Liquid-accommodation diversion type drop pipe

A downcomer and liquid receiving plate technology, which is applied in oil refining, biology, medical equipment, and chemical industry, can solve the problems of difficult outflow of liquid phase, increase of energy consumption of tower equipment, limit the load of the whole tower, etc., and achieve heat and mass transfer Improved effect, increased operational adaptability, and enhanced degassing measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

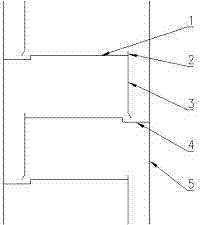

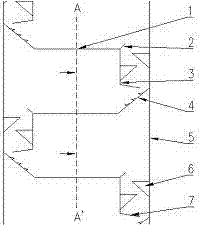

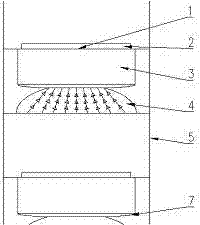

[0050] The present invention relates to an internal component of a plate tower, which is implemented in the process of assembling and welding cylindrical tube joints made of steel plates to manufacture tower walls. As shown in Figure 2(a), it is specifically composed of a tower wall, a pipe wall, an overflow weir, a liquid receiving chamber, a liquid receiving plate and a downcomer plate.

[0051] In general, the above-mentioned components are made of the same engineering materials as the main body of the tower equipment, such as carbon steel, stainless steel, etc., in order to facilitate manufacturing or prevent differences in physical properties such as thermal expansion coefficients, but due to some special purposes or strong acid / alkali, easy rust / In environments such as corrosion, other materials will also be used.

[0052] As shown in the structure [1][3][5][7] in Fig. 2(a)(b)(c), the downcomer wall and the liquid receiving plate are both flat solid plates, which are re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com