of the metal B; 3) treating the adhered metal plate A and metal plate B by using a rolling mode of a rolling machine or an explosion welding method, thereby obtaining the metal composite plate of the metal plate A and the metal plate B. By adopting the method for manufacturing the metal composite plate, the manufacturing cost of the metal composite plate can be remarkably reduced, and in addition, the obtained composite plate is relatively high in structural strength.

Owner:CHONGQING NANJINGLIN TECH DEV CO LTD

Micro asymmetric ceramic electrode plug

The invention discloses a micro asymmetric ceramic electrode plug. Compared with a traditional symmetric electrode plug with simple structure, the micro asymmetric electrode plug comprises a ceramic base body, a ladder-shaped groove and heading leg wires; ceramic powder materials are made into a finished product of an electrode plug through processes of mould forming, sintering, heading leg wire brazing and sealing and the like; the micro asymmetric ceramic electrode plug is suitable for being filled with a thin film type energy conversion element chip with the length of not more than 0.5mm, the width of not more than 0.5mm and the height of not more than 0.5mm; the micro asymmetric ceramic electrode plug has requirements on minimization of diameter and height and maintenance of structural strength and electric insulation strength under the condition that the electrode plug has a basic function of the traditional electrode plug; a force of connection between the electrode plug and each leg wire is not less than 50N and the antistatic value is not less than 1.9kV; compared with a firing assembly comprising a semiconductor bridge transduction element and an energetic material, the micro asymmetric ceramic electrode plug has the characteristics of low firing energy, short action time, good action consistency and good antistatic and anti-radio frequency capabilities, and is suitable for a microelectromechanical system.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

