Method and device for detecting assembly outline size of main air bag of automobile

A technology of airbags and contour dimensions, applied in the field of metrology, can solve problems such as low efficiency, high detection cost, and difficulty, and achieve accurate detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] 1. Testing equipment

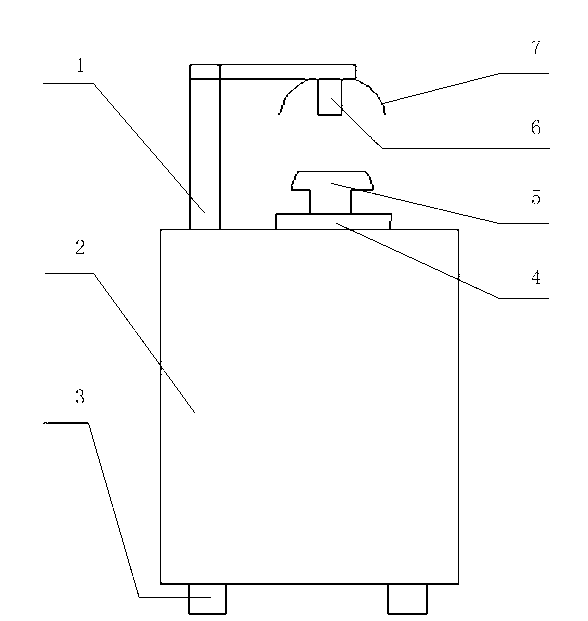

[0045] refer to figure 1 , detection equipment of the present invention comprises that the upper end face forms the working table top, the box body 2 that foot 3 is arranged at the lower end, the air bag positioning and fixing mechanism 4 on the mounting table, the airbag positioning and fixing mechanism 4 that is fixed on the table top or frame by the automobile main safety airbag contour detection equipment of the present invention The camera bracket 1 is composed of a camera 6 and a light source 7 installed on the upper end of the bracket, located above the bearing table, an image processing module installed on the frame or bracket or the table, an operation module and a working power supply.

