Patents

Literature

67results about How to "Suitable for online detection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

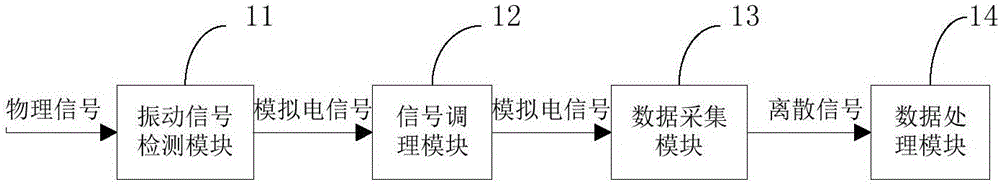

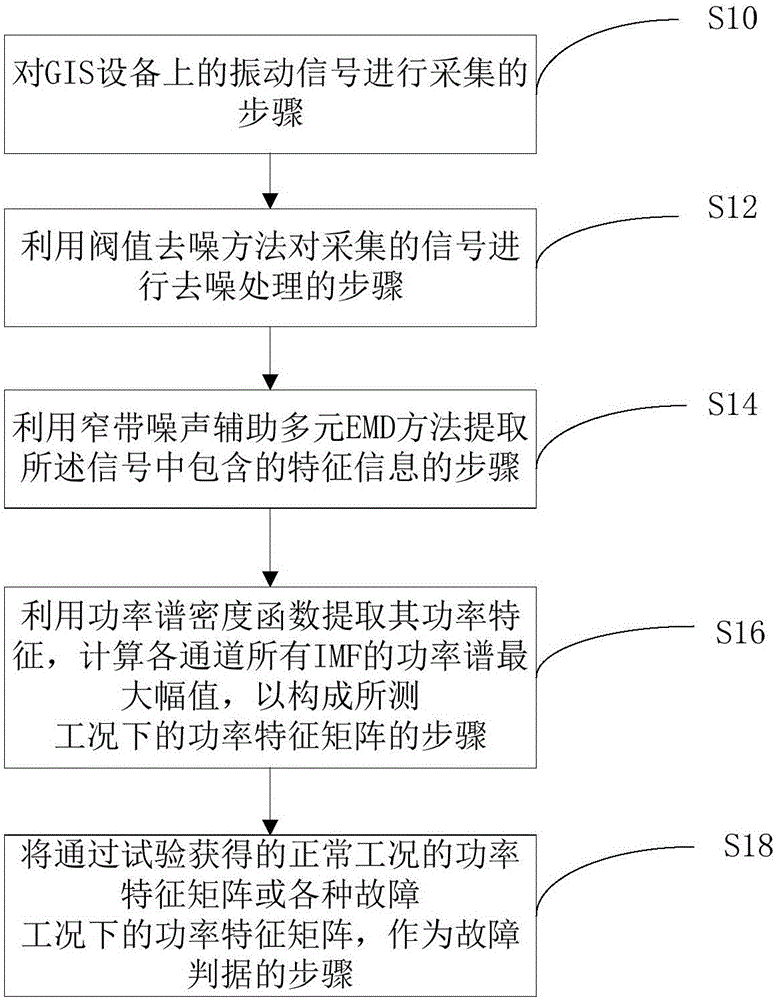

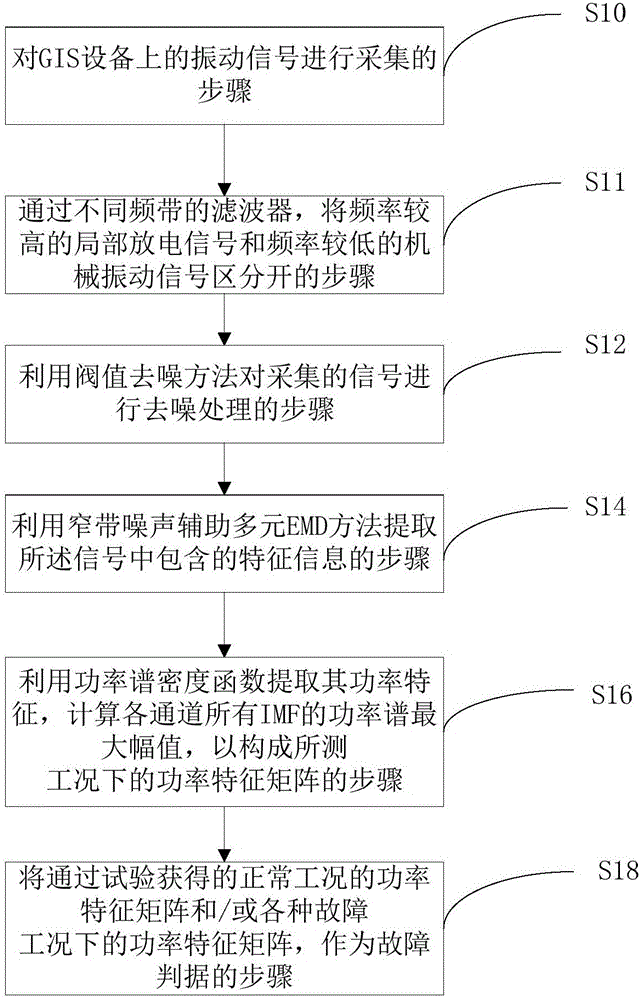

Abnormal vibration analysis-based GIS (gas insulated switchgear) mechanical fault diagnosis method and system

ActiveCN105973621ANormal operation without any impactNormal operation impactSubsonic/sonic/ultrasonic wave measurementUsing electrical meansSignal onElectric power system

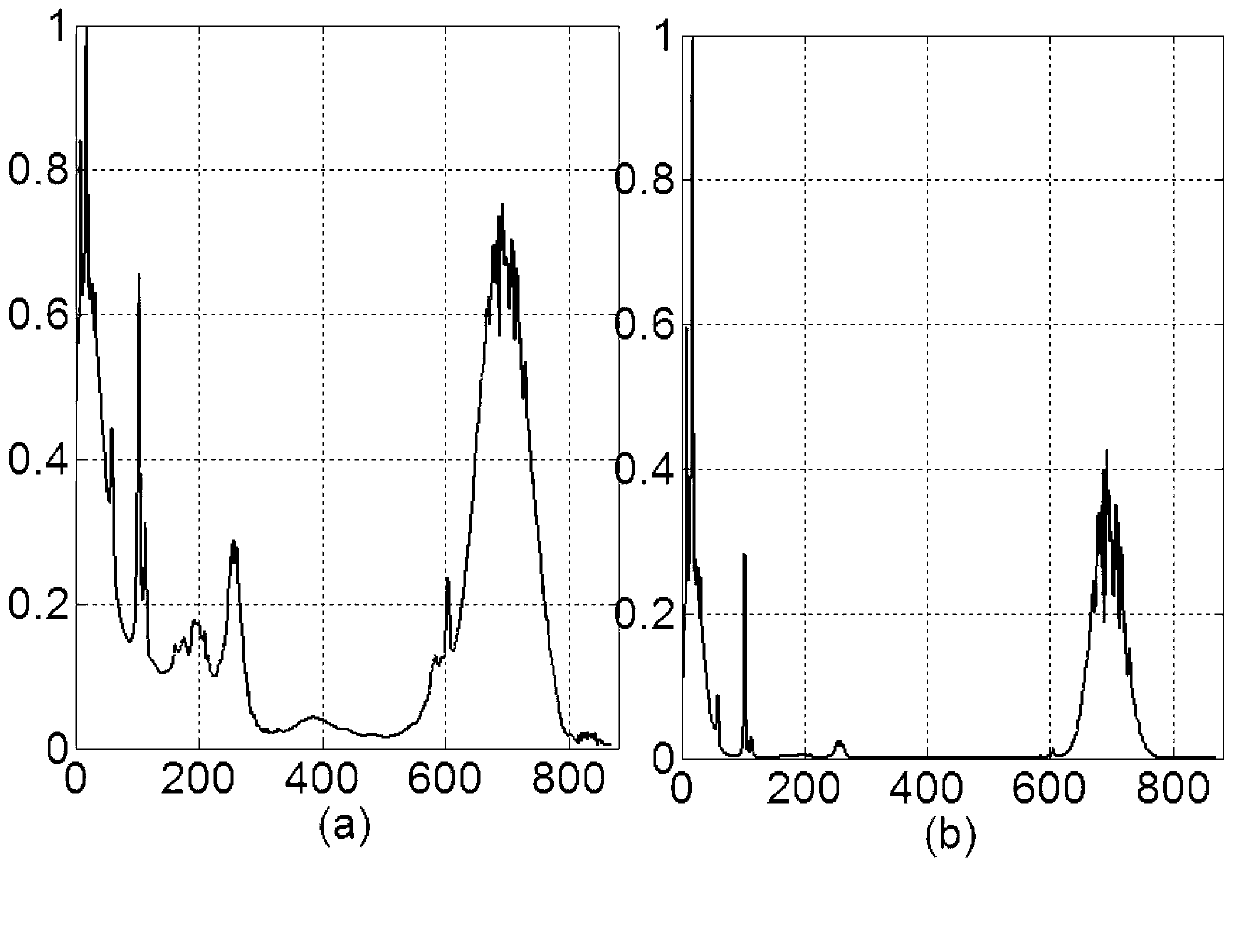

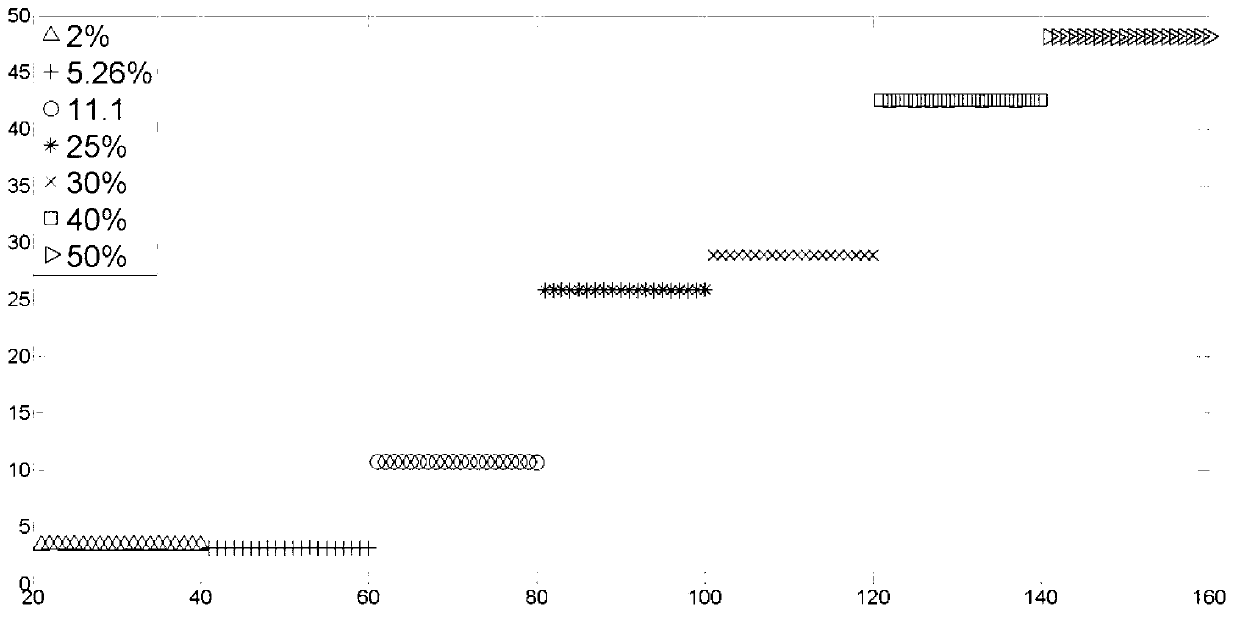

The invention discloses an abnormal vibration analysis-based GIS (gas insulated switchgear) mechanical fault diagnosis method and system. The GIS (gas insulated switchgear) mechanical fault diagnosis method includes the following steps that: vibration signals on a GIS are acquired; de-noising processing is performed on the acquired signals through using a threshold de-noising method; various kinds of feature information contained in the signals are extracted by using a narrowband noise aided multivariate empirical mode decomposition (EMD) method; the power feature of the signals is extracted by using a power density function, and the maximal amplitudes of the power spectra of all IMF of each channel are calculated so as to form power feature matrixes under measured conditions; and a power feature matrix under a normal condition and / or power feature matrixes under various kinds of fault conditions which are obtained through tests are adopted as judgment criteria of faults. Compared with a traditional method, the method and system of the invention have no influence on the normal operation of a whole power system, and can monitor the running state of the GIS safely and reliably, and are suitable for being applied to GIS substations of various voltage levels.

Owner:STATE GRID CORP OF CHINA +1

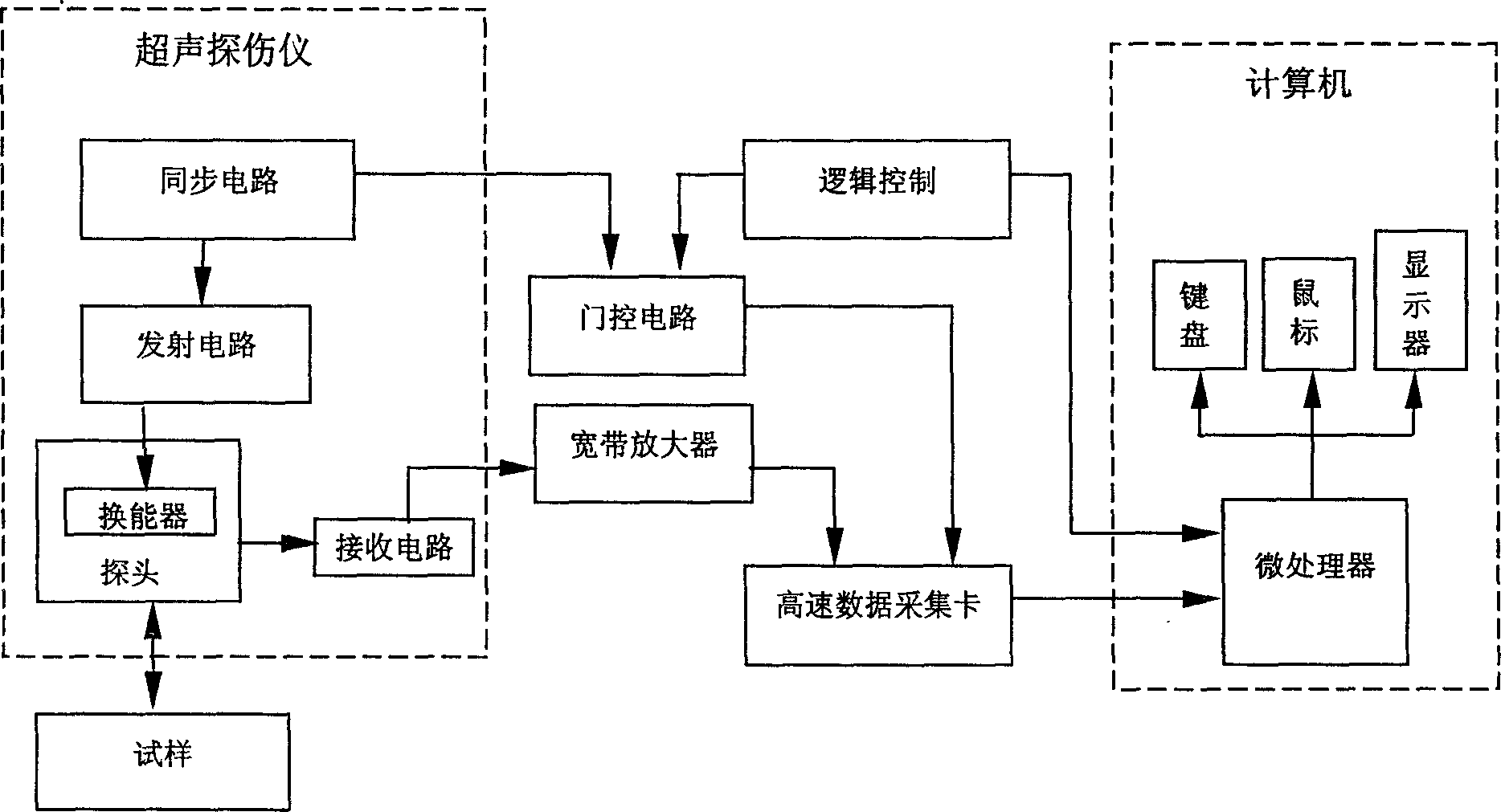

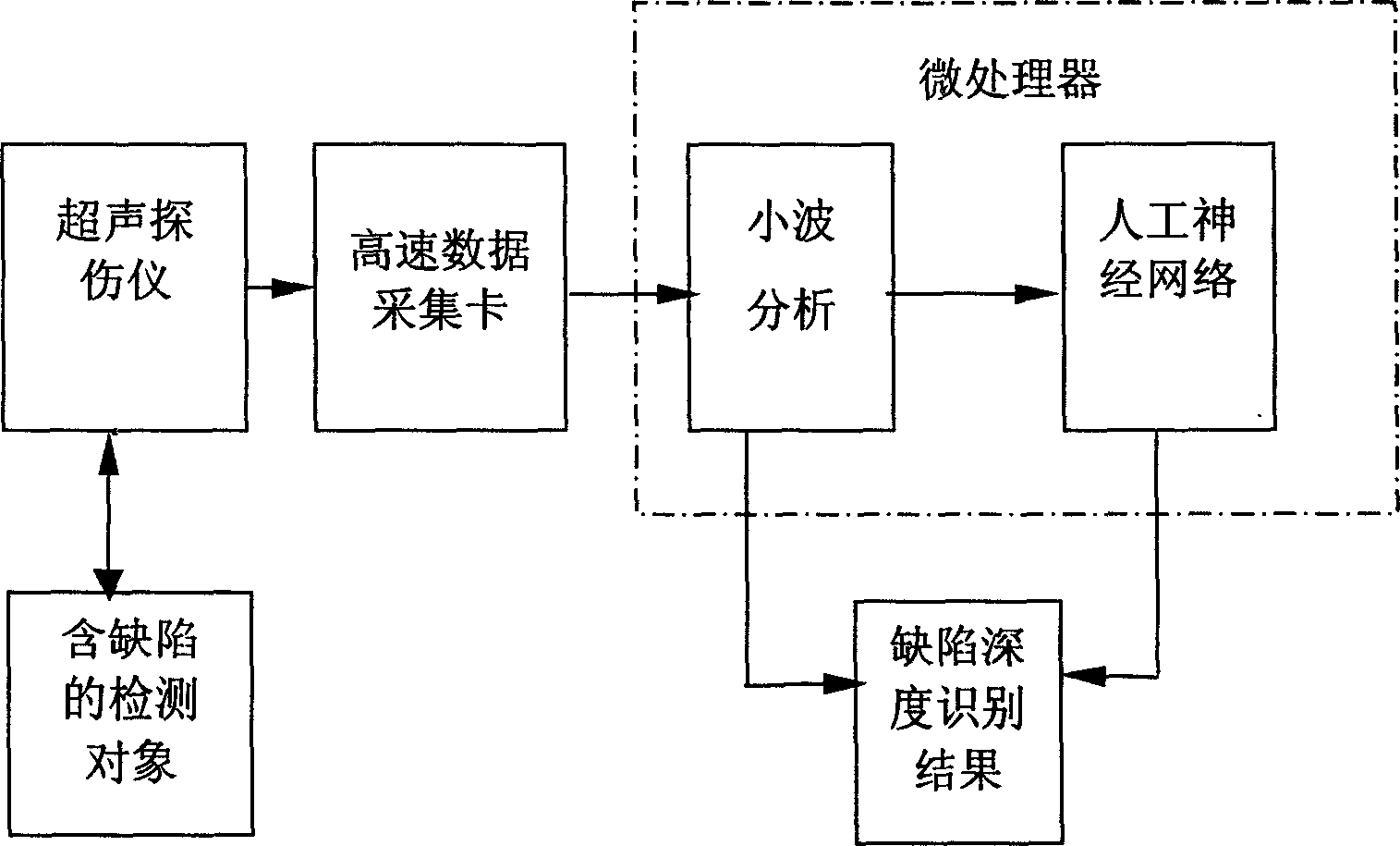

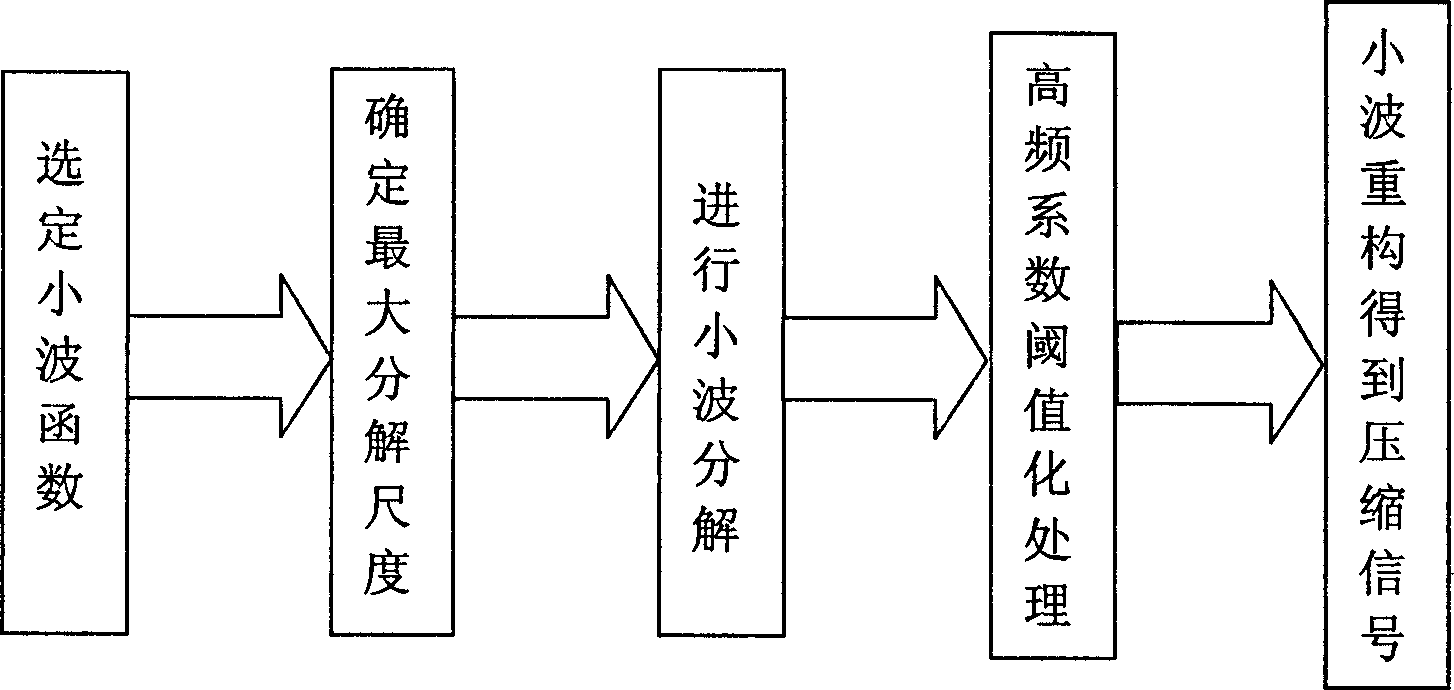

Structure defect ultrasonic on-line intelligent identifying system and identifying method

InactiveCN1743839AConvenient and effectiveHigh precisionAnalysing solids using sonic/ultrasonic/infrasonic wavesSpecial data processing applicationsSonificationTransducer

This invention provides a super acoustic online intelligent system for detecting structure defect, which contains super acoustic defect detector comprising synchronous circuit, emission circuit, probe with transducer and receiving circuit, high speed data sampling card connected with synchronous circuit by gate control circuit, and computer, wherein the the logic control circuit connected with gate control circuit and micro processor of computer, the micro processor having each other connected wavelet analysis module and artificial neural network.

