Patents

Literature

226results about How to "Reduce dead zone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

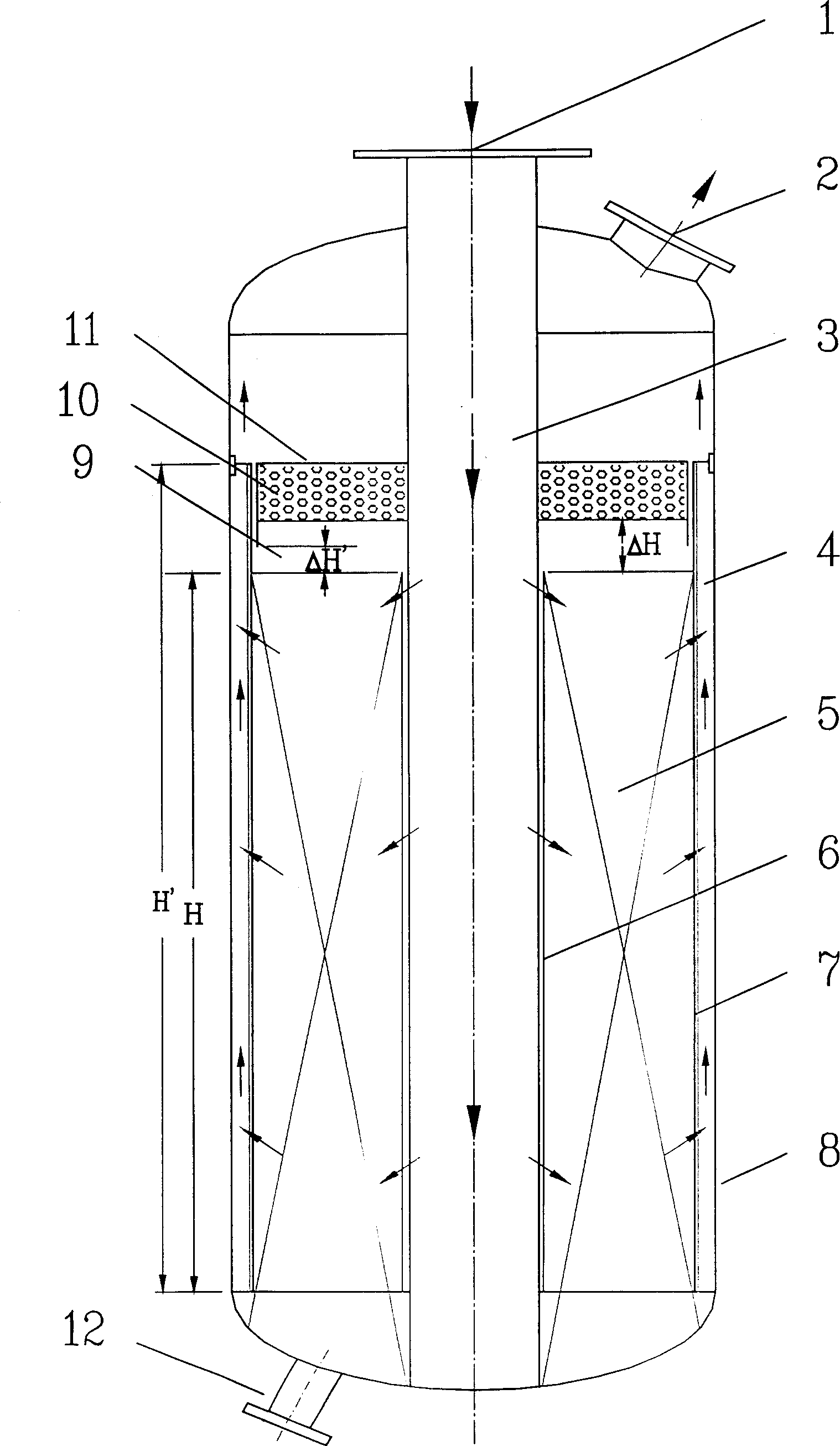

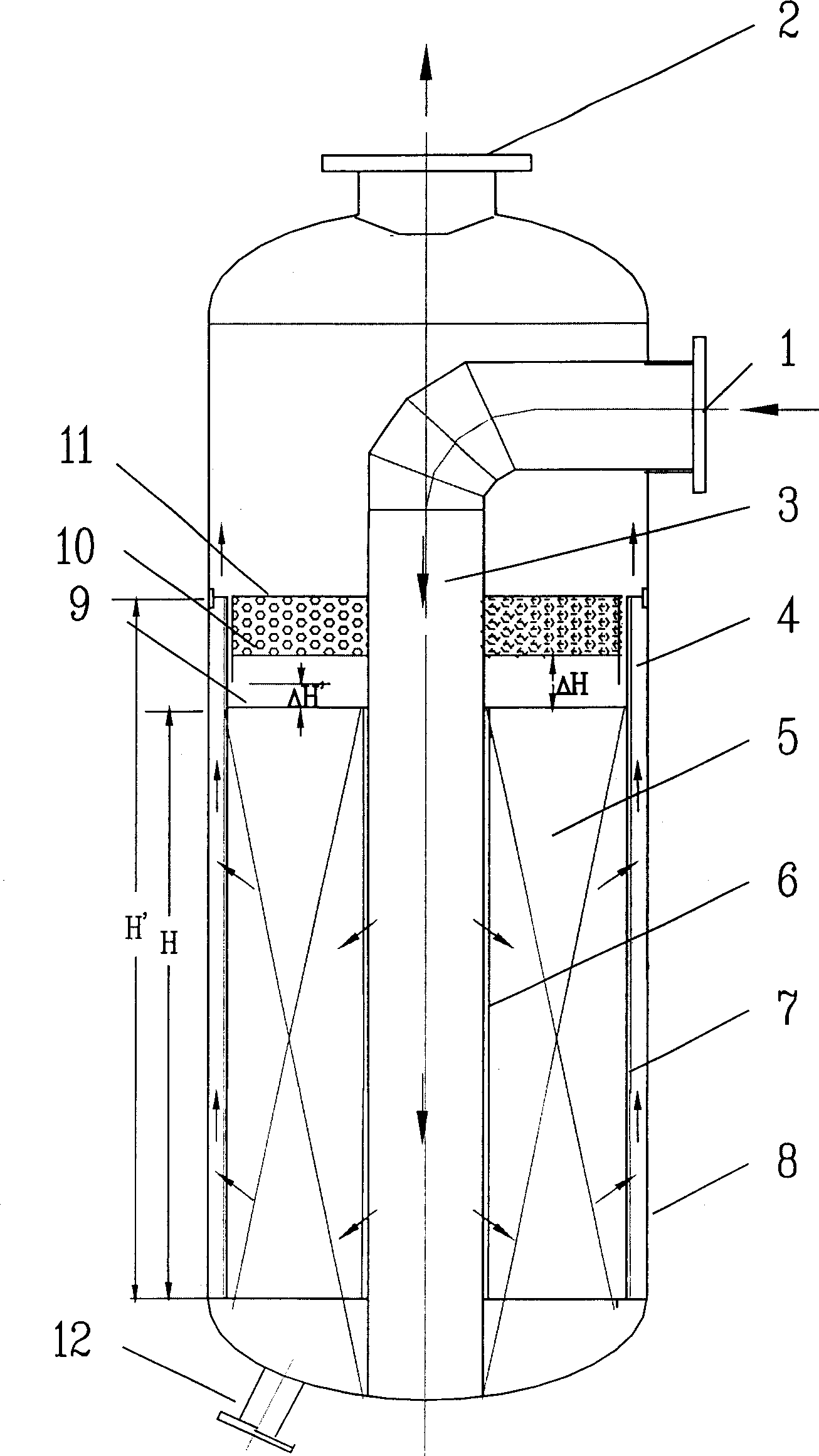

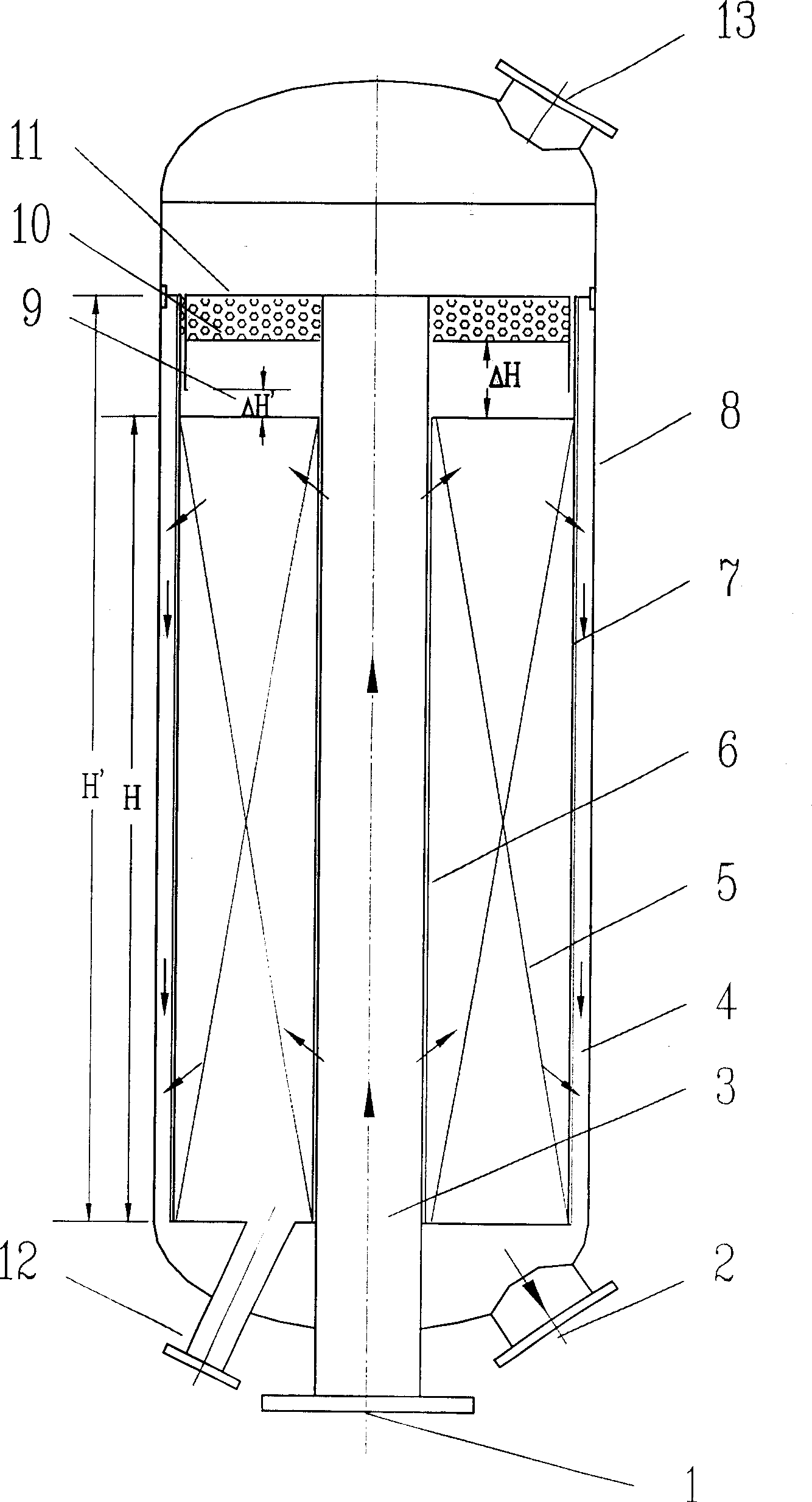

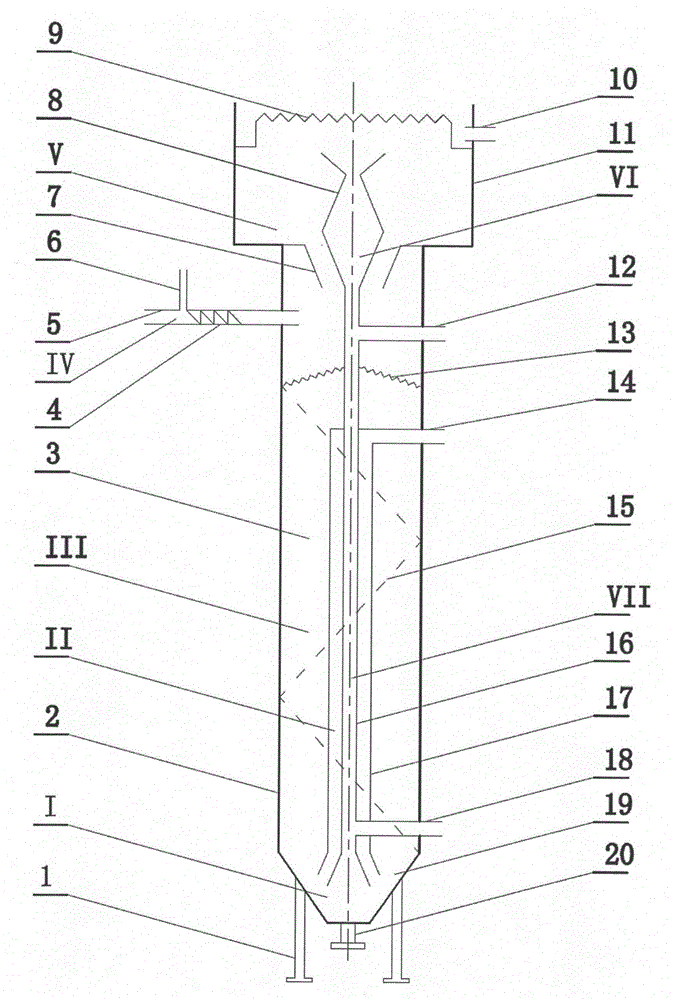

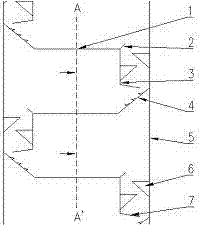

Catalytic reforming and catalytic dehydrogenation centrifugal type fixed bed radial reactor

InactiveCN1546217AAvoid heat lossUniform axial temperatureCatalytic crackingChemical/physical processesCatalytic reformingFixed bed

The invention discloses a kind of fixed bed reactor for catalytic reforming and dehydrogenation, the reactor uses a round pressure container which has a catalytic bed. The inlet and the outlet is at one side of the container, the catalytic bed is made up of outer multi-hole wall and round inner multi-hole wall, catalyst is filled in them, there has a cover sealing structure on the catalyst, the round inner multi-hole wall can uses variable hole-rate or zone structure. The reacting gas in the device flows centrifugally, the gas in the centre inner barrel and multi-hole outer barrel flow reversely.

Owner:EAST CHINA UNIV OF SCI & TECH

Minisize diffusion pump and preparation method thereof

InactiveCN1844681AReduce processing difficultyNo increase in processing difficultyMachines/enginesDiffusion pumpsMicrofluidicsPump chamber

The invention discloses a micro disperse pump which comprises a pump chamber, a one-way valve, a pump inlet, a pump outlet and a driving device inside the pump chamber; wherein, the one-way valve is between the pump chamber and the pump inlet, and between the pump chamber and the pump outlet; the one-way valve is a wedge disperse tube with different positive and passive fluxes; the fluid of pump chamber can be expanded and contracted to generate pressure difference, and according to the different pressures of positive and passive fluxes in the wedge disperse tube, to generate one-way continuous fluid transmission. The inventive micro disperse pump can drive fluid via adsorbing fluid or directly drive fluid. The production is based on silicon micro-mechanical processing technique and micro-mould technique, with simple process, lower cost, high reliability and the application for integrating other micro-fluid systems. It has wider application in the micro-fluid control analysis chip.

Owner:PEKING UNIV

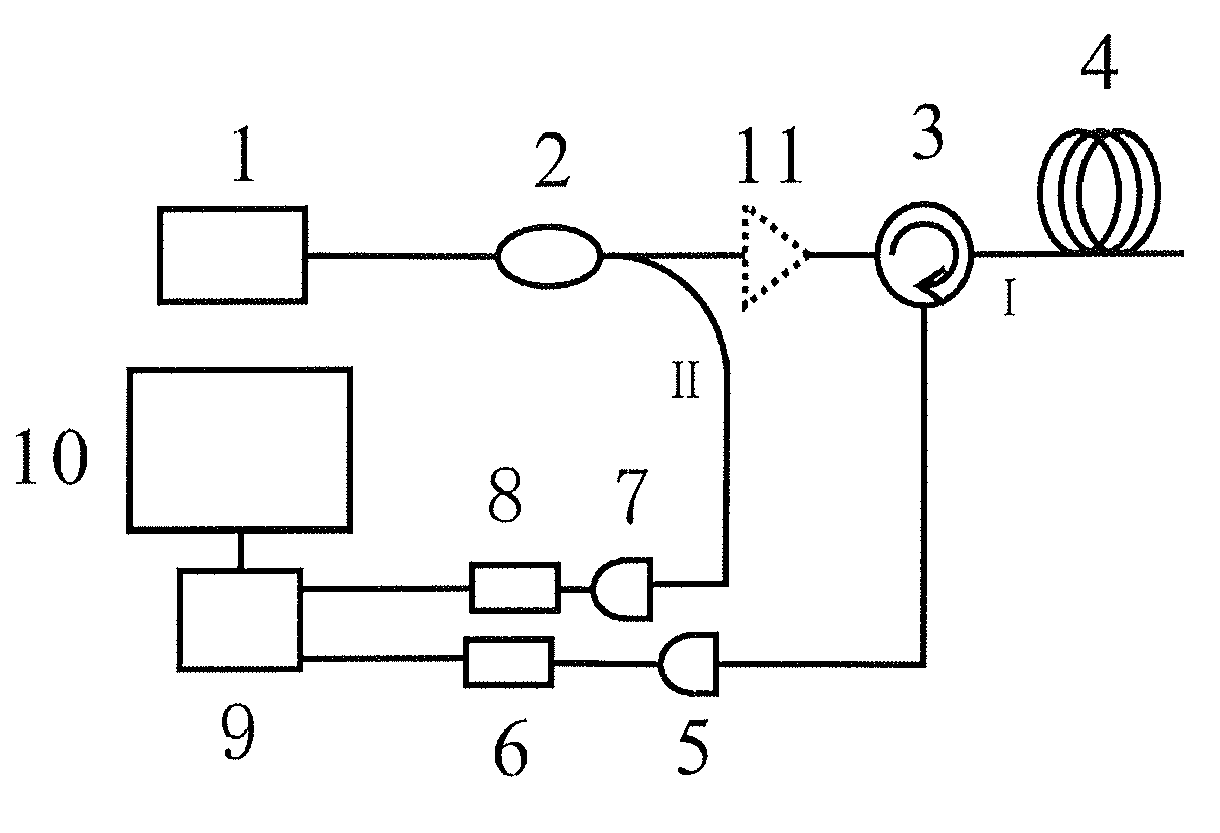

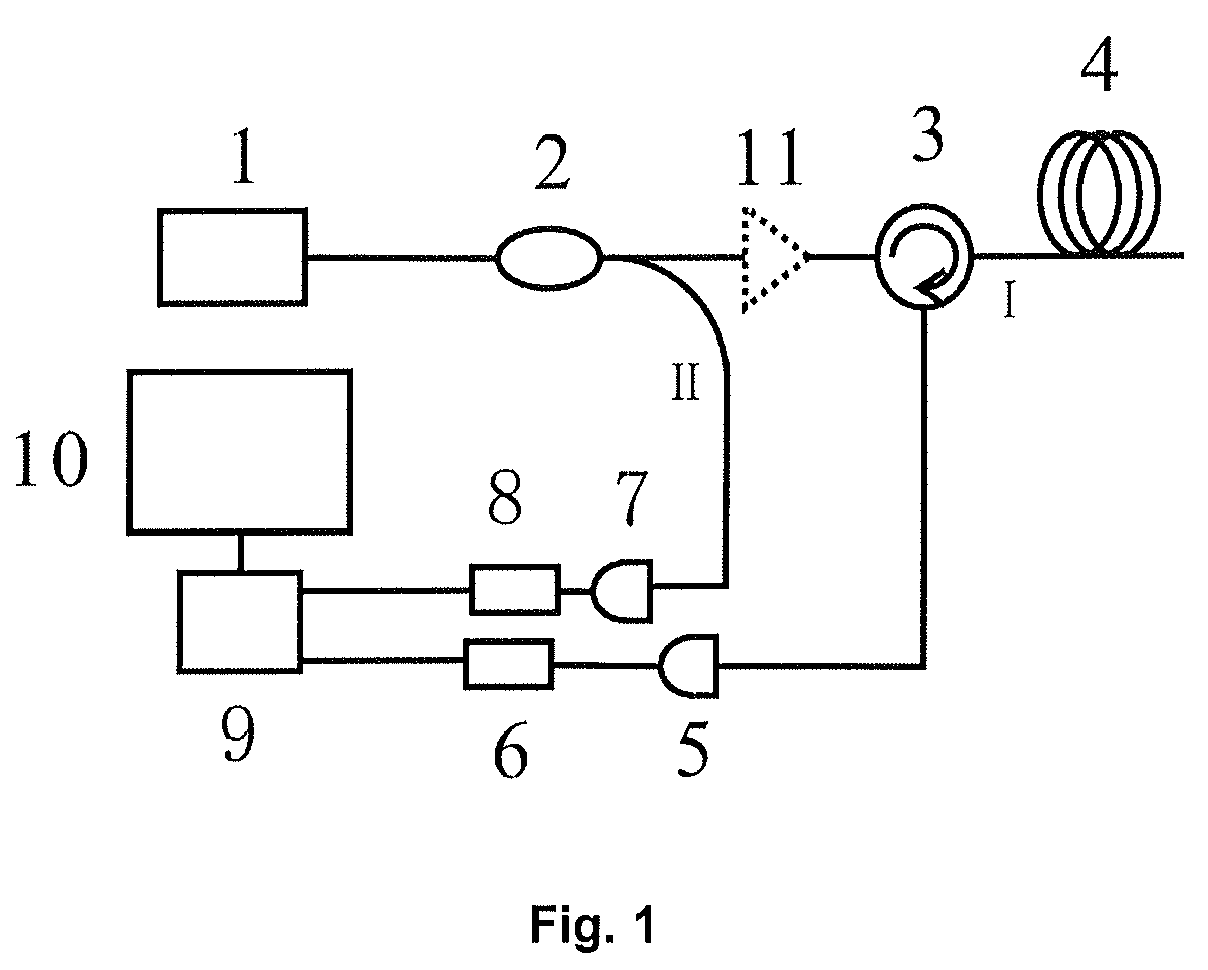

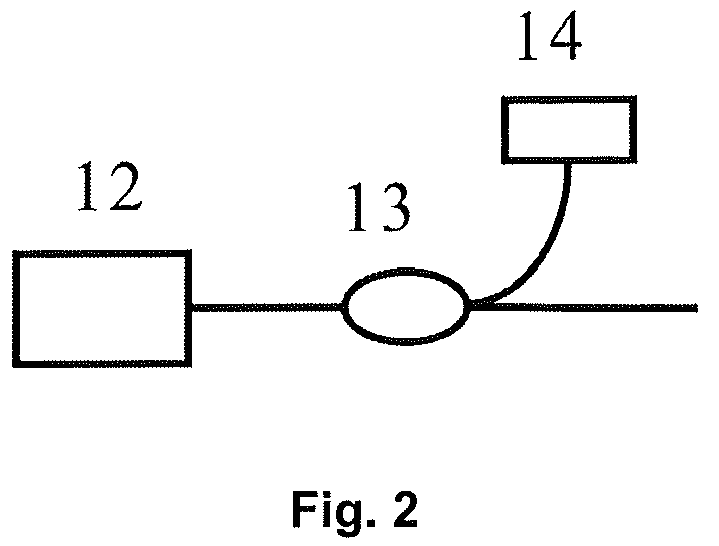

Chaotic optical time domain reflectometer method and apparatus

ActiveUS8502964B2High resolutionSimple structureAmplifier modifications to reduce noise influenceMaterial analysis by optical meansLaser transmitterPhotodetector

In a method and a corresponding apparatus for performing chaotic optical time domain reflectometer, the chaotic laser signal, generated by the chaotic laser transmitter, is split into probe signal I and reference signal II by a fiber coupler. Through an optical circulator, the probe signal I is launched into the test fiber and the echo light is converted into electrical signal by a photodetector and digitalized by an A / D converter. The reference signal II is converted into electrical signal by a photodetector and digitalized by another A / D converter. Two digital signals received from two A / D converters are correlated in a signal processing device to locate the exact position of faults in fibers. The result output is then displayed on a display device. This invention was developed to overcome the tradeoff problem between resolution and dynamic range of the pulse-based OTDR.

Owner:TAIYUAN UNIV OF TECH

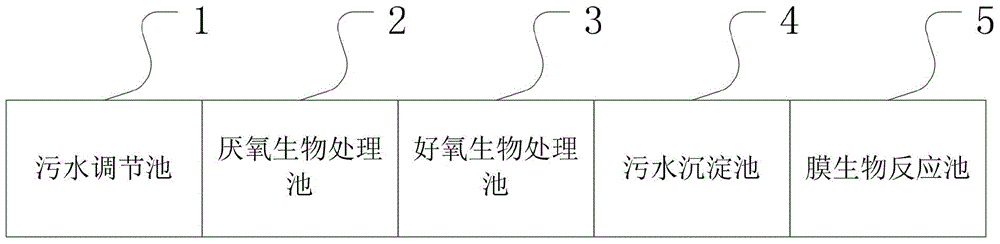

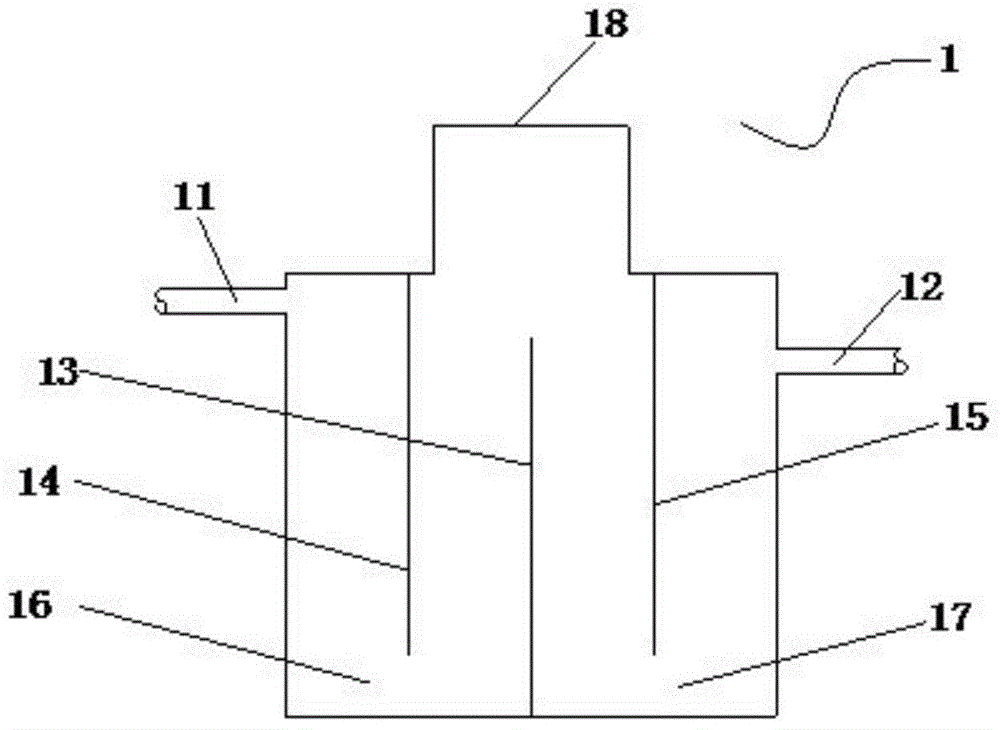

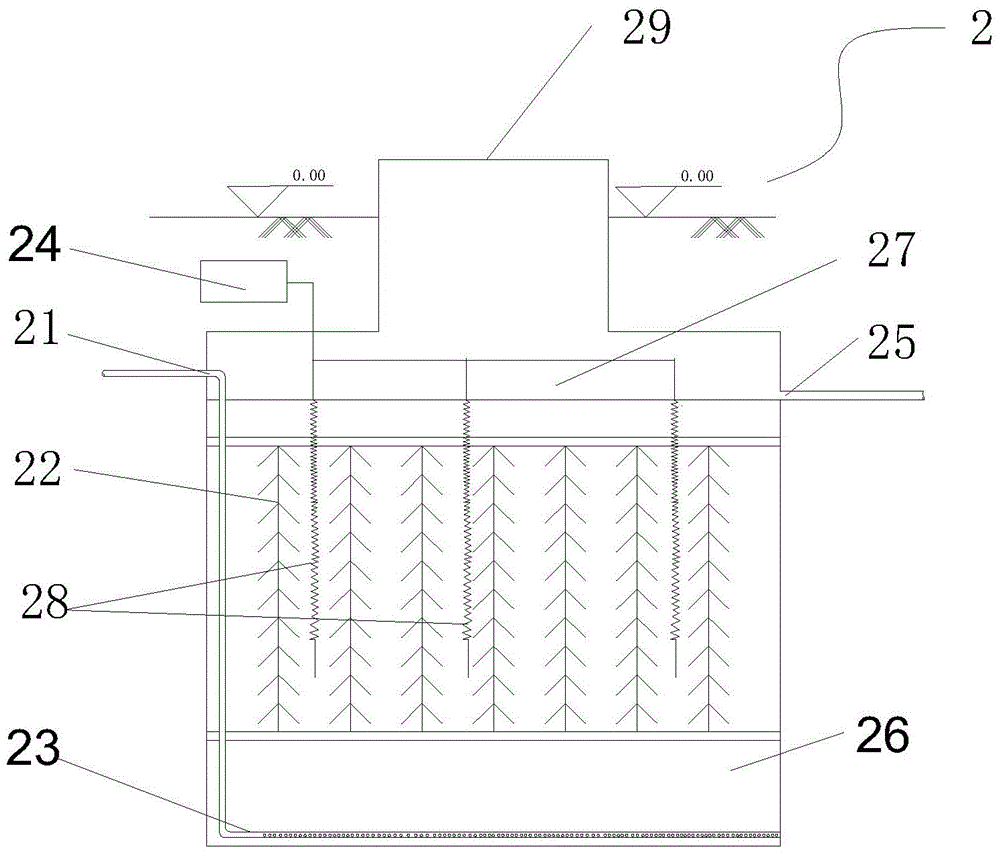

Integrated sewage treatment apparatus, and sewage treatment process flow using apparatus

InactiveCN104829056AImprove sealingEffective integrated processingTreatment using aerobic processesTreatment with anaerobic digestion processesOperational costsWater quality

The invention provides an integrated sewage treatment apparatus and a sewage treatment process flow using the apparatus. The sewage treatment apparatus comprises an anaerobic biological treatment pool, an aerobic biological treatment pool, a sewage sedimentation pool and a membrane biological reaction pool; and the anaerobic biological treatment pool, the aerobic biological treatment pool, the sewage sedimentation pool and the membrane biological reaction pool are sequentially connected. The apparatus is used to carry out effective integrated treatment on sewage. The integrated sewage treatment apparatus has the advantages of good sealing property, strong adaption ability to various foundation conditions, acid and alkali resistance, oxidation resistance, no deformation under high or low temperature, and long service life. The sewage production cycle and the onsite construction installation cycle are short, so the apparatus can be fast used; early disposable investment is small, so the operating cost is low; the quality of discharged water is stable, and pollution discharge is maximally treated; the sewage treatment apparatus has a small size, saves space, can be conveniently carried; and the apparatus can be used in a landfill mode, so the occupied earth's surface area is extremely small, noise is small, and the apparatus can be extremely well combined to surrounding living environment.

