Patents

Literature

44results about How to "Axially distributed evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

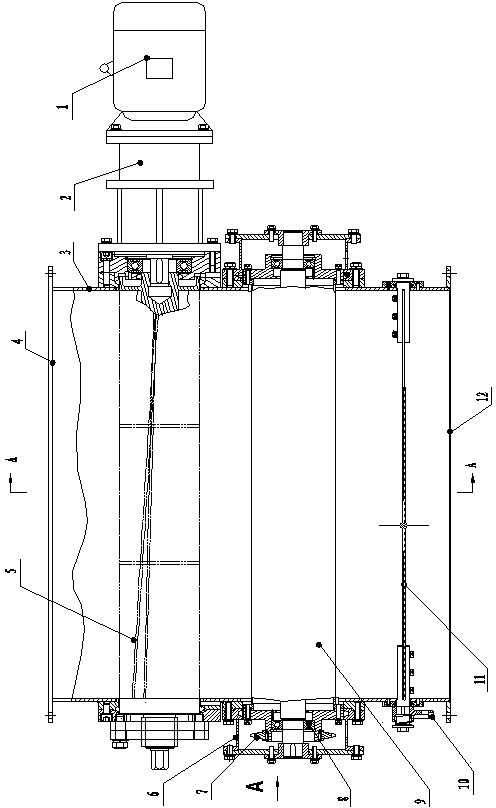

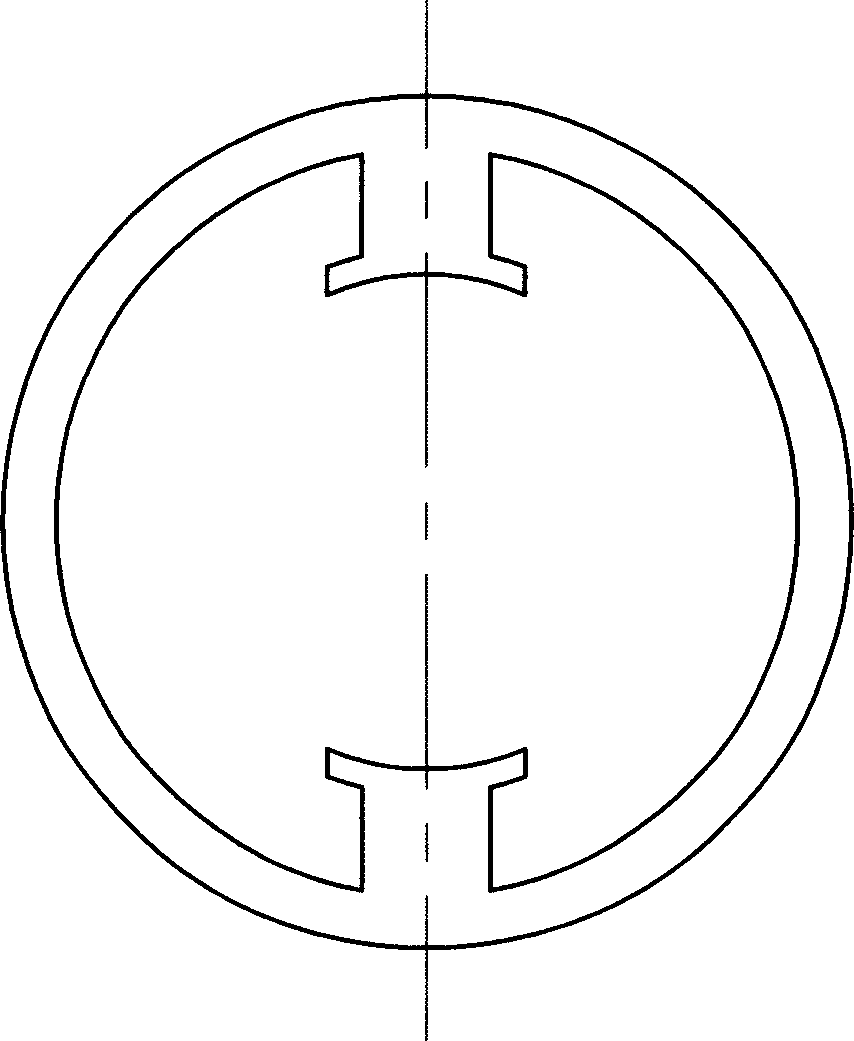

Catalytic reforming and catalytic dehydrogenation centrifugal type fixed bed radial reactor

InactiveCN1546217AAvoid heat lossUniform axial temperatureCatalytic crackingChemical/physical processesCatalytic reformingFixed bed

The invention discloses a kind of fixed bed reactor for catalytic reforming and dehydrogenation, the reactor uses a round pressure container which has a catalytic bed. The inlet and the outlet is at one side of the container, the catalytic bed is made up of outer multi-hole wall and round inner multi-hole wall, catalyst is filled in them, there has a cover sealing structure on the catalyst, the round inner multi-hole wall can uses variable hole-rate or zone structure. The reacting gas in the device flows centrifugally, the gas in the centre inner barrel and multi-hole outer barrel flow reversely.

Owner:EAST CHINA UNIV OF SCI & TECH

Residual oil hydrotreating method

ActiveCN103773429AReduce differential pressureSmall circulation resistanceRefining to eliminate hetero atomsPtru catalystHydrogenation reaction

Owner:CHINA PETROLEUM & CHEM CORP +1

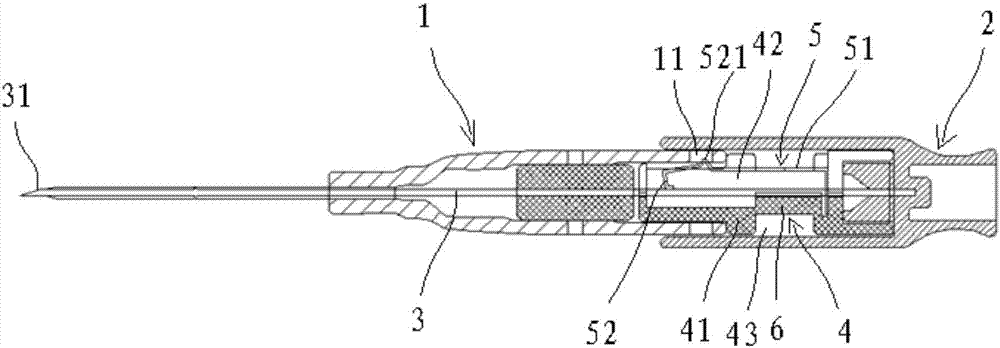

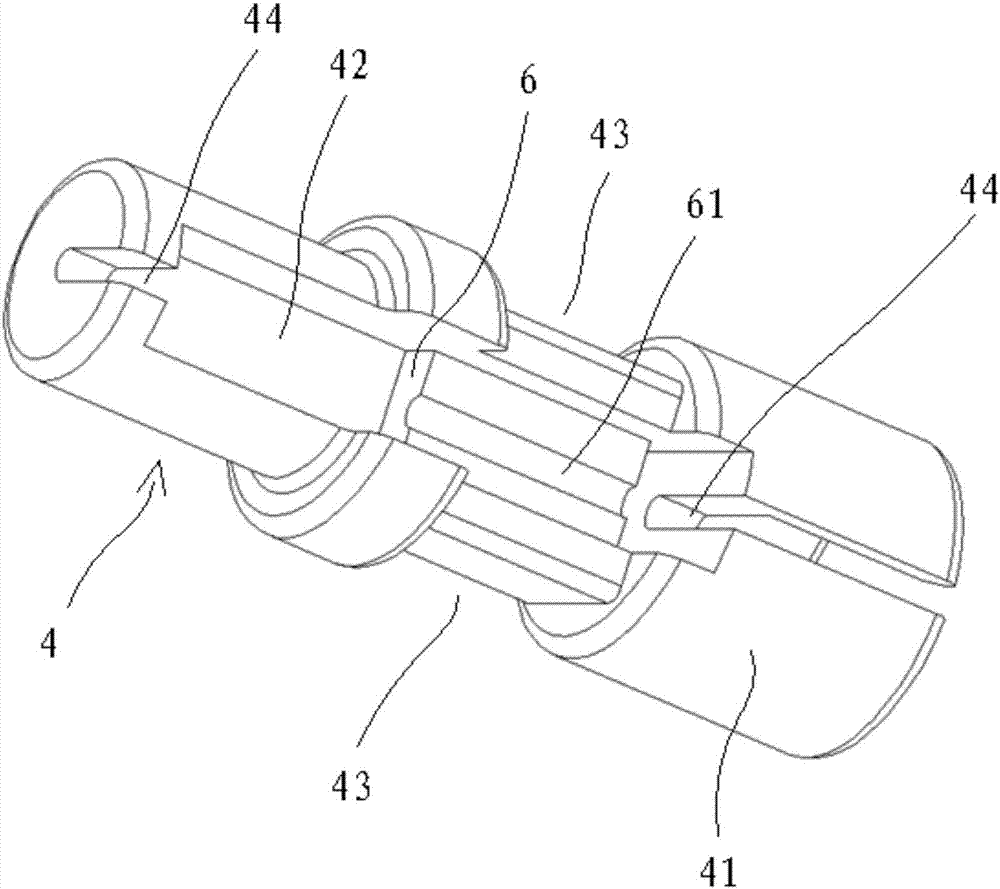

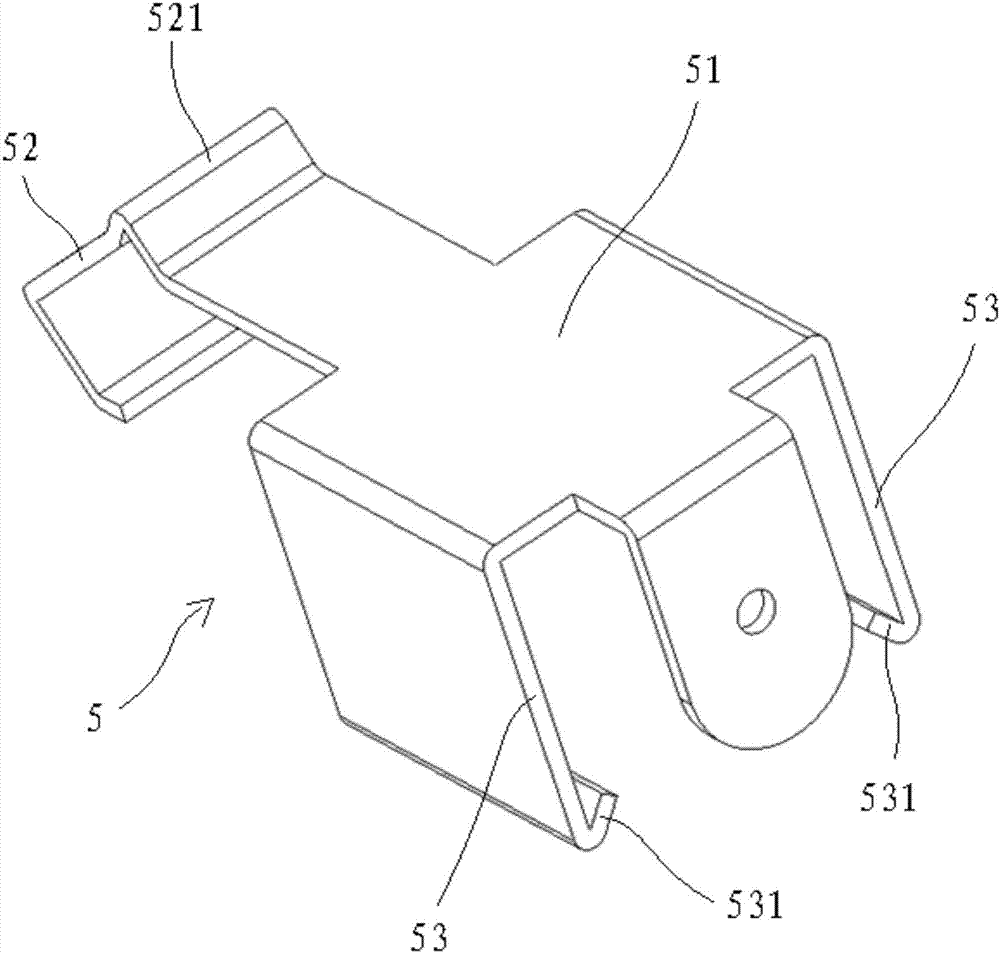

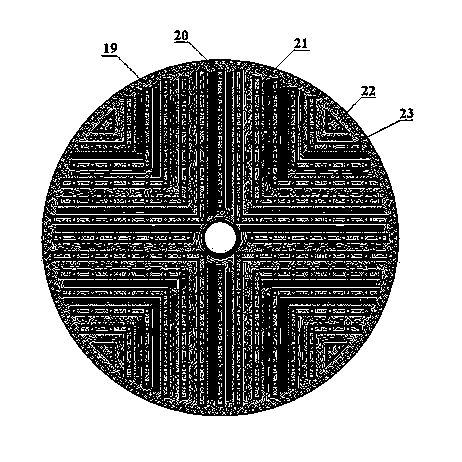

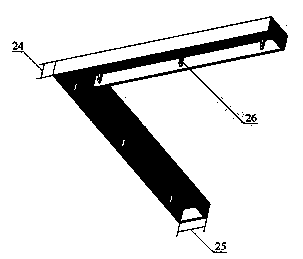

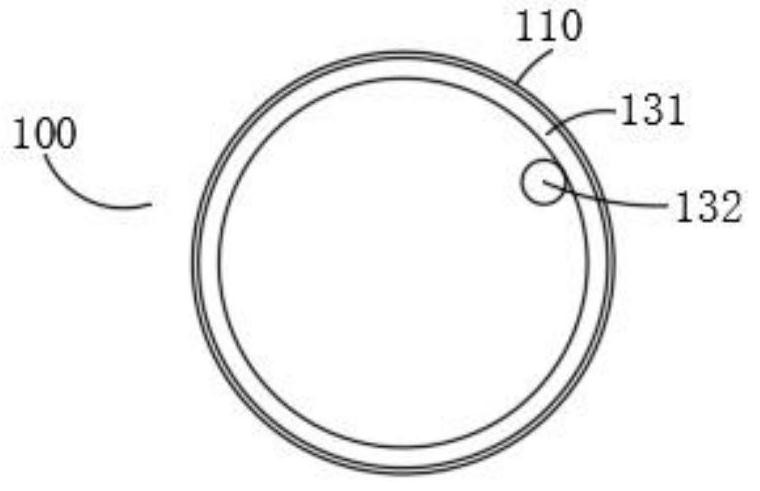

Puncture-preventing indwelling needle

PendingCN107050567AGuarantee normal implementationAvoid deformationCatheterInfusion needlesProtection mechanismCatheter

The invention provides a puncture-preventing indwelling needle. The puncture-preventing indwelling needle comprises a catheter base, a needle file, a needle tube and a protection mechanism, wherein the needle file sleeves the catheter base in a sliding manner; the needle tube is mounted to the needle file, and the needle point can penetrate through the catheter base; the protection mechanism is arranged between the catheter base and needle file, and is composed of a protection base and a protection plate mounted on the protection base, the protection base is provided with a protection base body allowing the needle tube to pass through, and an accommodating cavity for accommodating part of the needle tube is formed in the protection base body; the protection plate is provided with a protection plate body, a baffle plate accommodated in the accommodating cavity is formed at one end of the protection plate body, the baffle plate has the first state of pushing against the needle tube and a second state of sheltering the needle point, a support structure is arranged in the accommodating cavity, the support structure applies a supporting force to the needle tube, and the direction of the supporting force is opposite to that of the resisting force applied by the baffle plate. For the puncture-preventing indwelling needle, the support structure applies the supporting force to the needle tube, the direction of the supporting force is opposite to that of the resisting force applied by the baffle plate, so that the needle tube has small possibility of deformation under the pushing and pressing of the baffle plate.

