Manufacturing technology for handrail

A manufacturing process and handrail technology, applied in the field of handrail manufacturing technology, can solve problems such as inability to assemble accurately, reduce assembly efficiency, and impact deformation of connecting plates, and achieve the effects of reducing mold opening costs, improving production and manufacturing efficiency, and avoiding deformation and damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

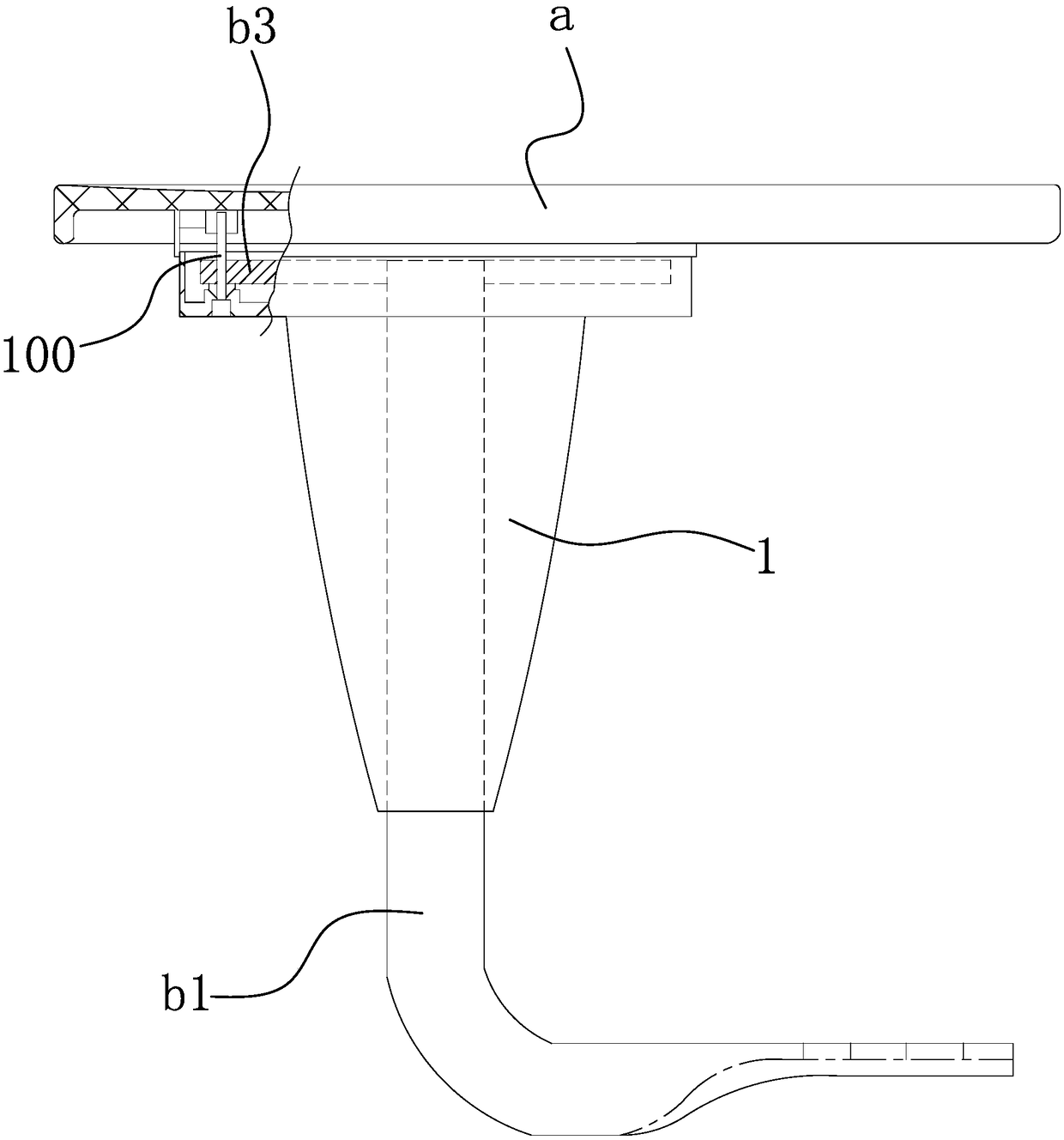

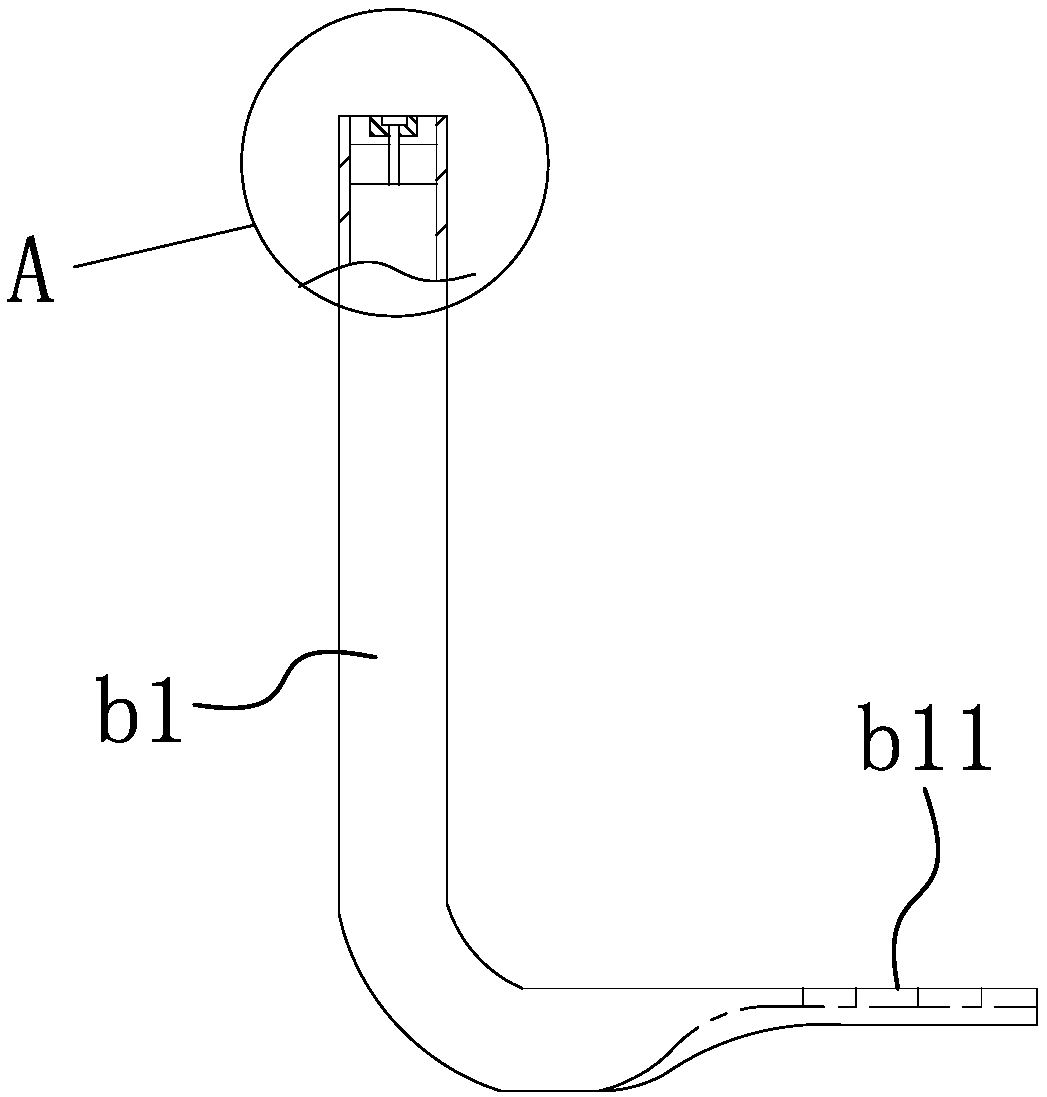

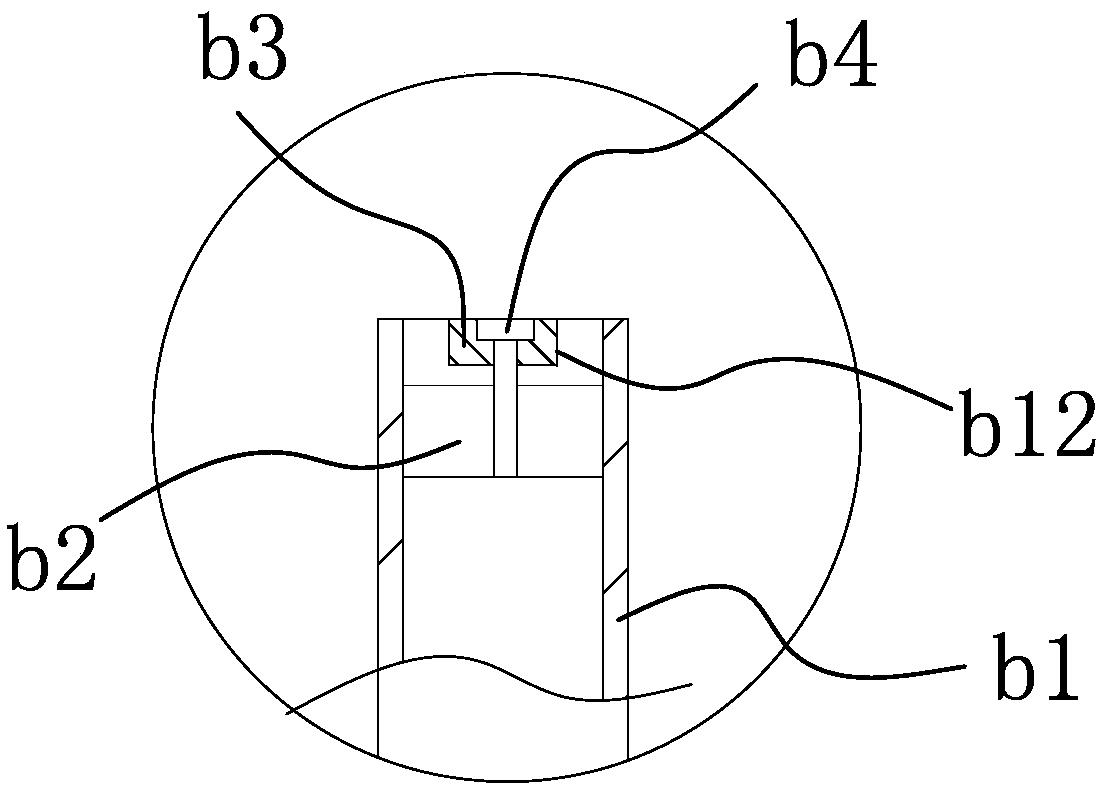

[0077] Such as Figure 1-5 with Figure 10 as shown,

[0078] This handrail manufacturing process comprises the steps:

[0079] A, material preparation: manufacture the armrest cover 10 of integral injection molding; manufacture inner support rod and armrest plate; the production process of this inner support rod comprises the following steps:

[0080] S1. Process the L-shaped elbow b1, take a metal pipe, fix the metal pipe horizontally, and then use a forming mold to process a U-shaped connection part b11 on one end of the metal pipe and punch several connection positioning holes on the U-shaped connection part b11 b111, mill out the positioning groove b12 at the other end of the metal pipe, and then bend the middle part of the metal pipe by 90°, that is, make an L-shaped elbow;

[0081] Process the strip connecting plate b3, take the metal plate, process at least one strip plate with a stamping die, then use the punching die to process nail holes b31 at both ends of the s...

Embodiment 2

[0115] The structure and working principle of this embodiment are basically the same as those of the first embodiment, except that the cylindrical column a14 is molded by injection molding and the metal connecting sleeve a2 is embedded.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com