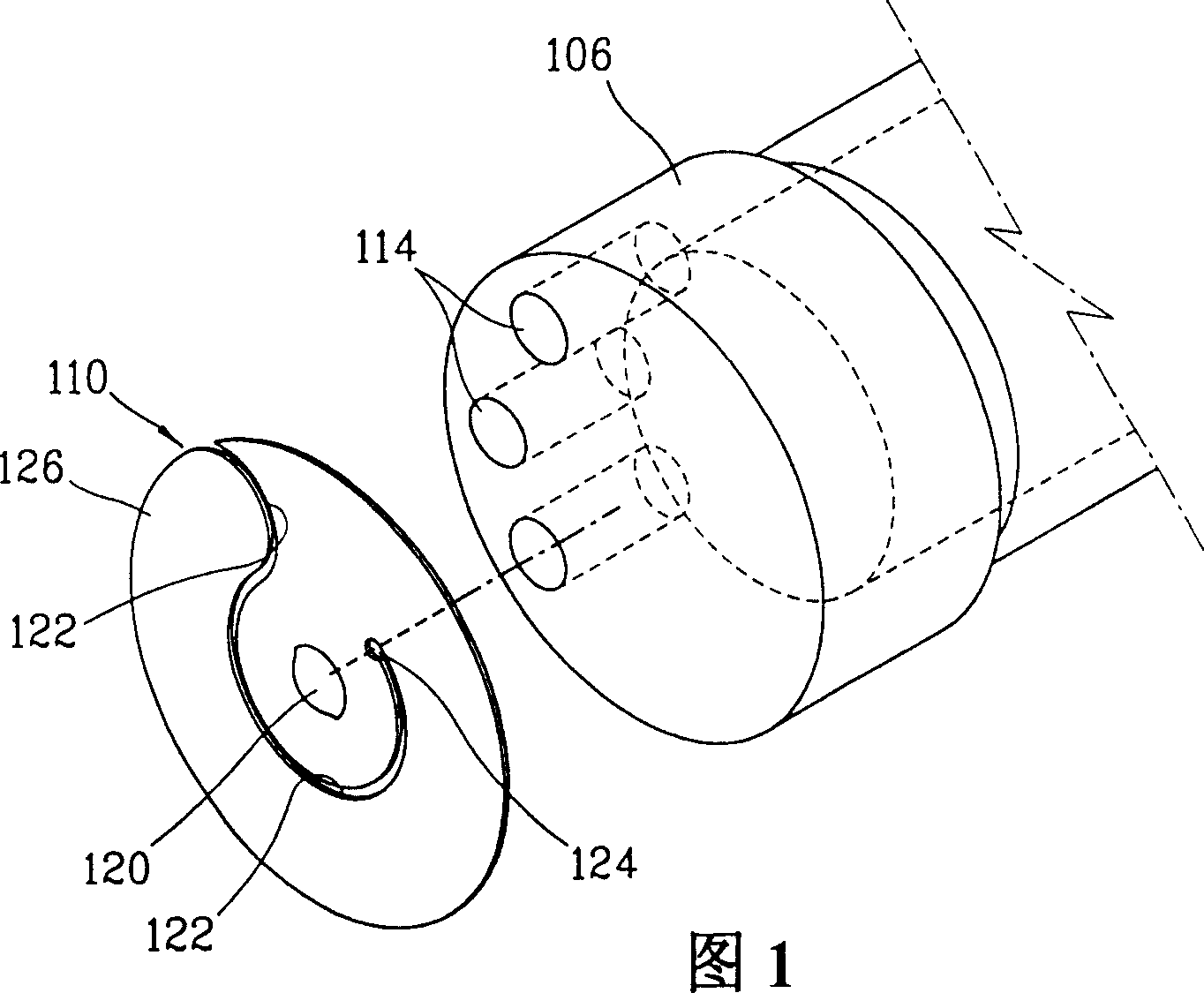

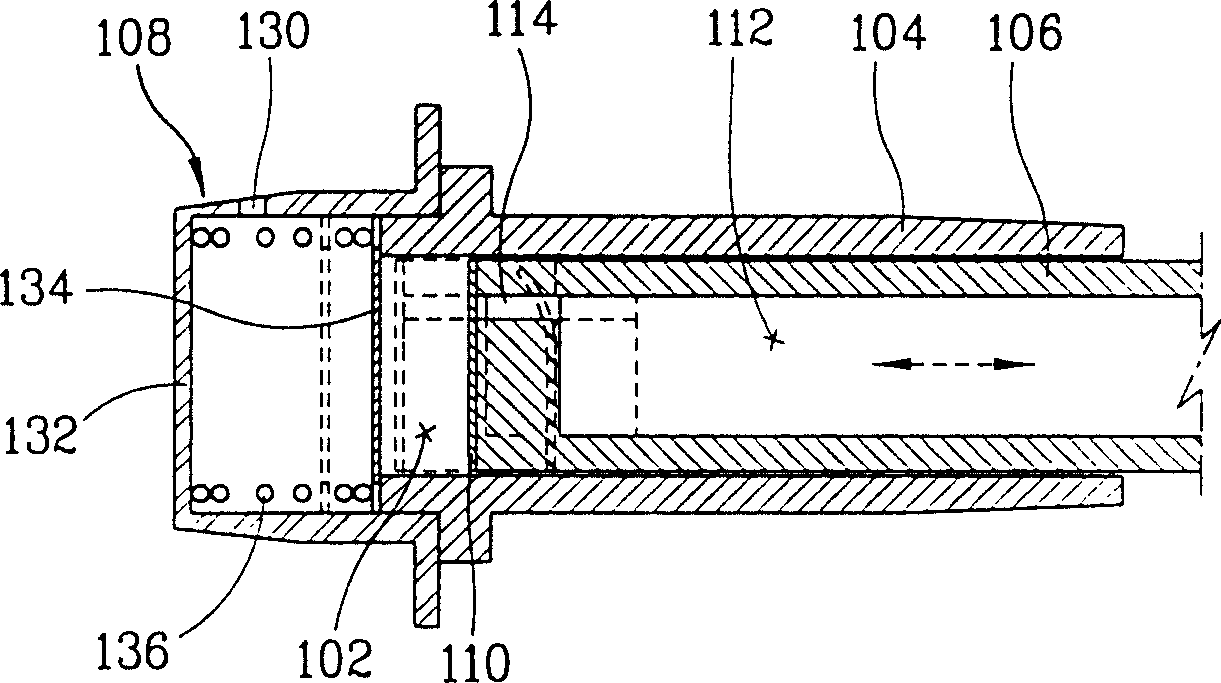

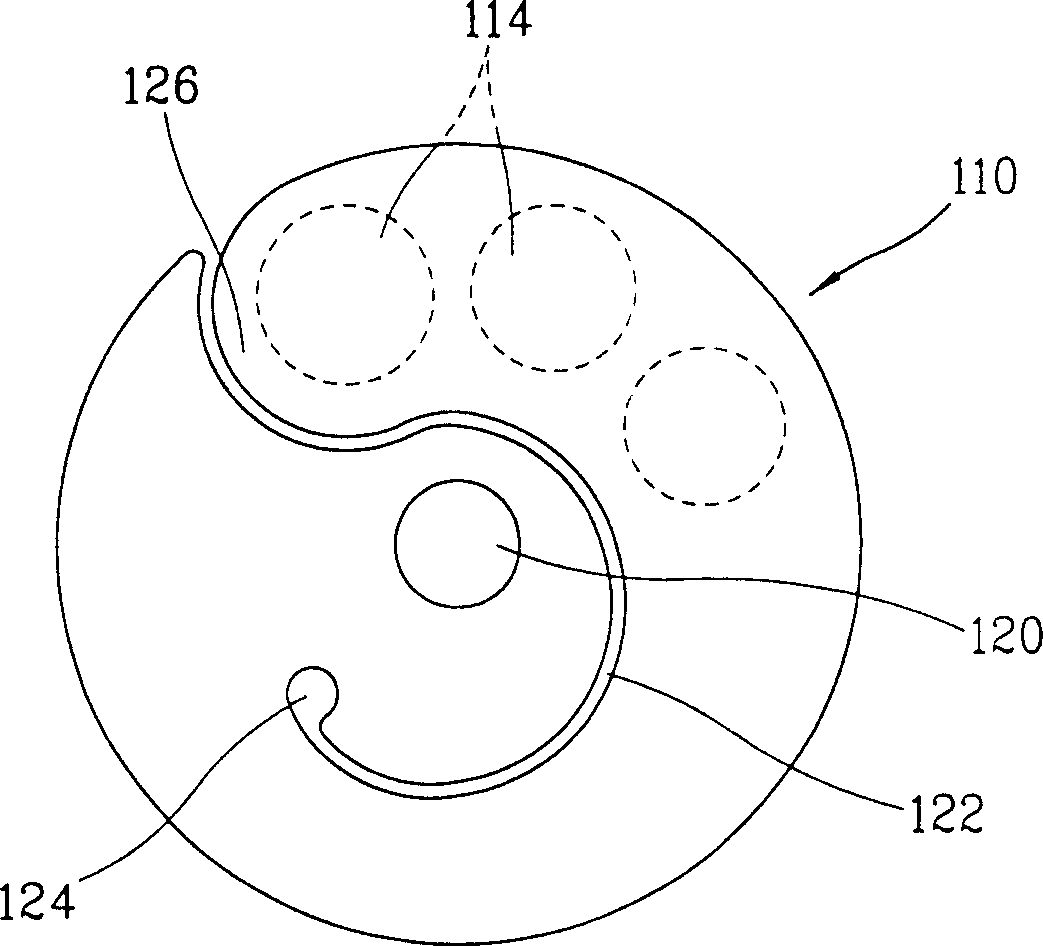

Suction valve assembly of reciprocating compressor

InactiveCN1229578CReduce dead zoneImprove the strength of the connection structurePositive displacement pump componentsPiston pumpsDead volumeEngineering

A suction valve assembly of a reciprocating compressor includes: an inertial valve having a valve plate detachably attached at a valve seat of a piston, and opening and shutting the suction passage, and a support bar extended from a rear side of the valve plate, inserted into the suction passage and a plurality of guide grooves at regular intervals in a circumferential direction thereof; and guide pins slidably inserted into the guide grooves of the inertial valve and fixed at the piston to limit an opening rate of the valve plate, thereby minimizing a dead volume inside a compression chamber by making a valve side forming the compression chamber to be plane and strengthening a structural coupling strength of a valve.

Owner:LG ELECTRONICS INC

Manufacturing technology for handrail

ActiveCN109106123AAvoid deformation damageImprove assembly efficiencyStoolsChairsManufacturing technologyAgricultural engineering

The invention belongs to the technical field of chair accessories and especially relates to a manufacturing technology for a handrail. The manufacturing technology for the handrail can be used for solving the technical problems of low assembling efficiency, and the like, of the prior art. The manufacturing technology for the handrail comprises the following steps: A) preparing raw materials: preparing an integrally injection-molded handrail sleeve, and manufacturing an