Owner:BEIJING GUODONG SHANGDE WATER INVESTMENT

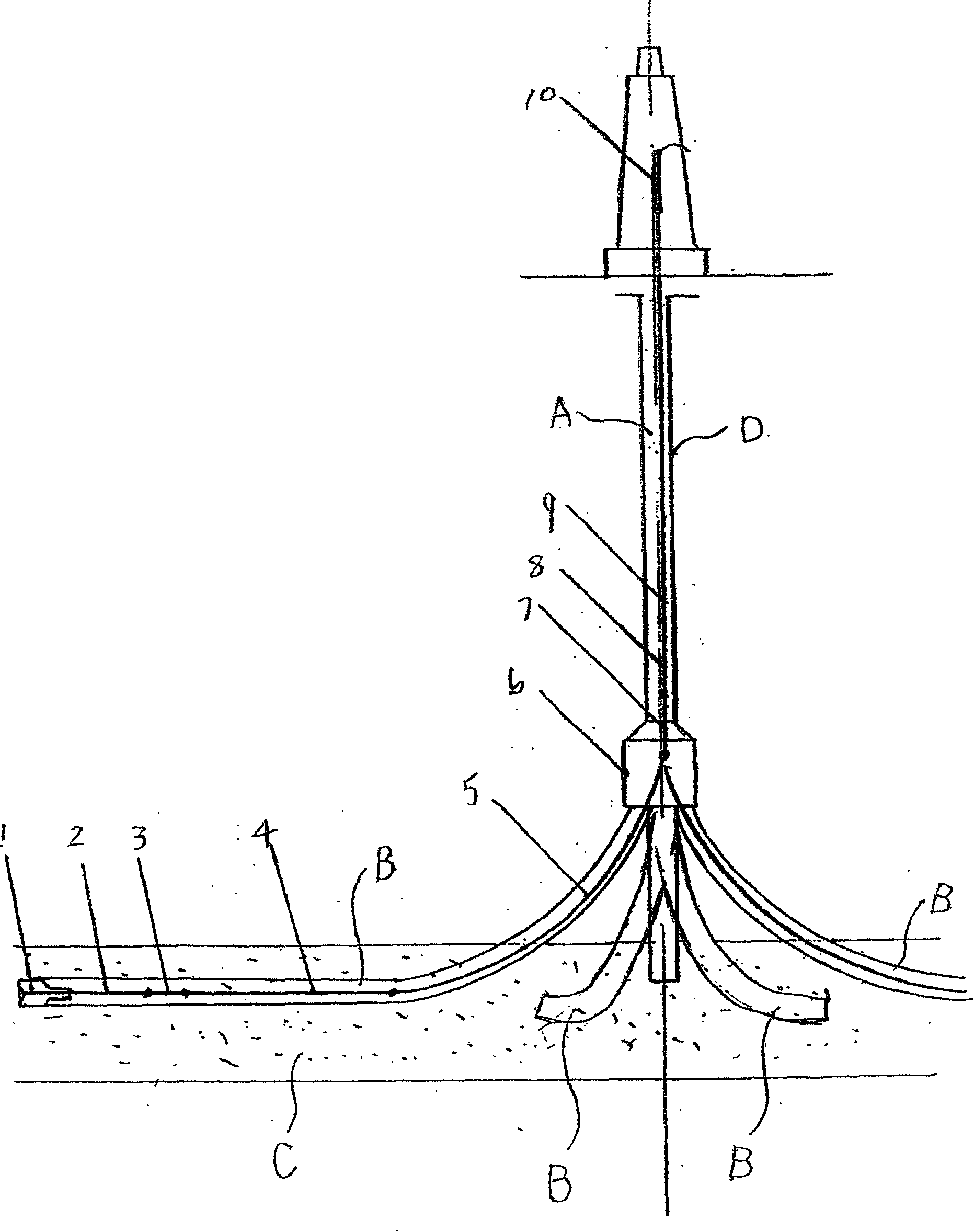

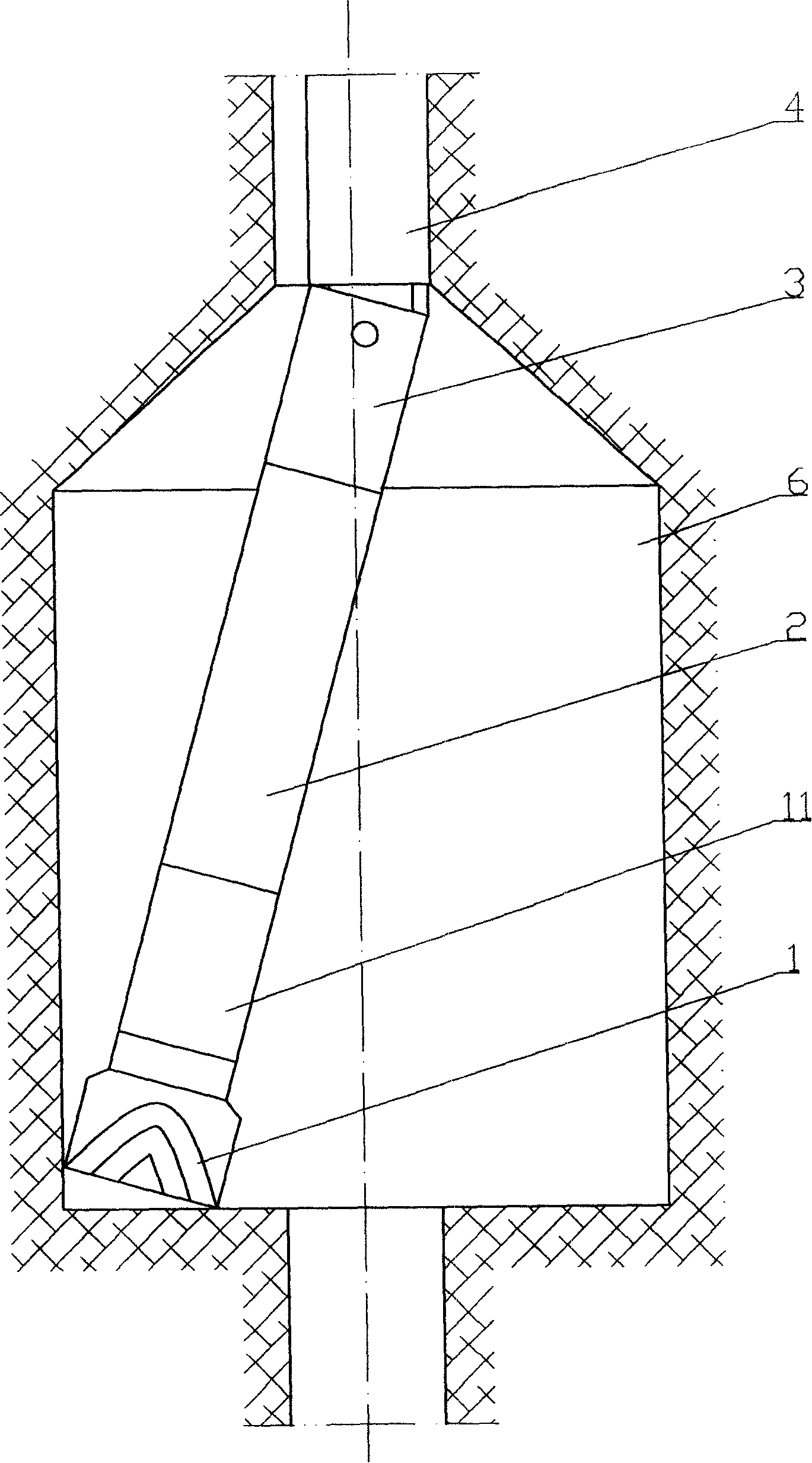

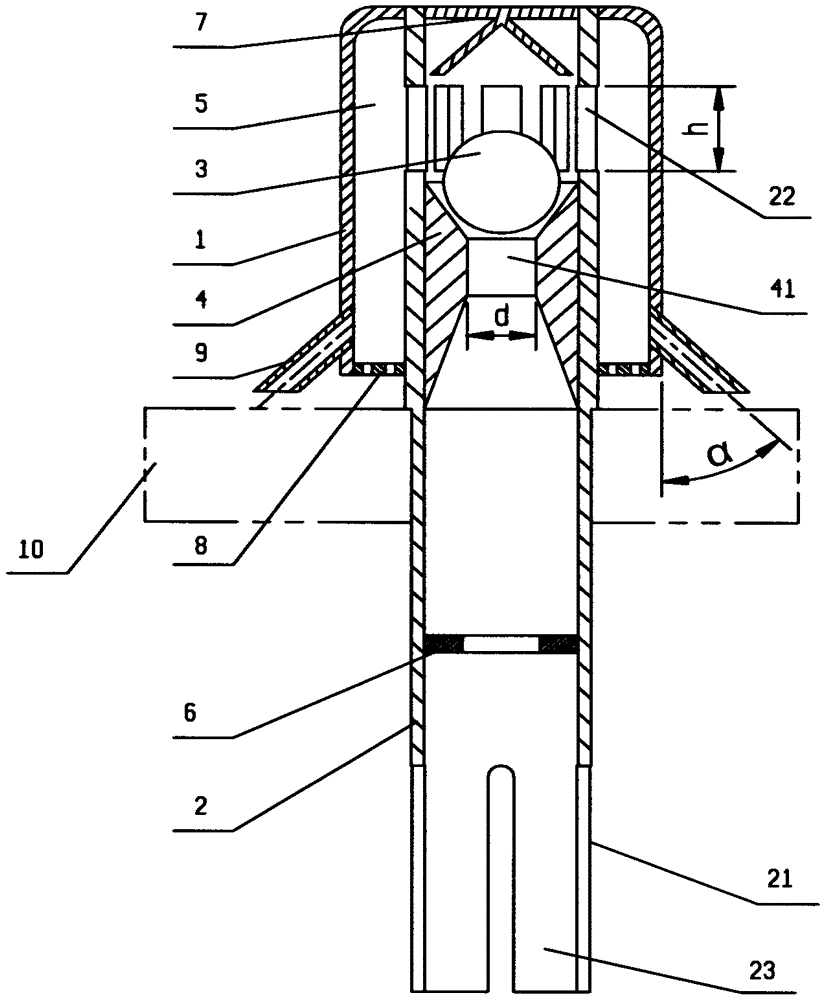

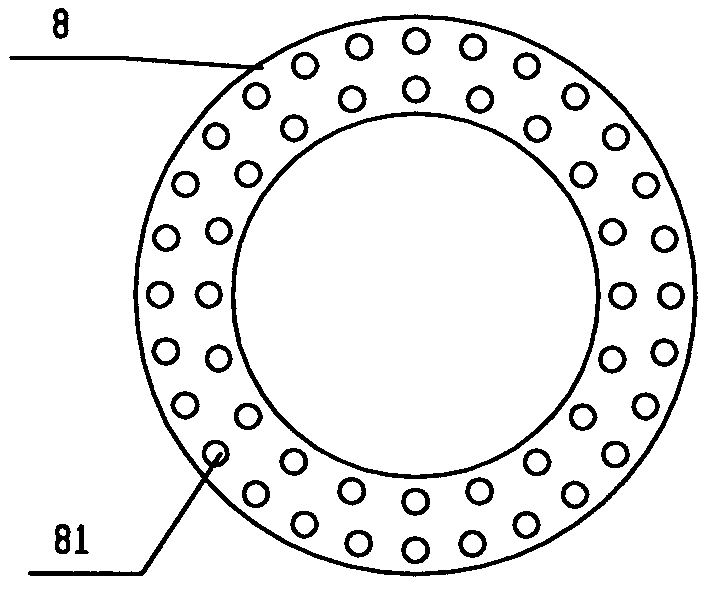

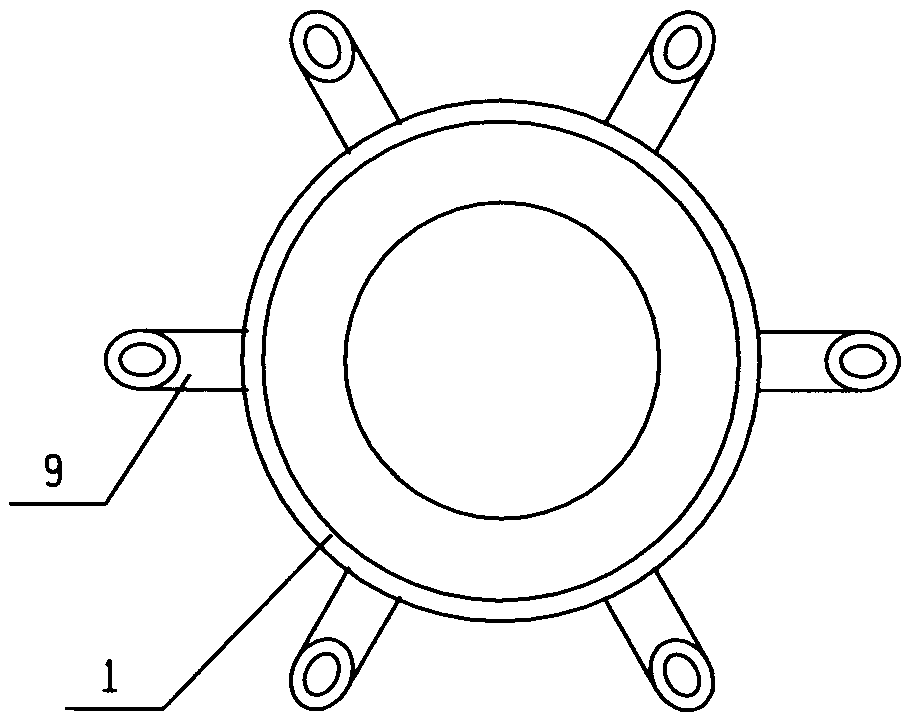

Large curvature radiation horizontal well drilling technique and device

InactiveCN101210481AIncrease permeable areaIncrease daily outputDirectional drillingWell drillingEconomic benefits

The invention discloses a large-curvature radioactive level horizontal drilling process and device includes drilling vertical well to oil layer, lowering the sleeve, drilling sleeve shoe, building up angle directionally, washing well, lifting the drill, lowering special sieve vessels, filling with gravels, decoupling the hanger for circulated well washing, lifting the hanger de-coupler and all drilling tools above, drilling other radial wells, etc. Through drilling a plurality of radial wells, the invention enlarges seepage area, expanding seepage range, increasing the daily production for single well and raises final recovery ratio, so as to achieve the purposes of making full use of energy, increasing economic benefits and benefiting the society.

Owner:杜晓瑞

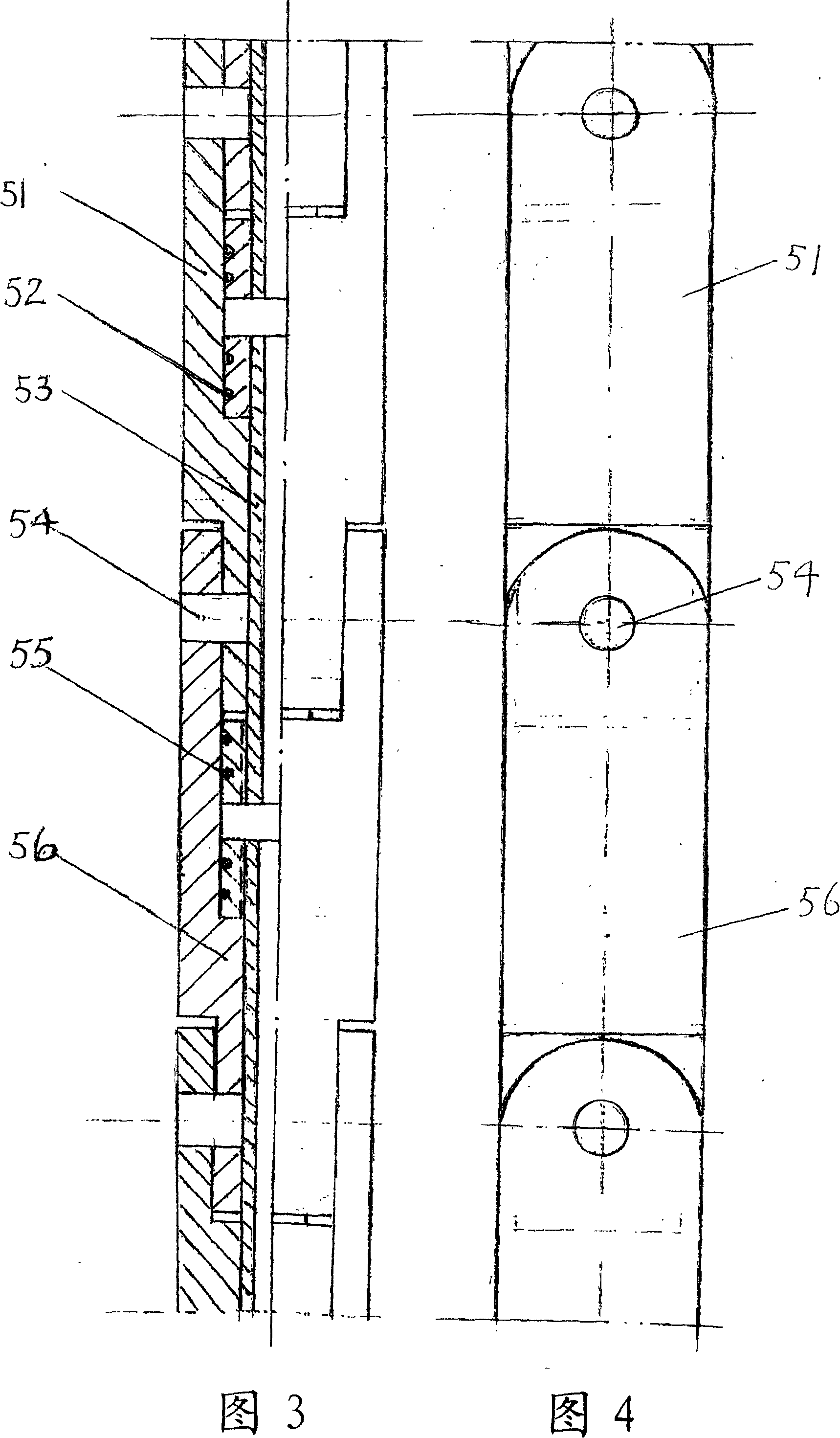

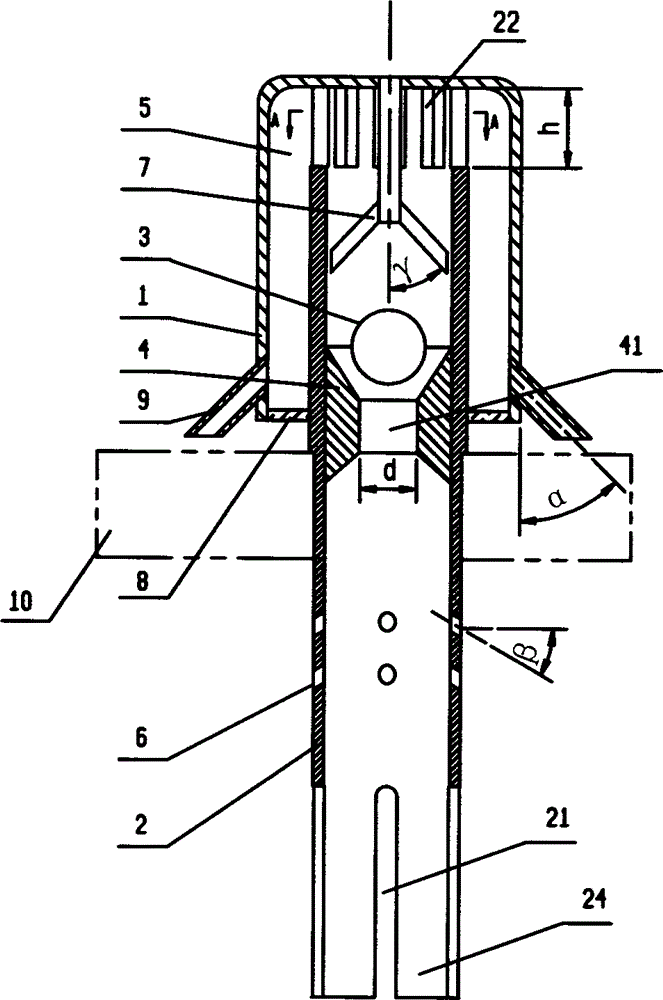

Gas-liquid distributor used for wood tar fluidized bed reactor

ActiveCN104923131AJumping up and down violentlyAvoid seal failureChemical/physical processesFluidized bedTar

The invention discloses a gas-liquid distributor used for a wood tar fluidized bed reactor, the gas-liquid distributor is mainly composed of a center pipe, a bubble cap, a non-return ball, a taper ball seat and a limit seat; the bubble cap is a cylindrical matter with a bottom opening, covers the upper end of the center pipe, and is fixedly connected with the center pipe, a material outlet is arranged on the pipe wall of the upper end part of the center pipe, the limit seat is arranged in the center pipe below the material outlet, the taper ball seat is arranged on the pipe wall of the center pipe located below the limit seat, the non-return ball is arranged on the taper ball seat; the bubble cap, the center pipe, the limit seat, the non-return ball and the taper ball seat are coaxially arranged, an annular channel is formed between the bubble cap and the center pipe, and the lower end of the center pipe is provided with a material inlet. The gas-liquid distributor can not only guarantee a gas is broken into continuous micro bubbles in a liquid, and can effectively solve or ease countercurrent congestion problem of a catalyst-carrying material when gas and liquid pressure is instable or gas and liquid material feed is suddenly interrupted, at the same time, an internal flow dead zone in the distributor is reduced, and the pressure drop is smaller.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