Owner:DRAGON HEART MEDICAL DEVICES

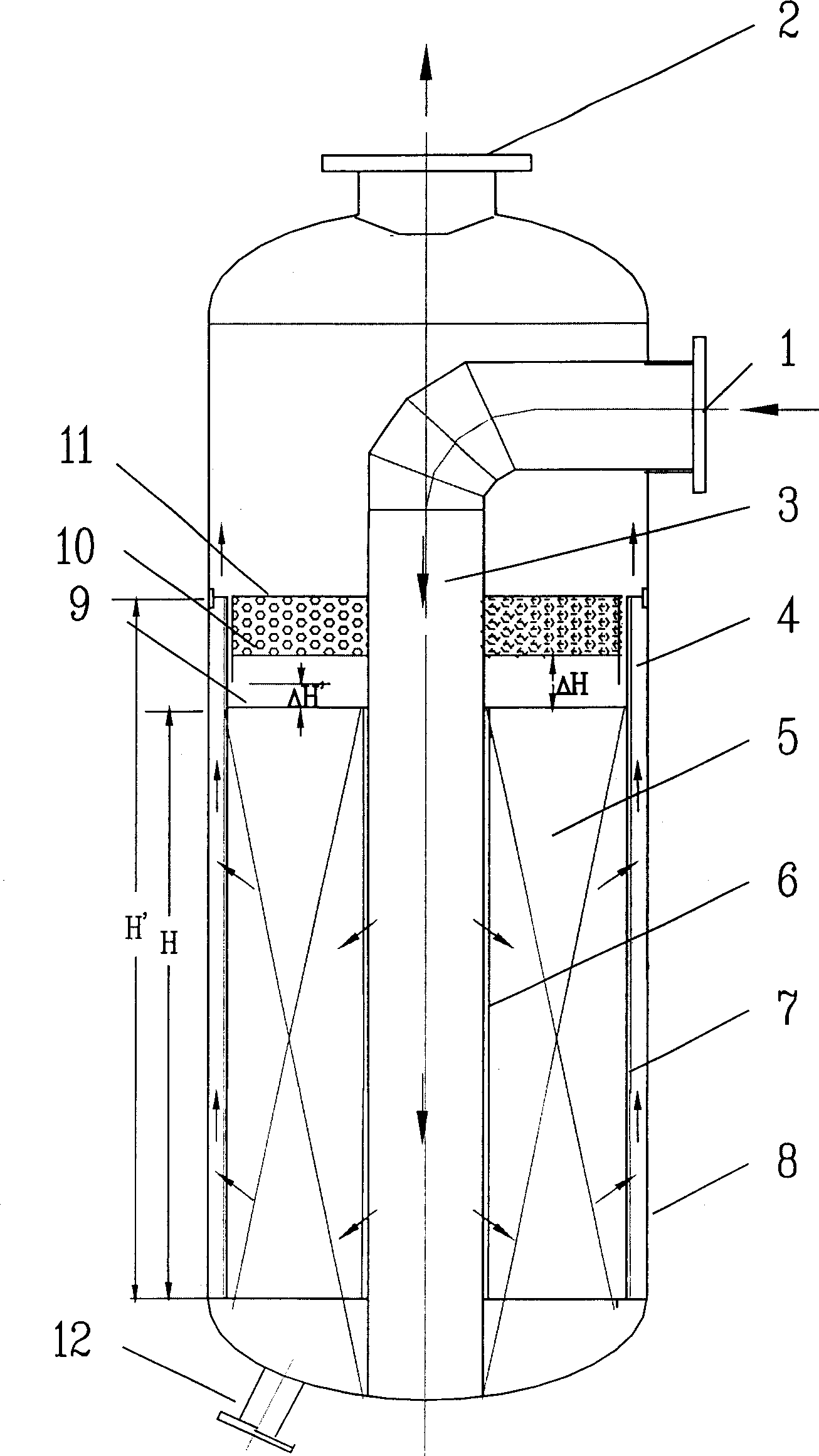

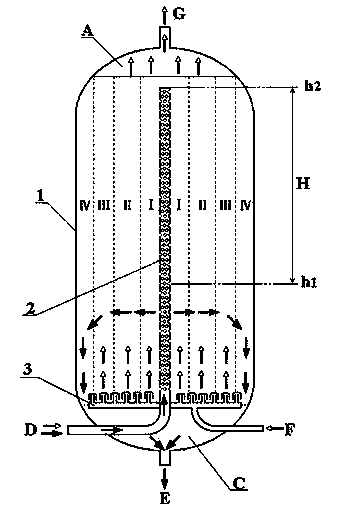

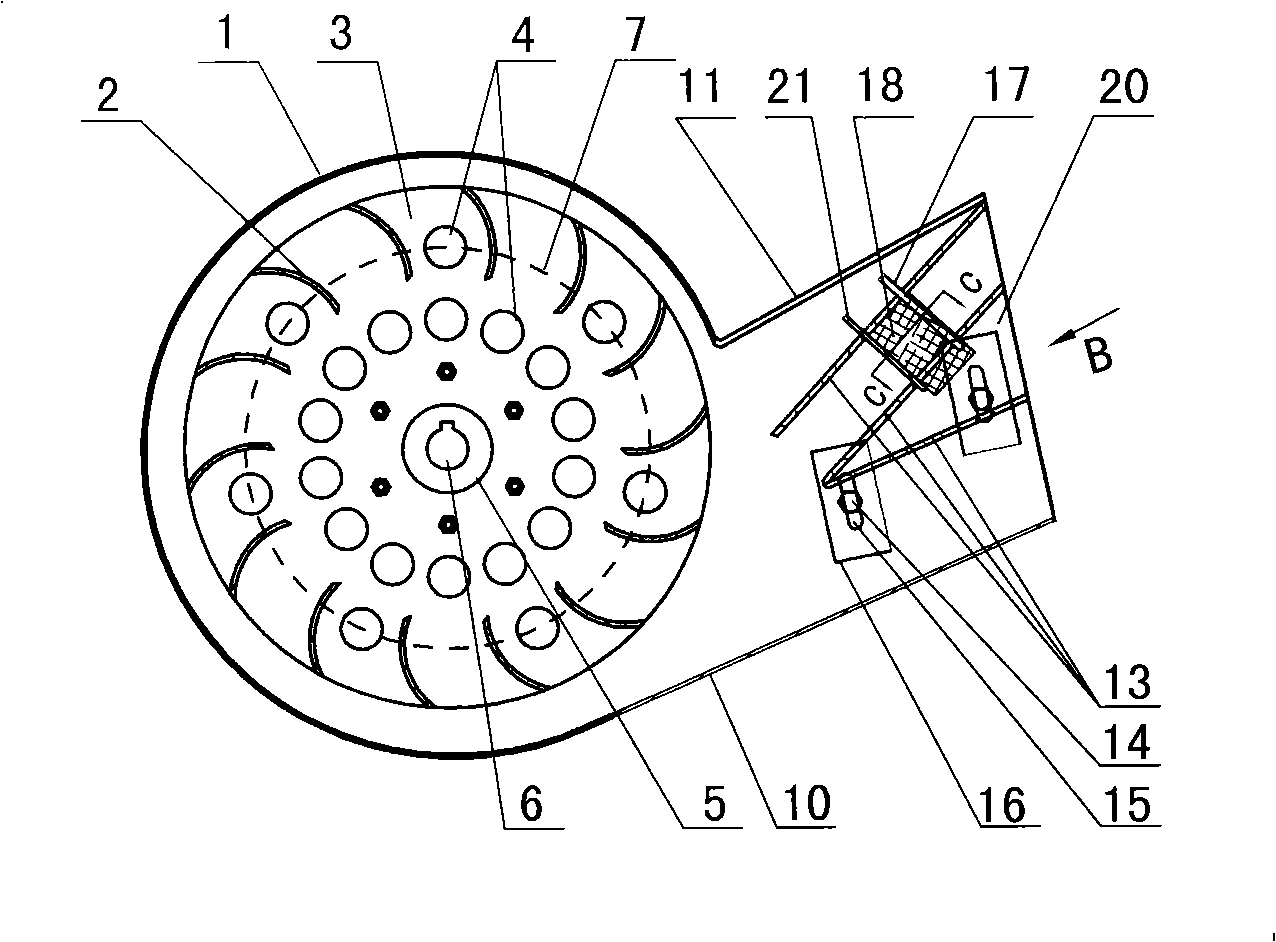

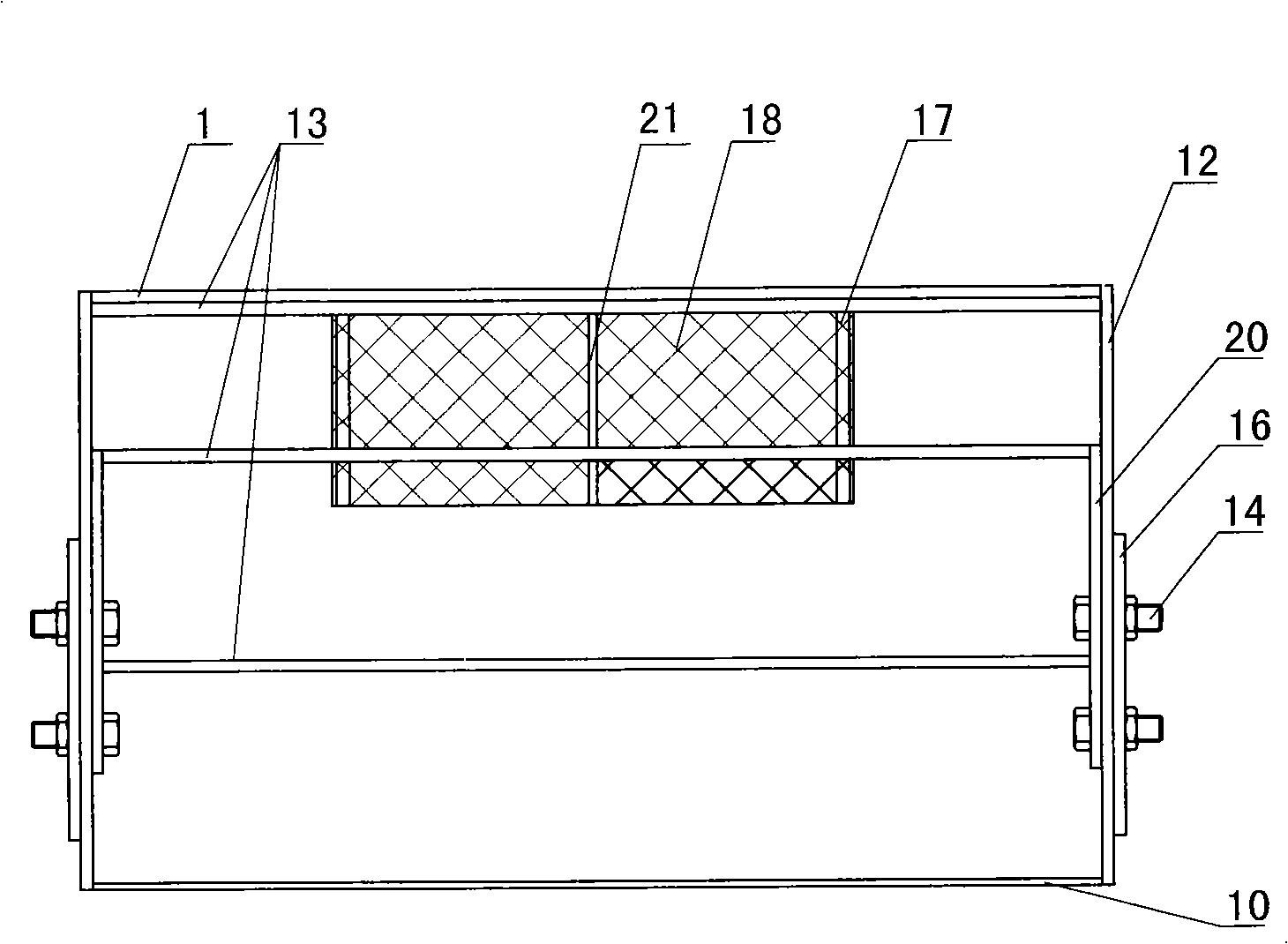

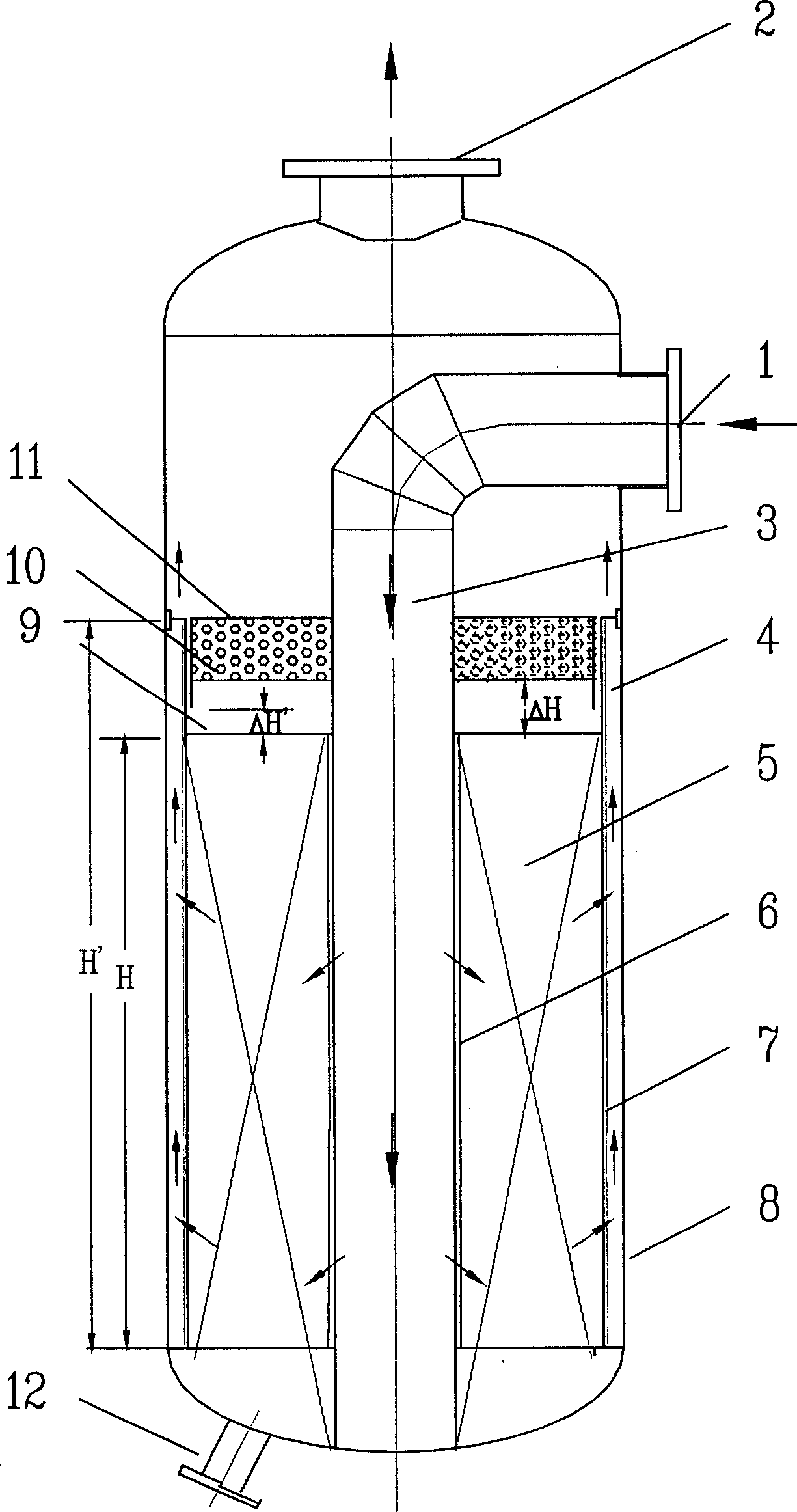

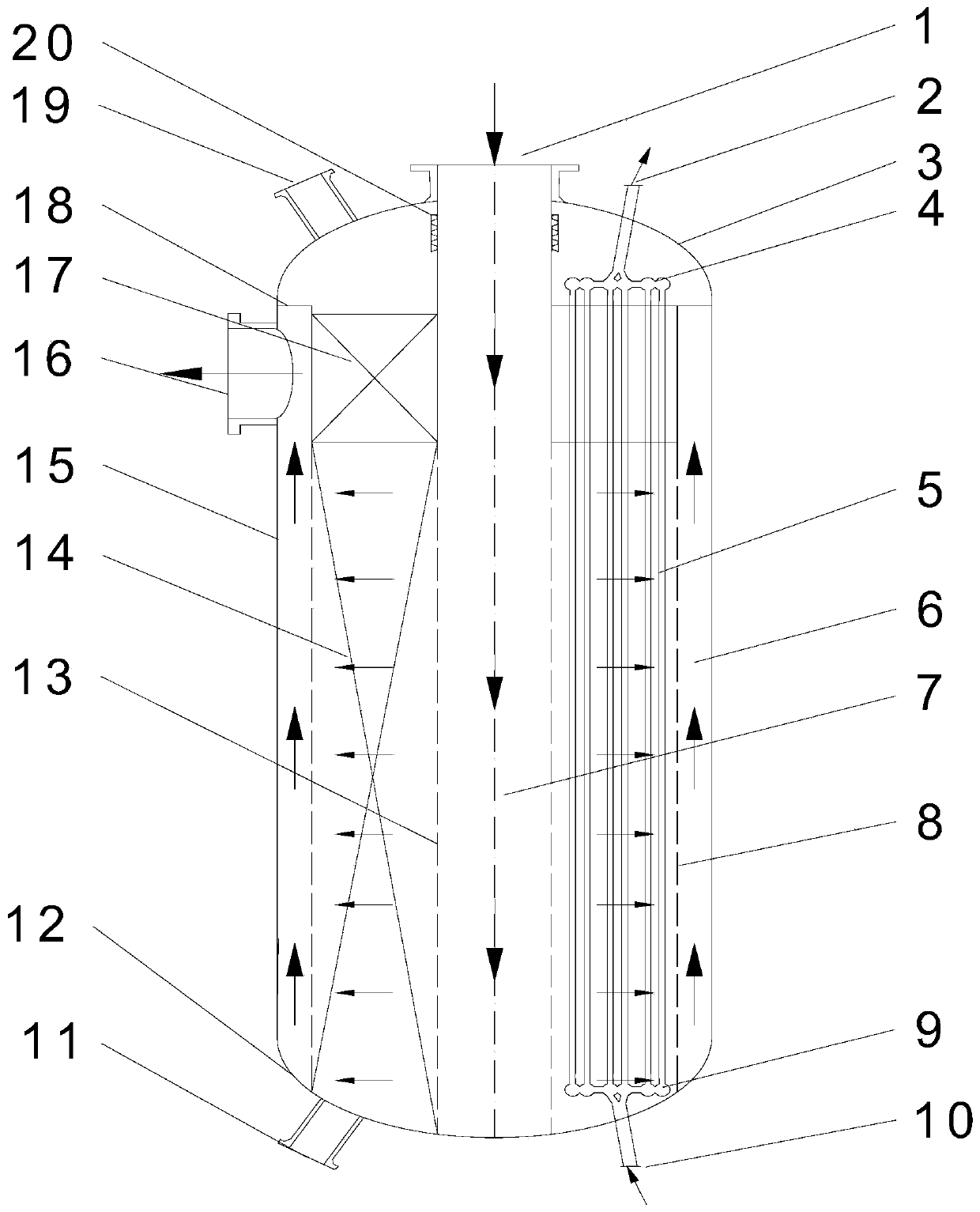

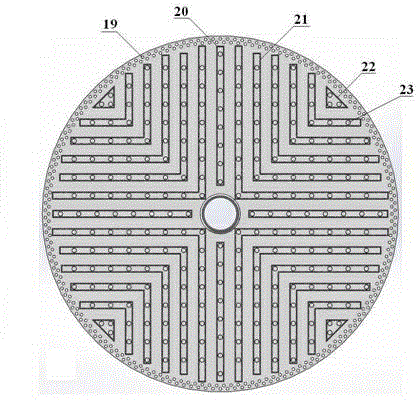

Radial flow-type residual oil hydrotreating reactor

ActiveCN103805234ASolve the problem that the radial flow residual oil hydrogenation reaction process cannot be realizedThe reaction space velocity is constantHydrocarbon oil crackingHydrocarbon oils refiningHydrogenation reactionFixed bed

The invention discloses a radial flow-type fixed bed residual oil hydrotreating reactor. The reactor of the present invention mainly comprises members of a housing, a central shaft oil inlet pipe, and a bottom hydrogen distribution disc; in a residual oil hydrogenation reaction process, raw oil mainly flows in a reaction diameter direction in a catalyst bed layer, and reaction supplemented hydrogen flows from bottom to top. The residual oil hydrogenation device of the invention has good operation flexibility, can realize synchronous inactivation of various catalysts, effectively prolongs the running period of the device, and makes full use of the active resources of residual oil hydrogenation catalysts.

Owner:CHINA PETROLEUM & CHEM CORP +1

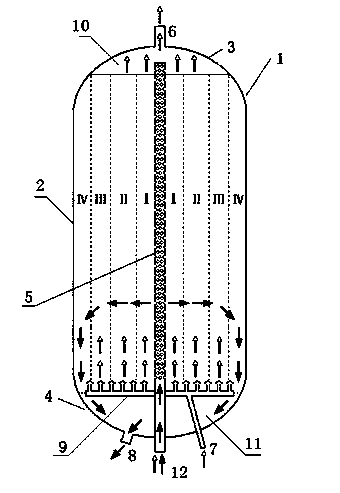

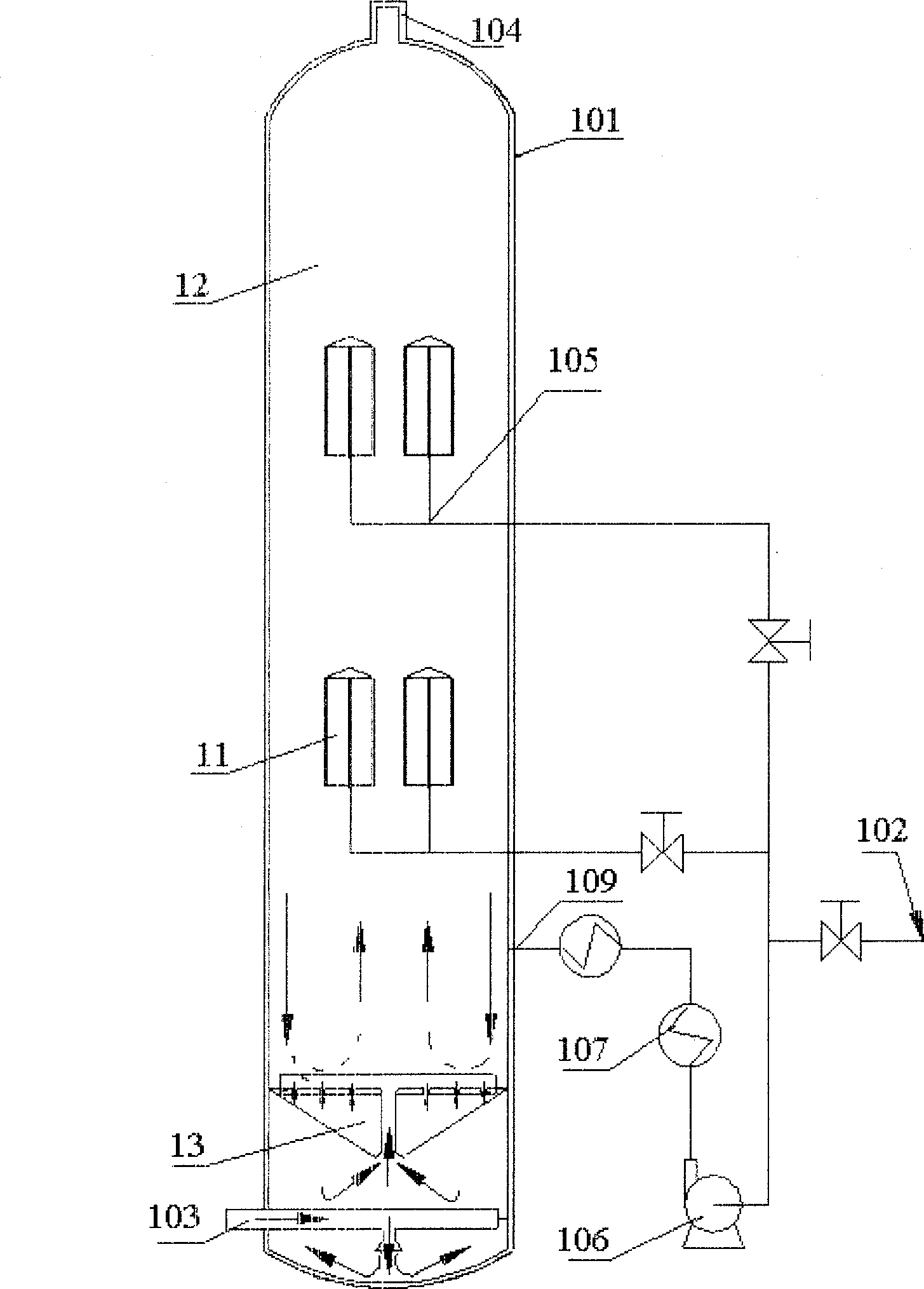

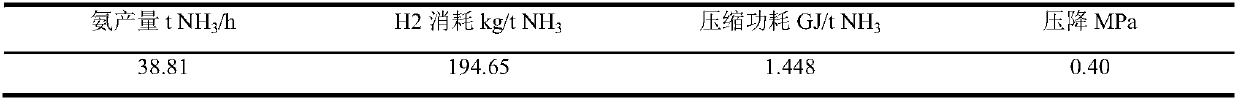

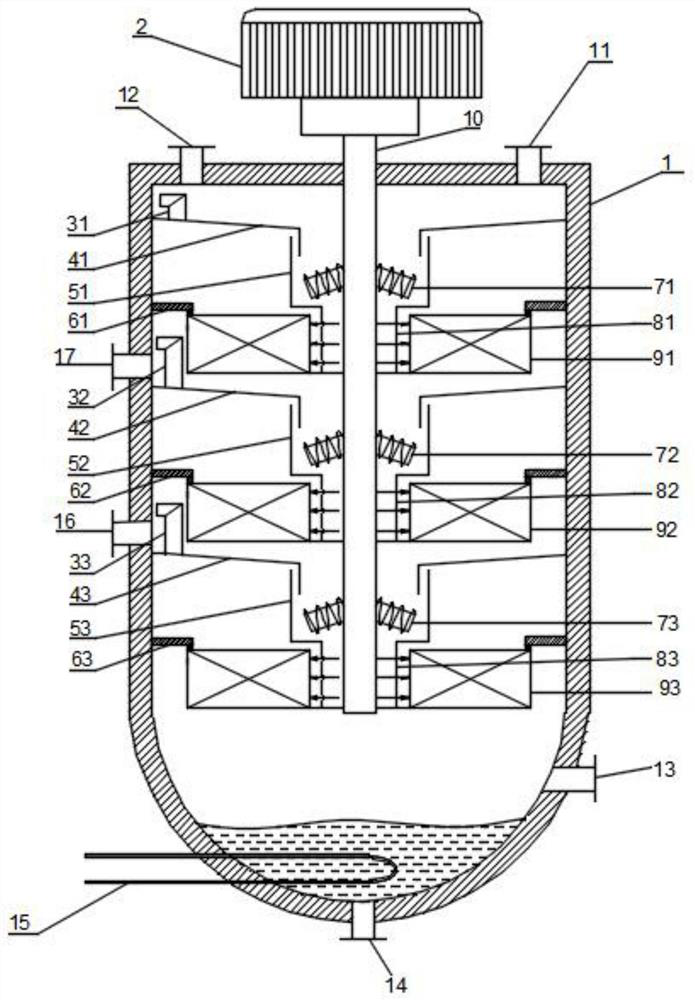

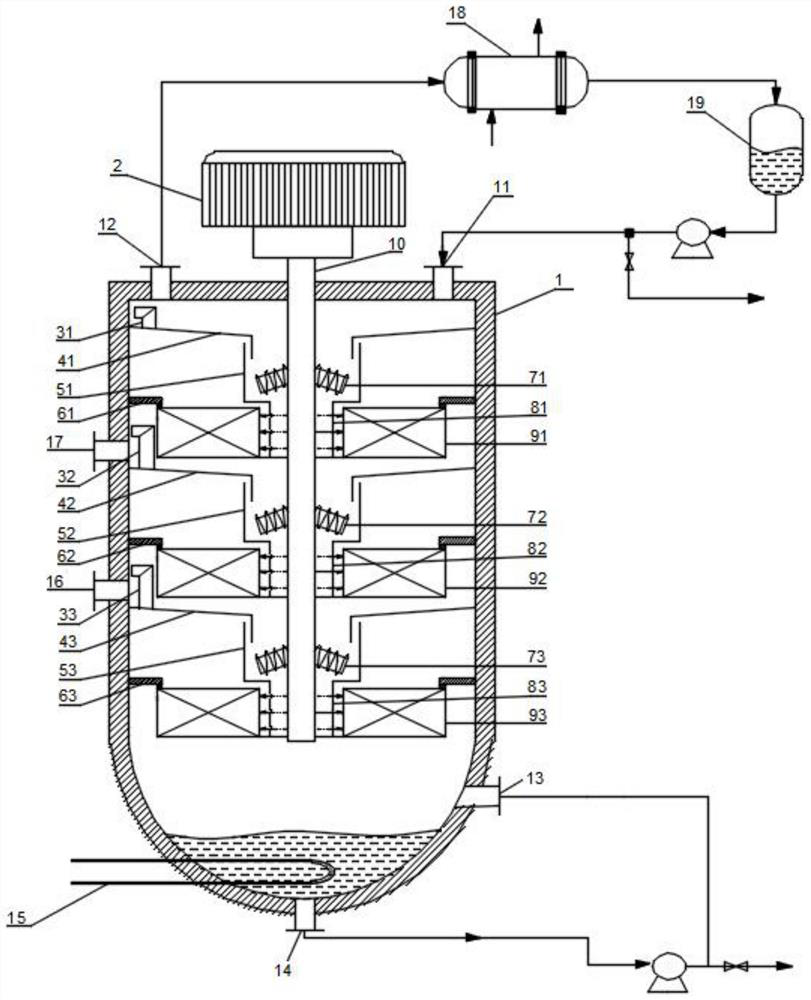

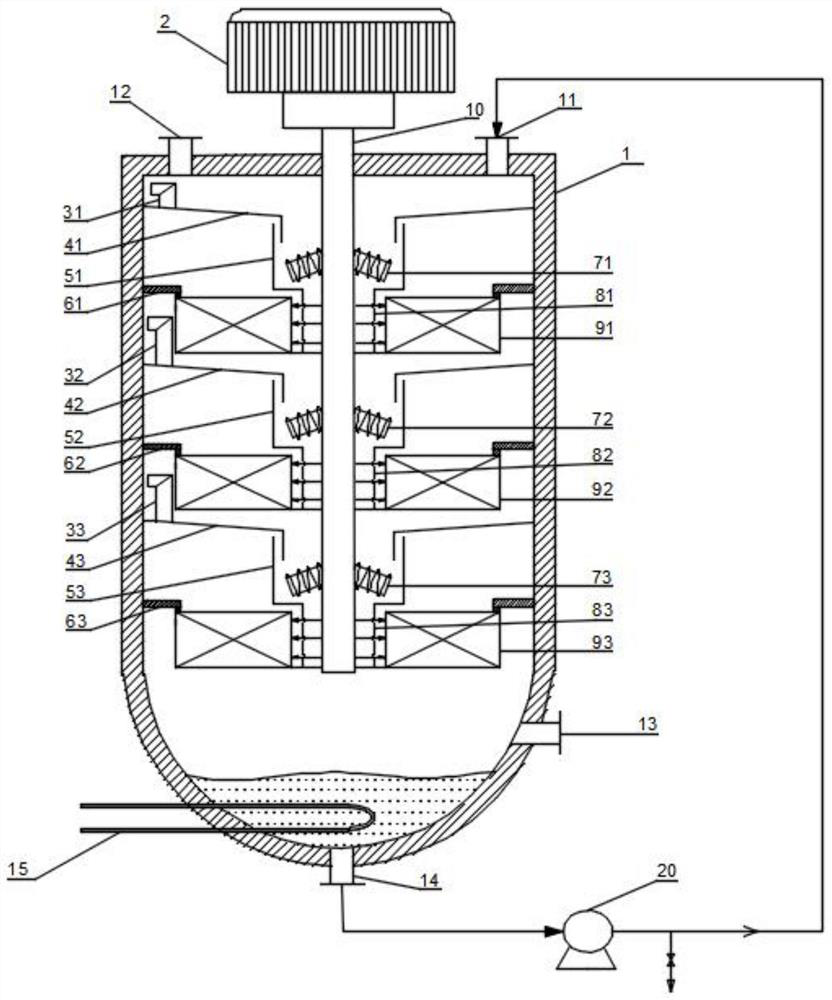

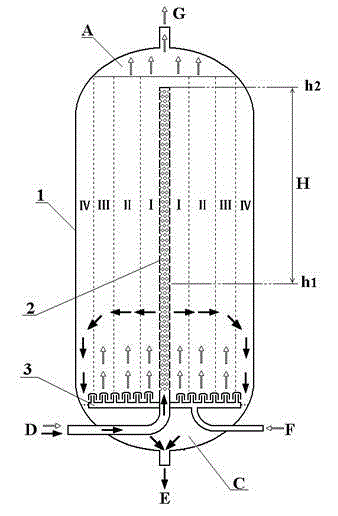

Slurry bubble columun reactor having internal circulation and external heat-exchanging and the application

ActiveCN100512941CAxially distributed evenlyPrevent subsidenceChemical/physical processesLiquid mediumCirculator pump

The invention discloses a slurry bed reaction device with internal circulation and external heat exchange and its application. Comprising a tower-type gas-liquid-solid three-phase slurry bed reactor (12) with a cylindrical shell, a tubular filter (11) vertically arranged in said reactor (12), an orifice gas distributor, a heat exchange device (107) and circulation pump (106). The device of the invention can be used for the reaction of synthesis gas to generate gas or liquid fuel in the presence of catalyst and liquid inert medium. In the present invention, there is an internal gas circulation at the bottom of the reactor, the catalyst is separated on-line inside the reactor, and the fluid carrying effect is used to form internal circulation and external heat exchange inside and outside the reactor, which can effectively prevent the catalyst from settling and promote The catalyst is evenly distributed in the axial direction of the reactor and the temperature distribution in the tower is improved, the space-time yield is high, the reaction heat is conveniently removed, the energy consumption is low, and it is easy to realize large-scale.

