Metal plate stamping die

A technology for stamping dies and metal sheets, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problem of inability to clean up waste in the lower die seat, and achieve the effects of preventing adhesion, tight coordination, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

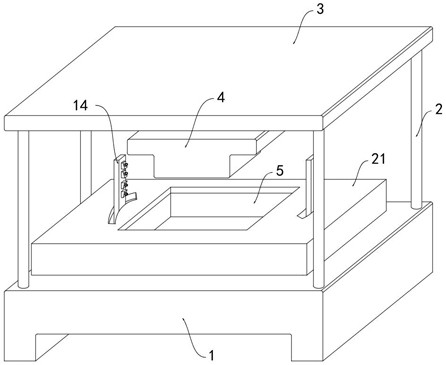

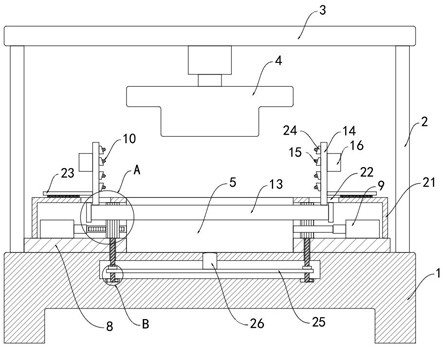

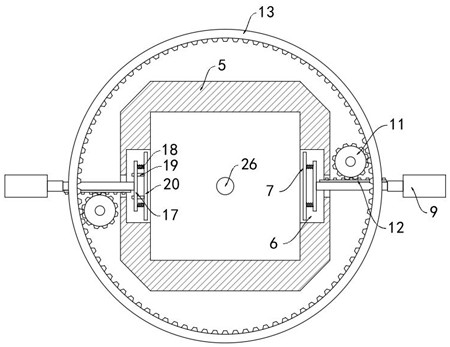

[0028] Such as Figure 1-6 As shown, a sheet metal stamping die includes a base 1, a pillar 2 and a top plate 3, an upper die 4 is installed on the top plate 3, and a stamping cylinder is arranged between the upper die 4 and the top plate 3 to drive the upper die 4 to move down Stamping, the base 1 is provided with a lower mold base 5 matching the upper punch 4, and both sides of the lower mold base 5 are provided with chute 6, and a clamping assembly 7 slides in the chute 6, and the two sides of the lower mold base 5 Both are provided with mounting base 8, on which hydraulic cylinder 9 is fixed, and the output end of hydraulic cylinder 9 is connected with clamping assembly 7, and the position of clamping assembly 7 can be controlled by controlling the expansion and contraction of hydraulic cylinder 9, that is, to realize the The metal plates of different specifications and sizes are fixed, and the base 1 is provided with a chip removal mechanism 10 .

[0029] The chip remova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com