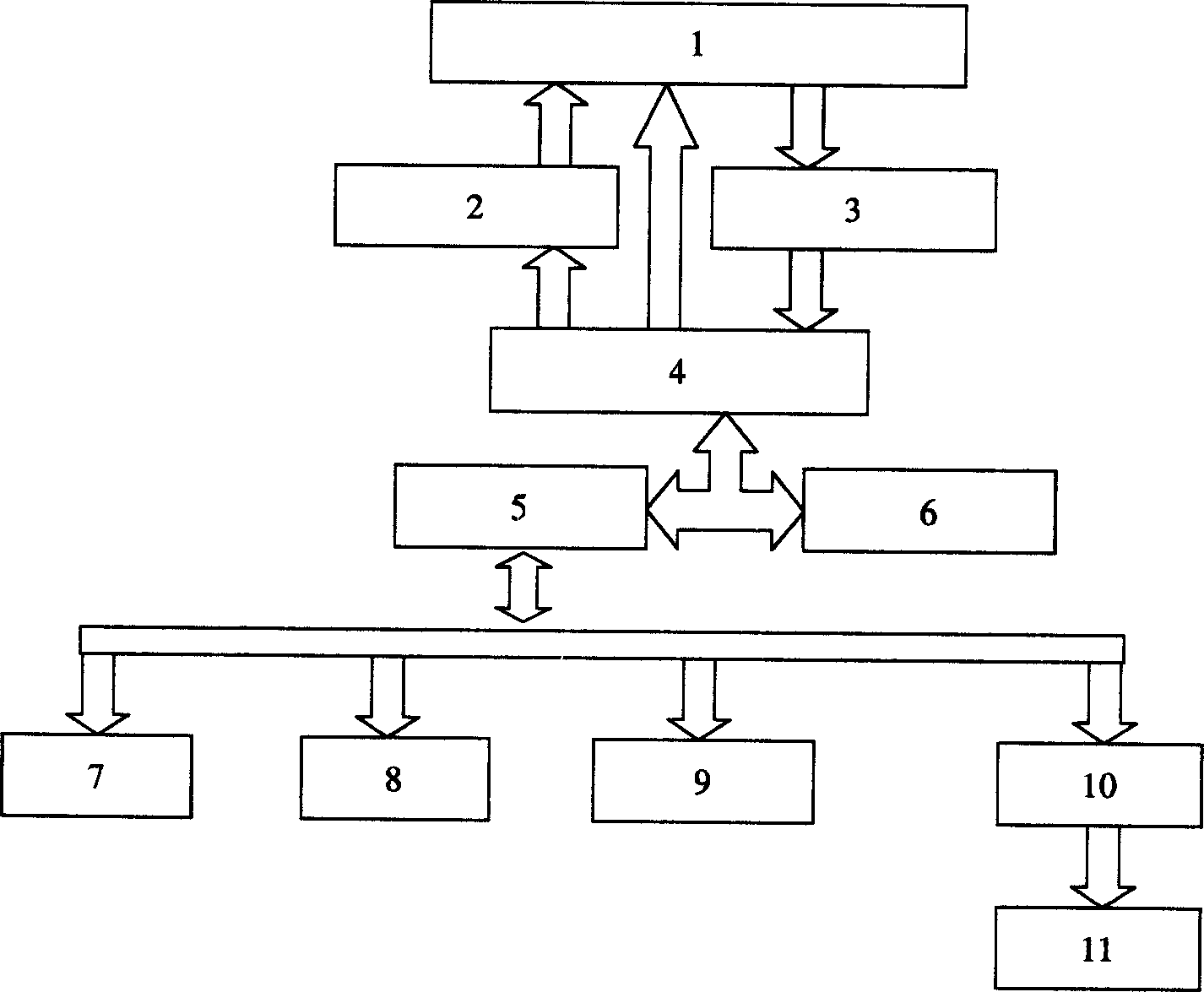

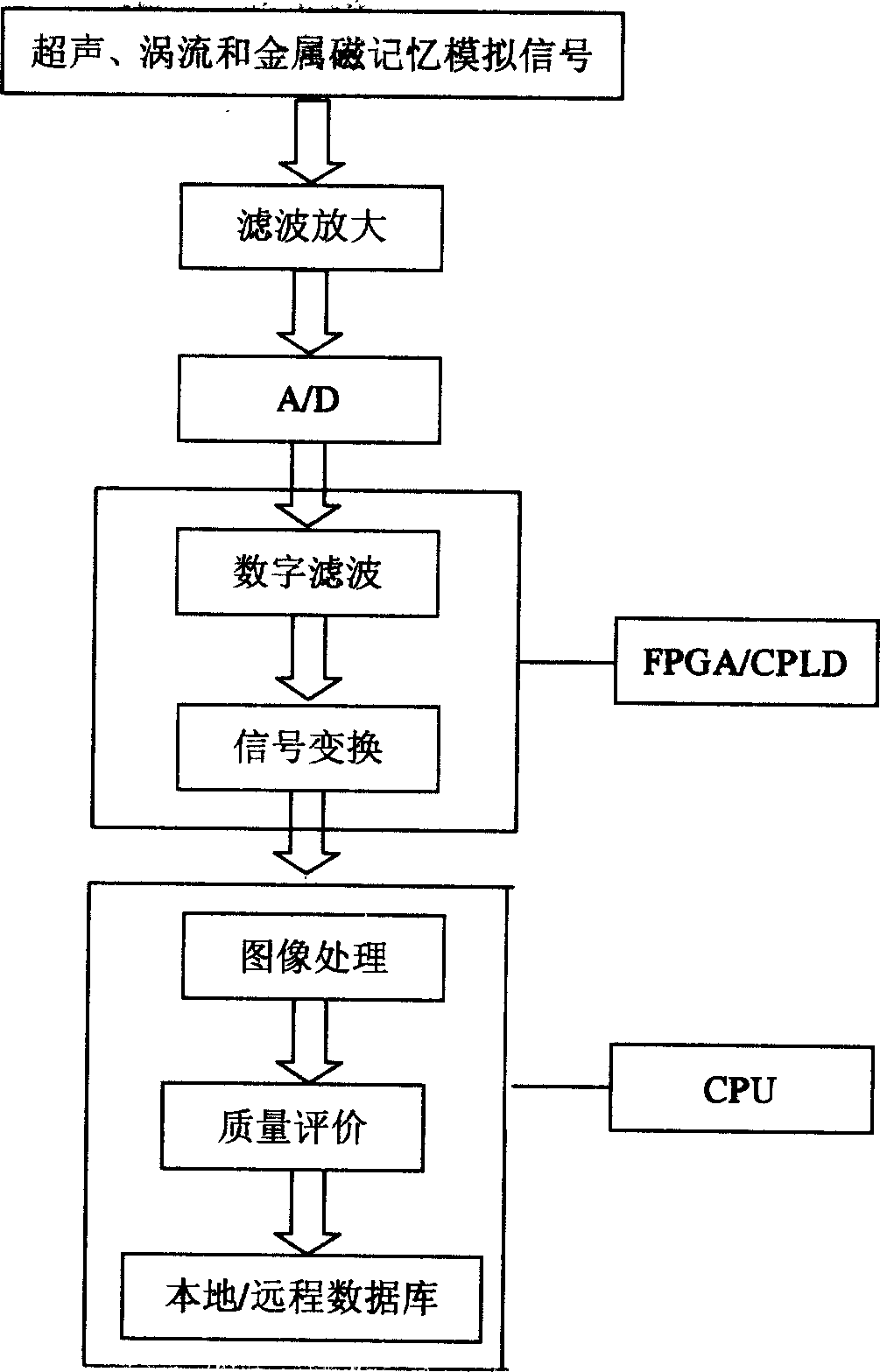

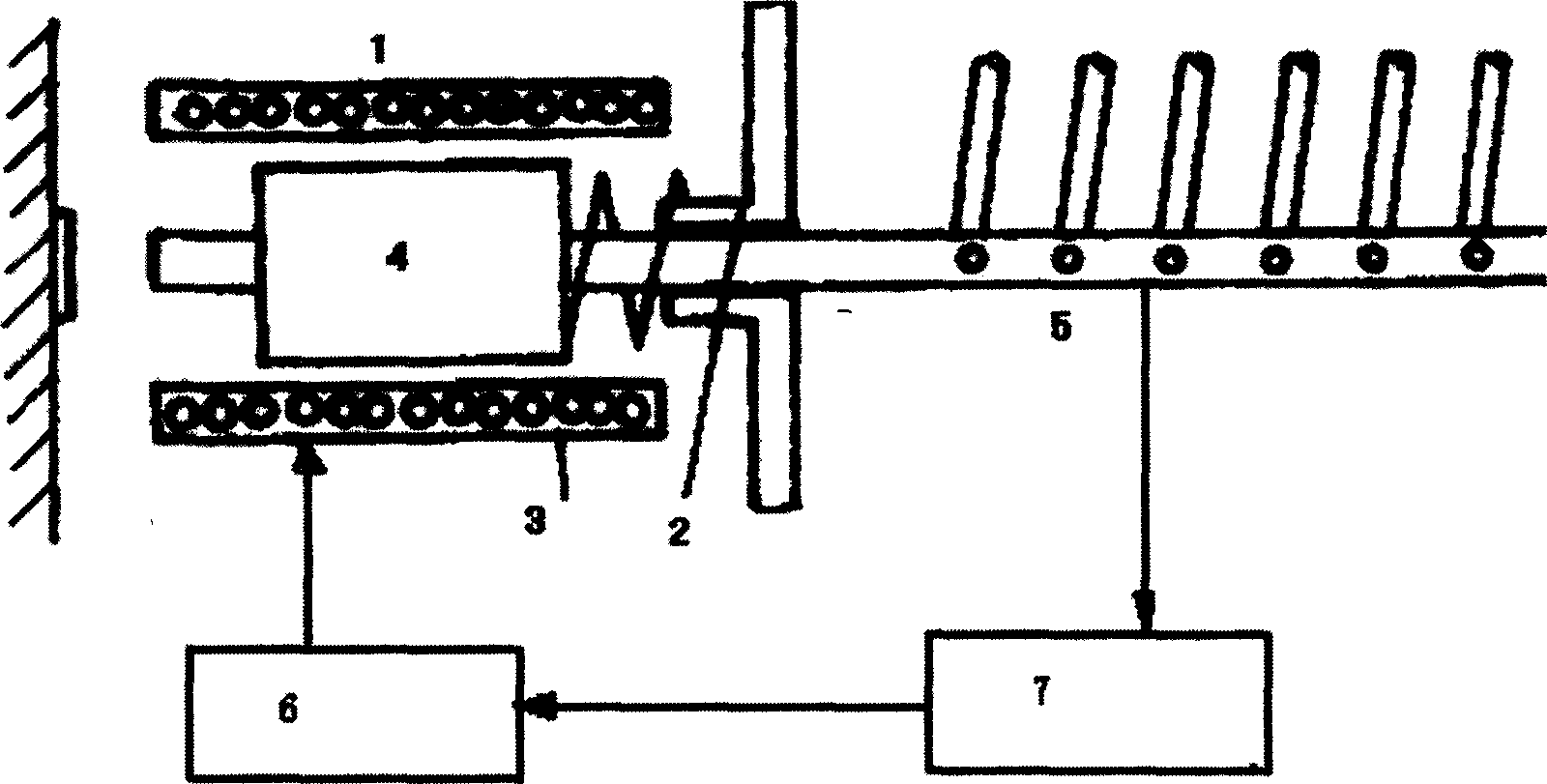

Supersonic vortex and metal magnetic memory composite detecting system

InactiveCN1588084ASuitable for real-time online detectionSuitable for online detectionAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial magnetic variablesSupersonic wavesControl system

The invention provides a compound detecting system with supersonic wave, vortex and metal magnetic memory. It is made up of detecting device, location scanning device, control system, displaying and recording device. The location scanning device is connected to the detecting device, the control system is connected to the detecting device, location scanning device, displaying and recording device respectively, its character lies in: the mentioned detecting device includes supersonic wave detecting device, vortex detecting device and metal magnetic memory detecting device. The invention carries on nondestructive testing by combining the supersonic wave, vortex and metal magnetic memory, and provides a detection method which is safer.

Owner:SOUTH CHINA UNIV OF TECH

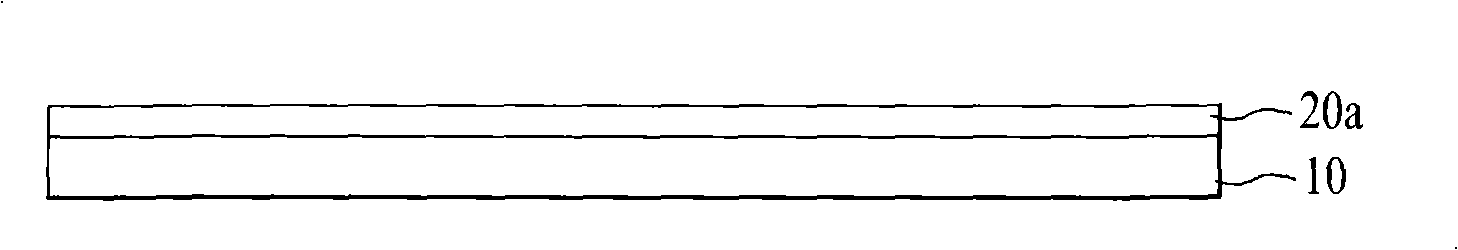

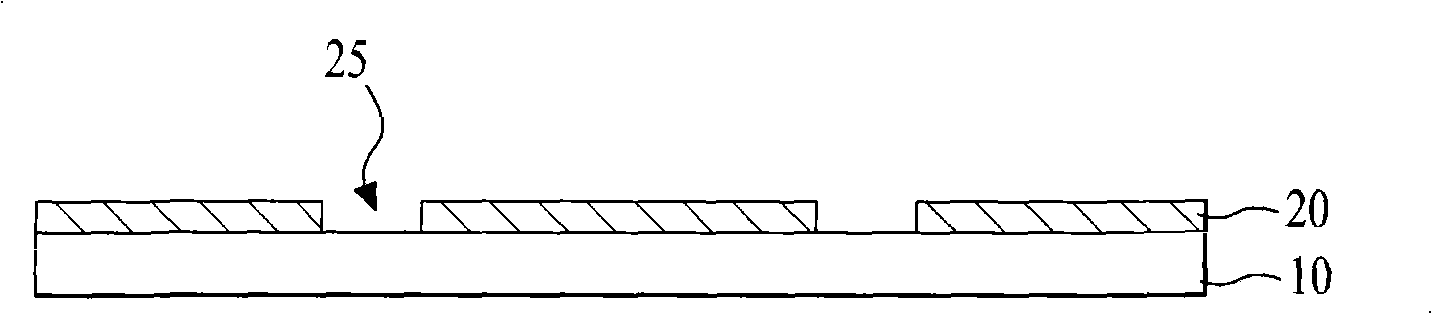

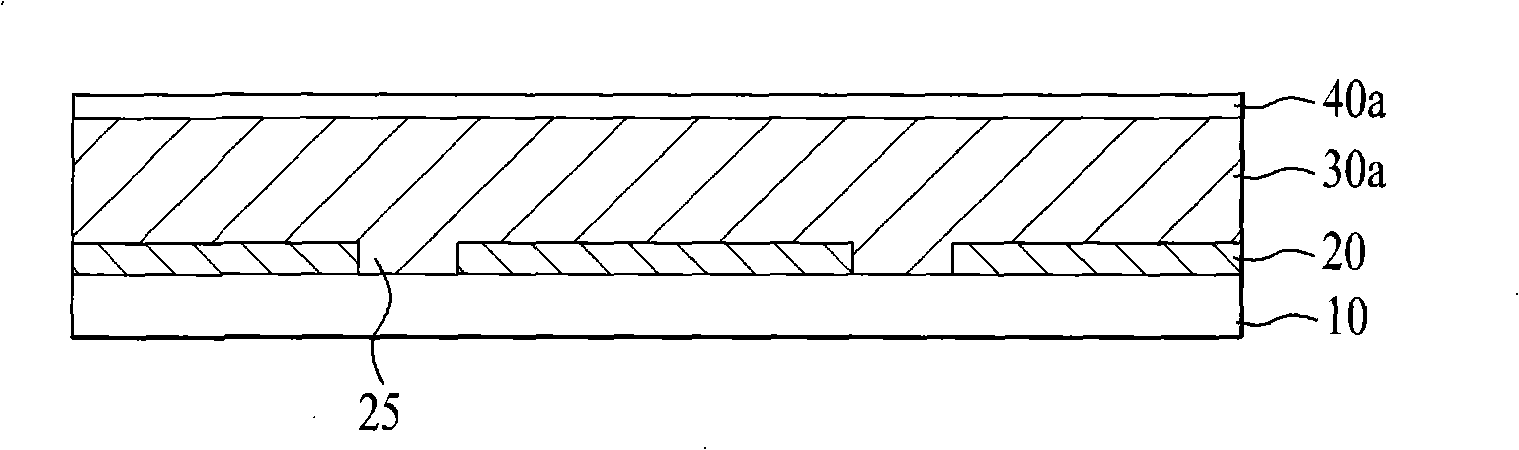

Thin film type solar cell and method for manufacturing the same

ActiveCN101515609AImprove efficiencyReduce dead zoneEnergy conversion devicesPhotovoltaic energy generationEngineeringSolar cell

Owner:JUSUNG ENG

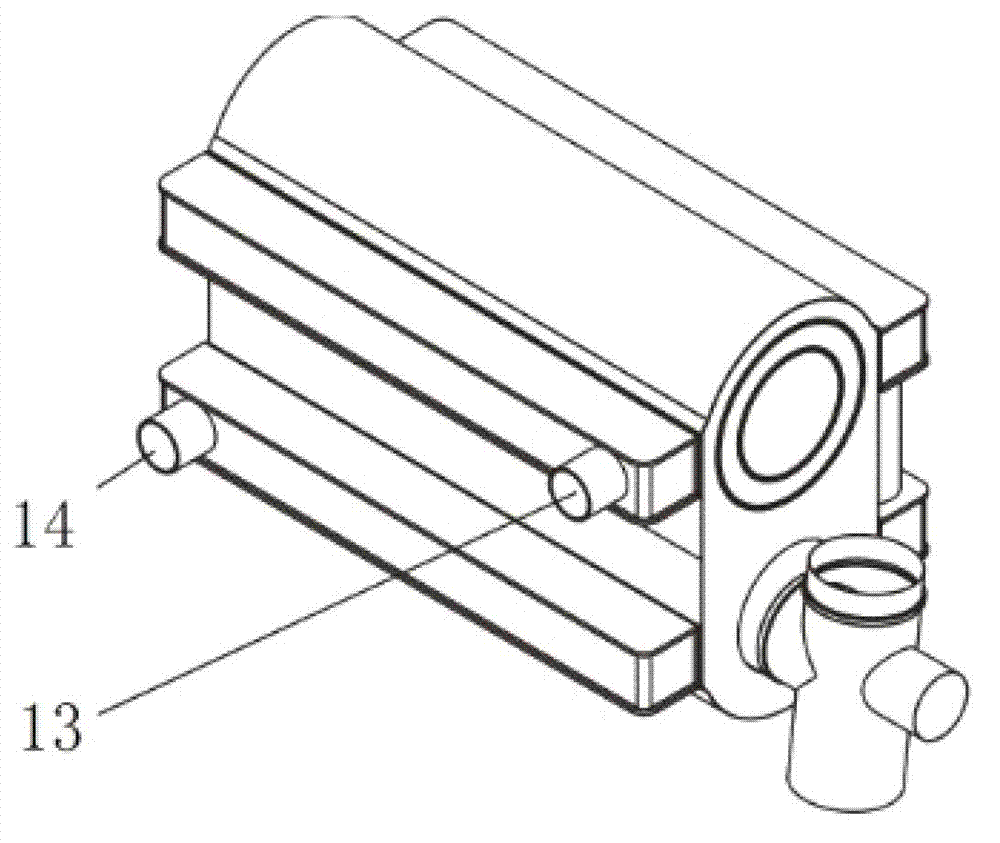

Forced finned straight pipe condensation heat-supply heat exchanger

ActiveCN102901221AImprove heat transfer efficiencyImprove heat transfer effectEnergy efficient heating/coolingAir heatersPlate heat exchangerCombustor

The invention discloses a forced finned straight pipe condensation heat-supply heat exchanger, which comprises a shell, a combustor and a plurality of finned straight pipes, wherein the combustor is positioned on the upper part of the shell; the periphery of the combustor is provided with a group of finned straight pipe bundles consisting of a plurality of finned straight pipes which are tightly and uniformly distributed along the circumference; a smoke exhaust pipeline which consists of the shell and a plurality of tightly arranged finned straight pipes is arranged below the combustor; the smoke exhaust pipeline is emptied through a smoke outlet; two ends of the finned straight pipes are respectively front water main pipes and rear water main pipes; clapboards are arranged in the rear water main pipes; the rear water main pipes are separated into a water inlet area and a water outlet area through the clapboards; and water flow enters part of the finned straight pipes through the water inlet area, reaches the front water main pipes and enters the water outlet area of the rear water main pipes through the other part of the finned straight pipes. The inwards folded finned straight pipes serve as basic elements of the forced finned straight pipe condensation heat-supply heat exchanger, and the heat exchange efficiency is obviously improved.

Owner:SUZHOU CQ HEAT EXCHANGER

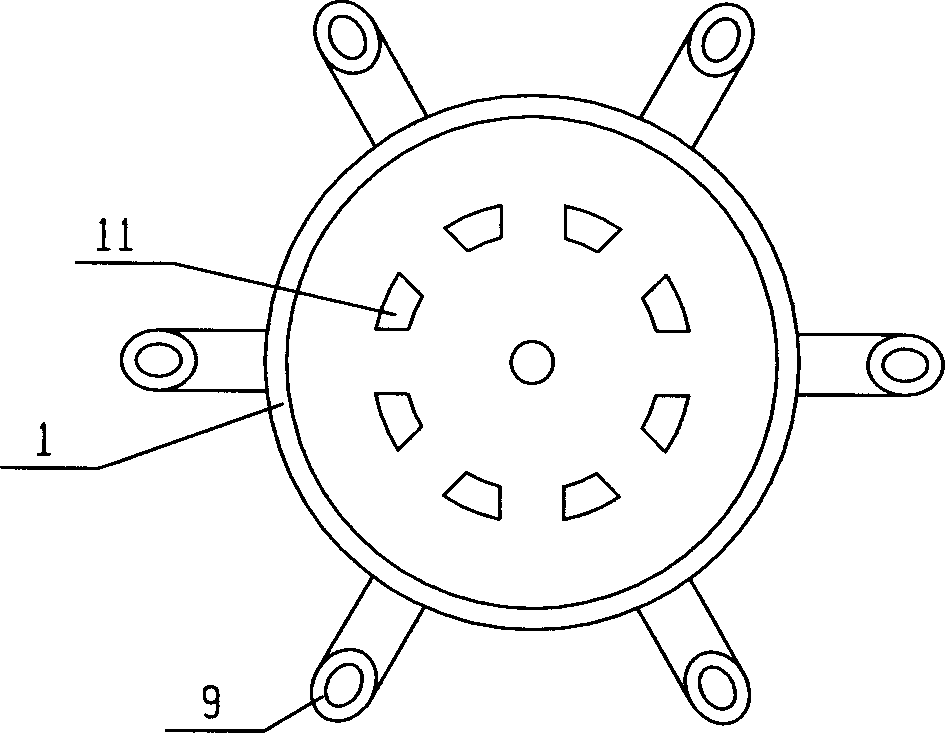

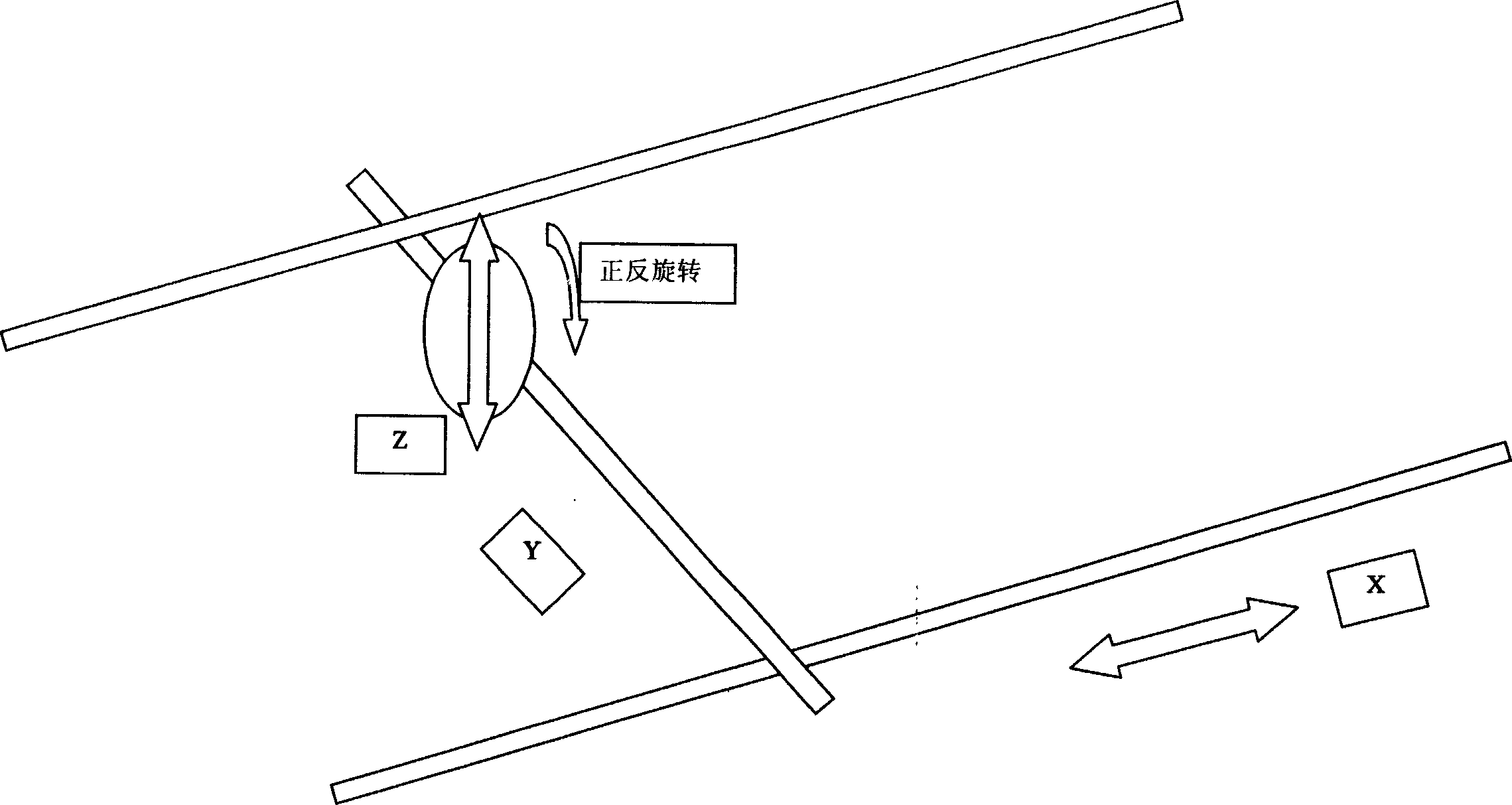

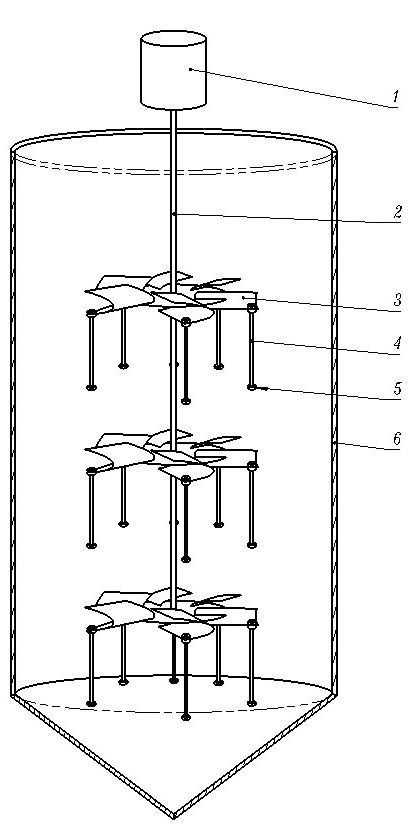

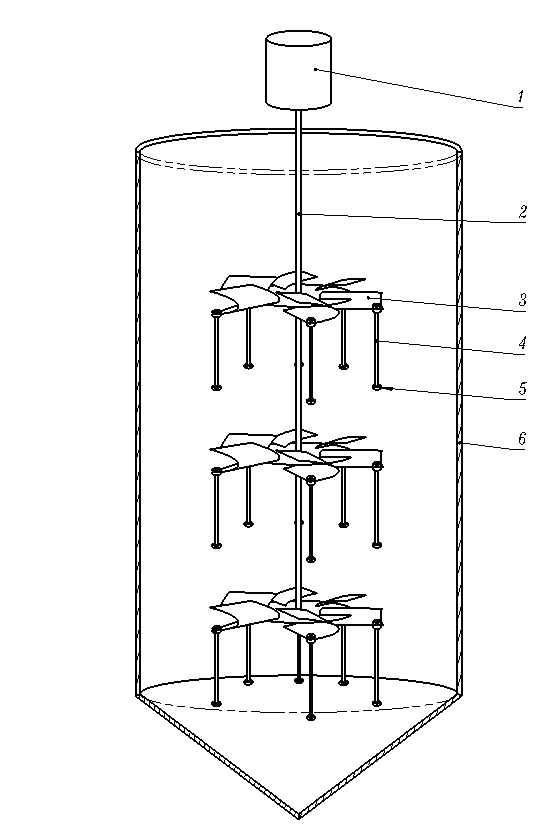

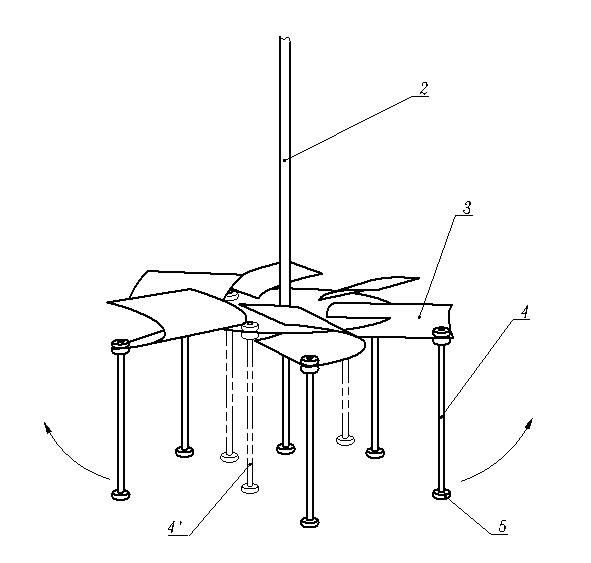

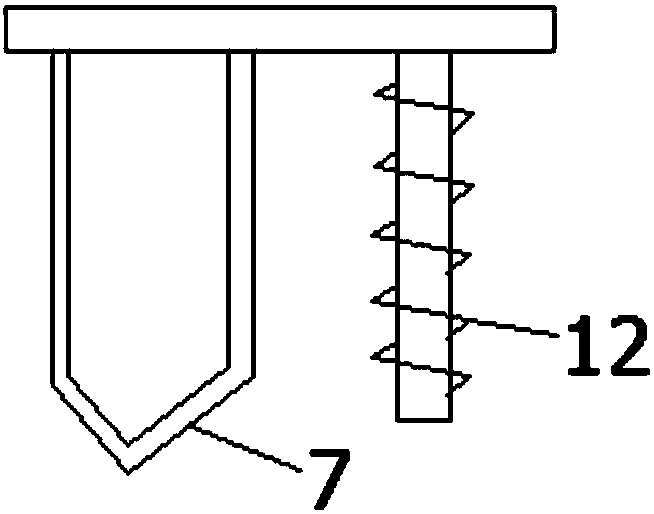

Agitator blade for improving leaching rate of metal manganese electrolyte

InactiveCN102094118AGood mixing effectHigh extraction rateRotary stirring mixersProcess efficiency improvementLeaching rateEngineering

The invention discloses an agitator blade for improving the leaching rate of metal manganese electrolyte. A plurality of layers of agitator blades are arranged, and are fixedly arranged on an agitating shaft coaxial with a leaching groove for the metal manganese electrolyte. The outer end of each agitator blade in each layer of agitator blades is fixedly suspended with a flexible belt; the length of the flexible belt of the agitator blade positioned on the upper layer meets the conditions that: the flexible belt in the vertical state cannot be scratched by the agitator blade on the lower layer, and when the flexible belt is unfolded due to centrifugal force and rotates in ore pulp, the flexible belt cannot be scratched by the side wall of the leaching groove; and the length of the flexible belt of the agitator blade positioned at the lowest layer meets the conditions that: the flexible belt in the vertical state cannot be scratched by a corresponding part at the bottom of the leaching groove, and when the flexible belt is unfolded due to centrifugal force and rotates in the ore pulp, the flexible belt cannot be scratched by the side wall of the leaching groove. The agitator blade can eliminate stirring dead zones under the condition of not increasing energy consumption basically, so the leaching rate of the metal manganese electrolyte can be improved. The agitator blade has the advantages of simple structure and low equipment cost.