Owner:EAST CHINA UNIV OF SCI & TECH

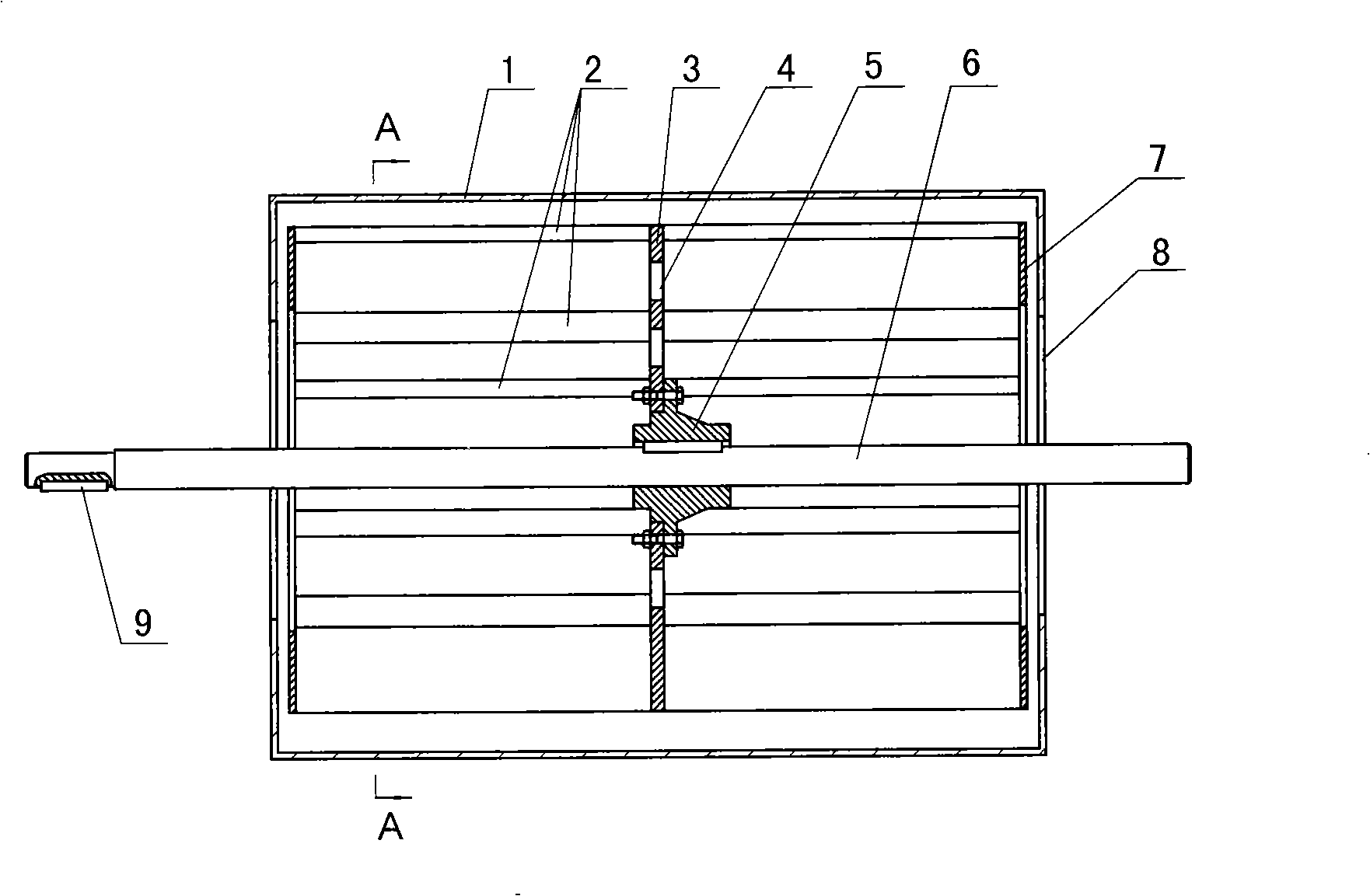

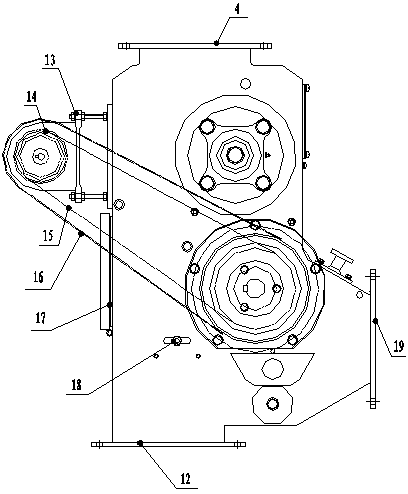

Through-flow double channel blower fan

InactiveCN101285479AWind speed can be adjustedWind pressure can be adjustedPump componentsPump installationsImpellerEngineering

The invention provides a cross flow two-channel blower which comprises a spiral casing provided with a wind inlet, a wind outlet and an impeller assembly; the invention is characterized in that a cross section and an outer port of the wind outlet are of parallelograms; the wind outlet is inside provided with three clapboards for dividing a wind channel into an upper wind channel and a lower wind channel with two adjustable longitudinal sections; the cross section of each wind channel is a parallelogram; the wind channel positioned on the upper part is blocked with a cambered sieve vertical tothe wind channel; the sieve is positioned in the middle of the wind channel; the arc length of the sieve is 1 / 2 to 2 / 3 of the width of the wind channel; the circle center of the sieve is positioned on one side of the sieve near the outer end of the wind outlet; the upper end of the sieve is fixedly connected with the first clapboard; two sides of the sieve wind on a guide pole vertical to the first clapboard; the lower end of the sieve is inserted into a cambered groove on the second clapboard arranged for the sieve; and the lengths of the three clapboards are less than the distance between the outer end of the wind outlet and an volute angle of the wind outlet. The blower can adjust the wind speed and wind pressure of the two wind channel outlets and has uniform airflow distribution and good working performance.

Owner:SHANDONG UNIV OF TECH +1

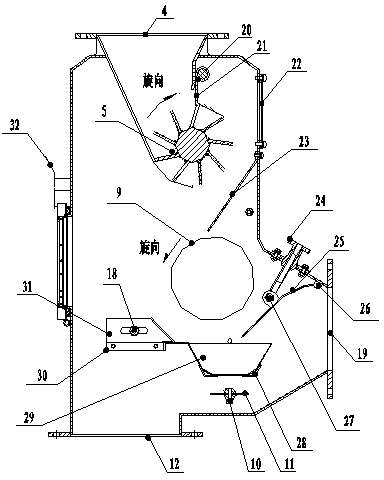

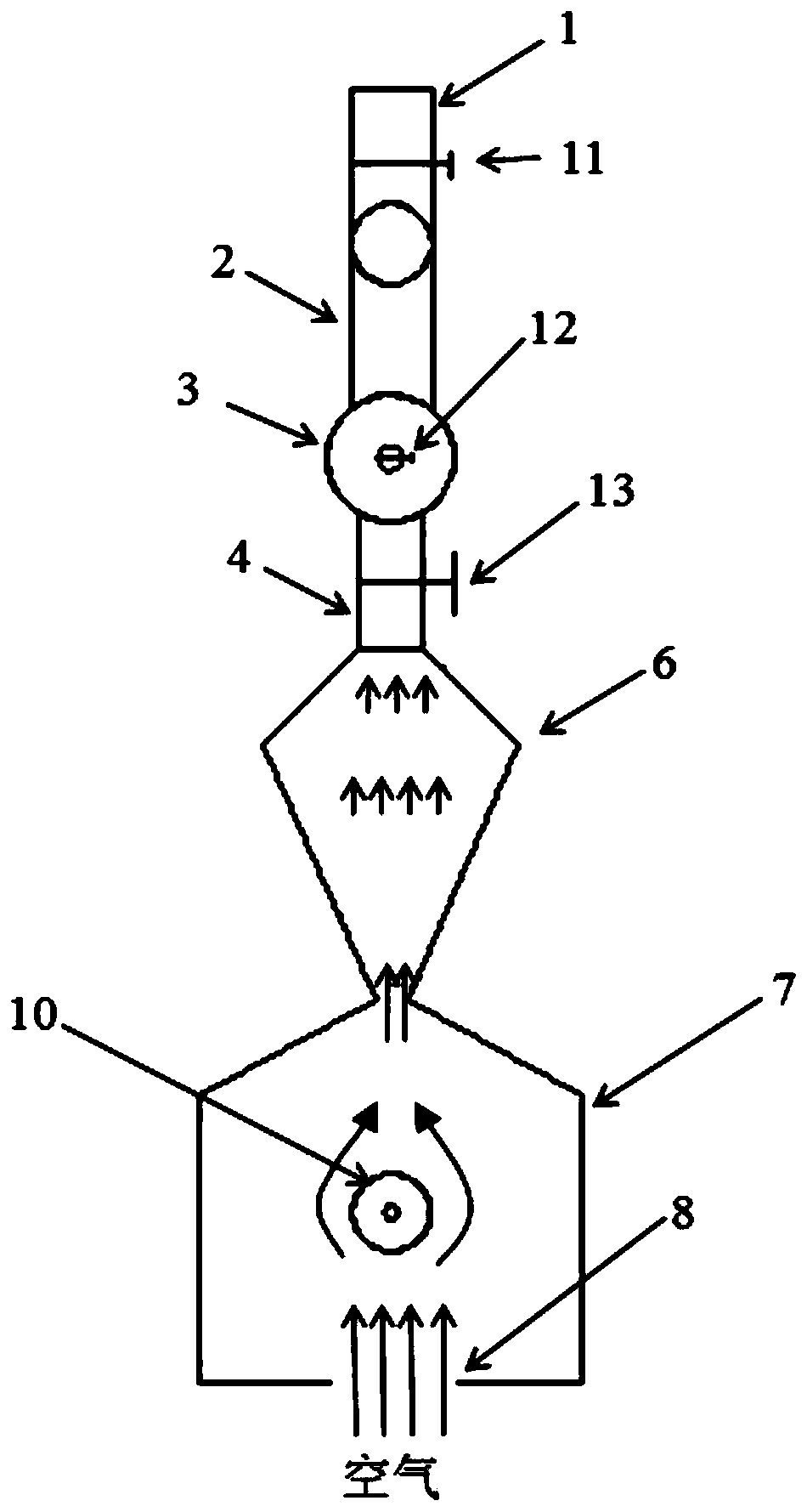

Integrated feeder

ActiveCN103861715AEfficient removalAxially distributed evenlyGas current separationMagnetic separationAir volumeEngineering

The invention relates to a feeding device used for screening and conveying a material by utilizing gravity flow, and in particular relates to an integrated feeder. The integrated feeder comprises a shell, and a feeding hole and a discharge hole which are arranged on the shell, wherein the shell is internally provided with a feed roller, a magnetic separation roller and a stone remover; the magnetic separation roller is arranged under the feed roller; a slide carriage is arranged between the magnetic separation roller and the feed roller; the stone remover is arranged under the magnetic separation roller; an air inlet is arranged on the side wall of the shell corresponding to the stone remover; the side wall of the shell is provided with an upper air volume adjustment plate at the inner side of the air inlet; a junk drawer is arranged between the stone remover and the air inlet; and the lower part of the junk drawer is provided with a lower air volume adjustment plate. After the integrated feeder is adopted, iron and steel impurities can be effectively removed; the stone remover is matched with the function of the airflow of the air inlet, so that the impurities with the specific gravity heavier than that of material can be separated from the material; the air speed for separating the material and the impurities can be obtained by the adjustment of air volume adjustment plates, so that the different impurities can be conveniently removed.

Owner:TANGSHAN CITY FENGNAN DISTRICT SHUANGYI FEED MACHINERY CO LTD

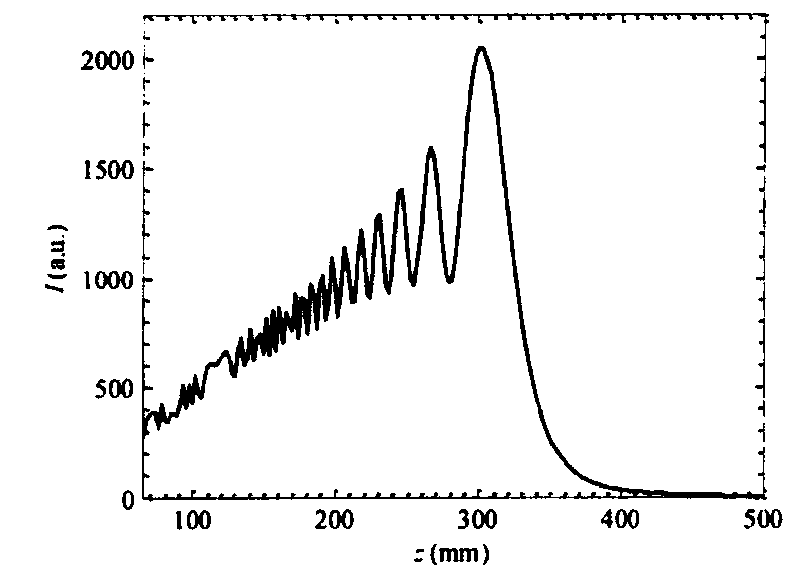

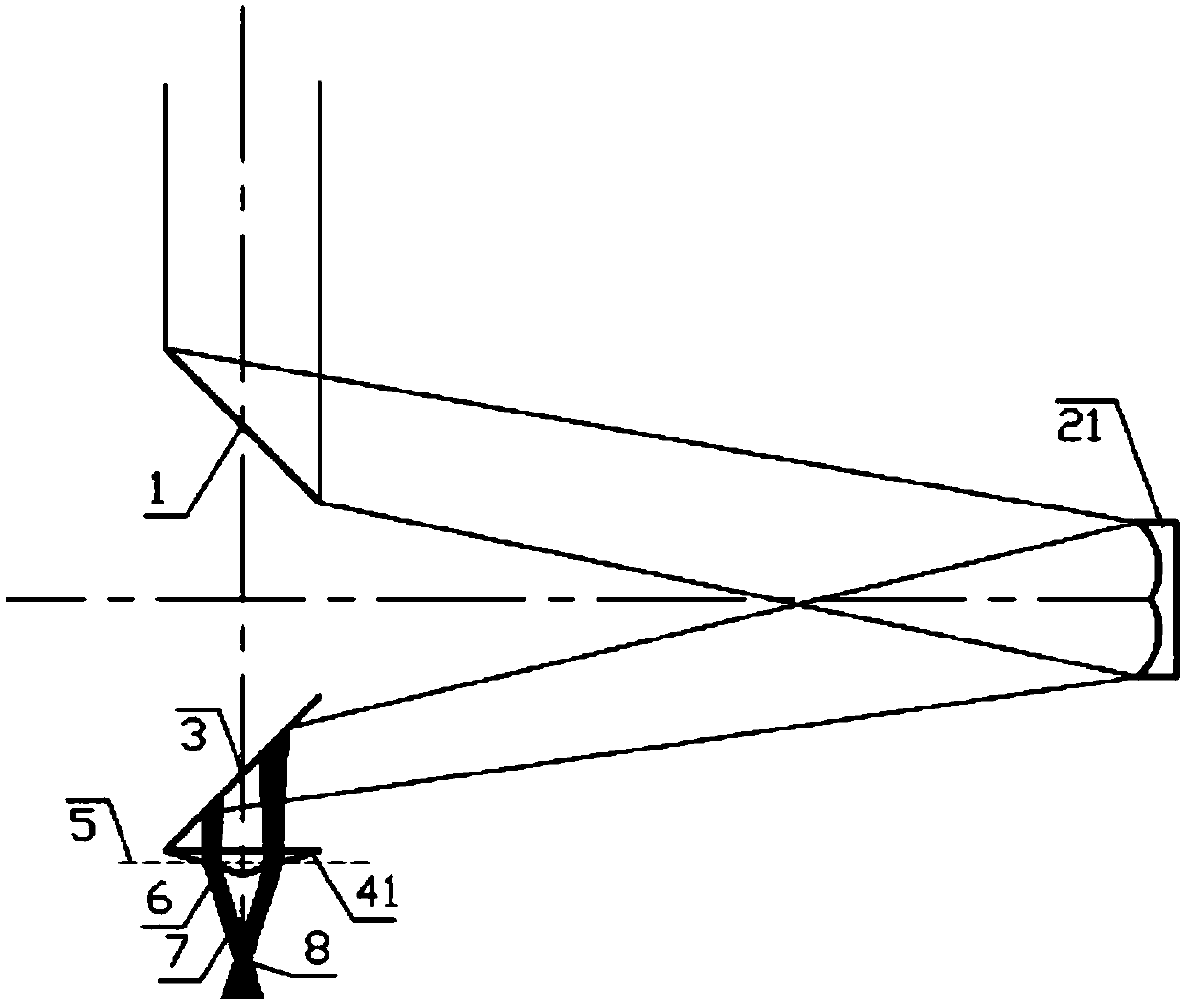

Split type laser focusing device

PendingCN109676246AAxially distributed evenlyImprove energy utilizationLaser beam welding apparatusLight beamOptoelectronics

The invention relates to a split type laser focusing device. The split type laser focusing device comprises a first reflecting mirror, a second reflecting mirror, a third reflecting mirror and an output focusing mirror, wherein the reflecting surface of the first reflecting mirror and the reflecting surface of the third reflecting mirror are planes; the reflecting surface of the second reflectingmirror is a ring-shaped circular-arc-shaped concave surface or an equivalent Fresnel surface; the output focusing mirror is equipped with a tapered surface; the first reflecting mirror is used for receiving and reflecting an incoming laser beam to the second reflecting mirror; emergent light of the first reflecting mirror comes into the second reflecting mirror with a small angle; the second reflecting mirror is used for receiving emergent light of the first reflecting mirror and reflecting the emergent light to the third reflecting mirror; the third reflecting mirror is used for receiving emergent light of the second reflecting mirror and reflecting the emergent light to the output focusing mirror; and the output focusing mirror is used for receiving emergent light of the third reflectingmirror, and is emitted by the tapered surface of the output focusing mirror, so that a similar bessel beam is formed. The split type laser focusing device is high in energy utilization rate; and thecenter spot size and light intensity of the output similar bessel beam are basically unchanged within a position focusing range on the axis of the output focusing mirror.

Owner:江苏先河激光研究院有限公司 +1

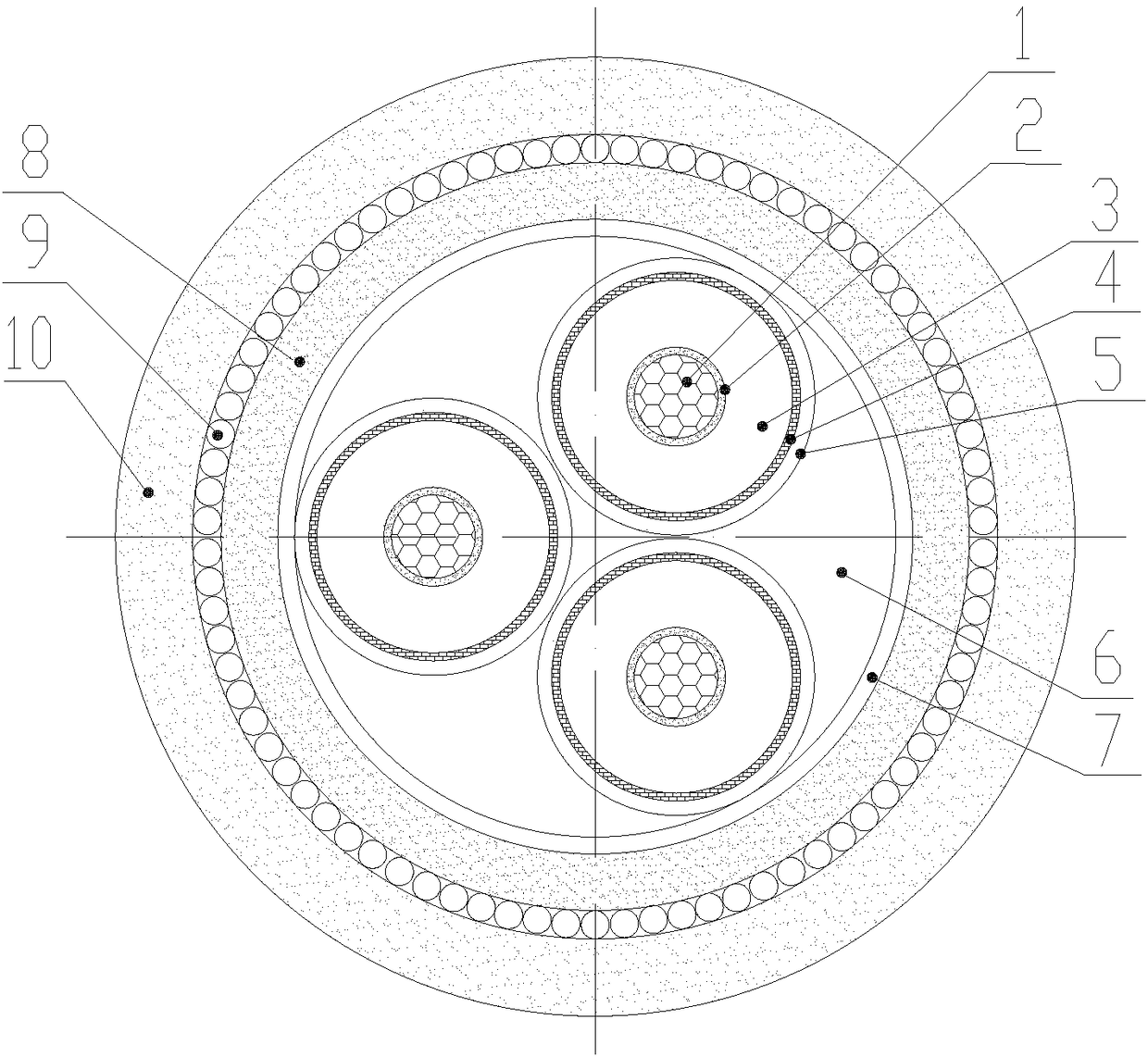

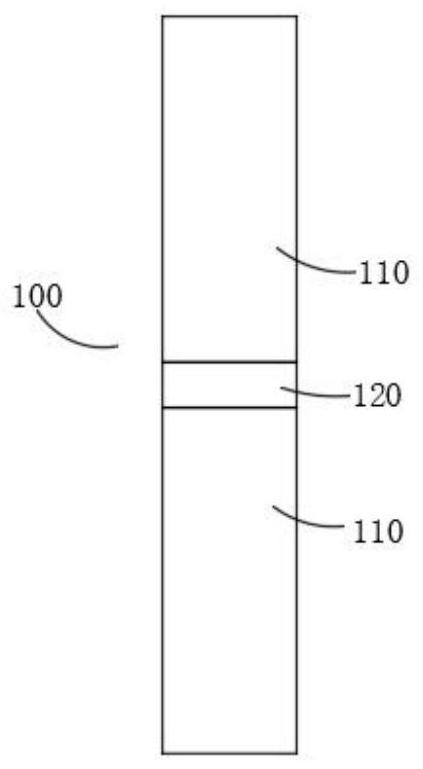

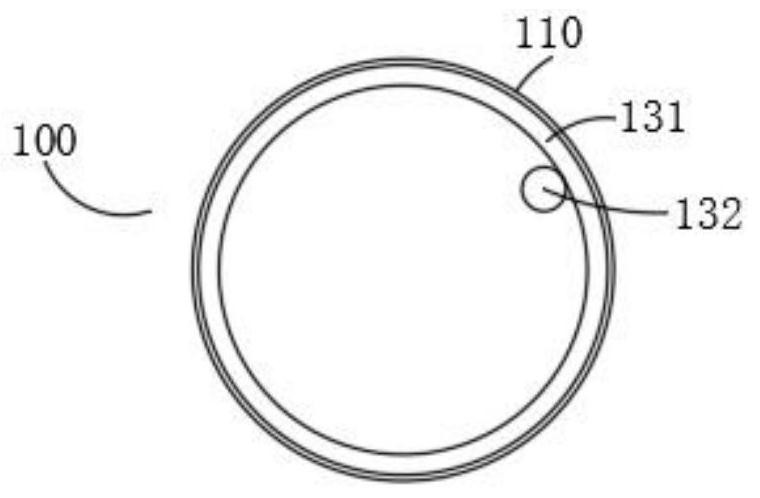

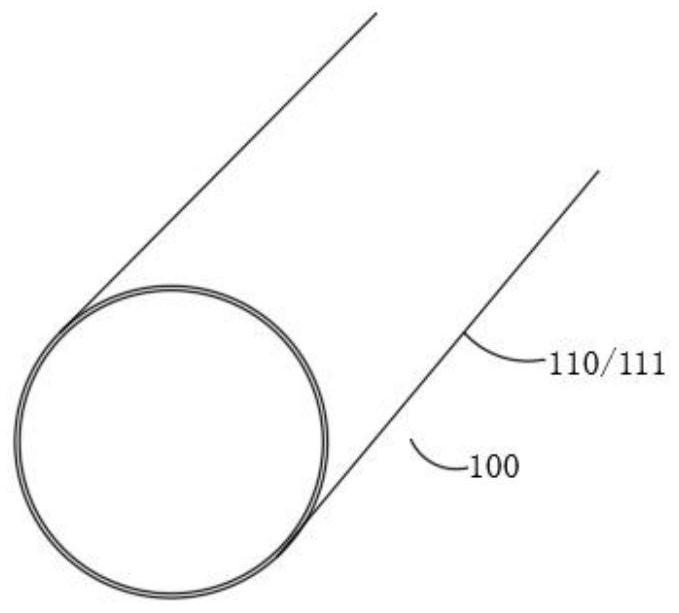

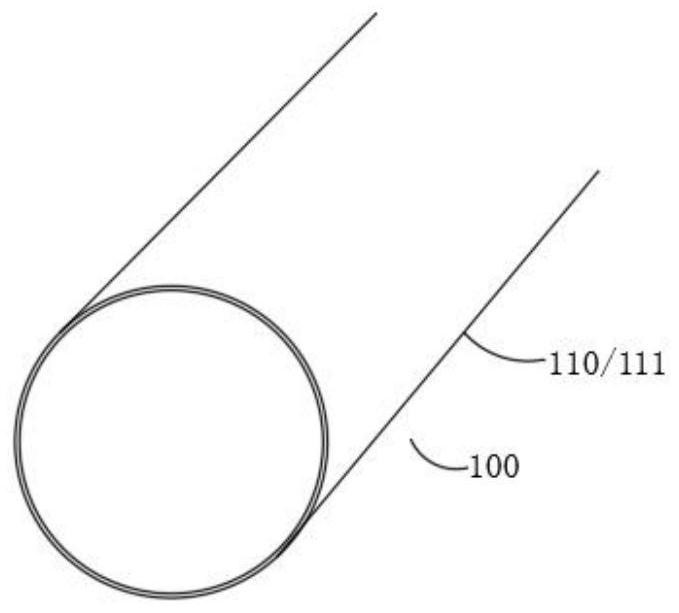

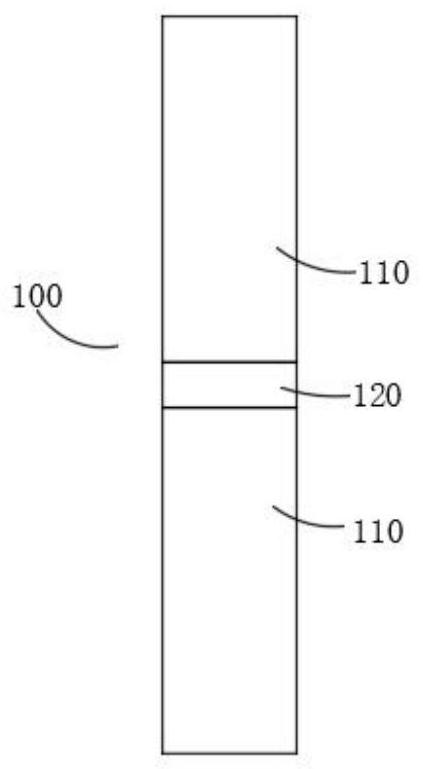

High-roundness cross-linked core medium-voltage power cable and manufacturing method thereof

InactiveCN108091442AImprove insulation roundnessExtended service lifePower cables with screens/conductive layersInsulated cablesCross-linkInsulation layer

The invention discloses a high-roundness cross-linked core medium-voltage power cable and a manufacturing method thereof. The cable is characterized in that three strands of conductive wire bodies arecovered through a polypropylene filling strip at a core part, a shape with a cross section of a round structure is formed, a thickened band is arranged outside the polypropylene filling strip, an inner sheath is arranged outside the band, a steel wire armor is arranged outside the inner sheath, and an outer sheath is arranged outside the steel wire armor. Starting from the entire manufacturing process of the cable, the roundness of conductors is controlled in a conductor production stage, the roundness of the cable is improved by adjusting material, temperature and other process requirementsof a cross-linked polyethylene insulation layer in an extrusion process, a long vulcanization pipe heating mode is designed, a large catenary vertical angle mode is set, a molecular chain structure ischanged to control a drip phenomenon, and the strong guarantee for the high roundness of the entire product is achieved through modes of conductor pre-heating and the like. Under the condition of ensuring basic use of the product, the insulation and roundness of the cable are improved, and thus the service life of the cable is improved.

