Circuit board component installation/soldering quality inspection method and system based on super-resolution image reconstruction

A super-resolution and image reconstruction technology, which is applied in the direction of measuring devices, analyzing materials, and material analysis through optical means, can solve the problems of high cost and slow speed, and achieve the effect of low cost, low cost and low material loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

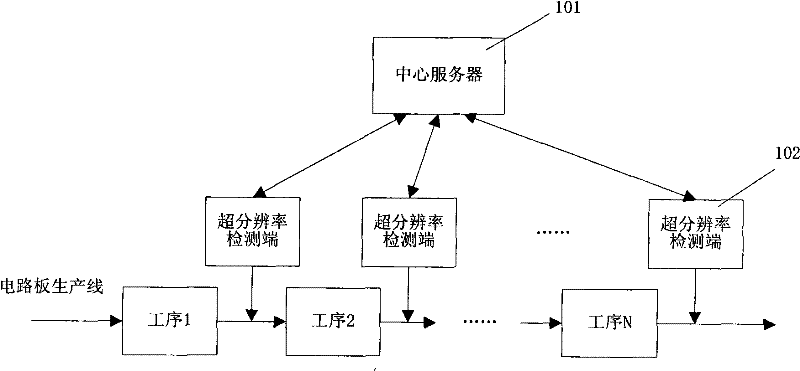

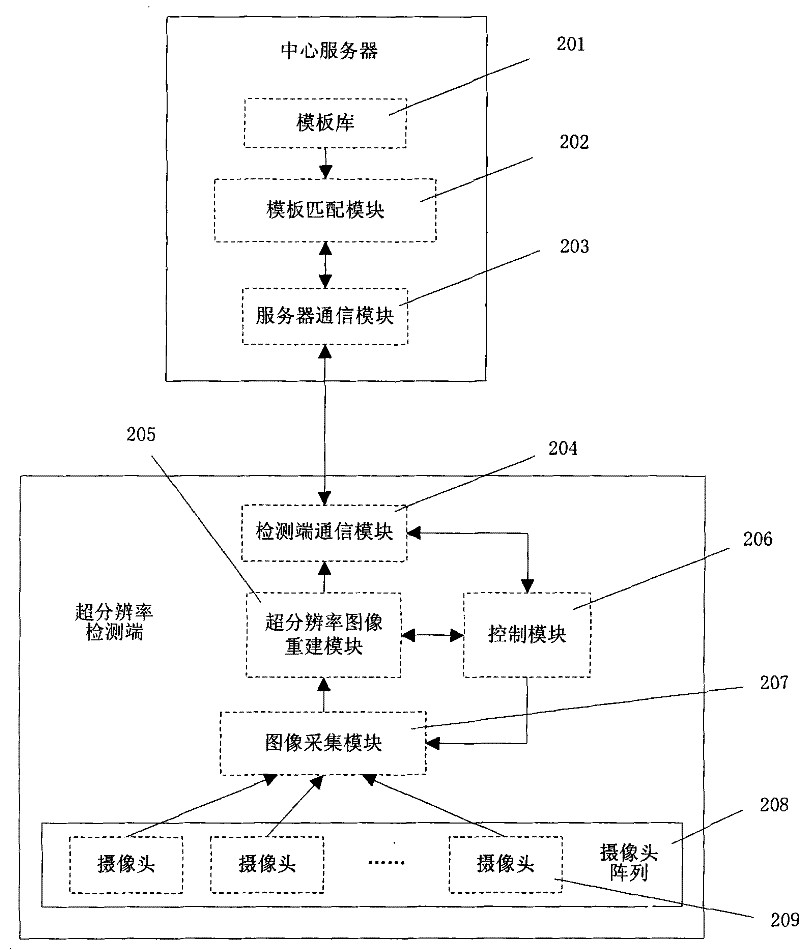

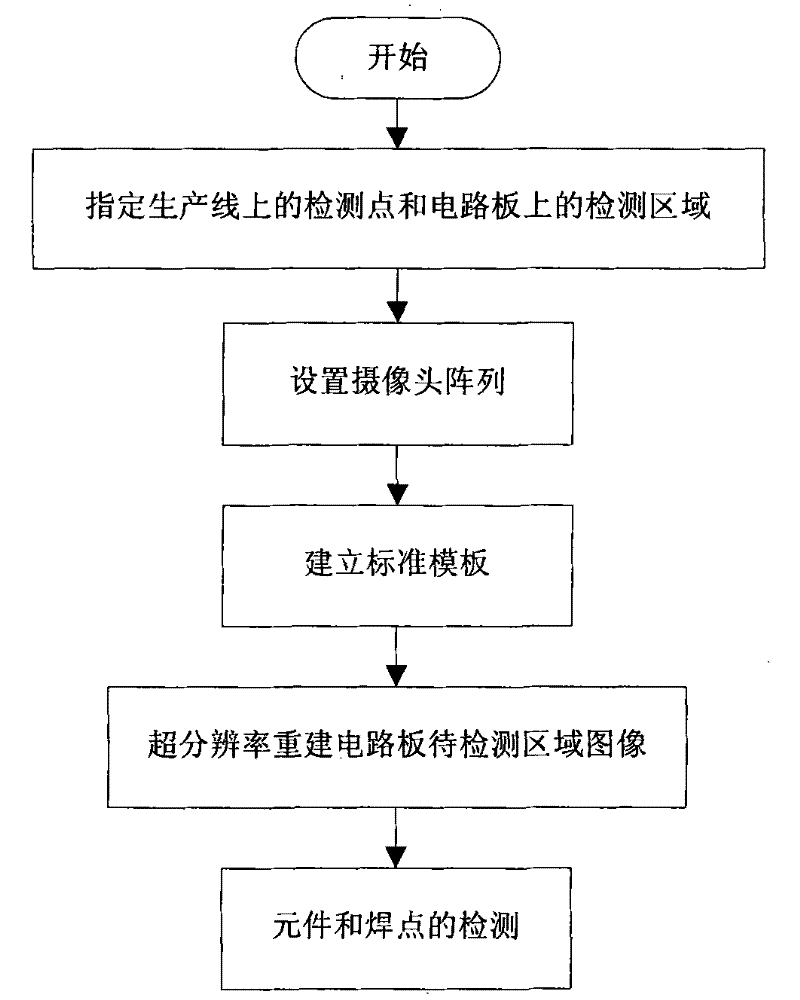

[0036] A preferred embodiment of the present invention, its system structure is as figure 1 As shown, it consists of a central server 101 and several super-resolution detection terminals 102, and the central server is connected to each super-resolution detection terminal through a wired or wireless communication network. The super-resolution detection end is installed on the detection point of the conveyor belt of the production line between the two processes. During normal operation, the super-resolution detection end performs image acquisition and super-resolution reconstruction of the circuit board passing the detection point on the conveyor belt, and then passes through the communication network. Send the reconstructed high-resolution image of the area to be inspected on the circuit board to the central server; the central server matches the high-resolution image of the area to be inspected on the circuit board collected at each inspection point with the corresponding stand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com