Vision-based steel ball surface defect detection apparatus and detection method

A defect detection and steel ball technology, which is used in measuring devices, material analysis by optical means, instruments, etc., can solve the problems that the spherical surface cannot be fully unfolded, the cleaning steps are added, and the unfolding device is complicated, and the detection results are stable and reliable. Improve the detection rate and apply a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

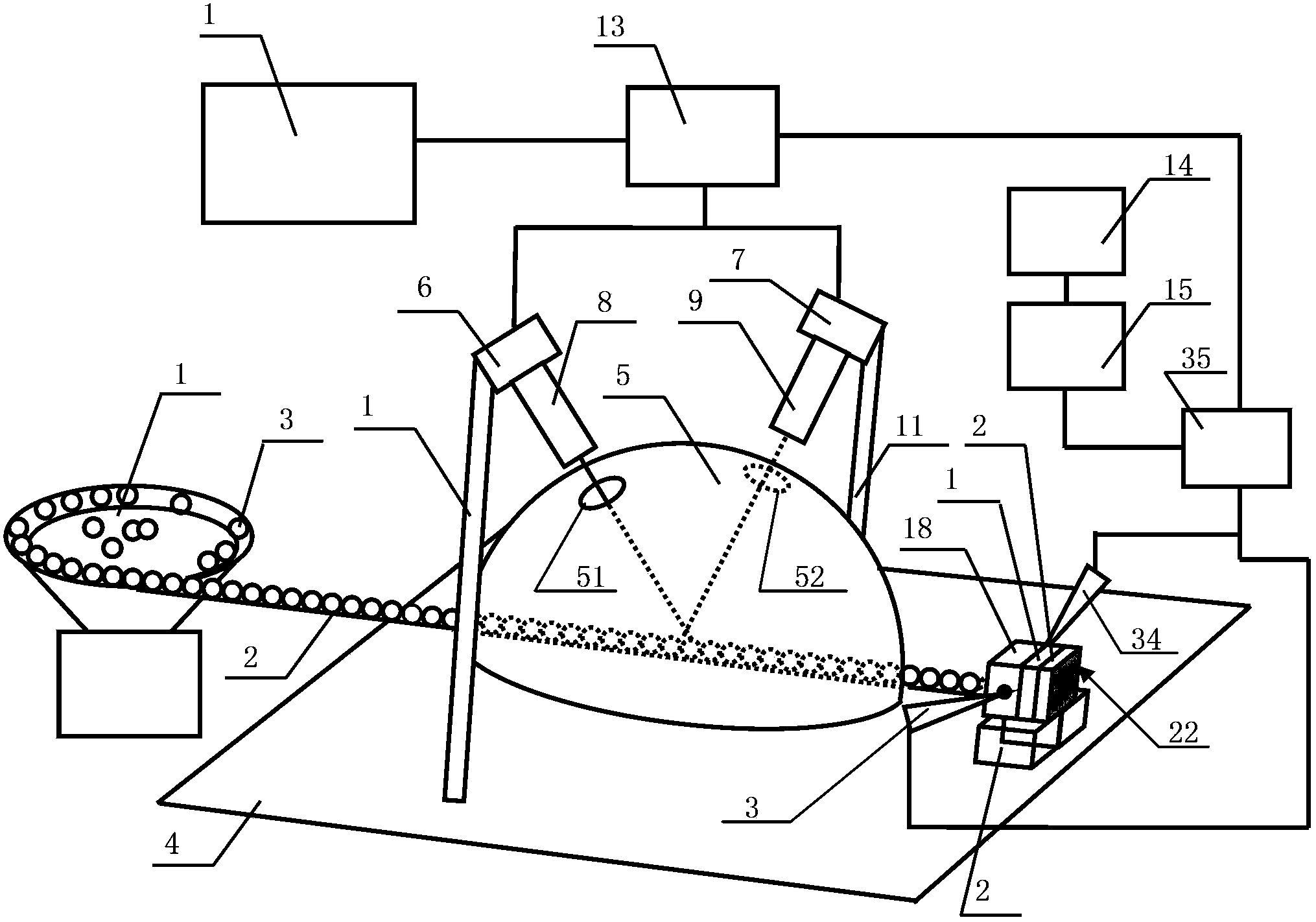

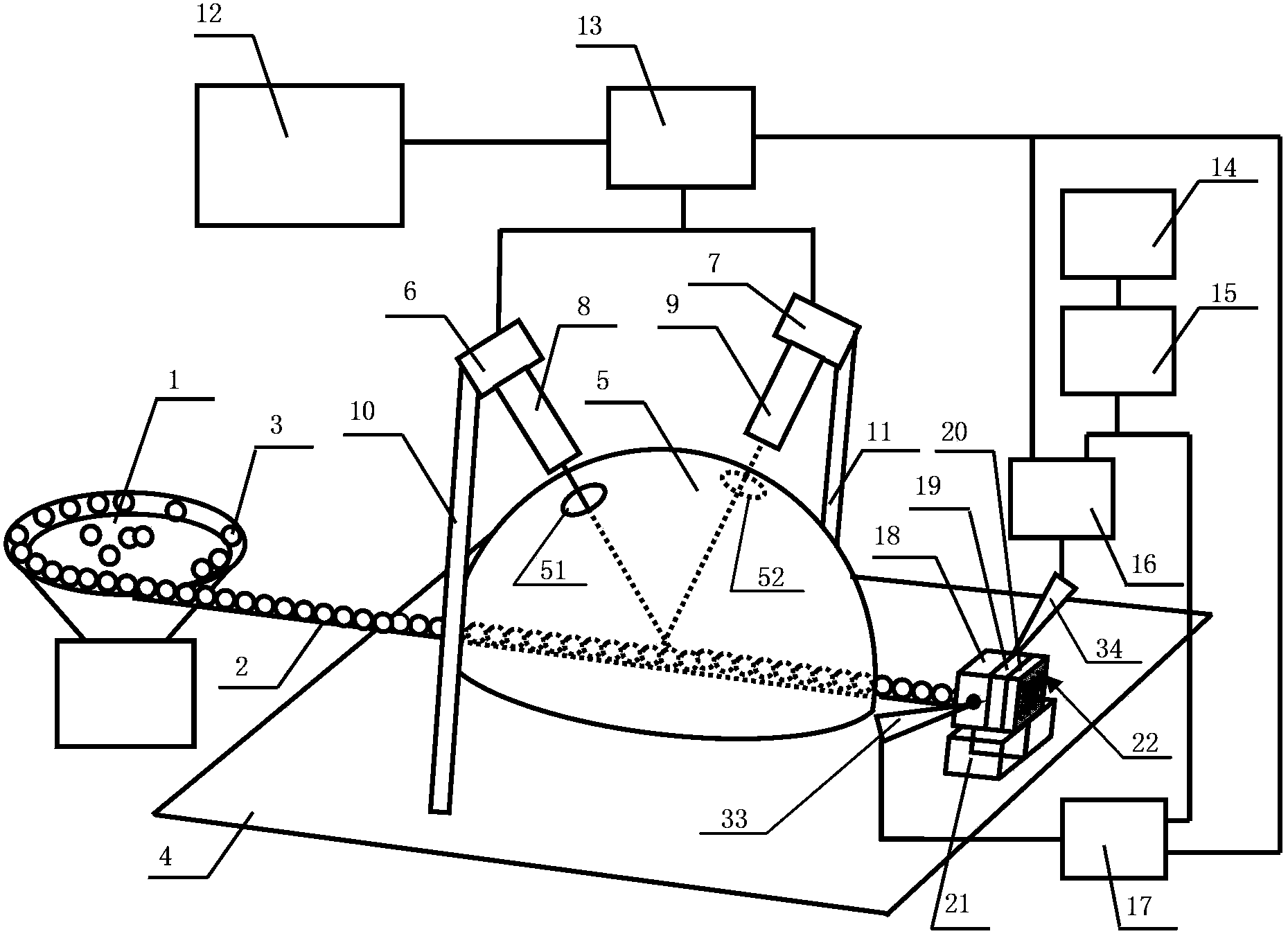

[0062] The visual-based detection method and device for steel ball surface defects of the present invention will be described in detail below in conjunction with the embodiments and the drawings.

[0063] In the vision-based steel ball surface defect detection method and device of the present invention, the sorting machine uses two industrial cameras to simultaneously collect the steel ball surface images, and the collected images are processed in real time in the PC to determine whether there are defects. The PCI acquisition card connected to the PC sends control commands to realize template image acquisition, real-time acquisition of steel ball images, steel ball queue stepping, steel ball sorting and delivery to the sorting box.