Owner:SOUTH CHINA UNIV OF TECH

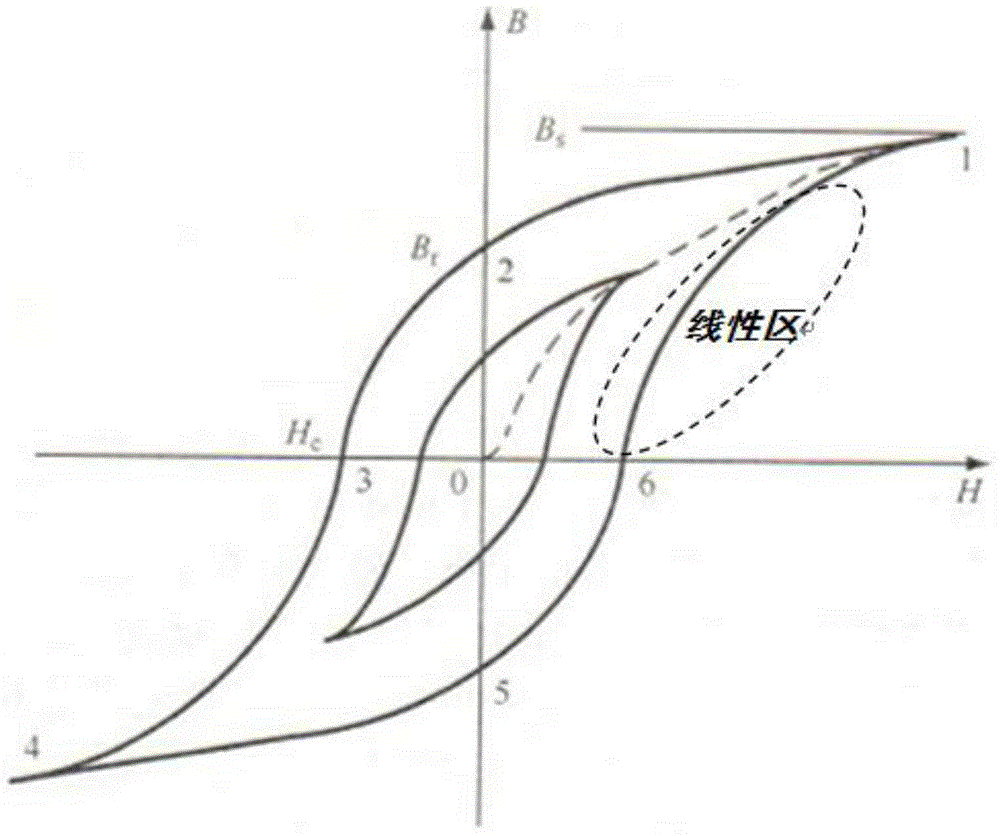

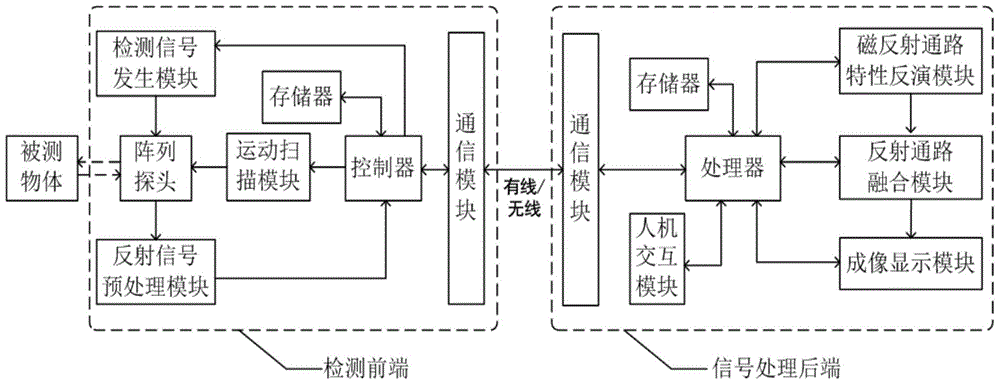

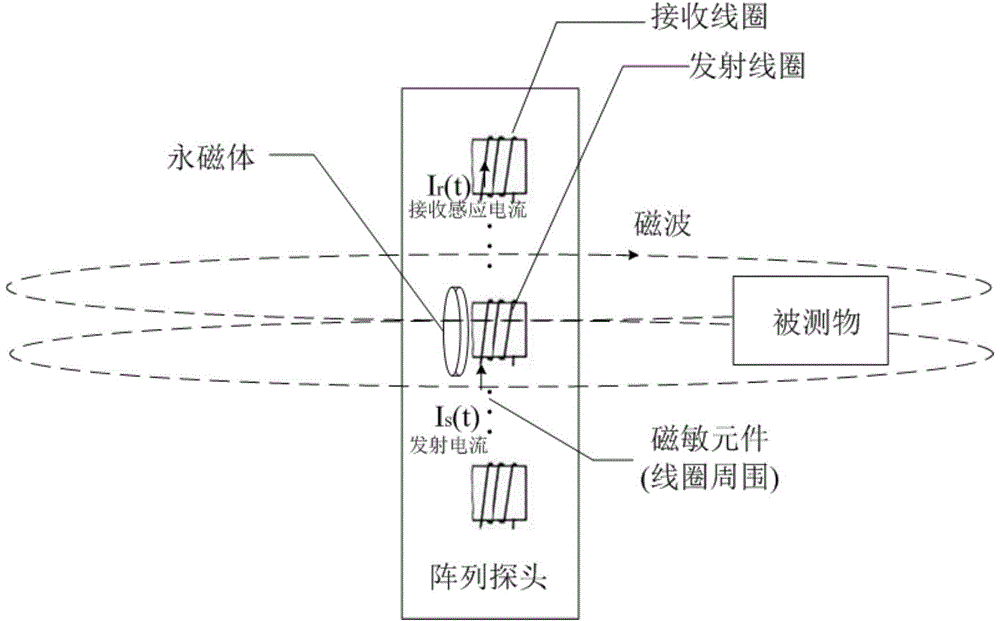

Detecting and imaging method and detecting and imaging device based on broadband magnetic wave reflection path parameter identification

InactiveCN104655714ARealize non-destructive testingFast decayMaterial magnetic variablesControl parametersSoftware

The invention discloses a detecting and imaging method and a detecting and imaging device based on broadband magnetic wave reflection path parameter identification. According to the method, broadband magnetic wave is taken as a carrier, a path through which magnetic wave reflection passes is used as a reflection channel, and electromagnetic parameter characteristics of different materials is utilized, so that the internal distribution characteristics of a detected object can be identified through inversion and fusion on transfer functions and various variable forms and lossless detection and imaging can be realized. The device comprises a detection front end for detecting generation of signals, microwave transmission and reflection magnetic wave receiving, and a signal processing back end for controlling the setting of parameters, processing of receiving signals, inversion and fusion of a magnetic wave reflection path and imaging display, wherein the detection front end and the signal processing back end are connected in a wire / wireless manner, and by using software processing, the detection accuracy is improved, and the miniaturization of the equipment is conveniently realized. According to the embodiment of the invention, coupling agents, strong magnetic fields, radioactive sources and radio frequency radiation are not needed; the method and the device have the advantages of non-contact form, high accuracy, low cost and the like, and have wide application prospect in the fields of underground pipeline detection, road and bridge detection, industry and agriculture, medicines and the like.