Owner:CHONGQING UNIV

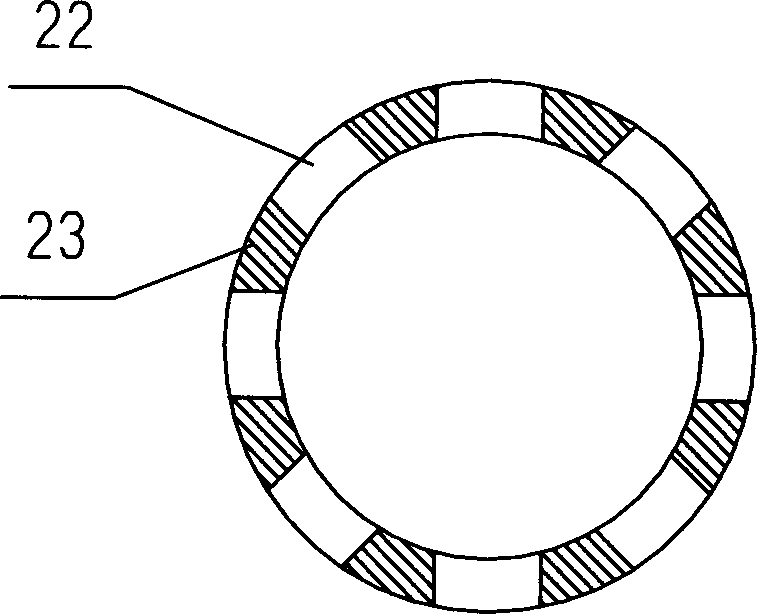

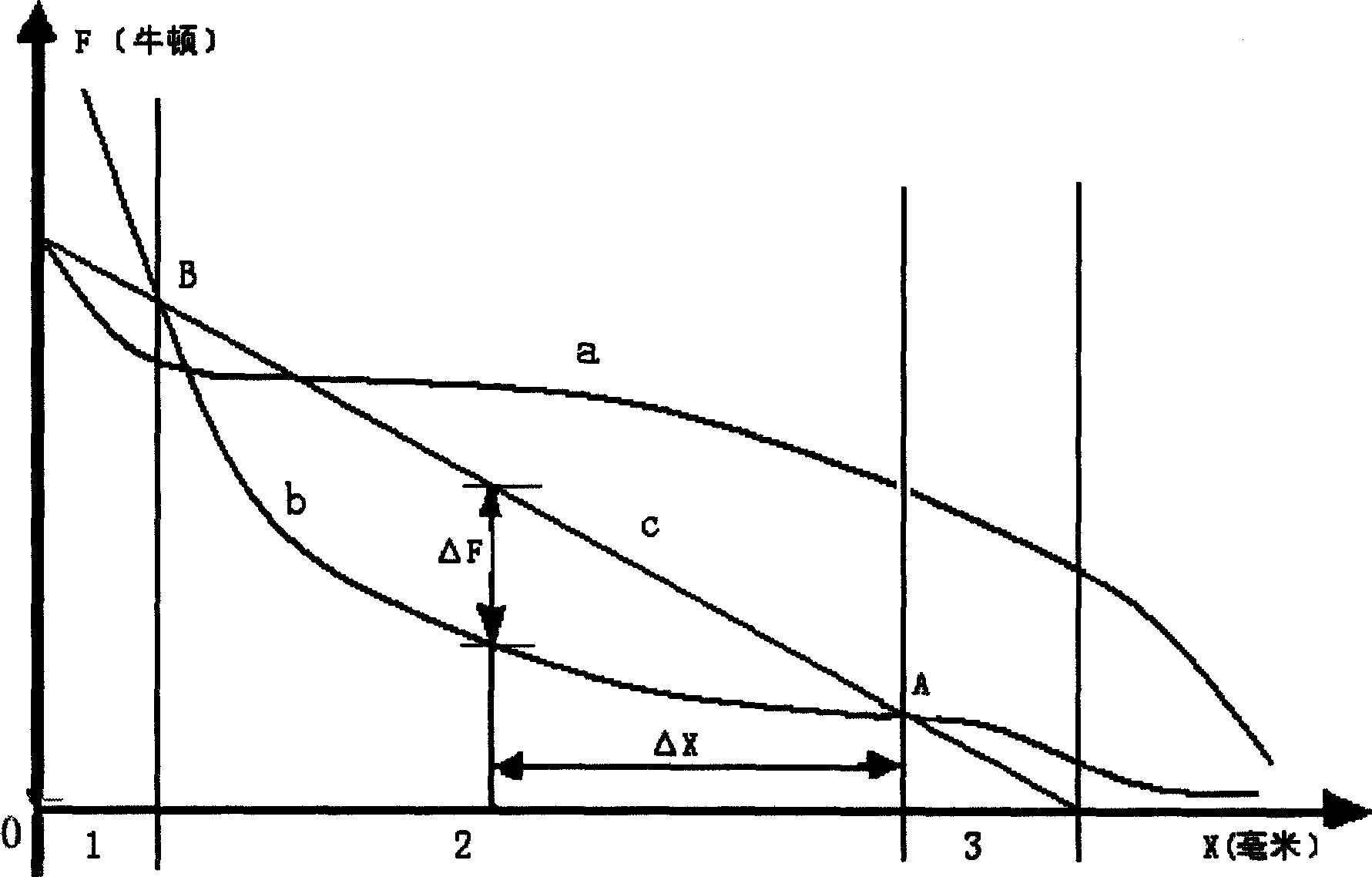

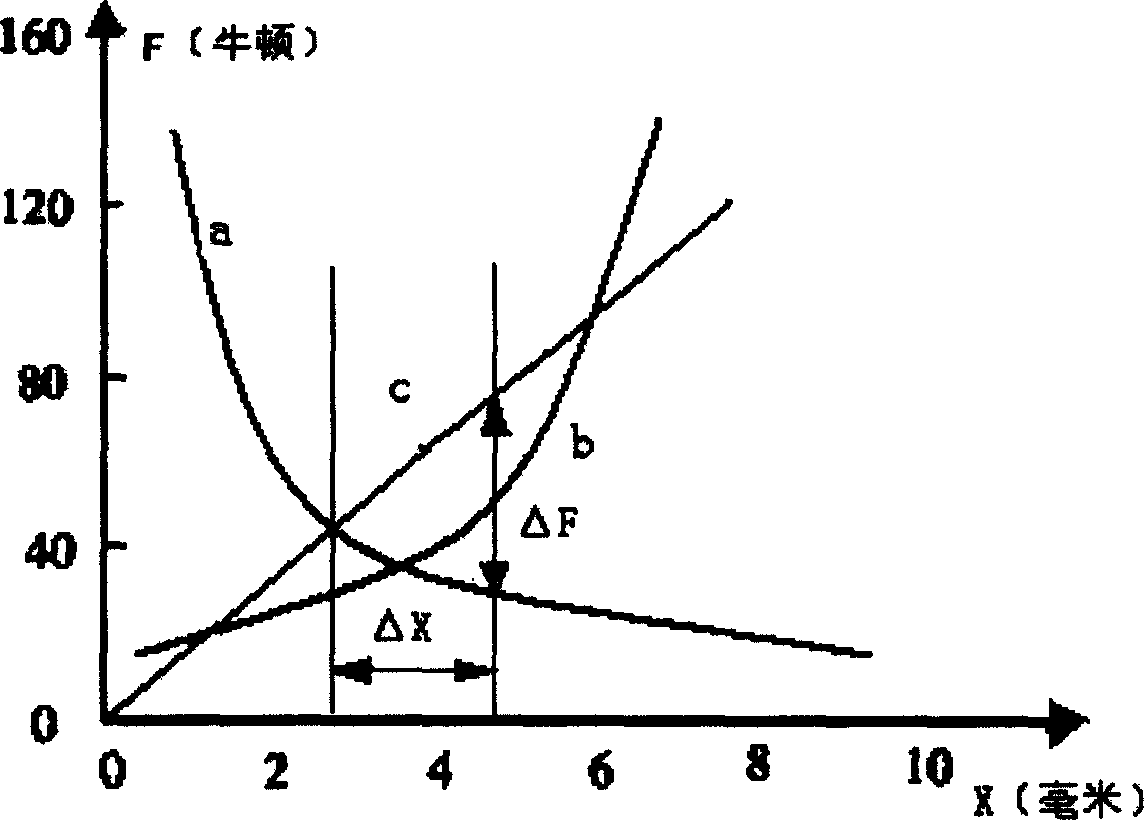

Repul sive force type electromagnetic shift executing system

InactiveCN1588586ASimple structureReduce volumeElectromagnets with armaturesRepulsion forceEngineering

The invention relates to a repulsion-type electromagnetic displacement actuator, adopting a principle of opposite magnets repulsing mutually to make a repulsion-type electromagnetic actuator, making the same pole tips of the magnetic filed generated by fixed helix tube in the actuator after electrified and the magnetic filed of an armature are opposite so as to generate a repulsion force to push the armature to move, balancing compression return spring or other balance return devices, thus primely solving the problem of nonlinear resultant force displacement property, and strengthening its control accuracy and stability. The material of the moving armature is a soft-magnetic material, both realizing excellent property of proportional electromagnet and avoiding the problems of process complexity, reliability reduction and effective travel reduction of the proportional electromagnet, etc. And it remedies the disadvantage of unstability and control difficulty caused by a system composed of ordinary electromagnet and spring.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

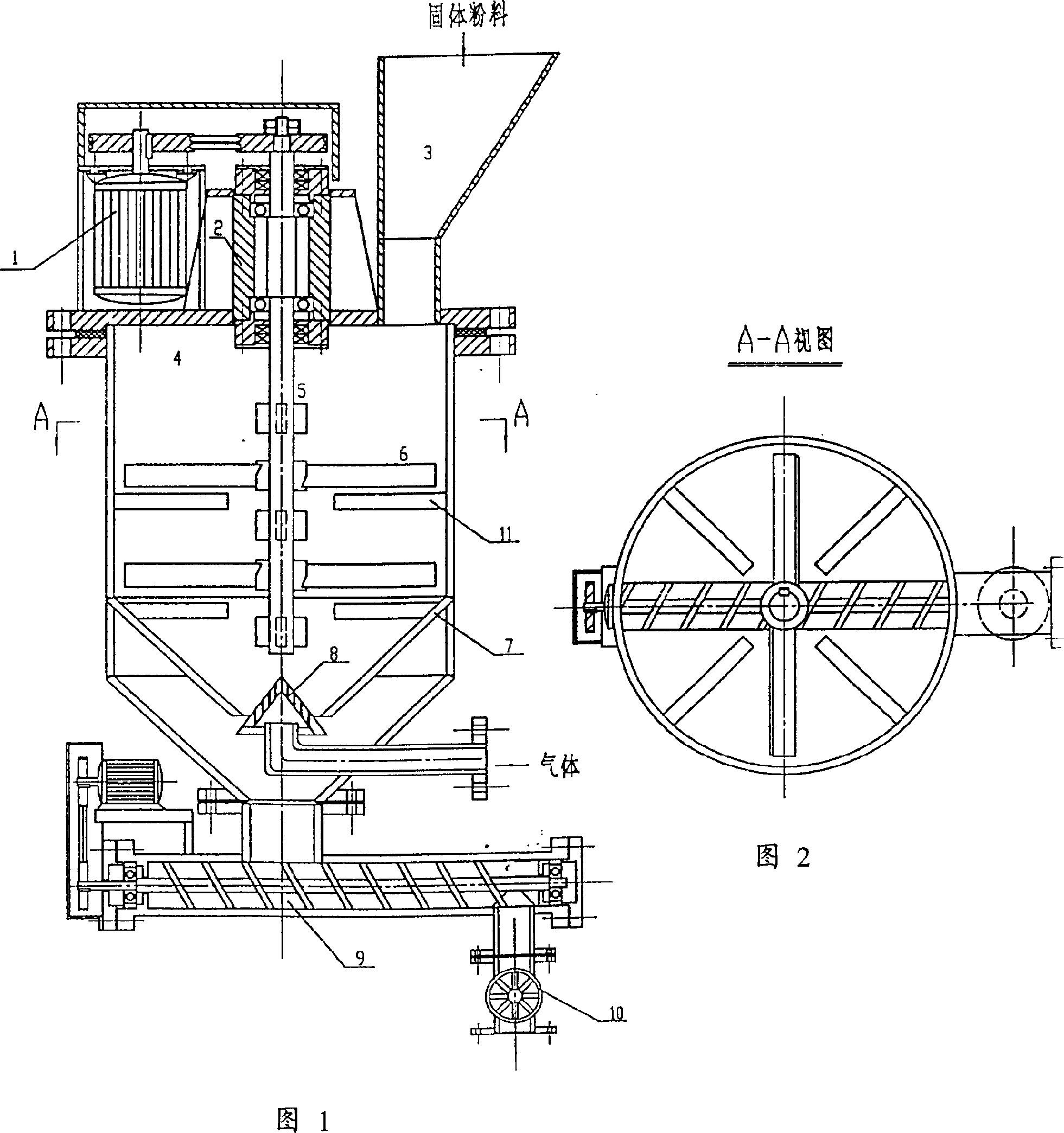

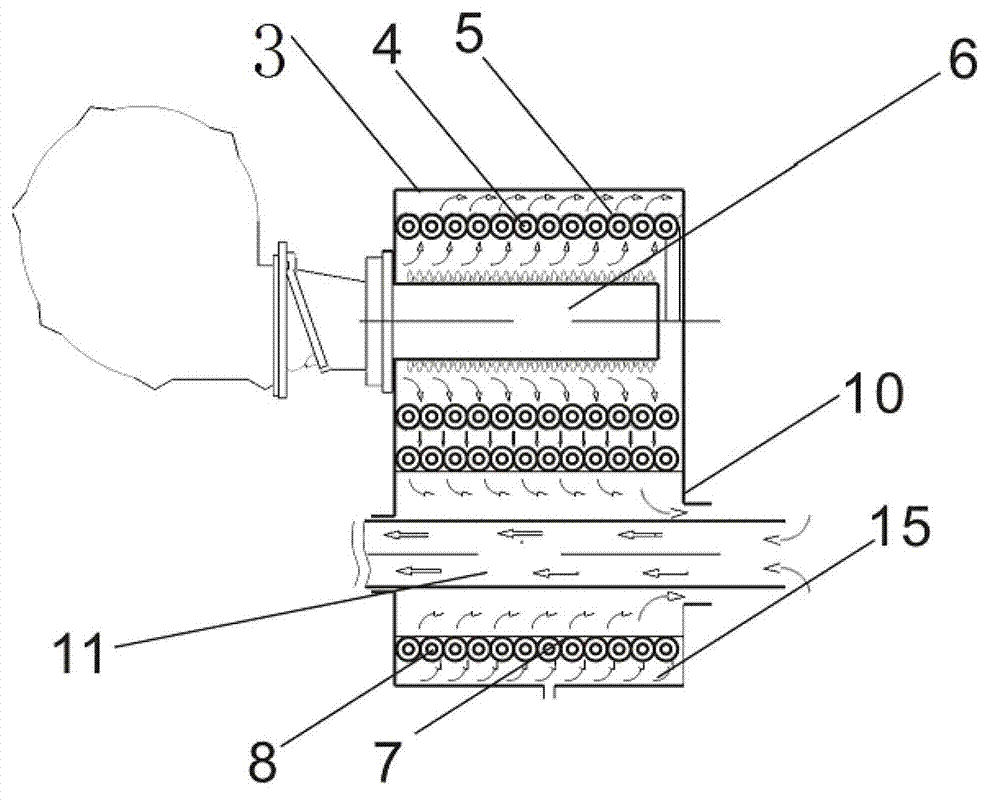

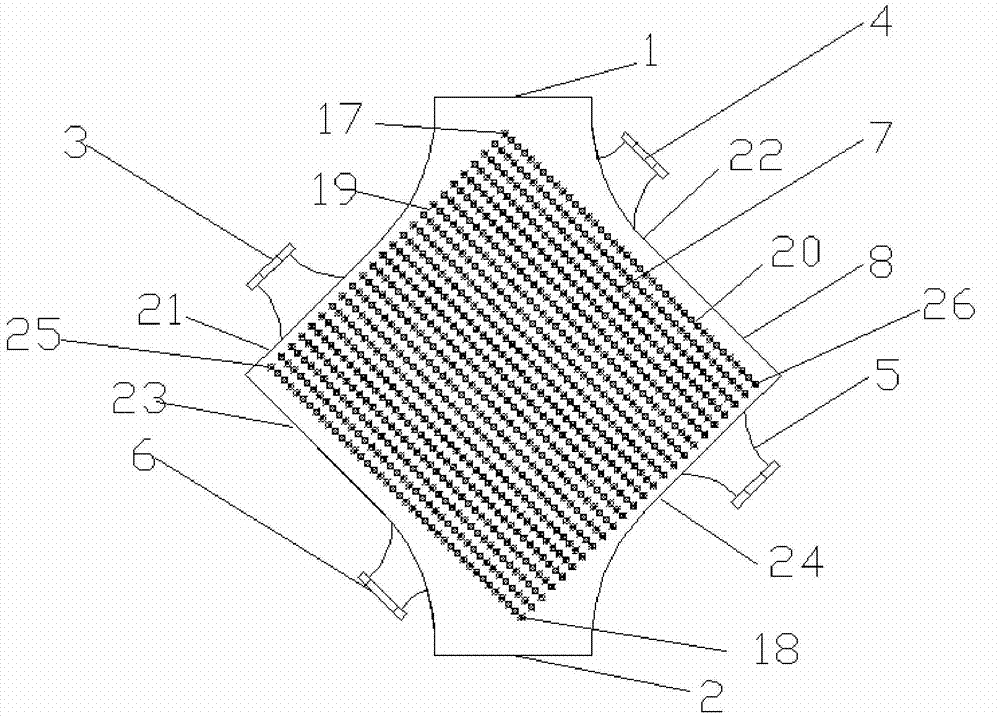

Gas-solid reactor

InactiveCN1448211ATake advantage ofImprove mass transfer conditionsMixing gases/vapours with solidsGas solidSpool valve

The gas-solid reactor includes the main parts of main body, solid feeding port, tail gas exhausting port, stirring shaft, stirring blades, truncated cone solid discharger, turned conic gas distributor, screw conveyor, air sealed slide valve and baffle. The main body includes cylindrical upper part and conic lower part; the solid feeding port and the tail gas exhausting port are in the top of thereactor; the stirring shaft with fixed stirring blades is perpendicular to the central axis of the reactor; the inner wall of the reactor has one or several layers of baffles set; the solid discharger is in the lower part of the reactor; the gas distributor with homogeneously distributed holes is below the solid discharger; and the bottom of the reactor is connected to the screw conveyor; and theslide valve is set on the material discharging pipe of the screw conveyor.

Owner:CHINA PETROLEUM & CHEM CORP +1

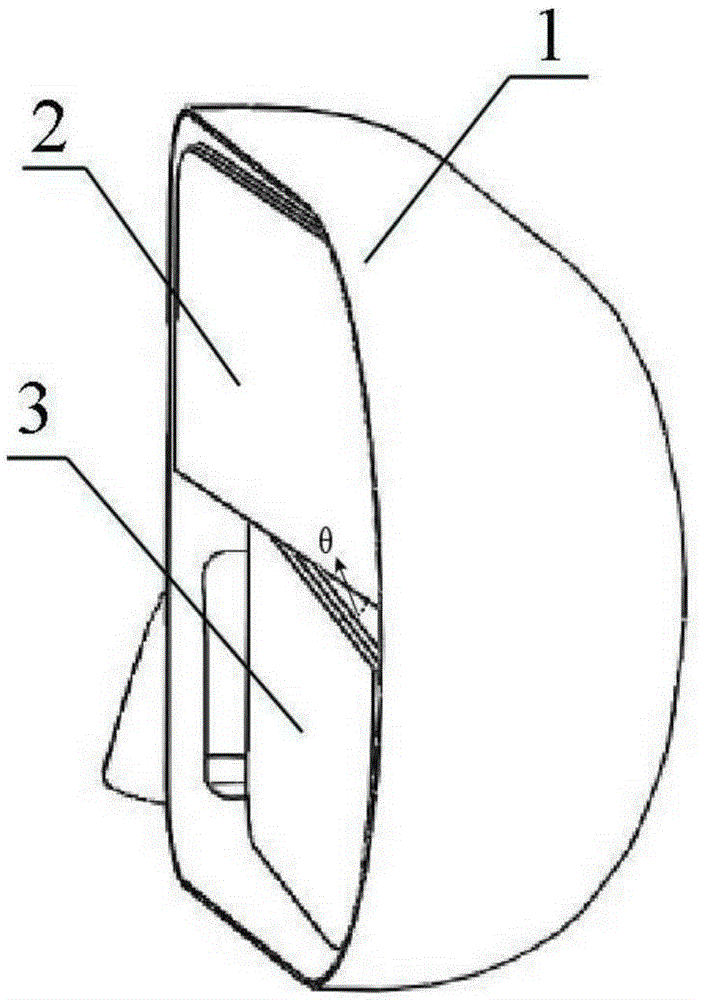

Polar coordinate reading type two-dimensional position sensitive detector with double wedge-strip anodes

InactiveCN104090290AReduce crosstalkHigh resolutionX/gamma/cosmic radiation measurmentCoincidencePhysics

The invention discloses a polar coordinate reading type two-dimensional position sensitive detector with double wedge-strip anodes. The wedge-strip anodes are partitioned into specific patterns formed by wedge electrodes, strip electrodes and compensation electrodes, wherein the six wedge electrodes, the strip electrodes and the compensation electrodes of one wedge-strip anode and the six wedge electrodes, the strip electrodes and the compensation electrodes of the other wedge-strip anode are respectively matched to form the two symmetric semi-circular wedge-strip patterns, all the electrodes are disconnected from one another, and the three types of electrodes of the wedge-strip anodes are arranged in the radial direction. When the detector is used for measuring an annular area to be detected, the distance and the polar angle between a particle and the center can be directly measured. The double wedge-strip anodes can achieve the coincidence measurement that the particle can be detected in the two semi-circular areas, and have the advantage that the dead zone is small.

