Strip-shaped article surface defect on-line visual attention detection method

A technology of visual attention and detection method, applied in the cross field, can solve the problems of inapplicable rapid detection requirements, increased production costs, and text on the surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

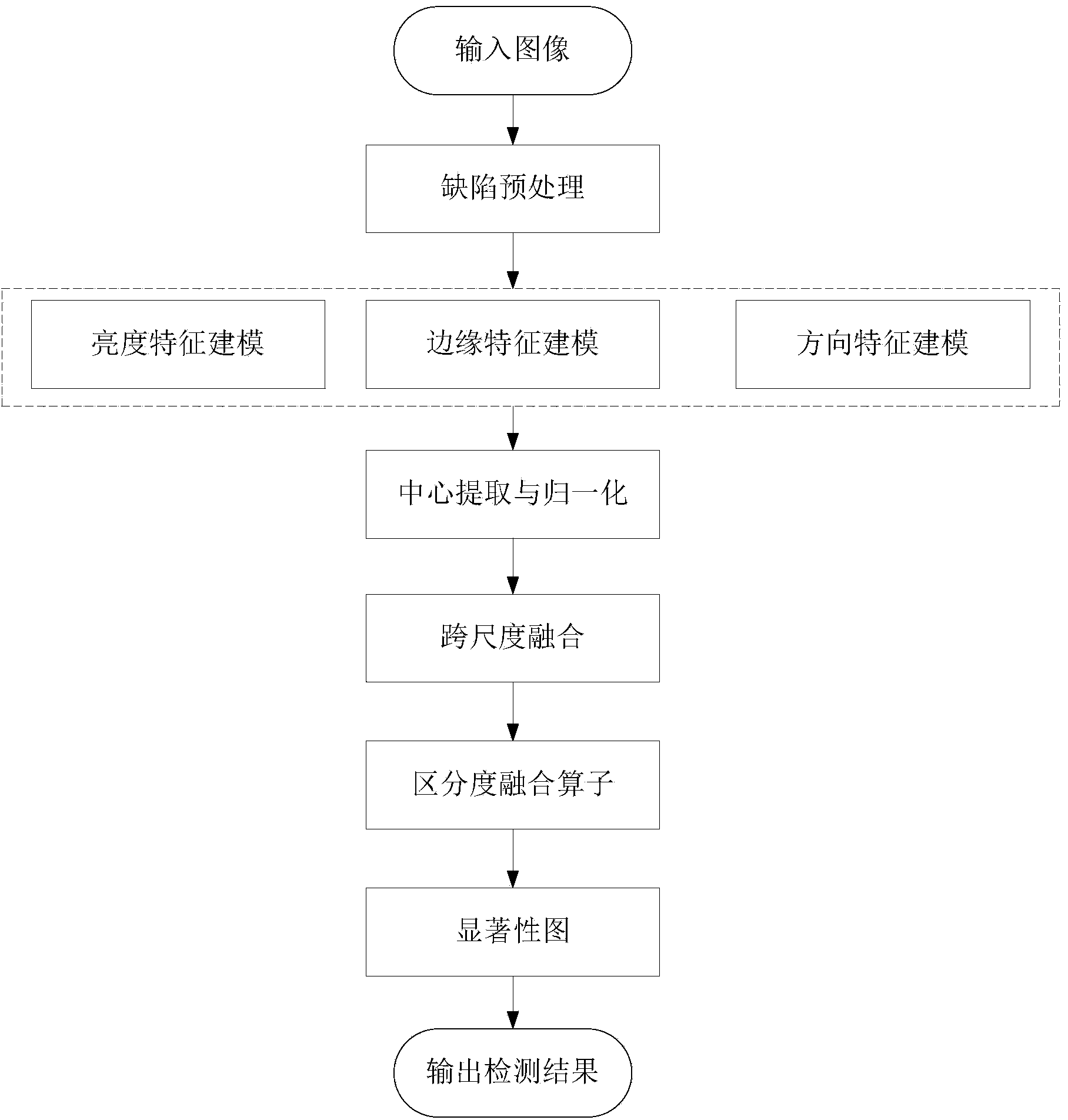

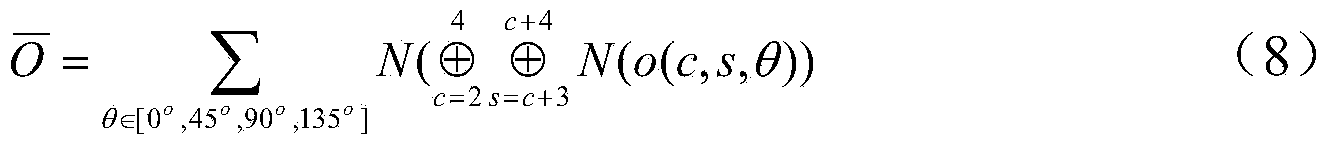

[0038] The present invention is an improved and comprehensive method, which is proposed through the improvement and synthesis of image processing technology and visual attention model. The contrast between the background and the target, and then estimate the background, so as to effectively segment the background, reduce or eliminate the influence of texture features on the crack defect of the drug roll; then, use the improved visual attention model to establish the intensity, edge and direction of the target image, etc. The feature pyramid model, through center extraction and multi-scale image fusion, obtains the defect dominant feature area in the image, highlights the crack information and effectively identifies and locates, and achieves the purpose of extracting the characteristics of the defect drug volume. The specific steps of the method are as follows:

[0039] Step 1: Defect image preprocessing. The present invention separates the crack defect from the background inf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com