Owner:GUANGZHOU FENGPU INFORMATION TECH CO LTD

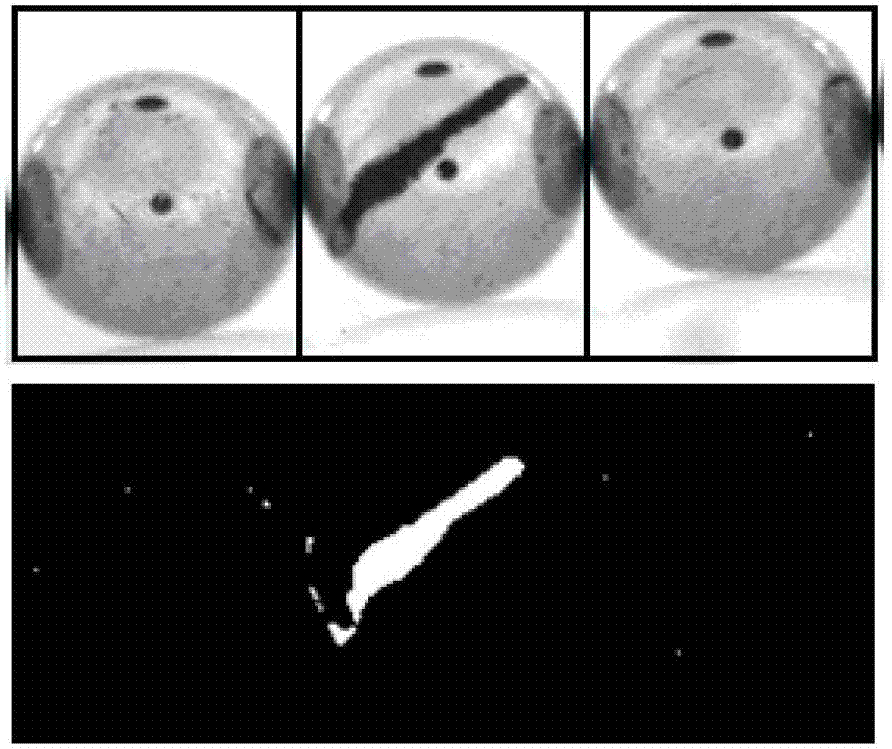

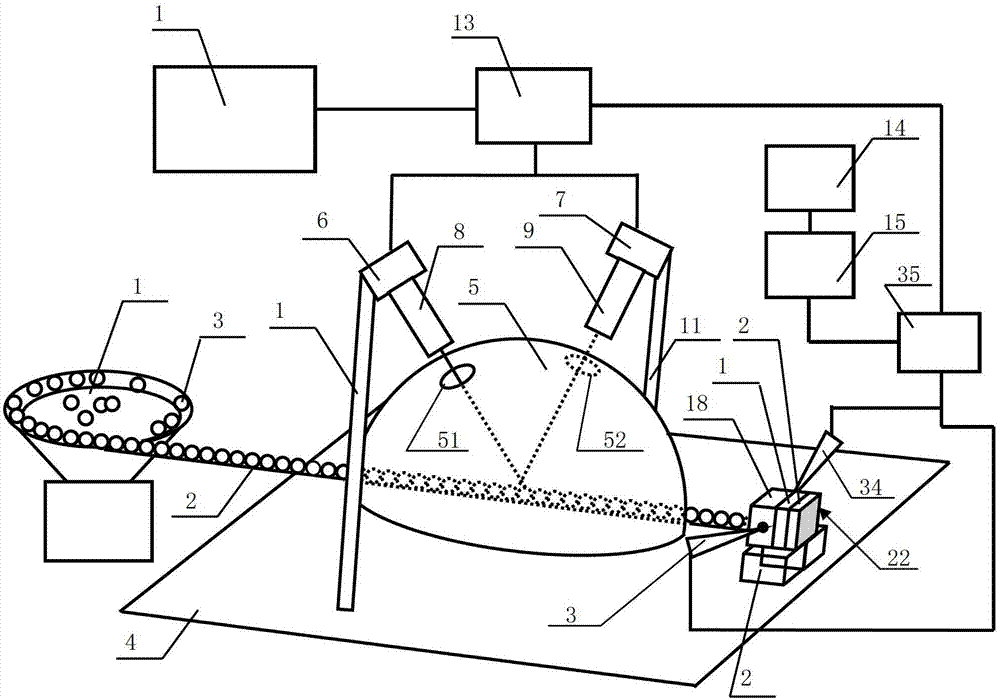

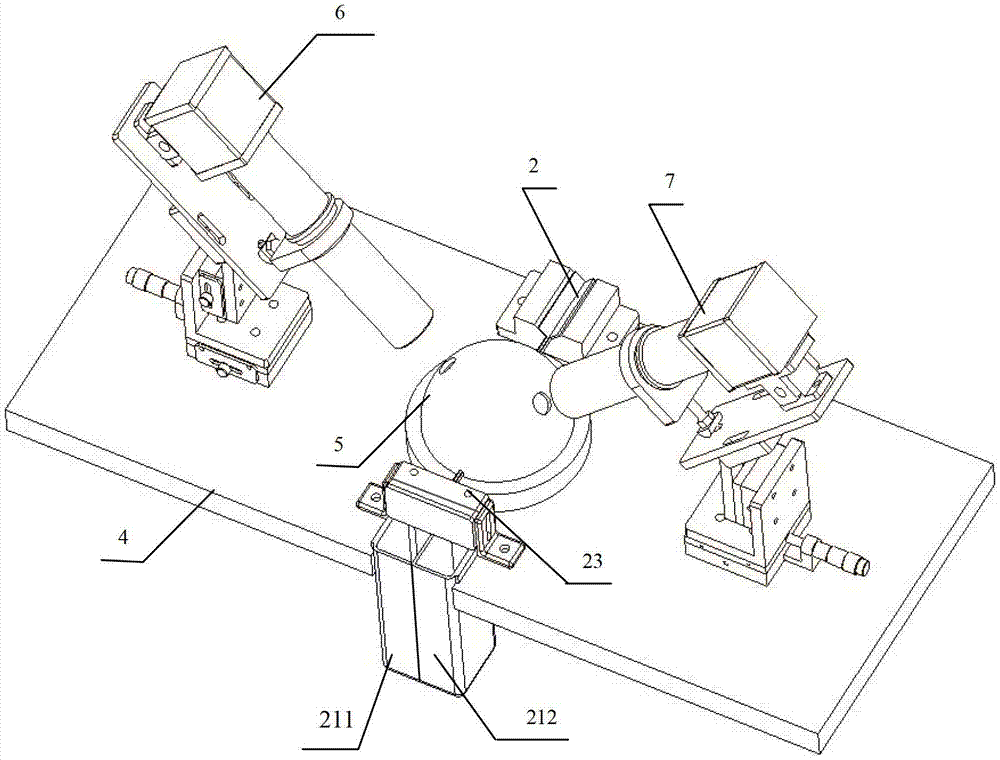

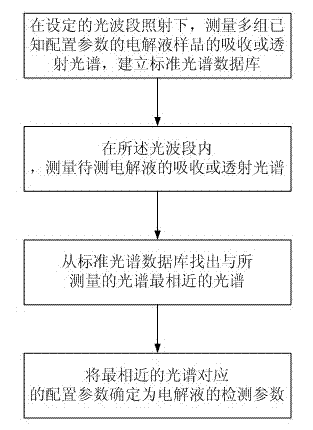

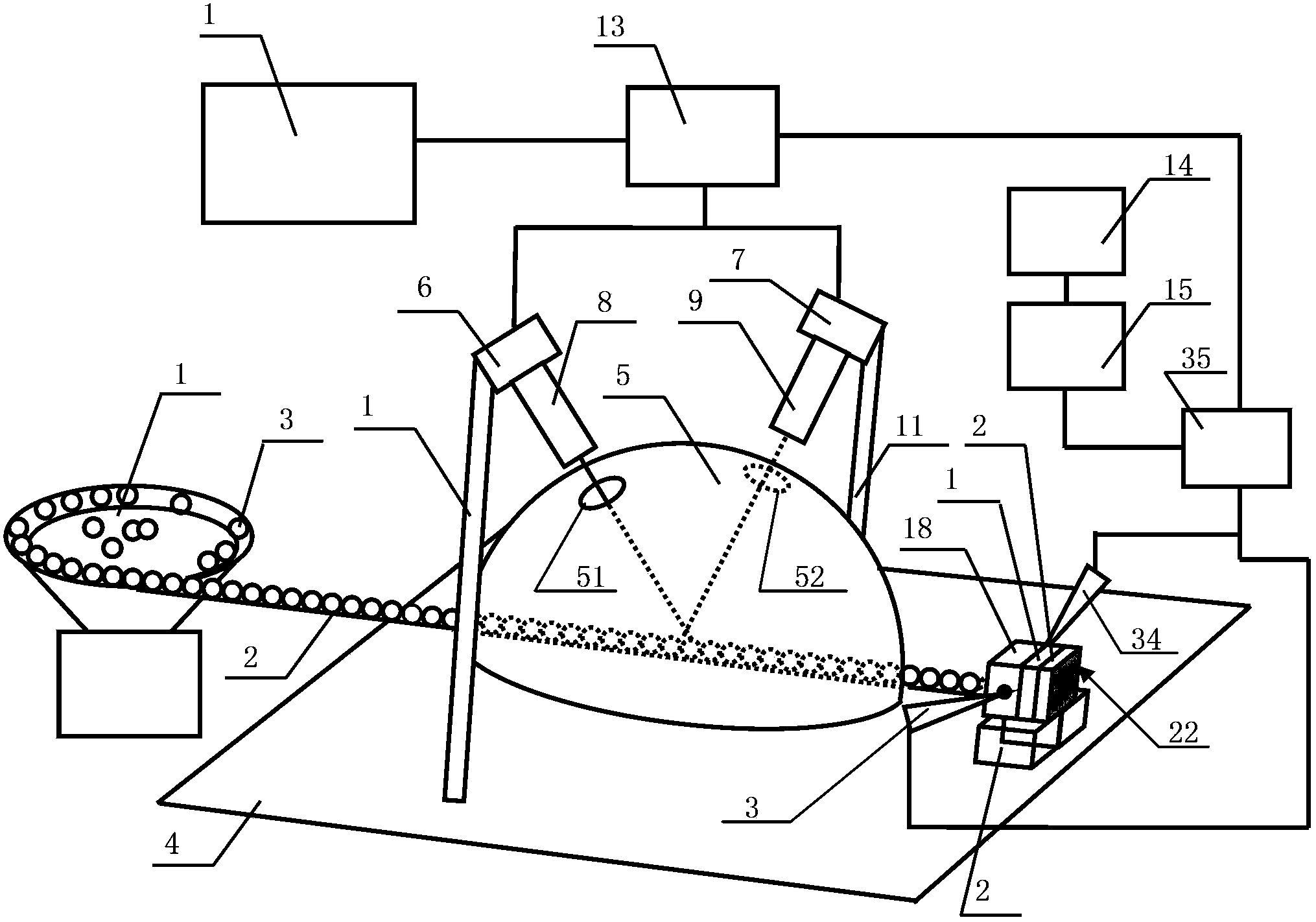

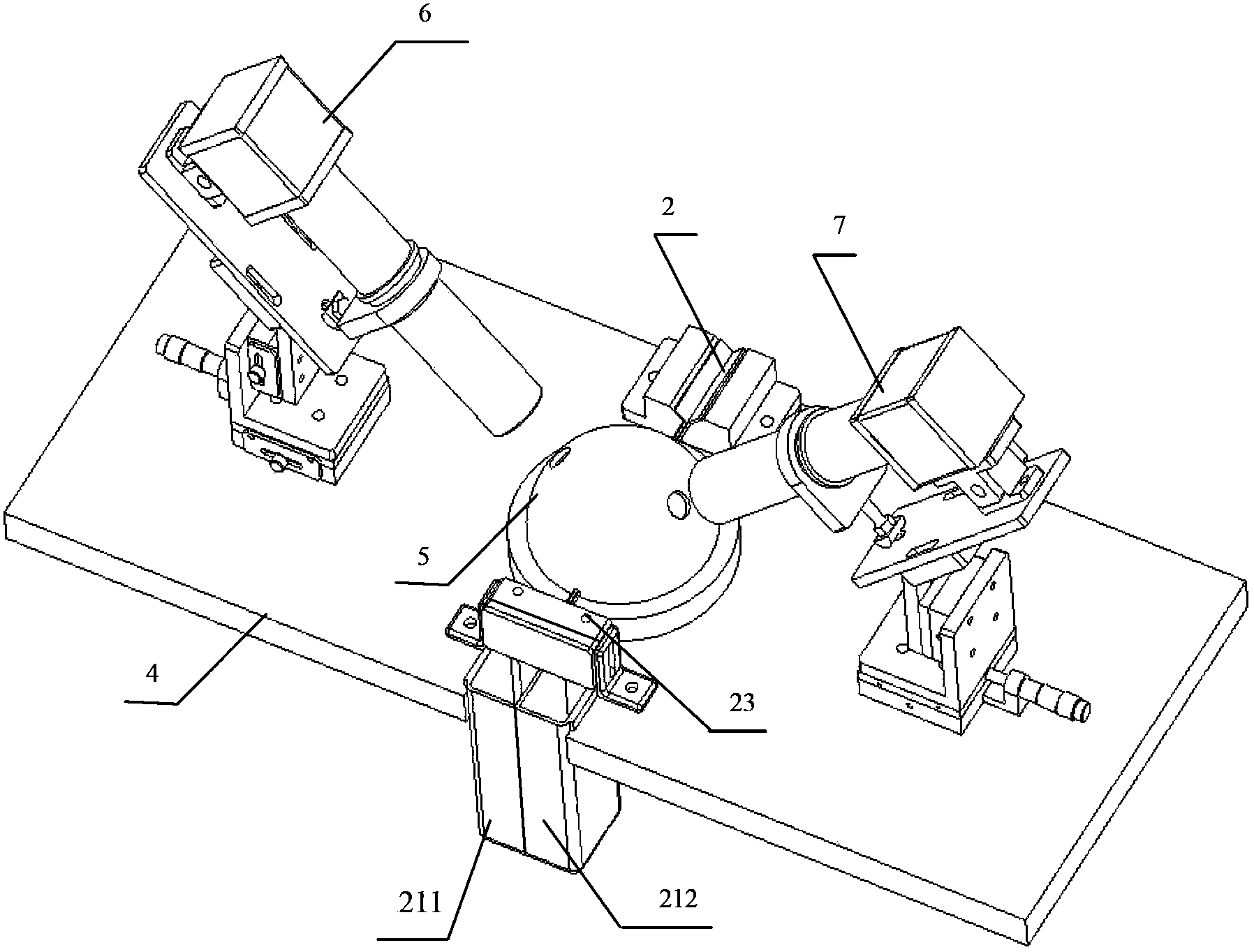

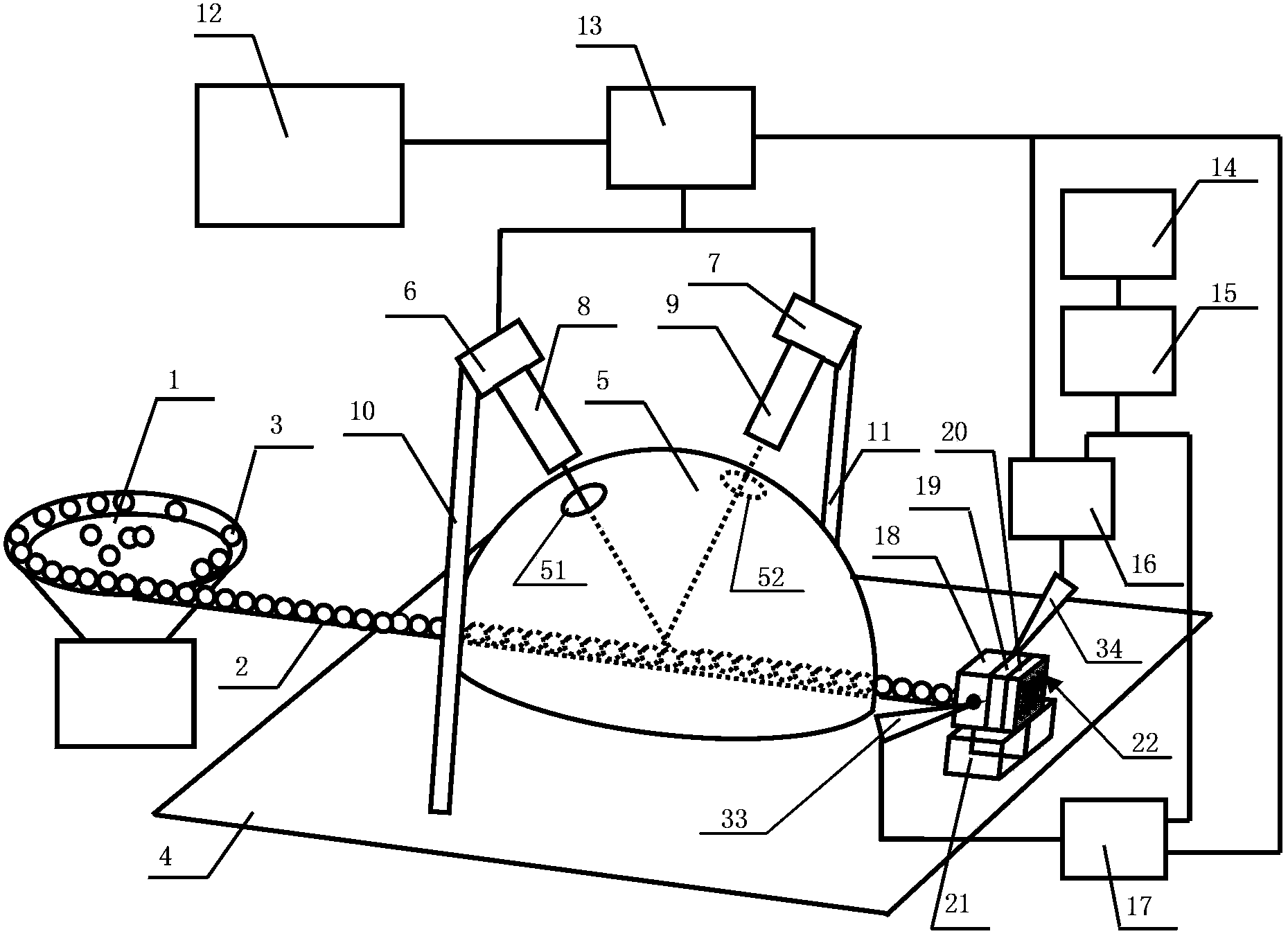

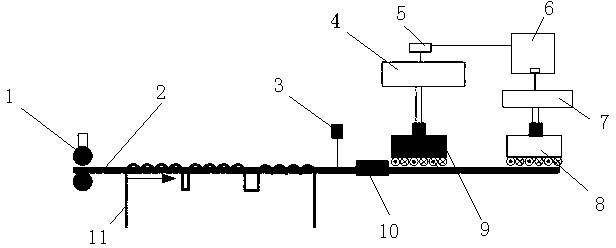

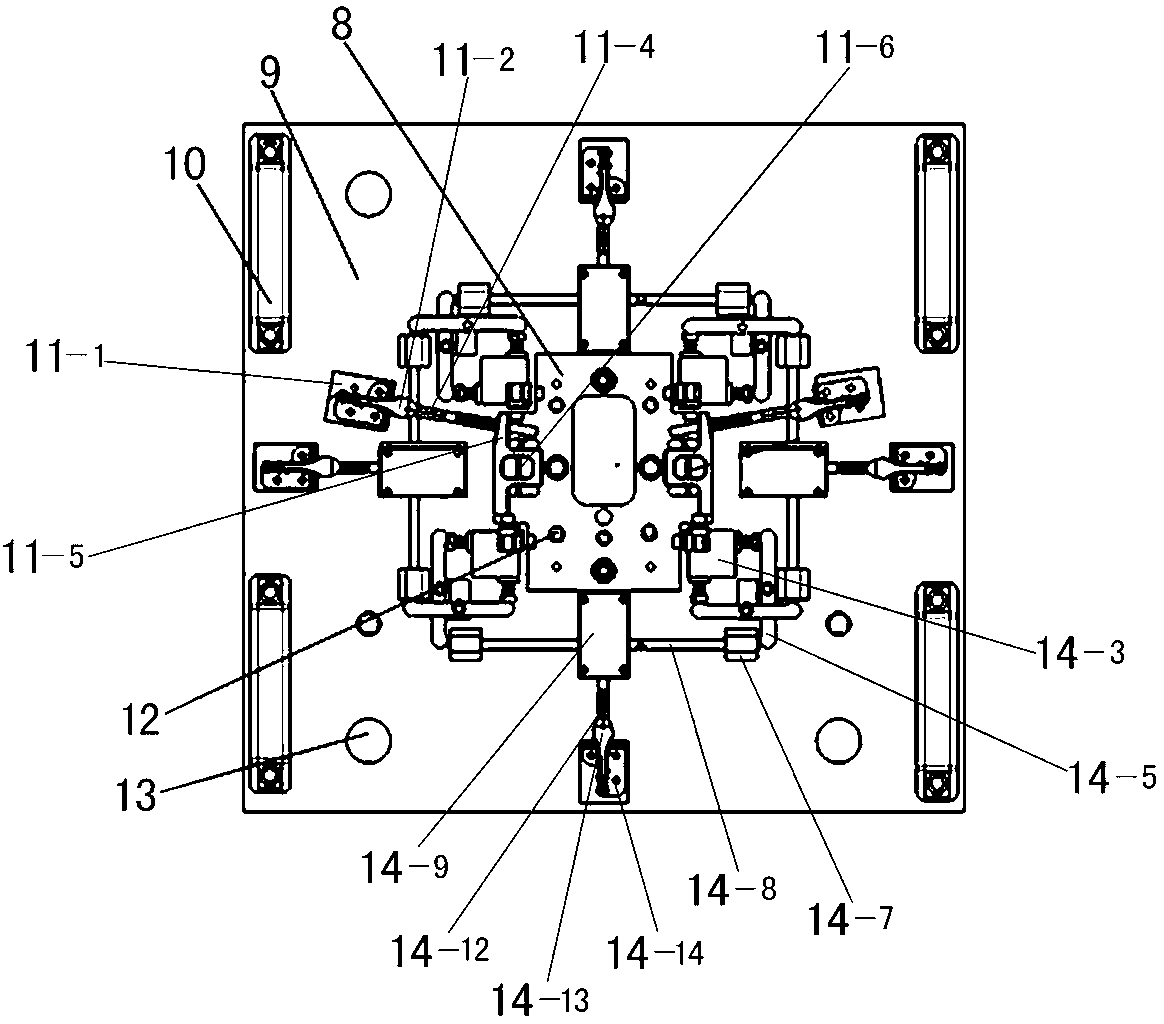

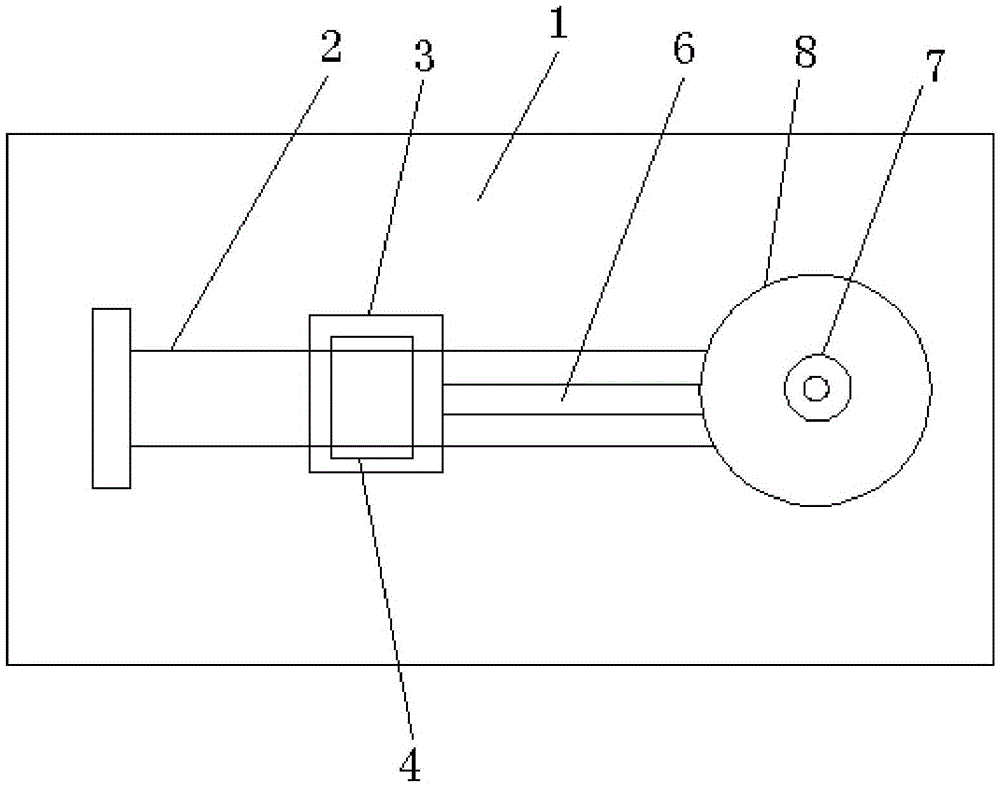

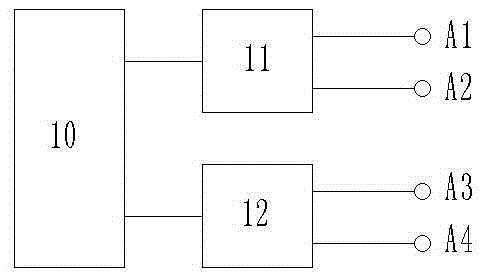

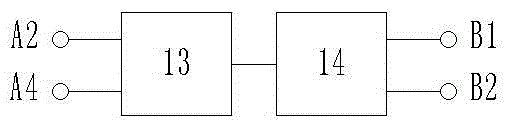

Vision-based steel ball surface defect detection apparatus and detection method

ActiveCN102735693AAcquired images are clearReliable test resultsMaterial analysis by optical meansVision basedEngineering

The invention relates to a vision-based steel ball surface defect detection apparatus and a vision-based steel ball surface defect detection method. According to the apparatus, a light source is arranged on a work bench; a left camera and a right camera are symmetrically arranged on the two sides of the light source; a vibration material supplying tray and a material conveying channel are arranged behind the light source; the material conveying channel penetrates a light source bowl cover and extends to the front side of the light source; a sorting mechanism and collecting boxes positioned below the sorting mechanism are arranged on the front side of the light source; a discharging terminal of the material conveying channel is inserted into a feeding terminal of the sorting mechanism; the left camera and the right camera are respectively connected to a PCI card, and the PCI card is respectively connected to a computer and a pneumatic unit; and the output end of the pneumatic unit is connected to the sorting mechanism. The method comprises the steps that: a template image is collected; the steel balls are driven to move along the material conveying channel; the left camera and the right camera respectively acquire steel ball images 3 times, and the images are compared with the template image; according to the comparison results, the PCI card controls a solenoid valve which controls the sorting mechanism, such that the detected steel ball can fall into a corresponding collecting box. According to the invention, the detection process is fully automated, and the defect detection is accurate and highly efficient.

Owner:TIANJIN UNIV

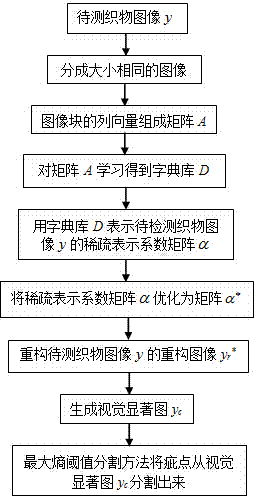

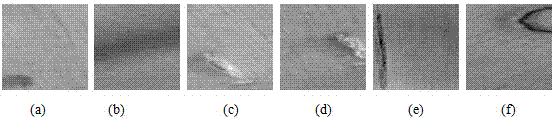

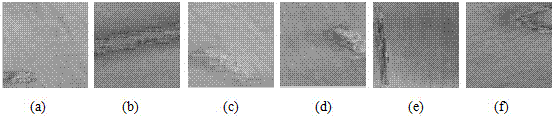

Fabric defect detection method based on sparse representation coefficient optimization

ActiveCN104778692AEffective positioningImprove detection accuracyImage analysisSaliency mapError processing

The invention discloses a fabric defect detection method based on sparse representation coefficient optimization. The detection method comprises self-adaptive dictionary database study, sparse coefficient matrix optimization and image reconstruction as well as generation and segmentation of a vision saliency map and specifically comprises steps as follows: an image is partitioned into blocks, self-adaptive dictionary database study is performed, and a dictionary database is obtained; a sparse representation coefficient matrix is solved with an L2-norm minimization method, and abnormal coefficient elements in the obtained matrix are optimized; a fabric image is reconstructed with adoption of the obtained dictionary database and the optimized sparse representation coefficient matrix, the fabric image and a to-be-detected image are subjected to residual error processing, and a residual error saliency map is obtained; the saliency map is segmented with a maximum entropy threshold segmentation method, and a fabric defect detection result is obtained. Randomness of fabric textural features and diversity of defect varieties are overall considered, the to-be-detected fabric image is taken as a detection reference for a dictionary database studying sample and a defect area, the method has higher detection accuracy, no defect information is required to be extracted, and the self-adaptive capability is high; the computation speed is higher, and the method is suitable for online detection.

Owner:ZHONGYUAN ENGINEERING COLLEGE

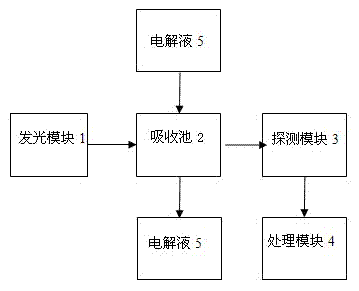

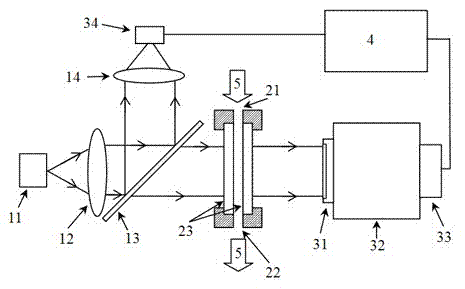

Electrolyte measurement method and electrolyte measurement device for vanadium redox flow battery

ActiveCN102507472ANot suitable for online testingSuitable for online detectionColor/spectral properties measurementsSpectral databaseElectrolyte Measurement

The invention relates to an electrolyte measurement method and an electrolyte measurement device for a vanadium redox flow battery. The electrolyte measurement method comprises the following steps of: measuring the absorption or transmission spectra of a plurality of groups of electrolyte samples with known configuration parameters under the irradiation of a set light waveband, recording the absorption or transmission spectra of the groups of electrolyte samples, and establishing a standard spectral database; in the light waveband, measuring the absorption or transmission spectrum of an electrolyte to be measured; finding out a spectrum closest to the measured spectrum from the standard spectral database; and determining configuration parameters corresponding to the closest spectrum to be measured parameters of the electrolyte to be measured. With the adoption of the electrolyte measurement method and the electrolyte measurement device for the vanadium redox flow battery, the concentrations of vanadium ions of various valences in the electrolyte of the vanadium battery can be effectively measured in an on-line manner, the measurement manner is simple, and the speed is fast.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Vision-based steel ball surface defect detection apparatus and detection method

InactiveCN102735693BReduce reflectionImprove the detection rateMaterial analysis by optical meansSolenoid valveVision based

The invention relates to a vision-based steel ball surface defect detection apparatus and a vision-based steel ball surface defect detection method. According to the apparatus, a light source is arranged on a work bench; a left camera and a right camera are symmetrically arranged on the two sides of the light source; a vibration material supplying tray and a material conveying channel are arranged behind the light source; the material conveying channel penetrates a light source bowl cover and extends to the front side of the light source; a sorting mechanism and collecting boxes positioned below the sorting mechanism are arranged on the front side of the light source; a discharging terminal of the material conveying channel is inserted into a feeding terminal of the sorting mechanism; the left camera and the right camera are respectively connected to a PCI card, and the PCI card is respectively connected to a computer and a pneumatic unit; and the output end of the pneumatic unit is connected to the sorting mechanism. The method comprises the steps that: a template image is collected; the steel balls are driven to move along the material conveying channel; the left camera and the right camera respectively acquire steel ball images 3 times, and the images are compared with the template image; according to the comparison results, the PCI card controls a solenoid valve which controls the sorting mechanism, such that the detected steel ball can fall into a corresponding collecting box. According to the invention, the detection process is fully automated, and the defect detection is accurate and highly efficient.

Owner:TIANJIN UNIV

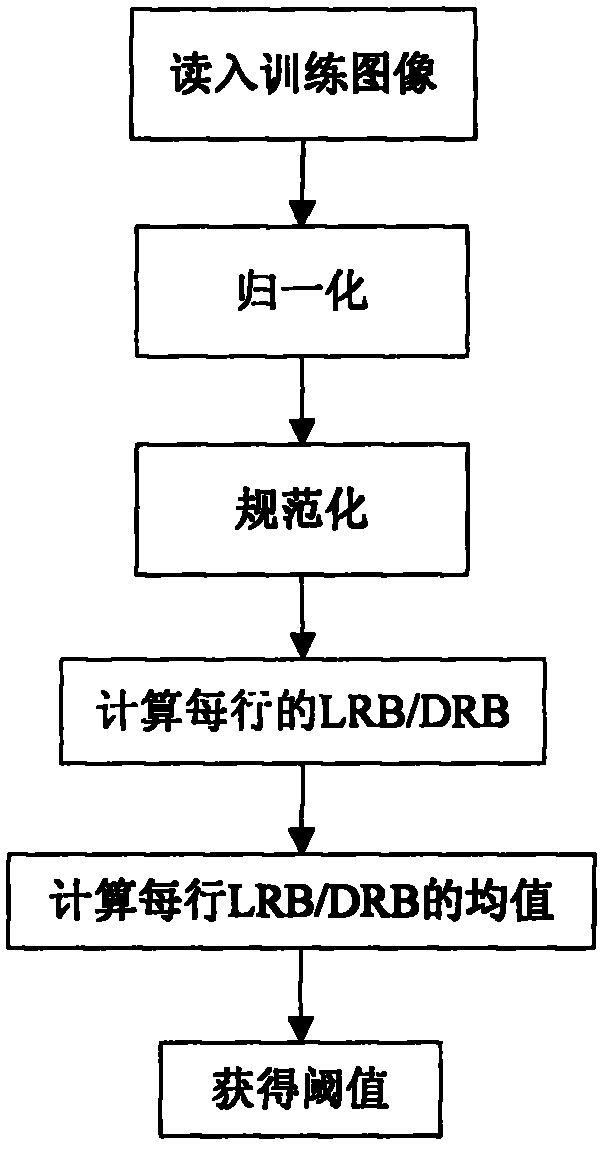

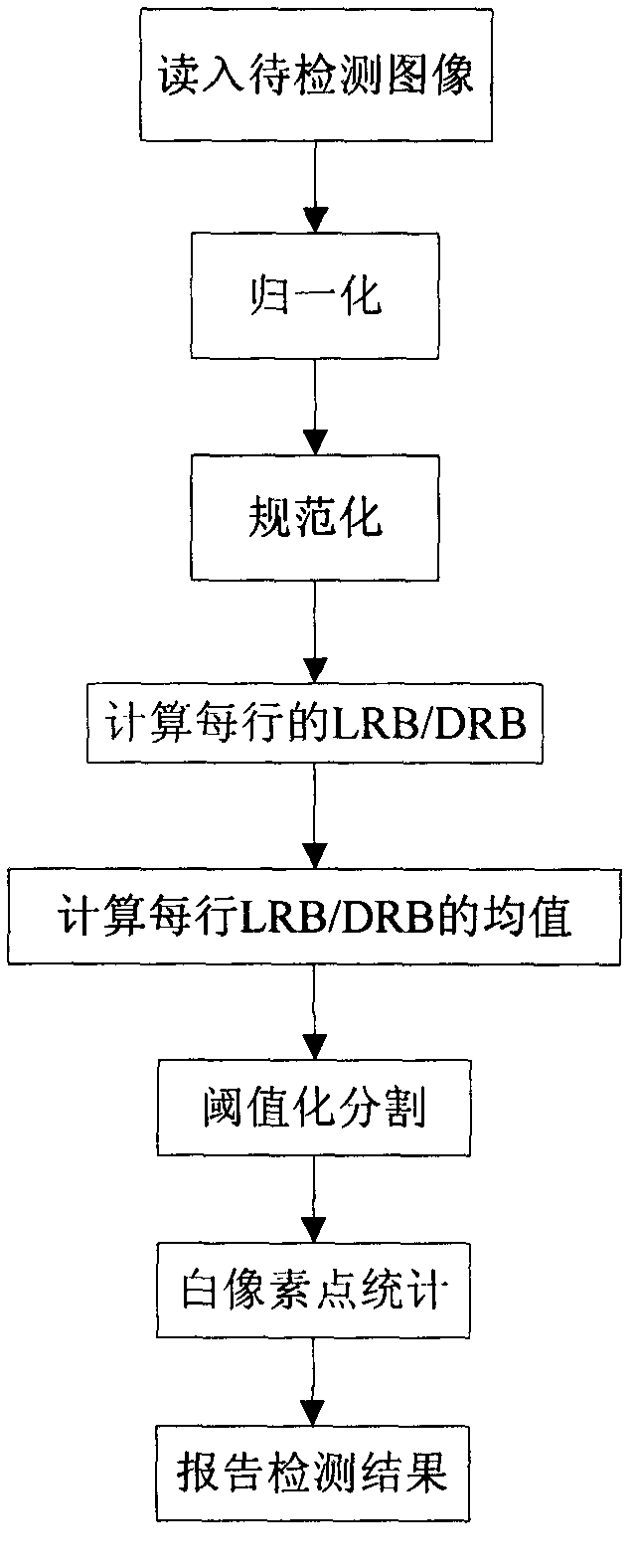

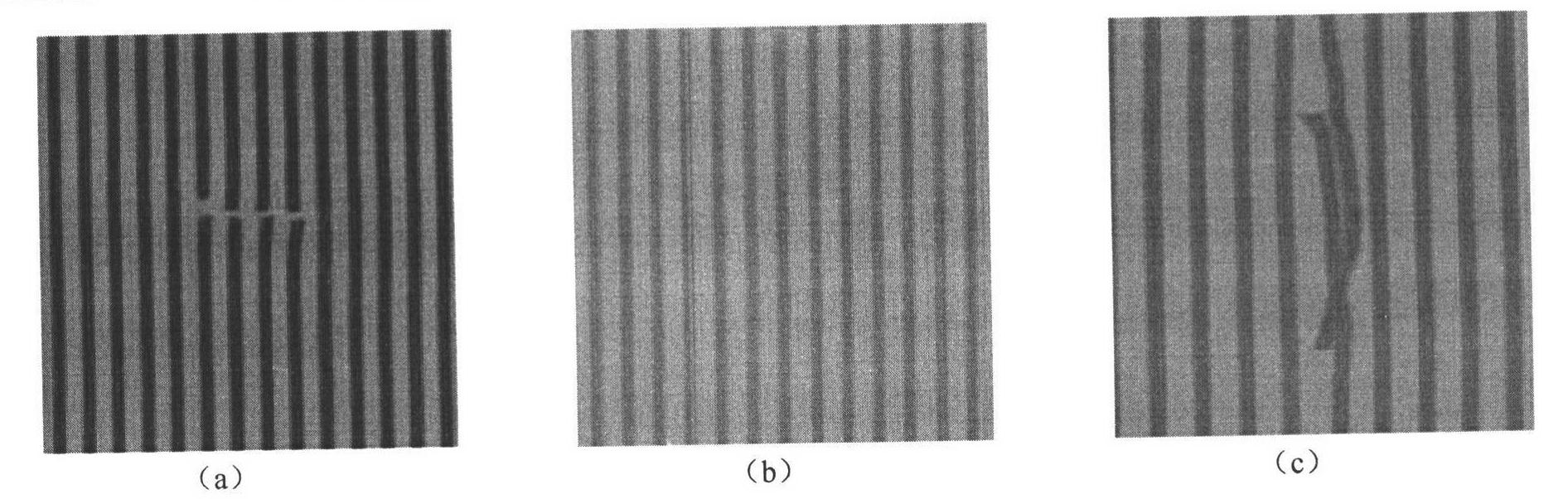

Fault on-line detection method of steel wire rope conveyer belt based on texture regularity analysis

ActiveCN102519990AImprove use valueHigh degree of automationCharacter and pattern recognitionMaterial analysis by transmitting radiationX-rayEngineering

The invention relates to a fault on-line detection method of a steel wire rope conveyer belt based on texture regularity analysis, belonging to the field of fault detection. The problems that in the current fault detection of the steel wire rope conveyer belt based on X-ray, the real-time performance is worse, the accuracy rate is not high, the fault detection is mainly done basing on manual analysis, and the like are solved. According to the characteristics that the gray scale of an X-ray image of the steel wire rope conveyer belt is in regular variation and the texture of the X-ray image of the steel wire rope conveyer belt is in regular strike-shaped distribution, after the input image is subjected to normalization and standardization processes, parameter values of LRB (Light Regular Band) and DRB (Dark Regular Band) of each pixel can be progressively scanned and calculated, the parameter values of the LRB and the DRB of each pixel can be subtracted from the parameter values of the LRB and the DRB of the whole image, then the difference value can be compared with a threshold value obtained in a training stage, thus whether the fault exists or not can be judged, and a fault area can be detected from the fault image. According to the fault on-line detection method of the steel wire rope conveyer belt based on the texture regularity analysis, disclosed by the invention, the fault detection of the steel wire rope conveyer belt can be online, automatically and accurately realized.