Owner:UNIV OF SCI & TECH OF CHINA

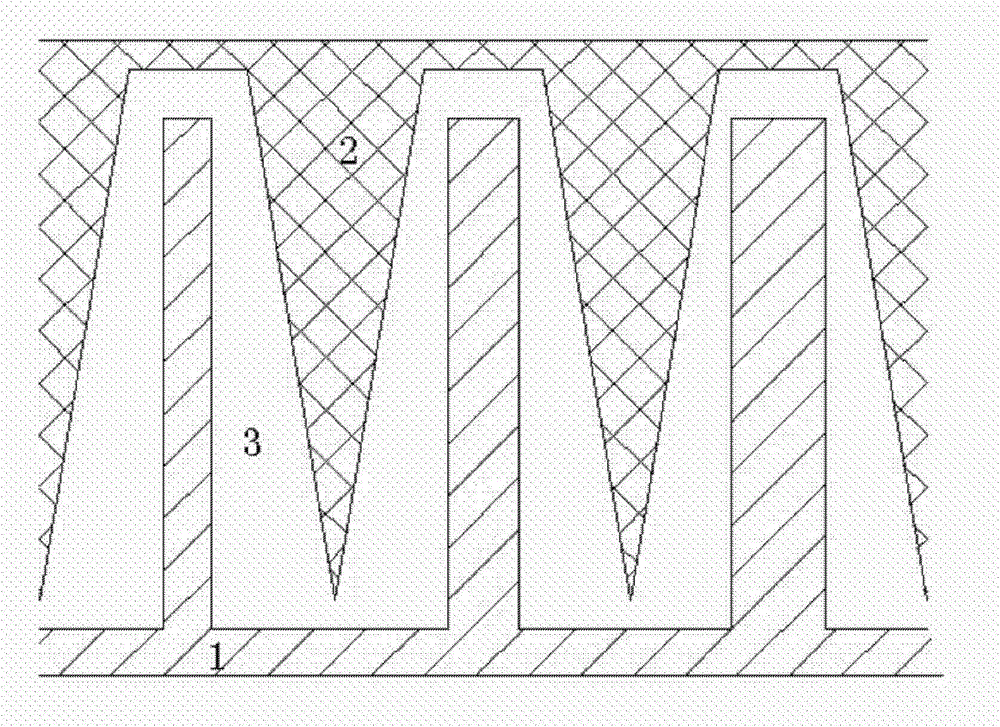

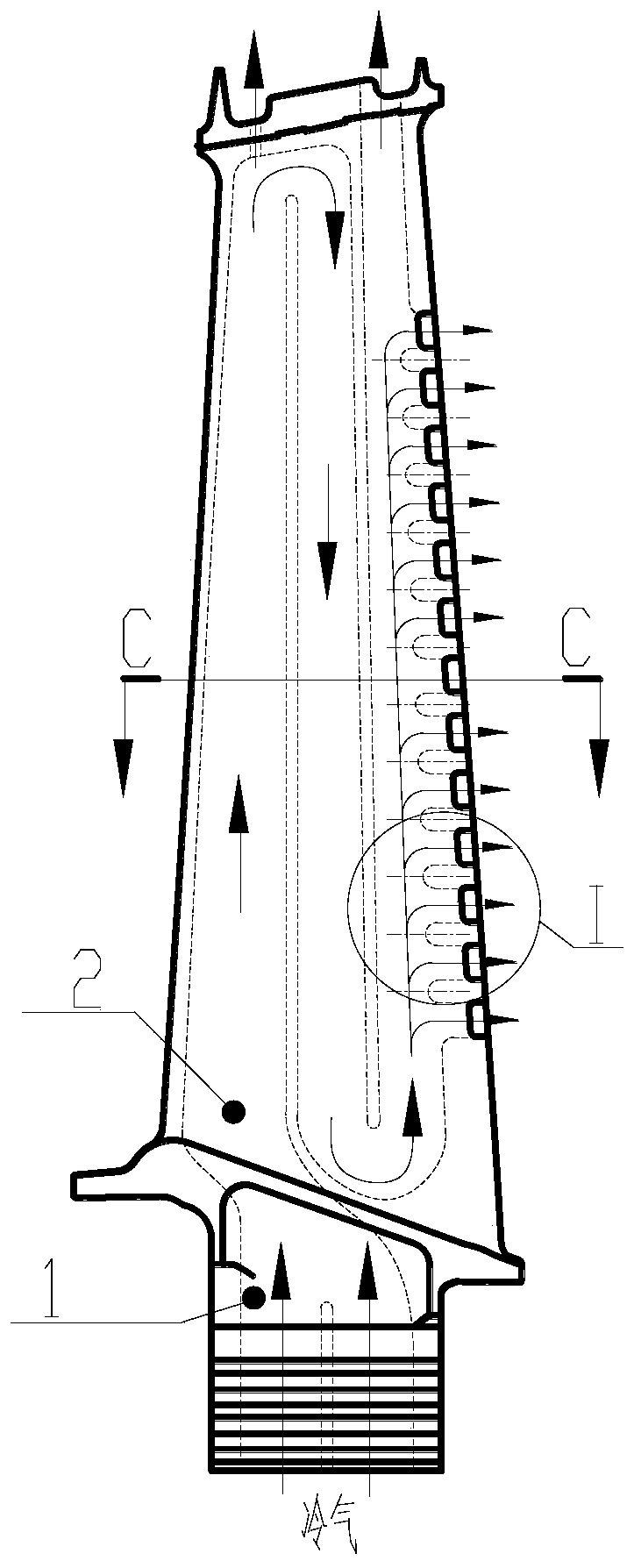

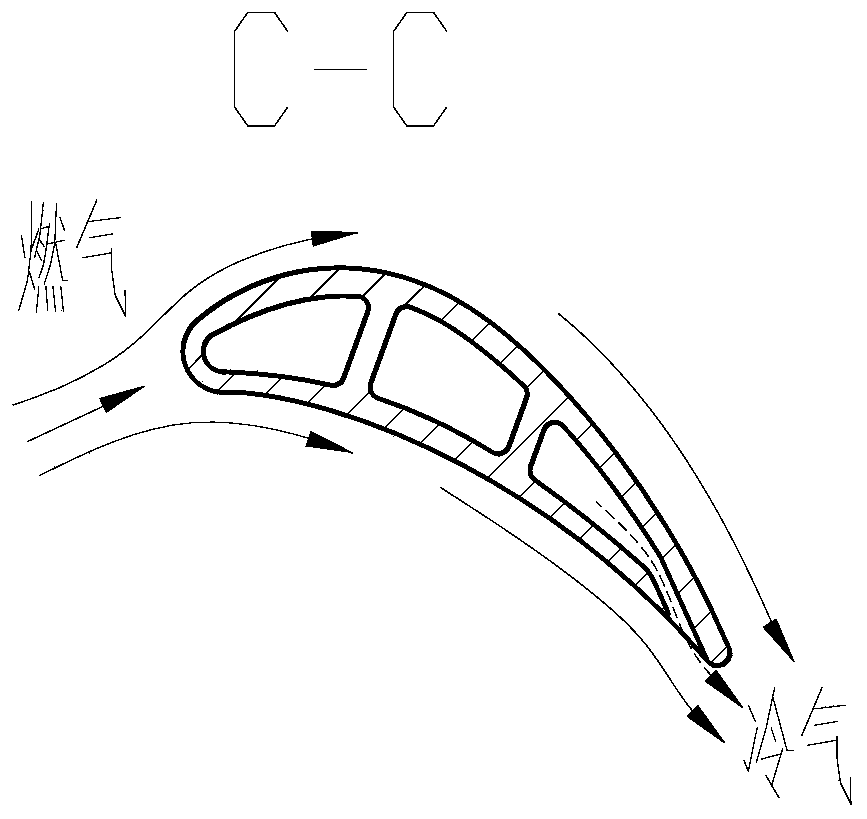

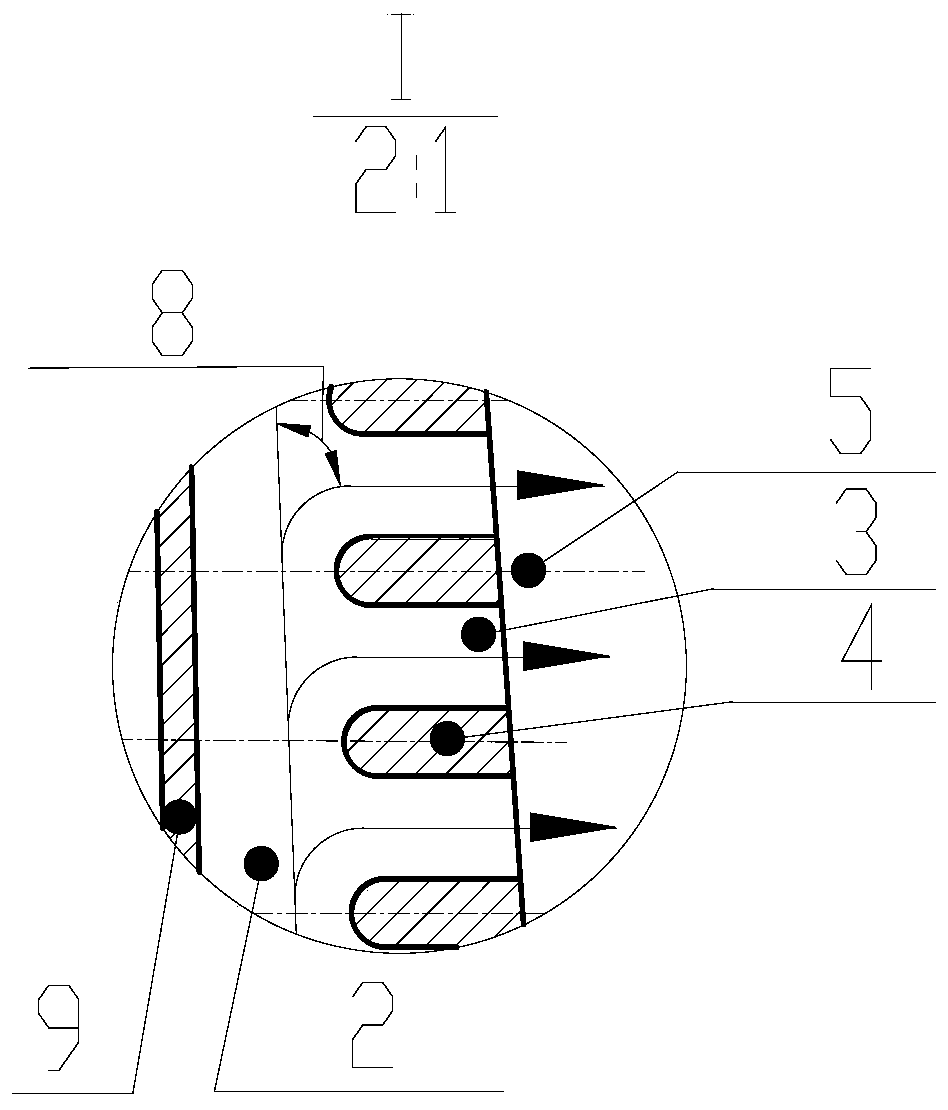

Tapered inclined exhaust splitting seam structure for turbine blade trailing edge

InactiveCN110925027AIncrease flow rateReduce blending lossBlade accessoriesMachines/enginesTurbine bladeCooling effect

The invention belongs to the technical field of aero-engine turbine cooling, and relates to a tapered inclined exhaust splitting seam structure for a turbine blade trailing edge. The inclined exhaustsplitting seam structure comprises a hollow turbine blade, an inner cavity cool air channel, a trailing edge exhaust splitting channel and trailing edge splitting seam partition ribs, wherein the inner cavity cool air channel is formed inside the hollow turbine blade, the trailing edge of the hollow turbine blade is provided with the trailing edge splitting seam partition ribs arranged side by side, and the trailing edge exhaust splitting seam channel is formed between the trailing edge splitting seam partition ribs arranged side by side for allowing cooling air to be discharged out of the blade and meanwhile carrying out air film coverage cooling on the blade trailing edge. According to tapered inclined exhaust splitting seam structure for the turbine blade trailing edge, the cool air canflow much smoothly, so that flow resistance and loss of the cool air in an cavity of the blade is reduced, and the flow resistance can be reduced by about 16%; and through designing an inclined exhaust trailing edge splitting seam into a tapered structure, the outflow speed of the cool air can be improved, internal convection heat exchange is strengthened, an air film coverage dead zone is reduced, in this way, comprehensive cooling effects of the blade trailing edge is further improved while blending loss is reduced, and heat exchange can be enhanced by about 8%.

Owner:DALIAN UNIV OF TECH

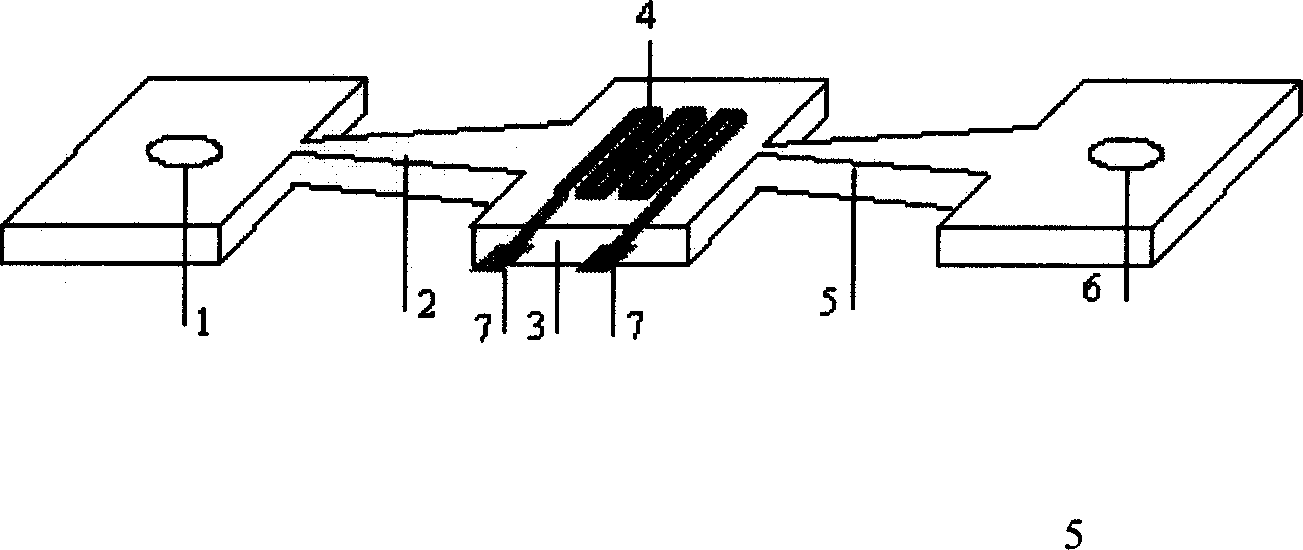

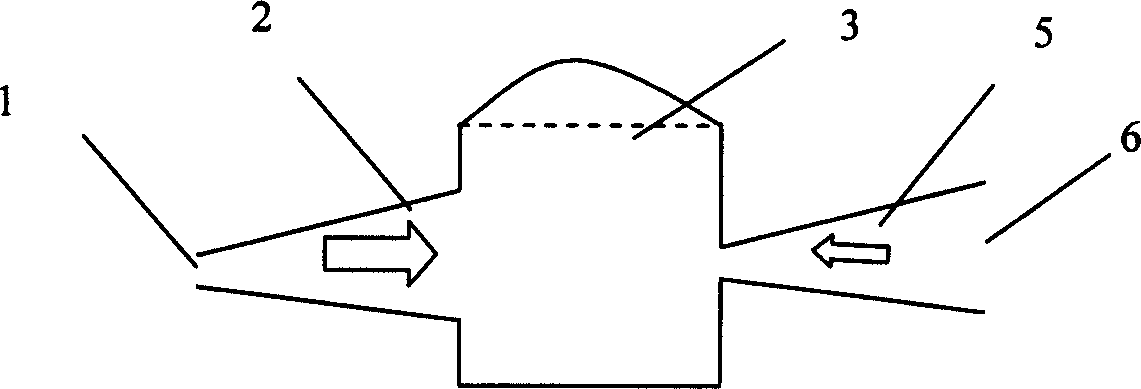

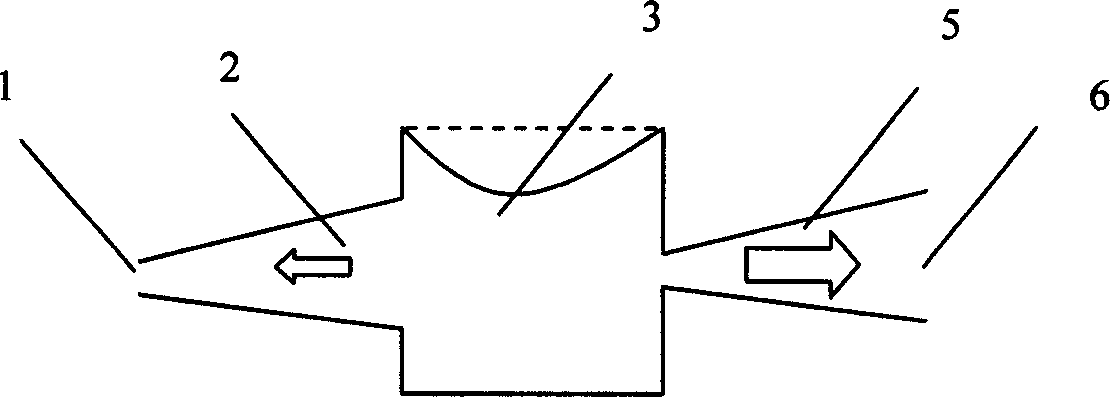

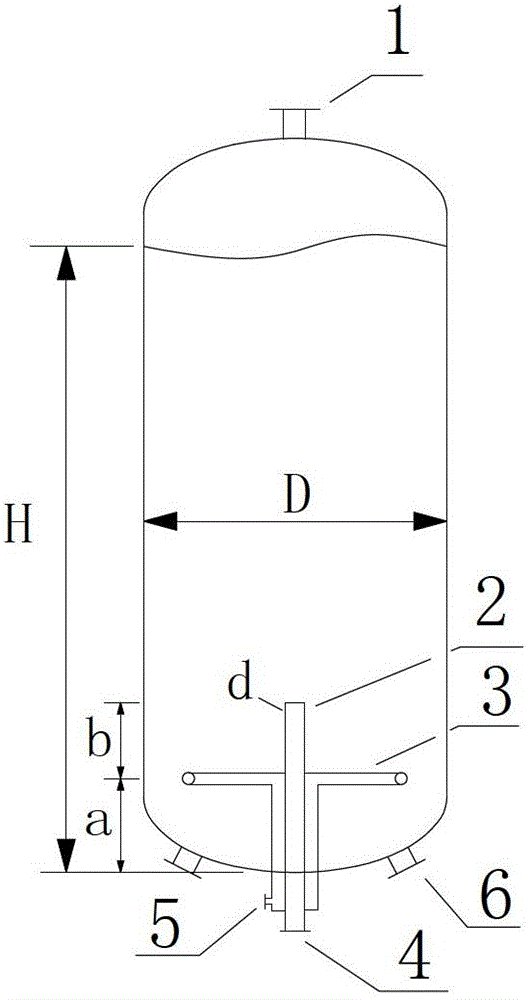

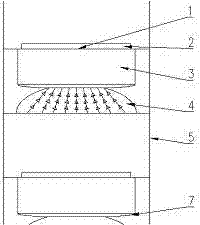

Method for preparing aldehyde by hydroformylation of low light olefins

ActiveCN104030900AEvenly distributedReduce instabilityOrganic compound preparationPreparation by carbon monoxide reactionLiquid jetHydrogen

The invention relates to a method for preparing aldehyde by hydroformylation of low light olefins, which solves the problems that the investment cost of stirring equipment is high, equipment fault is easy to generate, safe and stable operation of a reactor is influenced, a cycle reaction solution can interfere with the stirring effect, and the unevenness of concentration gradient and temperature is easily formed by the bubbling tower reactor. According to the invention, low carbon olefin and synthetic gas containing hydrogen and CO respectively pass through a liquid inlet 4 and an air inlet 5 for supplying to a jet reactor, the jet reactor comprises an air outlet 1, a liquid jet apparatus 2, a gas distributor 3, the liquid inlet 4, the air inlet 5 and liquid outlets 6; wherein the air inlet 5 and the liquid inlet 4 are positioned at the bottom of the reactor, the air outlet 1 is positioned at top of the reactor, and the liquid outlets 6 are symmetrically placed at two sides of a lower sealing head of the reactor; and the liquid jet apparatus 2 is positioned on the gas distributor 3; so that the technical scheme better solves the problems. The method can be used for industrial production for preparing aldehyde by hydroformylation of low light olefins.

