Image surface defect detection method based on MobileNets

A defect detection and image technology, applied in image enhancement, image analysis, image data processing and other directions, can solve the problems that need to be improved, the speed of defect detection needs to be improved, and the detection results have a great impact, so as to achieve fast defect detection, good reliability, etc. Portability, effect of reducing parameter size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: Experimental environment tensorflow1.3, based on personal 64-bit windows 10 operating system PC, hardware configuration is Intel(R) Core(TM) i5-4200H CPU@2.80GHz, GTX850M , The memory is 8GB, and the program code is written based on the Python programming language.

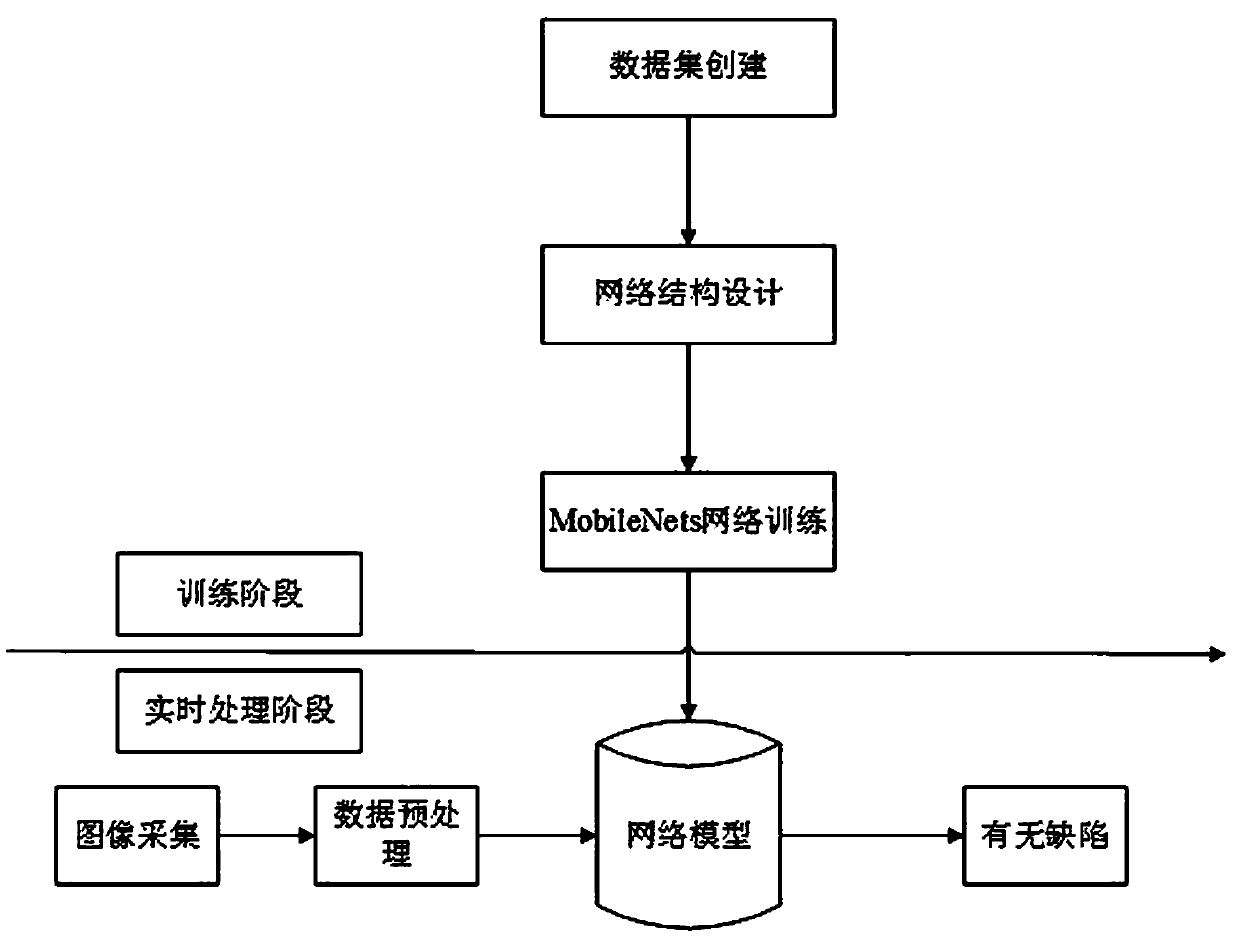

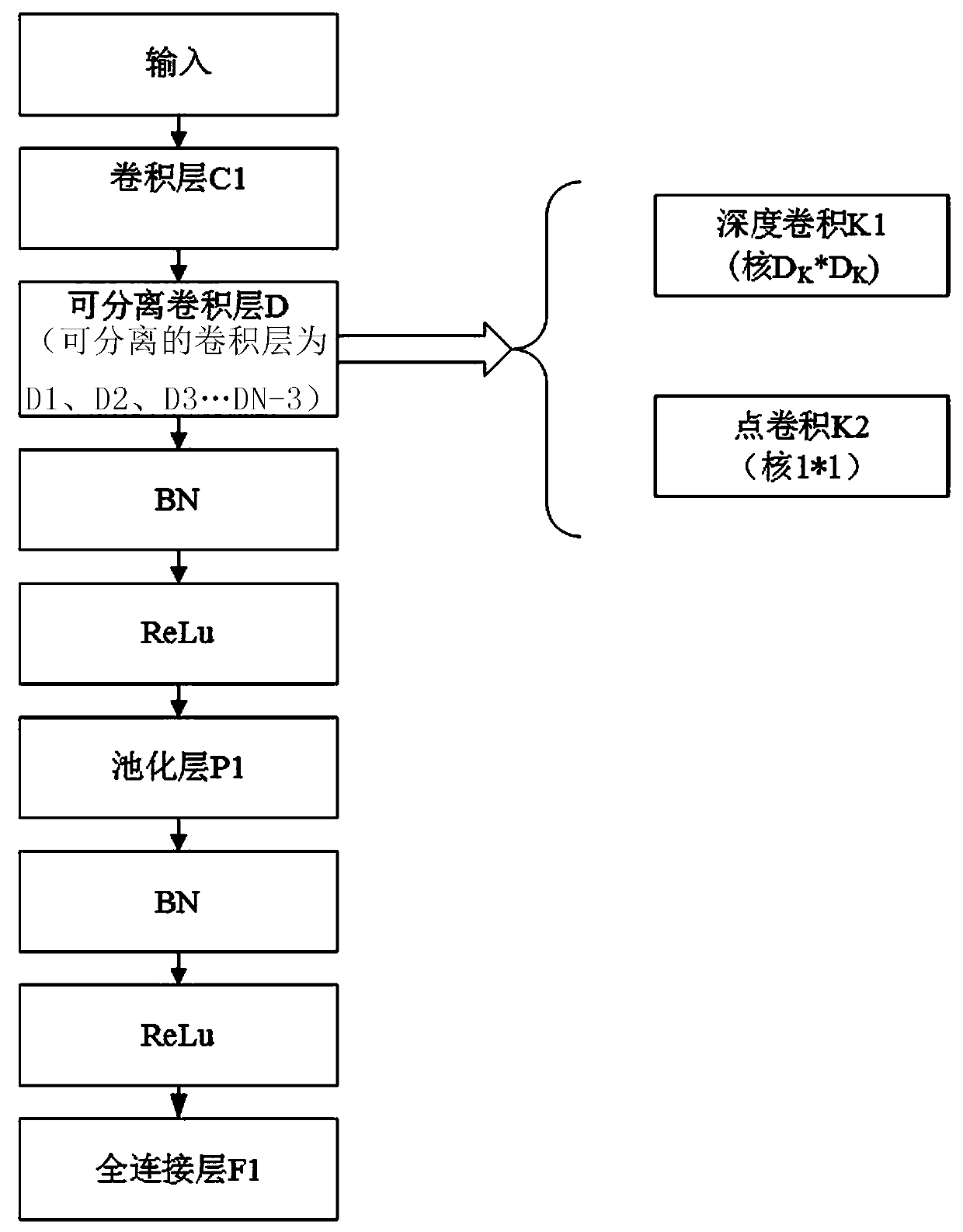

[0027] An image surface defect detection method based on MobileNets, such as figure 1 As shown, the method includes the following steps:

[0028] Step 1. Create image training set X train ={x 1 ,...,x n}, the category label of the image in the image training set is Y train ={y 1 ...,y n}, category labels are divided into defective and non-defective, where n is the number of training samples, n=250, the goal is to detect whether there are scratches in the image, there are 125 samples with scratches and 125 samples without scratches, and each A category label is converted into a one-hot vector; a one-hot vector is 0 in all dimensions except for a certain digit which is 1;

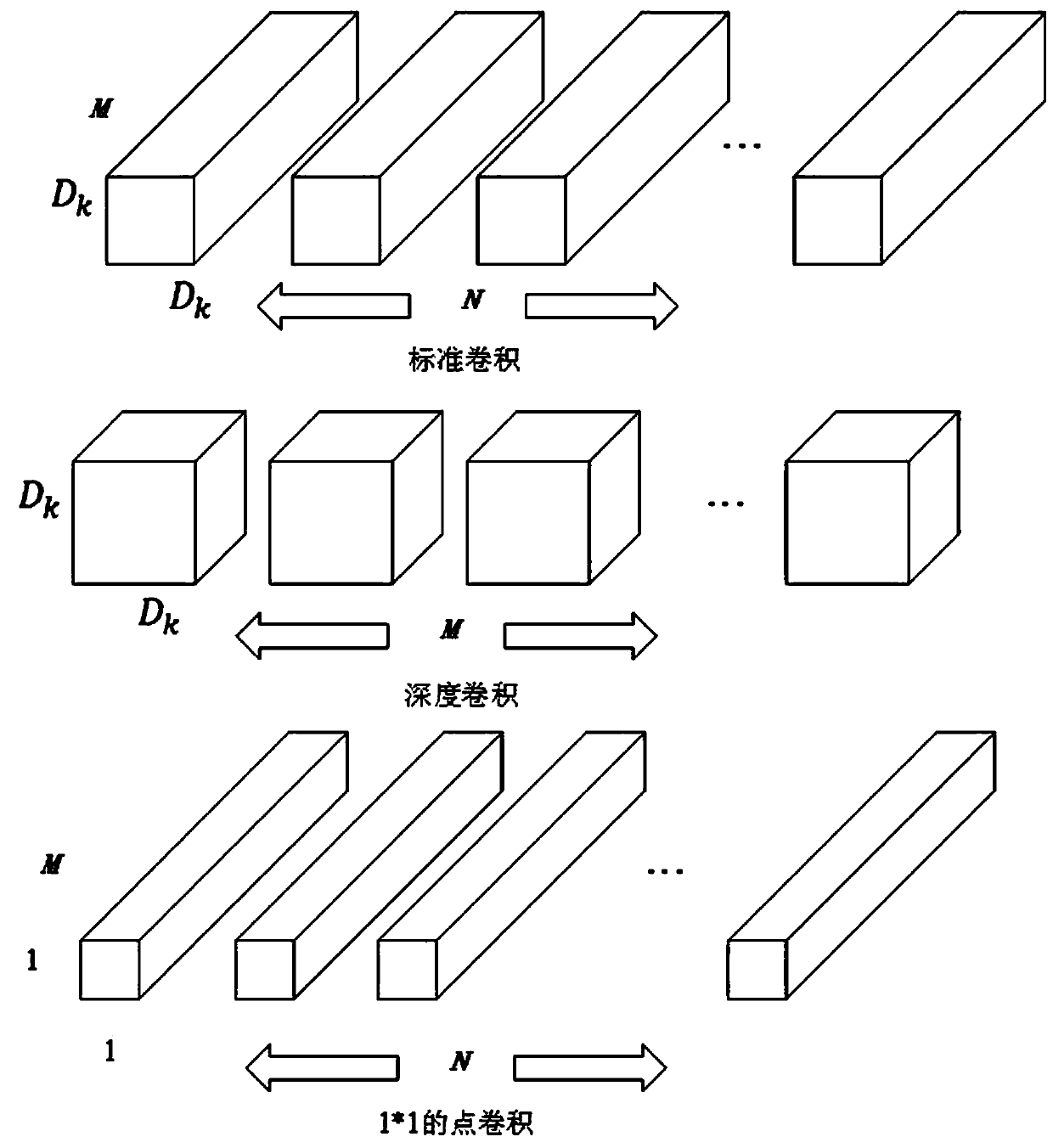

[0029] Step 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com