Method for preparing aldehyde by hydroformylation of low light olefins

A technology for hydroformylation of carbon olefins and low-carbon olefins, which is applied in the field of hydroformylation of low-carbon olefins, and can solve problems such as high investment cost of stirring equipment, equipment failure, and affecting the safe and stable operation of the reactor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

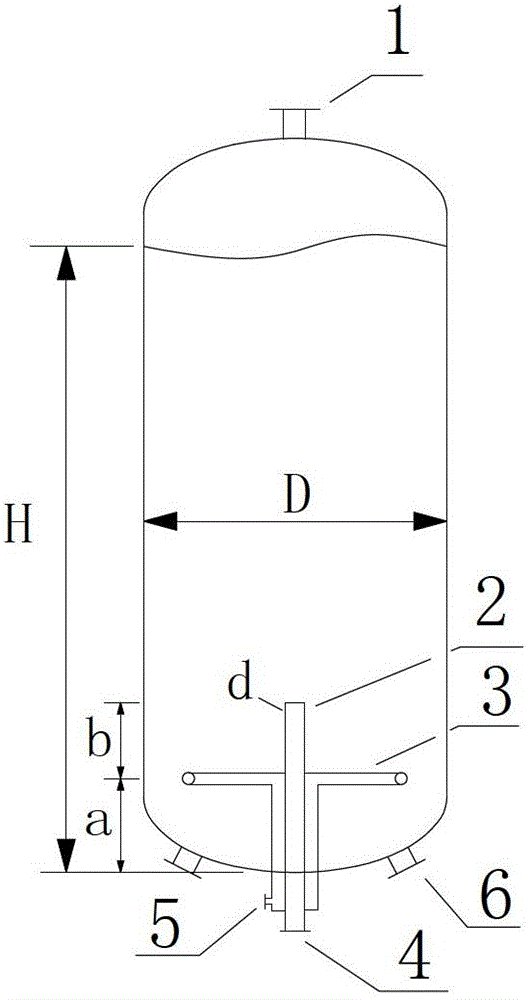

[0028] use figure 1 The jet reactor shown includes a gas outlet 1, a liquid injection device 2, a gas distributor 3, a liquid inlet 4, a gas inlet 5 and a liquid outlet 6; wherein, the gas inlet 5 and the liquid inlet 4 are located in the reactor At the bottom of the reactor, the gas outlet 1 is located at the top of the reactor, and the liquid outlet 6 is symmetrically placed on both sides of the lower head of the reactor; the liquid injection device 2 is located on the gas distributor 3. The liquid injection device is a reduced-diameter tube type, and the gas distributor is a disc-type gas distributor with holes on the upper part.

[0029] Among them, the relationship between the reactor liquid level H and the reactor diameter D is H / D=2. The distance between the gas distributor and the bottom of the reactor a=0.25D. The distance between the liquid injection device and the gas distributor b=0.15D. The diameter of the liquid ejection device d=0.05D. The number of openings of...

Embodiment 2

[0034] Same as [Example 1], except that the relationship between the reactor liquid level H and the reactor diameter D is H / D=1.5. The distance between the gas distributor and the bottom of the reactor a=0.25D. The distance between the liquid injection device and the gas distributor b=0.15D. The diameter of the liquid ejection device d=0.1D. The number of openings of the disc gas distributor is 1000, and the openings are evenly distributed at equal distances.

[0035] The above-mentioned reactor is used in the reaction of mixed butene oxo to produce valeraldehyde. The feed rate of mixed butene is 1970g / hr, the feed rate of synthesis gas is 775g / hr, CO / H 2 =1:1 (mol / mol), the reaction temperature is 80°C, the operating pressure is 1.6MPa, the rhodium catalyst concentration in the reactor is 250ppm, and the phosphine ligand / rhodium molar ratio is 8:1.

[0036] The result is: the total conversion rate of olefin is 89%, and the selectivity of aldehyde> 97%, the product n- / isovalerald...

Embodiment 3

[0038] Same as [Example 1], except that the relationship between the reactor liquid level H and the reactor diameter D is H / D=2.5. The distance between the gas distributor and the bottom of the reactor a=0.25D. The distance between the liquid injection device and the gas distributor b=0.2D. The diameter of the liquid ejection device d=0.1D. The number of openings of the disc gas distributor is 1000, and the openings are evenly distributed at equal distances.

[0039] The above-mentioned reactor is used in the reaction of mixed butene oxo to produce valeraldehyde. The feed rate of mixed butene is 1970g / hr, the feed rate of synthesis gas is 775g / hr, CO / H 2 =1:1 (mol / mol), the reaction temperature is 80°C, the operating pressure is 1.6MPa, the rhodium catalyst concentration in the reactor is 250ppm, and the phosphine ligand / rhodium molar ratio is 8:1.

[0040] The result is: the total conversion rate of olefin is 91%, the selectivity of aldehyde> 95%, the product n- / isovaleraldehyde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com