Electromagnetic ultrasonic detecting device and method for surface defects of cold rolled ribbed steel bar

A cold-rolled ribbed steel bar, electromagnetic ultrasonic technology, applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze solids, etc., can solve the problems of large inspection workload, inability to realize online inspection of rebar production lines, low inspection efficiency, etc., to improve the level of automation , Conducive to quantitative evaluation and production quality control, the effect of fast detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

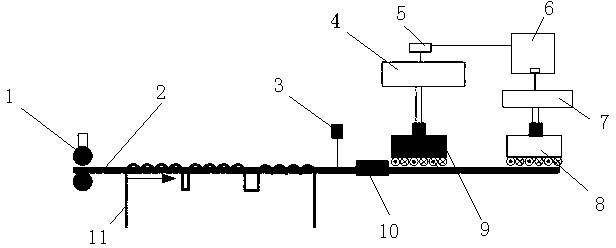

[0023] Now in conjunction with accompanying drawing, the present invention is described in further detail:

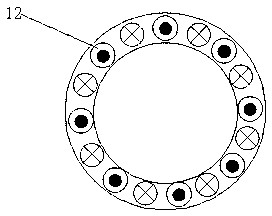

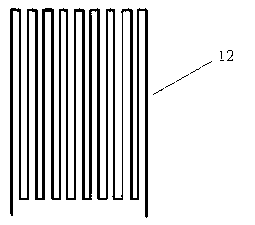

[0024] like figure 1 The shown electromagnetic ultrasonic detection device for surface defects of cold-rolled ribbed steel bars includes an encoder 1, an infrared thermometer 3, a function generator 5, a power amplifier 4, an electromagnetic ultrasonic emitting detector 9, an electromagnetic ultrasonic receiving detector 8, and a front Put amplifier 7 and control terminal 6, described encoder 1 is connected with control terminal 6, measure the moving speed of steel bar 2 in real time by encoder 1, and send to control terminal 6 to collect, described infrared thermometer 3 and control terminal 6 connected, the infrared thermometer 3 measures the surface temperature of the steel bar 2 after induction heating in real time, and transmits it to the control terminal 6 for collection, and the electromagnetic ultrasonic emission detector 9 passes through the power amplifier 4, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com