inner support rod and a handrail plate; B) assembling: sleeving the lower end of the handrail sleeve from the upper end of anL-shaped elbow, blocking the middle part of a bar-shaped connecting plate in a locating slot, and then inserting a fastener into a stepped hole on the middle part of the bar-shaped connecting plate, stretching the fastener into a nut and connecting with the nut through a thread, distributing the bar-shaped connecting plate and a U-shaped connecting part in a crossing form, penetrating two bolts through the upper end of the handrail sleeve, penetrating the bolts through bolt holes on the two ends of the bar-shaped connecting plate and connecting with the handrail plate, thereby obtaining the handrail. The manufacturing technology for the handrail has the advantage that the assembling efficiency can be improved.

Owner:安吉凯信转椅配件厂(普通合伙)

PTFE heat exchanger

ActiveCN106679454ALow costImprove the strength of the connection structureCorrosion preventionHeat exchanger casingsPlate heat exchangerEngineering

The invention discloses a PTFE heat exchanger and relates to the technical field of heat exchange equipment. The PTFE heat exchanger comprises a tube plate made from a PTFE material. A plurality of tube holes are formed in the tube plate. Heat exchange tubes made from the PTFE material are arranged in the tube holes. The heat exchange tubes and the tube plate are welded together through bonding materials. The PTFE is adopted as the raw material for the whole heat exchanger, so that the PTFE heat exchanger is low in weight, resistant to corrosion, high in strength of a connecting structure, and long in service life.

Owner:浙江赛迅环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com