Online monitoring numerical-control system based on network architecture

A technology of numerical control system and network architecture, which is applied in the fields of intelligent control and networked remote maintenance, online monitoring of numerical control system, and fault diagnosis. , to ensure real-time performance, predictable performance, and excellent portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

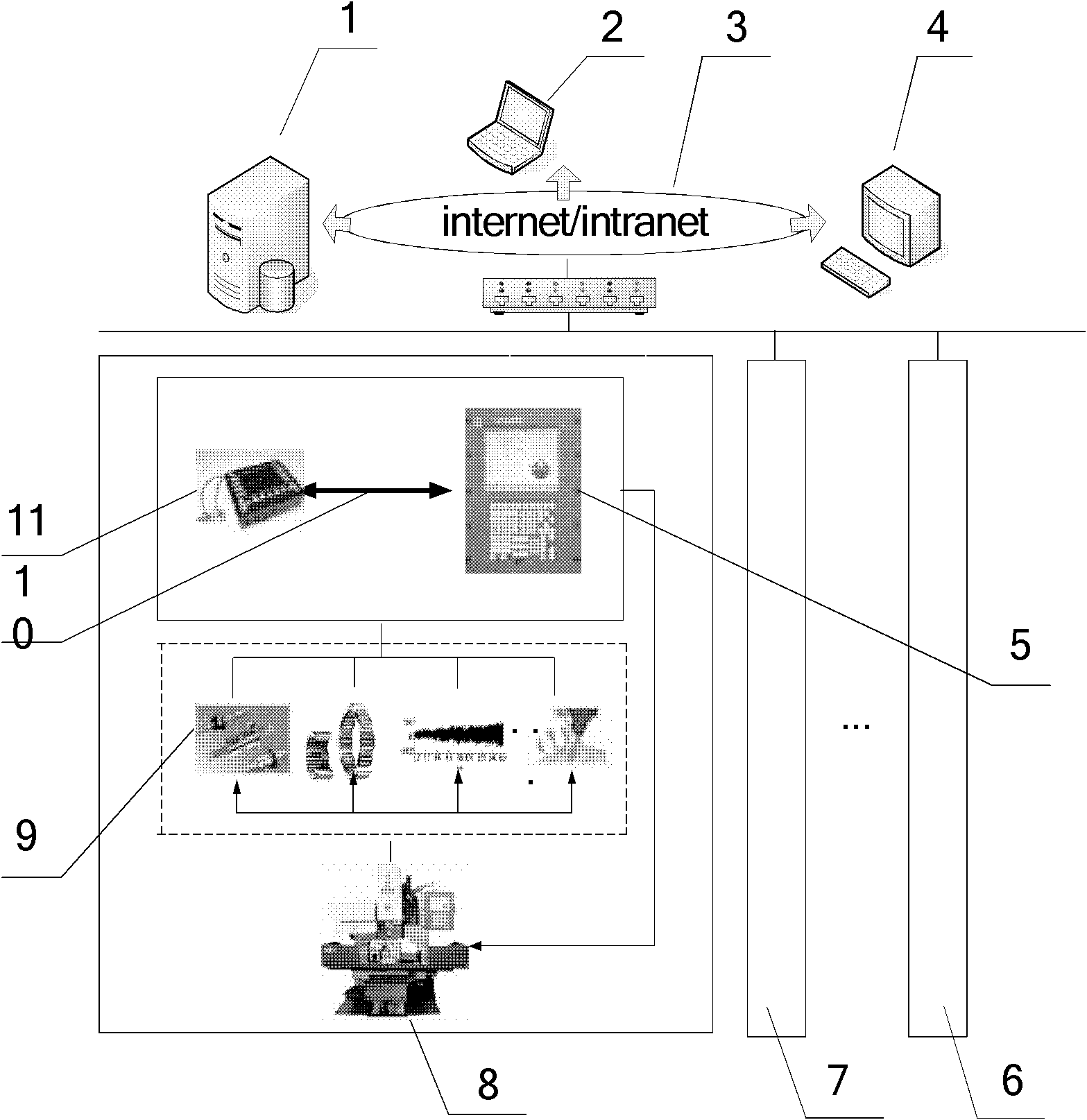

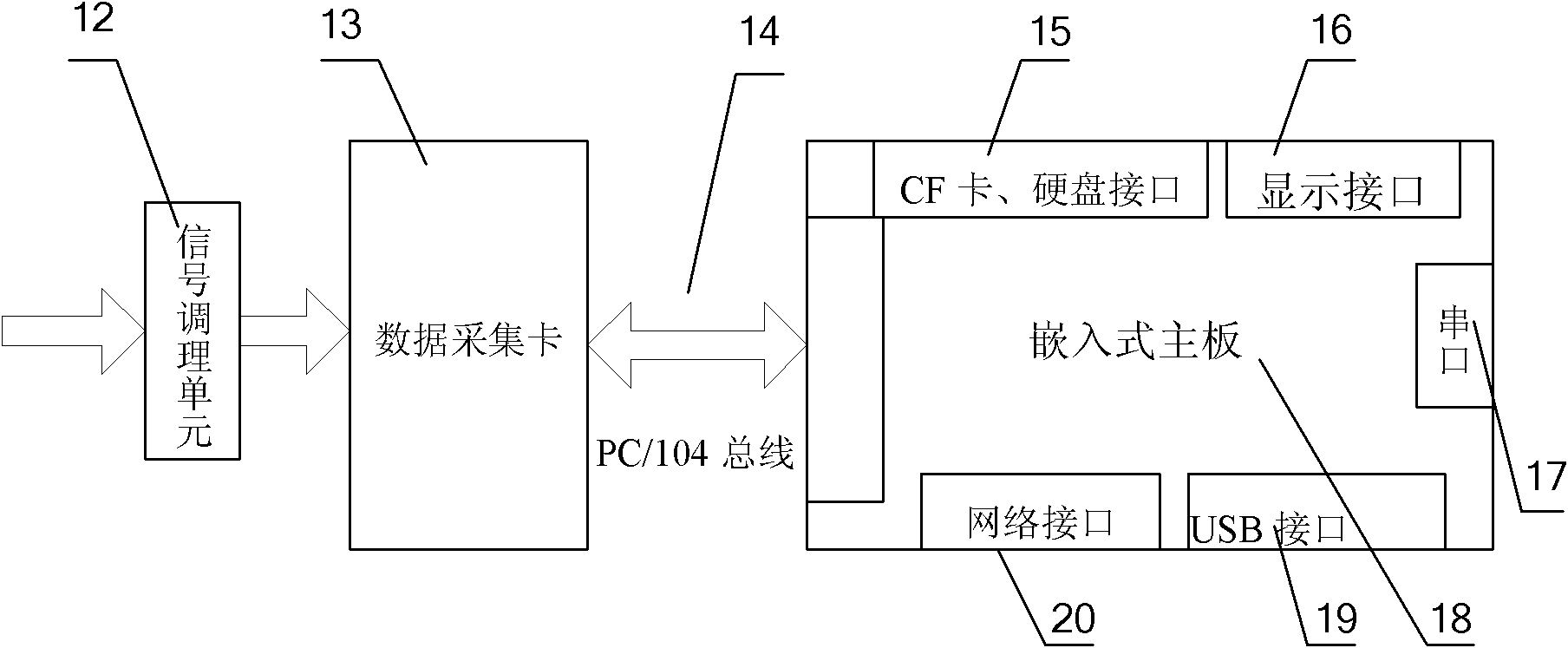

