System device for strengthening high-viscosity microbial polysaccharide fermentation and application

A microbial polysaccharide and system device technology, which is applied in the field of system devices to strengthen the fermentation of high-viscosity microbial polysaccharides, can solve the problems of limited mass transfer and mixing, long fermentation cycle of high-viscosity polysaccharides, low conversion rate and yield, etc., to achieve shortened fermentation cycle, increase yield and quality, and reduce apparent viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

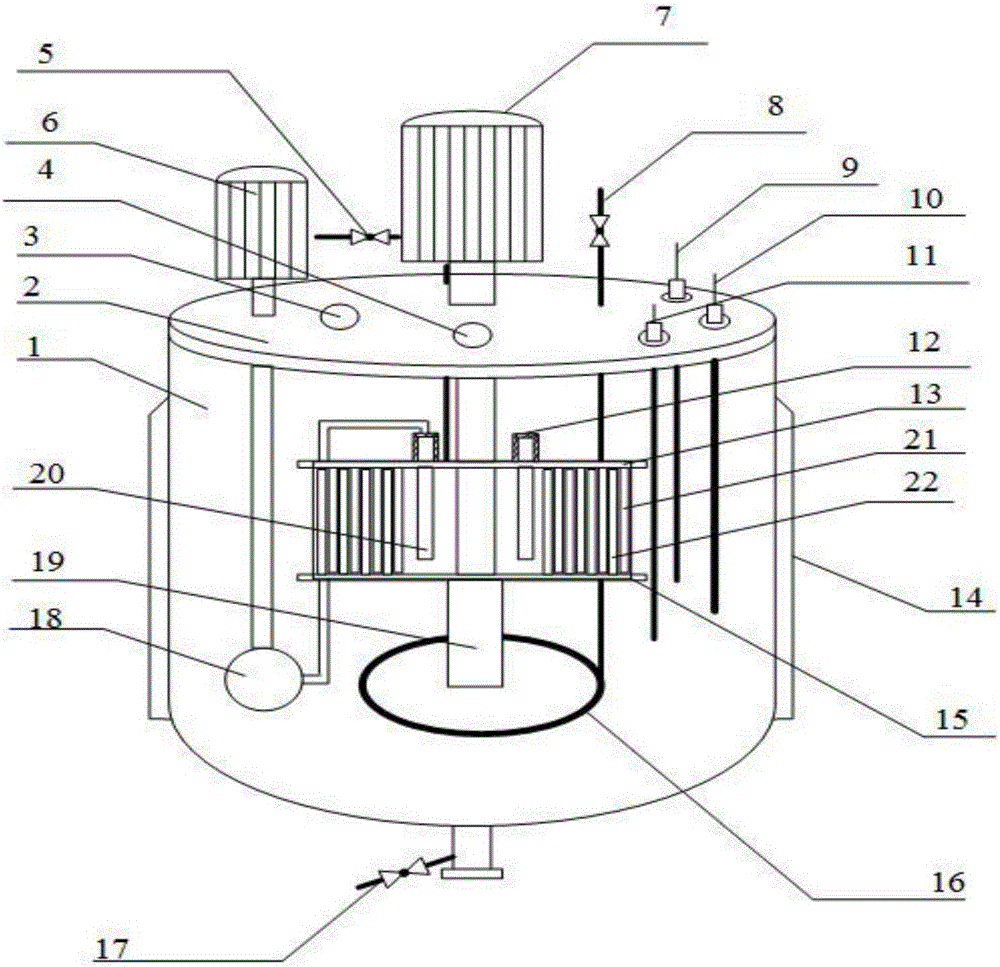

[0045] see figure 1 As shown, a system device for strengthening the fermentation of highly viscous microbial polysaccharides includes a tank body 1, a tank cover 2, a feeding port 3, an inoculation port 4, an exhaust pipeline 5, a second motor 6, and a first motor 7 , air / steam input pipeline 8, temperature sensor 9, pH electrode 10, dissolved oxygen electrode 11, annular liquid receiving tank 12, end cover 13, cooling interlayer 14, turntable 15, air distributor 16, material intake port 17, High temperature resistant submerged pump 18, lifter 19, liquid distributor 20, first pin 21, second pin 22.

[0046] The inner center of the tank body 1 is longitudinally provided with a rotating shaft, the upper end of the rotating shaft passes through the tank cover 2 and is connected to the first motor 7, and the lower end extends into the tank body 1 to connect with the supergravity rotating bed device; the supergravity rotating bed device is horizontally installed in the tank The in...

