Horizontal multifunctional stirring machine

A multi-functional, mixer technology, applied in the direction of mixer accessories, mixers with rotating stirring devices, mixers, etc., can solve problems such as poor polishing effect, short service life, and imperfect design schemes, and achieve economic benefits and social benefits. Significant benefits, reduction of broken grains and excessive damage, significant economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

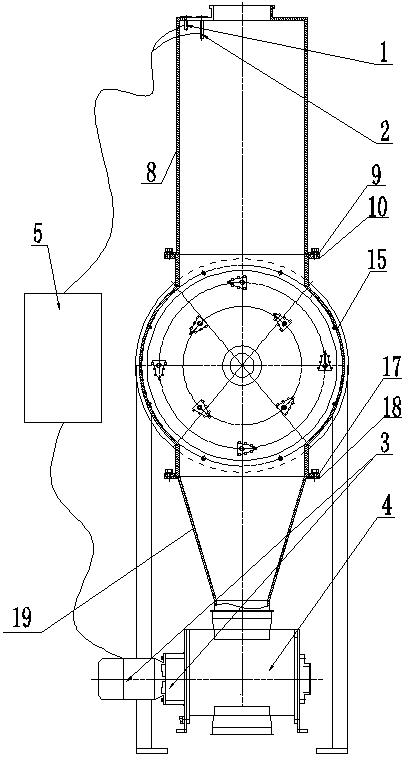

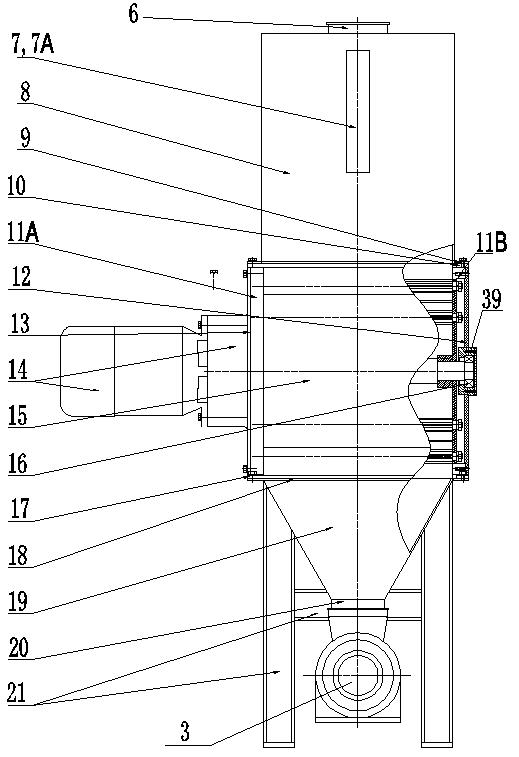

[0034] Such as figure 1 and figure 2 As shown, the horizontal multifunctional mixer of this embodiment includes a frame 21, on which a container part is arranged, and a (that is, one layer) wheel agitator is arranged inside the container part, and a silo is connected to and installed on the upper end of the container part The lower end of the container part is connected with a discharge hopper part, the bottom of the discharge hopper part is provided with a discharge port, and a discharge device is provided below the discharge port. When discharging, the material in the discharge hopper enters the discharge device through the discharge port. .

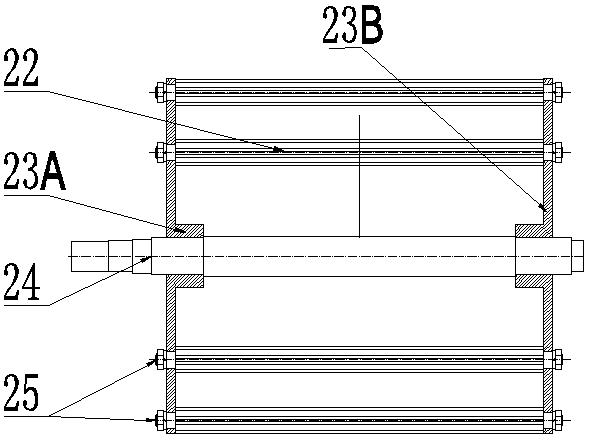

[0035] Such as image 3 , figure 1 and figure 2 As shown, the wheeled agitator includes a stirring shaft 24 placed horizontally, the two ends of the stirring shaft 24 are connected to the container part through bearing rotation support, and the two sides of the stirring shaft 24 are respectively equipped with disc-shaped end pl...

Embodiment 2

[0052] Such as Figure 10 As shown, the differences between this embodiment and Embodiment 1 are:

[0053] The wheel agitator is provided with two layers; the upper layer is provided with two wheel agitators, the lower layer is provided with a wheel agitator, and the two wheel agitators on the upper layer are parallel to each other in the same horizontal plane; the two wheel agitators on the upper layer are A deflector 26 is arranged on the symmetrical central plane of the silo parts above the device. The deflector 26 is composed of two horizontal triangular prisms connected up and down. The sharp edge of the upper triangular prism is aligned with the center line of the feed inlet pipe 6 , the sharp edges of the lower triangular prism are aligned with the symmetrical central plane of the upper two-wheeled agitator, and the lower wheeled agitator is installed directly below the symmetrical central plane of the upper two-wheeled agitator. In this embodiment, the diameter of eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com