Low-voltage rail-to-rail transconductance amplifier

A transconductance amplifier and low-voltage technology, applied in the direction of amplifiers, differential amplifiers, amplifiers with semiconductor devices/discharge tubes, etc., can solve the problems of limiting the connection effect, difficult to keep the tail current source constant, etc., to reduce the dead zone range , Improve the working range of common mode voltage and reduce the effect of common mode voltage dead zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

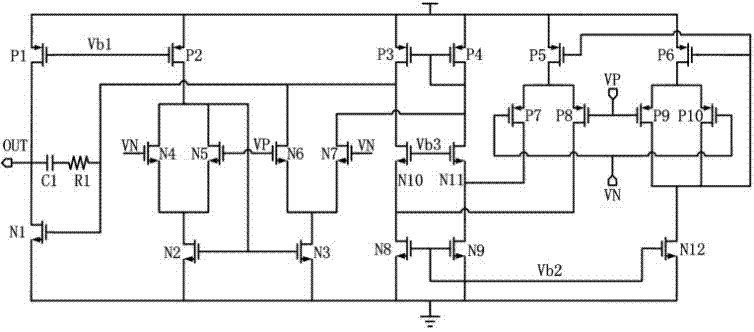

[0023] Such as figure 1 As shown, the present invention proposes a low-voltage rail-to-rail operational transconductance amplifier, including an input stage and an output stage, and the input stage is composed of an NMOS differential transconductance stage with a tail current source and a PMOS differential transconductance stage with a tail current source. Complementary master-slave differential amplifier composed of conducting stages, and the output stage is a common-source amplifier with folded structure; the output currents of the complementary master-slave differential amplifiers are respectively injected into the source and drain electrodes of the common-gate stage for superimposition, and converted into The first-stage voltage output; the common-source amplifier of the folded structure of the output stage amplifies the first-stage voltage and outputs it. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com