Embodiment 2

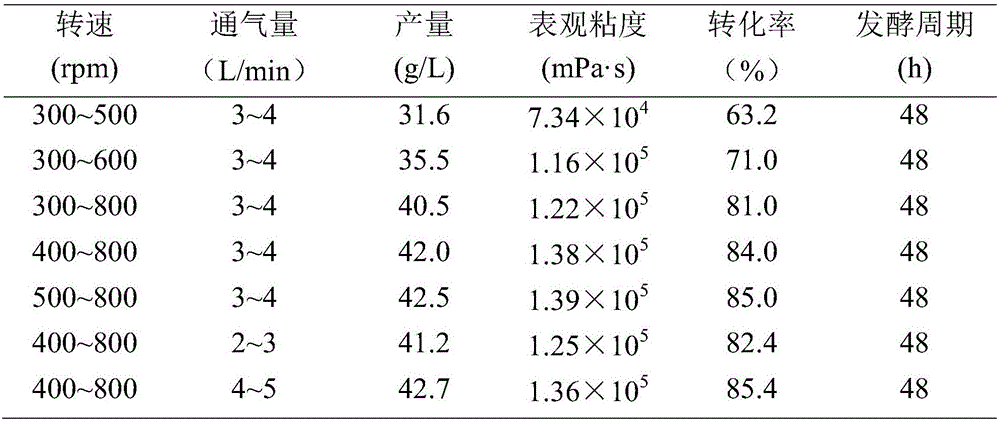

[0054] Taking xanthan gum as a representative and adopting the system device of embodiment 1 to strengthen the viscosity range is 5.0×10 4 ~1.6×10 5 The exopolysaccharide biological fermentation process of mPa·s, the specific steps are as follows:

[0055] Incline medium: sucrose 20g / L, peptone 5g / L, yeast extract powder 5g / L, beef powder 3g / L, agar 20g / L.

[0056] Seed medium: sucrose 20g / L, peptone 5g / L, yeast extract powder 5g / L, beef powder 3g / L.

[0057] Fermentation medium: sucrose 20g / L, glucose 30g / L, peptone 3g / L, potassium chloride 25g / L, magnesium sulfate 8g / L, calcium carbonate 10g / L, citric acid 0.25g / L, potassium dihydrogen phosphate 0.06 g / L.

[0058] 1) Put Xanthomonas BT-112, a slanted bacteria strain stored in a refrigerator at 4°C, into a shaker flask (50mL / 250mL) with seed medium, place it in a constant temperature culture shaker, and set it at 30°C, 190rpm Cultivate under the same conditions for 26 hours as the first-level seeds, insert the above-menti...

Embodiment 3

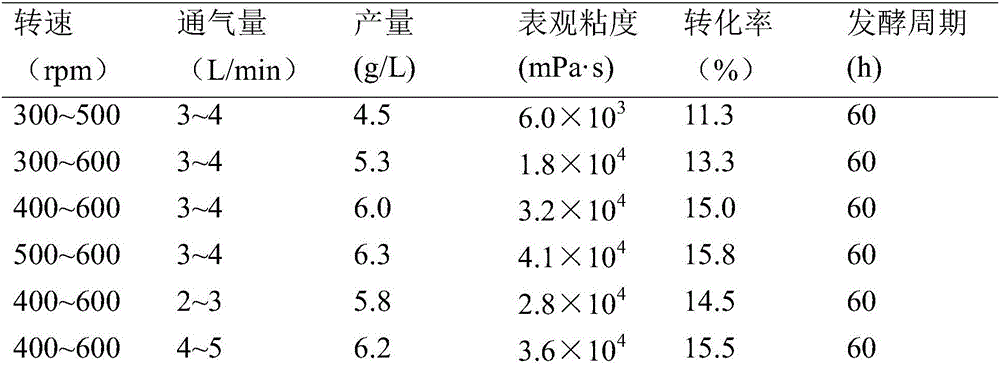

[0066] Taking hyaluronic acid as a representative, the system device of Example 1 is used to strengthen the viscosity range of 1.0×10 3 -5.0×10 4 The exopolysaccharide biological fermentation process of mPa·s, the specific steps are as follows:

[0067] Incline medium: sucrose 30g / L, peptone 10g / L, yeast extract powder 5g / L, magnesium sulfate 1g / L, dipotassium hydrogen phosphate 1.5g / L, sodium glutamate 2g / L, agar 20g / L.

[0068] Seed medium: sucrose 30g / L, peptone 10g / L, yeast extract powder 5g / L, magnesium sulfate 1g / L, dipotassium hydrogen phosphate 1.5g / L, sodium glutamate 2g / L, sodium bicarbonate 1g / L .

[0069] Fermentation medium: sucrose 40g / L, peptone 10g / L, magnesium sulfate 0.5g / L, dipotassium hydrogen phosphate 1.5g / L, sodium glutamate 2.5g / L, sodium bicarbonate 0.5g / L.

[0070] 1) Insert Klebsiella spp. H-112, which was stored in a refrigerator at 4°C, into the seed medium and culture it at 34°C and 160rpm for 13 hours as the primary seed, and insert the above ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com