Owner:TIANJIN POLYTECHNIC UNIV +2

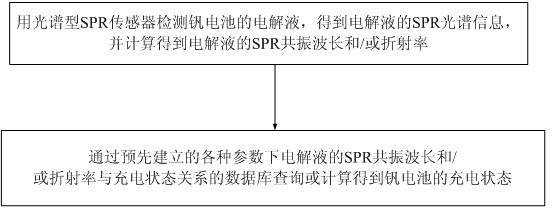

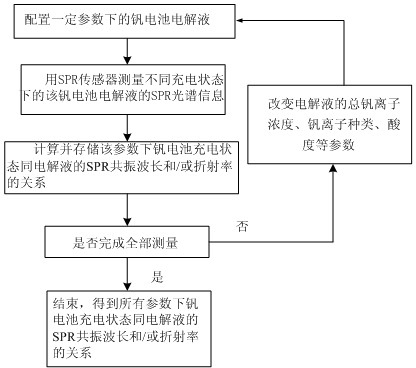

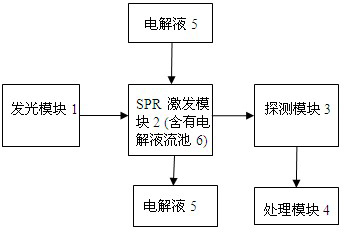

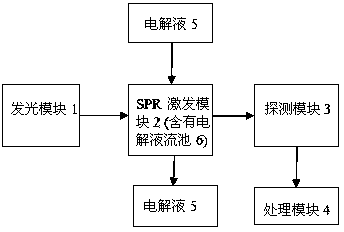

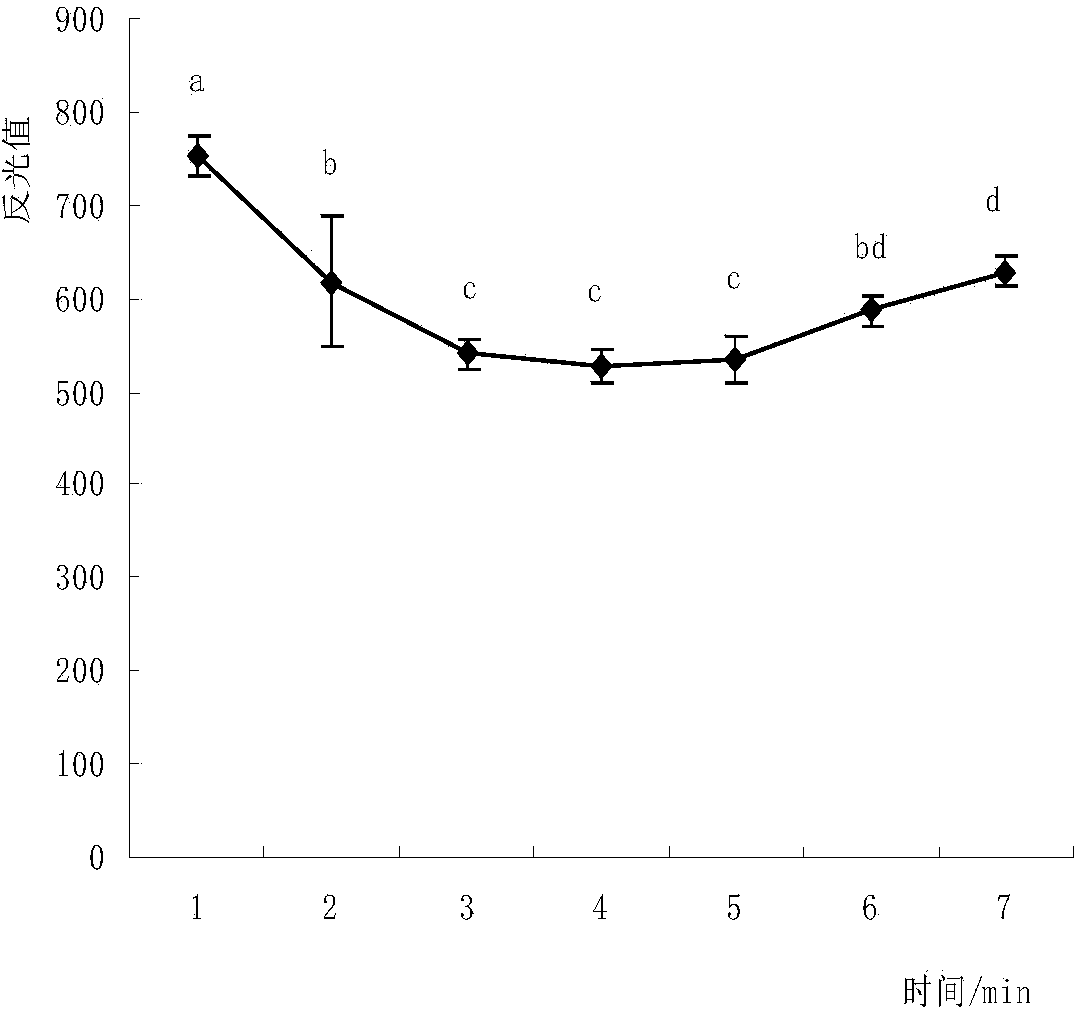

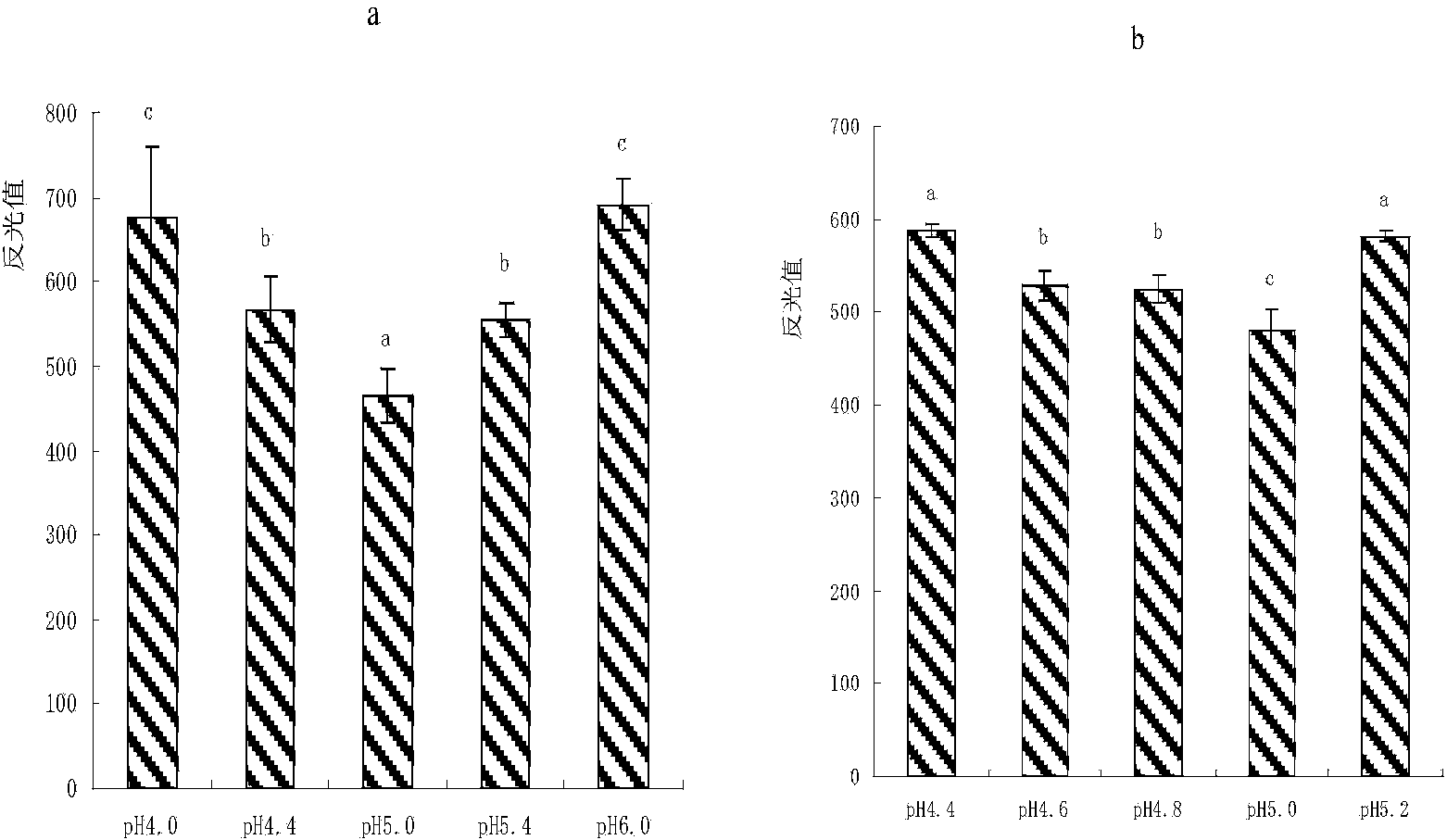

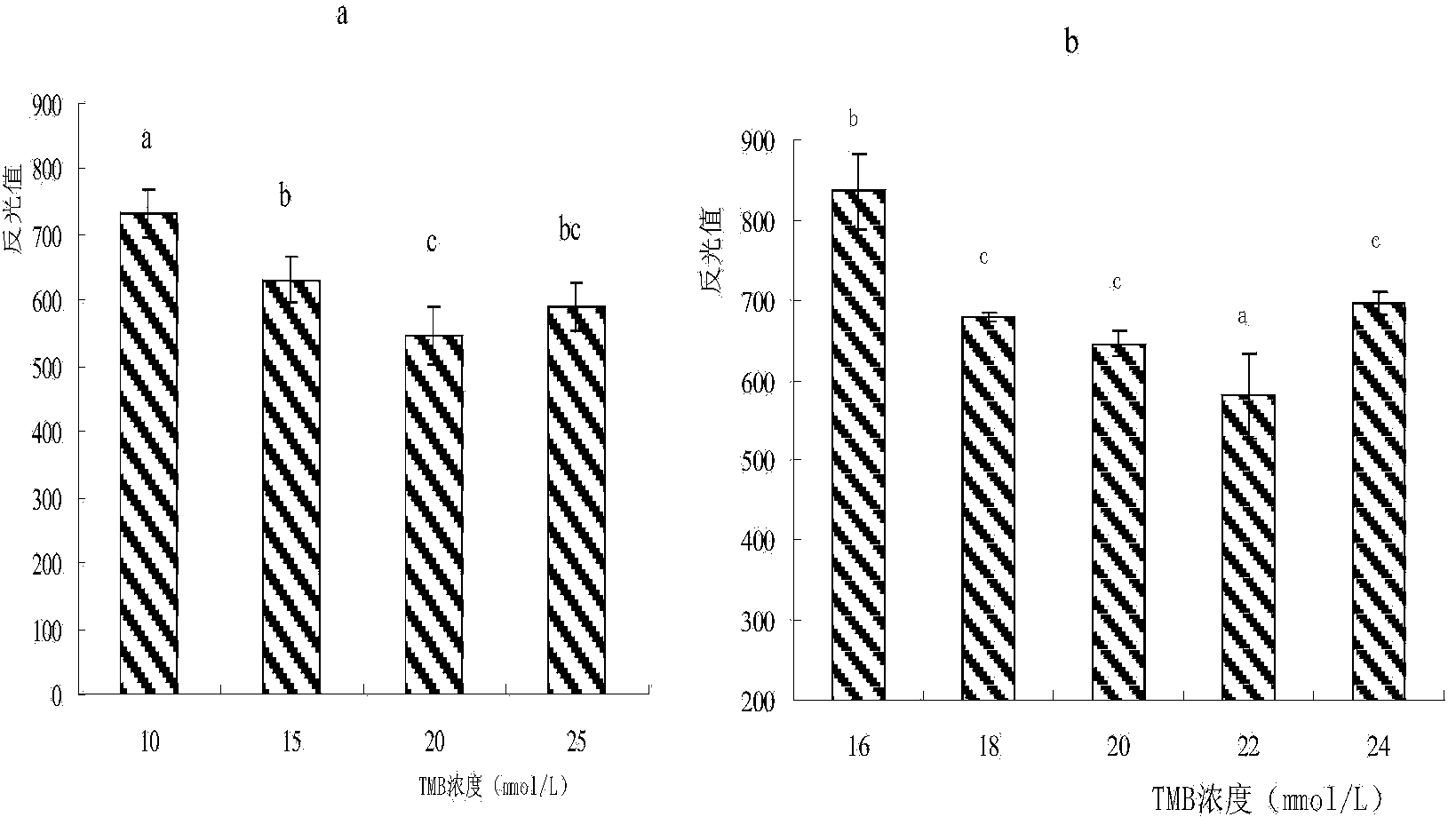

Method and device for detecting charging state of vanadium redox battery

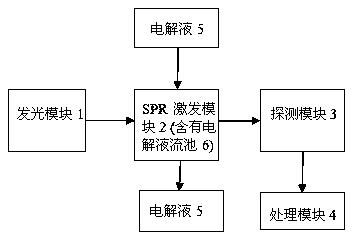

ActiveCN102621078AThe detection process is fastSuitable for real-time online detectionColor/spectral properties measurementsSurface plasmon resonance spectroscopyVanadium redox battery

The invention discloses a method for detecting charging state of a vanadium redox battery, which includes the following steps of firstly, detecting electrolyte of the vanadium redox battery by a spectral type surface plasma resonance sensor to obtain surface plasma resonance spectral information of the electrolyte and computing surface plasma resonance wavelength and / or refractive index of the electrolyte; and secondly, inquiring or computing charging state of the vanadium redox battery by a prebuilt database of relation between the surface plasma resonance wavelength and / or refractive index of the electrolyte with various parameters and the charging state. The method can detect the charging state of the vanadium redox battery online, can acquire imbalance degree in real time and can adjust the system when the vanadium redox battery is not at the perfect state.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

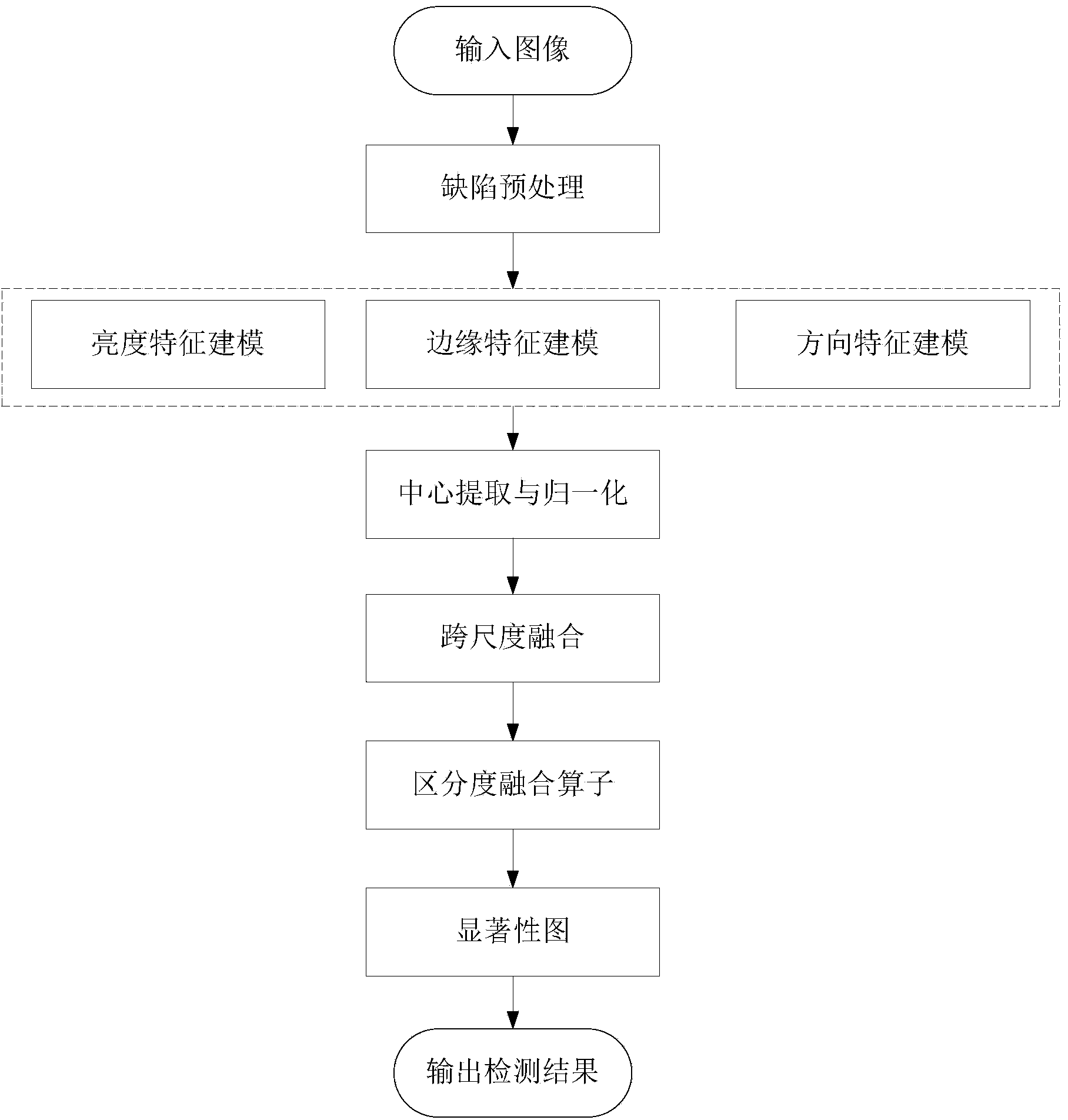

Strip-shaped article surface defect on-line visual attention detection method

InactiveCN104166986AThe detection process is fastAdaptableImage analysisImaging processingInterference resistance

The invention relates to a strip-shaped article surface defect on-line visual attention detection method. The invention fully utilizes the image pre-processing technology and the visual attention model. The method comprise steps of utilizing a background estimation image processing technology to reduce or eliminate the affect on the stick cracking defect caused by characters, trademarks, etc, highlighting surface defect information, and utilizing a visual attention model to obtain a defect characteristic remarkable diagram. The module which is based on extracting image low level visual characteristics analyzes characteristics of object image intensity, rims and directions, establishes a pyramid characteristic model, composites a characteristic image of the three characteristics through a center rotating around an operator, uses discrimination to fuse the operator, fuses the three characteristics to obtain an remarkable diagram, and highlights the cracking information to achieve the goal of extracting defect sticks. The invention can perform online detection on the surface defects of the strip-shaped article and has advantages of high speed, good interference resistance, good instantaneity and high detection accuracy.

Owner:GUANGDONG UNIV OF TECH

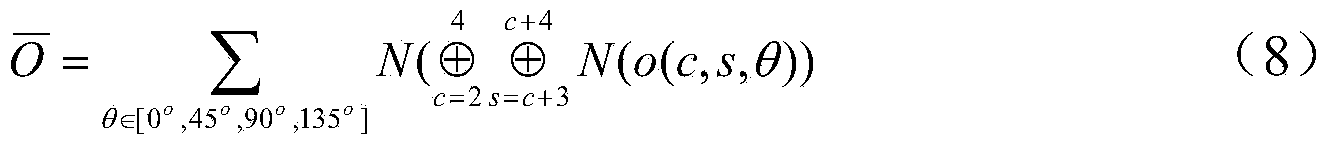

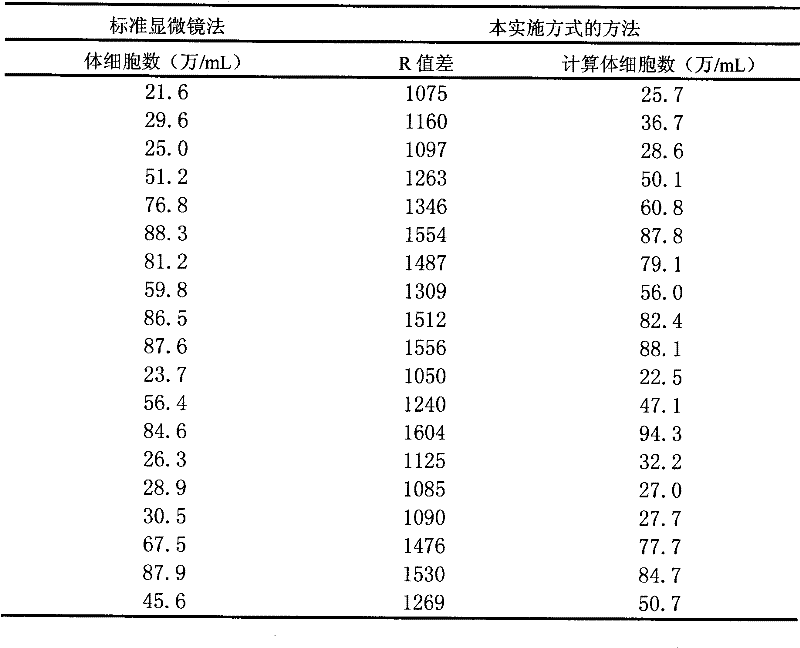

A kind of analytical test method of somatic cell content in raw milk

InactiveCN102279178AThe detection process is fastSuitable for online detectionMaterial analysis by observing effect on chemical indicatorQuantitative determinationSomatic cell

The invention discloses a method for analyzing and testing body cell content in raw milk. The method comprises the steps of preparing a reaction reagent, reacting, establishing a standard and detecting the raw milk to be detected. Besides a detecting method with a solution reagent, the invention also provides a method for detecting with reaction test paper prepared by the reaction reagent. The method disclosed by the invention has the advantages that: detection speed is fast, and the number of body cells in the raw milk can be quantitatively determined within one minute most quickly, thus being applicable to online detection; and detection cost is low, detection result is accurate, environmental requirement is low, and detection operation is simple and convenient.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

