Fault on-line detection method of steel wire rope conveyer belt based on texture regularity analysis

A technology of steel wire rope core and detection method, which is applied in the direction of material analysis, instrument and calculation using radiation, can solve the problems of relying on manual analysis, poor real-time detection and low accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

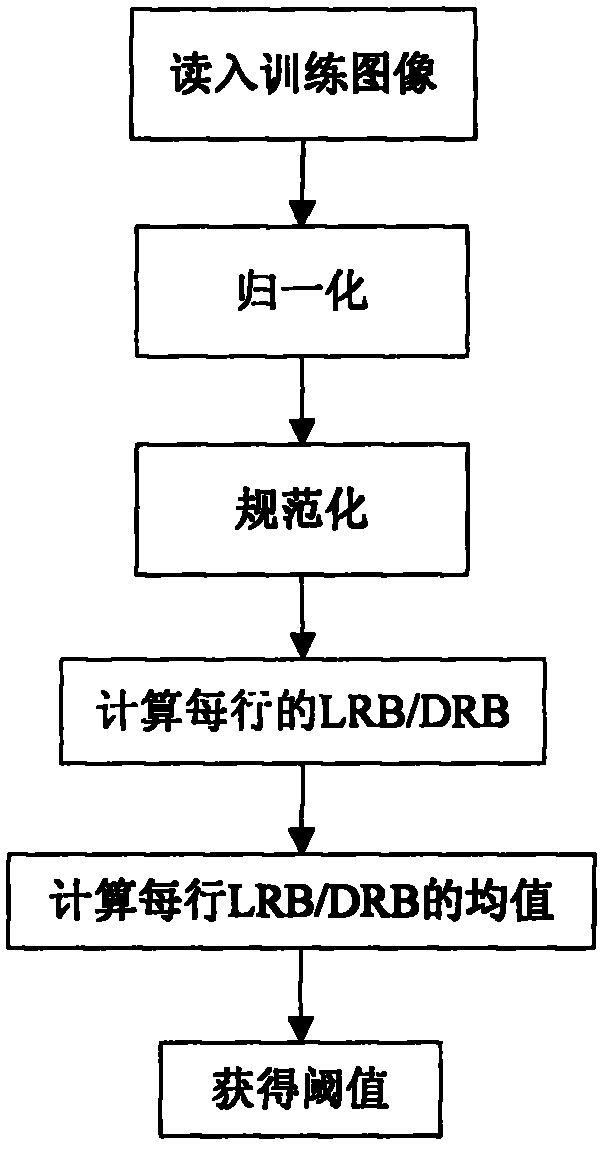

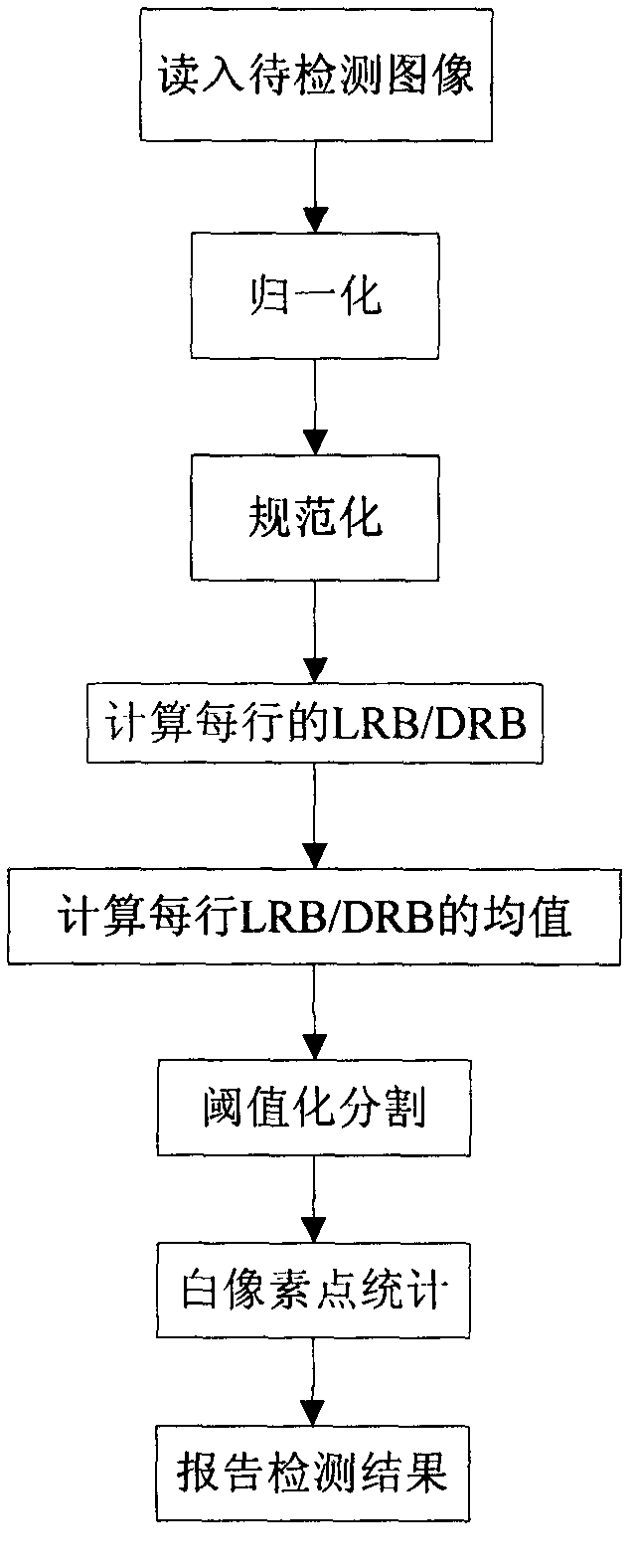

[0069] The method that the present invention proposes is divided into two phases during concrete implementation, promptly needs to obtain the threshold value needed for discriminating through training phase at first, and