Rotary type photo-thermal power station heat absorber and uniform heat absorption control method

A technology for a solar thermal power station and a heat absorber, which is applied to solar collector controllers, solar thermal power generation, solar collectors, etc. It can improve the effective utilization of energy, prolong the average service life, and reduce the operation and maintenance cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

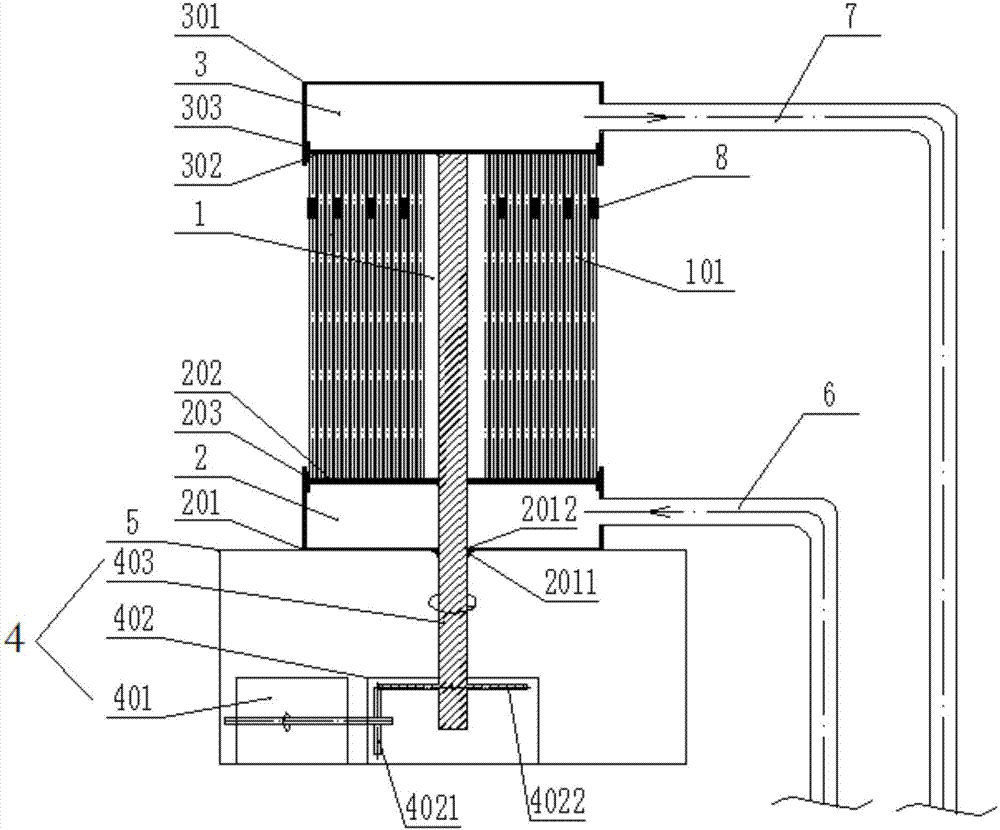

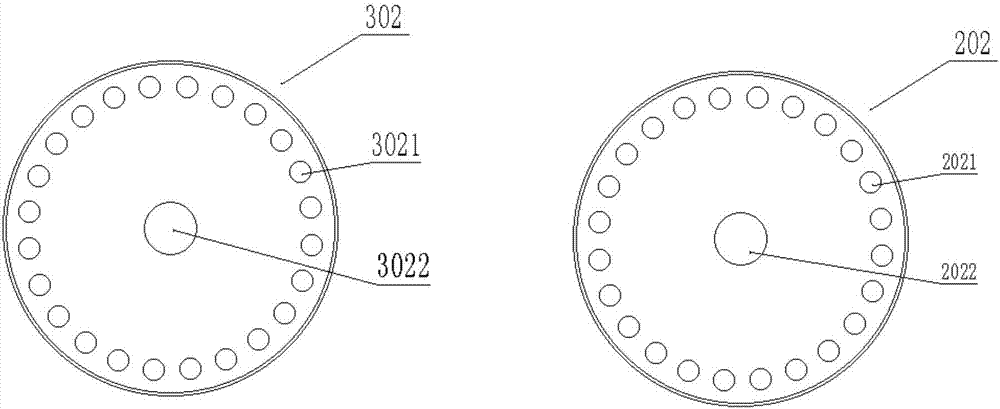

[0051] figure 1 Schematic diagram of the structure of the heat sink of the rotary solar-thermal power station provided in Embodiment 1 of the present invention;

[0052] like figure 1 As shown, a heat absorber of a rotating photothermal power station is used to absorb solar radiation heat energy and heat a heat collection medium. The heat absorber includes:

[0053] The cold medium header assembly 2 is connected with the cold medium pipeline 6 and is used to accommodate the cold heat collecting medium entering from the outside;

[0054] The heat medium header assembly 3 is connected to the heat medium pipeline 7, and is used to accommodate the heat heat collection medium generated after heating;

[0055] The cavity assembly 1 is arranged between the cold medium header assembly 2 and the hot medium header assembly 3 and is sealed and connected, and is used for circulating the heat collecting medium, absorbing solar radiation heat energy, and transferring heat energy to the he...

Embodiment 2

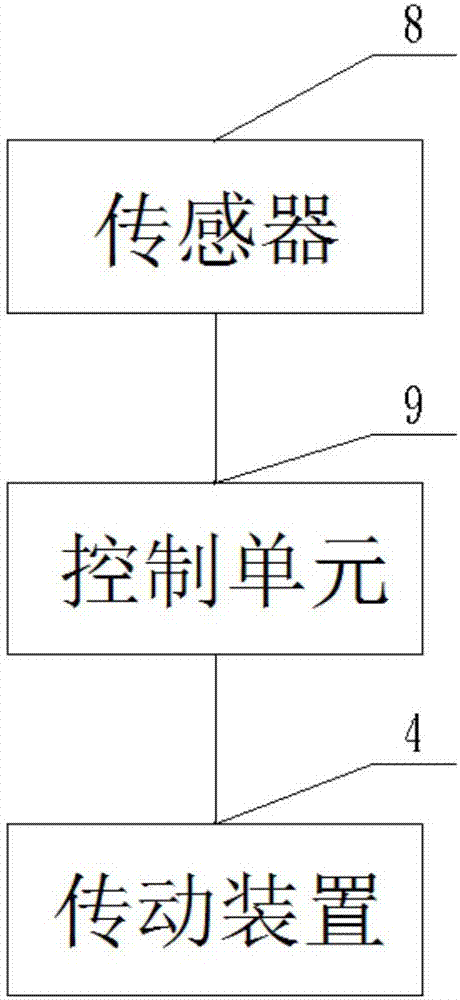

[0093] Figure 4 The flow chart of uniform endothermic control provided by Embodiment 2 of the present invention.

[0094] This embodiment provides a uniform heat absorption control method, which is applied to the heat absorber of the above-mentioned rotary solar thermal power station, such as Figure 4 As shown, the uniform endothermic control method comprises steps:

[0095] S1, obtain the temperature signal of each heat collecting tube 101, and calculate the average temperature of the heat collecting tube 101 in each zone in the circumferential direction of the heat absorber according to the acquired temperature signal of each heat collecting tube 101; in this embodiment, the upper collector of the heat absorber The heat pipe 101 is equally divided into a plurality of zones according to the circumferential direction, and the average temperature of the heat collector tubes 101 in each zone is calculated by averaging the temperatures detected by each heat collector tube 101 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com