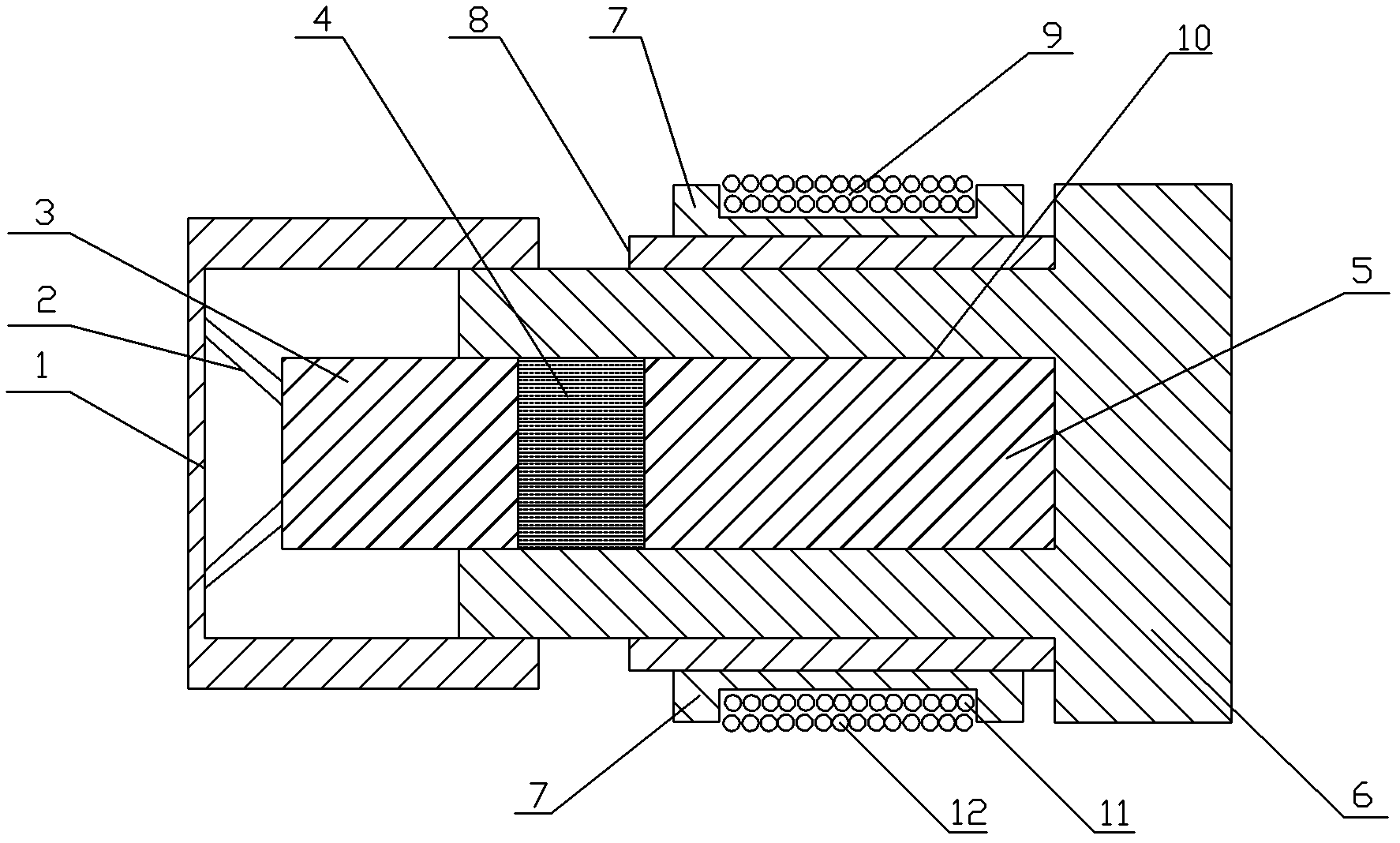

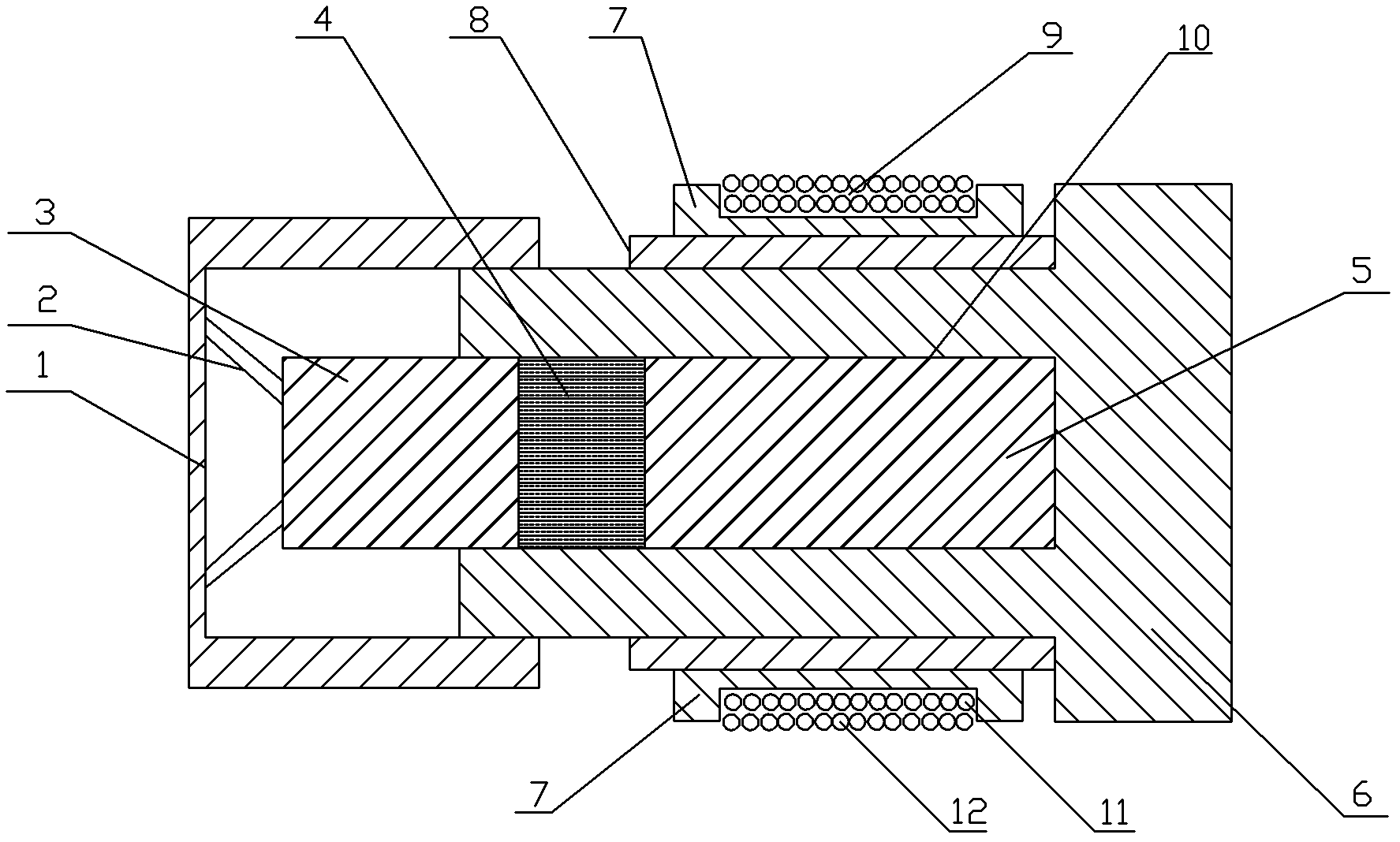

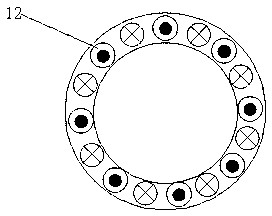

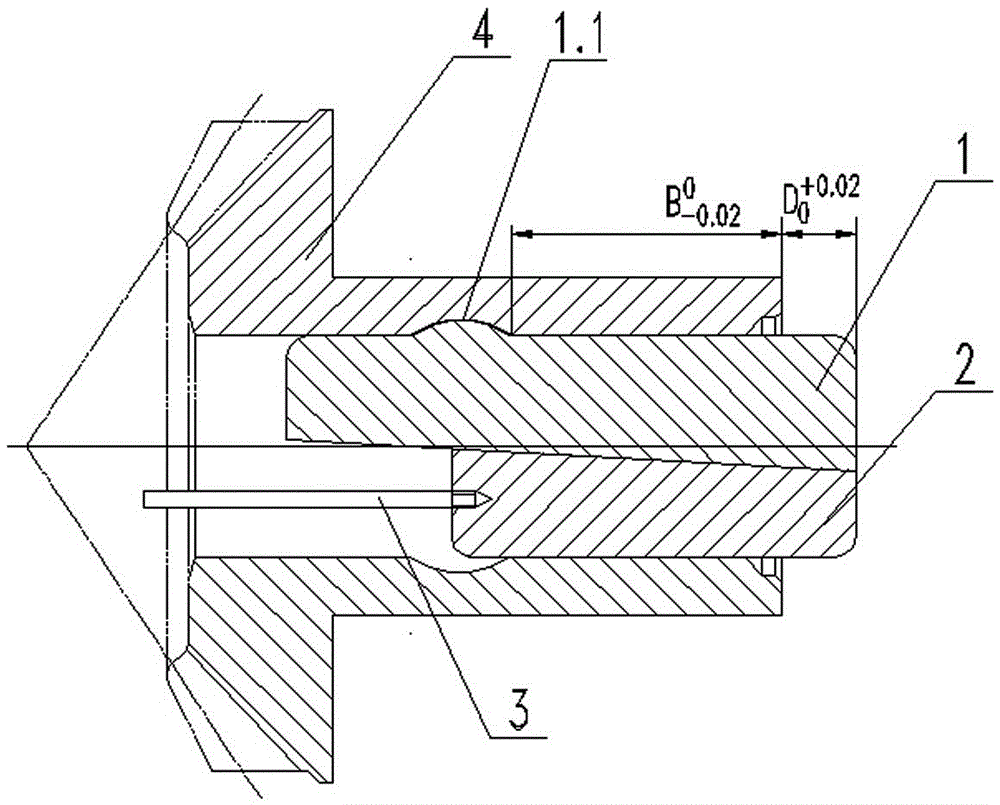

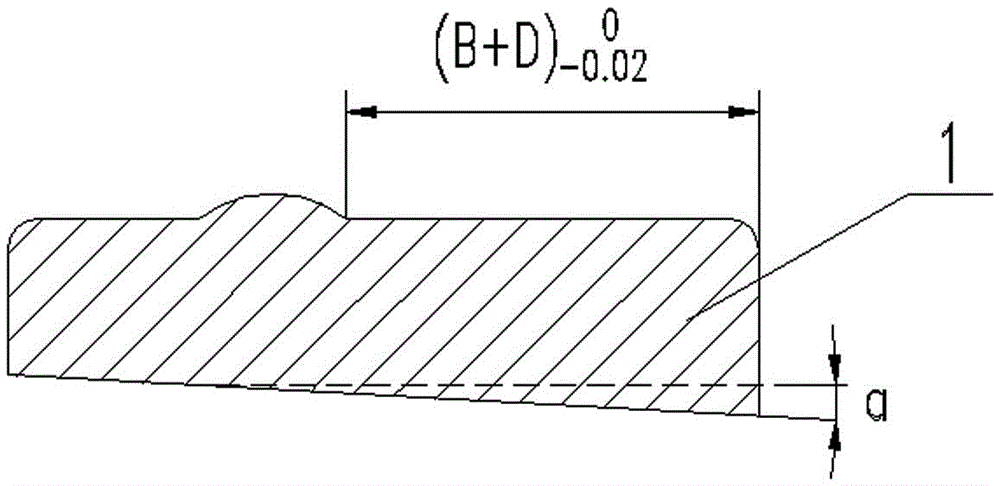

Giant magnetostriction transducer with function of ultrasonic guided wave excitation and receiving at same end

InactiveCN102539540ASuitable for online detectionLong detection distanceUltrasonic/sonic/infrasonic wave generationResponse signal detectionMagnetEngineering

The invention creatively discloses a giant magnetostriction transducer with the function of ultrasonic guided wave excitation and receiving at the same end, which includes an end cover, a disc spring, a permanent magnet, a damping element, a magnetostriction element, a base, a solenoid frame, a self-lubricating bearing and a solenoid, wherein the base serves as a reference; the magnetostriction element, the damping element and the permanent magnet are fixed in a cylindrical groove of the base respectively; and the front end of the base and the end cover form a pretension mechanism for pretension through the disc spring. Through adopting the structure, the giant magnetostriction transducer with the function of ultrasonic guided wave excitation and receiving at the same end has long detection distance, is simple to operate, is highly sensitive, and is suitable for the on-line detection of rotary machinery, does not influence the operation of machinery, and is an ultrasonic guided wave transducer based on the magnetostriction effect.

Owner:DALIAN JIAOTONG UNIVERSITY

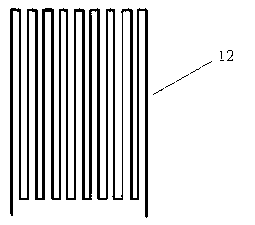

Electromagnetic ultrasonic detecting device and method for surface defects of cold rolled ribbed steel bar

InactiveCN103134856ASuitable for online detectionIncrease the level of automationAnalysing solids using sonic/ultrasonic/infrasonic wavesNon destructiveSteel bar

The invention relates to an electromagnetic ultrasonic detecting device and an electromagnetic ultrasonic detecting method for surface defects of a cold rolled ribbed steel bar. The electromagnetic ultrasonic detecting method for the surface defects of the cold rolled ribbed steel bar includes the following steps: installing an encoder on a cold rolling roller gear, installing an infrared thermometer on an outlet of an induction heating system, conducting real-time measurement for moving speed of the steel bar and surface temperature of the steel bar after inducting heating process, placing the steel bar after the heating process into an electromagnetic ultrasonic emitting prober, triggering a function generator through hardware to generate drive signals to high-frequency coils of the electromagnetic ultrasonic emitting prober, generating ultrasonic waves inside the steel bar and leak ultrasonic waves in a certain length pass through high-frequency coils of an electromagnetic ultrasonic receiving prober, collecting ultrasonic wave signals in real time, and conducting reconstruction on the defects through an electromagnetic ultrasonic signal reconstructing algorithm based on the temperature. According to the electromagnetic ultrasonic detecting device and the electromagnetic ultrasonic detecting method for the surface defects of the cold rolled ribbed steel bar, on-line non-destructive detection of the steel bar surface defects and steel bar near surface defects for the cold rolled ribbed steel bar in a condition of supersonic frequency induction heating is achieved, and the positions of the defects on surfaces or near surfaces can be determined.

Owner:CHONGQING QIANGBIN INDAL

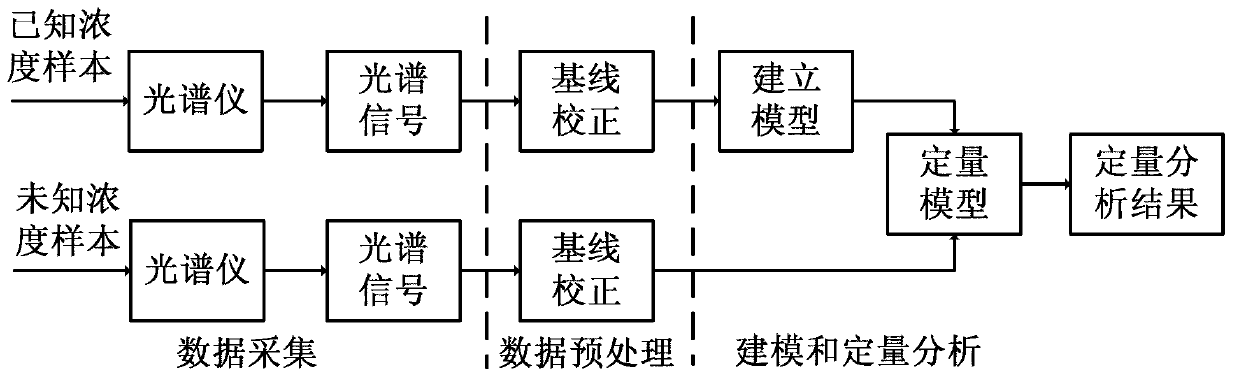

Quantitative liquid analysis method by spectrum baseline correction

InactiveCN103105369ANo preprocessing requiredReduce testing costsColor/spectral properties measurementsTest sampleData acquisition

The invention belongs to a chemical quantitative analysis method, and relates to a quantitative liquid analysis method by spectrum baseline correction, which aims to overcome the defects of long test time, high cost and large test result error of the prior art. The method comprises the following steps of: (1) data acquisition, comprising the steps of selecting an apparatus, setting parameters, firstly testing spectroscopic data without a sample, and secondly testing samples; (2) spectrum baseline correction, comprising the steps of figuring out a linear representation coefficient by optimizing a constraint model and acquiring a baseline-free spectrum according to the linear representation coefficient, thereby implementing the spectrum correction; (3) model building, comprising the step of building a quantitative analysis model by taking a sample with known concentration as a training sample through partial least squares; and (4) quantitative analysis, comprising the step of transmitting a sample with unknown concentration into the model, and computing to obtain a quantitative analysis result. The method has the advantages that the quantitative analysis of liquid materials does not need complex sample pretreatment; the test cost is low; the test speed is high, and the method is suitable for online testing; and the quantitative analysis result is exact and reliable.

Owner:HUAZHONG UNIV OF SCI & TECH

Method and device for detecting assembly outline size of main air bag of automobile

InactiveCN103017680AEfficient detectionQuick checkUsing optical meansDigital transformationTemplate matching

The invention discloses a method and a device for detecting an assembly outline size of a main air bag of an automobile and belongs to the field of metrology. The method and the device are used for detecting the dimensional precision of the assembly outline size of the air bag and can eliminate the defects that existing methods are high in cost, high in difficulty, a lot in influencing factor, low in efficiency and the like. The detecting method comprises the steps of A, manufacturing a digital template of an assembly outline image of the qualified automobile main air bag; B, conducting digital transformation for the assembly outline image of the air bag to be detected; and C, matching a digital image of a workpiece to be detected with the digital template of a qualified workpiece to obtain a result. The detecting device comprises a working platform, a frame or a box body, an air bag positioning fixing mechanism, a camera support, a camera, a light source, an image processing module, an operation module and a working power supply, wherein the frame or the box body supports the platform, the air bag positioning fixing mechanism is located on an installation platform, the camera support is fixed on the platform or the frame, the camera and the light source are installed at the upper end of the support and located above a bearing platform, and the image processing module, the operation module and the working power supply are installed on the frame or the support or the platform. The method and the device have the advantages of being capable of detecting the outline size of the air bag of the automobile efficiently, quickly and accurately and applicable to on-line detection of industrial production lines.

Owner:CHANGCHUN UNIV OF TECH +1

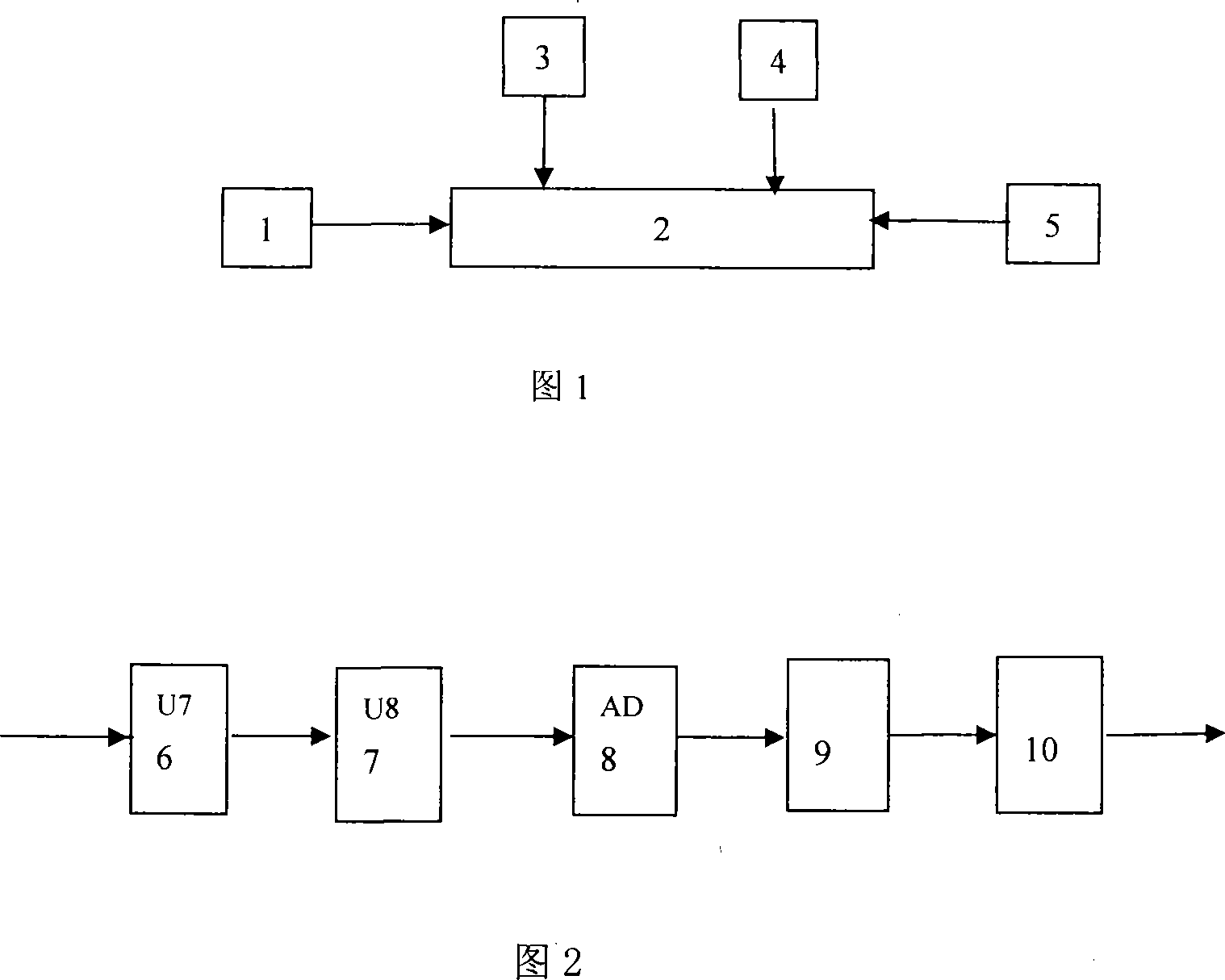

Combined electrode for determining sulphur ion of drilling fluids

InactiveCN101216446ACost-effectiveSuitable for online detectionBorehole/well accessoriesMaterial electrochemical variablesComposite electrodeSignal processing circuits

The invention relates to a composite electrode for measuring sulfur ions in drilling fluid, which is characterized in that the composite electrode is composed of a solid-state reference electrode, a signal processing circuit, a S<2-> measurement electrode, a PH<-> measurement electrode and a temperature probe, wherein, the signal processing circuit is respectively connected with the solid-state reference circuit, the S<2-> measurement electrode, the PH<-> measurement electrode and the temperature probe. The invention has the advantages that the solid-state electrode is more suitable for drilling liquid, the S<2-> measurement electrode and the PH<-> measurement electrode share the solid-state reference electrode, the S<2-> measurement electrode, the PH<-> measurement electrode and the solid-state reference electrode can be replaced independently with improved performance-price ratio. By combining three instruments into one instrument, the invention has compact structure and is especially suitable for online detection of sulfur ions of drilling liquid.

