Tool for detecting size from internal annular groove of axle hole of half axle gear to outer end surface

A technology with built-in rings and axle holes, applied in the direction of using mechanical devices, measuring devices, mechanical measuring devices, etc., can solve the problems of being unsuitable for on-line inspection of production sites, batch out-of-tolerance liability accidents, and high inspection conditions, and achieve easy production. , Efficient detection, easy installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

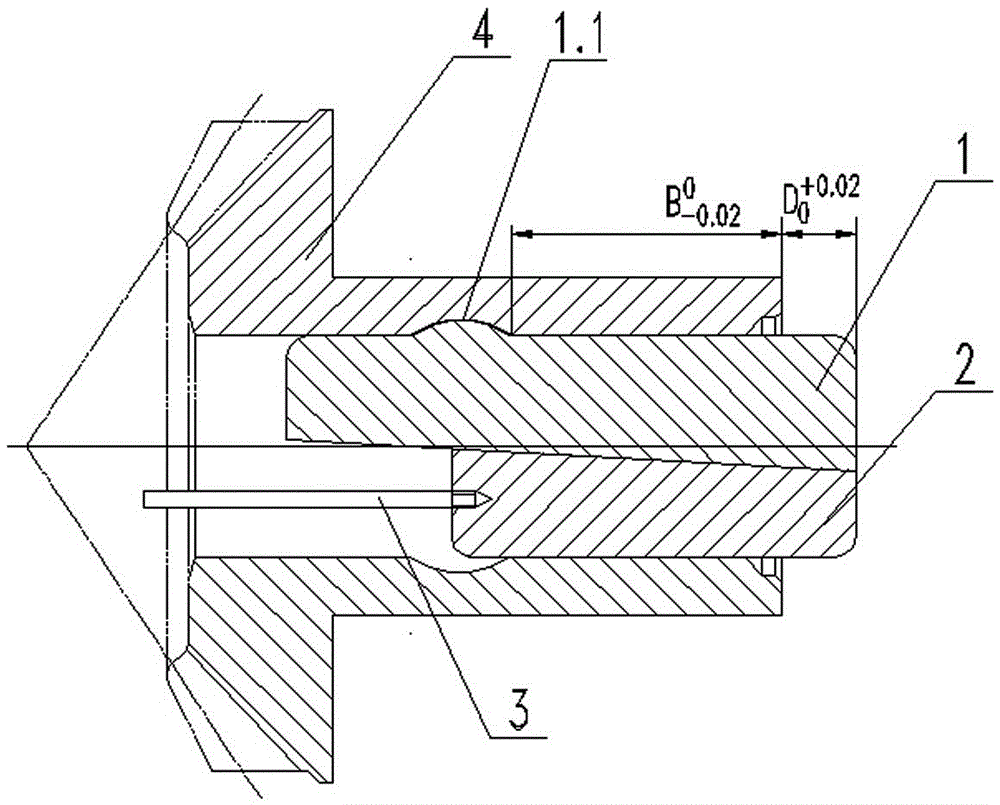

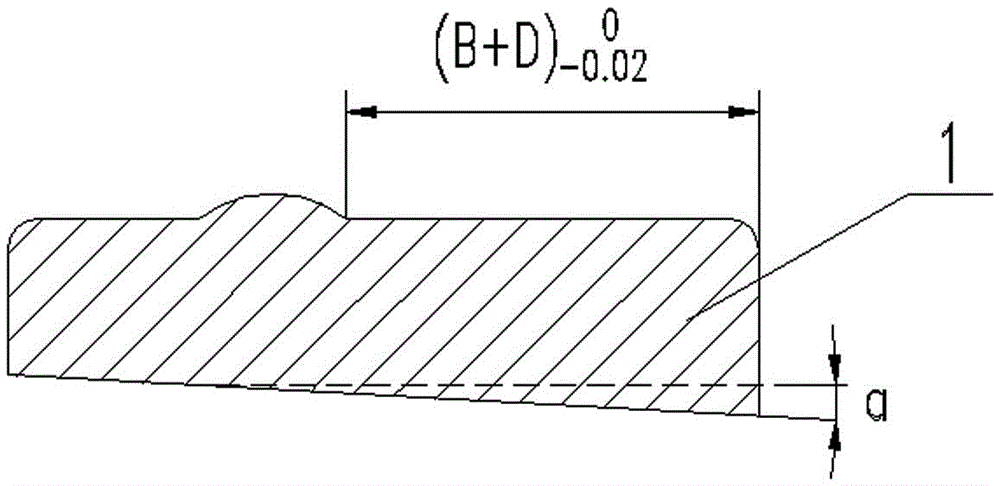

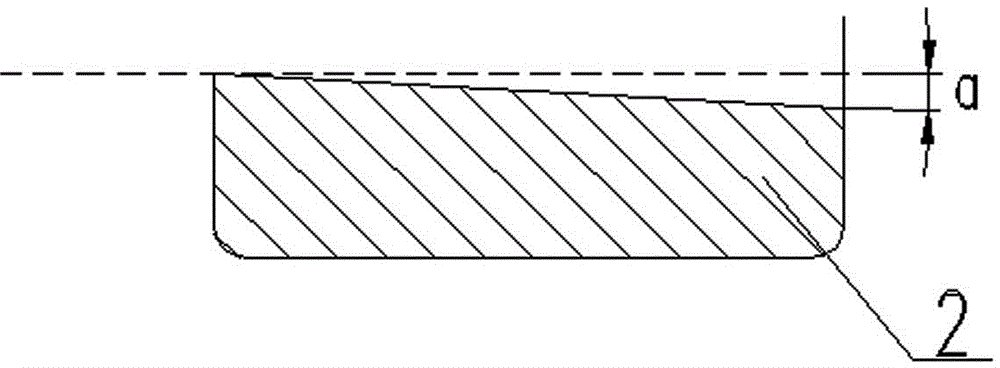

[0016] figure 1 The distance between the built-in ring groove and the outer end surface of the shaft hole of the side shaft gear for vehicles shown is a shaft mold 1 and shaft wedge 2 with different lengths paired to form a shaft with a circular cross section, which is in line with the shaft hole of the workpiece Cooperate. The workpiece 4 of this embodiment is the half-shaft gear supporting the car differential. The diameter of the shaft hole is only 18mm. There is a ring groove in the shaft hole. The design dimension of the ring groove side and the outer end surface is B mm. Because the shaft hole of the workpiece 4 is too small, the commercially available general-purpose measuring tools cannot be inserted into the shaft hole of the workpiece 4 to measure the ring groove due to the size limitation. A shaft-shaped measuring structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com