Owner:HANGZHOU CABLE

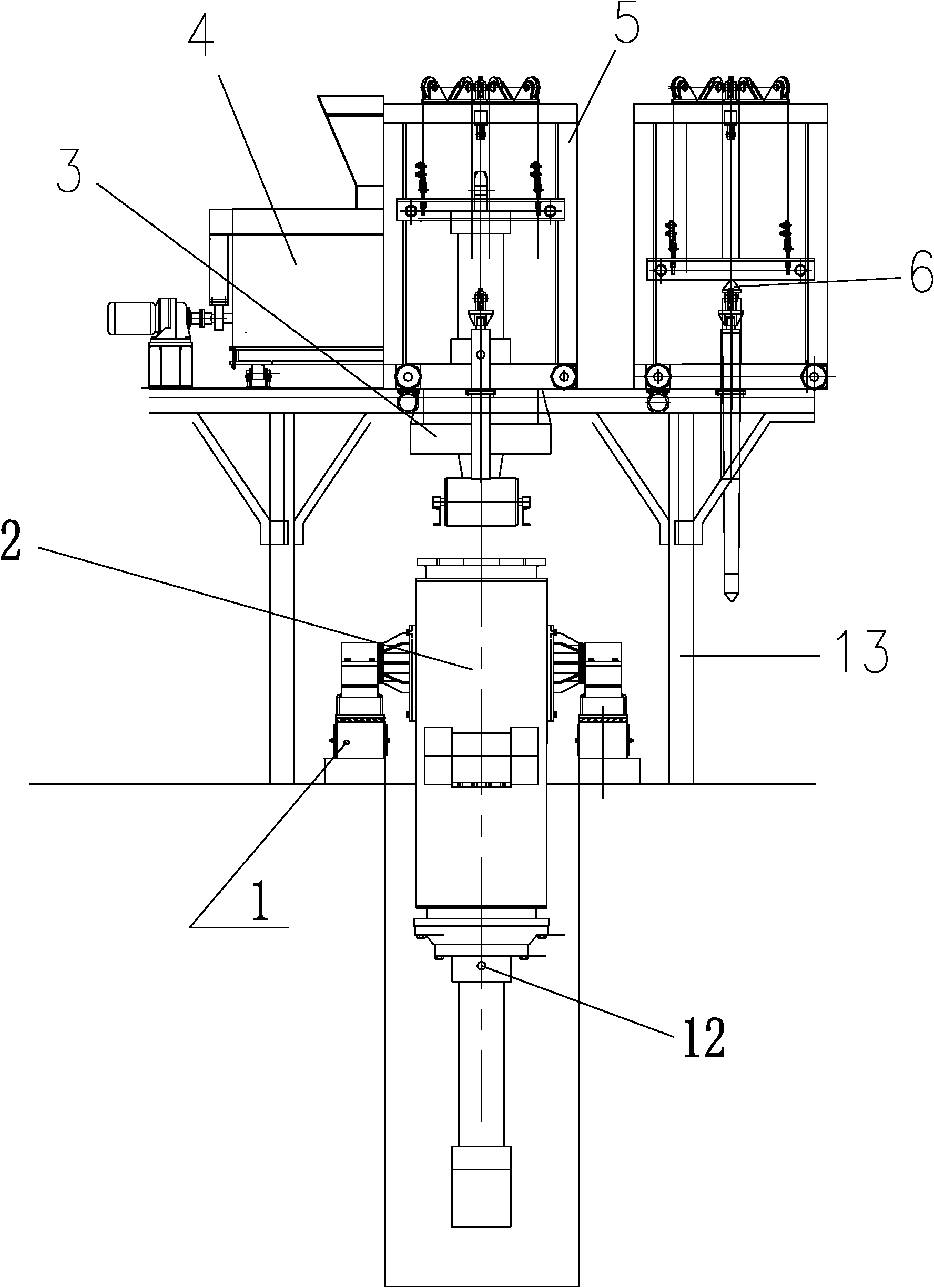

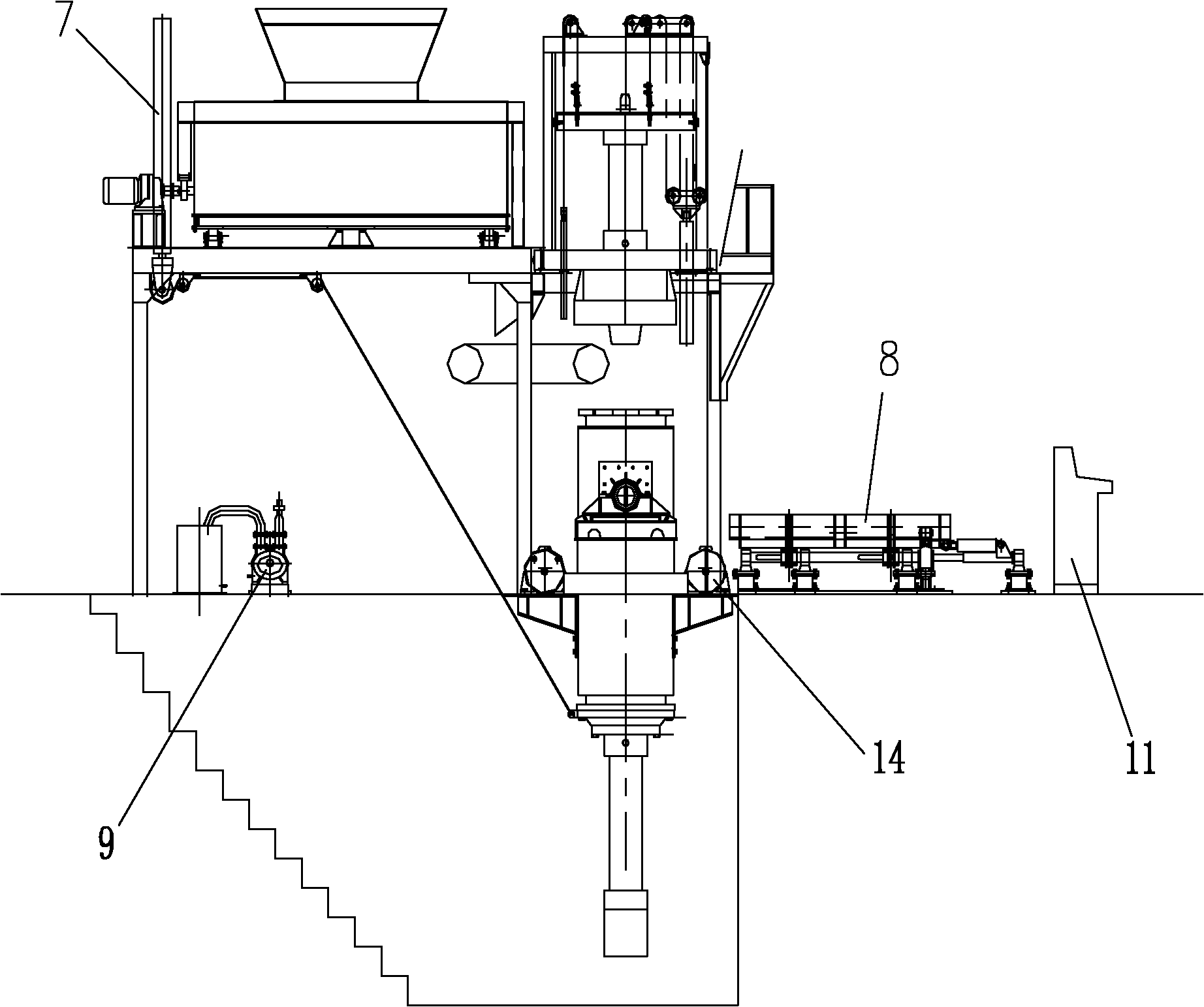

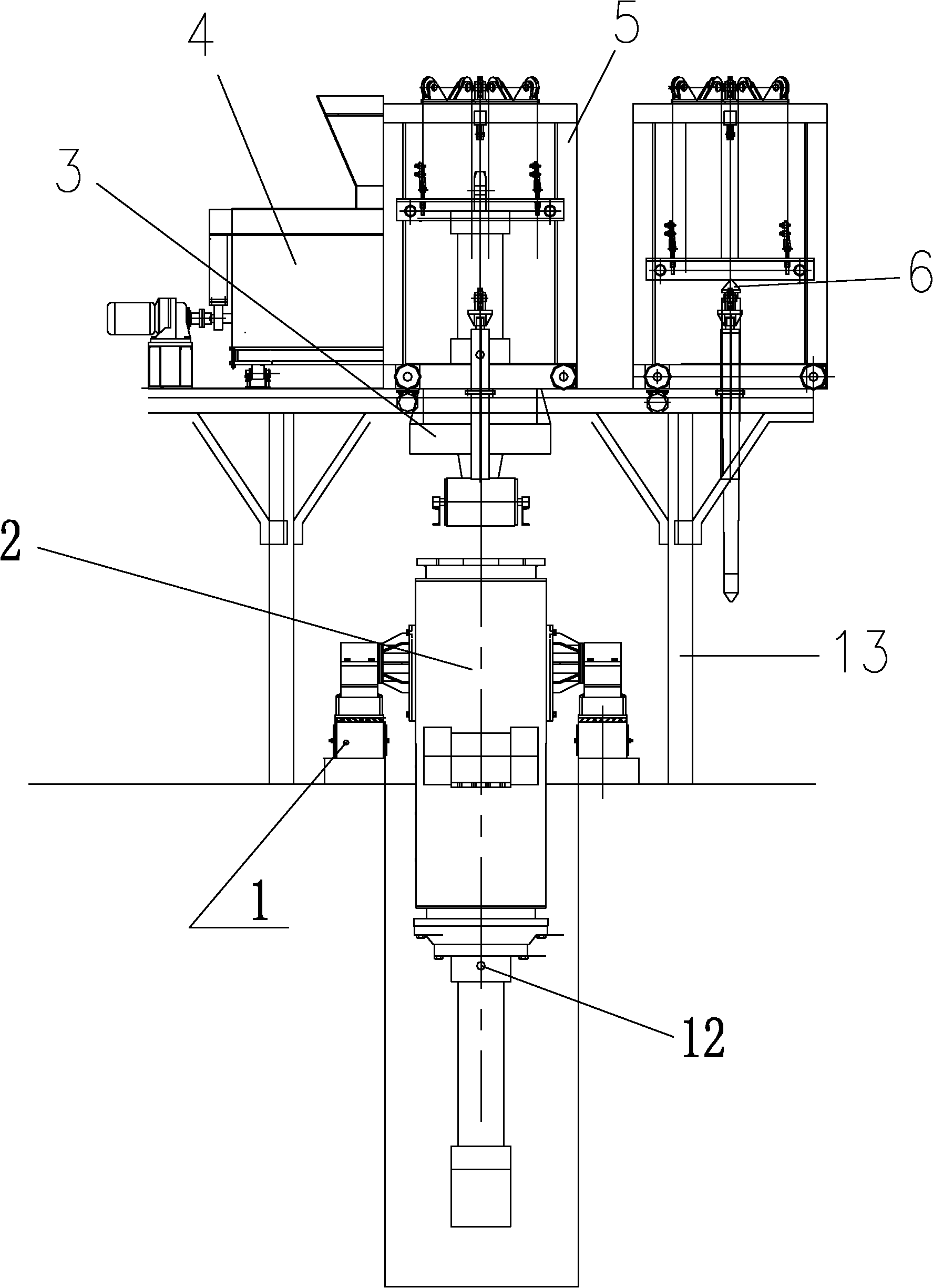

Graphite electrode molding machine

InactiveCN102248582AAchieve vacuumAvoid inner fissureCeramic shaping apparatusGraphite electrodeMolding machine

The invention provides a graphite electrode molding machine, relating to a press machine using a press head. A graphite electrode of the graphite electrode molding machine has a dimension of phi 820-1400 mm. The graphite electrode molding machine is provided with an electrode trolley, a vacuum system, a hydraulic system, an electric control system, a frame, a rubber spring stand, a mold, an upper press head, a material cooling system, an upper trolley, a core column and a central frame, a turnover mechanism, a lower press head and a vibrating motor. A rotating shaft of the mold is arranged on the rubber spring stand; a paste outlet of the material cooling system is connected with the mold by a belt machine; the upper press head and the lower press head are connected with the mold; the upper trolley is arranged on a track of the frame; the upper press head as well as the core column and the central frame are arranged on the upper trolley; the vibrating motor is used as a vibration source and arranged on the two sides of the mold; the vibrating motor is arranged in the middle of the graphite electrode; connecting teeth are arranged on both the upper press head and the mold; the upper press head is connected with the mold after rotating for 15 degrees; the lower press head is fixedly mounted at the lower part of the mold; and the turnover mechanism is connected with the material cooling system.

Owner:福建兴朝阳硅材料股份有限公司

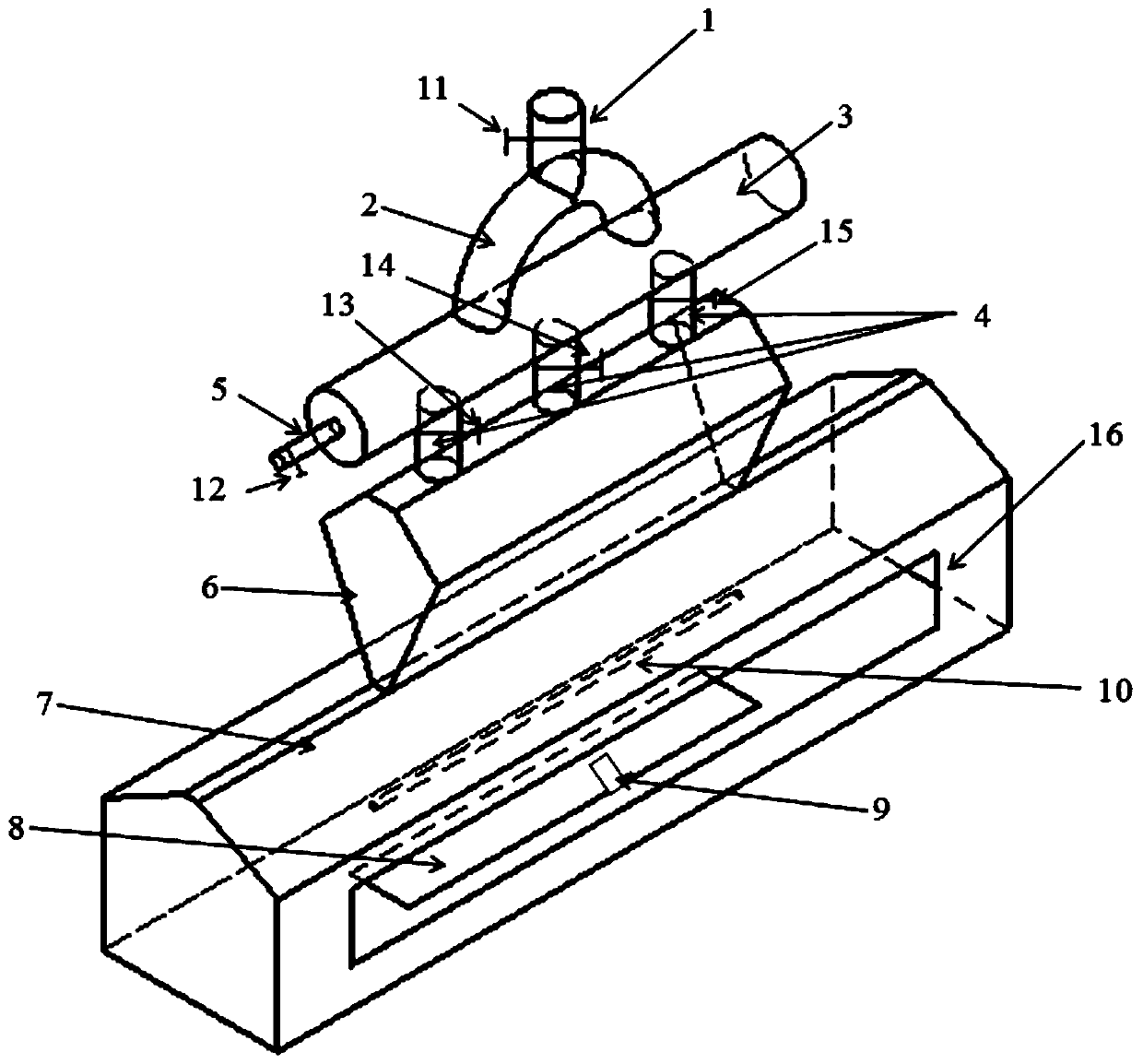

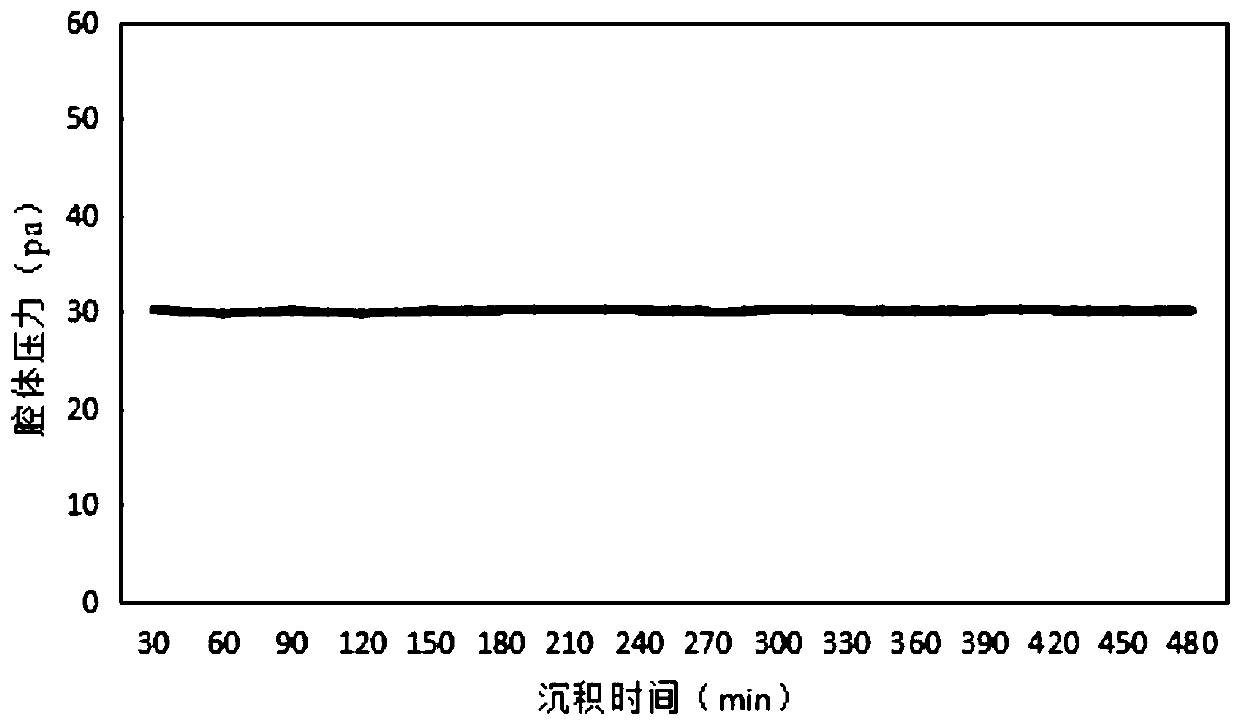

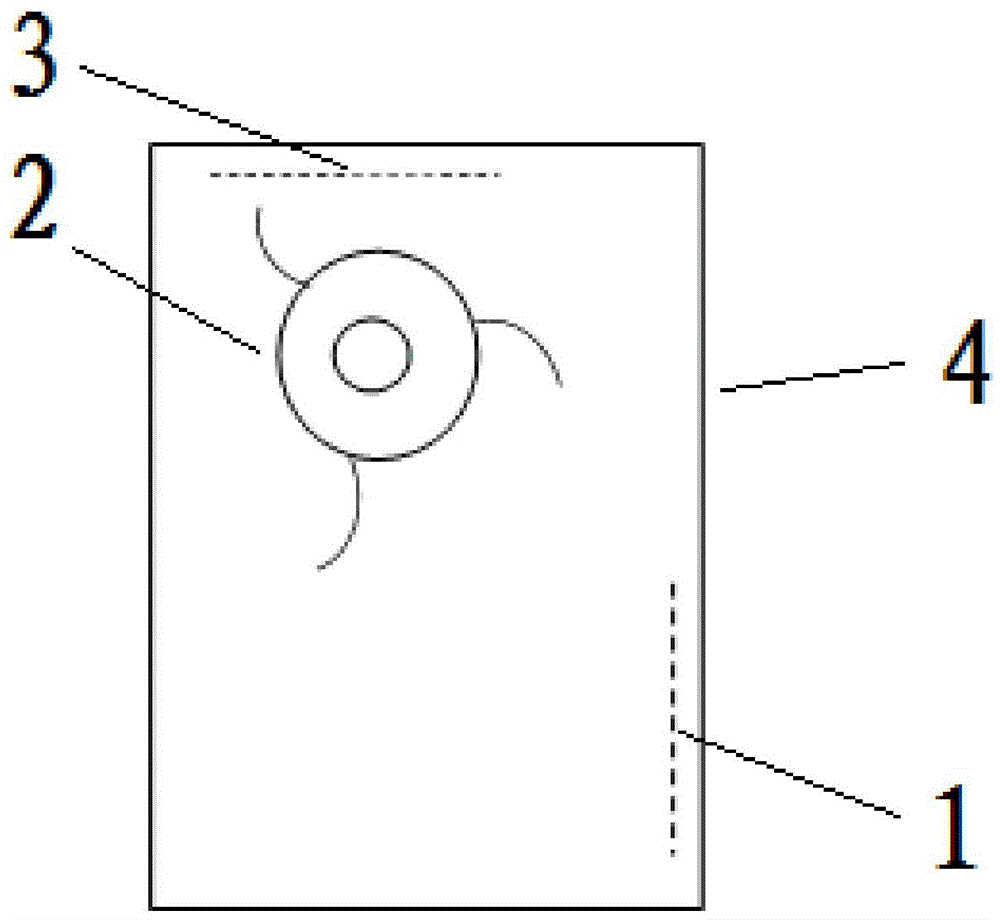

OVD deposition cavity device for preparing optical fiber preform

ActiveCN110963696AUniform suction pressureAxially distributed evenlyGlass making apparatusGlass productionEngineeringExhaust pipe

The invention relates to an OVD deposition cavity device for preparing an optical fiber preform. The device comprises an exhaust pipe, a first-stage buffer chamber, a second-stage buffer chamber and adeposition chamber, wherein the exhaust pipe, the first-stage buffer chamber, the second-stage buffer chamber and the deposition chamber are sequentially arranged from top to bottom, a wind inlet isformed in the bottom of the deposition chamber, a deposition core rod and a deposition blow lamp are arranged in the deposition chamber, the deposition chamber is in a house shape, the upper portion of the deposition chamber is trapezoidal, the lower portion of the deposition chamber is square, the top of the deposition chamber is in butt joint with the slit of the second-stage buffer chamber, thelower portion of the second-stage buffer chamber is inverted trapezoidal, the first-stage buffer chamber is in a circular tube shape, a wind supplementing pipe is arranged on the end surface of the first-stage buffer chamber, a wind supplementing valve is arranged on the wind supplementing pipe and used for adjusting the opening and closing size of the wind supplementing pipe, the first-stage buffer chamber is vertically communicated with the second-stage buffer chamber through a plurality of second-stage branch pipes distributed side by side in the axial direction, and the exhaust pipe is communicated with the first-stage buffer chamber through two arc-shaped pipes in a bilateral symmetry manner. According to the invention, the distribution uniformity of the gas flow in the deposition chamber along the axial direction of the deposition core rod is improved, the air pressure in the deposition chamber is stabilized, the wrapping area of the flame of the blow lamp on the deposition corerod is increased, and the collection rate of SiO2 powder is increased.