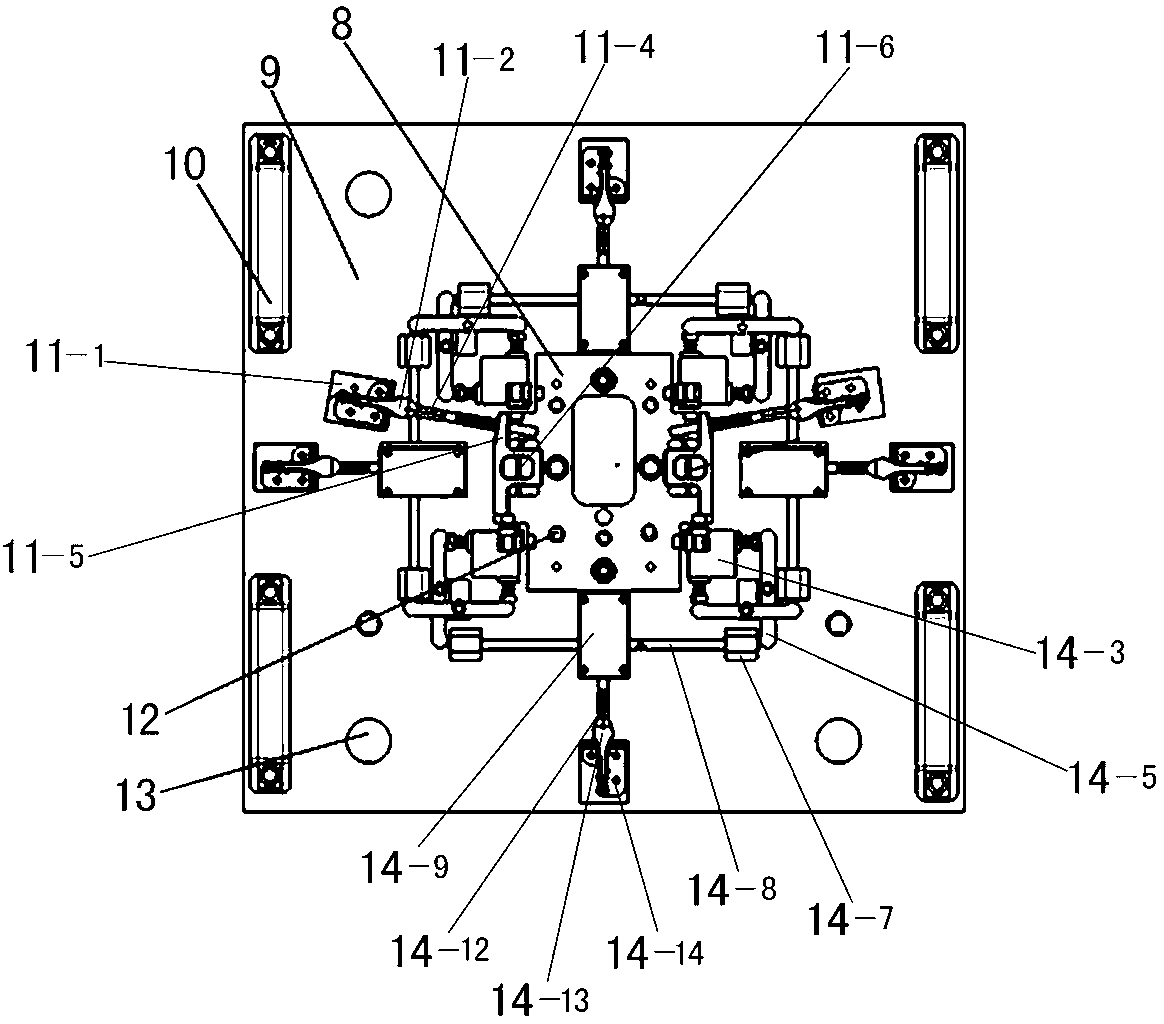

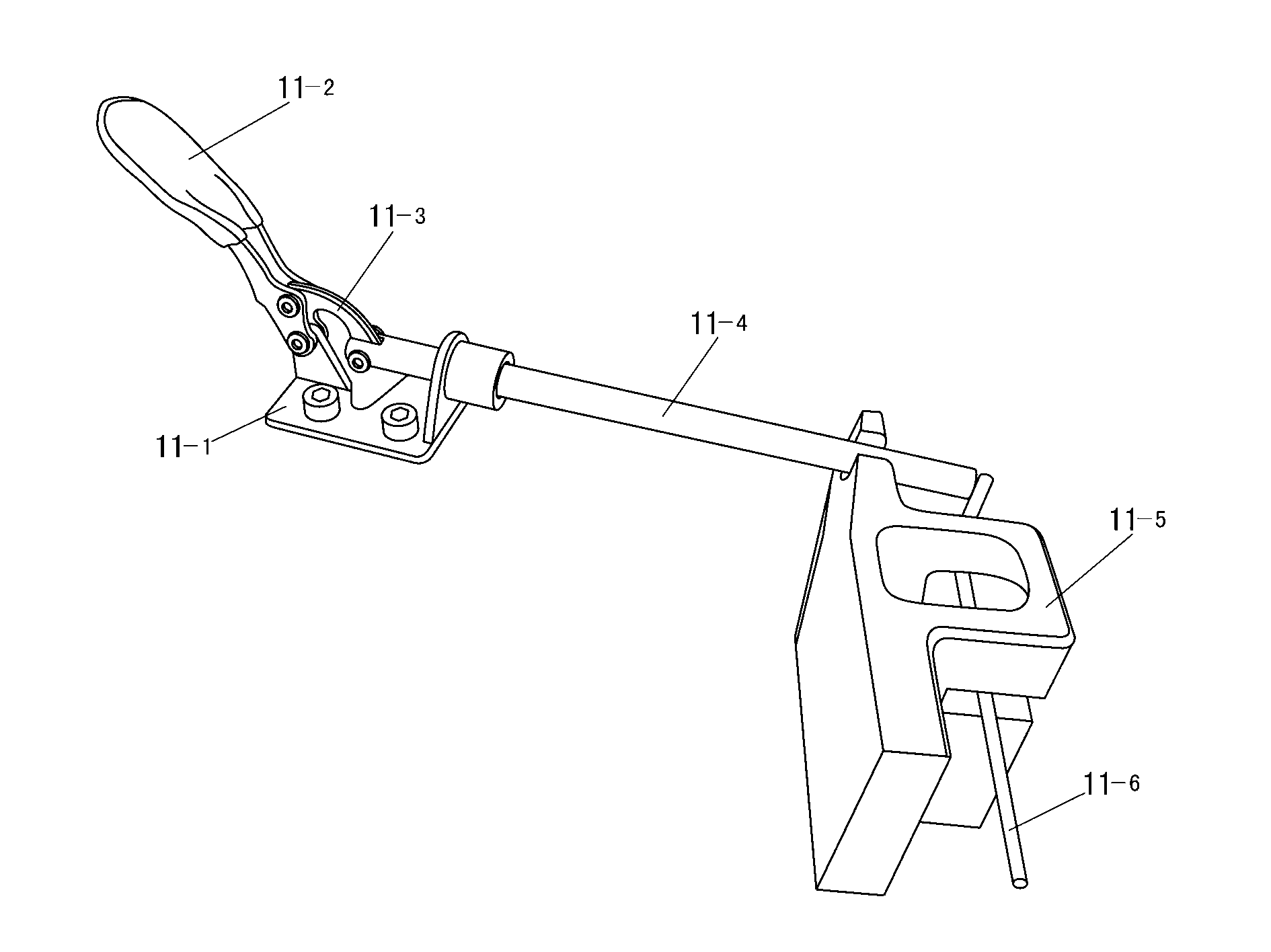

[0046] refer to figure 2 The airbag positioning and fixing mechanism includes a vertical positioning mechanism and a horizontal positioning mechanism. The airbag positioning and fixing mechanism is assembled on a base plate 9, and the base plate 9 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com