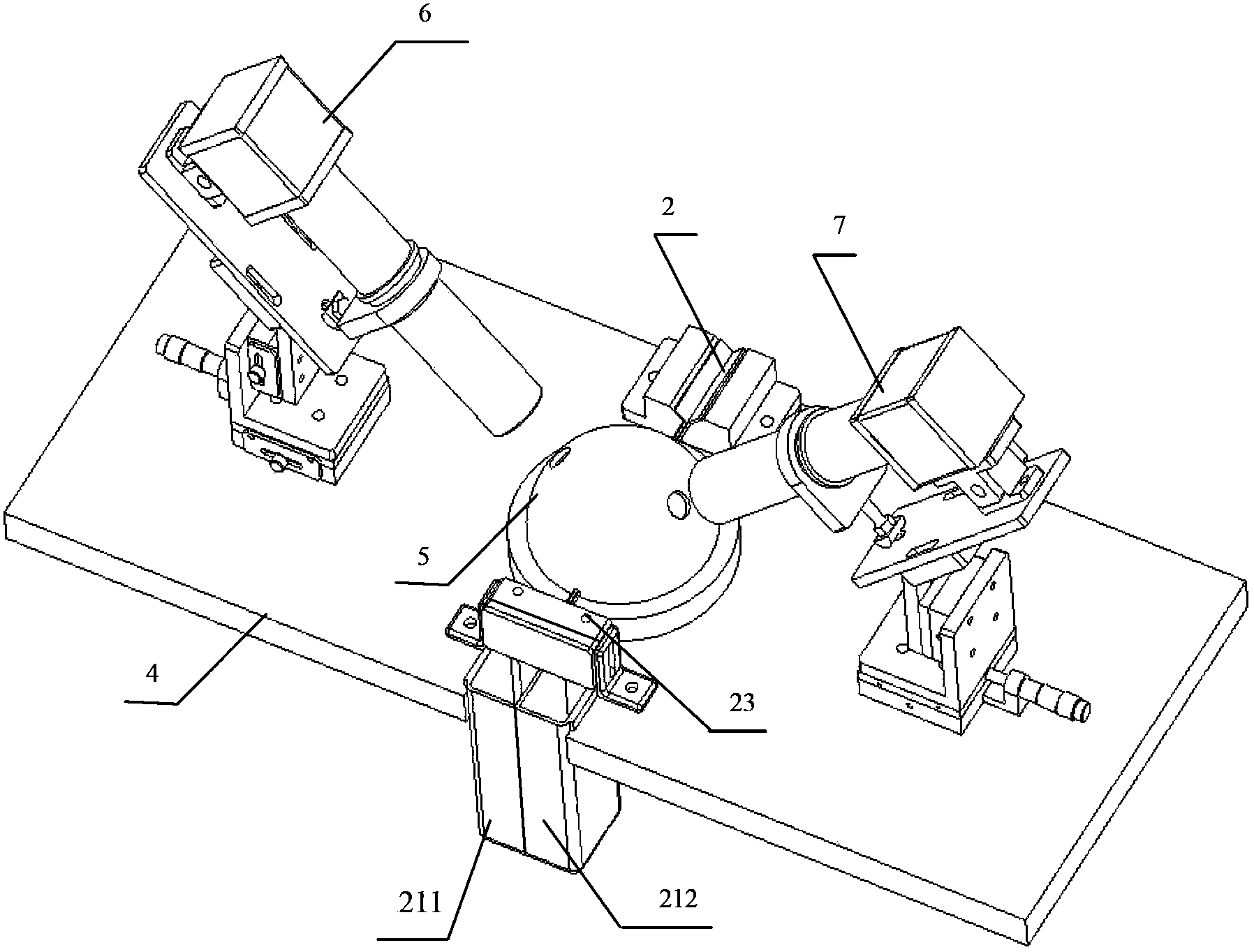

[0064] Such as figure 1 , figure 2 , image 3 As shown, the vision-based steel ball surface defect detection device of the present invention includes a workbench 4, and the workbench 4 is provided with a light source 5 composed of a light source bowl c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com