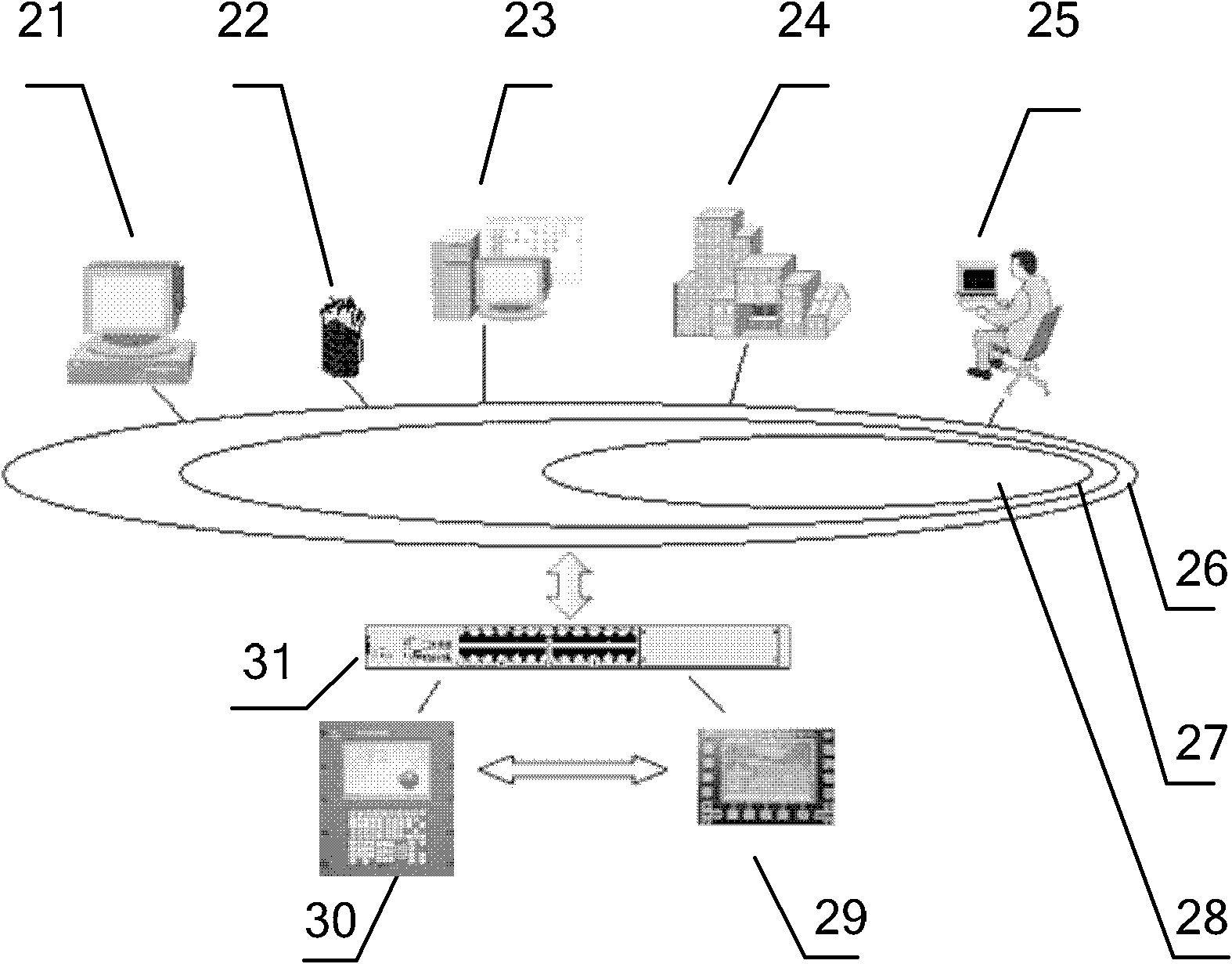

[0023] Figure 1 to Figure 3 Among them, the structure of the online monitoring numerical control system based on the network architecture of the present invention includes: an embedded online monitoring unit 11 and a CNC machine tool main control unit 5 with an independent central processing unit. During the online monitoring process, the embedded monitoring unit 11 is externally connected with multi-physical quantity sensors such as vibration, force, and current through the data acquisition card 13 and signal conditioning 12 to realize real-time monitoring of the machine tool state, and then through the PC / 104 bus 14, CF card, The hard disk interface 15 and the display interface 16 store and display the monitoring data. The embedded monitoring unit is connected to the main control unit 5 and HUB 31 through the serial port 17, USB interface 19, and network interface 20, and through the TDNC-Connect information exchange general call protocol, to realize the numerical control s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com