Structure defect ultrasonic on-line intelligent identifying system and identifying method

A technology for intelligent identification and structural defects, applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, special data processing applications, instruments, etc., can solve the problem of no crack depth quantitative detection equipment, etc., achieve good market promotion value and low investment cost. , the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

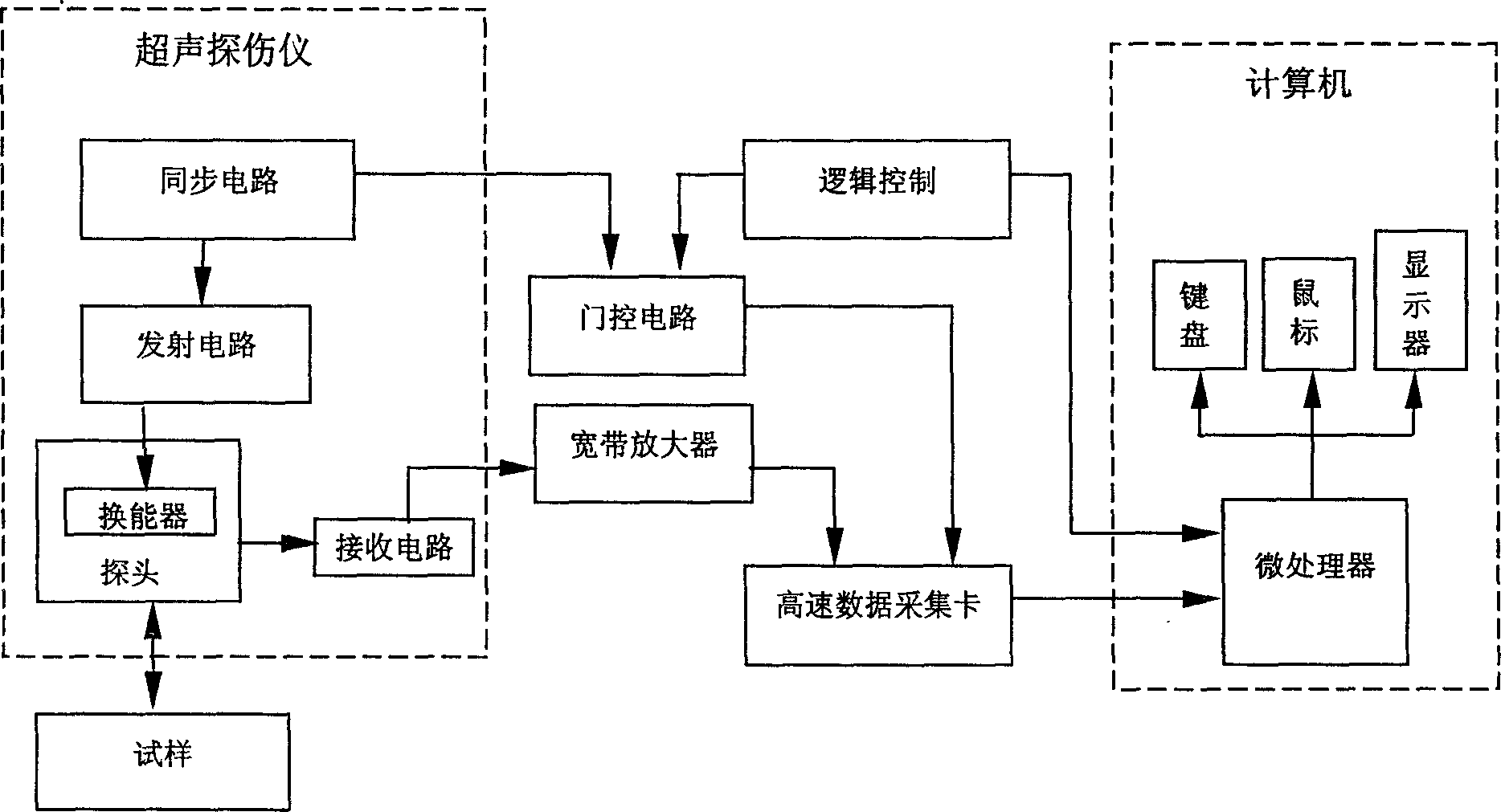

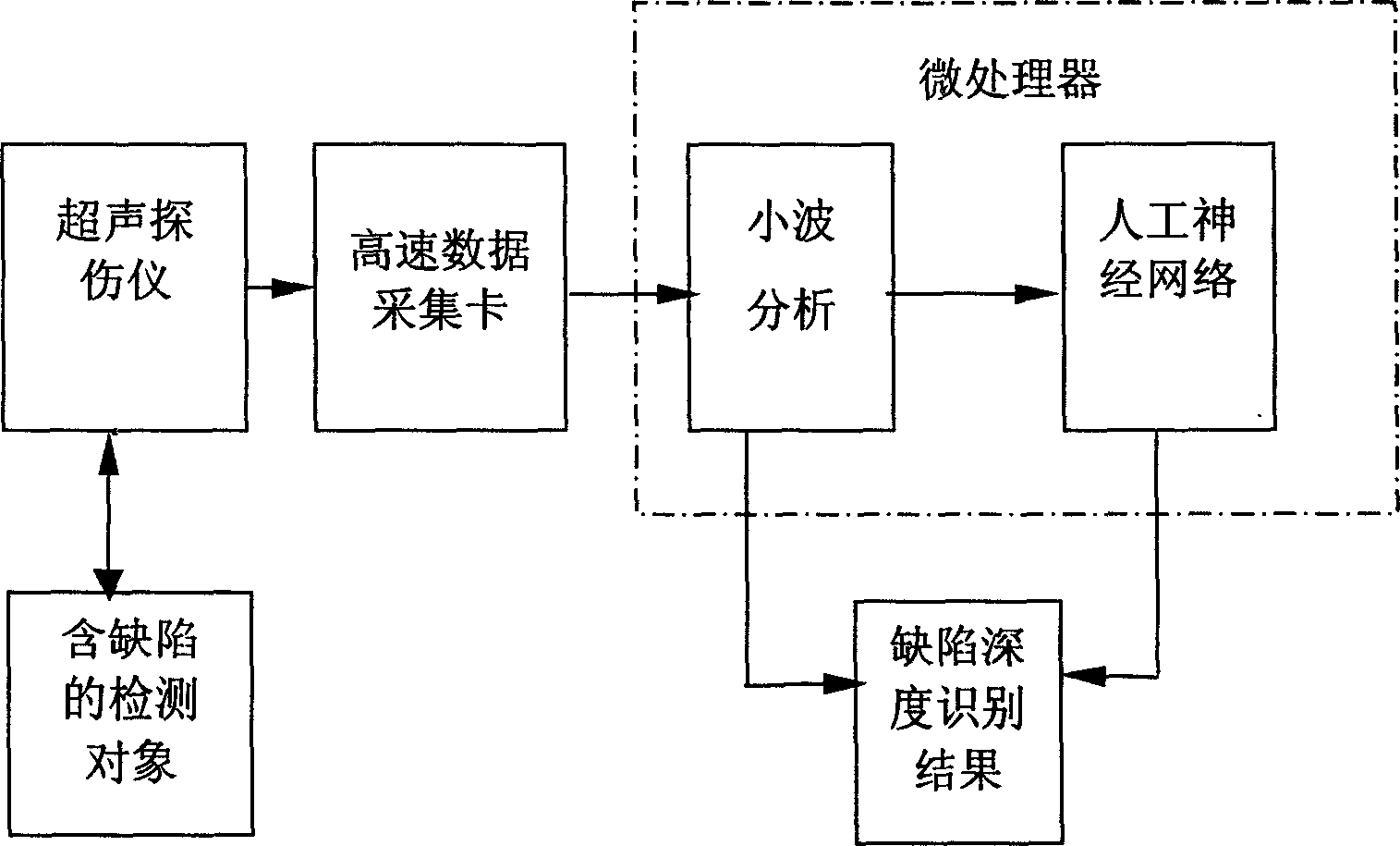