Owner:SINOPEC SHANGHAI ENG +1

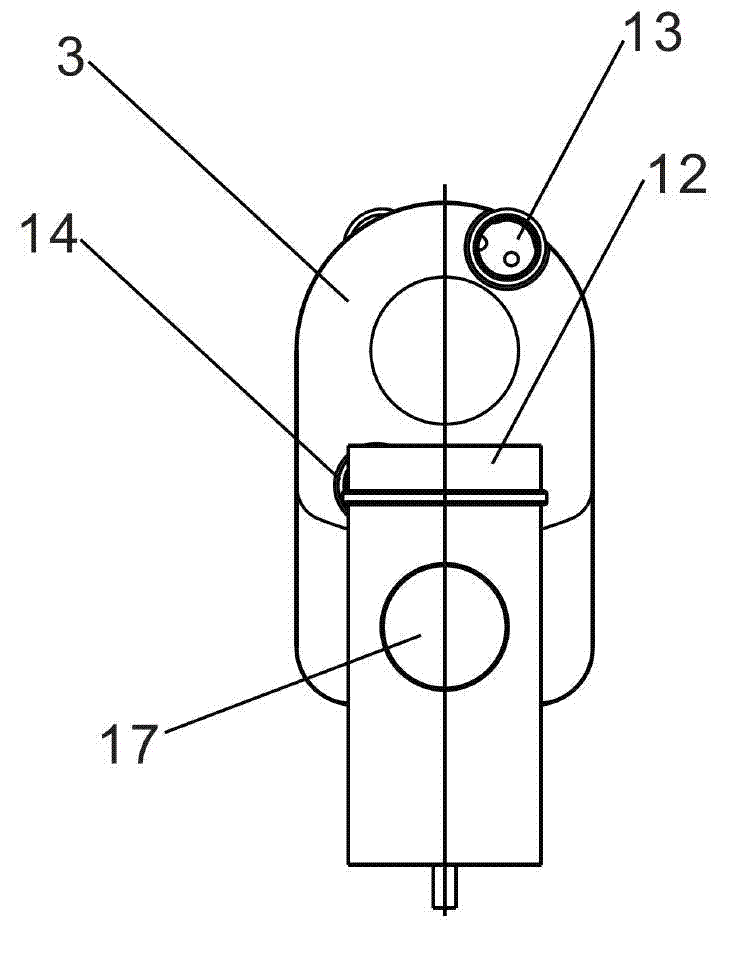

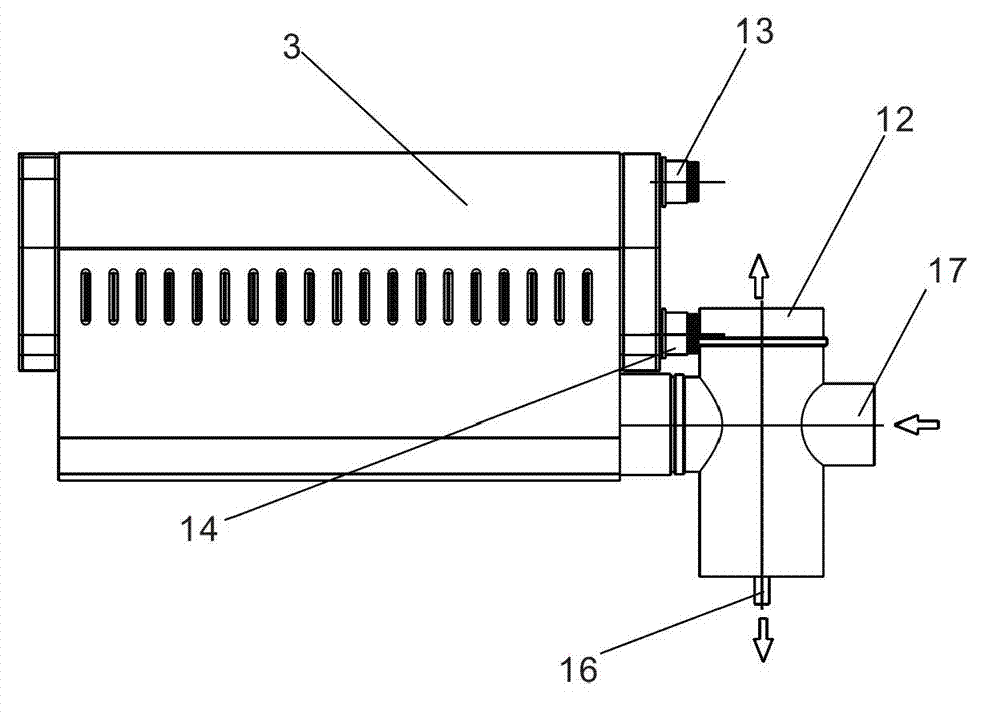

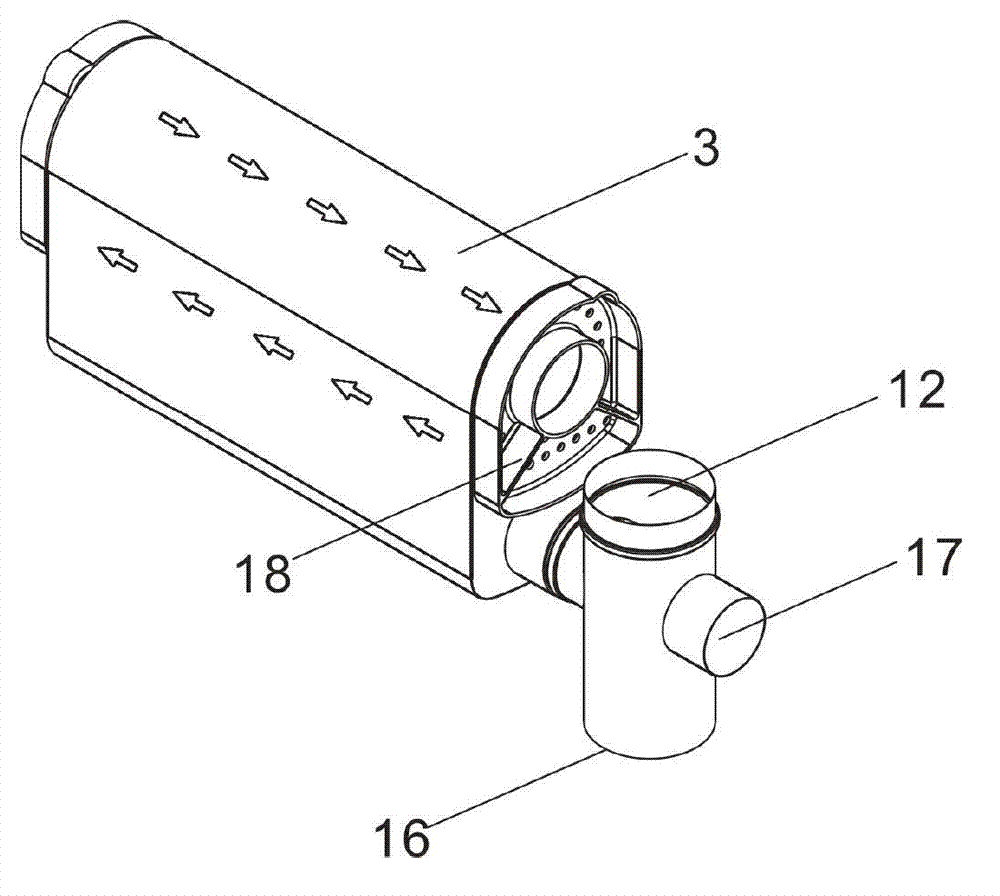

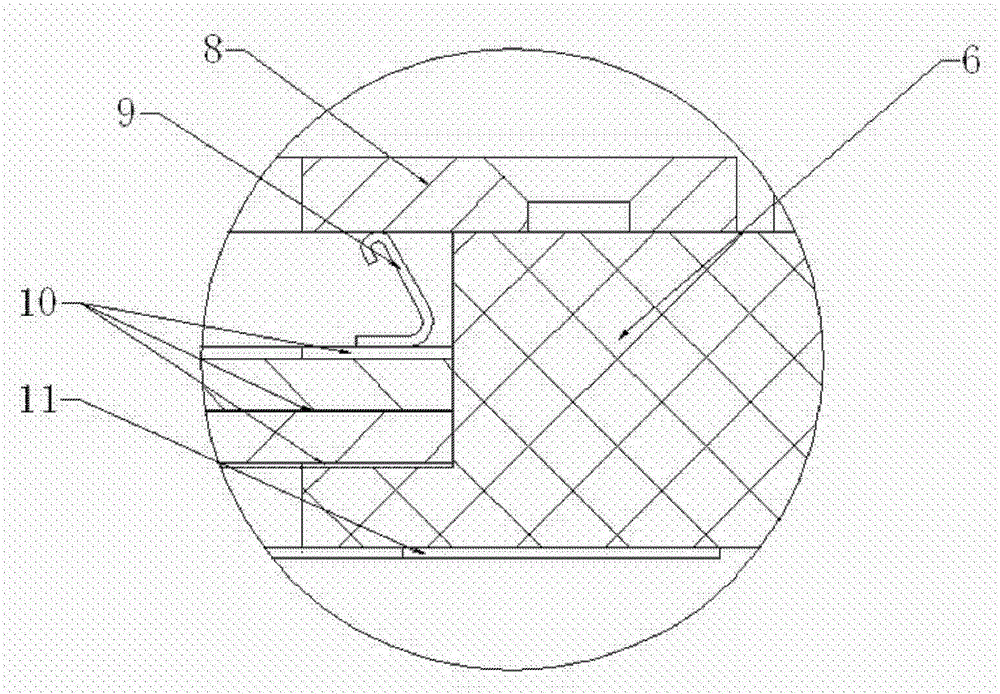

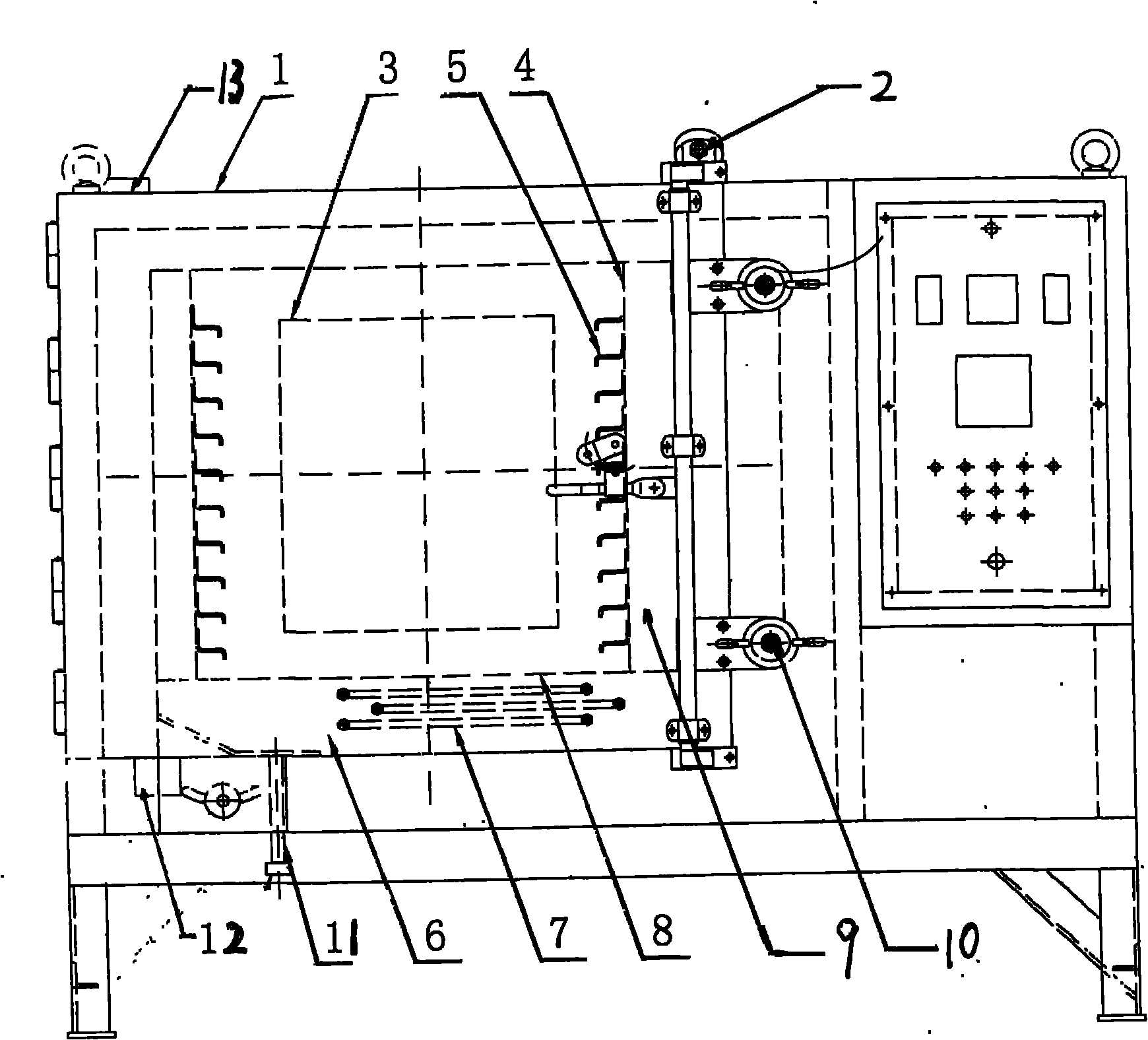

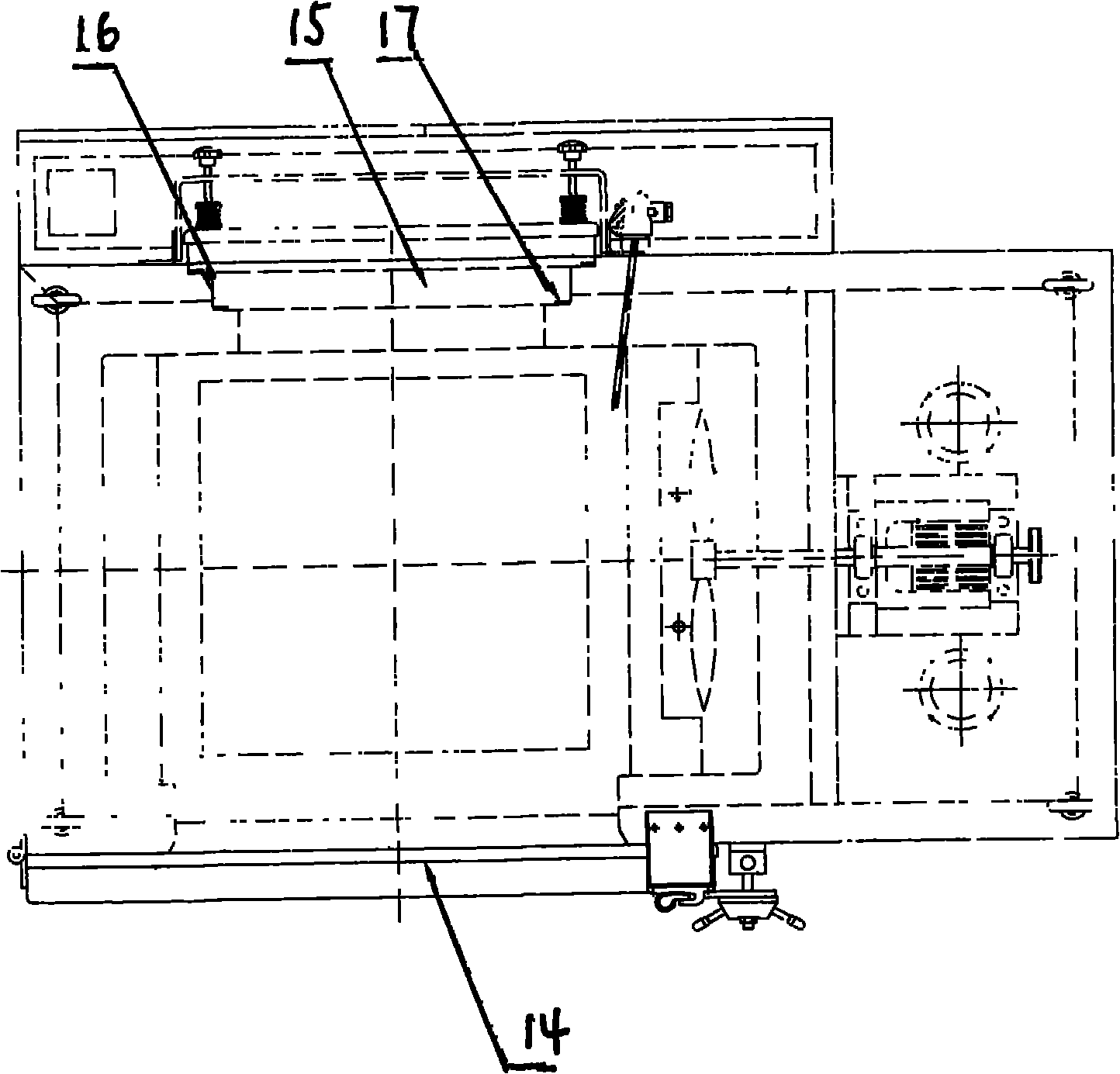

Debinding furnace

The invention discloses a debinding furnace and relates to the field of industrial furnaces, in particular to a drying debinding furnace for a ceramic ferrule for a photo-communication passive device. A hearth and a heating cavity welded by heat-resistant stainless steel plates are respectively formed in a mechanical frame; the hearth, the heating cavity, a hearth bottom plate and mesh plates on left and right sides of the hearth form an entire circulating air duct; an axial flow circulating fan is arranged inside the circulating air duct and is arranged on the right side of the hearth; and hot wind in the circulating air duct enters the hearth through the mesh plate on the right side of the hearth. The mesh plates are fixed on the left and right sides of the hearth; a slideway is fixed on a vertical steel bar of each mesh plate; the hearth bottom plate, the mesh plates on the two sides and the slideway are detachable; a hot-wind circulating system adopts an extremely-unique and timely air quantity-adjustable hot-wind circulating mode; the axial flow circulating fan regulates the speed by frequency conversion, the speed is continuously adjustable, the heat efficiency is greatly improved and the dead-space region is effectively reduced. A resistance wire has the characteristics of high material purity, stable performance, longer service life, high temperature resistance and corrosion resistance.

Owner:合肥高歌热处理应用技术有限公司

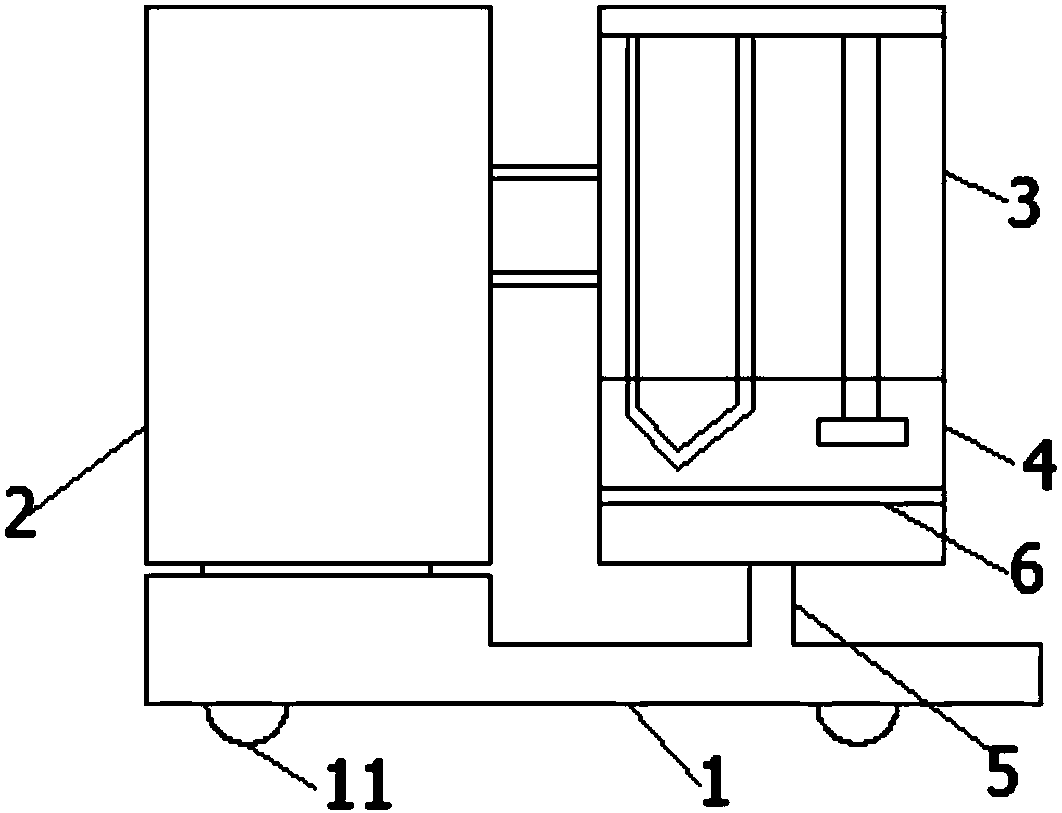

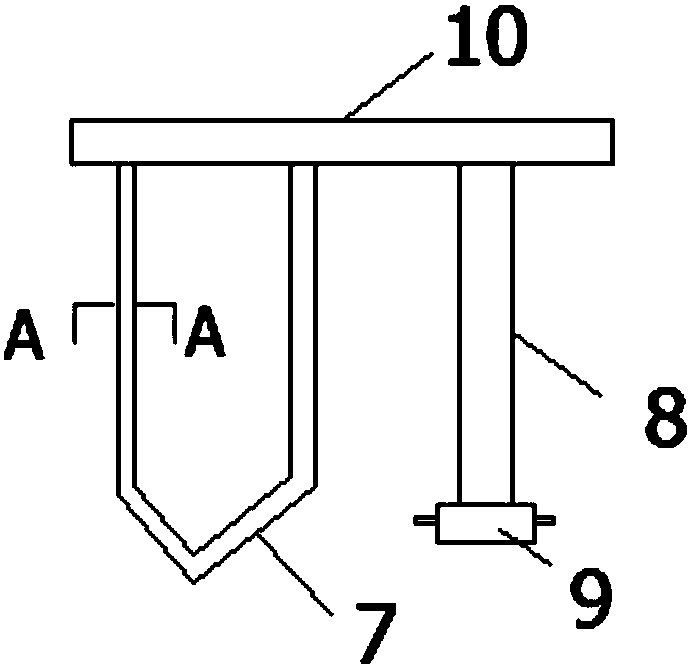

Gas-liquid distributor used for wood tar fluidized bed reactor

ActiveCN104927901AJumping up and down violentlyAvoid seal failureHydrocarbon oil crackingMicro bubbleFluidized bed

The invention discloses a gas-liquid distributor used for a wood tar fluidized bed reactor, the gas-liquid distributor is mainly composed of a center pipe, a bubble cap, a non-return ball, a taper ball seat and a limit seat; the bubble cap is a cylindrical matter with a bottom opening, covers the upper end of the center pipe, and is fixedly connected with the center pipe, the limit seat is arranged on the top of the bubble cap, and located in the center pipe, a material outlet is arranged on the pipe wall of the center pipe located below the limit seat, the taper ball seat is arranged on the pipe wall of the center pipe located below the material outlet, the non-return ball is arranged on the taper ball seat, the bubble cap, the center pipe, the limit seat, the non-return ball and the taper ball seat are coaxially arranged, an annular channel is formed between the bubble cap and the center pipe, and the lower end of the center pipe is provided with a material inlet. The gas-liquid distributor can not only guarantee a gas is broken into continuous micro bubbles in a liquid, and can effectively solve or ease countercurrent congestion problem of a catalyst-carrying material when gas and liquid pressure is instable or gas and liquid material feed is suddenly interrupted, at the same time, an internal flow dead zone in the distributor is reduced, and the pressure drop is smaller.

Owner:LUOYANG PETROCHEMICAL ENG CORP SINOPEC +1

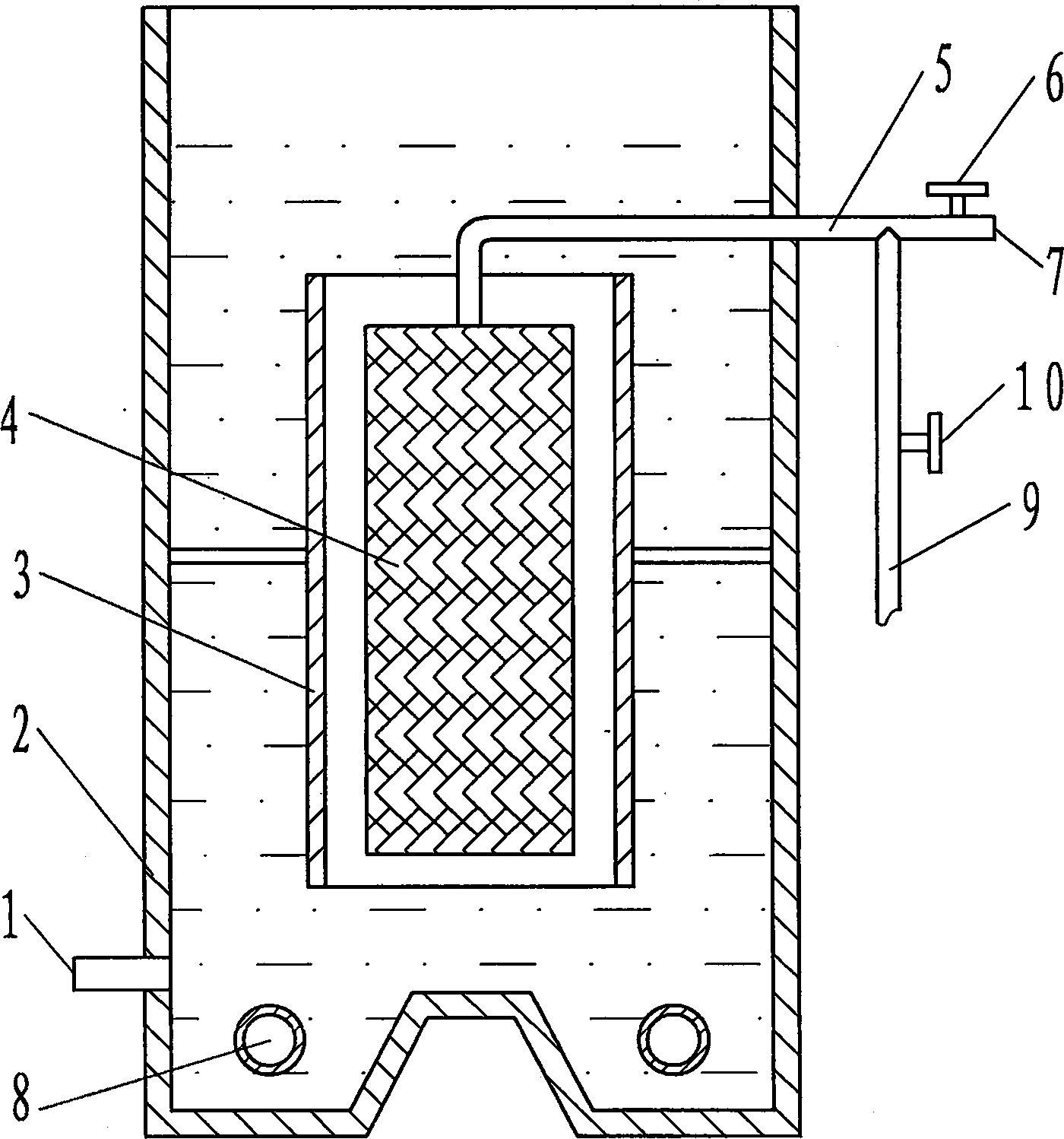

Internal circulation dynamic membrane bioreactor

InactiveCN1872733AReduce dead zoneImprove uniformityTreatment using aerobic processesSustainable biological treatmentDead bandEngineering

This invention provides an internal cycle dynamic membrane bioreactor. The bioreactor comprises an outer cylinder, an inner cylinder, a membrane component, an aeration pipe and a back-washing aeration pipe. The lower end of the outer cylinder is sealed while the upper end is open, and an water inlet is set at the lower end. The inner cylinder is set in the outer cylinder, and both ends of the inner cylinder are open. The membrane component is set in the inner cylinder, and a water outlet pipe is set at its upper end and extends out of the outer cylinder. The water outlet pipe is connected with the back-washing aeration pipe, which is set between the outer and the inner cylinders. The bioreactor has such advantages as reduced dead zones, improved uniformity of sludge mixing, increased cross flow speed of the mixed liquids in the inner cylinder, retarded membrane pollution, prolonged back-washing cycle, and improved operation stability.

Owner:SHANDONG UNIV

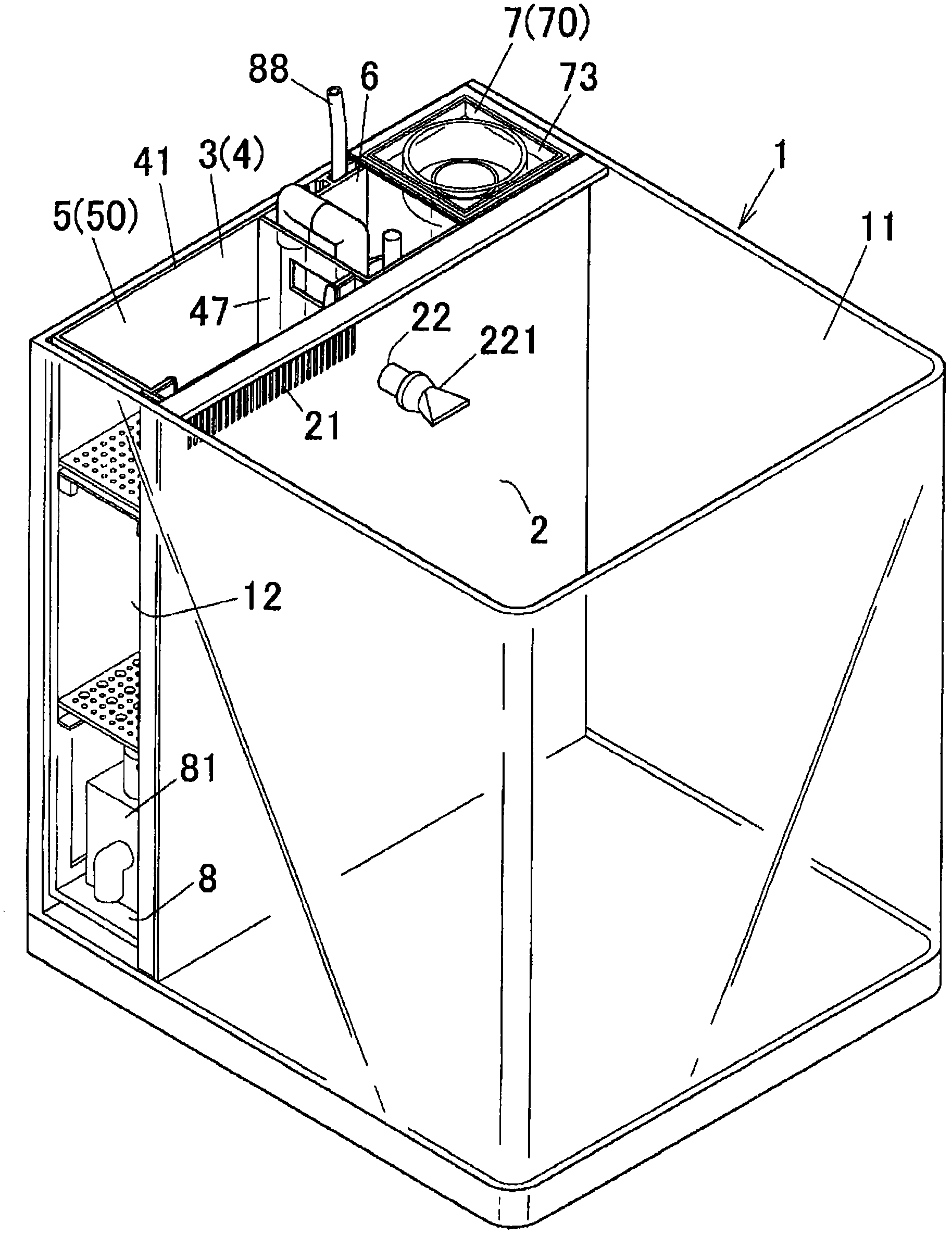

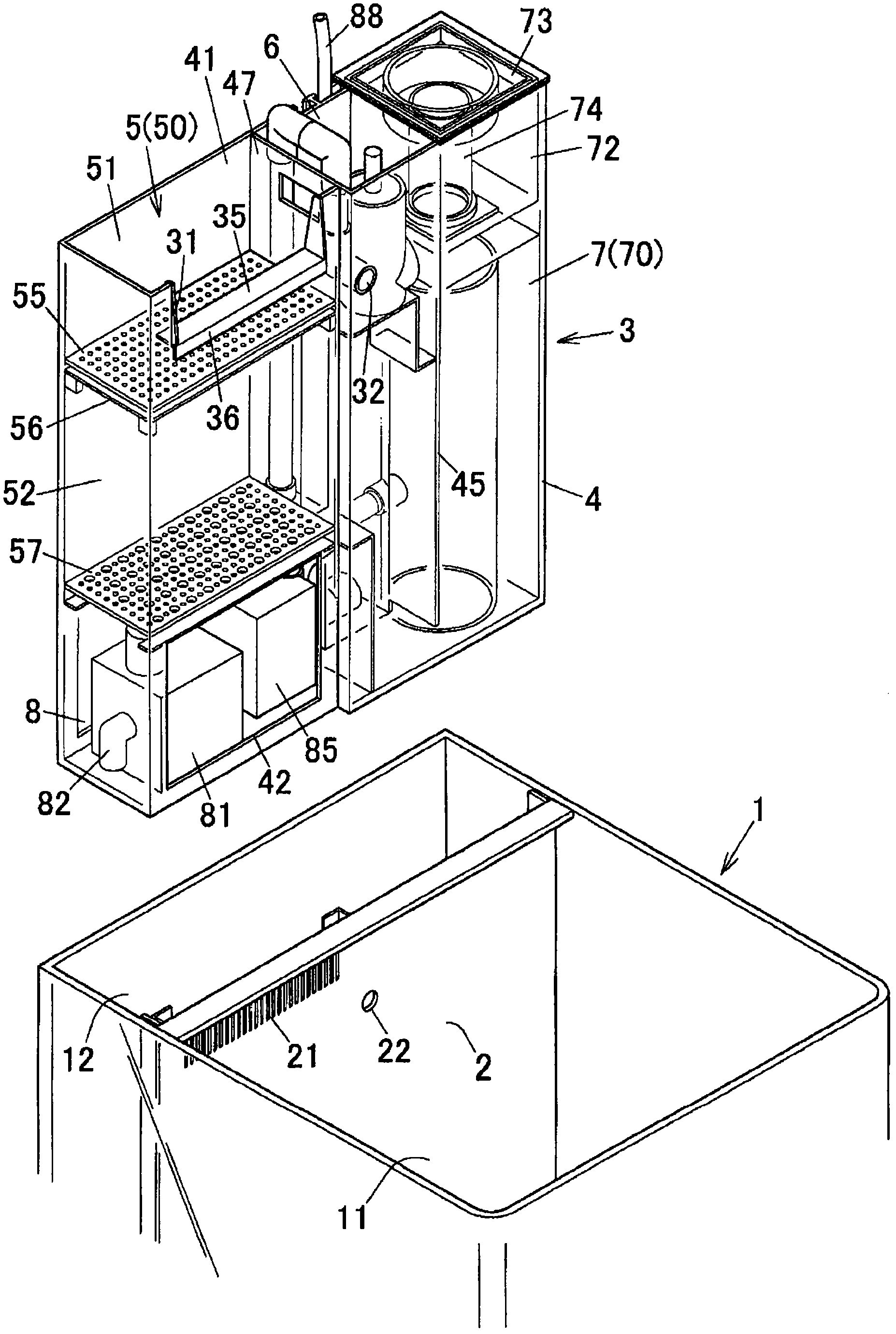

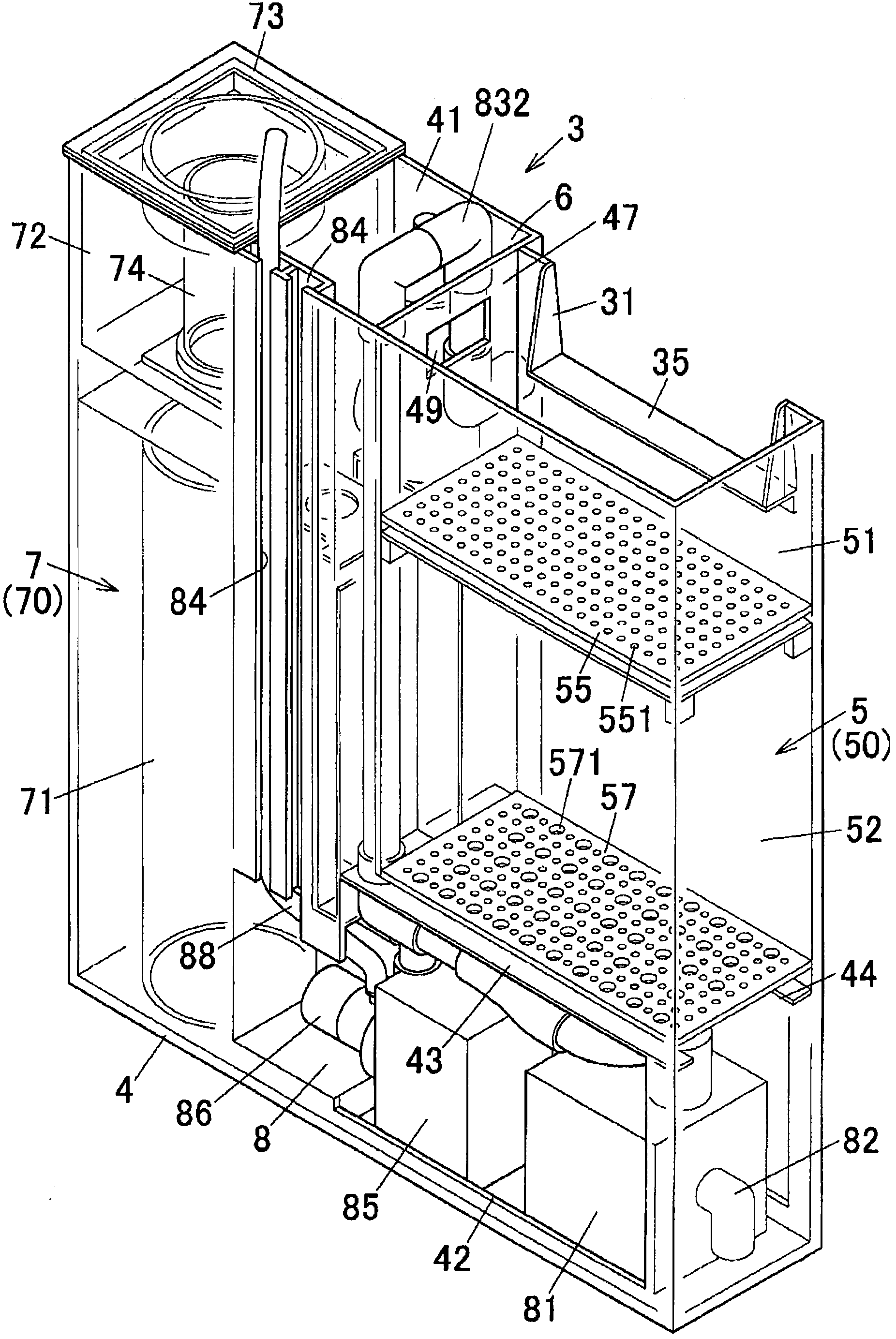

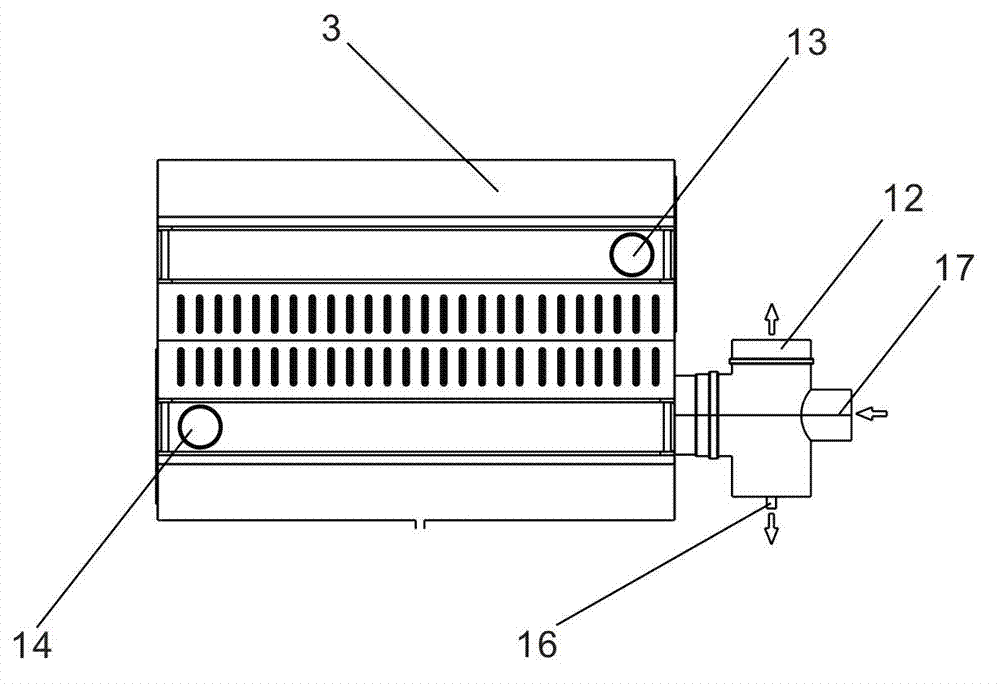

System for feeding aquatic organisms and cleaning unit for water tank

InactiveCN102036550AReliable removalReduce dead zoneTreatment using aerobic processesWater/sewage treatment by irradiationFiltrationUltraviolet lights

Provided is a system for feeding aquatic organisms in which the maintenance of a cleaning device, a circulating pump and so on can be easily conducted and the size of a cleaning zone can be reduced to give a compact device. A system comprising a water tank (1), a partition wall (2) for dividing the water tank (1) into a feeding zone (11) and a cleaning zone (12), a circulating pump (81) for circulating water between the feeding zone (11) and the cleaning zone (12) and one or more cleaning devices selected from among a filtration device (50) by which water is allowed to penetrate through a filter material and thus filtered, a protein skimmer (70) by which proteins contained in the water are adhered to bubbles and thus removed and an ultraviolet light irradiator by which the water is sterilized by ultraviolet light irradiation. The circulating pump and at least one cleaning device constitute components of a unit. These unit components are loaded on a load frame to construct a cleaning unit (3). As the unit components are loaded on the load frame, the cleaning unit (3) is put in the cleaning zone (12) in an insertable / ejectable manner.

