Supersonic vortex and metal magnetic memory composite detecting system

A metal magnetic memory and detection system technology, applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, material magnetic variables, instruments, etc., can solve the problems that are difficult to meet the needs of production, and achieve easy portability, light weight, and small size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

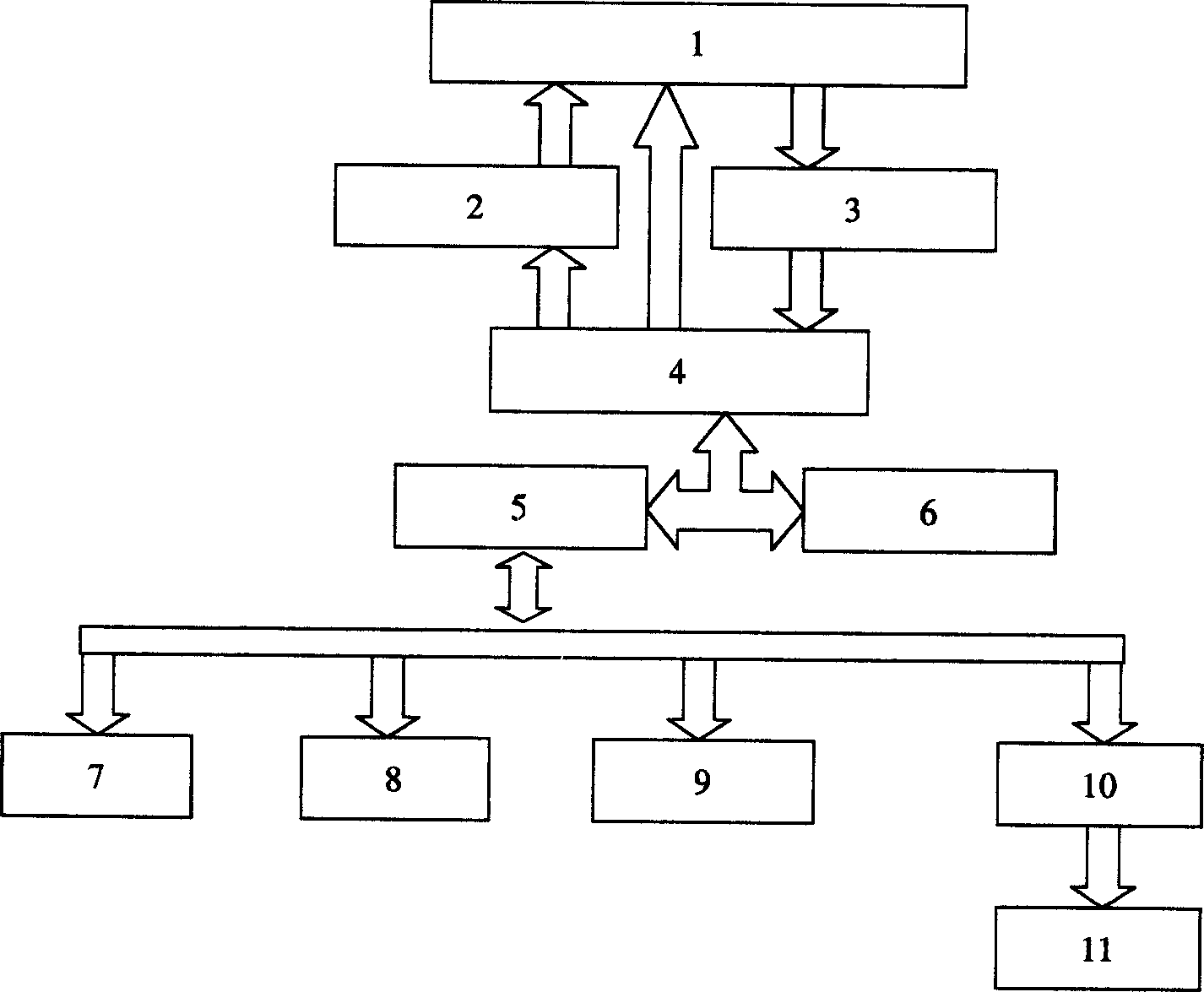

[0028] The present invention will be further described below in conjunction with accompanying drawing, appended figure 1 It is a structural schematic diagram of an embodiment of the present invention, consisting of ultrasonic, eddy current and metal magnetic memory detection device 1, positioning scanning device 2, A / D converter 3, FPGA / CPLD4, CPU5, SDRAM6, LCD display screen 7, audio frequency 8, USB interface 9, network interface 10 and computer 11 are formed.