Owner:SHANGHAI GASOLINEEUM & CHEM EQUIP +1

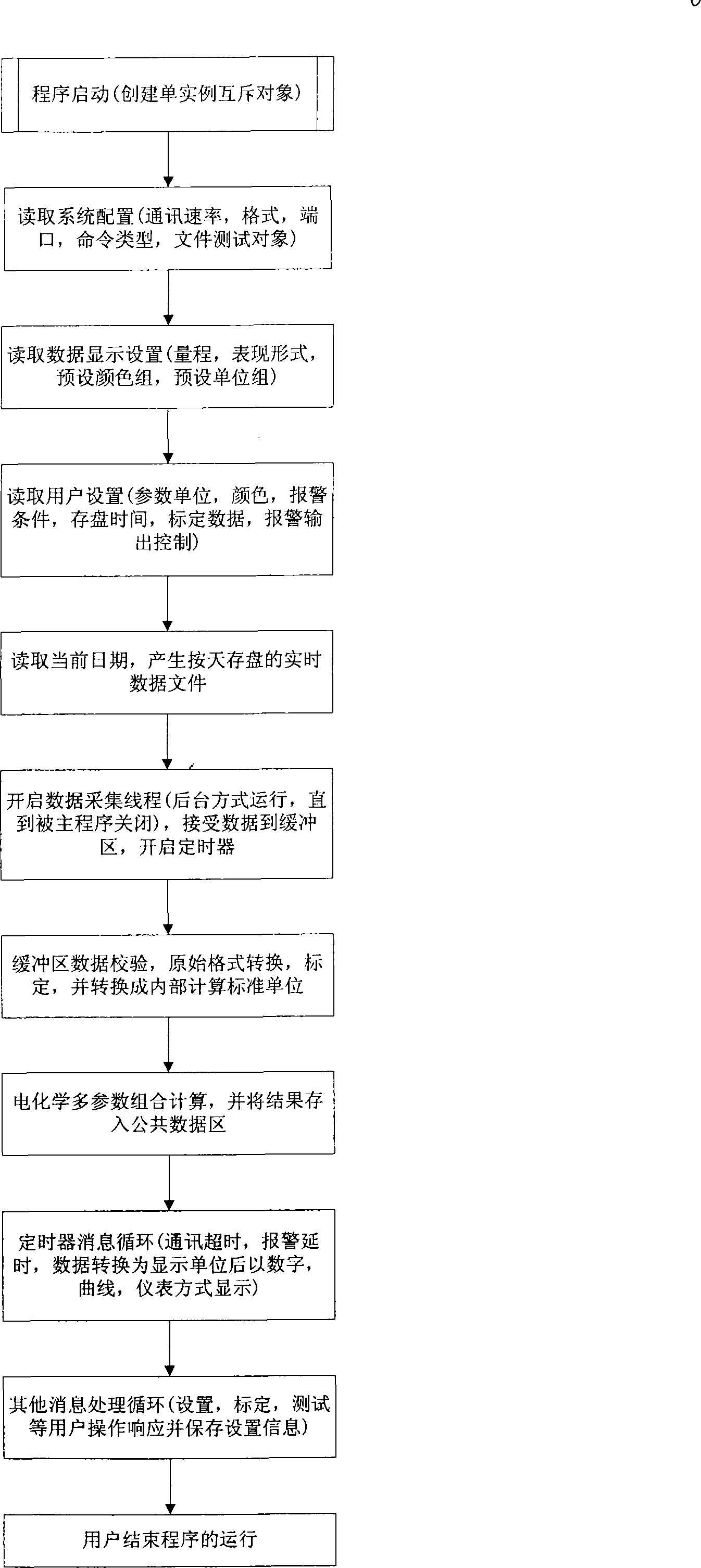

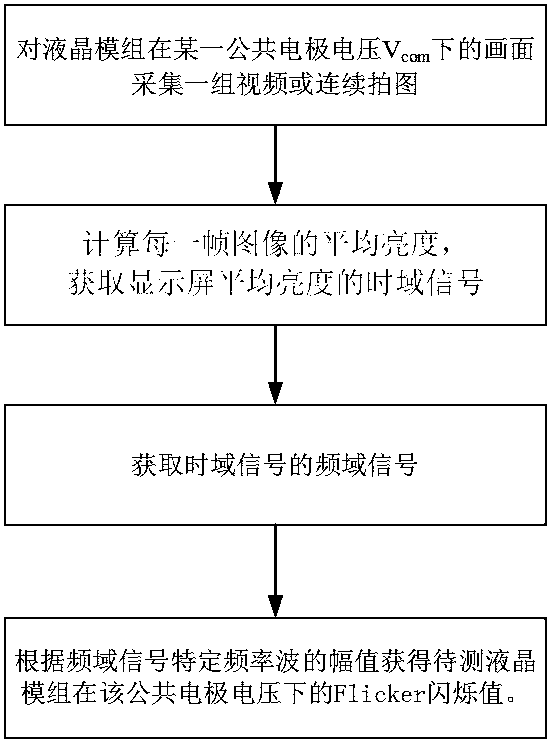

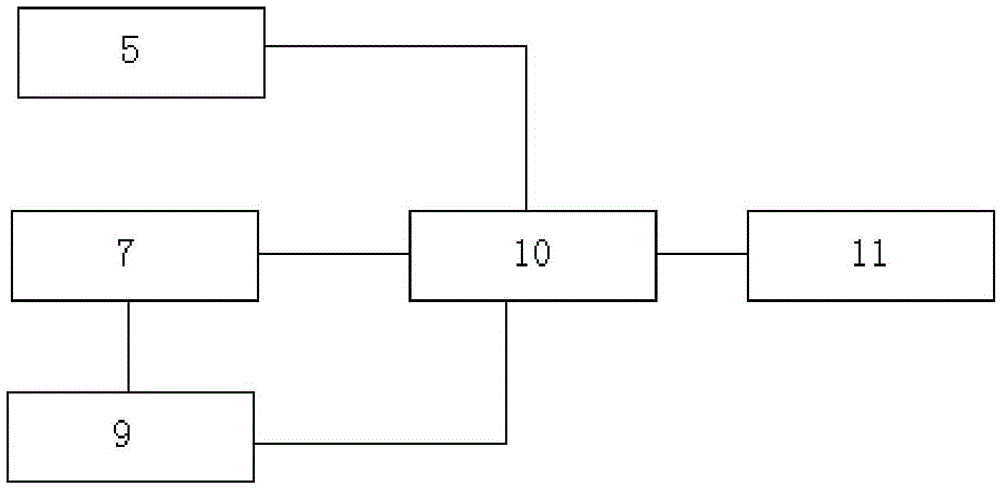

Method, device and system for remotely measuring Flicker scintillation value of liquid crystal module

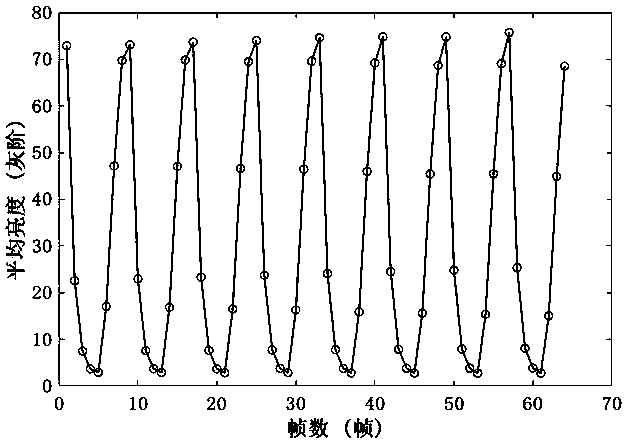

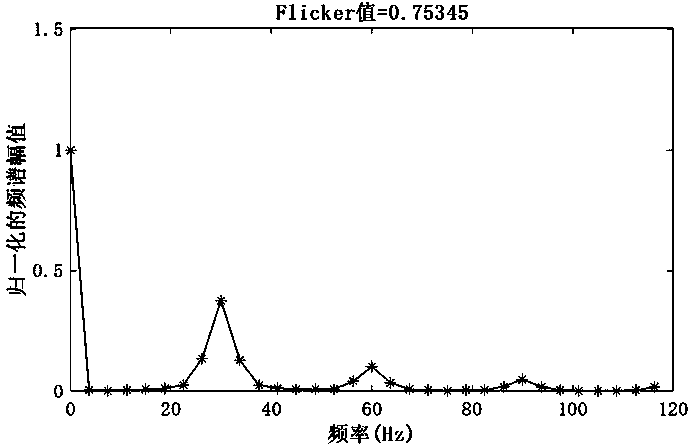

ActiveCN110211523AMeasurement does not affectQuick measurementStatic indicating devicesFrequency waveLiquid crystal

The invention belongs to the technical field of display panel detection, and discloses a method, a device and a system for remotely measuring a Flicker scintillation value of a liquid crystal module.The method includes: carrying out continuous image capturing on a display image of the liquid crystal module under a certain common electrode voltage; obtaining the average brightness of the image frames, obtaining the change relation of the brightness with the number of collected frames or time, i.e., the time domain signal of the brightness, obtaining the spectrogram of the brightness through the time domain signal, and obtaining the Flicker scintillation value of the liquid crystal module to be detected under the common electrode voltage through the amplitude of the specific frequency wave.The device comprises equipment for continuously capturing images of a liquid crystal module under a certain common electrode voltage, A calculation processing module used for calculating the averagebrightness to obtain a time domain signal of the brightness, A Fourier transform module used for carrying out fast Fourier transform on the time domain signal of the brightness, and A Flicker scintillation value calculation module used for calculating a Flicker scintillation value. according to the method and the system, the Flicker scintillation value of the display screen can be remotely measured, and the method and the system are used for monitoring the flicker degree of the liquid crystal display screen in real time in a panel production line.

Owner:WUHAN JINGLI ELECTRONICS TECH +1

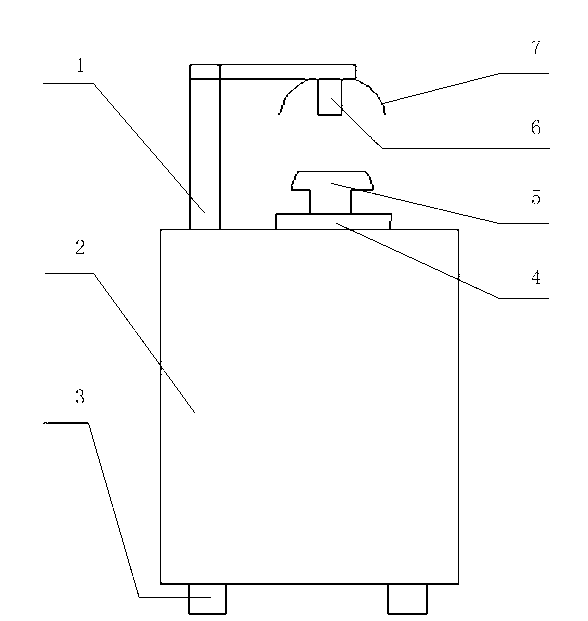

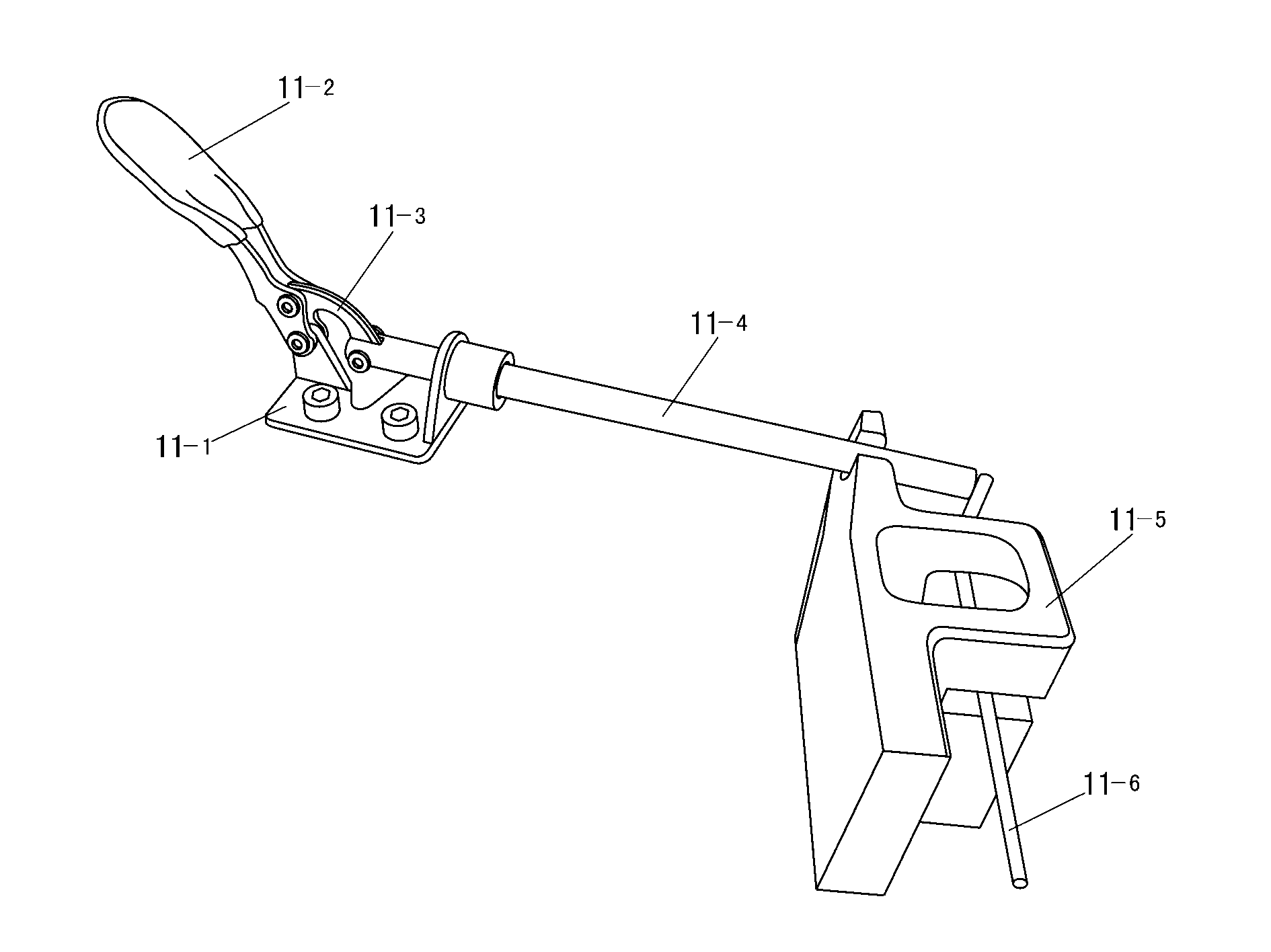

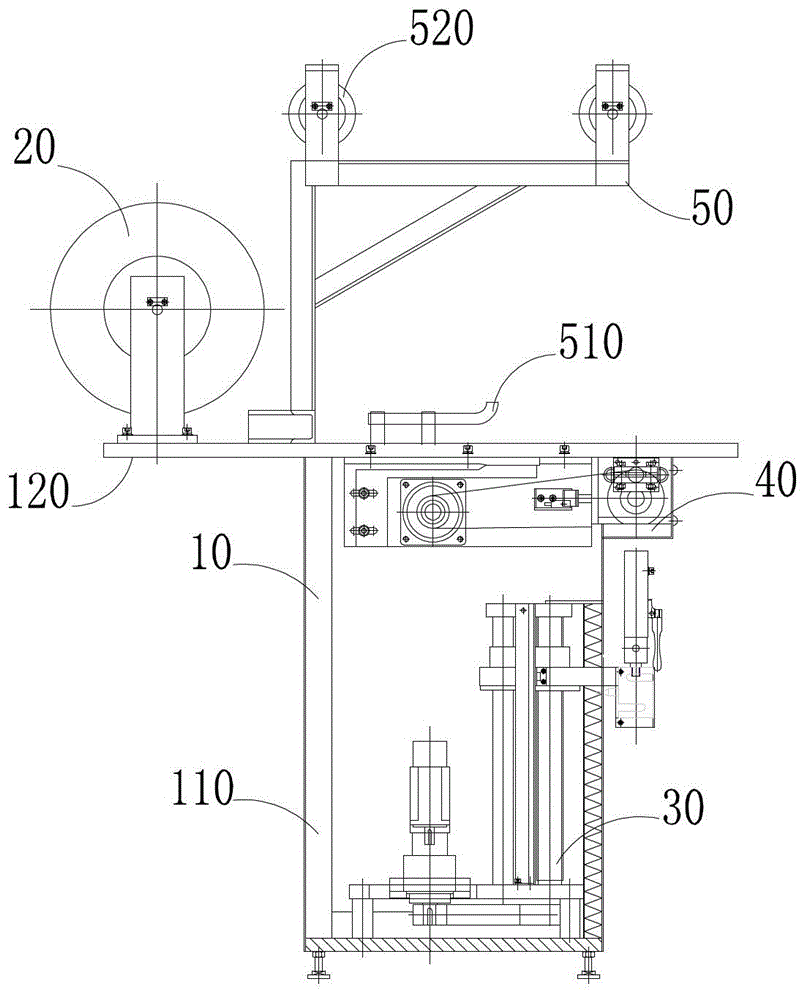

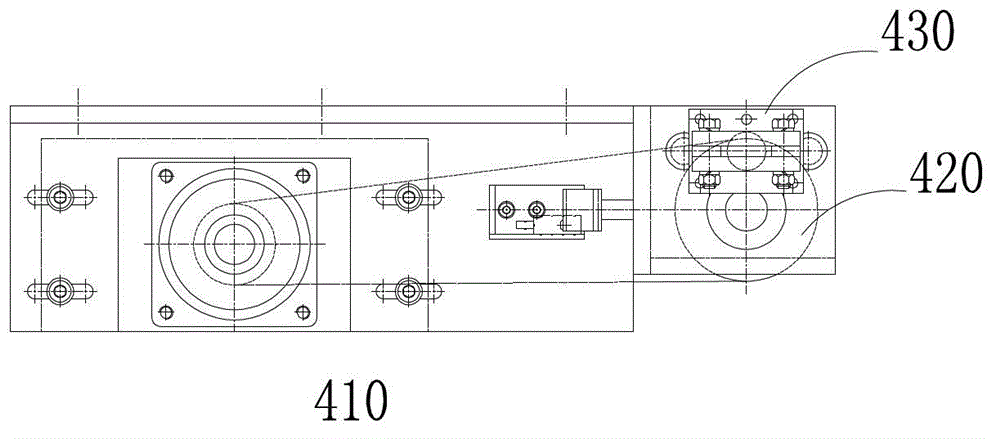

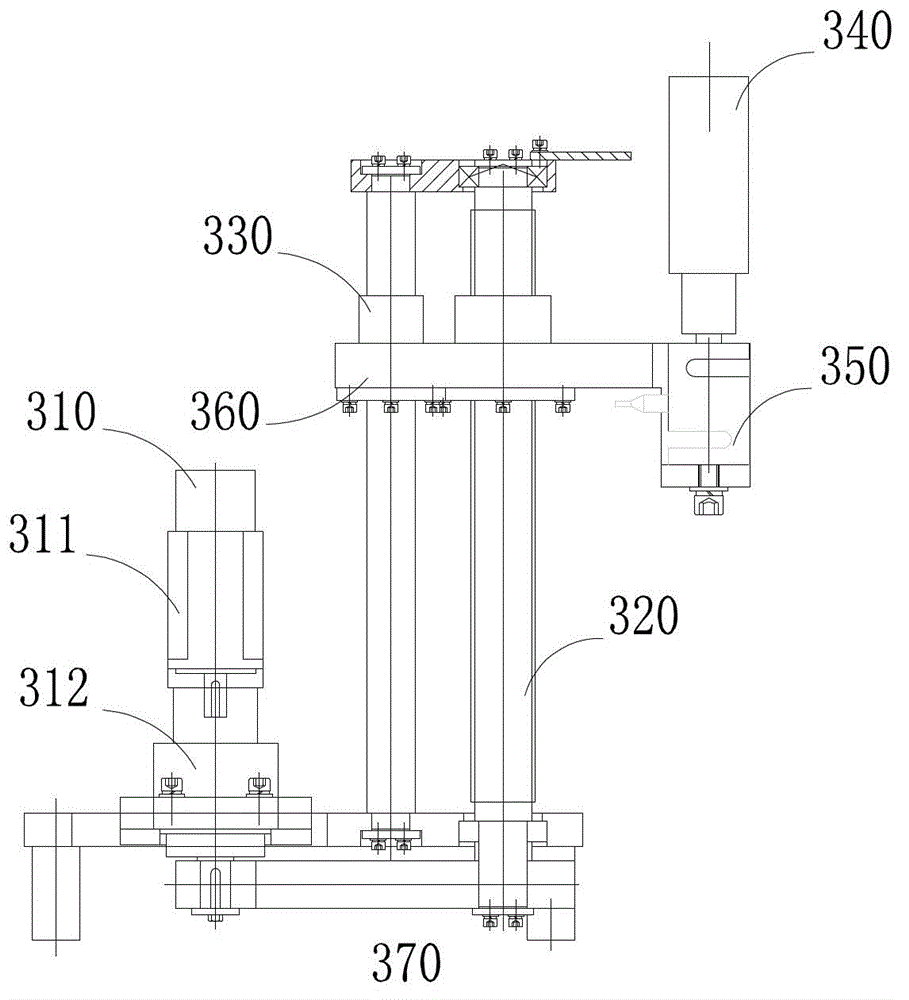

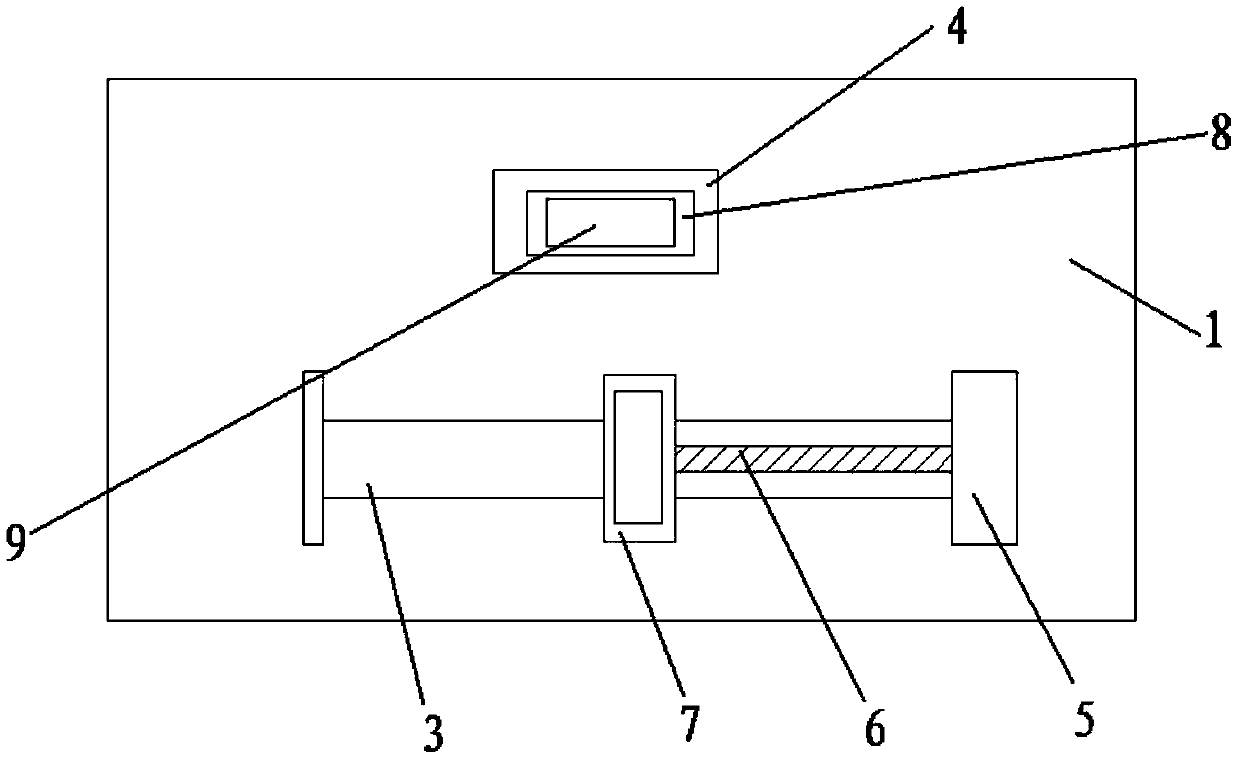

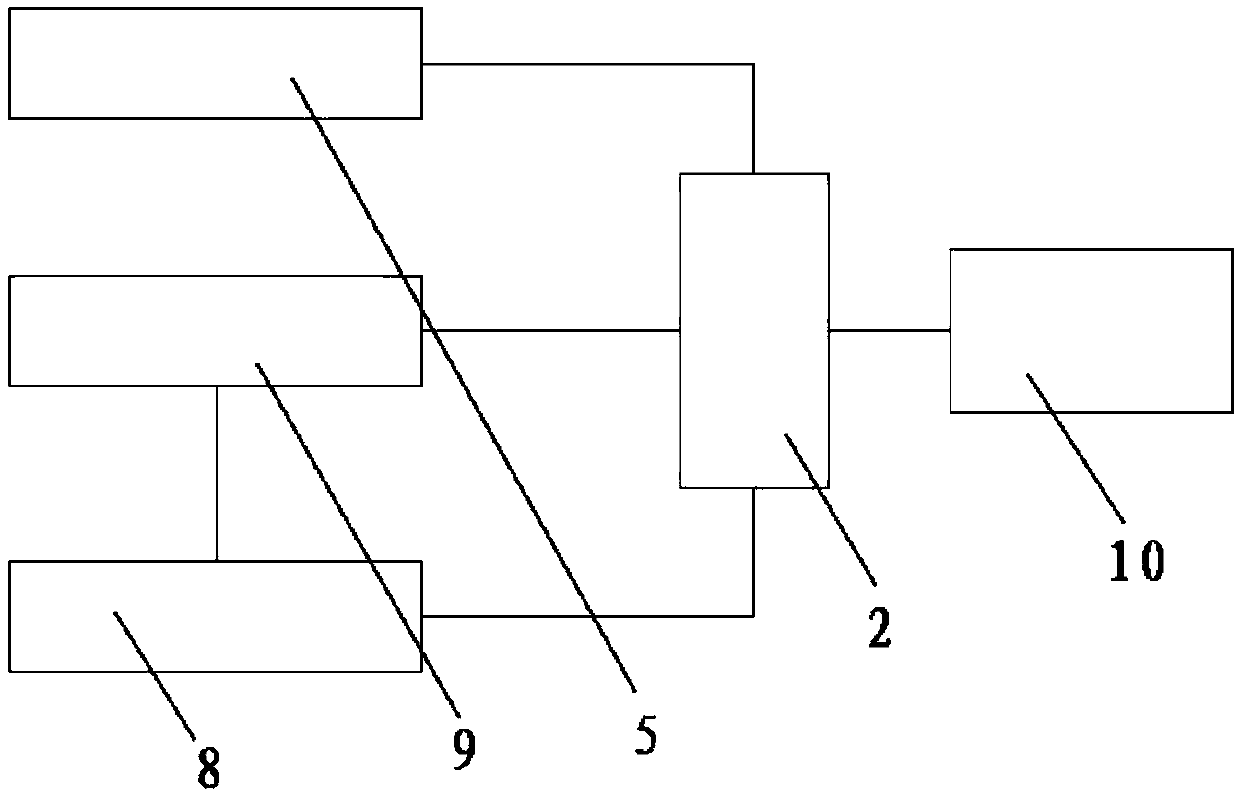

Speed governor testing device

ActiveCN102944394AEasy to operateGuaranteed correctnessMachine part testingEngineeringConductor Coil

The invention discloses a speed governor testing device which comprises a test table, a rope winding mechanism, a stretching mechanism and a shearing mechanism, wherein the shearing mechanism, the rope winding mechanism and the stretching mechanism are respectively connected with the test table; the rope winding mechanism is used for storing and placing the test rope; the stretching mechanism is used for stretching the test rope when testing to detect tension of the speed governor; and the shearing mechanism is used for shearing the test rope after the test. The speed governor testing device can automatically load and measure the speed governor, is simple in the structure, easy to operate, high in efficiency, and suitable for online detection of the speed governor batch production.