Owner:JIANGSU FASTEN PHOTONICS +2

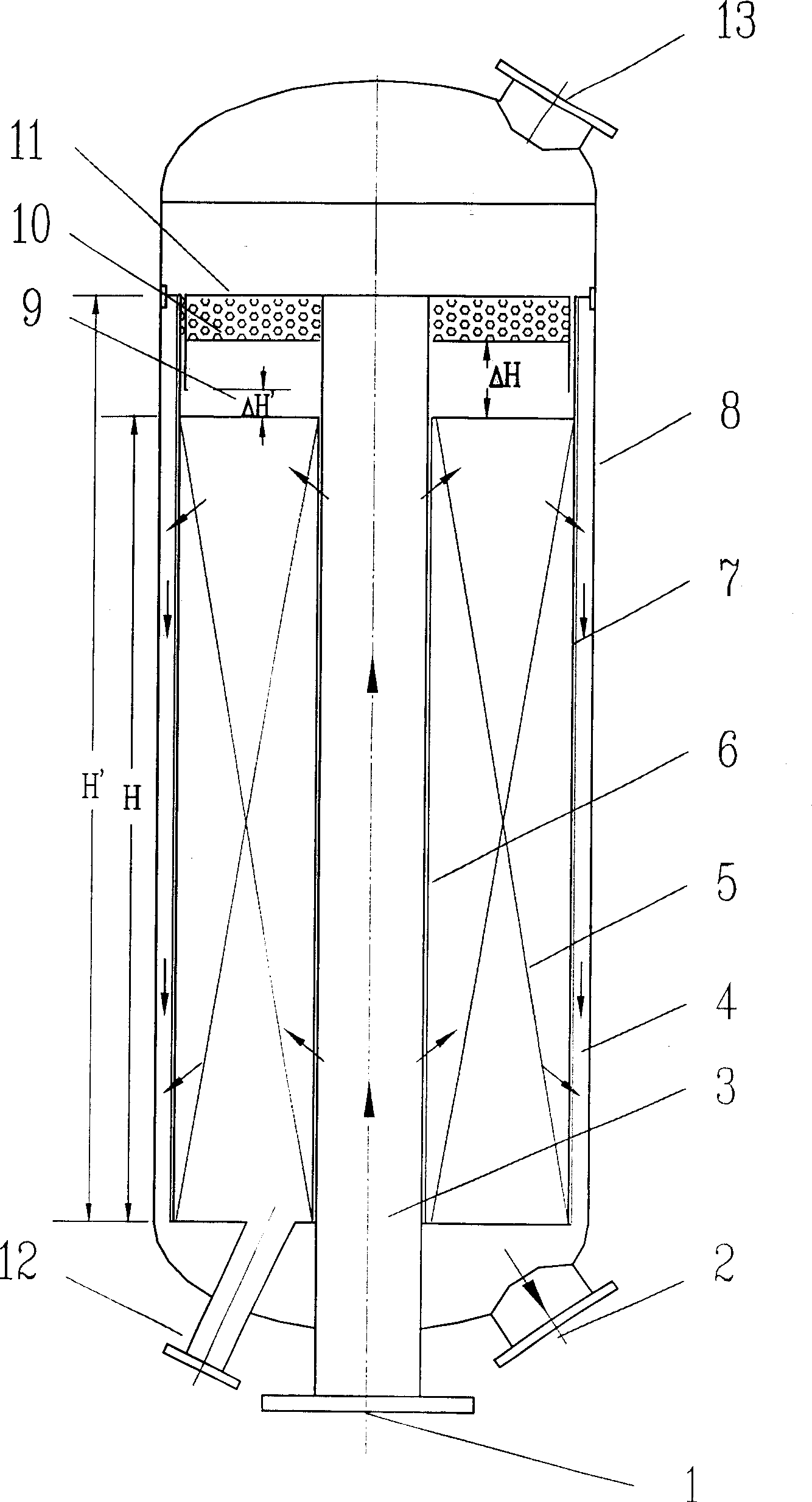

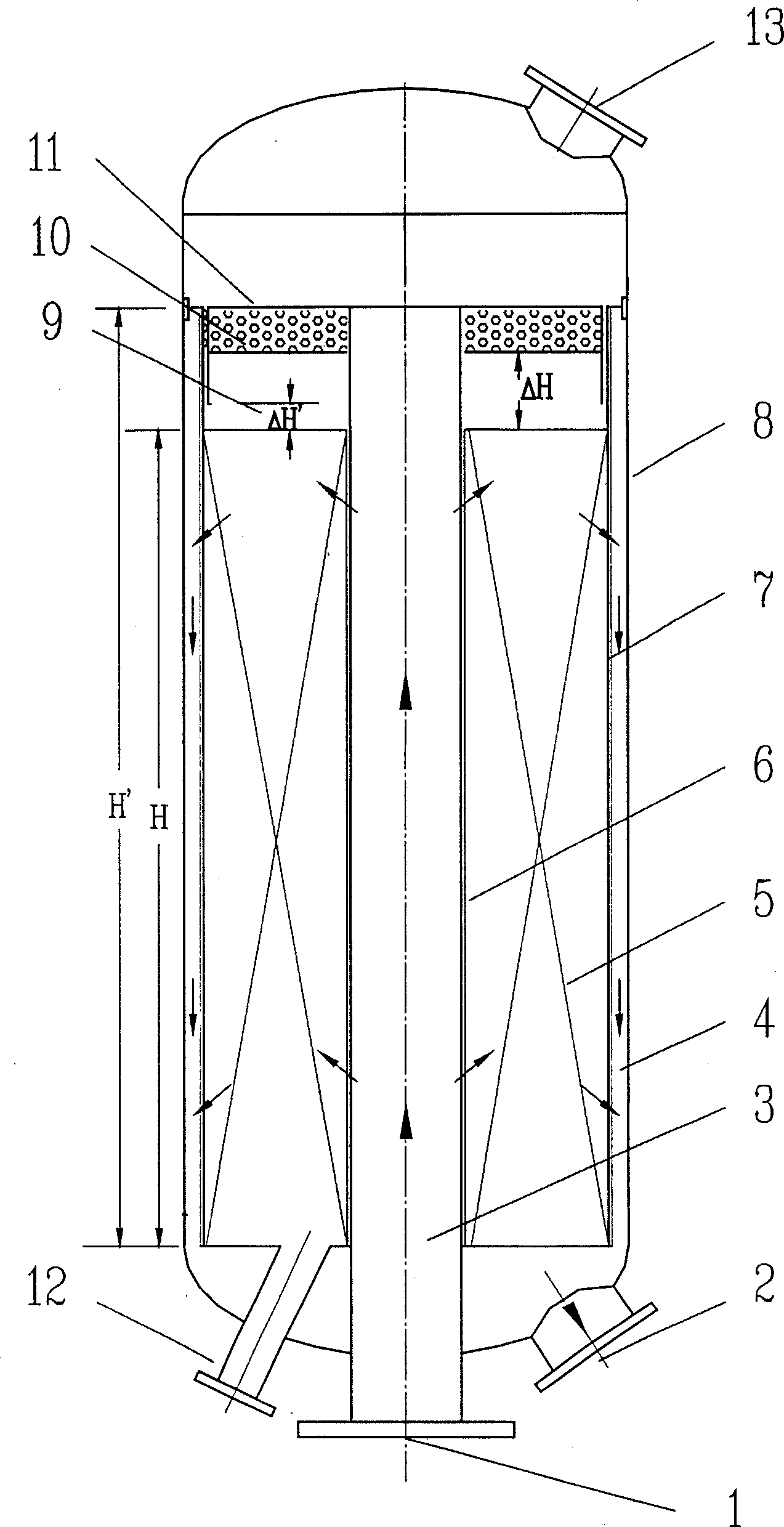

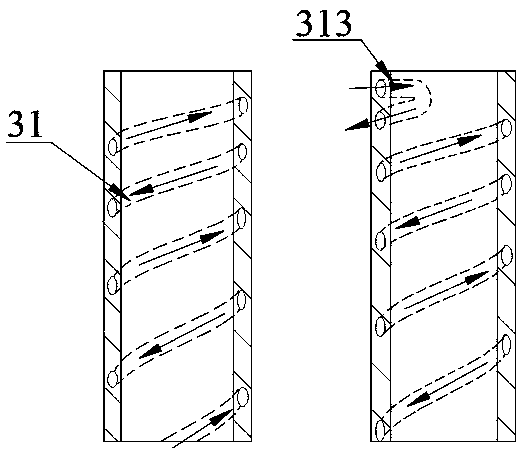

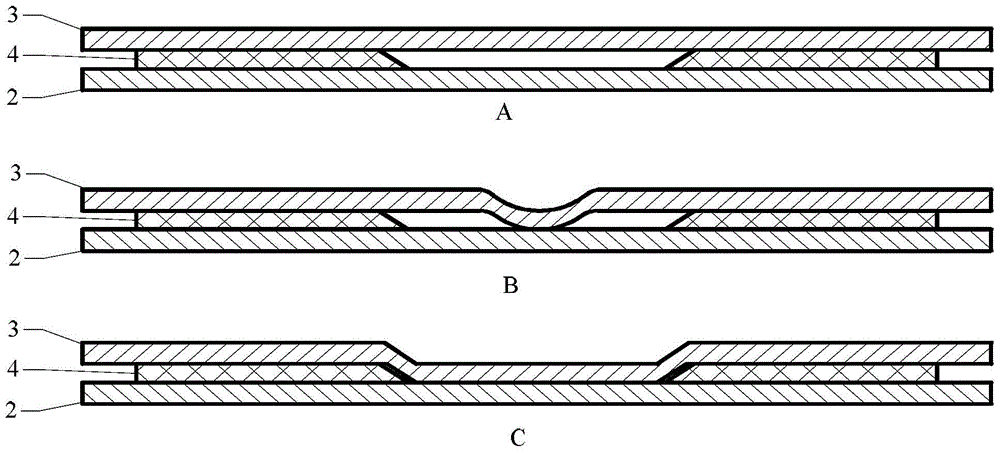

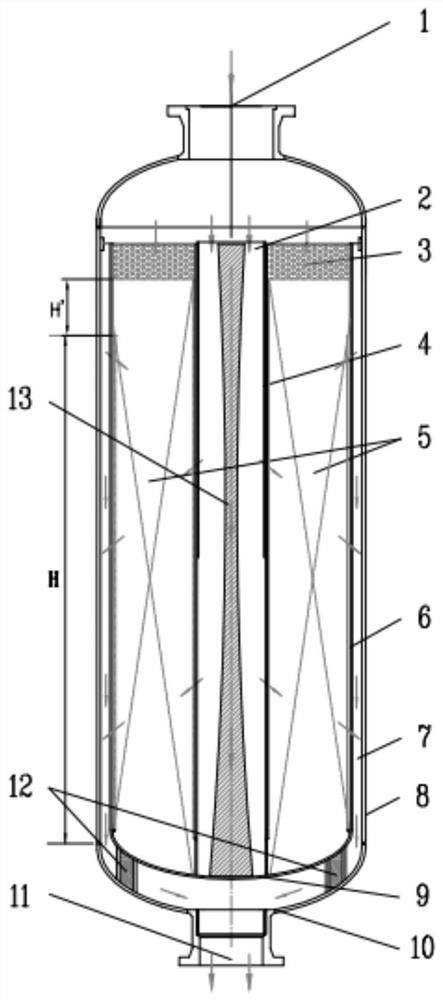

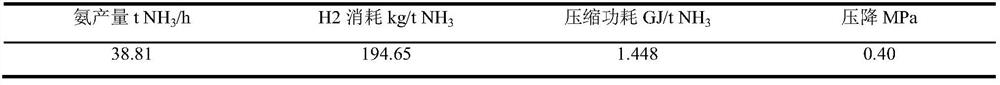

Low-pressure-drop Z-type radial centrifugal flow fixed bed reactor

ActiveCN110871046AOvercoming the Effects of Pressure ChangesSmall pressure dropChemical/physical processesFixed bedEngineering

The invention provides a low-pressure-drop Z-type radial centrifugal flow fixed bed reactor which includes: a cylindrical pressure container, an inner cylinder, an outer cylinder, and a catalyst bed,wherein the inner cylinder, the outer cylinder and the cylindrical pressure container are arranged coaxially. An interlayer is formed between the outer wall surface of the inner cylinder and inner wall surface of the outer cylinder. The catalyst bed is formed by enclosing a lower support seal, the inner cylinder and the outer cylinder; the lower support seal is arranged in the cylindrical pressurecontainer and located on the bottom of same. The inner cylinder is communicated with a gas inlet to form a bypass path of reaction gas. A reaction gas collection flow path is formed between the outerwall surface of the outer cylinder and the inner wall surface of the cylindrical pressure container and is connected to the gas outlet. The bypass path is a diameter-variable flow path. The whole inner cylinder is provided with pores while a part of the outer cylinder is provided with pores. The reaction gas flows from the inner cylinder to the exterior radially via the bypass path and passes through the catalyst bed, then flows into the collection flow path and flows out of the fixed bed reactor through the outer cylinder. In the reactor, the flowing path of the reaction gas is Z-like in shape.

