Timing angle detecting device for crankshaft assembly chain wheel

An angle detection and assembly technology, applied in the direction of angle/taper measurement, etc., can solve the problems of inability to objectively reflect product quality, unfavorable quality statistics and quality analysis, and inability to display energy values, etc., to achieve convenient installation, reliable positioning, and measurement. Precise results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below based on the drawings.

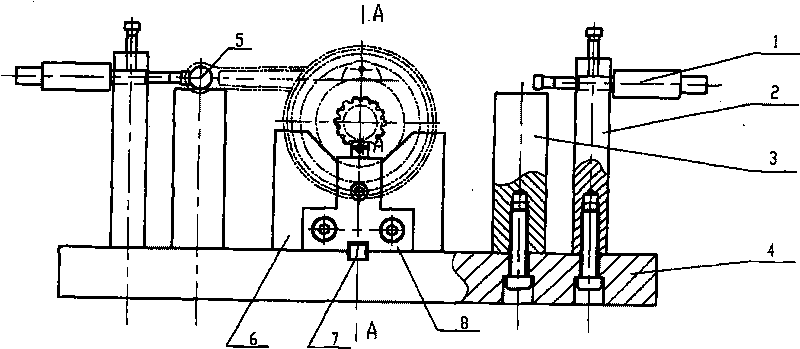

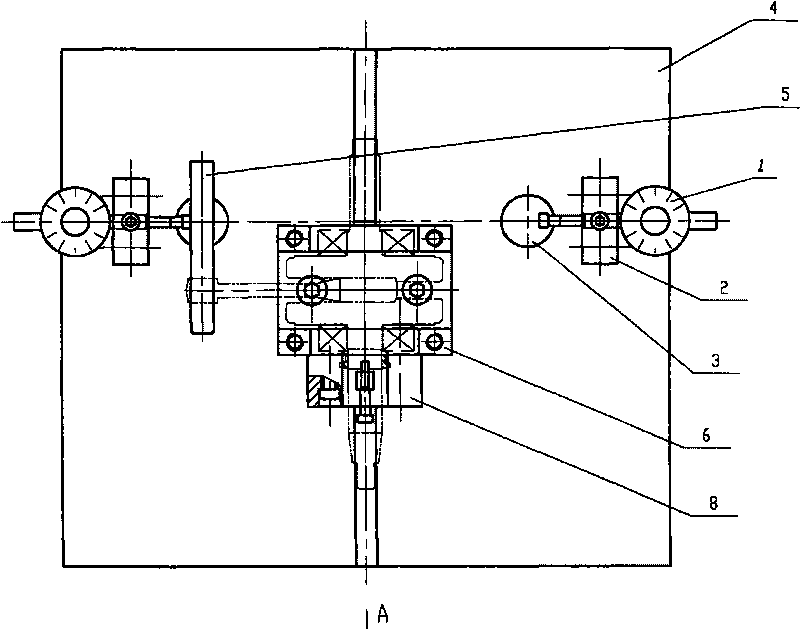

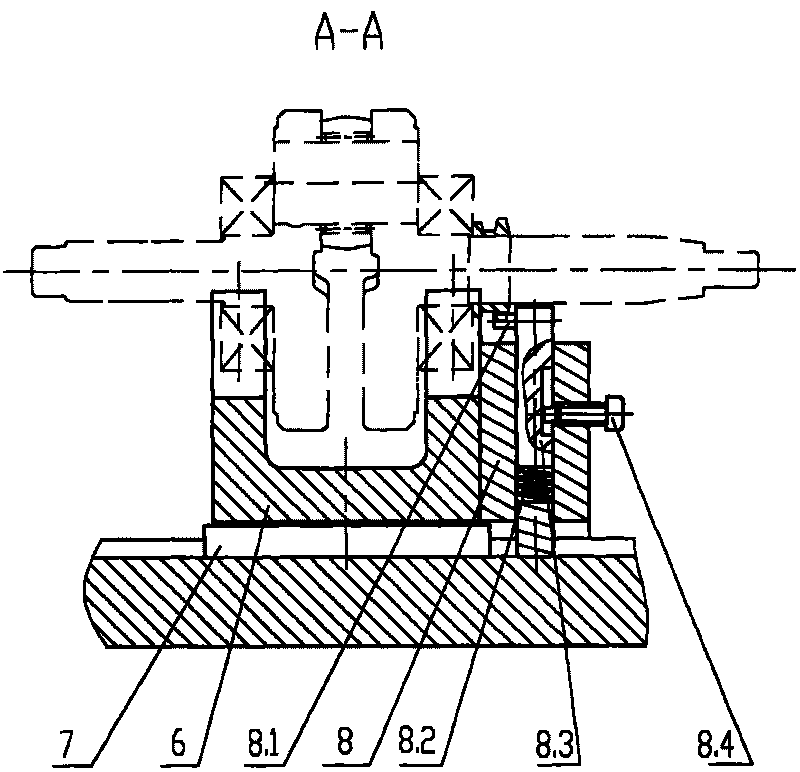

[0014] The crankshaft assembly sprocket timing angle detection device shown in the attached drawing includes dial indicator 1, meter rod 2, vertical rod 3, base 4, taper mandrel 5, V-shaped iron 6, key 7 and limit frame 8. The rectangular flat base 4 has a flat surface, and the left and right ends are symmetrically connected to the two opposite vertical rods 3 and the meter rod 2. The top of the meter rod 2 is horizontally installed with the dial indicator 1 with the meter head facing inward, and the top surface of the vertical rod 3 is flat. , The taper mandrel 5 for connecting rod assembly detection in the crankshaft assembly is directly supported on this plane. The center line of the head of the dial indicator 1 is higher than the top surface of the vertical rod 3, and the difference is equal to the radius value of the middle section of the taper mandrel 5. The upper surface of the base 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com