Owner:HITACHI BUILDING TECH GUANGZHOU CO LTD

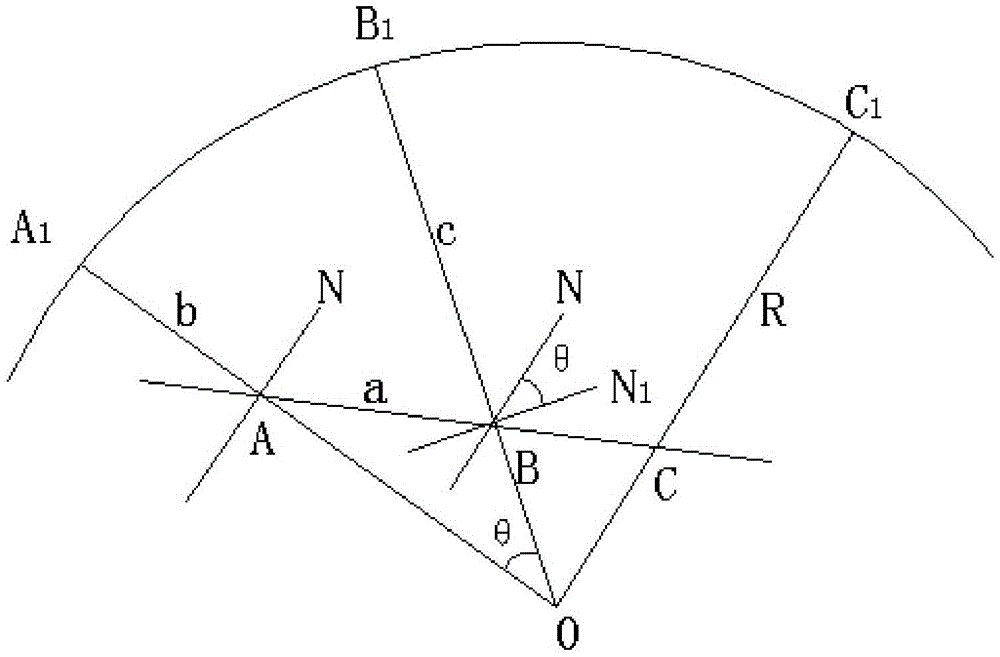

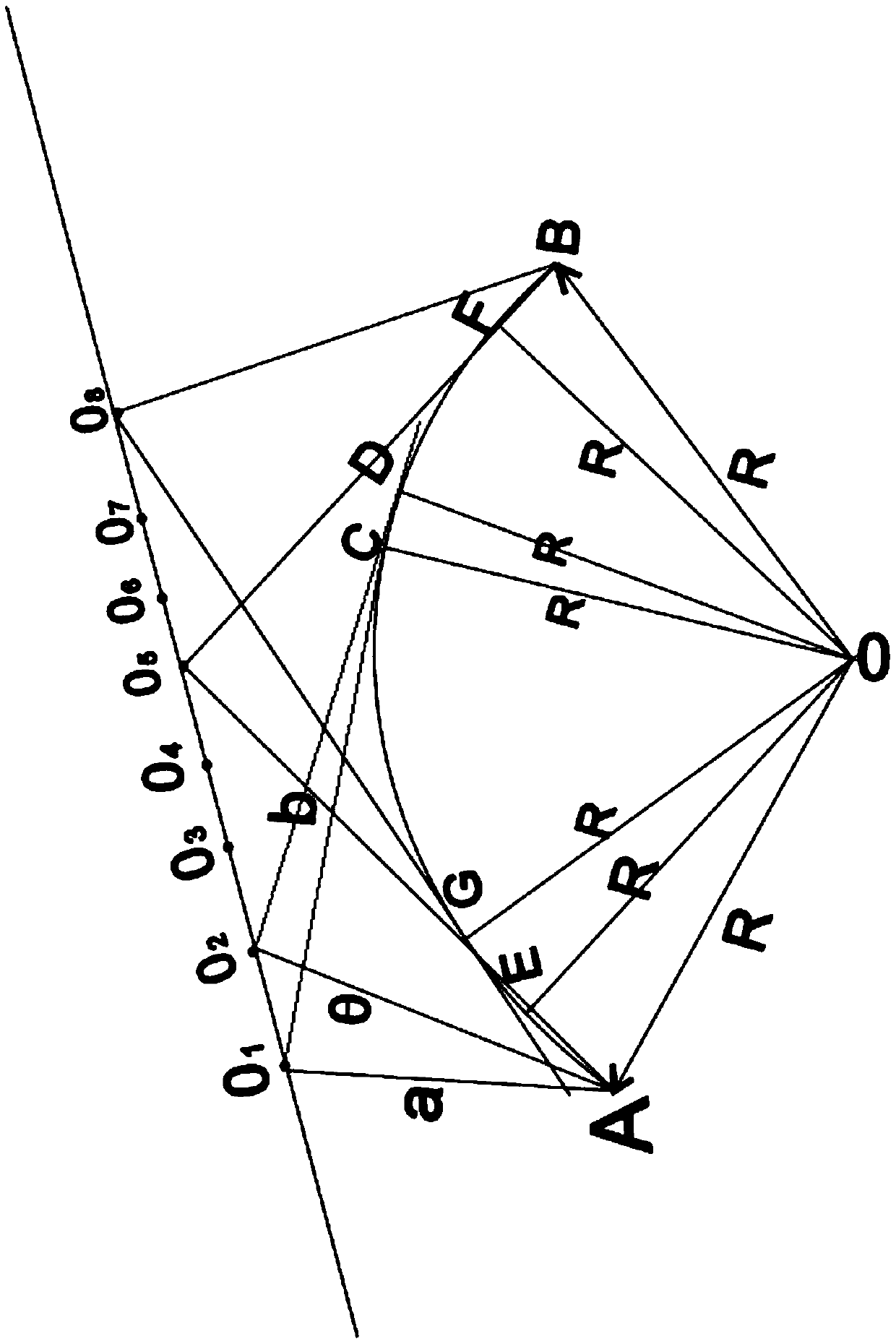

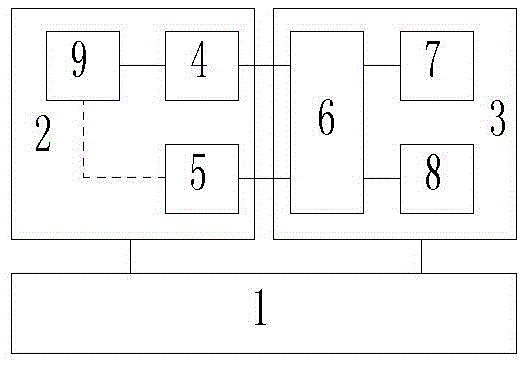

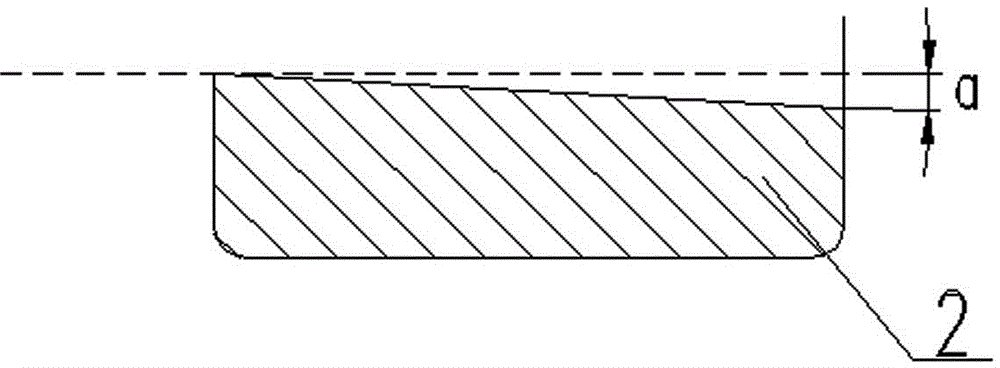

Concave arc radius detection and arc degree determination apparatus and method

The invention discloses a concave arc radius detection and an arc degree determination apparatus and method, and the apparatus comprises a detection bench; a linear guide rail is arranged on the surface of the detection bench; a slide block is arranged on the linear guide rail; a measuring probe is arranged on the slide block; and 4 range finding sensors are arranged on the measuring probe. The 4 range finding sensors are vertical to each other and are arranged at the same plane; the slide block is connected with a turntable of a motor through a ball screw rod; an angle sensor is arranged on a rotating shaft of the motor; the range finding sensors, the motor and the angle sensor are connected to a data processor; and the data processor is connected to a controller. By introducing the step of geometric calculating, the method of concave arc radius detection and arc degree determining in prior art is substantially simplified; the over-complex device is simplified; the cost is reduced; the product surface won't be damaged thanks to non-contact measuring; advantages like wide application scope, easy operation, high security, high detection precision and high efficiency are provided; and the method is very suitable for on-line detection.

Owner:LISHUI VOCATIONAL & TECHN COLLEGE

Defect positioning method based on laser ultrasonic B scanning

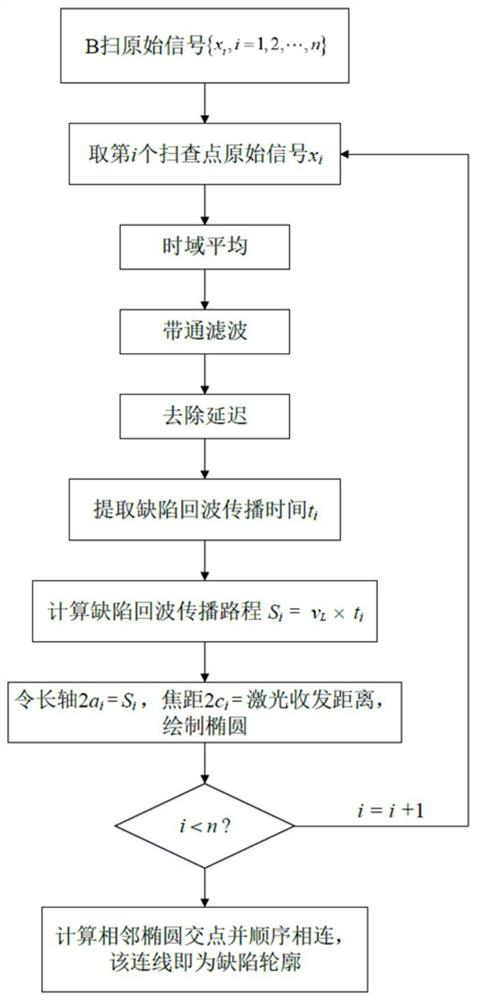

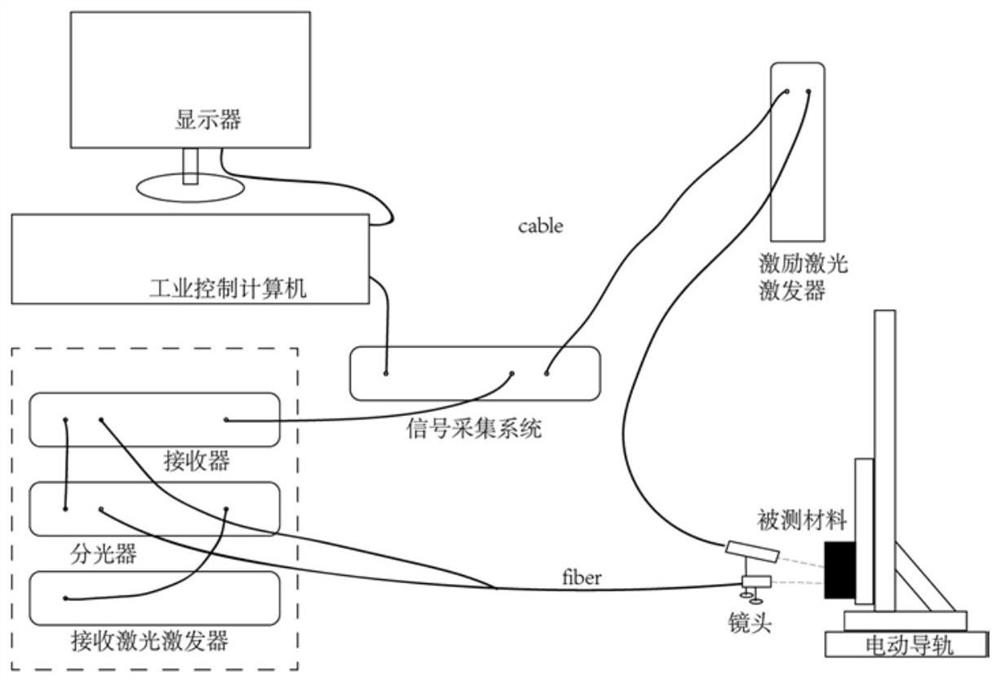

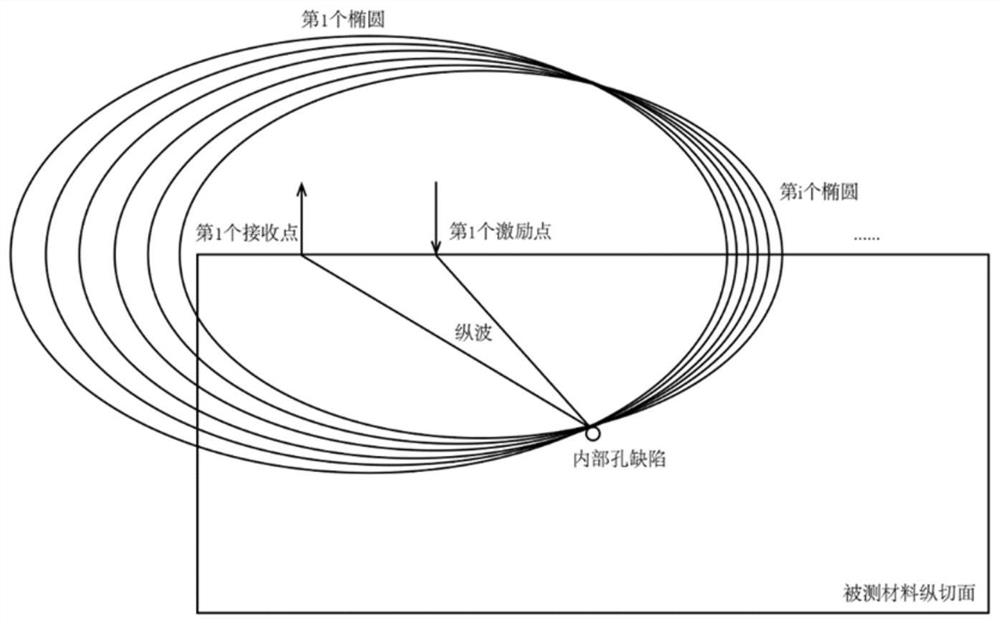

PendingCN112067697AAvoid cumbersomeAvoid errorsAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalFeature extractionLongitudinal wave

A defect positioning method based on laser ultrasonic B scanning comprises the steps of carrying out B scanning on the surface of a metal material, and acquiring a B scanning signal; preprocessing theB scanning signal, decomposing the B scanning signal into different frequency bands, and extracting a wave crest moment of a longitudinal wave defect echo to obtain a propagation distance of the longitudinal wave of each scanning point; drawing n ellipses by taking an excitation laser point and a receiving laser point as two focuses of the ellipses and taking a longitudinal wave propagation pathas a long axis of the ellipses; and solving the intersection points of the adjacent ellipses, and connecting the intersection points in sequence to obtain the contour of the defect and the position coordinates of the defect. A metal material with internal defects is used as a target verification object, internal defects in a certain longitudinal section are detected through longitudinal waves in aB scanning mode by means of a laser ultrasonic detection platform, reconstruction of B scanning signals is achieved by means of signal noise reduction, feature extraction and the like, and information such as a shape, a size and a position of the defects is detected. And a purpose of visual quantitative identification of defects is achieved.

Owner:XI AN JIAOTONG UNIV

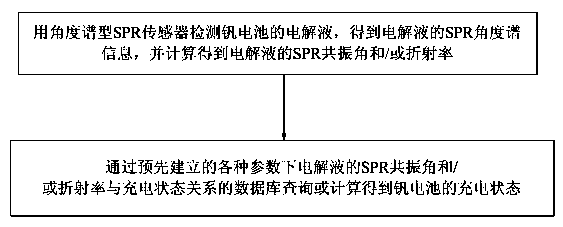

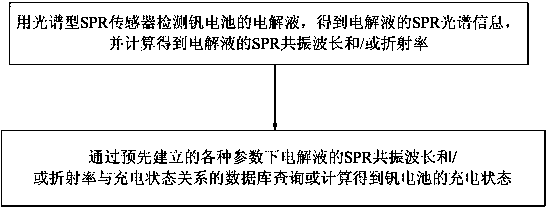

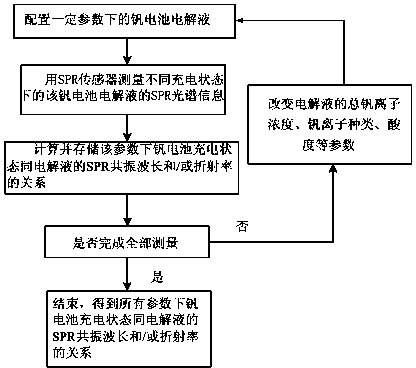

Method and device for detecting charging state of vanadium cell

ActiveCN102608041BThe detection process is fastSuitable for real-time online detectionPhase-affecting property measurementsColor/spectral properties measurementsRefractive indexPlasma resonance

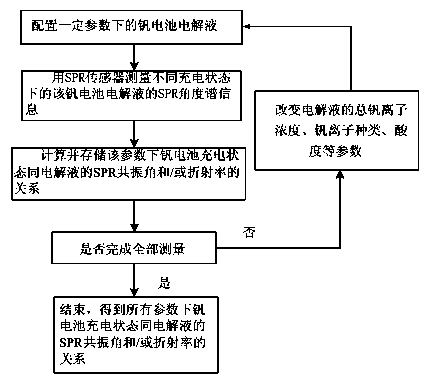

The invention discloses a method for detecting a charging state of a vanadium cell, which comprises the following steps of: (1) using an angular spectrum type surface plasma resonance sensor to detect electrolyte of the vanadium cell, obtaining surface plasma resonance angular spectrum information of the electrolyte, and calculating to obtain a surface plasma resonance angle and / or refractive index of the electrolyte; and (2) inquiring or calculating to obtain the charging state of the vanadium cell according to the preset surface plasma resonance angle and / or the refractive index of the electrolyte under various parameters and a data bank related to the charging state. According to the method, the charging state of the vanadium cell can be detected on line, the imbalance can be known in real time, and thus a system can be adjusted when the vanadium cell is in an unideal state.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Method and device for detecting charging state of vanadium redox battery

ActiveCN102621078BThe detection process is fastSuitable for real-time online detectionColor/spectral properties measurementsSurface plasmon resonance spectroscopyPerfect state

The invention discloses a method for detecting charging state of a vanadium redox battery, which includes the following steps of firstly, detecting electrolyte of the vanadium redox battery by a spectral type surface plasma resonance sensor to obtain surface plasma resonance spectral information of the electrolyte and computing surface plasma resonance wavelength and / or refractive index of the electrolyte; and secondly, inquiring or computing charging state of the vanadium redox battery by a prebuilt database of relation between the surface plasma resonance wavelength and / or refractive index of the electrolyte with various parameters and the charging state. The method can detect the charging state of the vanadium redox battery online, can acquire imbalance degree in real time and can adjust the system when the vanadium redox battery is not at the perfect state.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Method for detecting elements in alloy

InactiveCN103472007ANo supportSuitable for online detectionMaterial analysis using wave/particle radiationColor/spectral properties measurementsCalculated dataStandard samples

The invention discloses a method for detecting elements in an alloy. The detecting method comprises the following steps of detecting the content of impurity elements by determining the light intensity ratio through a spectrograph; selecting a standard sample the content of which is closest to the to-be-controlled content numerical value of to-be-determined elements in the alloy; selecting, determining and analyzing a base body, inputting the content of the standard sample into the spectrograph, and setting stimulating parameters; acquiring calculating data, and stimulating the standard sample so as to obtain the light intensity ratio of the standard sample; stimulating a sample sent for detection so as to obtain the light intensity ratio of the sample sent for detection; and comparing the light intensity ratios of the standard sample and the sample sent for detection so as to obtain the detection result. The method provided by the invention is used for detecting the content of the elements in the alloy rapidly and qualitatively, and is especially suitable for on-line detection in a production field.