Owner:PETROCHINA CO LTD

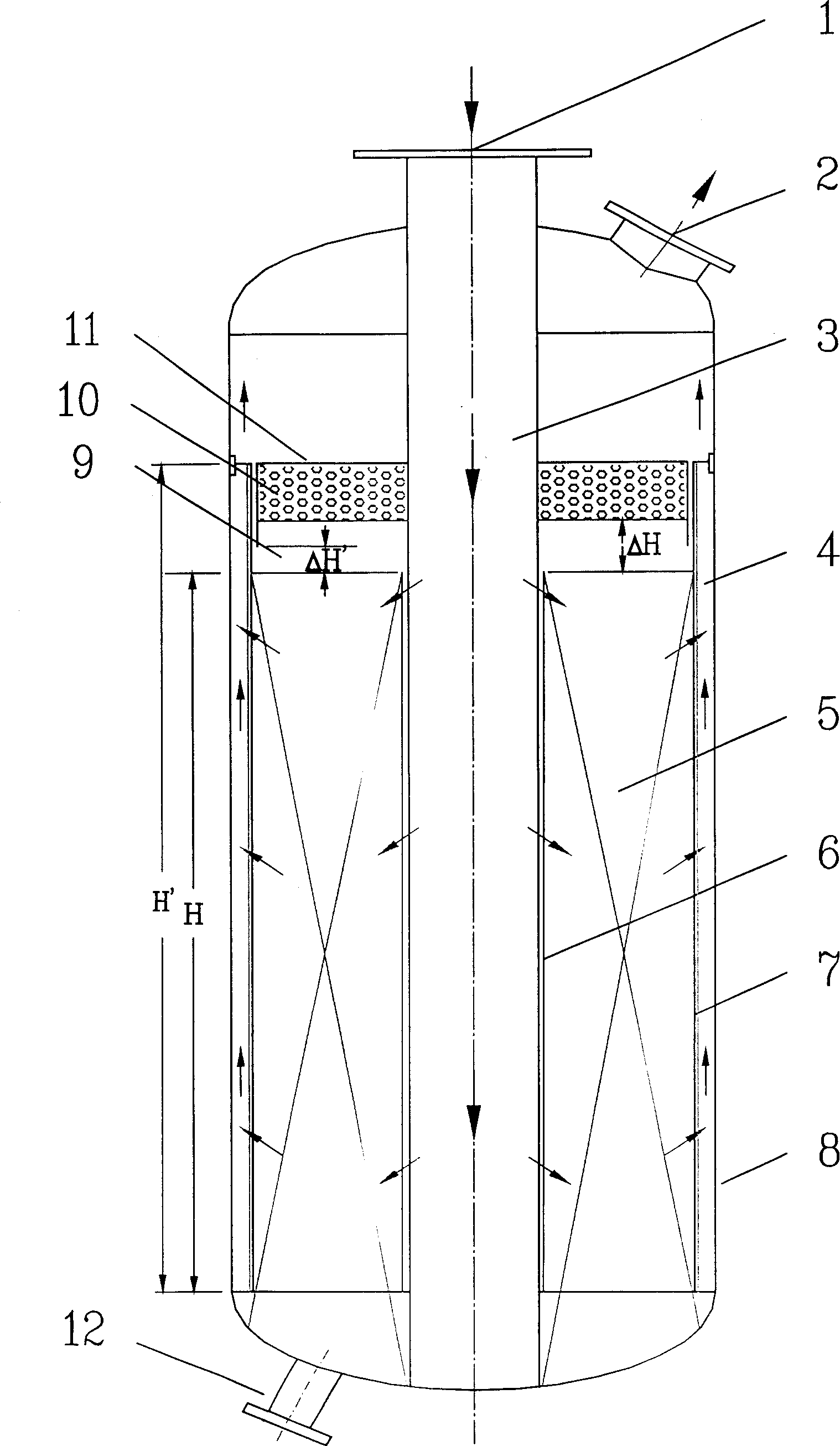

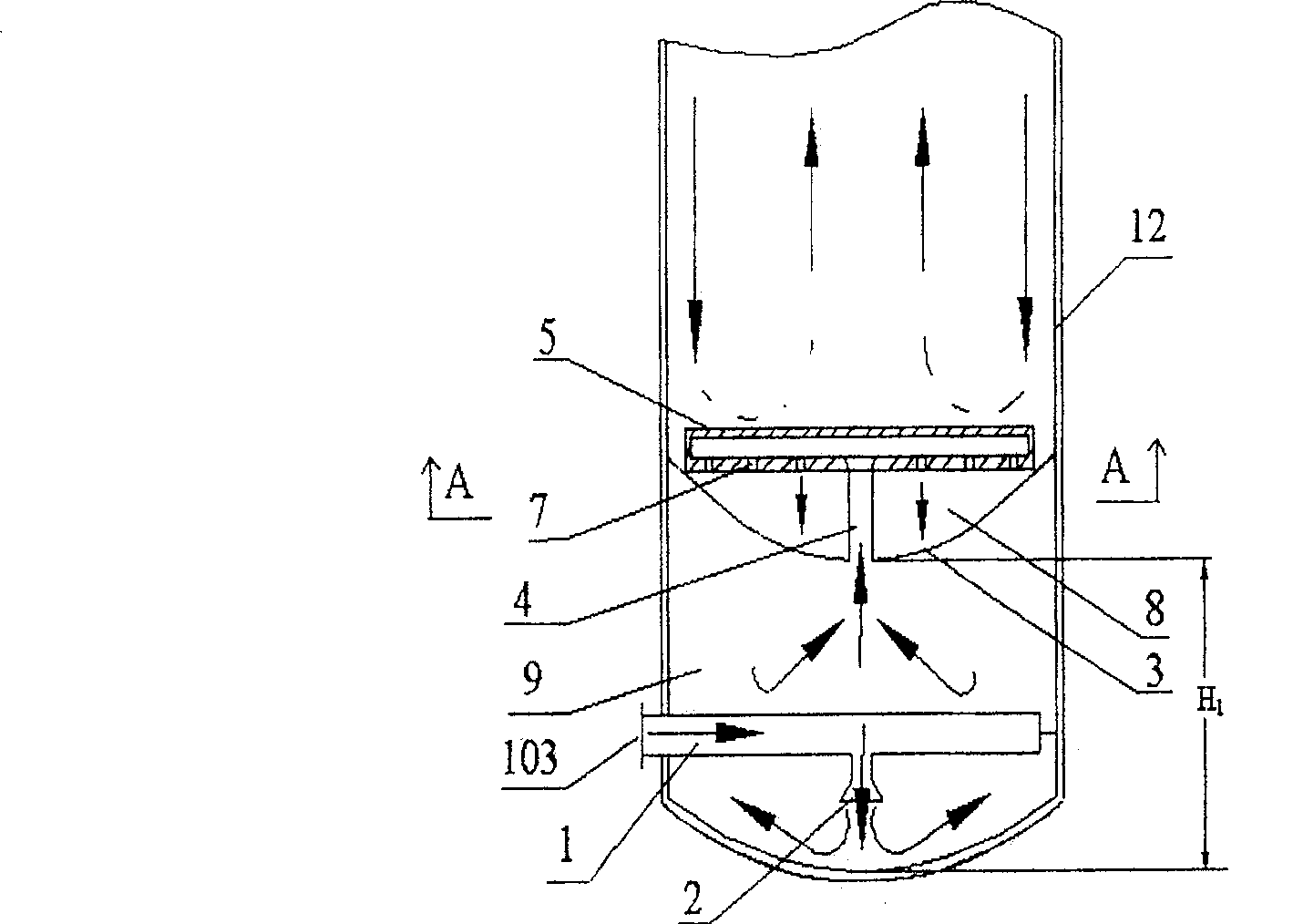

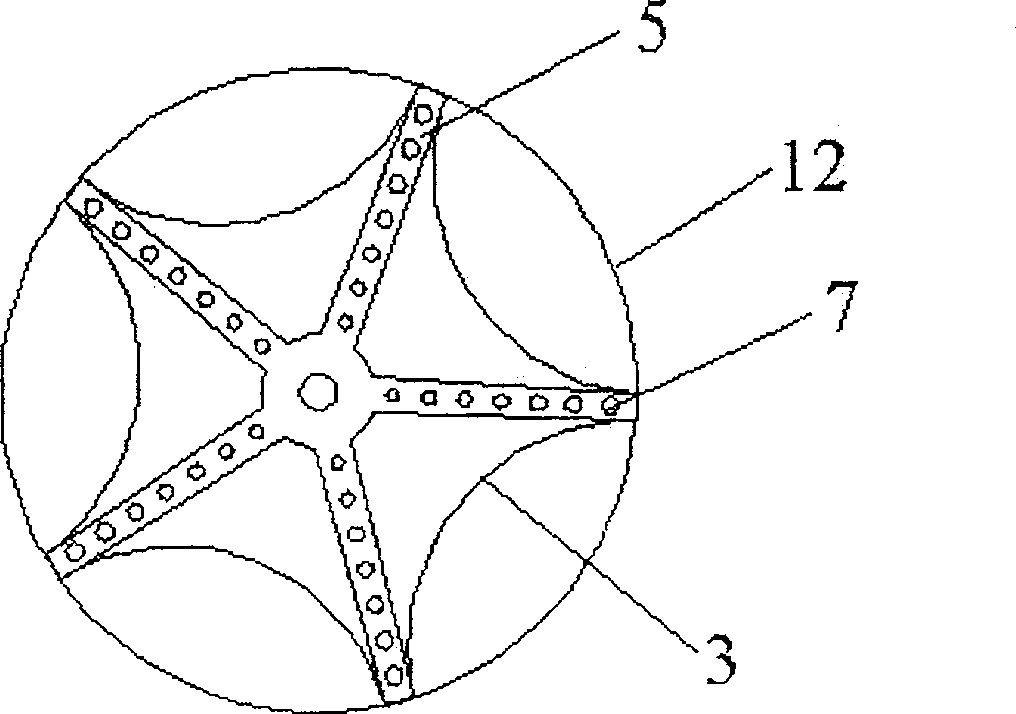

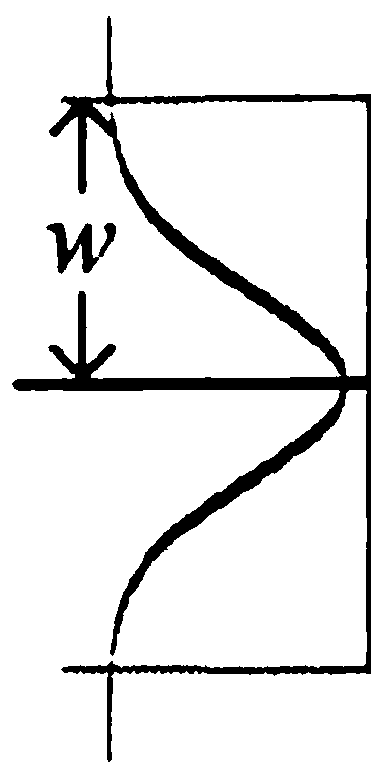

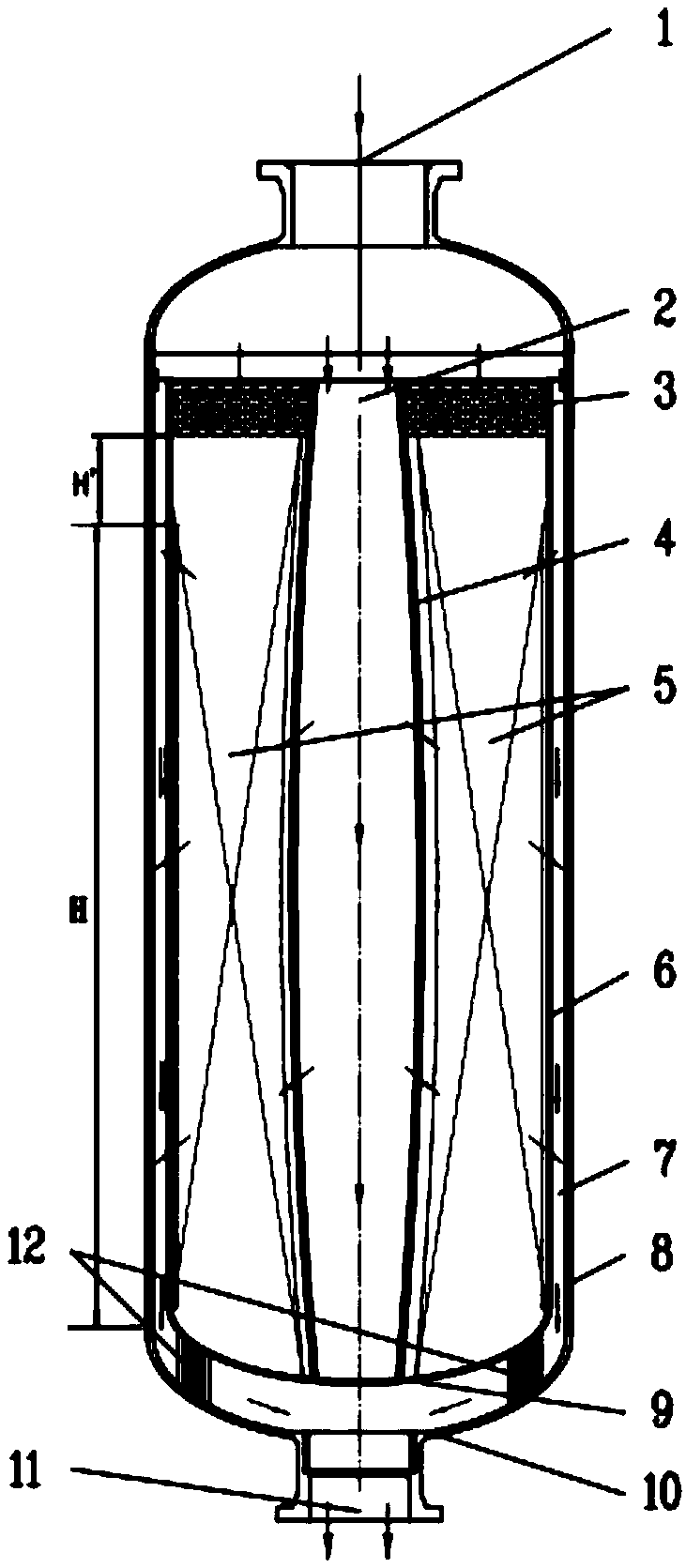

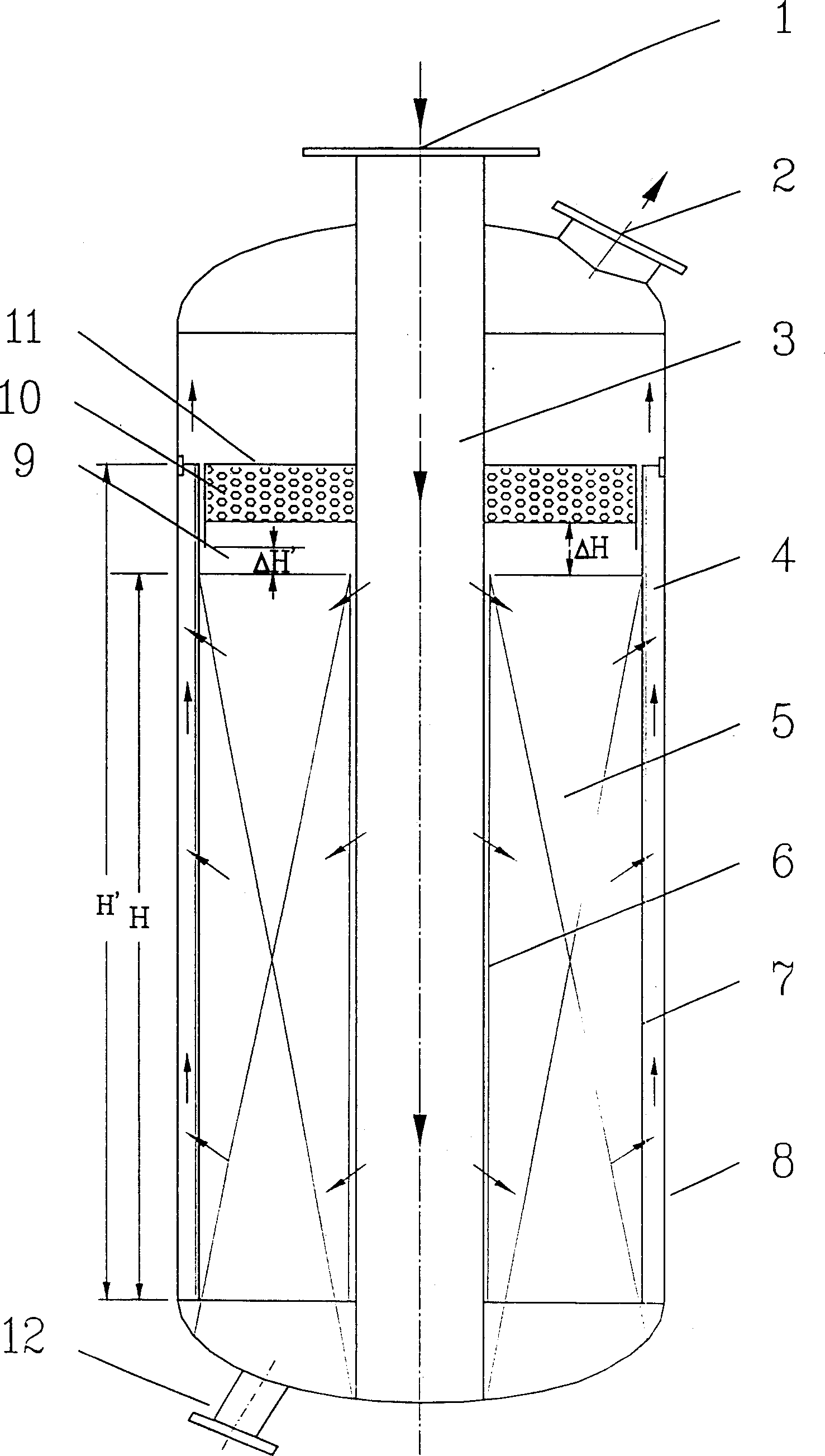

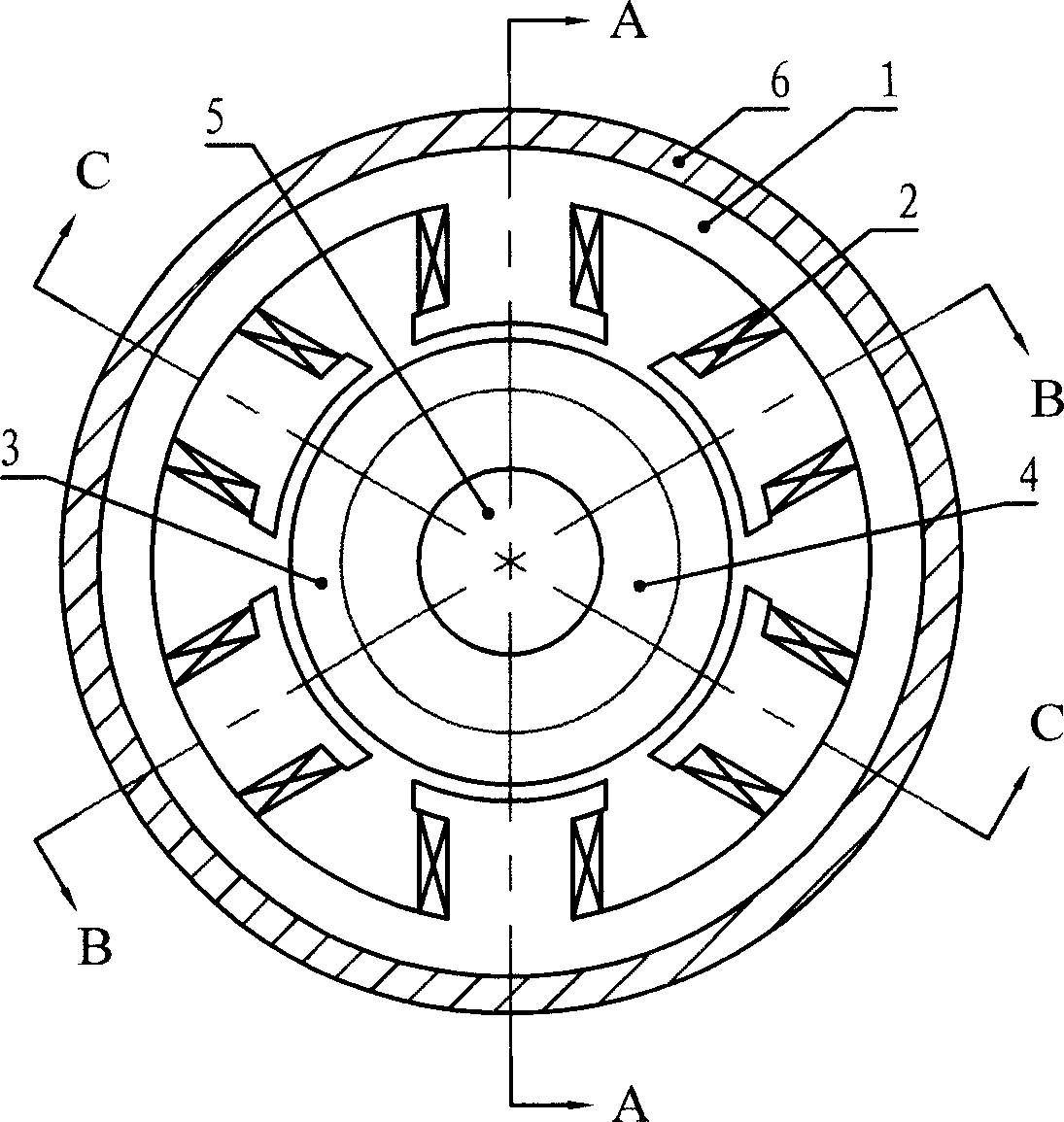

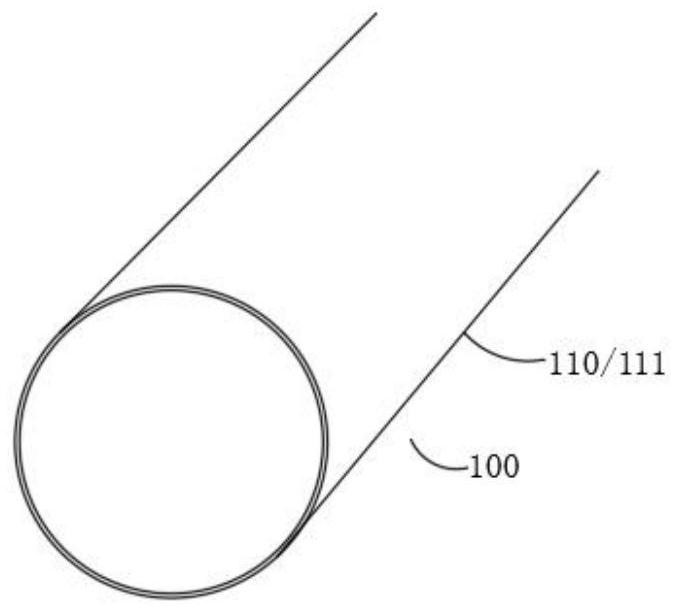

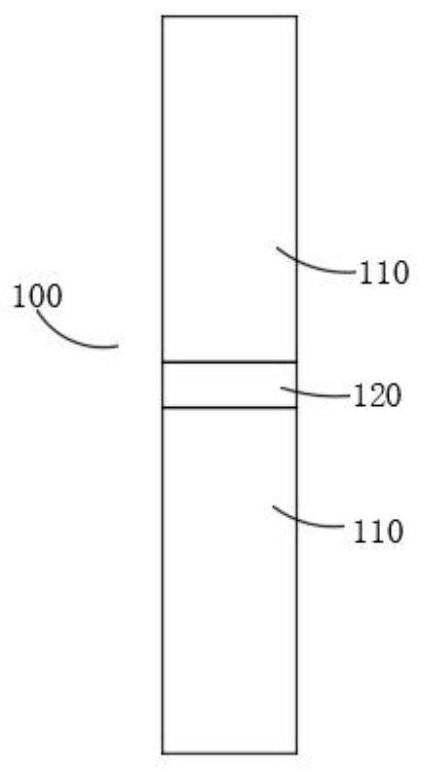

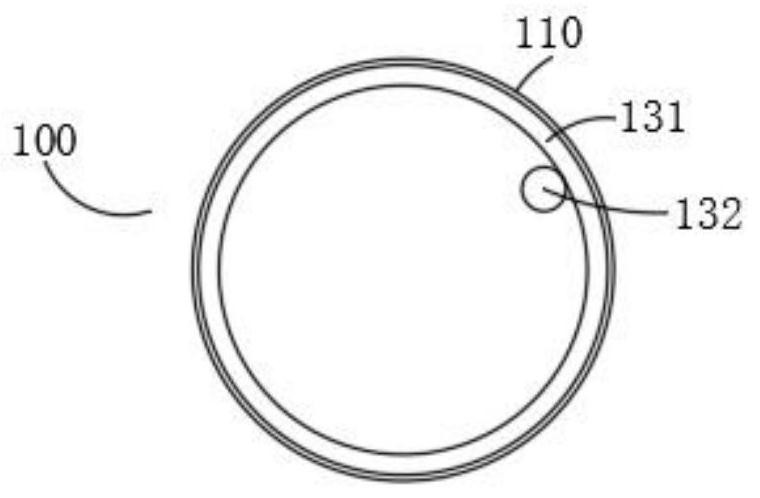

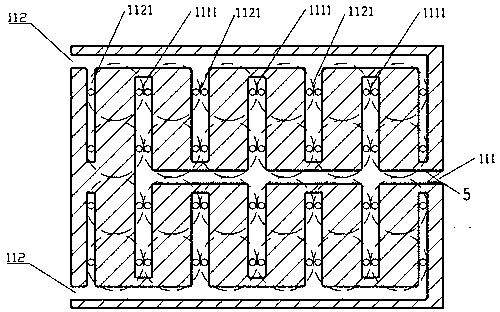

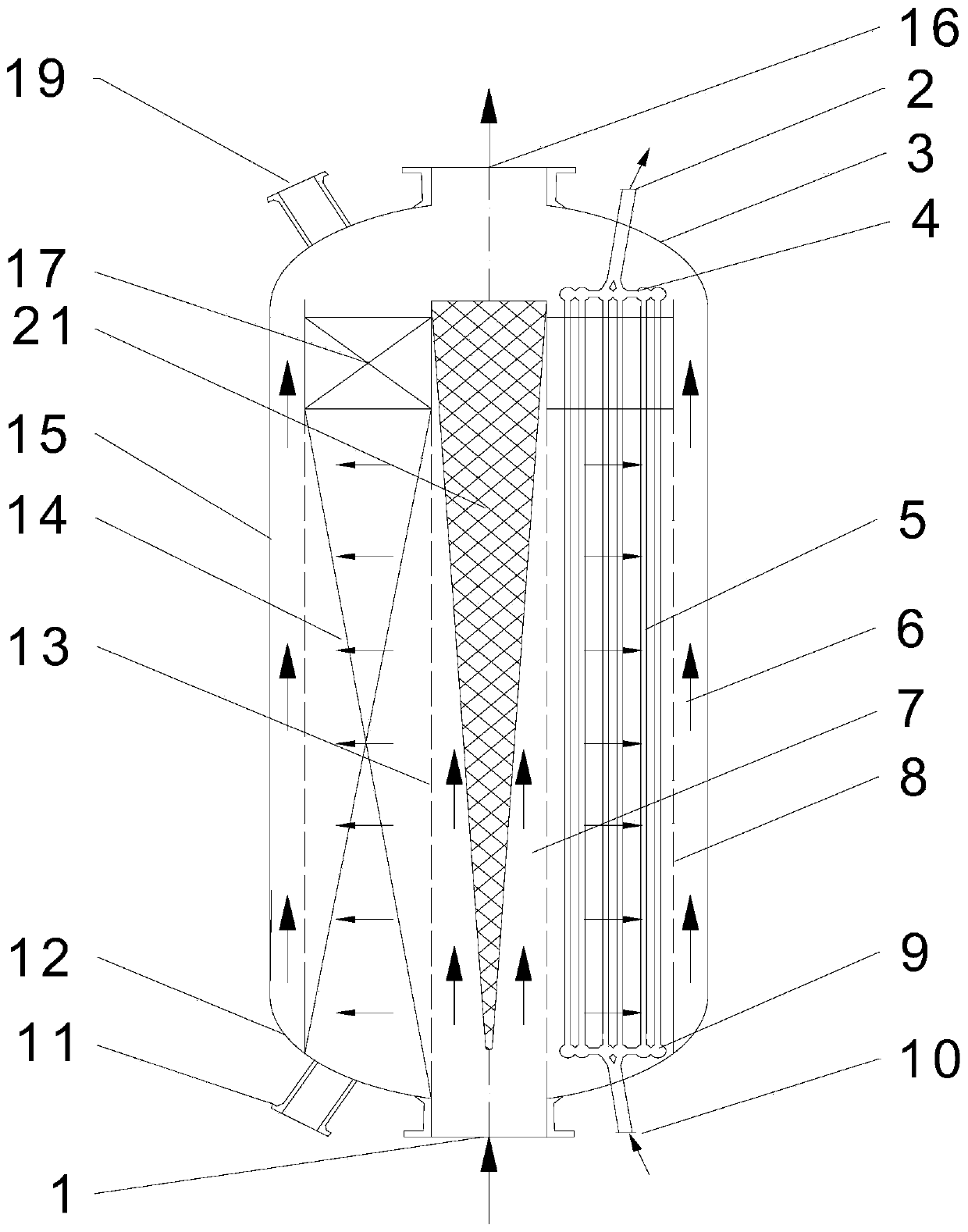

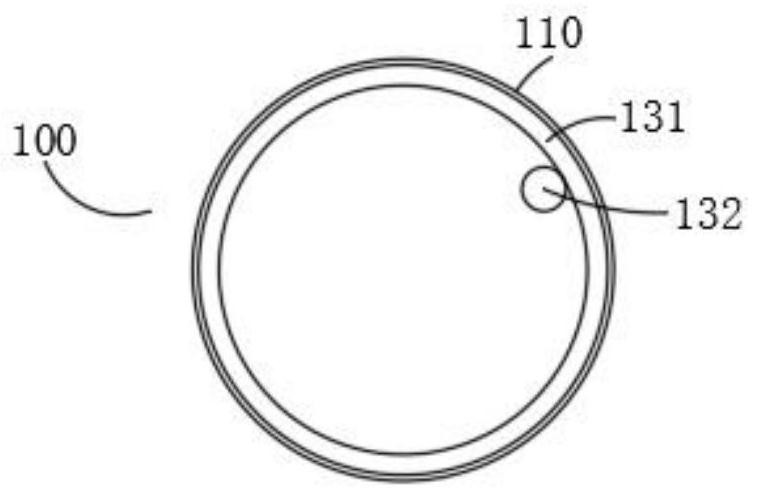

Catalytic reforming and catalytic dehydrogenation fixed bed radial reactor

InactiveCN1232341CEliminate static pressure differencesReduce control pressure dropCatalytic crackingChemical/physical processesCatalytic reformingReactor pressure vessel

The invention discloses a fixed-bed reactor for catalytic reforming and catalytic dehydrogenation. The reactor adopts a circular pressure vessel (8) with a catalytic bed (5), and the gas inlet (1) and outlet (2) are located at At the same end of the container (8), the catalytic bed (5) is composed of an outer porous wall (7) and a circular inner porous wall tube (6). The catalyst is filled in the middle, and there is a cover plate sealing structure above the catalyst. The circular inner porous wall The barrel (6) can adopt forms such as variable opening ratio or conical structure. The reaction gas flows centrifugally from the central inner porous cylinder to the porous outer cylinder in the reaction device, and the reaction gas flows in the opposite direction in the central inner cylinder and the porous outer cylinder, forming a centrifugal П-type radial reactor. This method has the characteristics of uniform distribution of reaction gas along the axial direction, pure radial flow in the catalyst bed, and small pressure drop through the reactor. The reactor is also suitable for other medium, low pressure or negative pressure gas-solid phase catalytic reactions.

Owner:EAST CHINA UNIV OF SCI & TECH

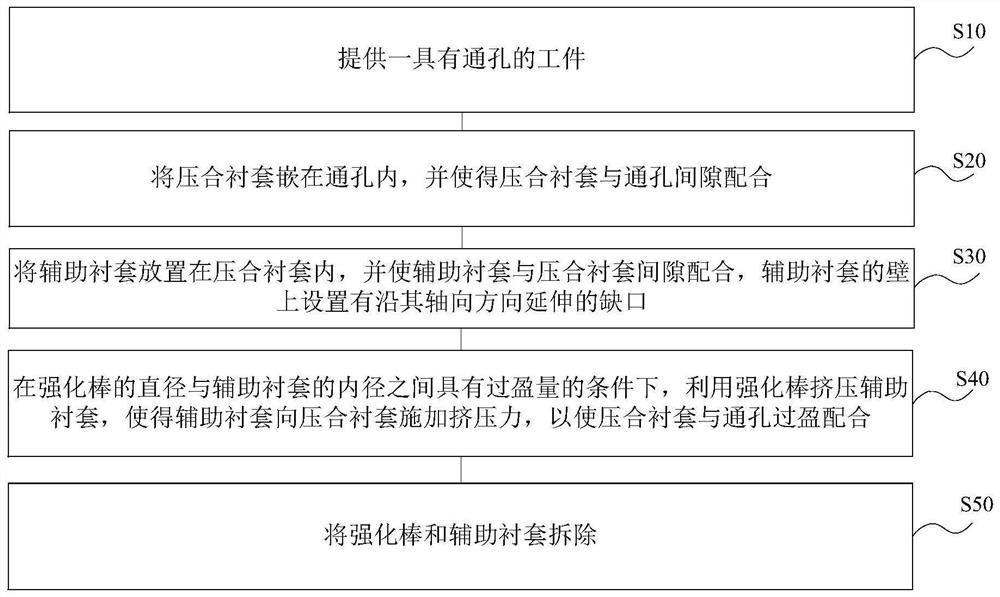

Installing method of pressing bushing and structural part

ActiveCN112077564AImprove fatigue strengthening effectImprove fatigue lifeMetal working apparatusInterference fitAxial distribution

The invention relates to an installing method of a pressing bushing and a structural part. The installing method comprises the following steps of providing a workpiece with a through hole; embedding the pressing bushing in the through hole to form clearance fit between the pressing bushing and the through hole; placing an auxiliary bushing in the pressing bushing to form clearance fit between theauxiliary bushing and the pressing bushing, and forming a gap, which extends in the axial direction of the auxiliary bushing, in the wall of the auxiliary bushing; under the condition that magnitude of interference exists between the diameter of an reinforced rod and the internal diameter of the auxiliary bushing, extruding the auxiliary bushing by the reinforced rod so as to apply extruding forceto the pressing bushing by the auxiliary bushing to form interference fit between the pressing bushing and the through hole; and dismounting the reinforced rod and the auxiliary bushing. The pressingbushing is installed by using the installing method, so that the tangential residual stress of the wall of the through hole in the workpiece is uniformly distributed in the axial direction, and the tangential residual stress caused at the extruding end of the reinforced rod can be eliminated, which can improve the fatigue reinforcing effect of the hole and further prolong the fatigue life of thehole.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Filter element

PendingCN112237811AReduce areaSolve the costCombination devicesDispersed particle filtrationFiltrationEngineering

The invention discloses a filter element. The filter element is placed in a filter to be used for carrying out gas-solid separation filtration and / or liquid-solid separation filtration on an object tobe filtered during use; the filter element comprises at least two filter tubes which are arranged at intervals, and tube bodies of the filter tubes are formed by shaping metal or sheet-shaped materials taking the metal as a base body in a rolled mode and carrying out sealing processing on joints; the outer diameter of the tube body formed by rolling is only 20-200 mm, preferably 20-90 mm, furtherpreferably 20-60 mm, and further preferably 25-50 mm, and the outer diameter of the tube body formed by rolling is only 20-200 mm, preferably 20-90 mm; the lengths of the filter tubes range from 100mm to 5000 mm, preferably range from 100 mm to 3000 mm, further preferably range from 100 mm to 2000 mm, and further preferably range from 200 mm to 1500 mm. A plurality of small-diameter filter tubesare bundled, so the filtering area can be remarkably increased in a limited mounting space; the length of the filter element is reduced, so the blowback effect can be more uniformly distributed in the axial direction of the filter tubes. Therefore, the technical problems that in the prior art, a filter element is small in filtering area and poor in back flushing effectiveness are effectively solved.