Owner:TOMINAGA JYUSHI INDSSHO

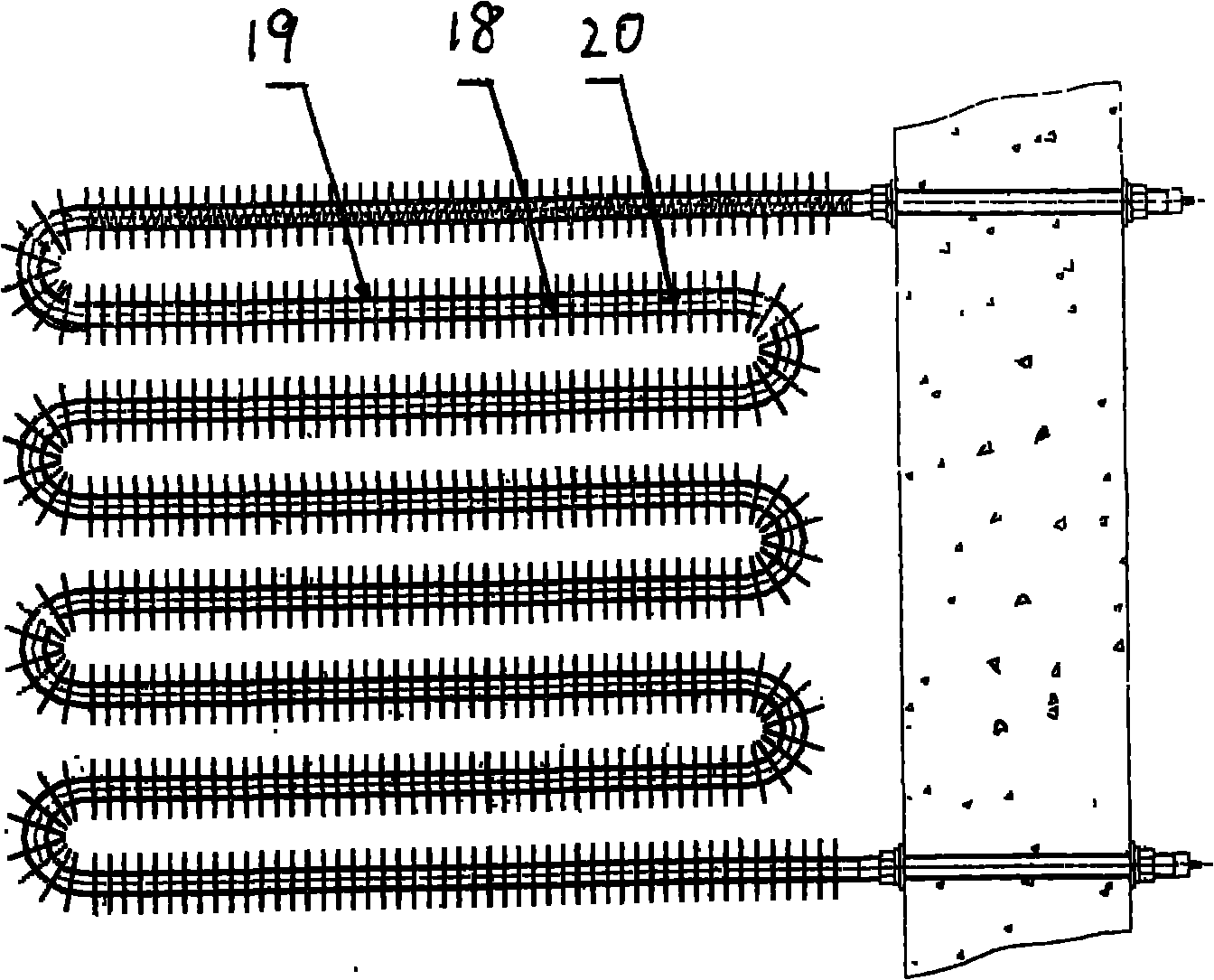

Forced spiral finned coil pipe condensation heat-supply heat exchanger

ActiveCN102901225AImprove heat transfer efficiencyImprove heat transfer effectEnergy efficient heating/coolingAir heatersCombustorPlate heat exchanger

The invention discloses a forced spiral finned coil pipe condensation heat-supply heat exchanger, which comprises a shell, a combustor arranged in the shell and a plurality of spiral finned coil pipes, wherein a water inlet, a water outlet and a smoke outlet are formed on the shell; the combustor is connected with an air and gas inlet device; the combustor is positioned on the upper part of the shell; the periphery of the combustor is coaxially provided with a group of pipe bundles consisting of a plurality of spiral finned coil pipes; a smoke exhaust pipeline which consists of a plurality of tightly arranged spiral finned coil pipes is arranged below the combustor; the smoke exhaust pipeline is emptied through a smoke outlet; the water inlet is communicated with the spiral finned coil pipes which are tightly arranged below the combustor; the spiral finned coil pipes which are tightly arranged below the combustor are communicated with the spiral finned coil pipes at the periphery of the combustor; and the spiral finned coil pipes at the periphery of the combustor are communicated with the water outlet. The inwards folded finned straight pipes serve as basic elements of the heat exchanger, the heat exchange on the smoke side is intensified, and the size of the whole heat exchanger is further reduced.

Owner:SUZHOU CQ HEAT EXCHANGER

Helical flow dephosphorization reactor

ActiveCN104478121AEnhanced plug flowImprove performanceWater contaminantsTreatment involving filtrationWater dischargeEnvironmental engineering

The invention provides a helical flow dephosphorization reactor. The helical flow dephosphorization reactor comprises a pre-backwashing zone, a gas stripping lifting zone, a water discharging zone, a filtering zone, a water feeding zone, a backwashing zone and a solid-liquid separation zone from bottom to top; the pre-backwashing zone comprises an inverted bench body, and an escape tube is arranged below the inverted bench body; the gas stripping lifting zone comprises a gas stripping tube, and the lower end of the gas stripping tube is provided with a gas stripping gas inlet tube; the water discharging zone comprises a filtered water collecting tube, and the filtered water collecting tube is coaxially arranged outside the gas stripping tube; the filtering zone comprises a lower cylinder, and the lower cylinder is coaxially arranged outside the filtered water collecting tube; the water feeding zone comprises a water feeding tube, and the water feeding tube is connected with the upper end of the lower cylinder; the backwashing zone comprises a backwashing air tube, the backwashing air tube is connected with the upper end of the gas stripping tube, and an efficient stripping tube is connected with the top of the gas stripping tube; and the solid-liquid separation zone comprises an upper cylinder, and the upper cylinder is connected with the top of the lower cylinder. The reactor has the advantages of continuous running, tending towards a laminar flow state, small dead zone area, high filtering and backwashing efficiency, reasonable and concise structure, convenient processing and convenient popularization application.

Owner:浙江沃乐科技有限公司

Waste-heat utilization heat exchanger with constant output fluid temperature

InactiveCN103615919AStable temperatureLow flow resistanceStationary tubular conduit assembliesRecuperatorEngineering

A waste-heat utilization heat exchanger with a constant output fluid temperature comprises heat exchange tube bundles, a shell, an inlet header and an outlet header. The heat exchange tube bundles are arranged in the shell, and the two ends of each heat exchange tube bundle are connected with the inlet header and the outlet header respectively. The inlet header is provided with an inlet pipe, the outlet header is provided with an outlet pipe, and a tail gas inlet and a tail gas outlet are formed in the upper portion and the lower portion of the shell respectively. The inlet pipe is provided with a valve and a temperature sensor, and an outlet temperature sensor is arranged in the outlet pipe. The temperature sensor and the valve are both in communication connection with a central control unit. The waste-heat utilization heat exchanger is an efficient clean type heat reclaim unit and has the advantages of being strong in heat-transfer capability and the like, the outlet water temperature is kept constant by the way of controlling the flow of heat exchange fluid which is input to the heat exchanger, the technical effect that the temperature of output water is constant can be achieved, and therefore intelligent control over the heat exchanger is achieved.

Owner:SHANDONG UNIV

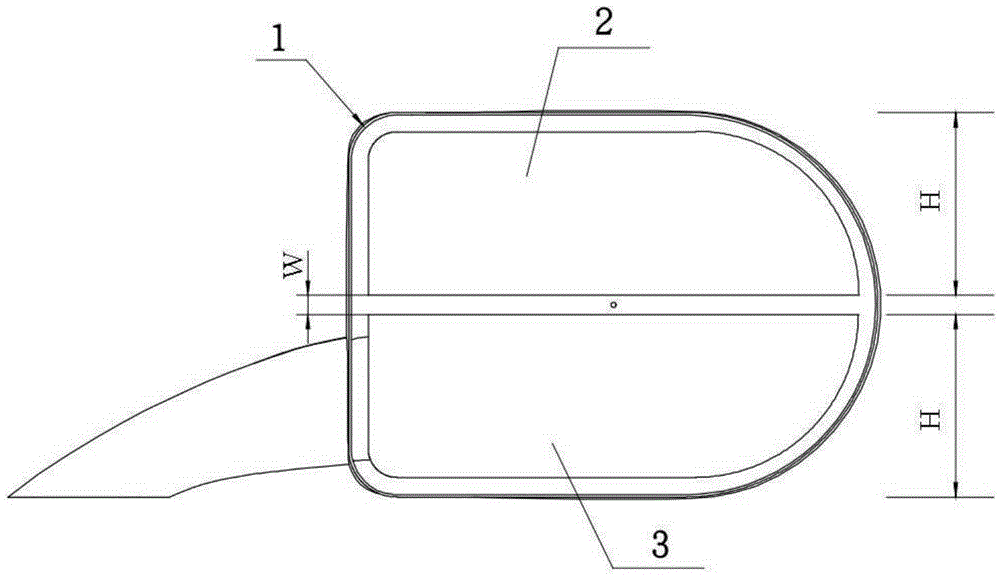

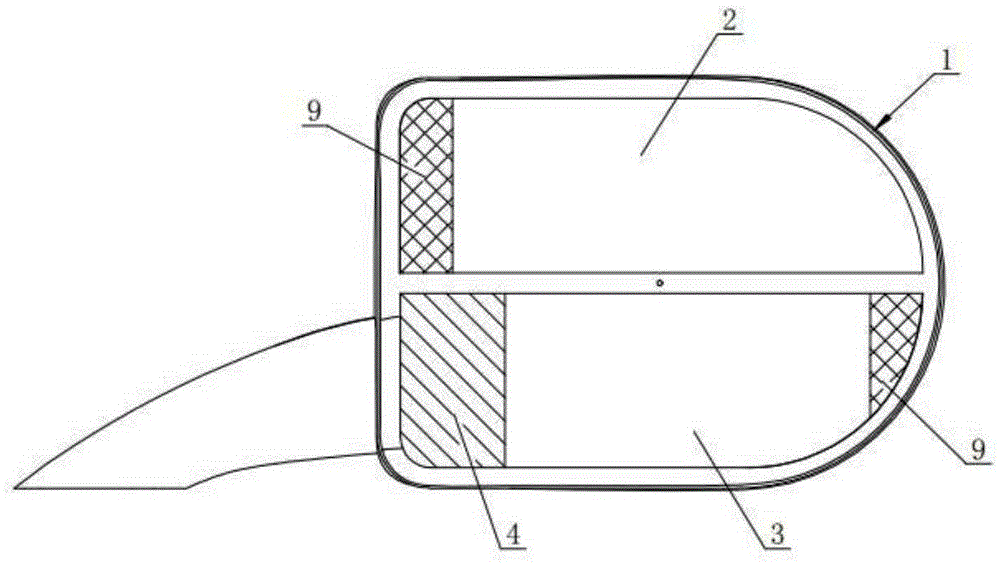

Outside rear-view mirror and method for adjusting outside rear-view mirror when used for vehicle

InactiveCN105416183AReduce dead zoneObserve comprehensivelyOptical viewingOptoelectronicsWing mirror

The invention belongs to the technical field of vehicle accessories, and particularly relates to an outside rear-view mirror and a method for adjusting the outside rear-view mirror when used for a vehicle. The outside rear-view mirror comprises a reflective mirror set and a shell. The reflective mirror set is composed of a first reflective mirror and a second reflective mirror. The first reflective mirror and the second reflective mirror are vertically arranged in the shell in the vertical direction. A drive mechanism is located in a cavity formed between the reflective mirror set and the shell and connected with the first reflective mirror and the second reflective mirror to drive the first reflective mirror and the second reflective mirror to rotate in the shell. Both the first reflective mirror and the second reflective mirror are convex lenses. The curvature radius of the first reflective mirror is the same as that of the second reflective mirror. By the adoption of the outside rear-view mirror, the dead zone phenomenon of a conversional outside rear-view mirror can be greatly and effectively avoided, vision disparity is reduced, and erroneous judgment is reduced; and the method for adjusting the outside rear-view mirror is reliable, practical and suitable for being widely applied and popularized as a vehicle accessory.

Owner:曹德州 +1

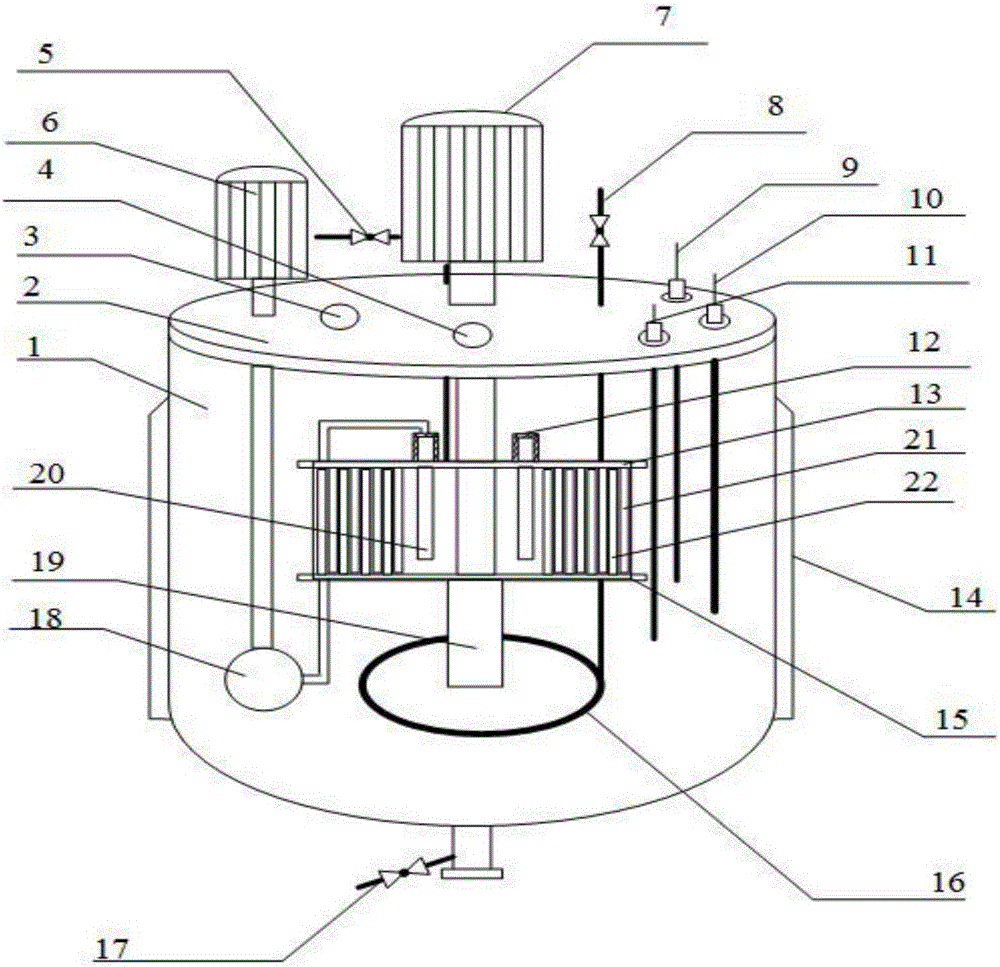

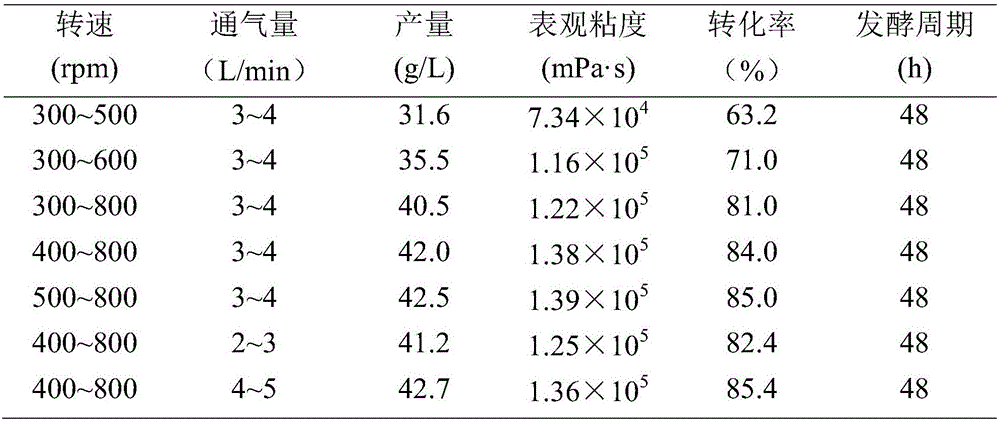

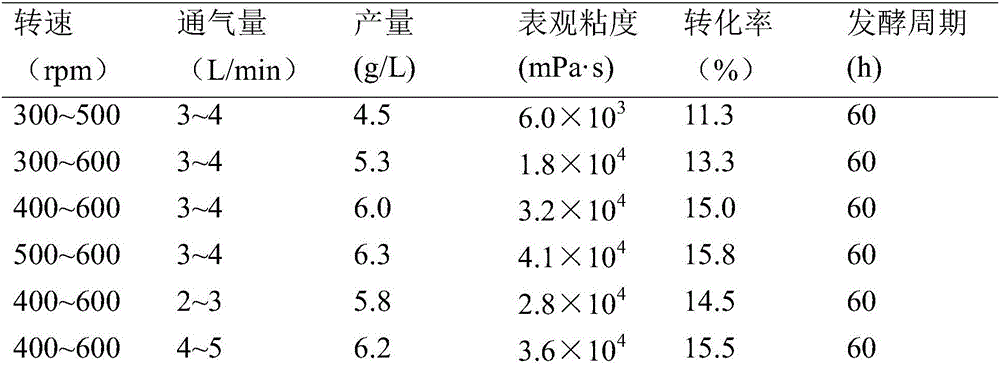

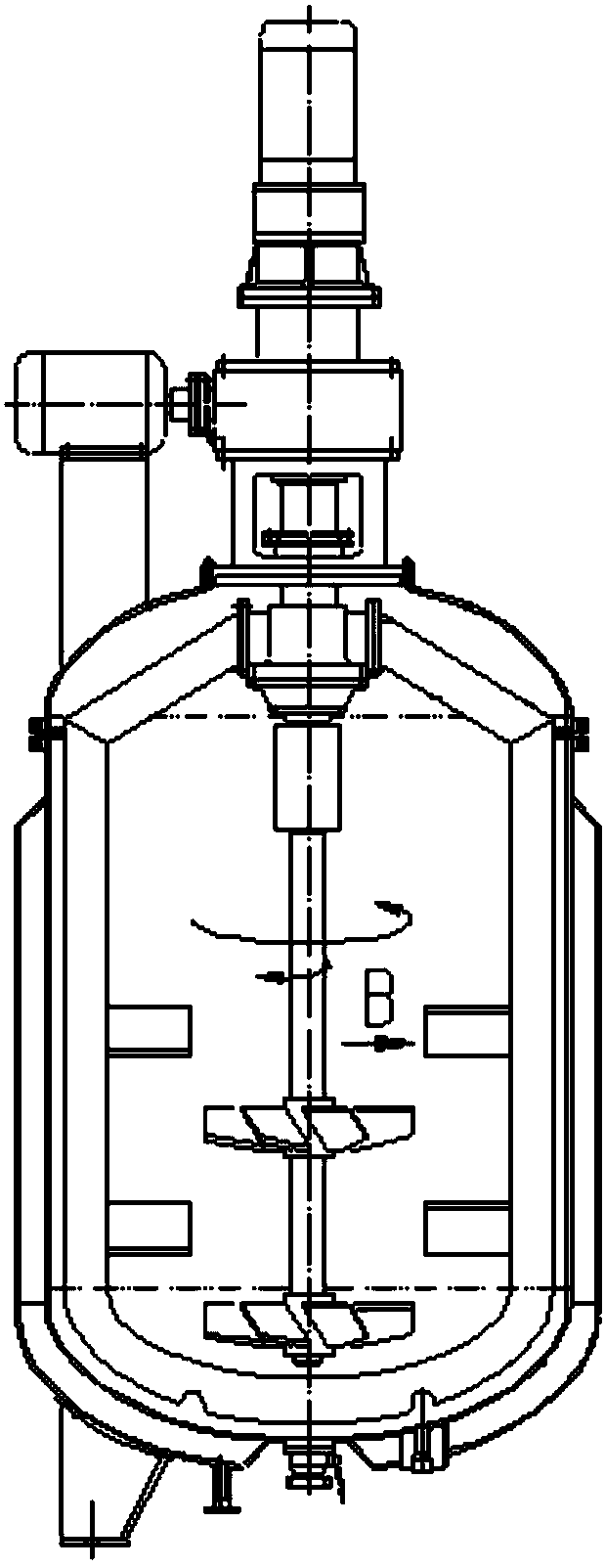

System device for strengthening high-viscosity microbial polysaccharide fermentation and application

InactiveCN106635753AGrow fastDissolved oxygen is goodBioreactor/fermenter combinationsBiological substance pretreatmentsBiochemical engineeringOxygen mass transfer

The invention discloses a system device for strengthening high-viscosity microbial polysaccharide fermentation. The system device comprises a tank body, a tank cover, a cooling interlayer, an air distributor, a first motor, a second motor, a supergravity revolving bed device and a high-temperature-resisting submerged pump. A rotary shaft is longitudinally arranged inside the tank body. The upper end of the rotary shaft penetrates through the tank cover to be in driven connection with the first motor, and the lower end of the rotary shaft extends into the tank body to be connected with the supergravity revolving bed device. The supergravity revolving bed device is transversely arranged at the center of the inside of the tank body. The air distributor is arranged at the lower end of the supergravity revolving bed device and is an annular pipeline. The high-temperature-resisting submerged pump is arranged on one side of the lower end of the inside of the tank body. One end of the high-temperature-resisting submerged pump is connected with the supergravity revolving bed device through a pipe, and the other end of the high-temperature-resisting submerged pump is connected with a rotary shaft of the second motor. The cooling interlayer is arranged outside the tank body. A fermentation period is greatly shortened by strengthening dissolved oxygen mass transfer, gas, liquid and solid phase mixing, rotating speed optimization, ventilatory capacity and other conditions, the yield and mass of high-viscosity polysaccharide are increased, and the cost is remarkably reduced.

Owner:BEIJING UNIV OF CHEM TECH

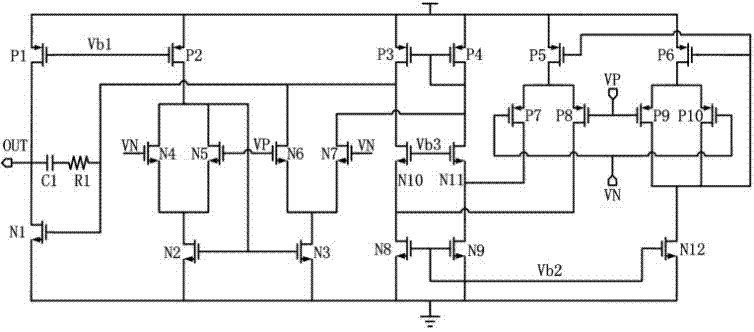

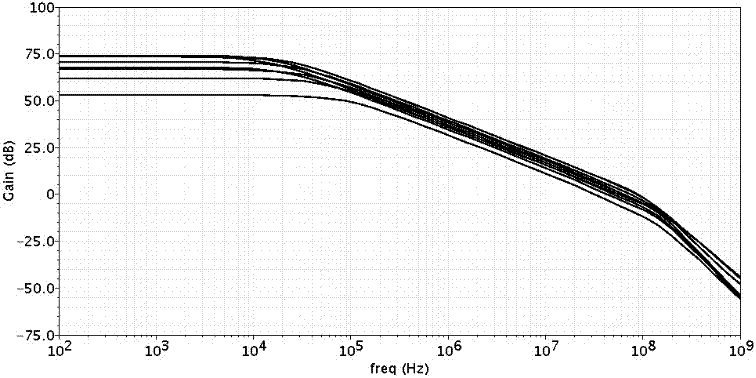

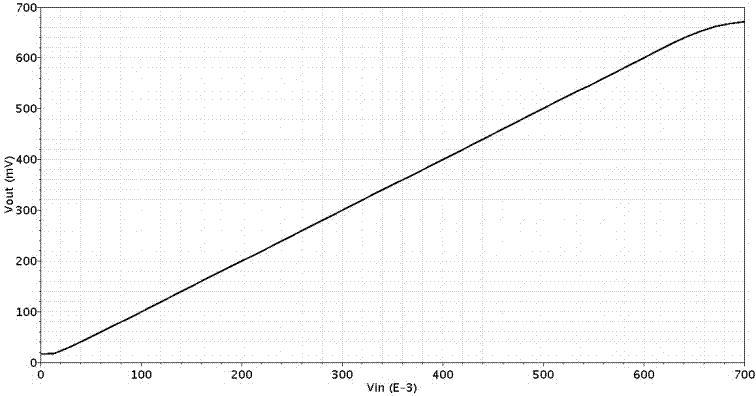

Low-voltage rail-to-rail transconductance amplifier

InactiveCN107154786AReduce dead zoneConstant currentDifferential amplifiersDc-amplifiers with dc-coupled stagesAudio power amplifierLow voltage

The invention discloses a low-voltage rail-to-rail calculation transconductance amplifier. The transconductance amplifier comprises an input stage and an output stage, wherein the input stage is a mutually complementary master-slave differential amplifier composed of an NMOS differential transconductance stage of a band-tail current source and a PMOS differential transconductance stage of the band-tail current source, and the output stage is a common-source amplifier of a folded structure; the output current of the mutually complementary master-slave differential amplifier is input into the source electrode and the drain electrode of a common-grid tube respectively, then overlaid, and converted into a first voltage, and the first voltage is output; the output signal of a first stage is amplified through the common-source amplifier of the output stage, and the amplified output signal of the first stage is output through the common-source amplifier of the output stage. The minimum working voltage of the low-voltage rail-to-rail transconductance amplifier can be a power voltage of 0.6 V, and that no dead zone of the amplifier exists within a whole common-mode input range can be guaranteed; the voltage of the grid electrode of a tail-current tube can be dynamically adjusted under varying conditions of different input voltages, the common-mode voltage dead zones are significantly reduced, and rail-to-rail input or output can be achieved.