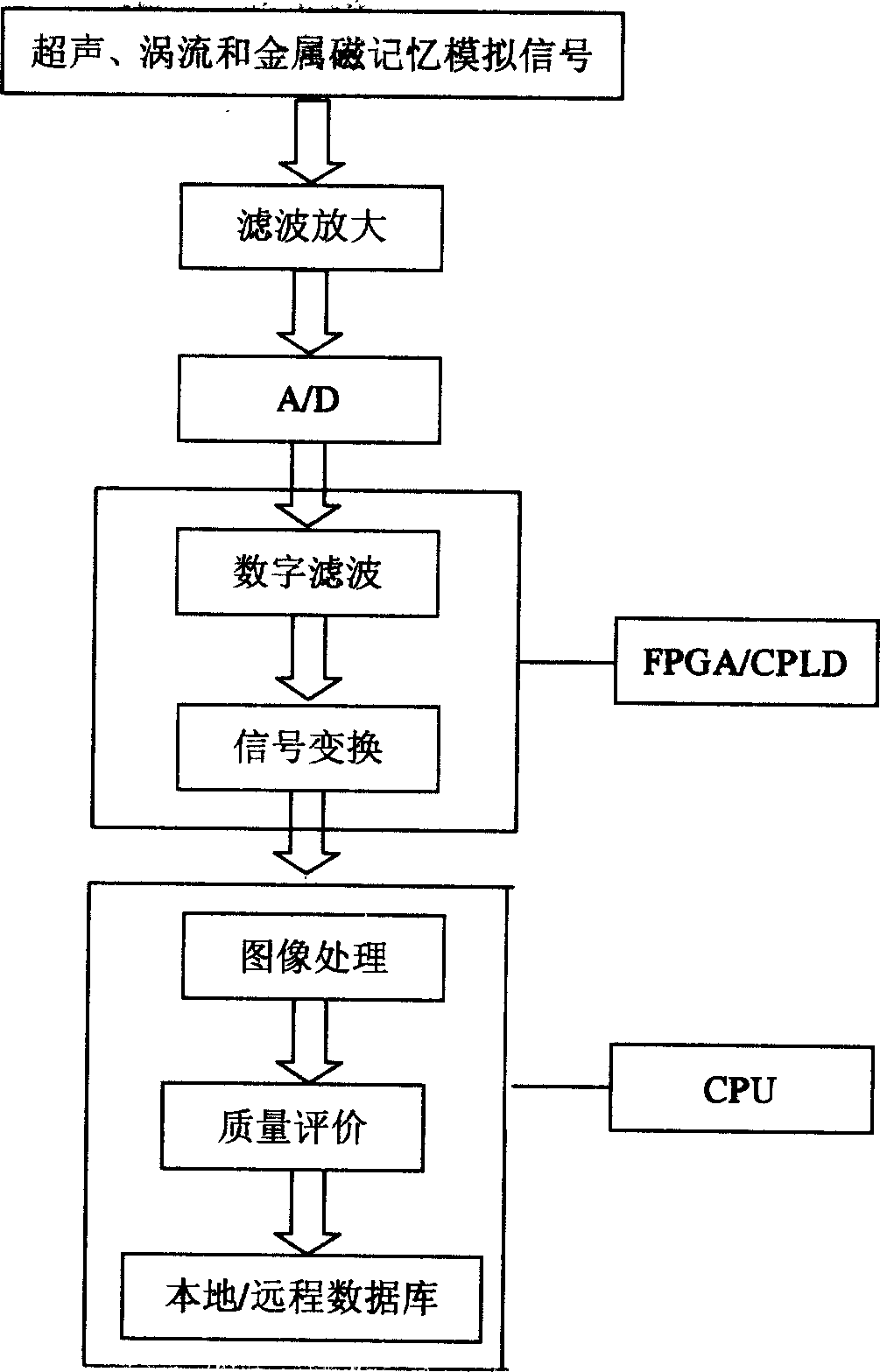

[0029] Operation process of the present invention is attached figure 2 As shown, the analog signal detected by the ultrasonic, eddy current and metal magnetic memory detection device 1 is filtered and amplified and converted into a digital signal through the A / D converter 3, and then the digital signal is filtered and transformed by the FPGA / CPLD4, and then transmitted to In SDRAM6, CPU5 performs image display and processing according to the data in SDRAM6, and can display one or more detection methods of ultrasoni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com