Owner:CHENGDU INTERMENT TECH

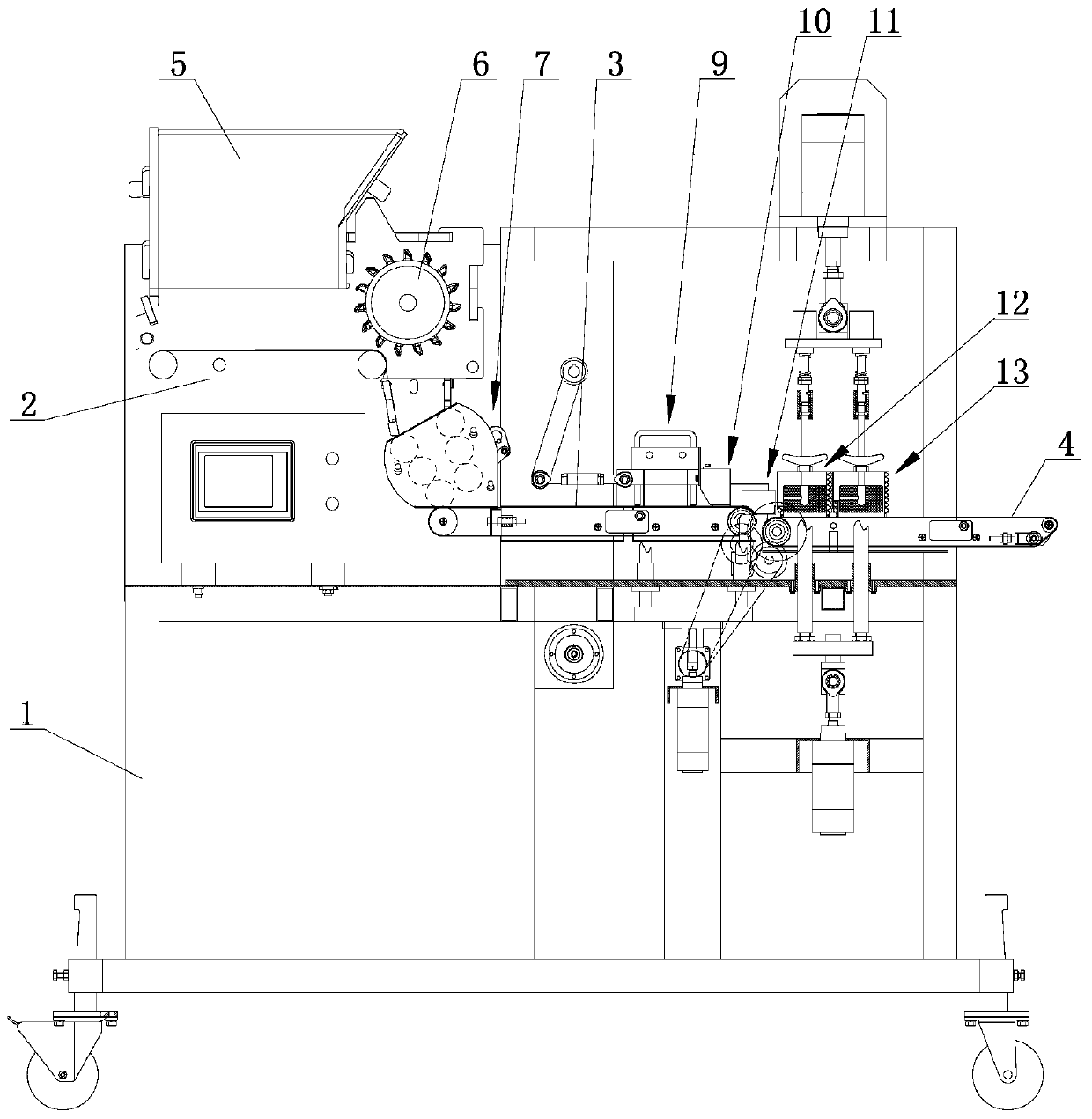

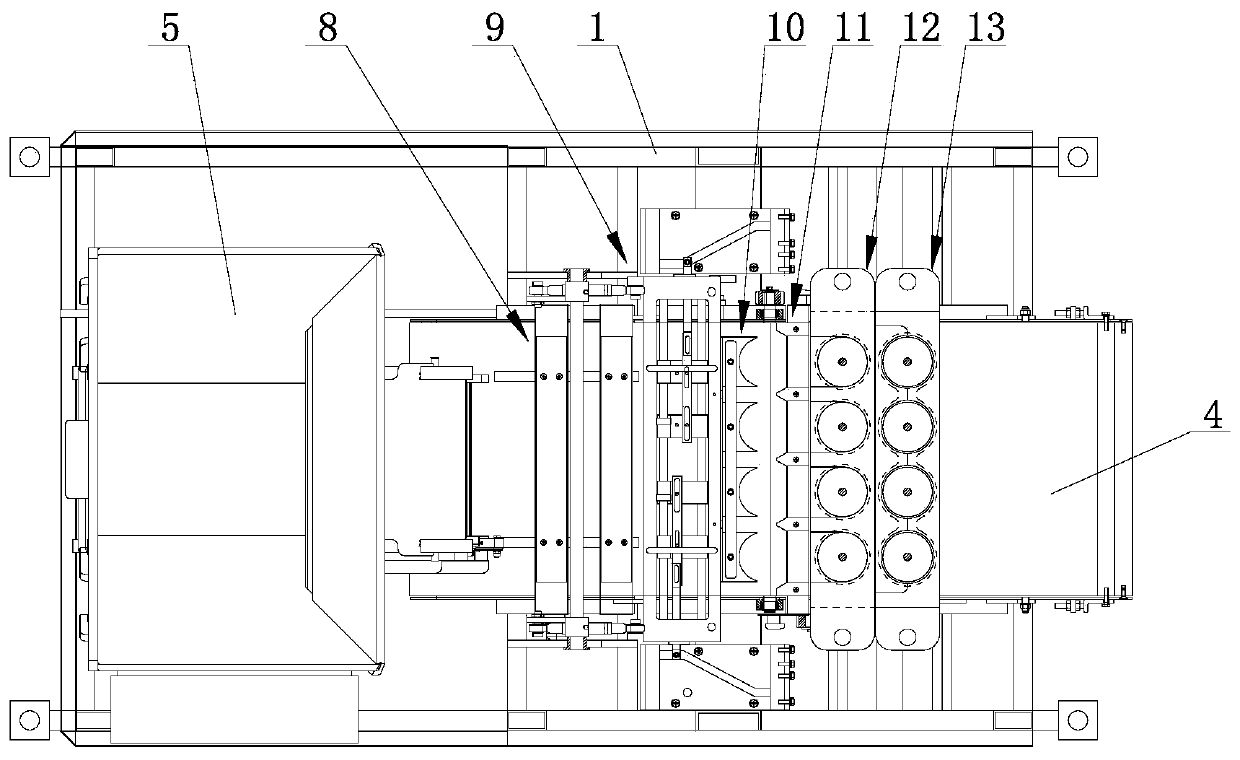

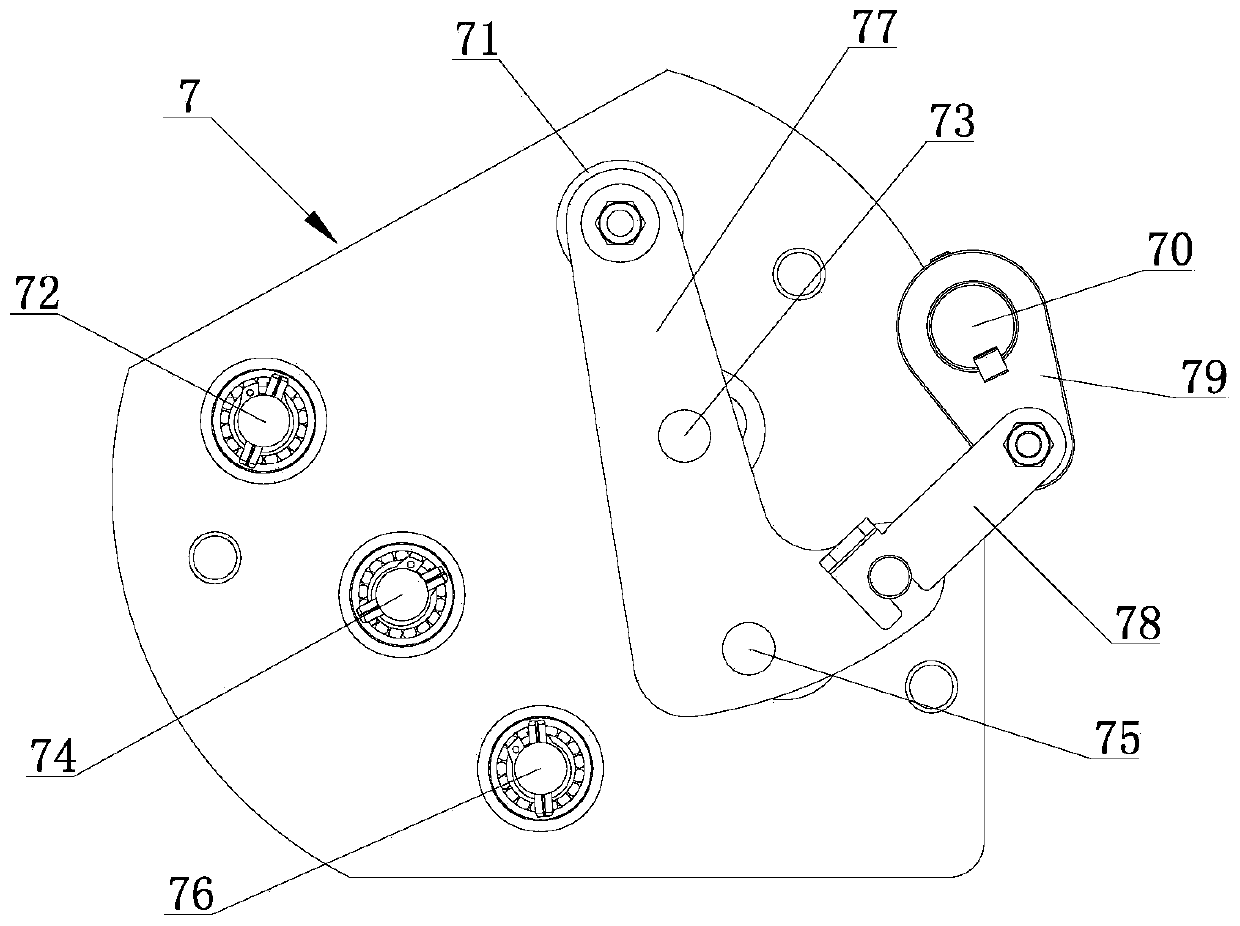

Formation machine for rice cake

PendingCN110292146ARealize automated productionReduce the burden onFood scienceEngineeringFully automatic

The invention discloses a formation machine for a rice cake. In the motion direction of materials, a rack is provided with a hopper, a stirring roller, an extrusion device, a pushing device and a formation device and further provided with a horizontally-arranged hopper conveying belt, a cutting conveying belt and a formation conveying belt, the hopper is located above the hopper conveying belt, and the stirring roller is located above the discharging end of the hopper conveying belt; a feeding port of the extrusion device is located below the discharging end of the hopper conveying belt, a discharging port of the extrusion device is located above the feeding end of the cutting conveying belt, and the cutting device and the pushing device are located above the cutting conveying belt; the feeding end of the formation conveying belt corresponds to the discharging end of the cutting conveying belt, and the formation device is located above the formation conveying belt. The whole productionprocess of the rice cake is fully automatic, automation production of the rice cake is achieved, the production efficiency is greatly improved, the cost is low, the rice cake cannot be sticky to a mold and does not need to be dug out, the time and labor are saved, and the burden of workers is reduced.

Owner:JINAN HIWELL MACHINERY

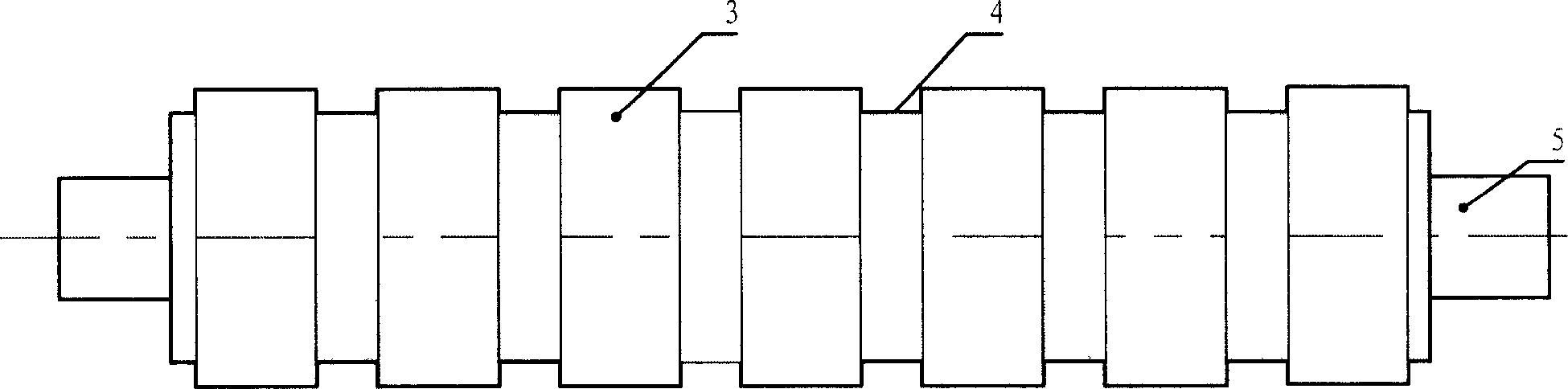

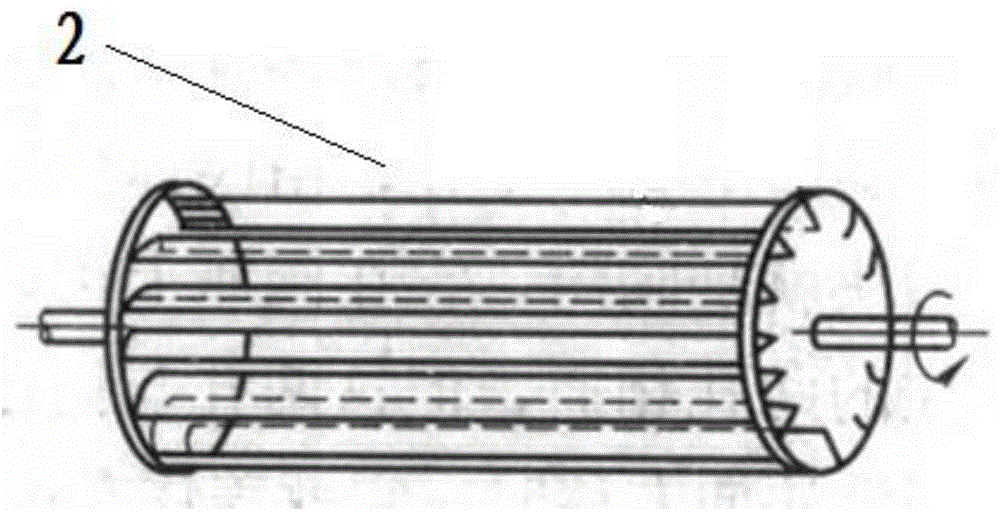

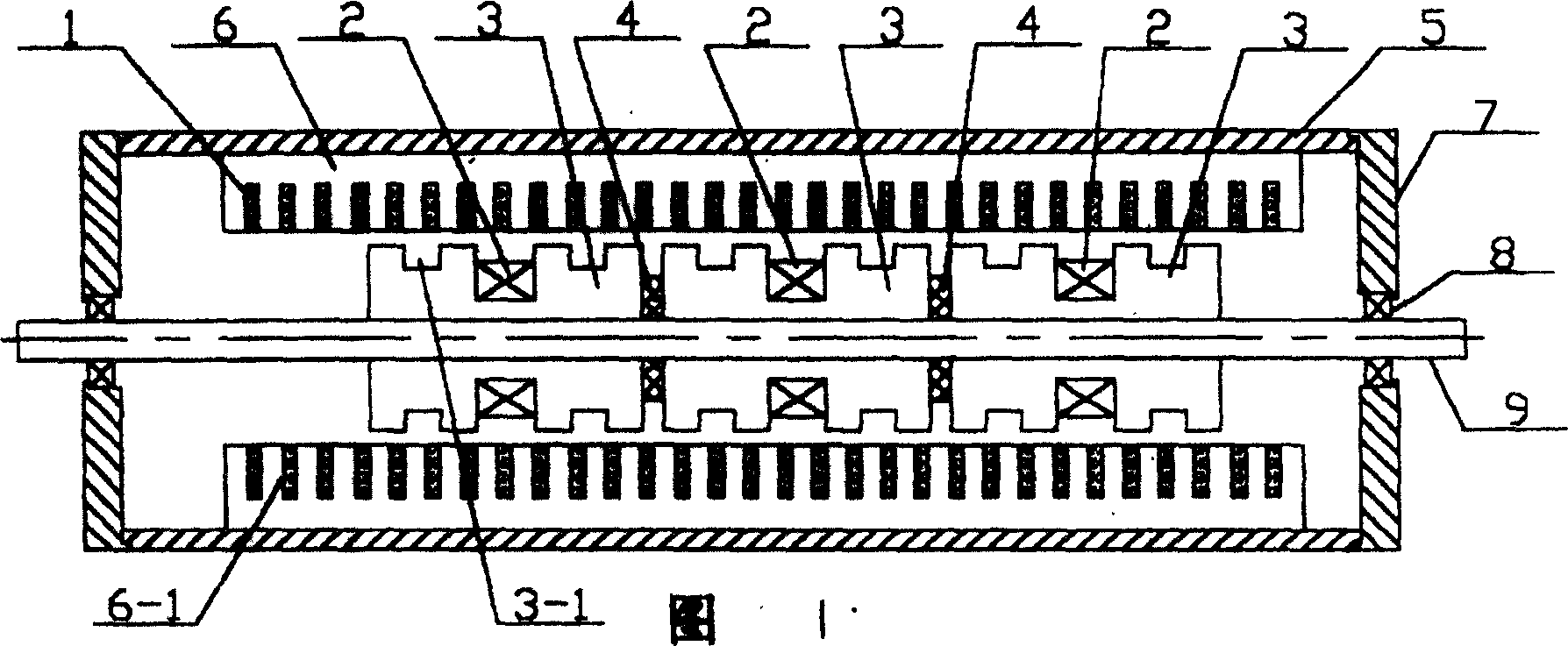

Transverse flux cylinder linear reluctance motor

InactiveCN1976186BHigh material utilizationIncrease output thrustPropulsion systemsTransverse fluxElectric machine

A cylindrical linear magnetic resistance motor of horizontal magnetic flow relates to the motor field, which overcomes uneven distribution of exciter field in the prior cylindrical mixed horizontal magnetic motor structure and eddy current loss caused by the parallel of the part of flux path and the motor axial direction. The invention includes a casing (6), an armature core (1), an armature winding (2), a rotor tooth (3), a spaced ring (4) and a shaft (5), wherein each phase of armature core (1) is fixed closely to an internal wall of the casing (6), the rotor tooth (3) and the spaced ring (4) are fixed and jacketed in sequence on the shaft (5) in an alternative arrangement way, 2n numbers of teeth are set on each armature core (1), n is a natural number, each phase of armature core (1) is staggered by an angle of 360degrees / 2mn in the peripheral direction, m is a phase number of the motor, the coil winding direction of the armature winding (2) on adjacent tooth of each phase of armature core (1) is reverse, and all coils on the same phase armature winding (2) are series-connected together. The invention can replace the prior cylindrical mixed horizontal resistance motor.

Owner:HARBIN INST OF TECH

Cooling system and server system

InactiveCN104597993AAxially distributed evenlyReduce speedDigital data processing detailsData centerElectric machinery

The invention provides a cooling system, which comprises a casing (4) provided with an air inlet (1) and an air outlet (3), wherein the air inlet (1) and the air outlet (3) are respectively formed in the first side wall and the second side wall of the casing (4), a through flow fan (2) is arranged in the casing (4), and airflow from the air inlet (1) to the air outlet (3) flows to a direction vertical to the motor shaft extending direction of the through flow fan (2). On the other hand, the invention also provides a server system adopting the cooling system. The invention aims at providing the cooling system and the server system, the effect of greatly reducing the computer noise in the use process is at least realized, the noise of a data center machine room is favorably reduced, and the mute machine room is realized.

Owner:SUGON DATAENERGYBEIJING CO LTD

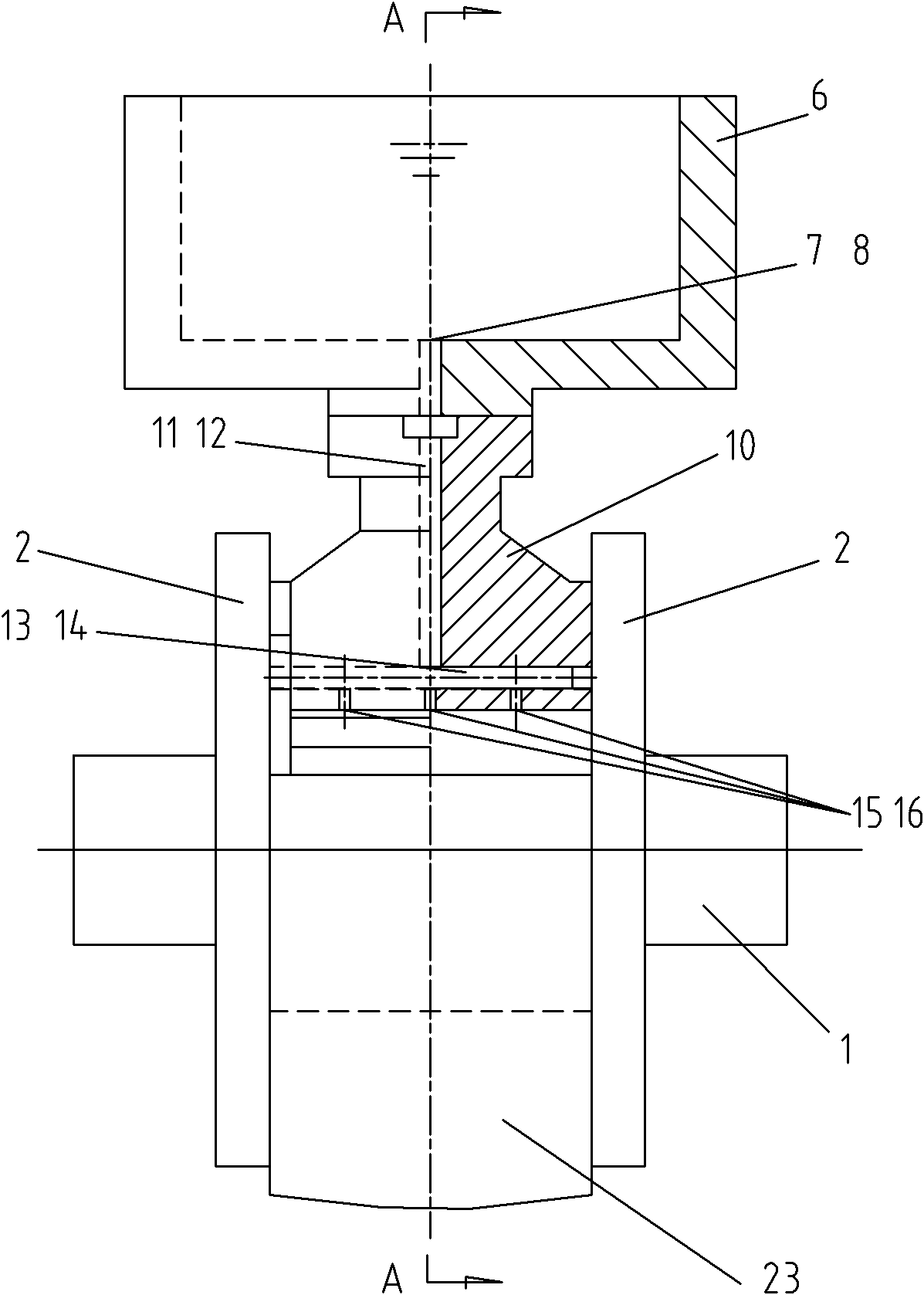

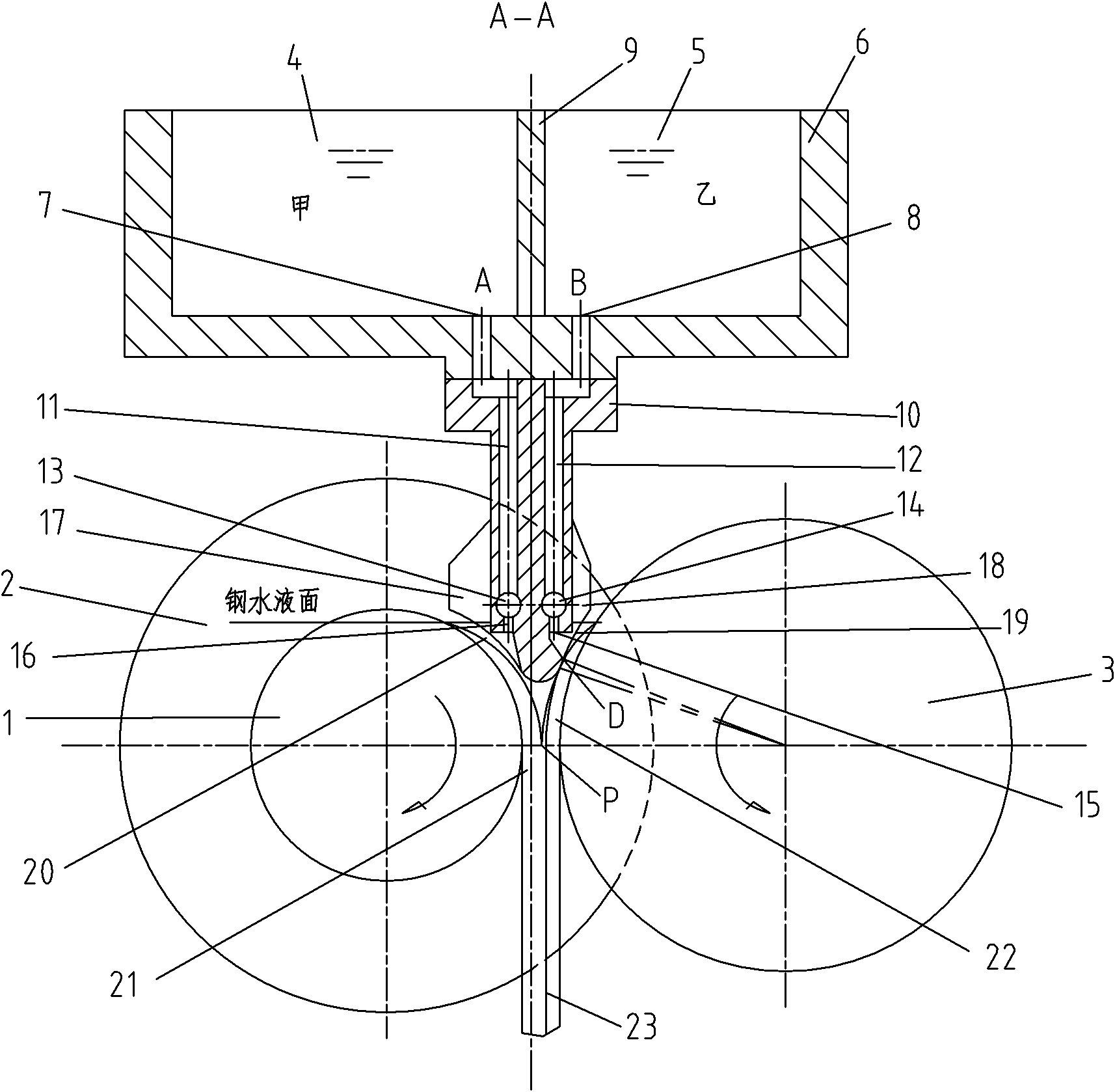

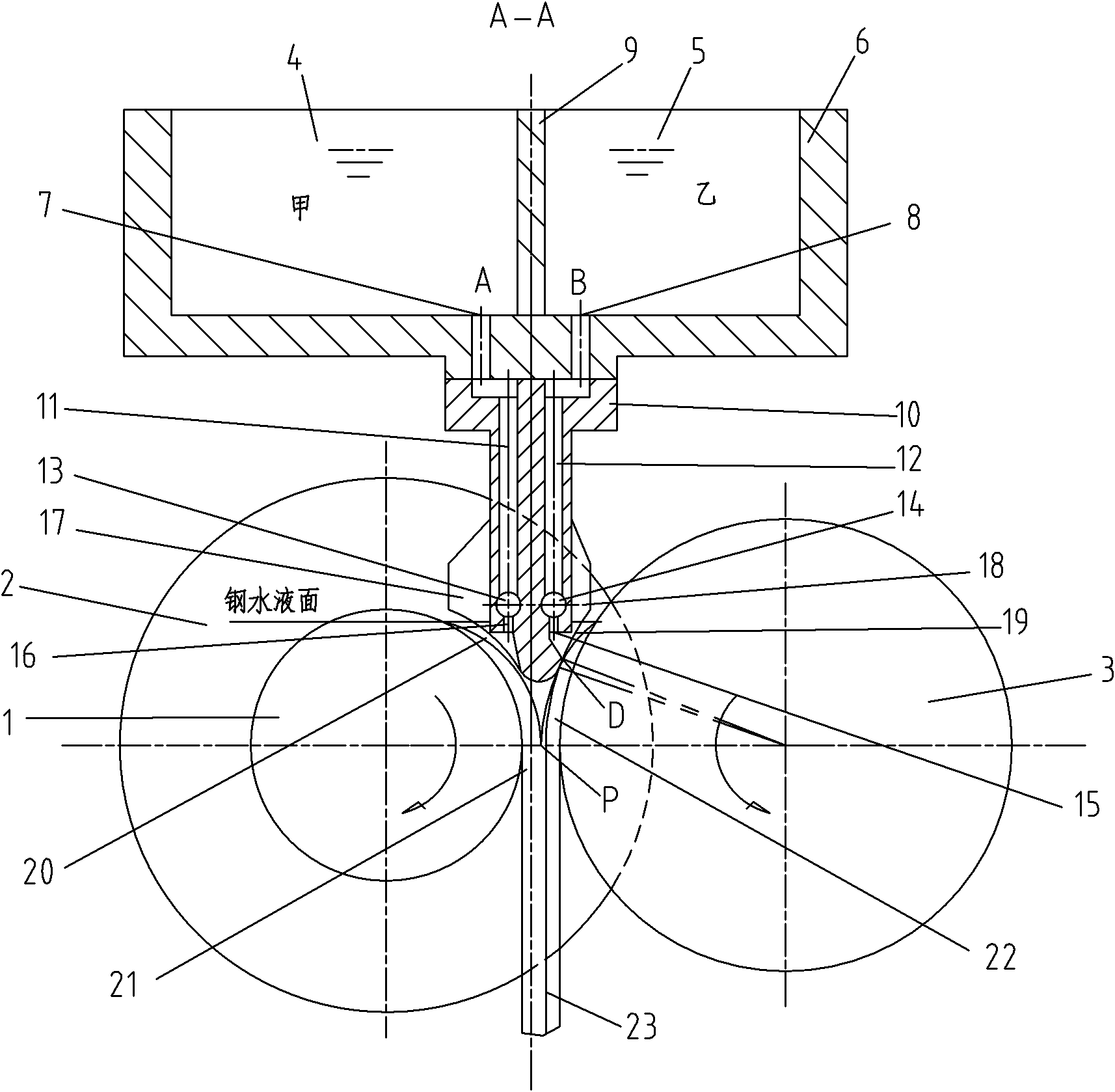

Partition plate device of casting system of double-roller continuous casting machine

The invention discloses a partition plate device of a casting system of a double-roller continuous casting machine. The partition plate device comprises a partition plate, a tundish, a tundish casting passage A, a tundish casting passage B, a tundish partition wall, a partition plate casting passage A, a partition plate casting passage B, a collecting hole A, a collecting hole B, a shunting hole A, a shunting hole B, a lateral wing plate A and a lateral wing plate B, wherein the tundish casting passage A, the partition plate casting passage A, the collecting hole A and the shunting hole A form a molten steel casting passage A; and the tundish casting passage B, the partition plate casting passage B, the collecting hole B and the shunting hole B form a molten steel casting passage B. Underthe condition that the molten steel is not mixed when two kinds of molten steel are solidified on crystallization rollers respectively, the two casting passages and the partition plate are combined together to form a whole; the head can be dipped into the molten steel of a melt bath so as to effectively prevent secondary oxidation of the molten steel; and the collecting holes and the shunting holes are added in the structural design, so impact of the molten steel is reduced, the molten steel is uniformly distributed and the liquid level is stable.

