Giant magnetostriction transducer with function of ultrasonic guided wave excitation and receiving at same end

A giant magnetostrictive and ultrasonic technology, which is applied in the generation of ultrasonic/sonic/infrasonic waves and the detection of response signals, which can solve problems such as time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

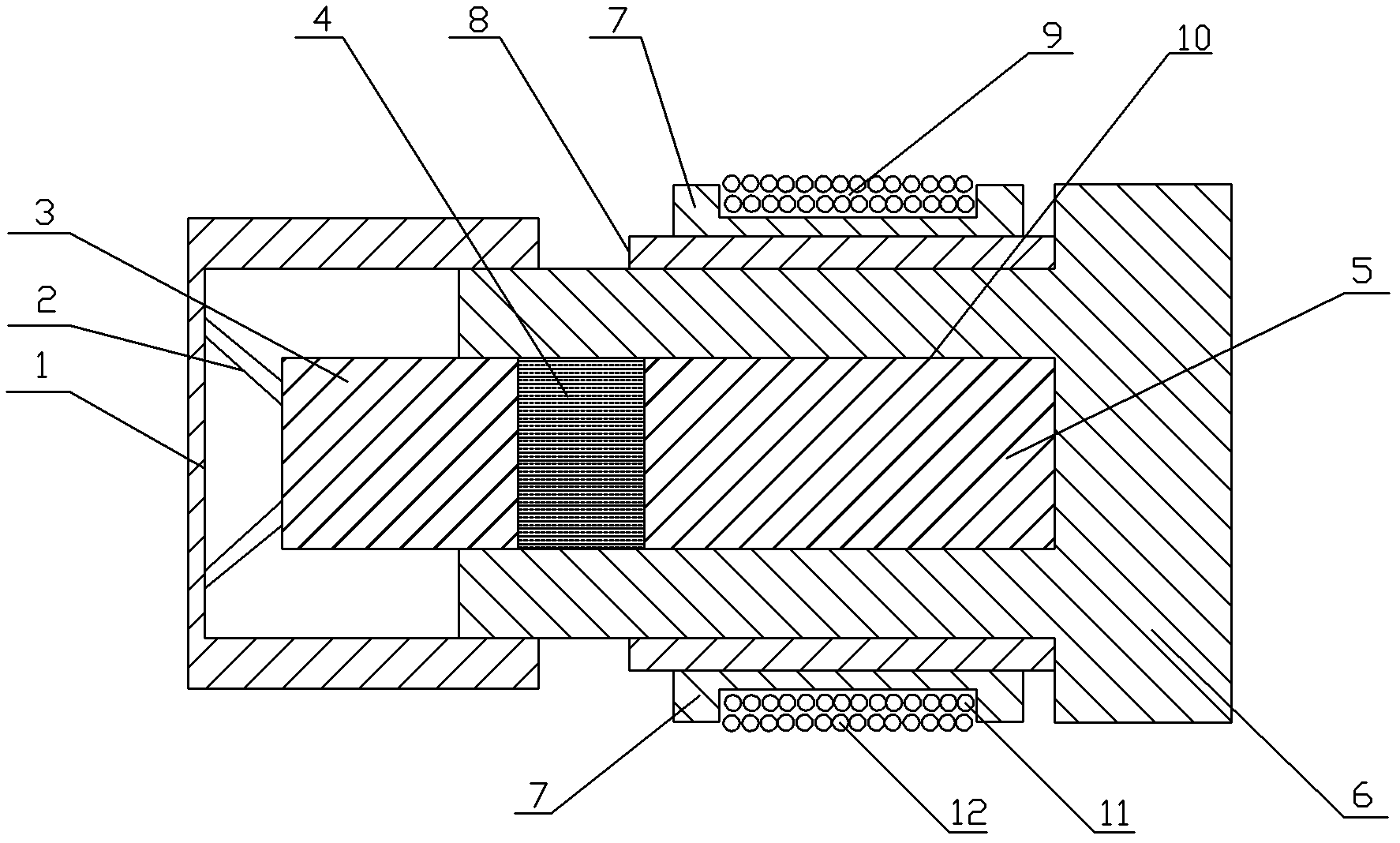

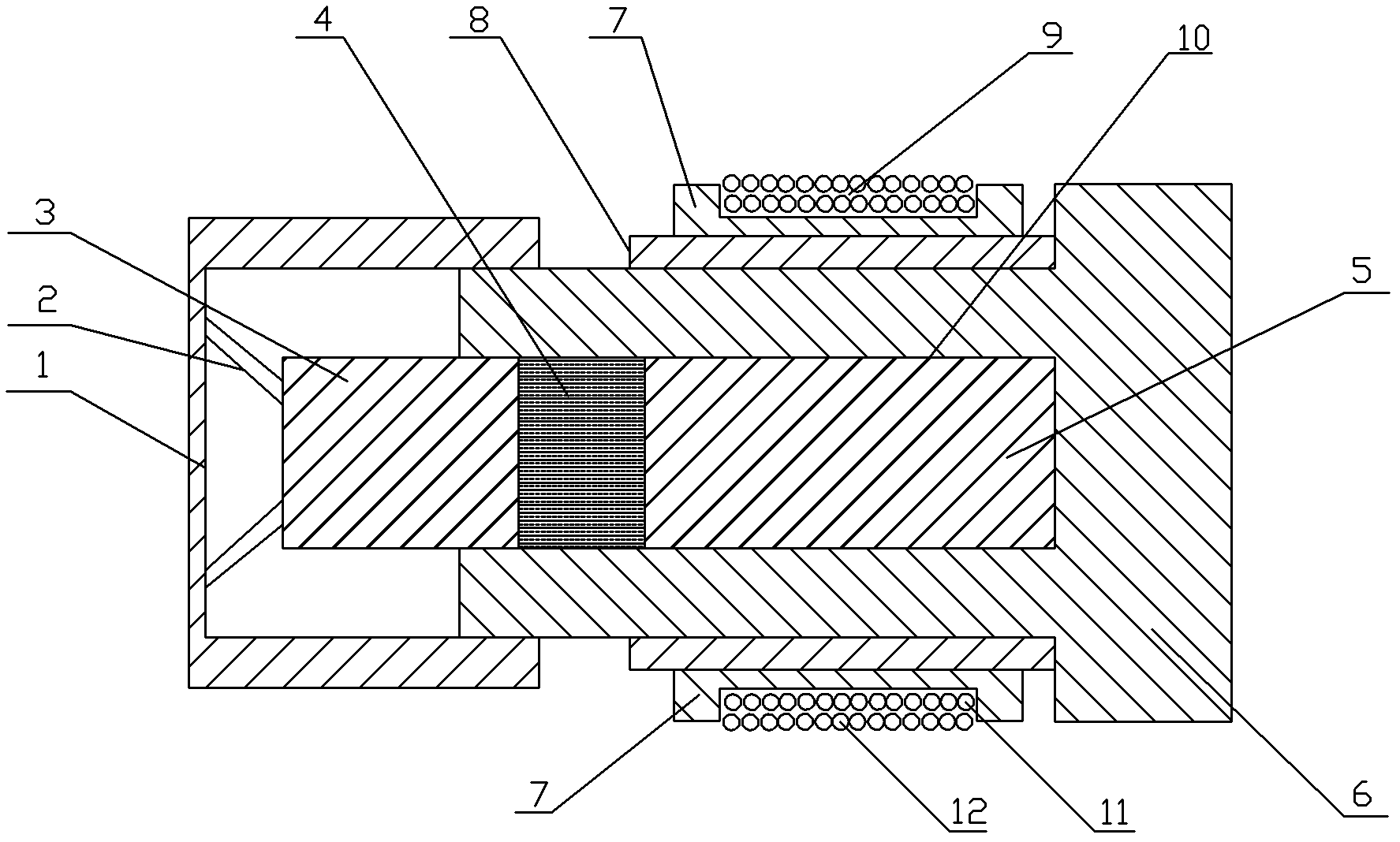

[0009] Such as figure 1 A giant magnetostrictive transducer with ultrasonic guided wave excitation and reception at the same end as shown, including an end cover 1, a disc spring 2, a permanent magnet 3, a damping element 4, a giant magnetostrictive element 5, and a base 6 , spiral coil skeleton 7, self-lubricating bearing 8, spiral coil 9; base 6 is cylindrical, and the outer side of the bottom end of base 6 is radially extended with annular protrusions, and the central part of the front end of base 6 is axially provided with cylindrical The groove 10; the giant magnetostrictive element 5, the damping element 4 and the permanent magnet 3 are cylindrical; the giant magnetostrictive element 5 is placed in the bottom end of the cylindrical groove 10 and fixed with the base 6 through ultrasonic gel, and the damping element 4 is placed on the front end of the giant magnetostrictive element 5 and is in contact with the front end of the giant magnetostrictive element 5, the permanen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com