Owner:SOUTHEAST UNIV

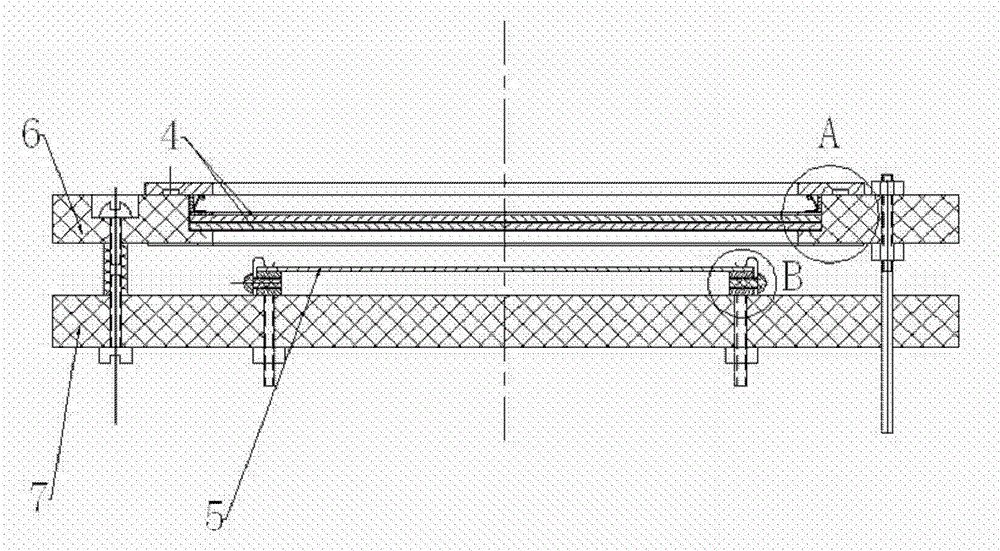

Liquid-accommodation diversion type drop pipe

InactiveCN104722095AOutflow smoothlyFinely dispersedDispersed particle separationDistillation separationPlate pressureSingle stage

The invention discloses a liquid-accommodation diversion type drop pipe comprising a pipe body, overflow weirs, single-stage or multiple-stage liquid accommodating chambers clinging to the tower wall and pipe wall, liquid accommodating plates of the bottom of the pipe body and drop plates. According to the drop pipe, the liquid phase and gas phase flowing and contacting state in a tower is changed, the gas and liquid contacting and separating strength is enhanced, the purposes of improving the tower distillating efficiency and operational flexibility and increasing the tower flux can be achieved, the tower blockage prevention capability is improved, the tower plate pressure drop is reduced, energy consumption and equipment investment are reduced, and the comprehensive performances of the tower are improved.

Owner:万强

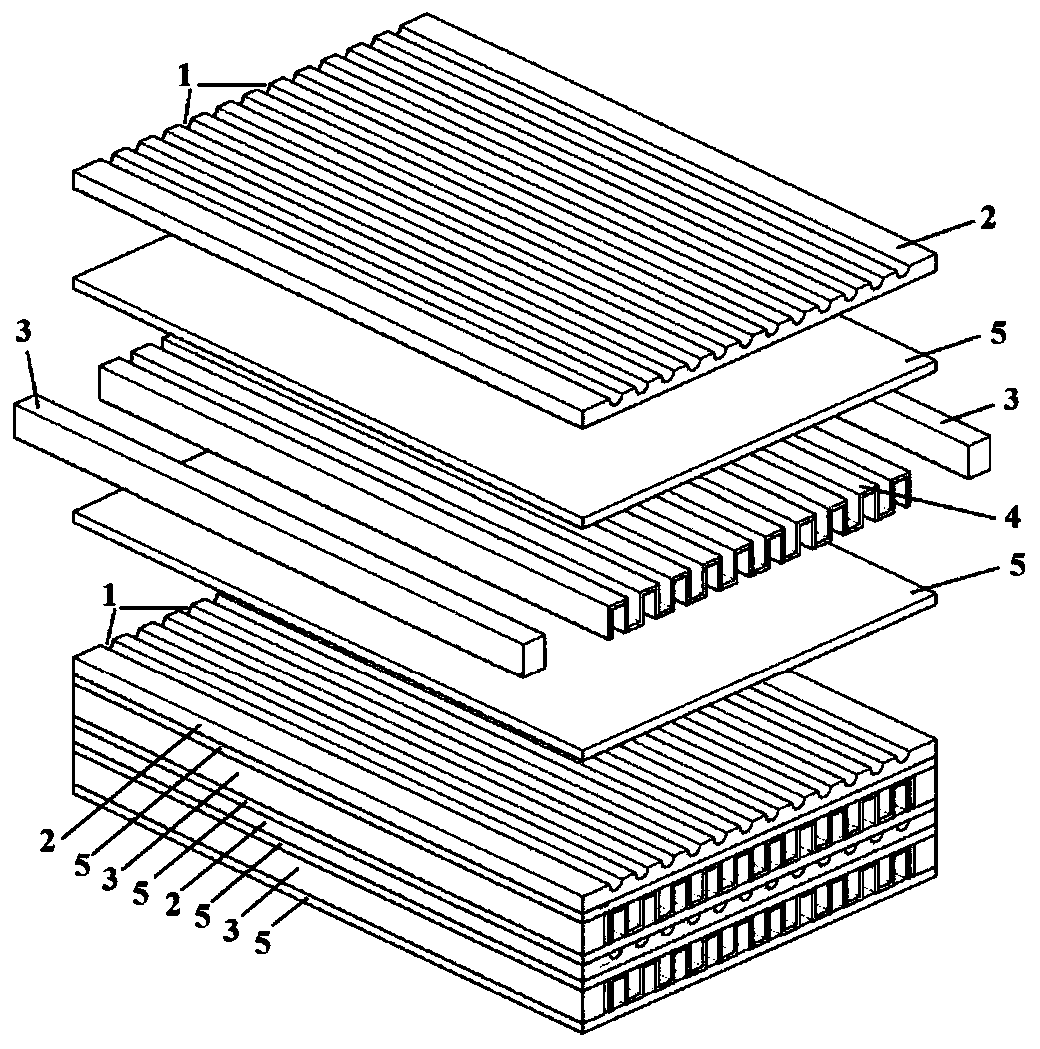

Composite structure printed circuit board type heat exchanger core body

PendingCN111059934AMeet high temperature requirementsImprove high temperature resistanceLaminated elementsStationary plate conduit assembliesHeat flowMolten salt

The invention relates to a composite structure printed circuit board type heat exchanger core body. A plurality of etching plates, fin plates and septa are alternately stacked and arranged in the height direction, the upper surfaces of the etching plates are etched with micro-flow channels for sCO2 medium to flow, seals are arranged on the left and right sides of the fin plates, an interlayer is formed by each fin plate, the seals on the left and right sides and the septa on the upper and lower sides, and a channel for molten salt or liquid metal medium to flow is formed. The composite structure printed circuit board type heat exchanger core body can be resistant to high temperature, high pressure and large pressure difference, and has the characteristics of large heat load, high heat fluxdensity, compactness and high efficiency.

Owner:XIAN THERMAL POWER RES INST CO LTD

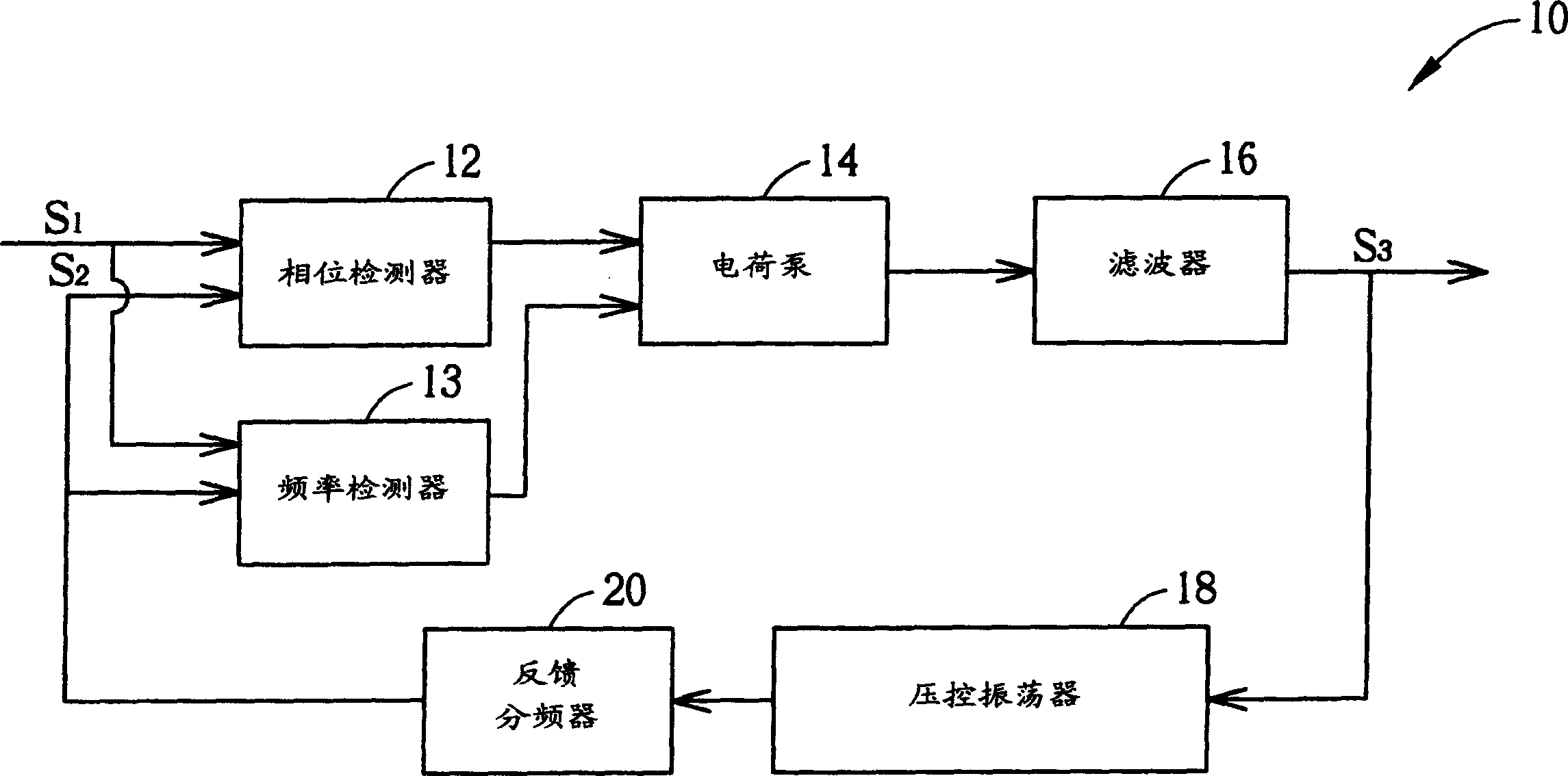

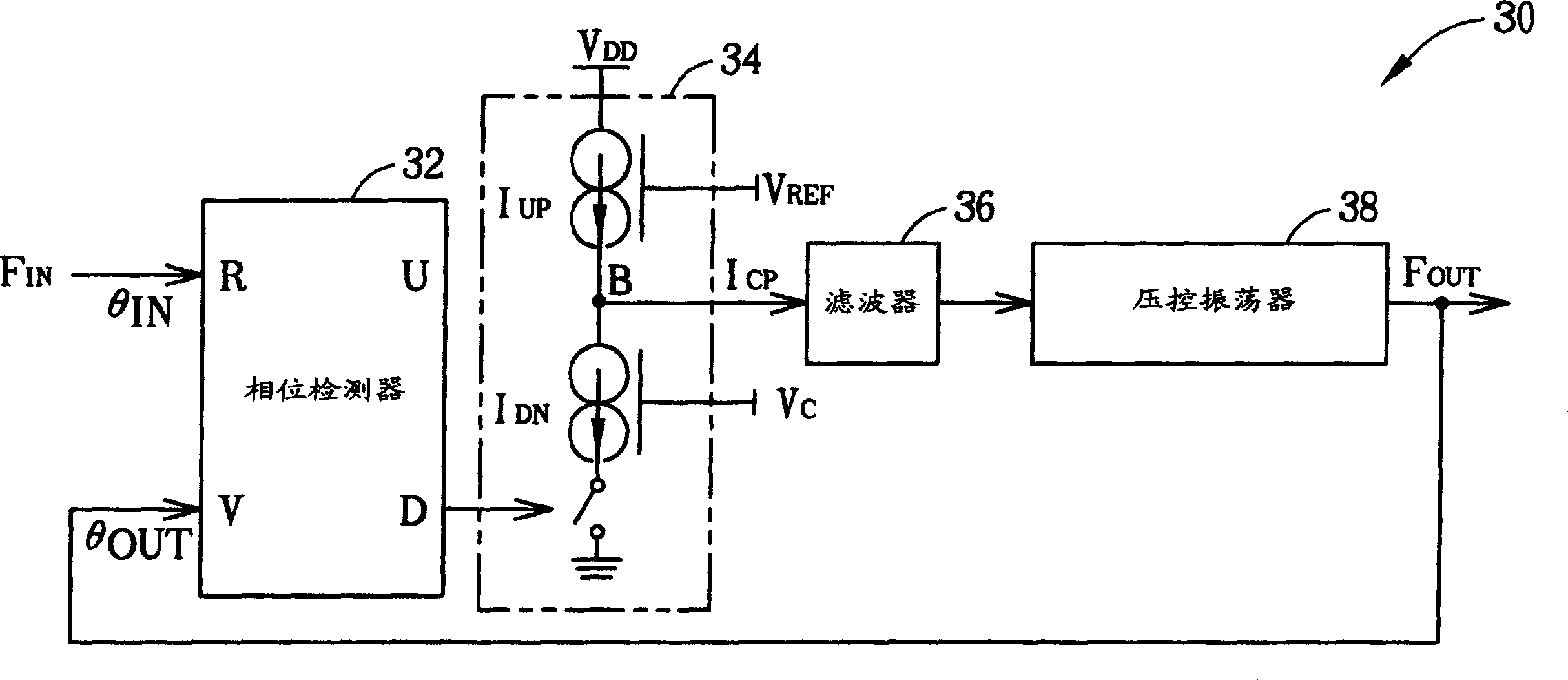

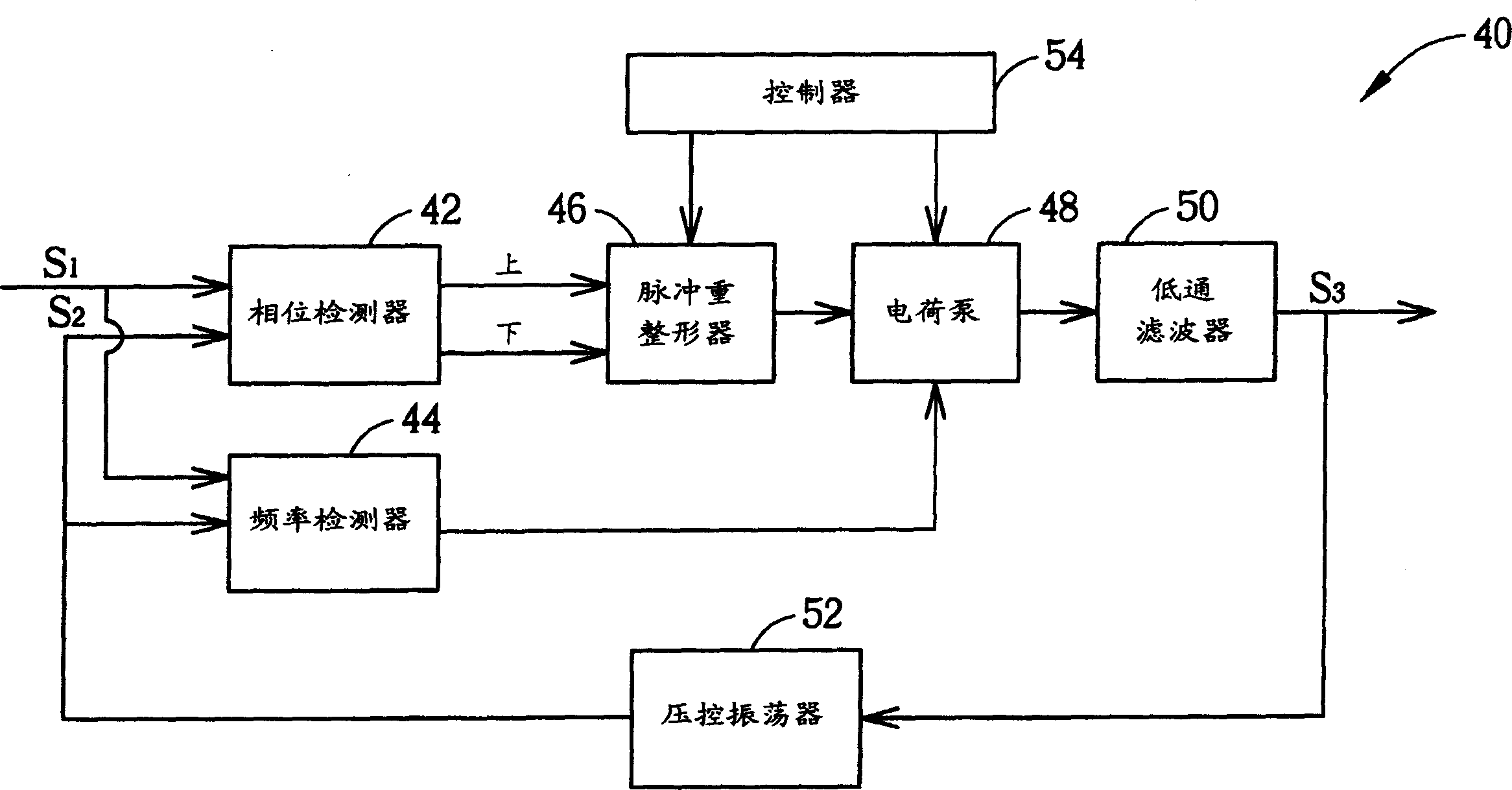

Phase-locked loop having phase detector error signal reshaping and method thereof

A phase-locked loop includes a signal reshaper connected between a phase detector and a charge pump. The signal reshaper can be controlled by a controller to reshape the phase error signal based on the difference between the frequency of an output signal, output from a low pass filter, and a target frequency. The signal reshaper outputs a reshaped or unreshaped phase error signal to the charge pump. The unreshaped phase error signal causes the phase-locked loop to lock the frequency of a feedback signal to the frequency of an input signal. The reshaped phase error signal causes the charge pump to output a charge pump signal that synchronizes the frequency of the output signal with the target frequency.

Owner:MEDIATEK INC

Lithium battery electrode slurry stirring processing method and lithium battery electrode slurry obtained by processing

ActiveCN108172753AWell mixedHigh viscosityElectrode manufacturing processesTransportation and packagingSlurryEngineering

The invention relates to the field of lithium battery manufacturing, and particularly provides a lithium battery electrode slurry stirring processing method and lithium battery electrode slurry obtained by processing. The lithium battery electrode slurry stirring processing method comprises the following steps of (a) performing premixing: mixing a solvent and a bonder uniformly to obtain a first mixture, and mixing active substances and a conductive agent uniformly to obtain a second mixture; (b) performing primary stirring: mixing and stirring part of the first mixture and all of the second mixture to obtain a third mixture; (c) performing secondary stirring: mixing and stirring the rest of the first mixture and all of the third mixture; (d) performing third mixing; (e) performing fourthstirring; (f) performing fifth stirring; and circulating the steps (d)-(f). According to the processing method, the uniformity and stability of the electrode slurry in lithium battery production can be remarkably improved, and the uniformity of the next coating process can be improved, so that the controllability of the lithium ion battery production process and the consistency of product performance are improved.

Owner:BEIJING NAT BATTERY TECH

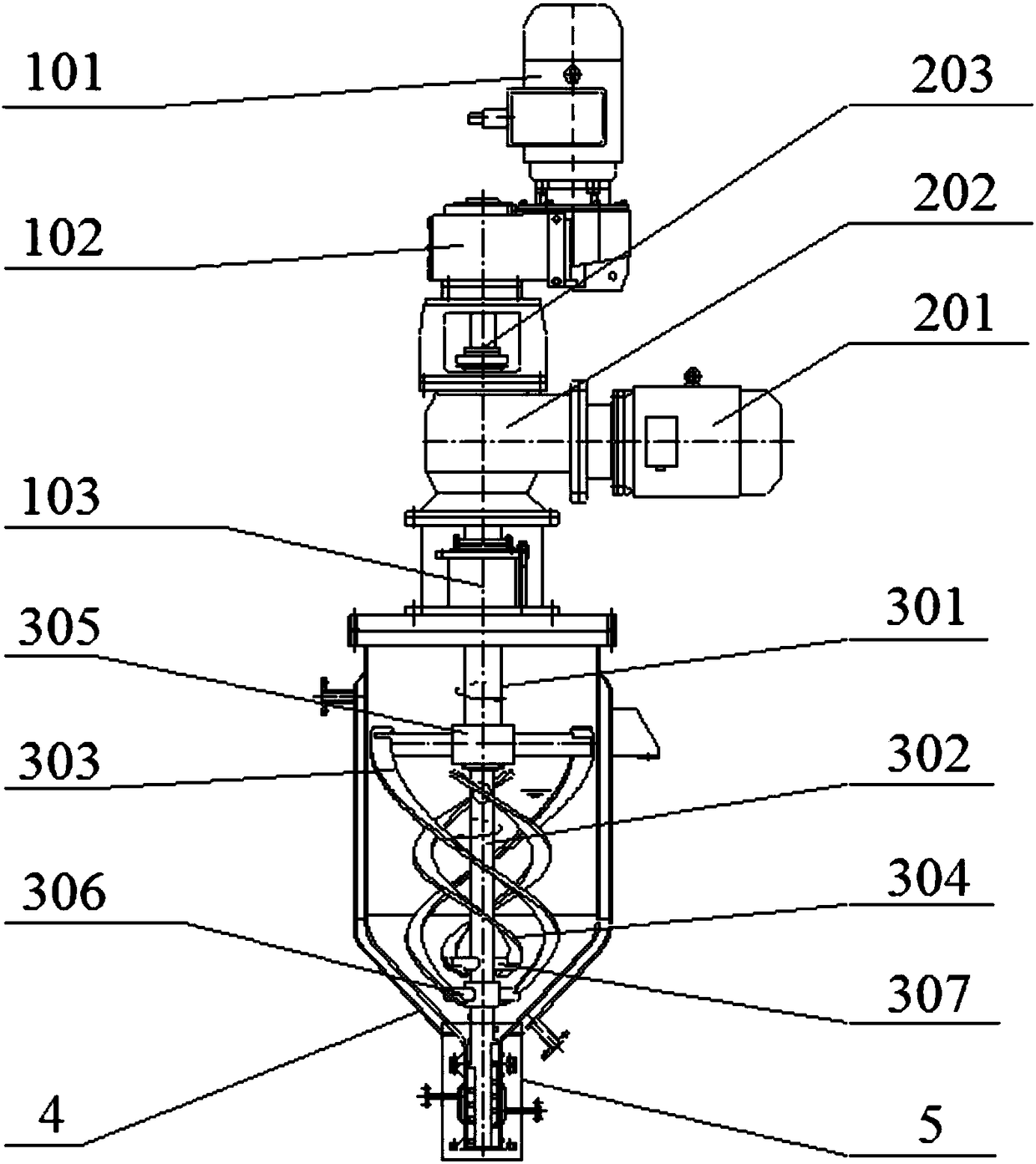

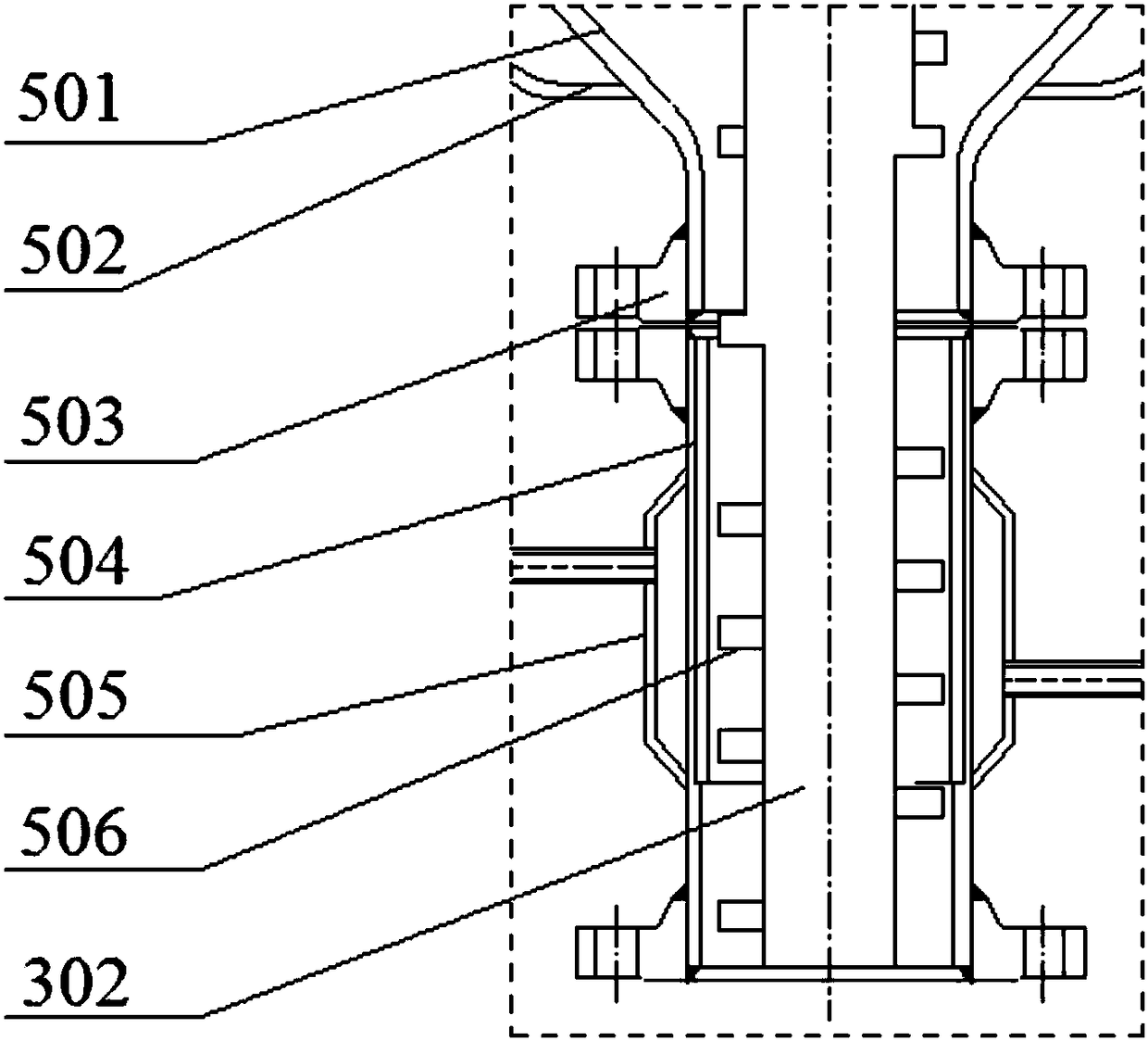

Stirrer suitable for ultrahigh-viscosity polymerization system

PendingCN108479682AStir wellReduce dead zoneChemical/physical/physico-chemical stationary reactorsReducerViscosity

The invention discloses a stirrer suitable for an ultrahigh-viscosity polymerization system. The stirrer suitable for the ultrahigh-viscosity polymerization system comprises two sets of stirring systems formed by coaxially arranging an inner stirring shaft and an outer stirring shaft; an external spiral ribbon motor and an external spiral ribbon speed reducer control the outer stirring shaft to drive an external spiral ribbon to rotate; an internal spiral ribbon motor and an internal spiral ribbon speed reducer control the inner stirring shaft to drive an internal spiral ribbon to rotate; thetwo sets of stirring systems operate independently so as to achieve sufficient stirring of materials inside a kettle body and reduce the dead zone in the kettle body, so that the problem that the mixing function fails due to polymer agglomeration during a polymerization reaction of the ultrahigh-viscosity materials can be prevented.

Owner:杭州原正工程技术装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com