Owner:GUIZHOU ANJI AVIATION PRECISION CASTING

Method for detecting lactoperoxidase in raw milk using test paper

InactiveCN104406977ARealize qualitative detectionThe detection process is fastMaterial analysis by observing effect on chemical indicatorMilk sampleQuantitative determination

The invention discloses a method for detecting lactoperoxidase in raw milk using test paper. The method includes the following steps: preparing a reaction reagent; conducting test paper reaction; establishing detection standards; detecting lactoperoxidase in a milk sample. The method provided by the invention has the advantages that the detection speed is high, and a quantitative detection of lactoperoxidase can be finished in a few seconds at the soonest; the content of lactoperoxidase in raw milk can be quantitatively detected in 3 minutes; the method is suitable for the online detection of lactoperoxidase; the detection cost is low; the detection result is accurate, and the lowest detected concentration is 1-2 mg / L; the requirements for the environment are low; the detection operations are simple and convenient.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

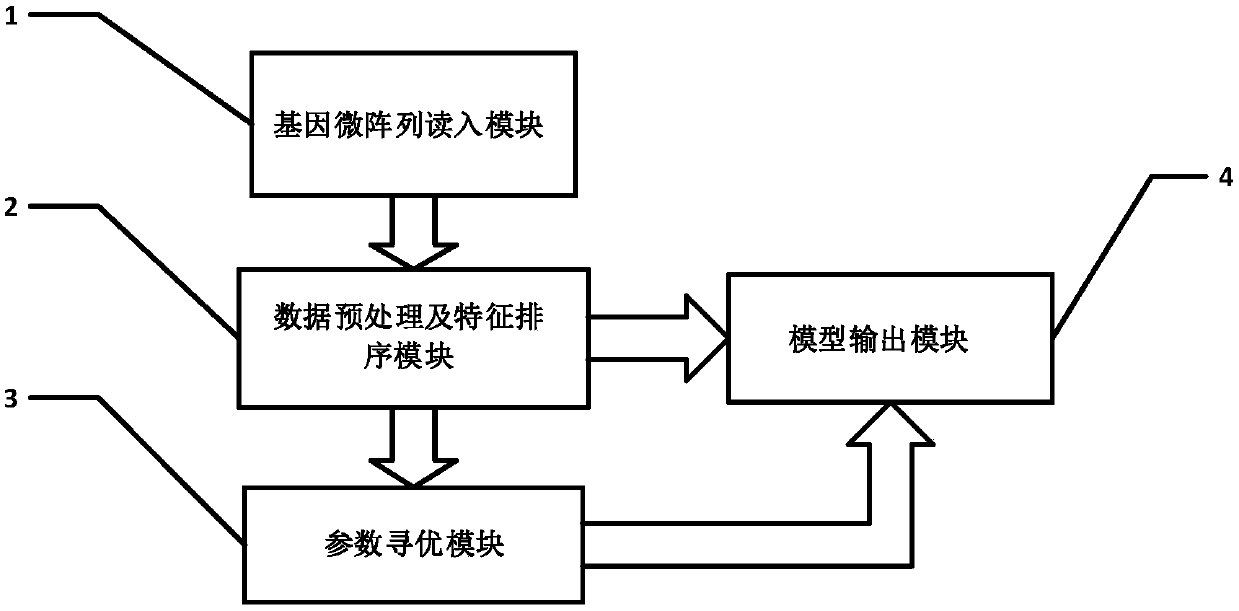

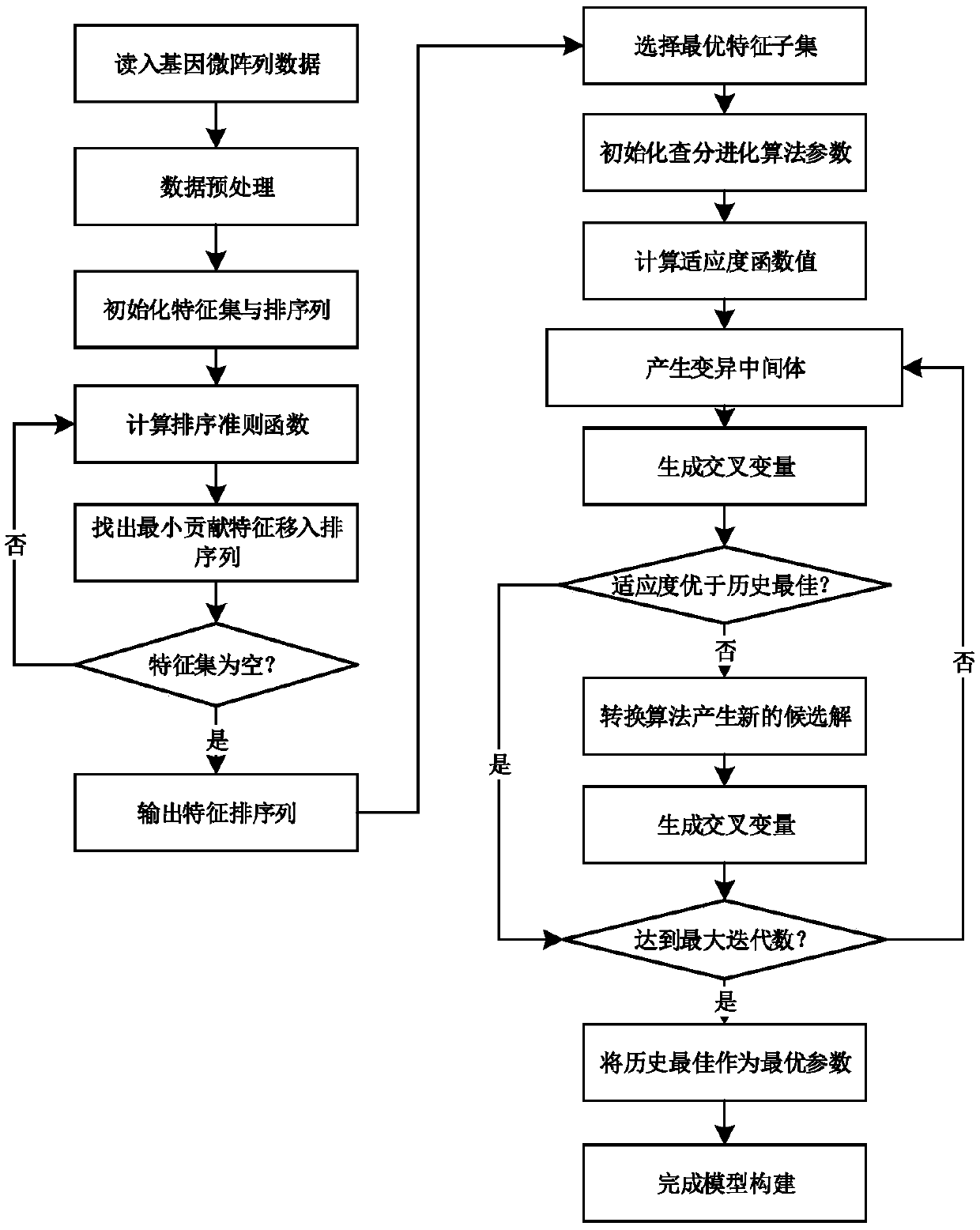

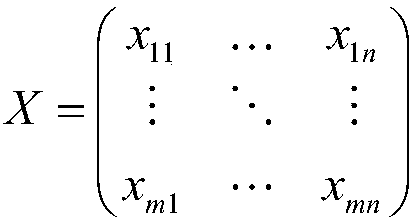

Parameter-optimized lung cancer cell detector

The invention discloses a parameter-optimized lung cancer cell detector. The system is composed of a gene microarray read-in module, a data preprocessing and characteristic ranking module, a parameteroptimizing module and a model outputting module. The system preprocesses input gene microarray data first, and then ranks various remaining genes according to importance, wherein relevance is calculated through calculated scores, contribution degrees are calculated by using a classifier criterion function, and the importance of all the genes is ranked. On the basis of an original intelligent optimizing algorithm, fitness detection and population perturbation are added to an improved optimizing method, and the situations that the population diversity is lost and the optimizing process gets into local optimization can be avoided. The searched optimized parameter serves as a classifier parameter to complete model construction, and a result is output. The system is high in speed and suitablefor on-line detection.

Owner:ZHEJIANG UNIV

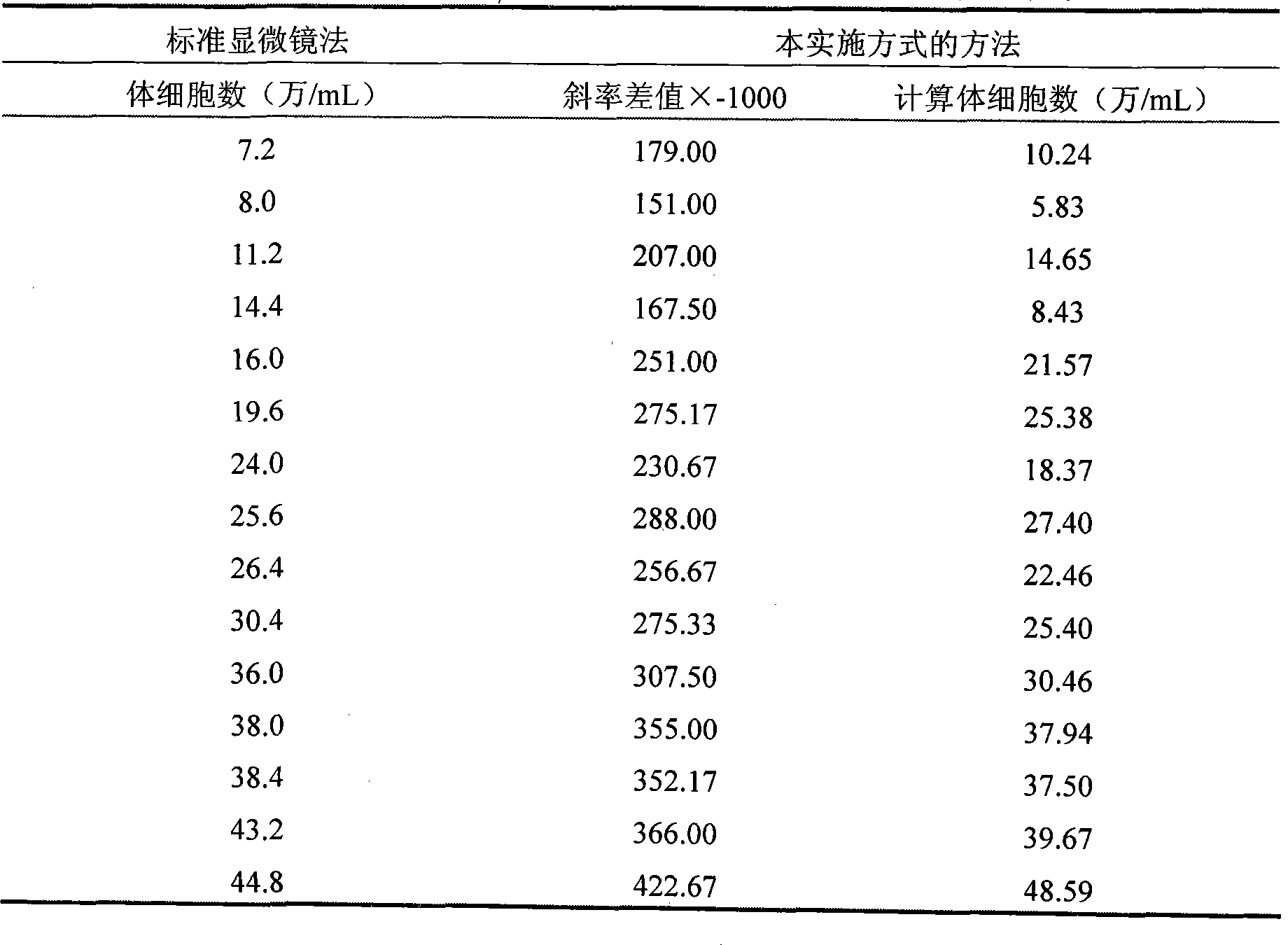

Method for detecting somatic cell number in raw milk

InactiveCN101382481AThe detection process is fastSuitable for online detectionMicrobiological testing/measurementColor/spectral properties measurementsTime efficientSomatic cell

A method for measuring the number of somatic cells in raw milk relates to a method for measuring the number of somatic cells in milk. The invention solves the problems of long time consuming, tedious operation and carrying out operation by professional technical personnel, or high lost, or inaccuracy existing in the existing method for measuring the number of somatic cells in raw milk. The method is carried out by following steps: firstly, pretreatment; secondly, addition of reactive reagent; thirdly, measurement of change in color; and finally the number of somatic cells in raw milk is obtained. The method has the advantages of low cost, time saving, simple and convenient operation and accurate measurement result.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

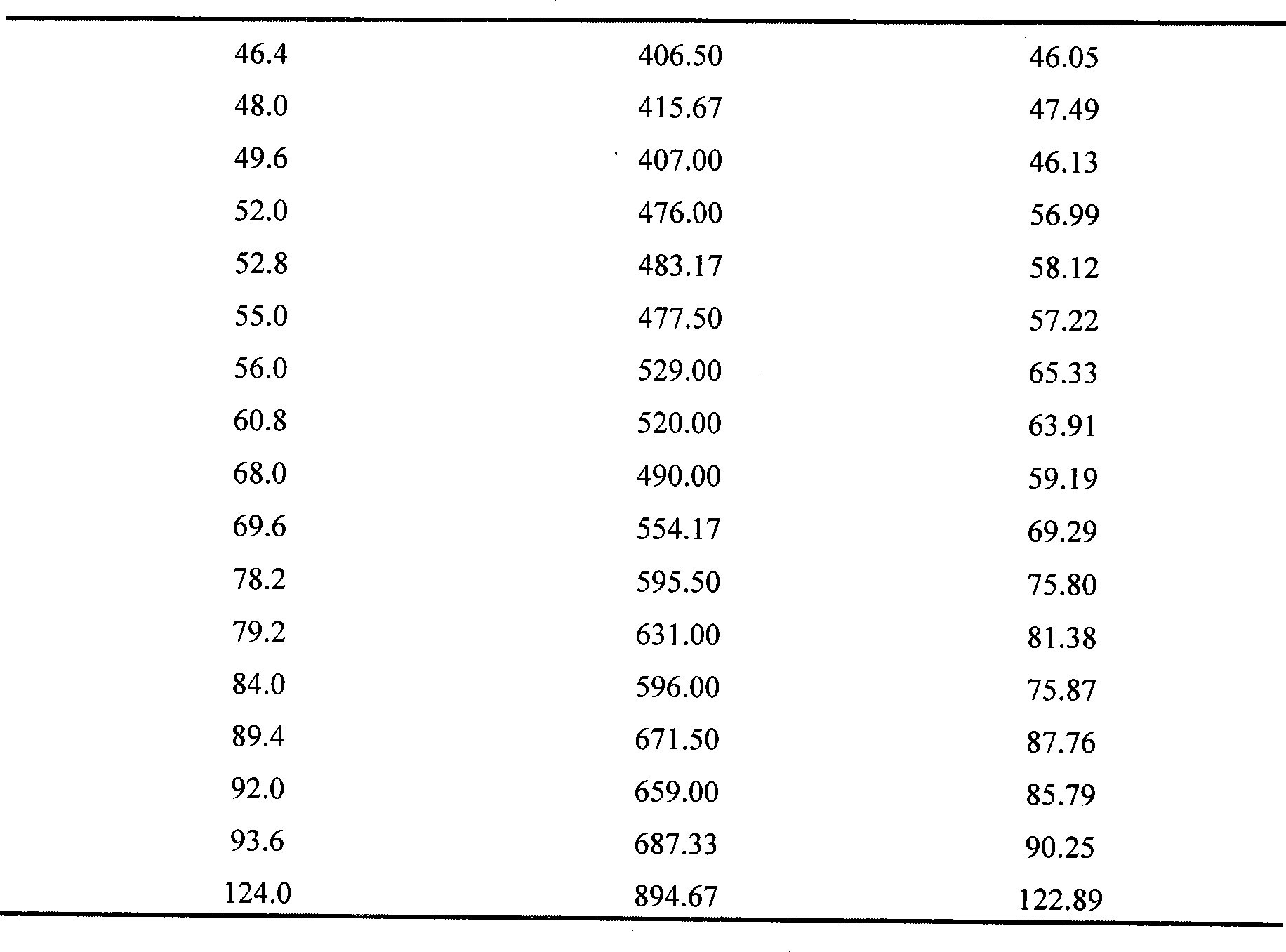

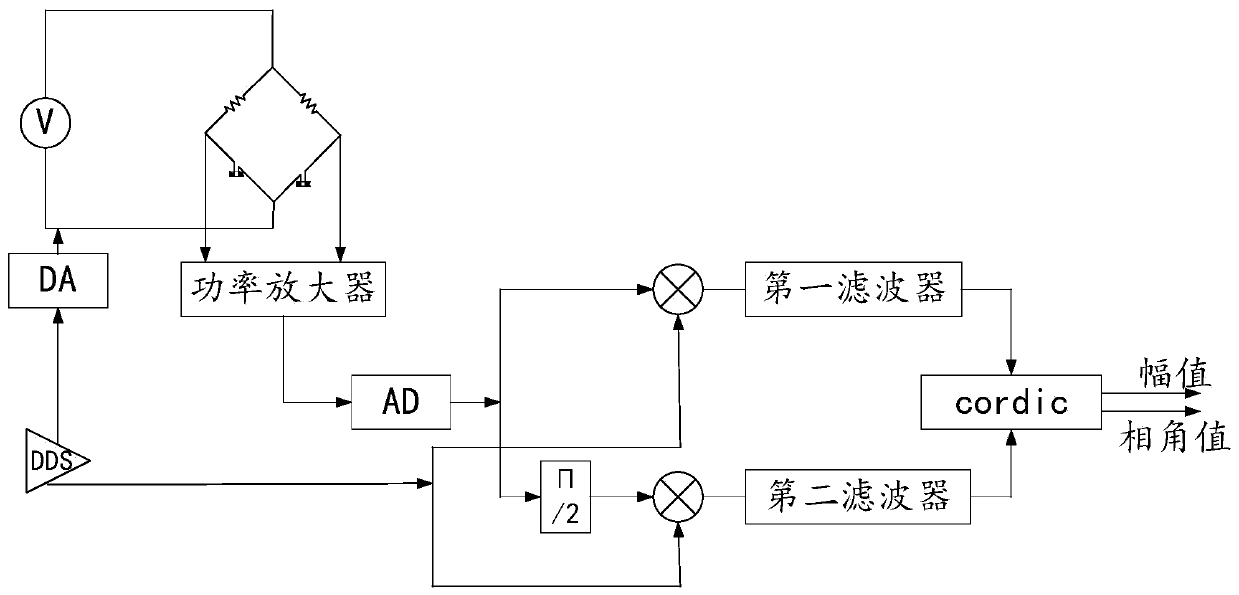

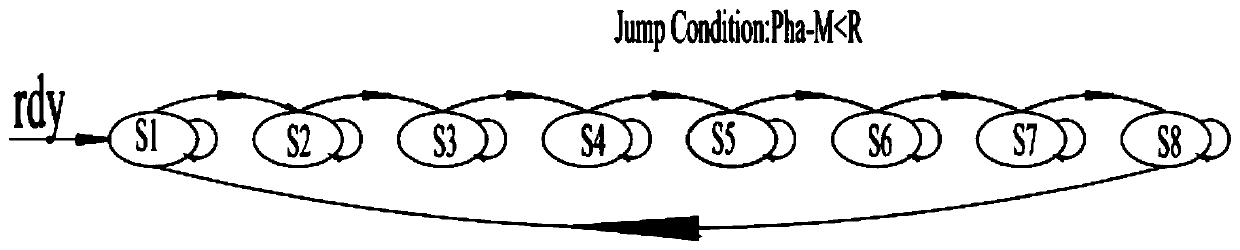

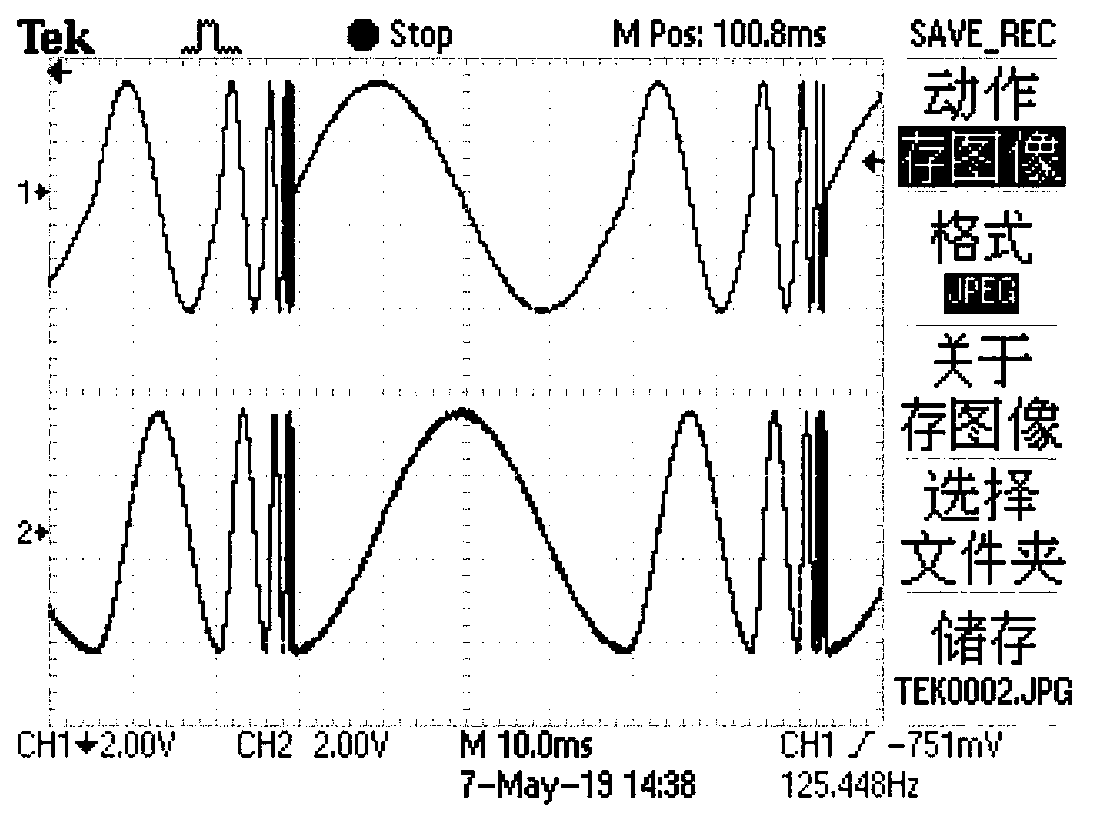

Eddy current impedance solving method and device based on cross-correlation algorithm

ActiveCN110263482AImprove accuracyStrong real-timeDigital technique networkNuclear energy generationMoving averageMiniaturization

The invention discloses an eddy current impedance solving method and device based on a cross-correlation algorithm. On the basis of explaining a cross-correlation algorithm principle, digital design of a core assembly of the cross-correlation algorithm is given based on an Xilinx FPGA hardware platform, and the algorithm can be achieved only through a single-chip FPGA and a small number of interface devices, so that miniaturization and portability of detection equipment are facilitated; the result obtained through the cross-correlation algorithm is compared with the LCR test result, the error is kept within + / -0.5%, and the algorithm accuracy is high; the cross-correlation algorithm completes single workpiece sorting under eight groups of frequency responses in about 2.4 s, the algorithm real-time performance is high, and the method is suitable for online detection; the degree of in-phase and quadrature branch component output approaching the direct current is the reflection of the precision of a cross-correlation algorithm. The direct current output of the in-phase branch circuit still has low-frequency jitter, the development of subsequent work starts from introducing a moving average filtering algorithm after forming filtering, component data of more cycles participate in mean value operation, and the calculation accuracy of the direct current component is further predicted to be improved.

Owner:贵州装备制造职业学院

Device and method for detecting different convex circular arc radiuses and judging circular arc degrees

The invention discloses a device for detecting different convex circular arc radiuses and judging circular arc degrees. The device comprises a workbench, a controller, and a linear guideway and a detection device arranged on the workbench, wherein a driving motor is arranged on one end of the linear guideway; a detection station connected with the driving motor through a ball screw is arranged on the linear guideway; a workpiece to be detected is arranged on the detection station; a detection motor and a probe are arranged on the detection device; a distance measuring sensor and an angle sensor are respectively arranged on the probe and the detection motor; the driving motor, the probe and the detection motor are respectively connected with the controller; the controller is further connected with a touch screen. The device for detecting the different convex circular arc radiuses and judging the circular arc degrees has the beneficial effects that a method for detecting the convex circular arc radiuses and judging the circular arc degrees in the prior art is greatly simplified through the introduction of a geometric calculation step, complicated equipment is simplified, the cost is reduced, and non-contact measurement is adopted, so that the surface of a product cannot be damaged; the device is wide in application range, easy to operate, high in safety, high in detection accuracy, high in efficiency, and very suitable for on-line detection.

Owner:ZHEJIANG SIQIANG BEARING MFG

Particulate matter concentration measuring system in low-concentration particulate matter on-line tester

ActiveCN105547951AAvoid measurement errorsHigh measurement accuracyParticle suspension analysisPhysicsPower circuits

The invention provides a particulate matter concentration measuring system in a low-concentration particulate matter on-line tester, belongs to the technical field of particulate matter detection, and solves the technical problems to provide a particulate matter concentration measuring system with high measuring accuracy and small measuring error in the low-concentration particulate matter on-line tester. The adopted technical scheme is as follows: the particulate matter concentration measuring system in the low-concentration particulate matter on-line tester comprises a power circuit board, an analog circuit board and a digital circuit board, wherein the power circuit board is used for supplying power to the analog circuit board and the digital circuit board; the analog circuit board comprises a laser, a laser light-emitting circuit and a signal conditioning circuit, the digital circuit board comprises a master control circuit, a voltage-current conversion circuit and a communication circuit, and the laser light-emitting circuit, the signal conditioning circuit, the voltage-current conversion circuit and the communication circuit are respectively connected with the master control circuit; the particulate matter concentration measuring system in the low-concentration particulate matter on-line tester is suitable for the field of environmental monitoring.

Owner:SINOGREEN ENVIRONMENTAL PROTECTION SCI & TECH

Tool for detecting size from internal annular groove of axle hole of half axle gear to outer end surface

InactiveCN105928444ASimple positioning detection structureEasy to manufactureMechanical clearance measurementsGear wheelRidge

The invention discloses a tool for detecting the size from an internal annular groove of an axle hole of a vehicle half axle gear to the outer end surface. An axle die is paired with an axle wedge to form an axle whose cross section is circular, and the axle cooperates with the work-piece axle hole. The outer circular wall of the axle die is provided with a segment of annular ridge which cooperates with the internal annular groove of the work-piece axle hole, and a bottom plane of the axle die is an inclined plane whose axial inclination angle alpha equals 3-7 degree. The axle wedge is a piece whose cross section is semicircular, a bottom plane of the axle wedge is also an inclined plane whose axial inclination angle alpha equals 3-7 degree, the inclination angle alpha of the inclined plane of the axle wedge is opposite to that of the inclined plane of the axle die. The end, in the work-piece axle hole, of the axle wedge is provided with a pull bar which extends outwardly. The annular groove to be measured in the work-piece axle hole is converted into an outer measuring structure via the axle die, such structure provides convenience for accurate measurement by general measuring tools, and the detection efficiency is high. The tool of the structure has no special requirements for detection conditions, detection is carried out directly, and the tool is especially suitable for online detection.

Owner:JIANGSU AIRSHIP GEAR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com