Main cable saddle head structure and forming method thereof

A forming method and the technology of the main cable saddle, which are applied to the edge of the workpiece, buildings, bridges, etc., can solve the problems that are not conducive to improving the stability and reliability of the permanent main cable saddle structure, weak shear resistance of the saddle head, and structural strength. Poor connection strength and other problems, to achieve the effect of strong operability and practicability, strong shear resistance, and enhanced connection structure strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

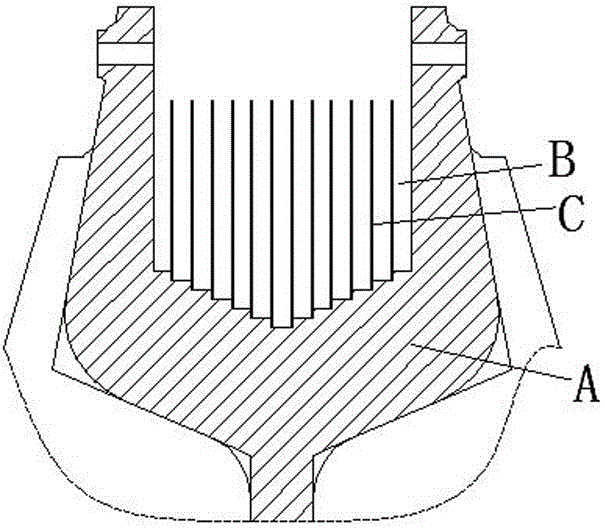

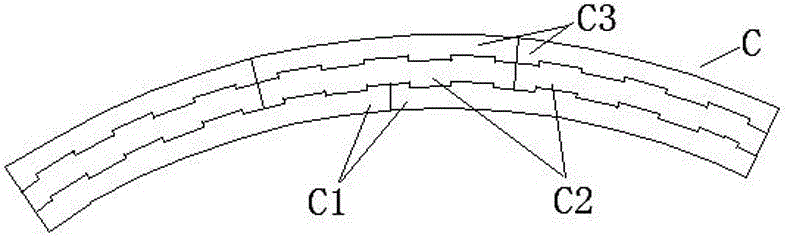

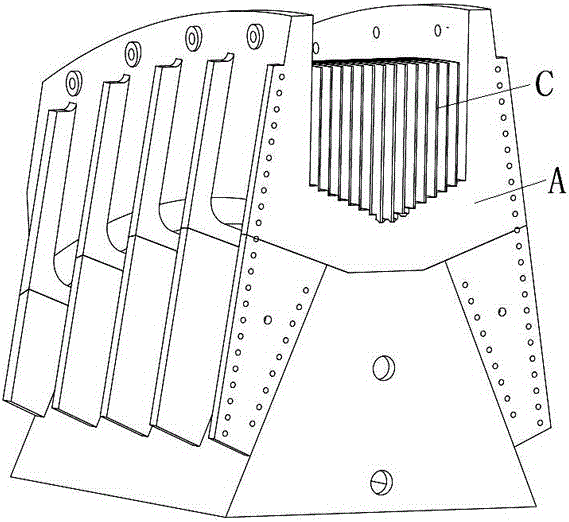

[0026] see image 3 and Figure 4 As shown, the present invention is the saddle head structure of the main cable saddle of the suspension bridge engineering, which includes the saddle body A. The saddle head body A is a cast-welded structure with a saddle groove B, and a plurality of partitions C are vertically welded in the saddle groove B in the form of groove welds, and each partition C is an integral structure; each of the aforementioned partitions The thickness of C is in the range of 10-16mm, such as 10mm, 13mm or 16mm, and it only needs to match the design requirements.

[0027] see Figure 5 , Figure 6 and Figure 7 As shown, the forming method of the saddle head structure of the above-mentioned main cable saddle comprises the following steps:

[0028] Step 1. Casting and finish machining a pommel body A that meets the design requirements, and the pommel body A has a saddle groove B;

[0029] According to the design requirements, taking the central area of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com