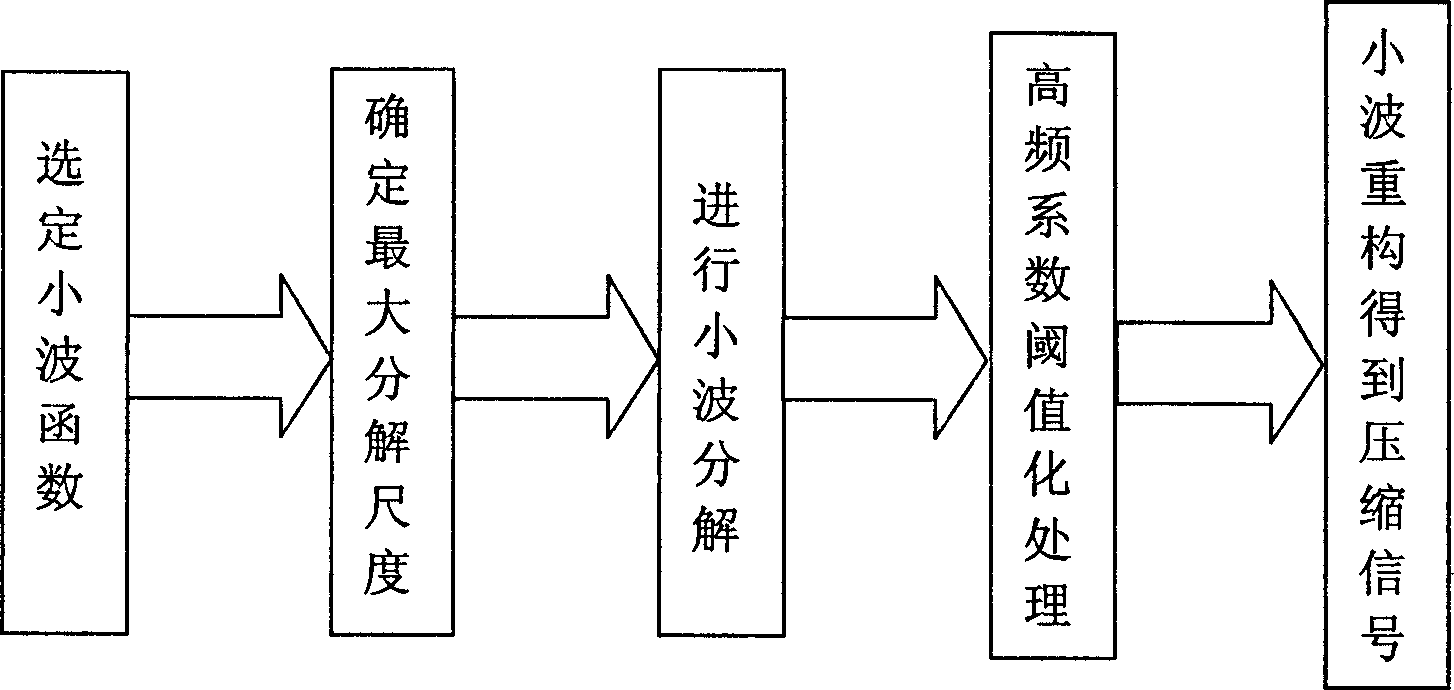

[0030] Such as figure 1 As shown, the ultrasonic online intelligent identification system for structural defects includes an ultrasonic flaw detector, a high-speed data acquisition card, and a computer. , the high-speed data acquisition card is connected with the synchronous circuit through the gate control circuit, and connected with the probe through the broadband amplifier. There is also a logic control circuit connected between the gate control circuit and the microprocessor of the computer. The microprocessor has a built-in wavelet analysis module connected to each other, Artificial neural network module.

[0031] The transducer is used to convert high-frequency electrical oscillation energy into sound energy through mechanical vibration through the reverse piezoelectric effect.

[0032] The gate control circuit is mainly used to select the defect echo signal and exclude the emission signal and the bottom echo signal.

[0033] The logic control circuit is mainly used to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com