Owner:DALIAN DESIGN INST CO LTD CHINA FIRST HEAVY IND +1

Filter

PendingCN112237810AReduce areaSolve the costCombination devicesDispersed particle filtrationProcess engineeringControl theory

The invention discloses a filter. The filter comprises a filter structure, and the filter structure comprises at least two filter elements which are arranged at intervals; the filter element comprisesat least two filter tubes which are arranged at intervals, and tube bodies of the filter tubes are formed by shaping metal or a sheet-shaped material taking the metal as a base body in a rolling manner and performing sealing processing on joints; and the outer diameter of the pipe body formed by rolling is only 20-200 mm. The bundled filter element formed by bundling a plurality of small-diameterfilter tubes is adopted, so that the filtering area can be remarkably increased; for a filter with a large size, the weight of a single filter element can be reduced by adopting a plurality of cluster type filter elements while a high filtering area is ensured, and the installation is simplified; for a filtering structure needing a large number of filter tubes, a plurality of cluster type filterelements are respectively mounted, so that a relatively uniform blowback effect can be ensured. Therefore, compared with the prior art, the filter has the advantages that a larger filter area can be achieved, and the problems of installation and blowback after the filter pipes are bundled are solved.

Owner:CHENGDU INTERMENT TECH

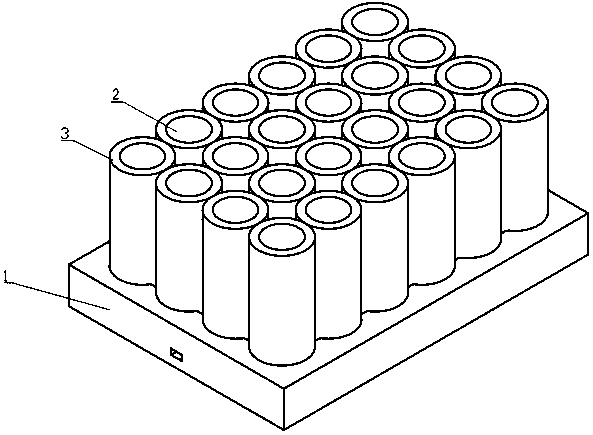

A high power density power battery cooling system

The invention provides a high-power density power battery cooling system. The system comprises simplicial heat dissipation modules and a heat dissipation base, each simplicial heat dissipation modulecomprises a power battery and a cooling sleeve, each power battery is arranged in the corresponding cooling sleeve, and each cooling sleeve is internally provided with a spiral cooling channel; the bottom of each cooling channel is provided with an inlet and an outlet; the simplicial heat dissipation modules are regularly arranged on the heat dissipation base; the heat dissipation base is internally provided with a plurality of water inlet conduits and a plurality of water outlet conduits; any water inlet conduit is communicated with the inlet of at least one cooling channel, and any water outlet conduit is communicated with the outlet of at least one cooling channel. The high-power density power battery cooling system has the advantages that it can be achieved that the power batteries arecooled more fully and evenly and the temperature of each battery is controlled.

Owner:JIANGSU UNIV +1

Filter element

PendingCN112237809AReduce areaSolve the costCombination devicesDispersed particle filtrationFiltrationEngineering

Owner:CHENGDU INTERMENT TECH

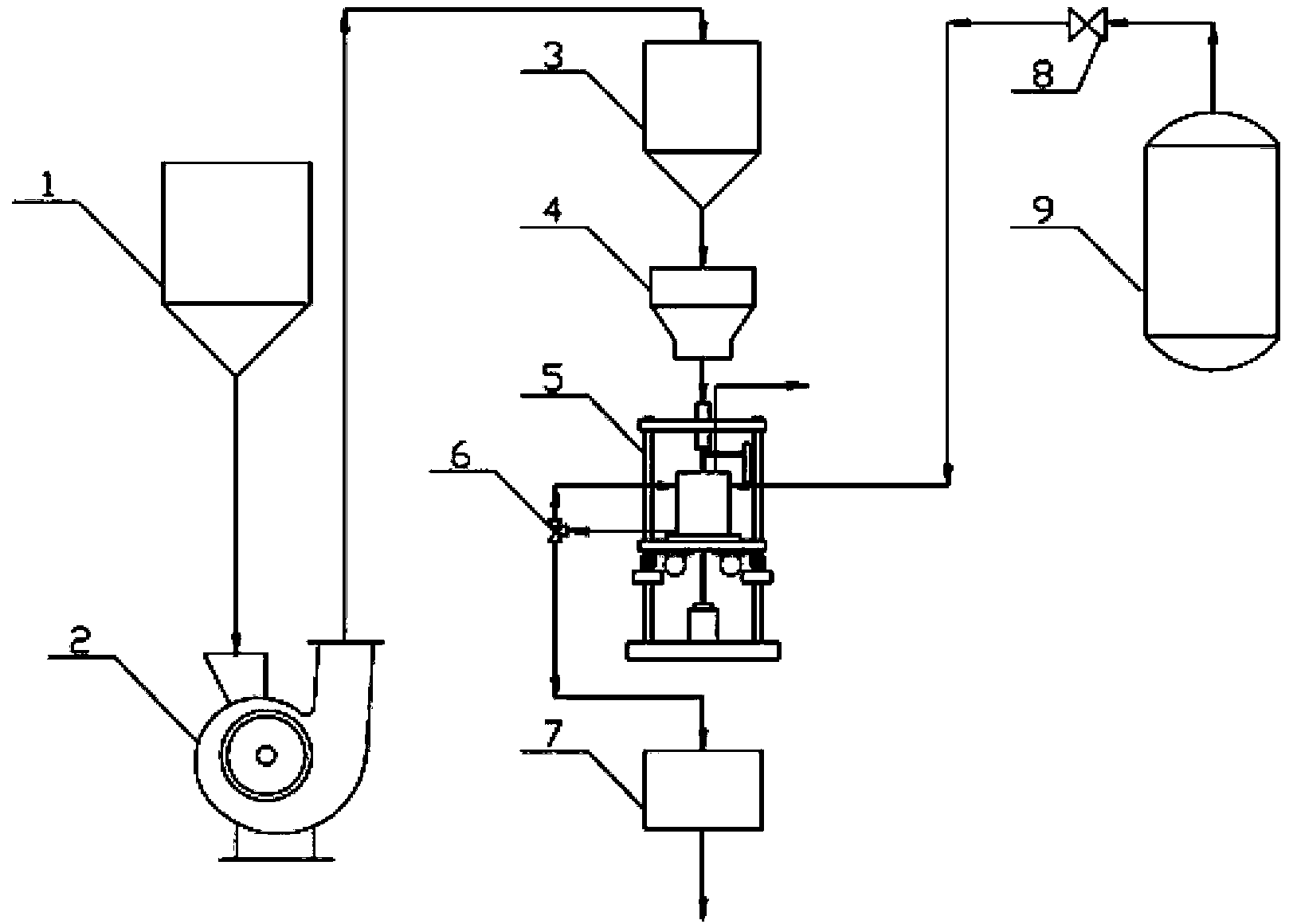

Process and system for vibration hot-pressing dehydration and quality improvement of brown coal

InactiveCN103087796BEfficient removalPrevent relapseBiofuelsSolid fuelsSpontaneous combustionBrown coal

Owner:CHINA UNIV OF MINING & TECH

Linear electric motor with movable armature core

InactiveCN101154875AAxially distributed evenlyIncrease capacity to volume ratioPropulsion systemsElectric machineAxial distribution

The invention relates to a linear motor with a movable armature core. Two end covers are separately connected with two ends of a shell; the outer rings of two bearings are respectively fixed inside the inner holes of the two end covers; the inner ring of the bearing is connected with an axle; the axle is sheathed with the armature core; the outer periphery of a cylindrical non-armature core closely matches with the inner face of the shell; an air gap is formed between the armature core and the non-armature core; Annular tooth spaces are arranged one by one along the axial direction on the surface of the armature core and the non-armature core facing the air gap; each tooth space on the non-armature core is provided with a permanent magnet. The invention has the advantages of evenly distribution of the exciting magnetic field along with the axial direction and the improved performance-volume ratio of the motor.

Owner:TIANJIN DEXIN ELECTRIC MACHINERY

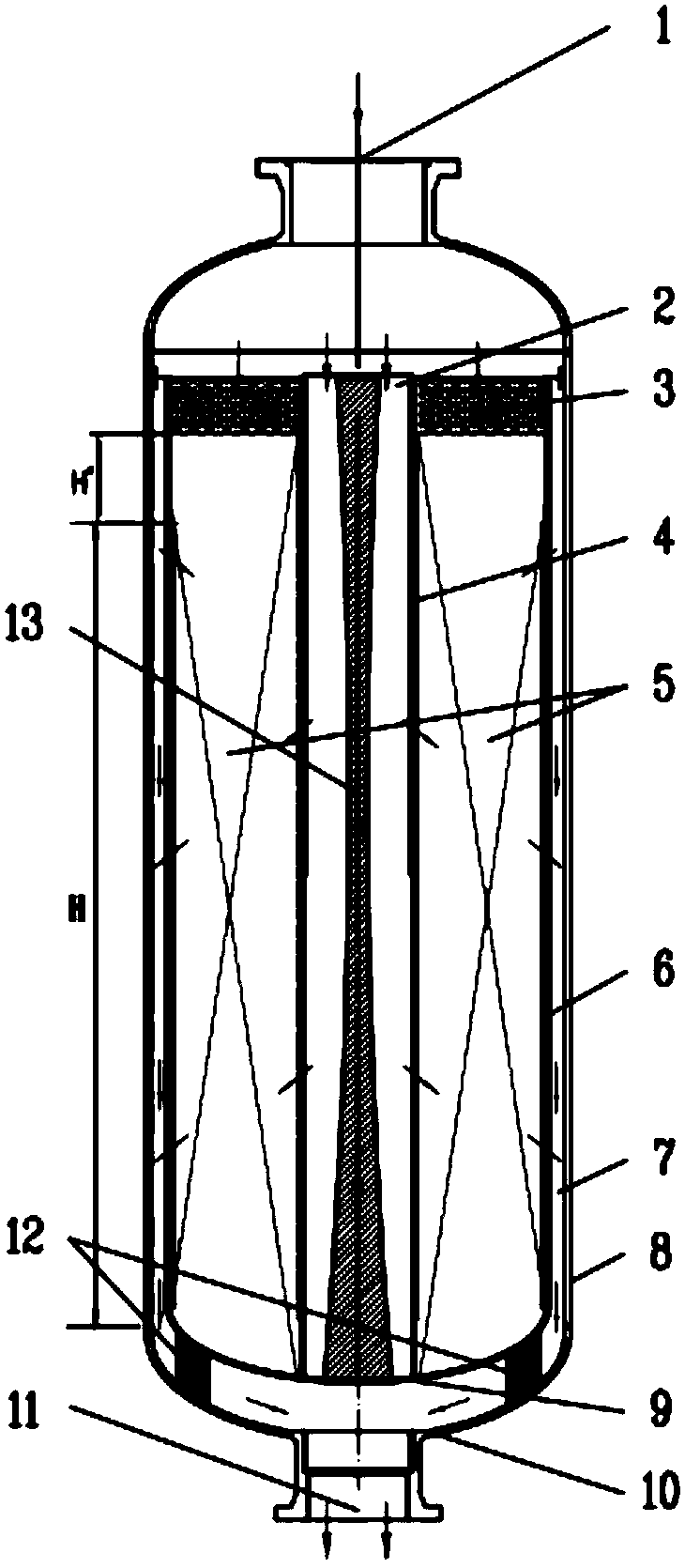

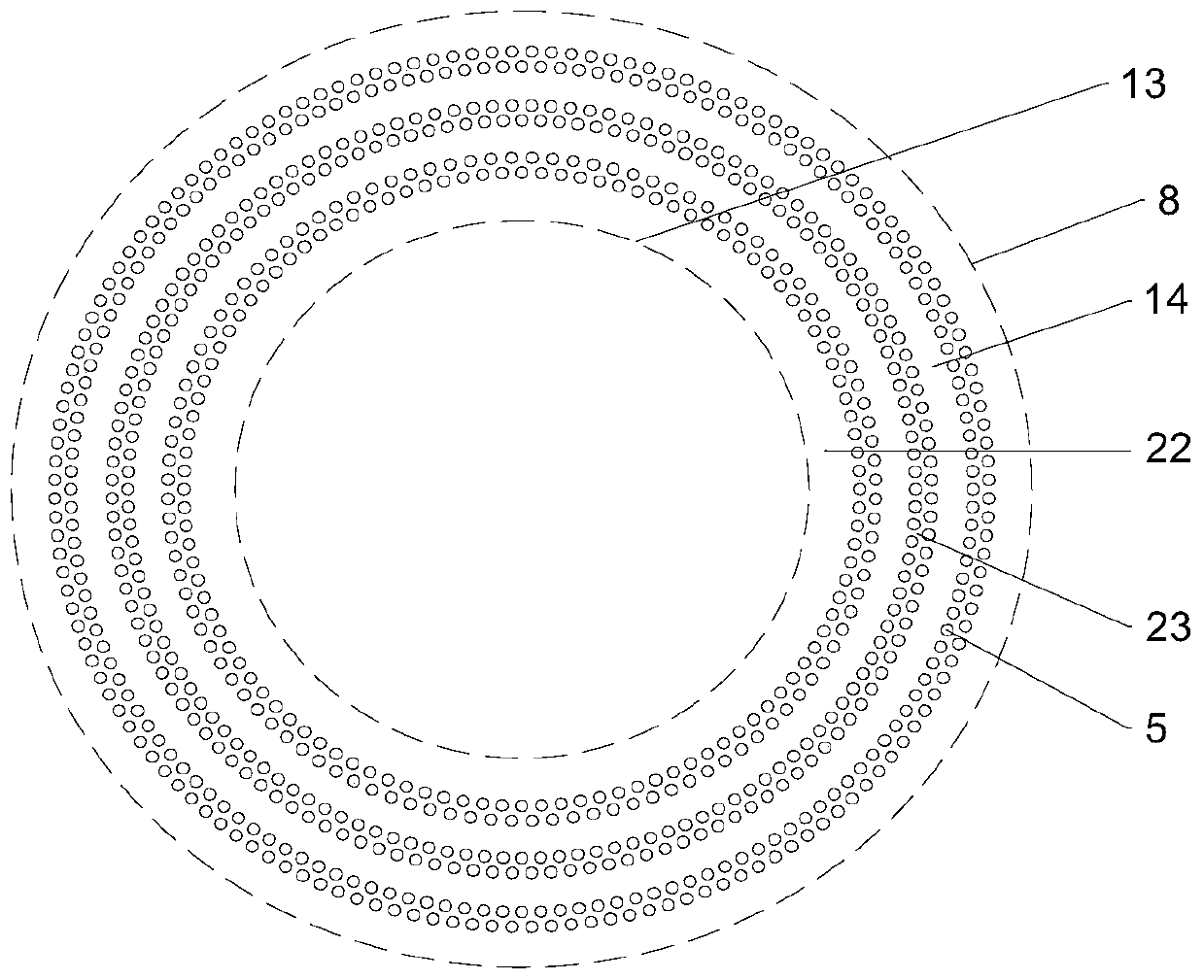

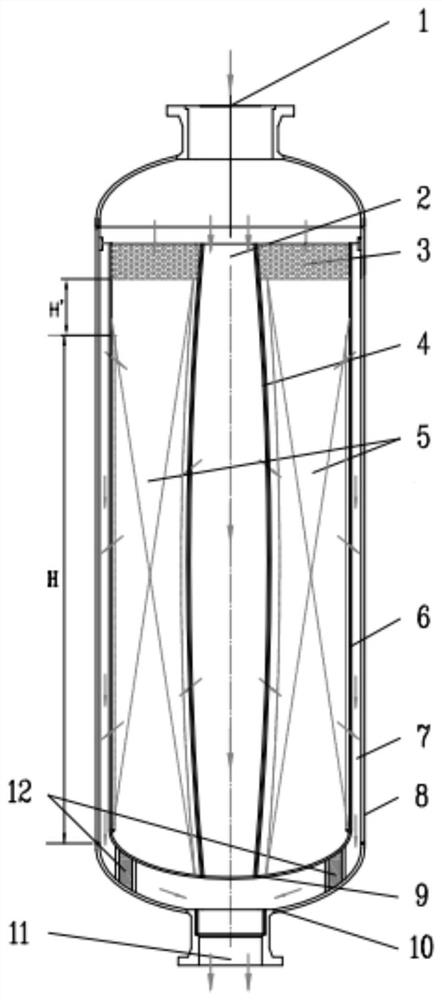

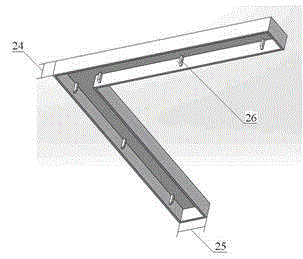

Radial flow fixed bed catalytic reactor for producing oxalate through CO carbonylation coupling

PendingCN111589378AEliminate temperature differencesAvoid overheatingPreparation by carbon monoxide or formate reactionChemical/physical processesCarbonylationFixed bed

The invention discloses a radial flow fixed bed catalytic reactor for producing oxalate through CO carbonylation coupling. The reactor comprises a cylindrical vessel composed of an upper end socket, acylindrical barrel and a lower end socket in sequence from top to bottom. A reaction gas feeding port, a reaction gas discharging port, a heat exchange medium inlet, a heat exchange medium outlet, acatalyst feeding port and a catalyst discharging port are formed in the outer portion of the cylindrical vessel. The catalytic bed layer is divided into a heat insulation area and a heat exchange areafrom inside to outside, and the heat exchange area is provided with multiple groups of heat exchange tubes which are concentrically arranged in two rows as a group. The radial flow fixed bed catalytic reactor for producing oxalate through CO carbonylation coupling has the characteristics of uniform distribution of reaction gas along the axial direction, reasonable bed layer temperature distribution, high catalyst utilization rate, small reactor pressure drop and the like, is suitable for a reaction for producing oxalate through carbonylation coupling, and is also suitable for other exothermicgas-solid phase catalytic reactions.

Owner:EAST CHINA UNIV OF SCI & TECH

Liquid self-accelerating multi-stage supergravity device and application

ActiveCN114682159AAxially distributed evenlySpray evenlyLiquid distribution in distillationChemical/physical/physico-chemical stationary reactorsImpellerLiquid storage tank

The invention discloses a liquid self-acceleration multi-stage supergravity device which comprises a shell, a motor, a rotating shaft, a multi-stage gas channel, a multi-stage guide plate, a multi-stage liquid storage tank, a multi-stage sealing ring, a multi-stage spiral acceleration impeller, a multi-stage liquid distributor, a multi-stage filler, a reflux inlet, a gas outlet, a liquid outlet and a heating coil. According to the multi-stage supergravity device, acceleration of liquid in the liquid distributor is achieved through the design of internal components, uniform distribution of the liquid in the axial direction of the filler is achieved, and the gas-liquid contact efficiency of the multi-stage supergravity device is improved; meanwhile, the equipment investment cost is saved, and the equipment is more simplified.

Owner:BEIJING UNIV OF CHEM TECH

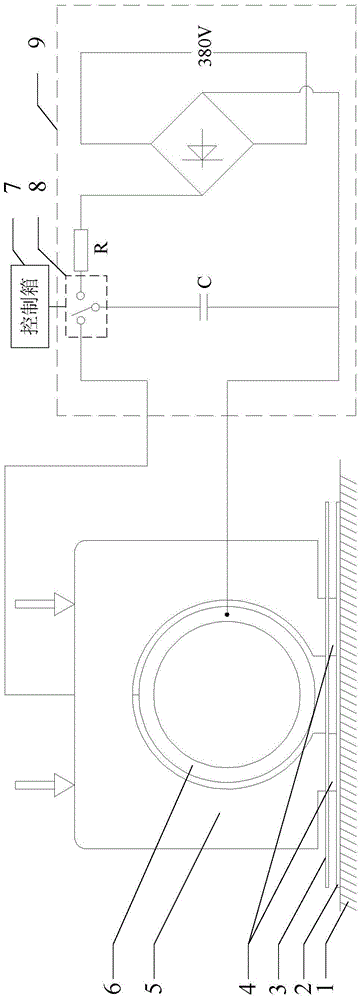

A high-speed deformation connection method and device for dissimilar metal plates

ActiveCN105014224BFirmly connectedIncrease flexibilityNon-electric welding apparatusHigh ratePower flow

The invention provides a high-speed deformation connecting method and device for dissimilar metal sheets and belongs to the field of plastic deformation connection. The high-speed deformation connecting method and device for the dissimilar metal sheets aim at solving the problem that the energy utilization rate existing in an existing sheet magnetic pulse connecting technology is low. According to the high-speed deformation connecting method and device for the dissimilar metal sheets, a magnetic pulse deformation connecting device is used for conducting discharging on a solenoid coil placed in an induced current channel, and the current of the coil enables an induced current to be produced in a connecting plate adjacent to the coil. The induced current flows in a loop formed by the connecting plate and the induced current channel. The coil current magnetic field and the induced current magnetic field produce superposition to be enhanced in gaps of the series loop of the solenoid coil and the connecting plate-induced current channel. The function for enhancing the magnetic field and the induced current of the connecting plate enables the connecting plate to bear normal downward high-strength pulse pressure load action, downward high-speed deformation and accelerated movement are generated, and then collisions happen between the connecting plate and a connected plate. Acute shearing plastic deformation occurs on the impact contacting interface, and the connection of the dissimilar metal sheets is achieved.

Owner:HARBIN INST OF TECH

Low pressure drop z-type radial centrifugal flow fixed bed reactor

ActiveCN110871046BOvercoming the Effects of Pressure ChangesSmall pressure dropChemical/physical processesFixed bedHead (vessel)

The invention proposes a low pressure drop Z-shaped radial centrifugal flow fixed bed reactor. The reactor includes a cylindrical pressure vessel, an inner cylinder, an outer cylinder and a catalytic bed, and the inner cylinder and the outer cylinder are coaxial with the cylindrical pressure vessel. It is arranged that an interlayer space is formed between the outer wall surface of the inner cylinder and the inner wall surface of the outer cylinder, the lower support head, the inner cylinder and the outer cylinder are enclosed to form a catalytic bed, and the lower support head is located in the cylindrical pressure vessel and It is located at the bottom of the cylindrical pressure vessel; the inner cylinder is connected with the gas inlet to form a split flow channel for the reaction gas, and the reaction gas collecting flow channel is formed between the outer wall surface of the outer cylinder and the inner wall surface of the cylindrical pressure vessel, and the reaction gas The collecting flow channel is connected with the gas outlet; the splitting flow channel is a variable diameter flow channel, the inner cylinder is all provided with openings, and the outer cylinder is partially open; the reaction gas flows radially from the splitting flow channel through the inner cylinder to the outside through the catalytic bed , and enters the collecting channel through the outer cylinder and flows out of the fixed-bed reactor, and the direction of the reaction gas in the fixed-bed reactor is "Z" type.

Owner:PETROCHINA CO LTD

Filter tubes and preparation method thereof

PendingCN112237808AReduce areaSolve the costCombination devicesDispersed particle filtrationFiltrationMechanical engineering

The invention discloses filter tubes and a preparation method thereof. When in use, the filter tubes are densely distributed in a filter in an array manner and are used for carrying out gas-solid separation filtration and / or liquid-solid separation filtration on a to-be-filtered object, and tube bodies of the filter tubes are formed by shaping metal or a sheet-shaped material taking metal as a matrix in a rolling manner and carrying out sealing processing on joints; and the outer diameter of the tube bodies formed by rolling is only 20 to 200 mm, preferably 20 to 90 mm, further preferably 20 to 60 mm, and further preferably 25 to 50 mm. The preparation method of the filter tubes comprises the steps: rolling the sheet-shaped material with the thickness of 0.2-2.5 mm into the tube bodies with the outer diameter of 20-200 mm; and when the diameter of the filter tubes is reduced to be 200 mm or less, the strength of the filter tubes can be maintained in a tube shape even if a support bodyis not arranged any more, and self-support can be realized, so that the weight and the cost can be remarkably reduced; therefore, the technical problems of high cost and low strength of a filter element in the prior art are effectively solved.

Owner:CHENGDU INTERMENT TECH

A radial flow residual oil hydrotreating reactor

ActiveCN103805234BThe reaction space velocity is constantGreat operating flexibilityChemical/physical processesHydrogenation reactionFixed bed

The invention discloses a radial flow-type fixed bed residual oil hydrotreating reactor. The reactor of the present invention mainly comprises members of a housing, a central shaft oil inlet pipe, and a bottom hydrogen distribution disc; in a residual oil hydrogenation reaction process, raw oil mainly flows in a reaction diameter direction in a catalyst bed layer, and reaction supplemented hydrogen flows from bottom to top. The residual oil hydrogenation device of the invention has good operation flexibility, can realize synchronous inactivation of various catalysts, effectively prolongs the running period of the device, and makes full use of the active resources of residual oil hydrogenation catalysts.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com