the operation flow diagram of wire rope core conveyer belt fault on-line detection training phase is as attached figure 1 shown; then in the detection stage, the detection of the image to be detected is realized, and the operation flow chart of the online detection detection stage of the steel cord conveyor belt fault is shown in the attached figure 2 shown.

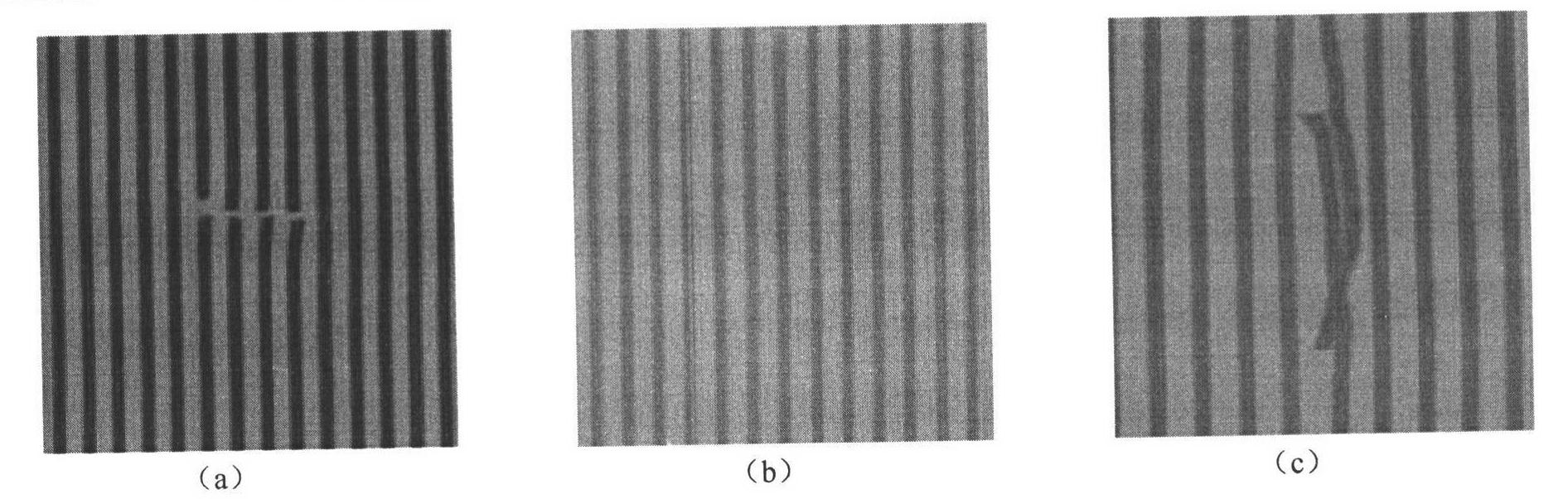

[0070] The steel cords in the steel cord conveyor belt are arranged longitudinally at a certain interval, and its X-ray images have strong texture characteristics, that is, the gray scale of the image changes regularly, and the texture is distributed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com